Manufacturing method of chip type inductor

A manufacturing method and inductor technology, applied in the field of inductors, can solve the problems of costly procedures and working hours, and achieve the effects of high current resistance, avoiding leakage current phenomenon, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

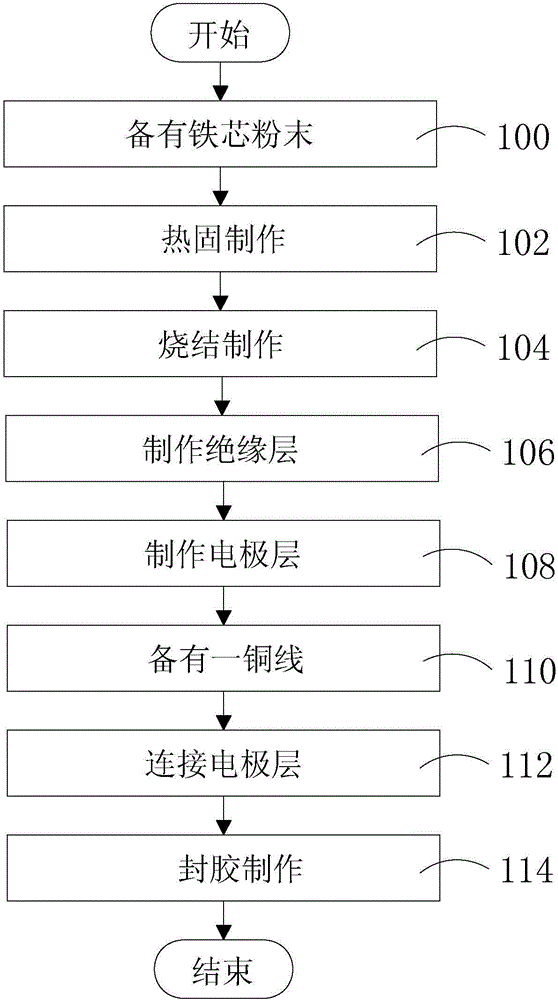

[0049] Hereby relevant technical content and detailed description of the present invention, now coordinate drawing description as follows:

[0050] see Figure 1~Figure 7 , is a schematic diagram of the manufacturing process and structure of the chip inductor of the present invention. As shown in the figure: the manufacturing method of the chip inductor of the present invention, at first, as step 100, has iron core powder, and this iron core powder is the iron-nickel 50 powder of iron-silicon powder material (FeSi) or soft magnetic material ( FeNi50).

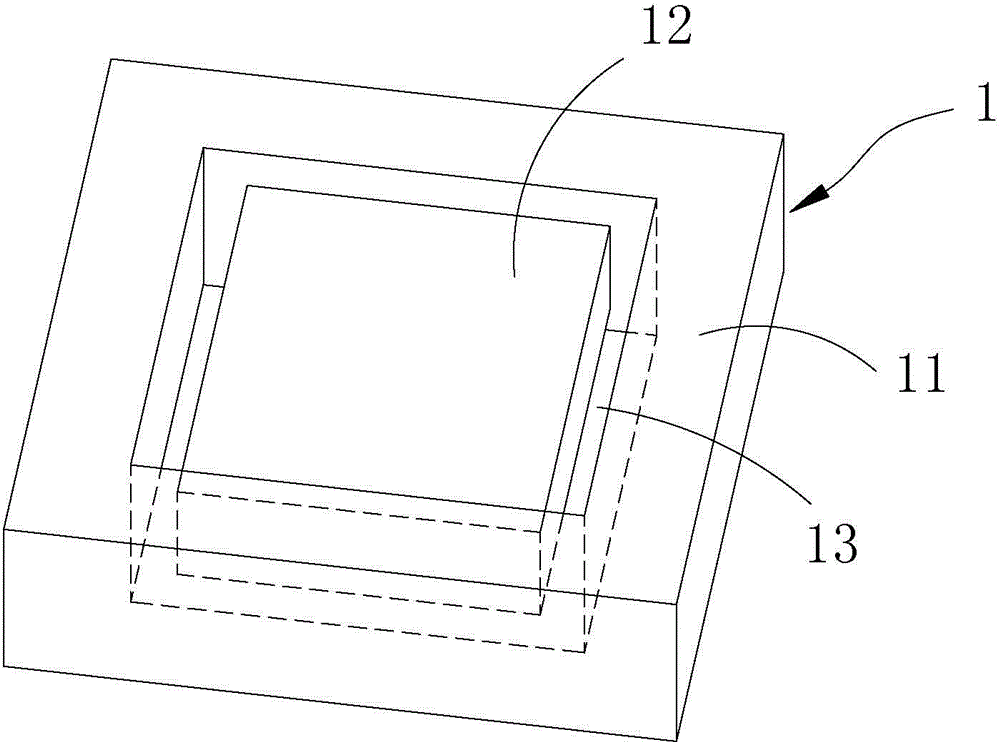

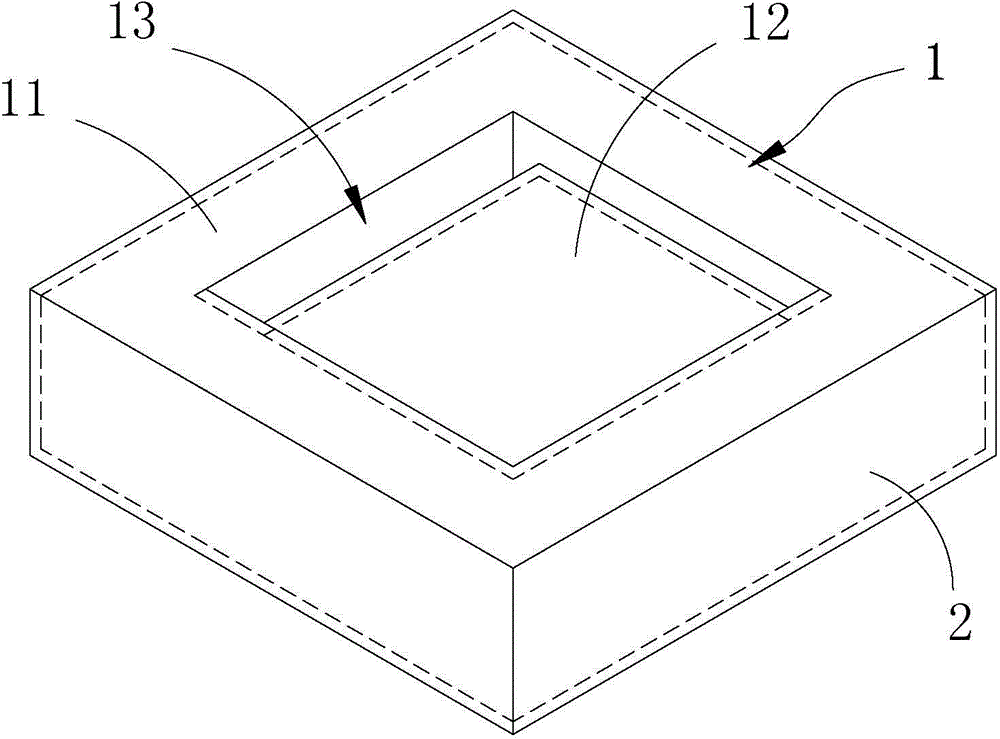

[0051] Step 102, thermosetting production, using the thermosetting process to press the above-mentioned iron core powder into a "day"-shaped powder core (such as figure 2 shown).

[0052] Step 104, sintering production, sintering the above-mentioned pressed "day" shaped powder core, and after low temperature sintering, the "day" shaped powder core is formed into a "day" shaped iron core (powder core sintered body) 1, the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com