Patents

Literature

123results about How to "Improve the degree of automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

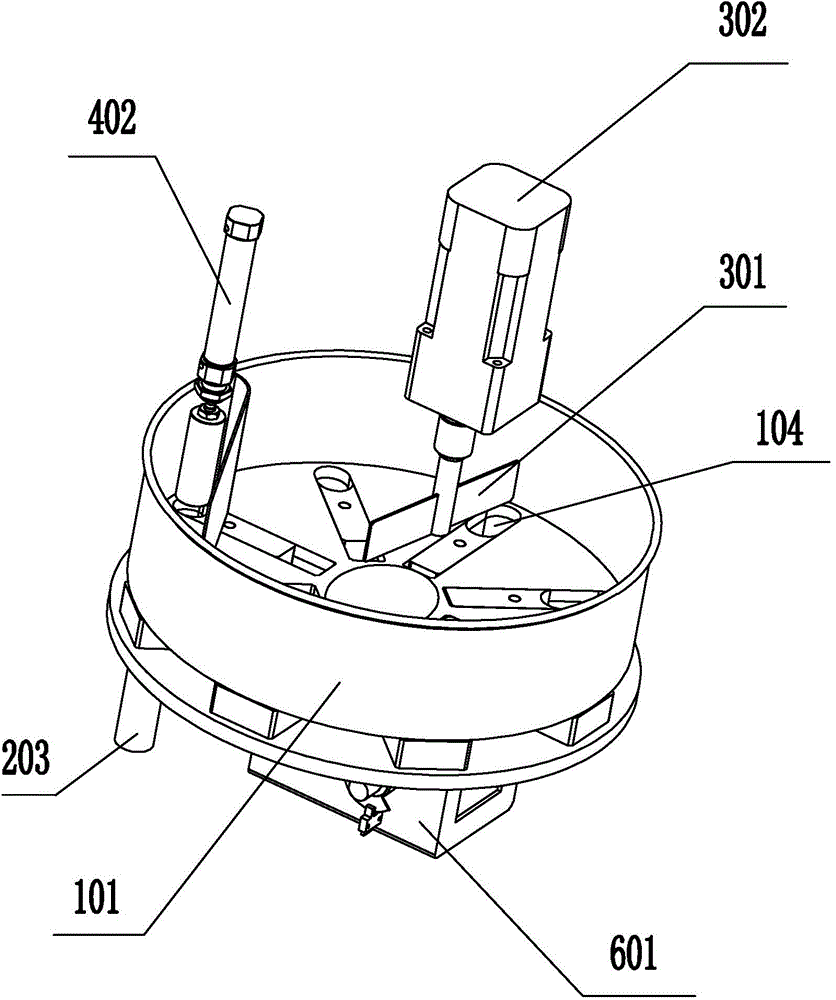

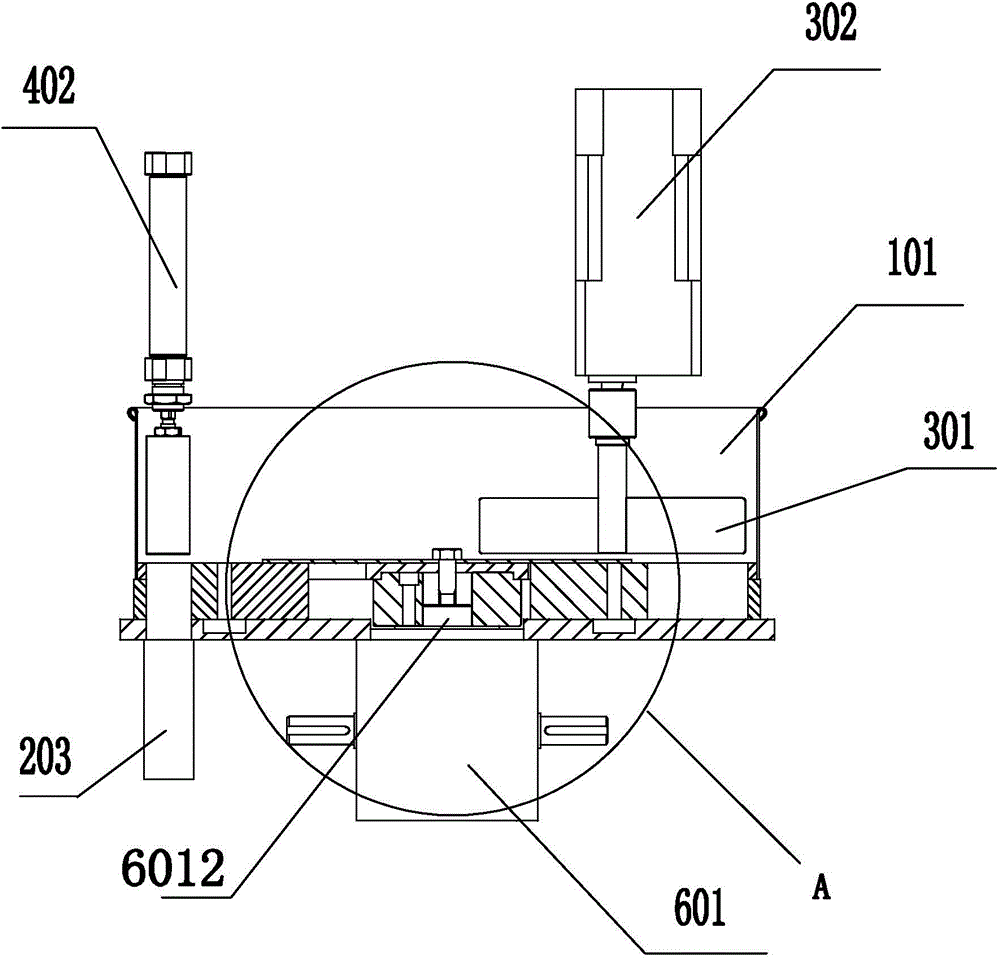

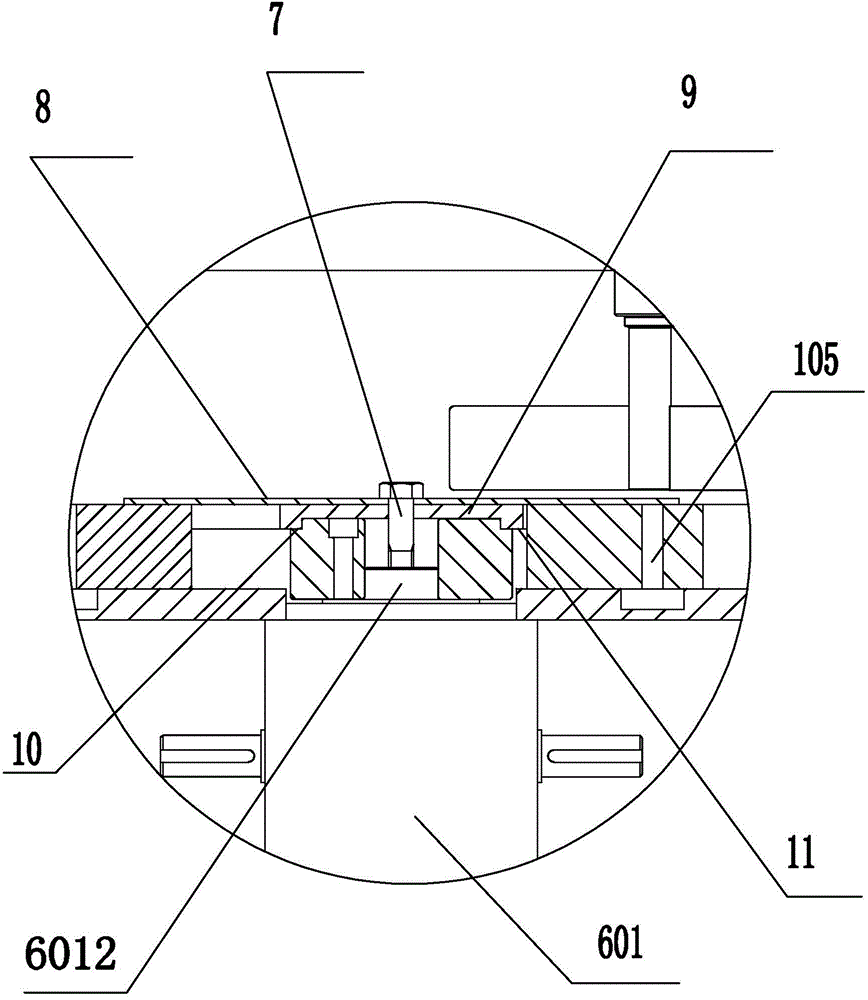

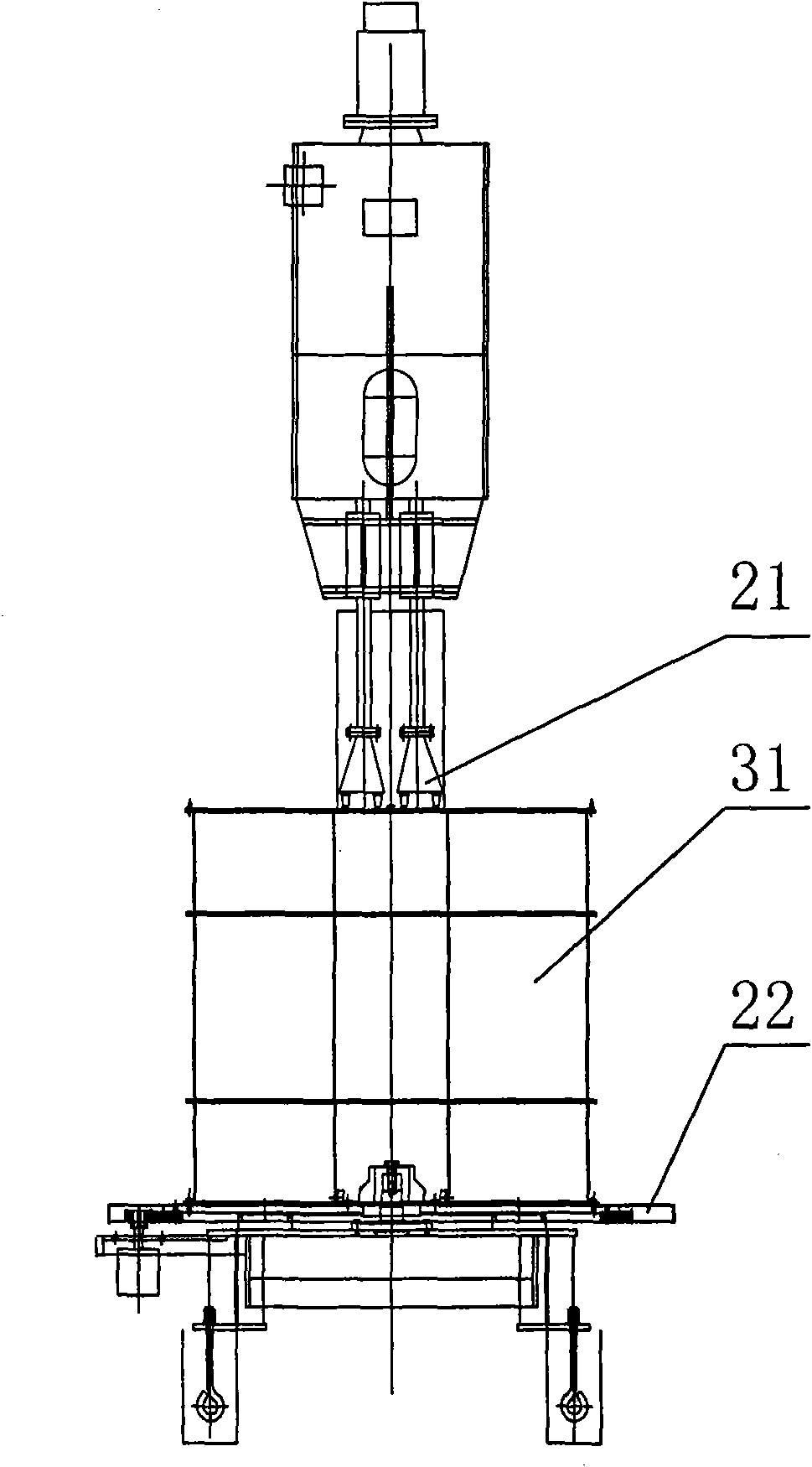

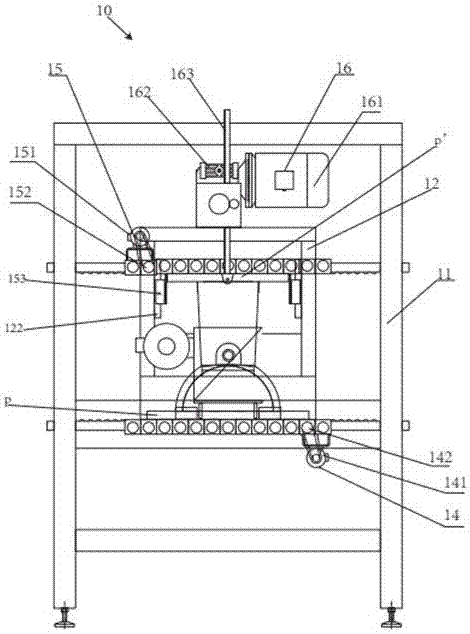

Disc cam type packaged food metering device

ActiveCN104528004AImprove the degree of automated productionIncrease productivitySolid materialEngineeringCam

The invention provides a disc cam type packaged food metering device and belongs to the field of composite leisure food packaging metering techniques. The disc cam type packaged food metering device comprises a rack, a cylindrical turntable composite structure, a disc cam and a stirring paddle. The cylindrical turntable composite structure comprises a cylindrical turntable, 6-18 fixed metering cups, 6-18 sliding blocks and 6-18 bearings, the cylindrical turntable comprises a bottom and 6-18 bottom slots, a fixed metering cup slot is formed in the middle of each fixed metering cup, the bottom slots and the fixed metering cup slots are stacked in an upper and lower mode to form 6-18 sliding block slots, and 6-18 movable metering cups are formed between inwards concave semicircles of the sliding blocks and outwards concave semicircles of the sliding block slots; the disc cam comprises a cam groove and is arranged below the fixed metering cups; each bearing comprises a bearing head, the bearing heads are arranged in the cam groove and can rotate along the cam groove, and the sliding blocks can slide in the sliding block slots forwards or backwards; the stirring paddle is horizontally arranged. The disc cam type packaged food metering device has the advantages that metering is precise, the automated production degree is high, production efficiency is high, and materials are easy to put in.

Owner:RUIAN GUCHUAN PACKAGING MACHINERY CO LTD

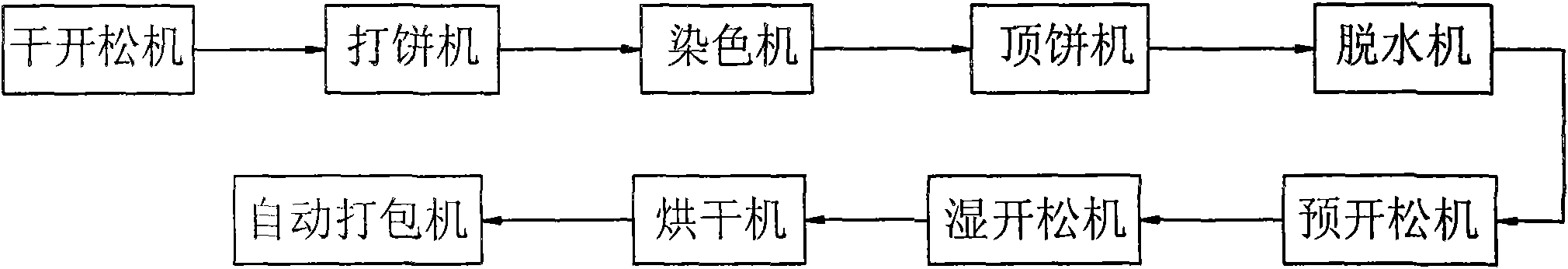

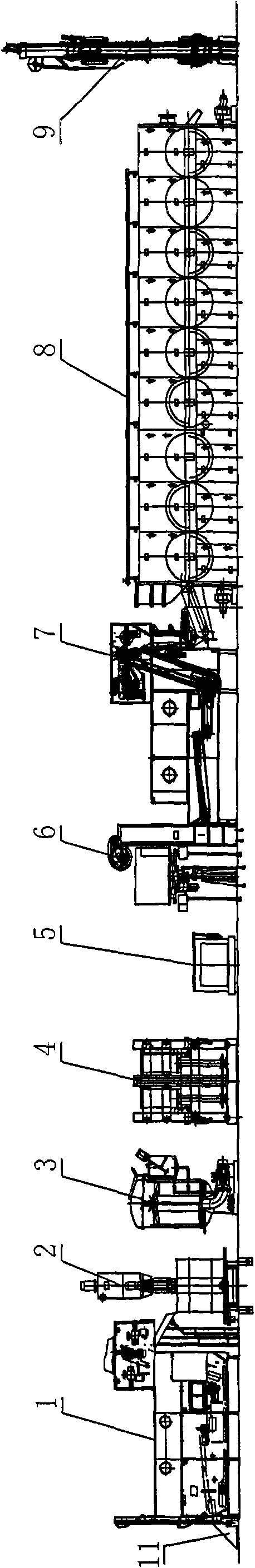

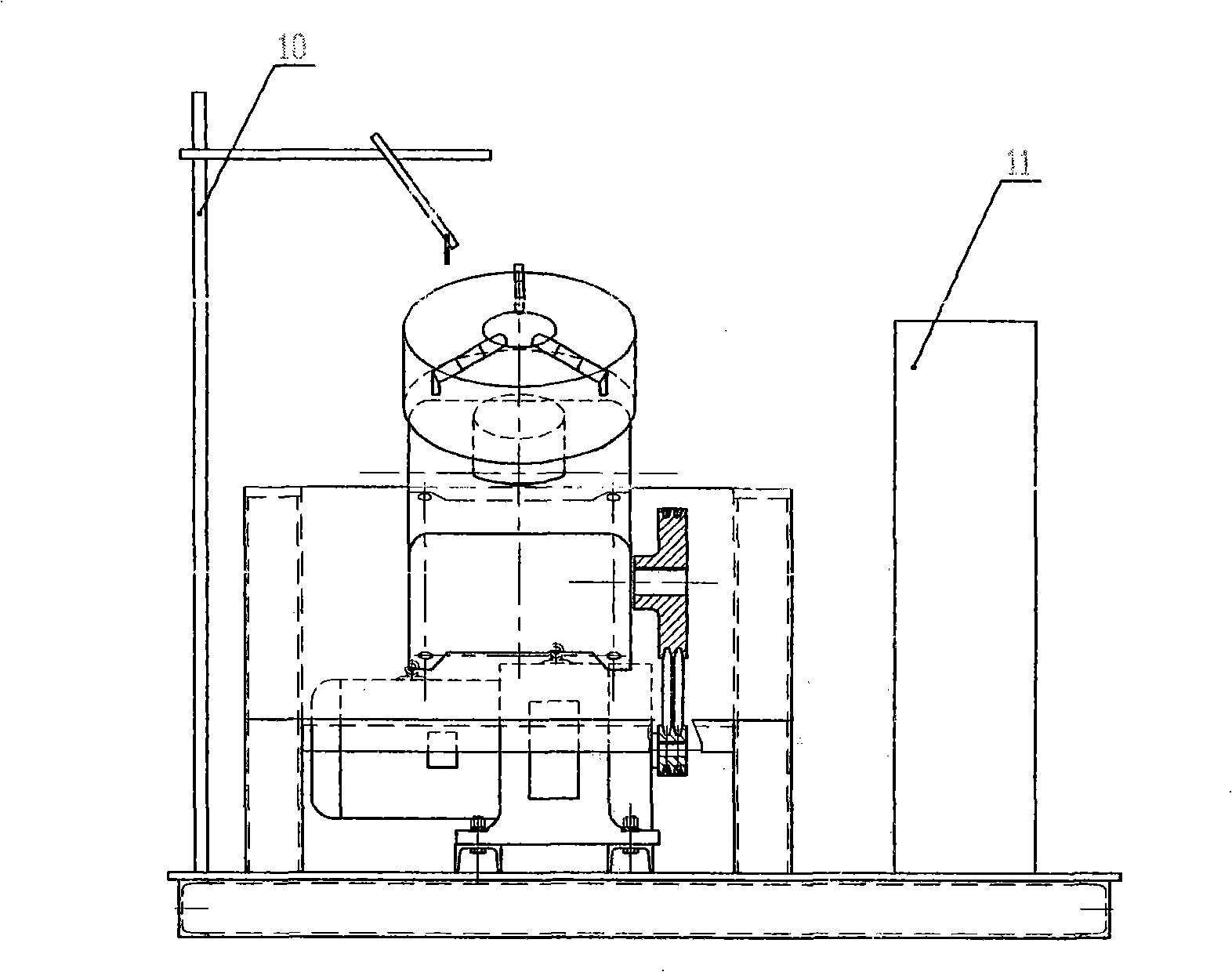

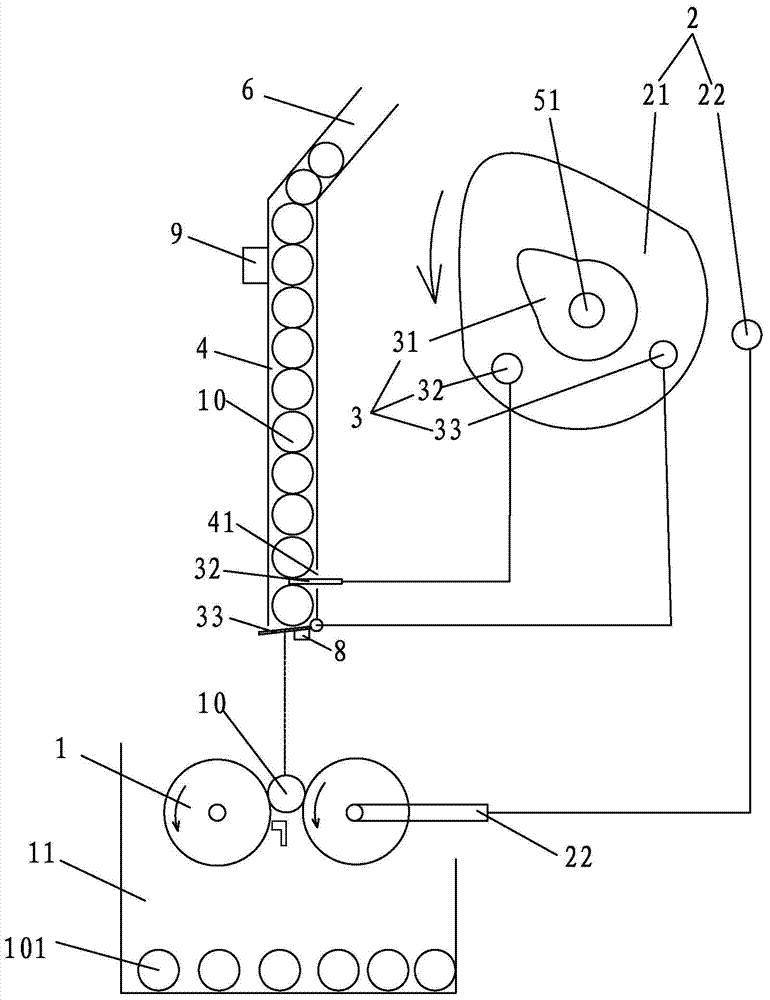

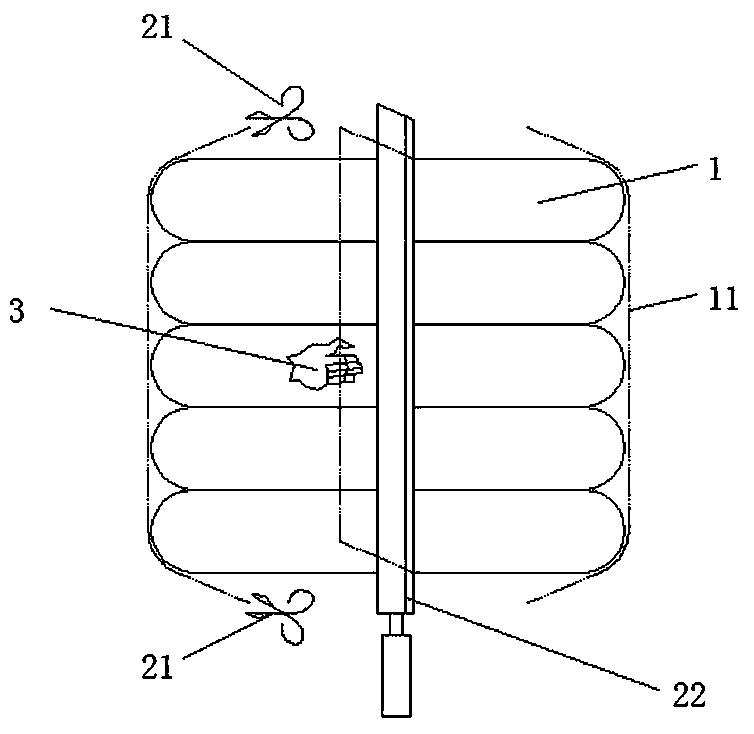

Automatic processing system for dyeing loose fibers

ActiveCN101629365AImprove the degree of automated productionIncrease productivityTextile treatment machine partsFibre cleaning/openingCircular discProduction line

The invention discloses an automatic processing system for dyeing loose fibers. The system comprises a dry opening machine, a disk forming machine, a dyeing machine, a dewatering machine, a wet opening machine, a drying machine and an automatic packing machine which are sequentially connected, wherein, a pre-opening machine is connected between the dewatering machine and the wet opening machine, the pre-opening machine comprises a rotatable disk, the disk is installed on a lifting rack, and a cotton peeling roller is arranged above the disk. A hydraulic disk jacking machine can also be arranged between the dyeing machine and the dewatering machine. The invention is the first automatic production line for dyeing the loose fibers, can be suitable for dyeing various fibers, and can increase the degree of automatic production, shortens the production period of entire dyeing processing, increases the production efficiency, reduces the intensity of labor production, and especially greatly increases safety.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

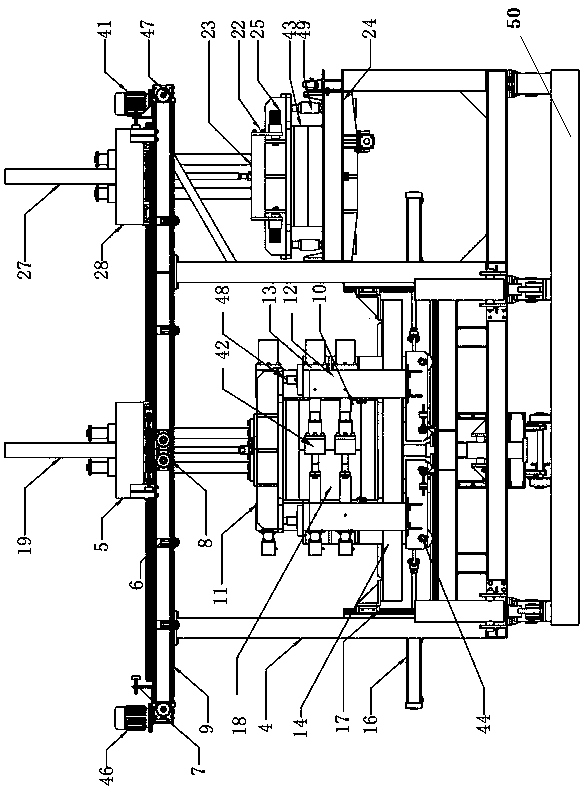

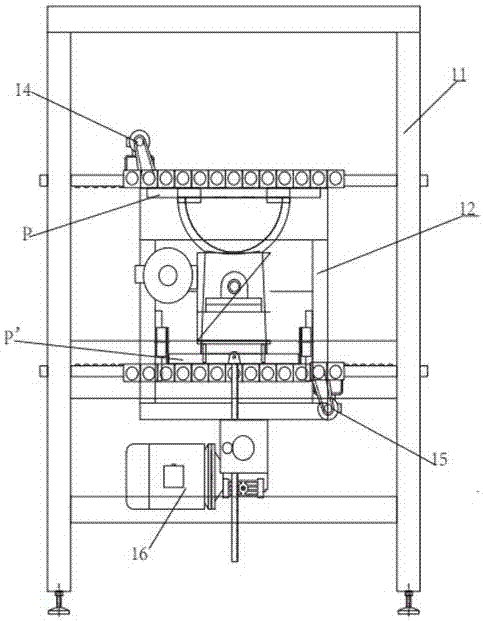

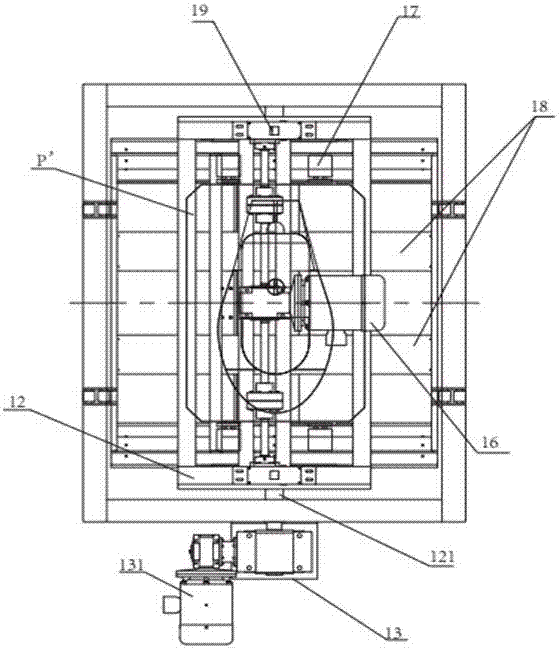

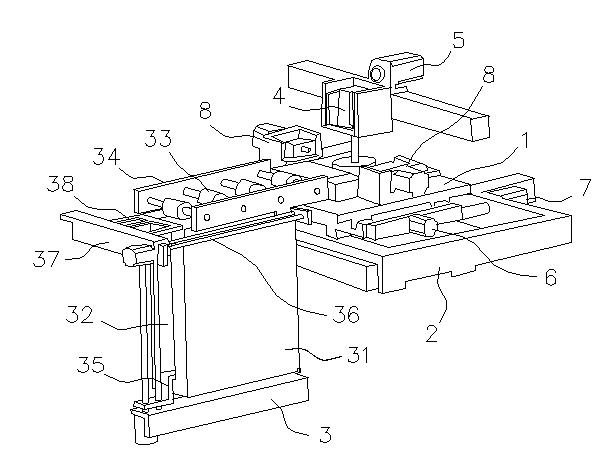

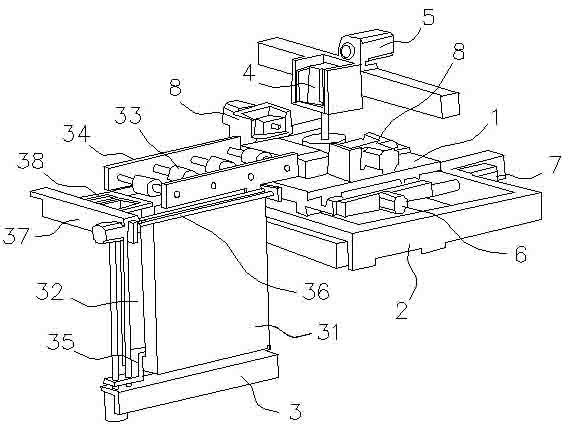

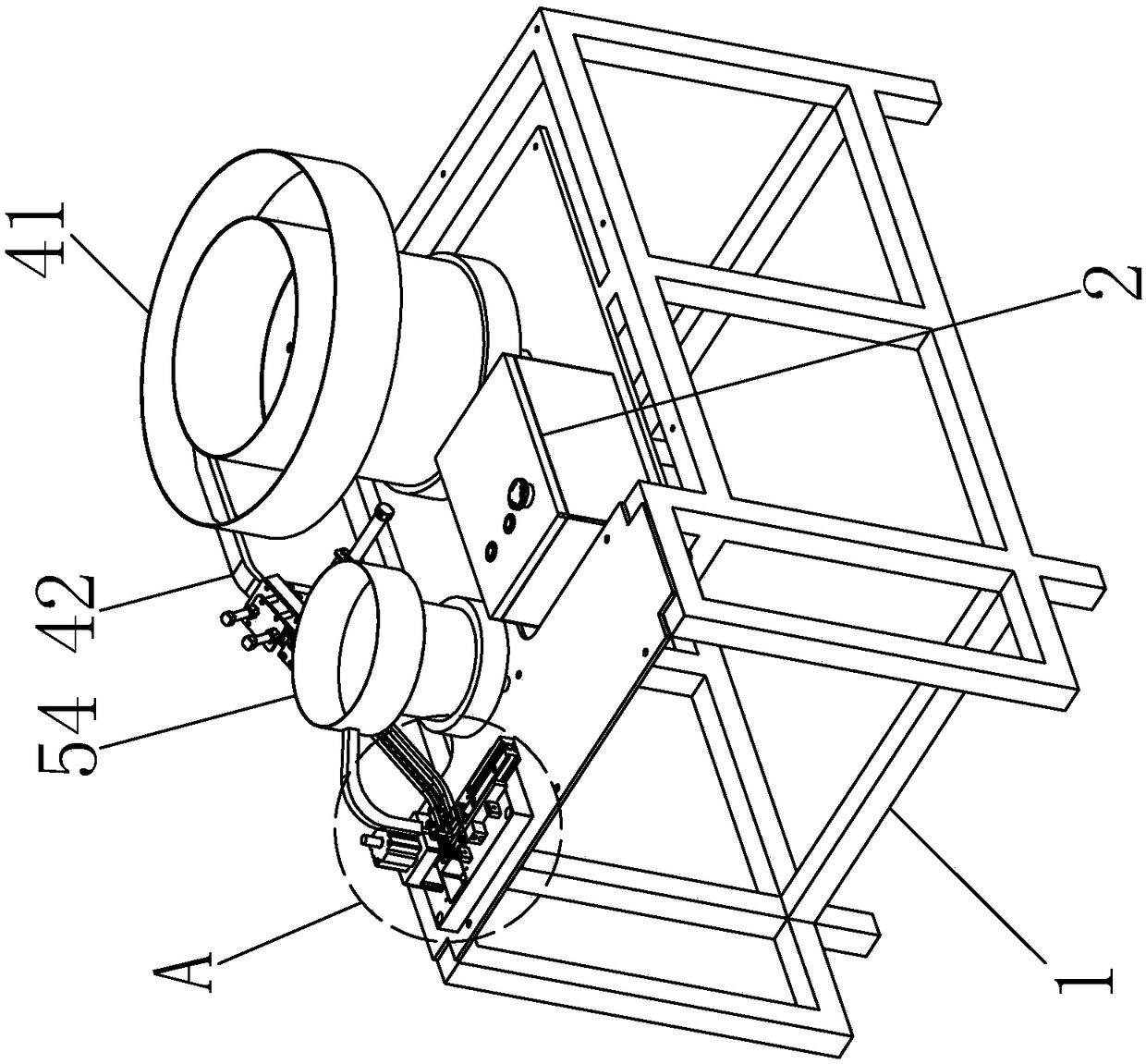

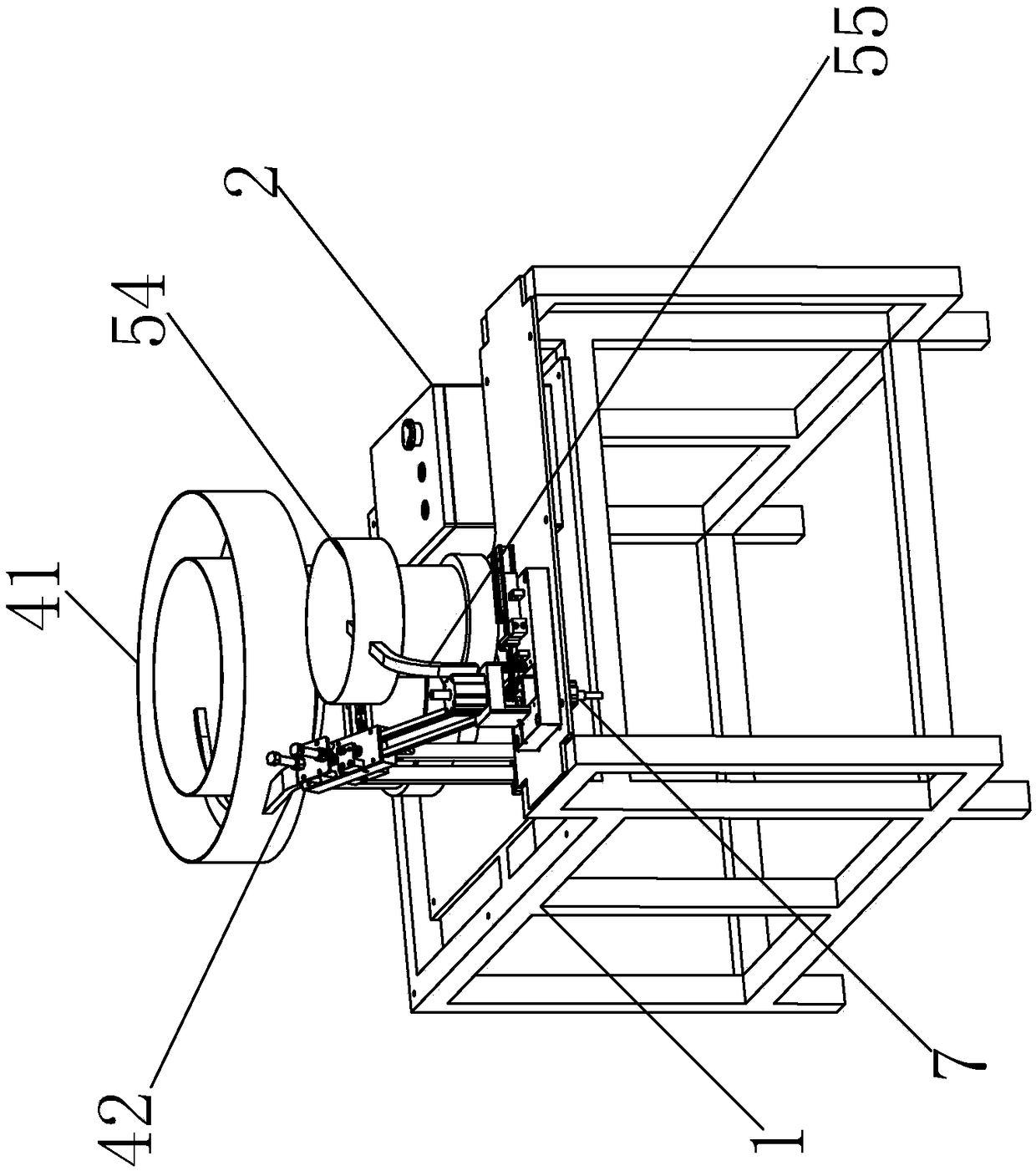

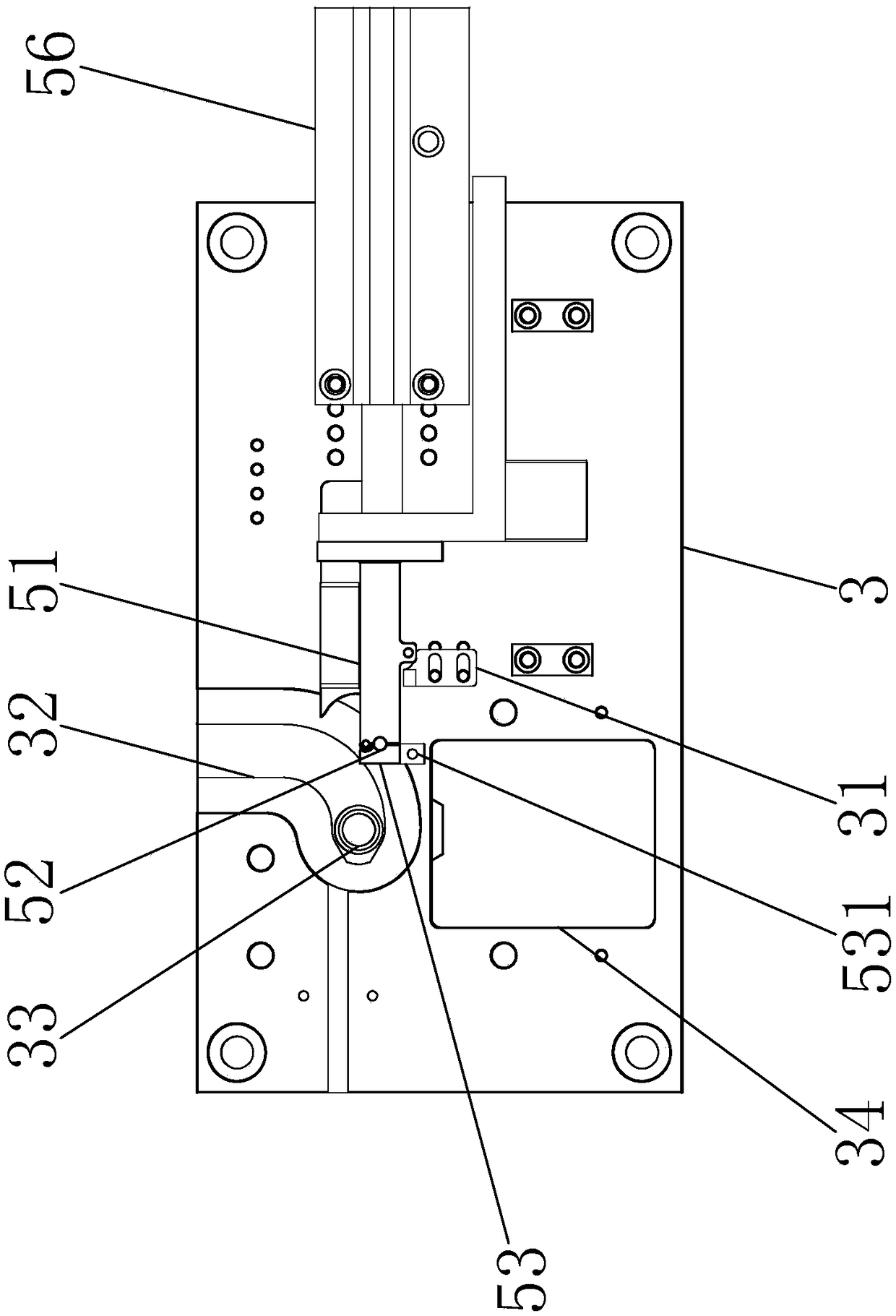

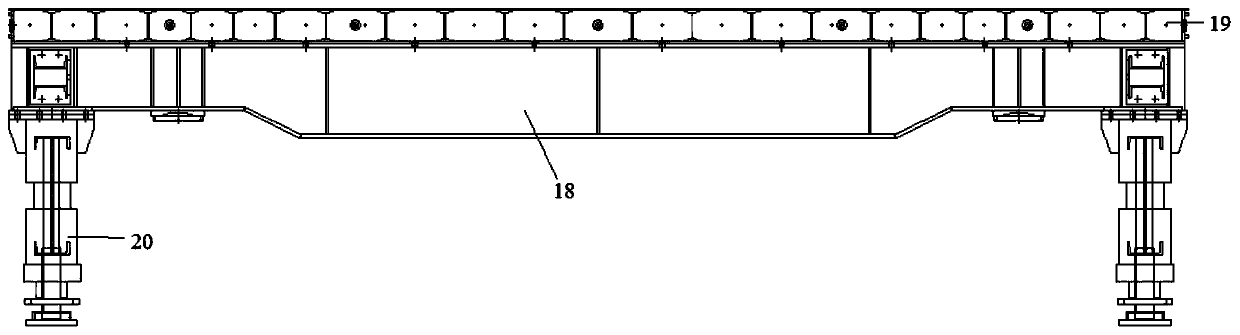

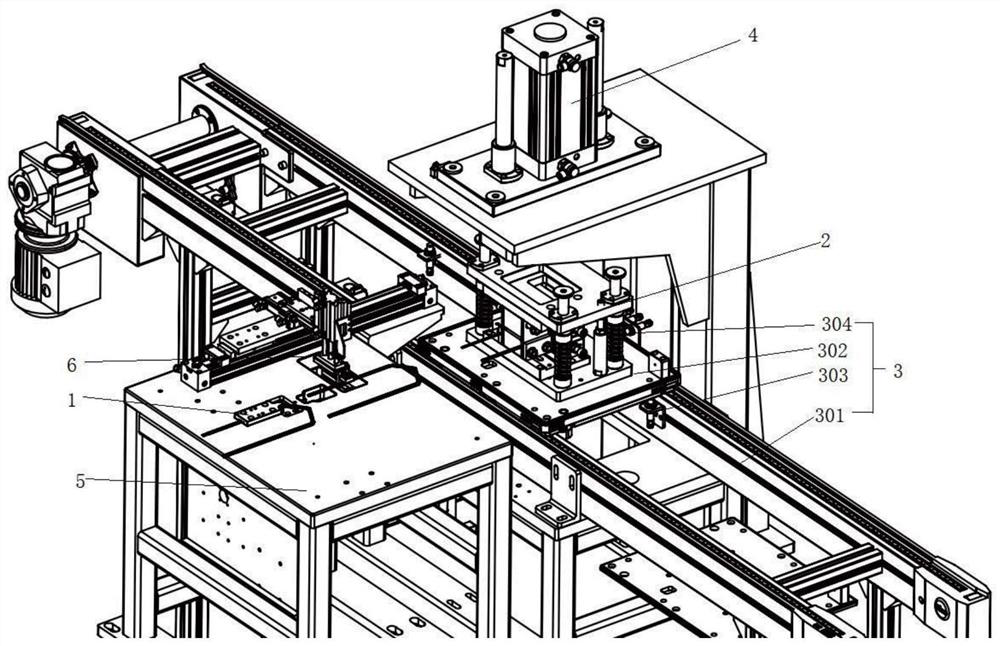

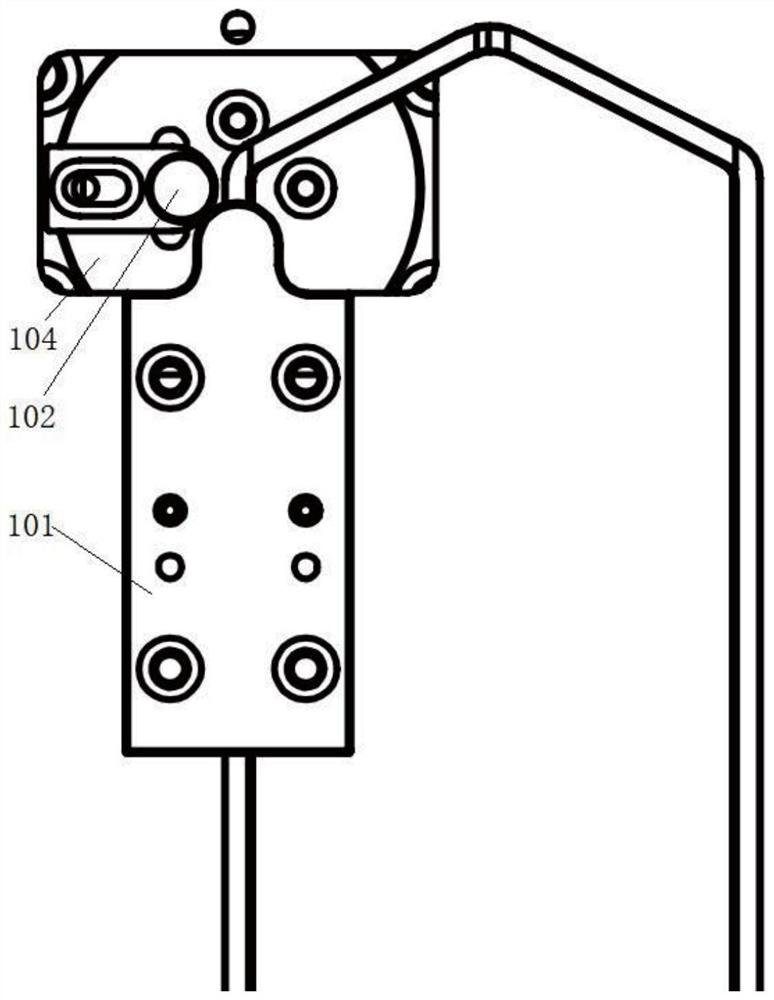

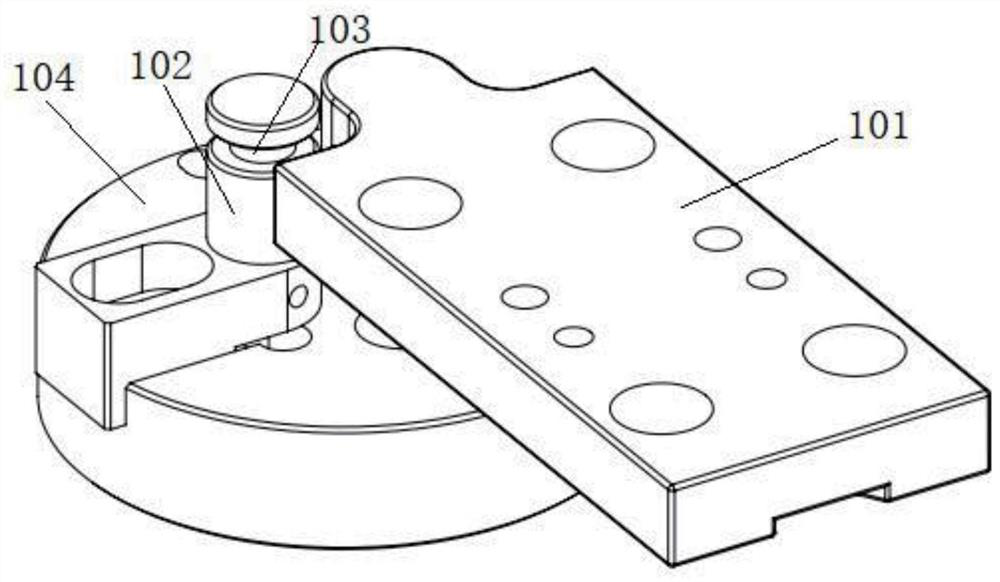

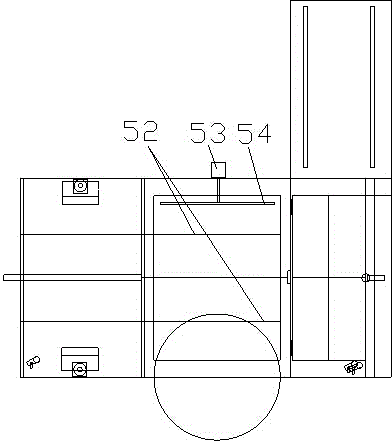

High-pressure automatic forming system of pedestal pan

ActiveCN103722607AImprove work efficiency and yieldImprove work efficiencyCeramic shaping apparatusAutomatic controlHigh pressure

The invention discloses a high-pressure automatic forming system of a pedestal pan. The high-pressure automatic forming system comprises a base, a door-shaped main frame, a mud spraying device, a high-pressure forming machine of a pedestal-pan body, a high-pressure forming machine of a pedestal-pan ring body and a transplanting machine, wherein two supporting legs on one side of the door-shaped main frame are hinged with the base; two supporting legs on the other side are hinged with the base by means of an inclined oil cylinder; the axes of the hinging shafts between the four supporting legs and the base are parallel; the high-pressure forming machine of the pedestal-pan body and the high-pressure forming machine of the pedestal-pan ring body are respectively arranged on the inner side of the door-shaped main frame; the mud spraying device is fixedly arranged on one side of the door-shaped main frame; the transplanting machine is arranged on the other side of the door-shaped main frame by means of a track. The high-pressure automatic forming system disclosed by the invention has the advantages that automatic bonding of the pedestal pan body and the pedestal pan ring body is realized by automatic control, the forming procedure and the bonding procedure are integrated in the same system, so that the operating efficiency is improved, the carrying in the forming and bonding process in different systems is avoided and the labor intensity is reduced.

Owner:HUIDA SANITARY WARE

Plastic pelletizing production line

ActiveCN110640929AImprove the degree of automated productionSave human resourcesDrying gas arrangementsProcess engineeringManufacturing line

The invention relates to the technical field of plastic pelletizing processing equipment, in particular to a plastic pelletizing production line. According to the main points of the technical scheme,the plastic pelletizing production line comprises a feed hopper; a mixing assembly is connected to the feed hopper and is connected with a plastic extruder; a water cooling mechanism is connected to the discharge end of the plastic extruder; a pelletizer is connected to the water cooling mechanism; a collecting and screening device for receiving and screening plastic particles are arranged at thedischarge end of the pelletizer; the water cooling mechanism comprises a cooling water trough, a water removal mechanism and a drier which are connected sequentially; a conveying roller is rotationally connected to the side, toward the plastic extruder, of the cooling water trough; cooling water is arranged in the cooling water trough; and the water removal mechanism comprises a cooling water groove of which the top is open, a plurality of installation plates arranged at the top of the cooling water groove in the length direction of the cooling water groove, and bristles arranged on the installation plates. Through the plastic pelletizing production line, drawn plastics can be well cooled and dried.

Owner:东莞市凯柏塑胶科技有限公司

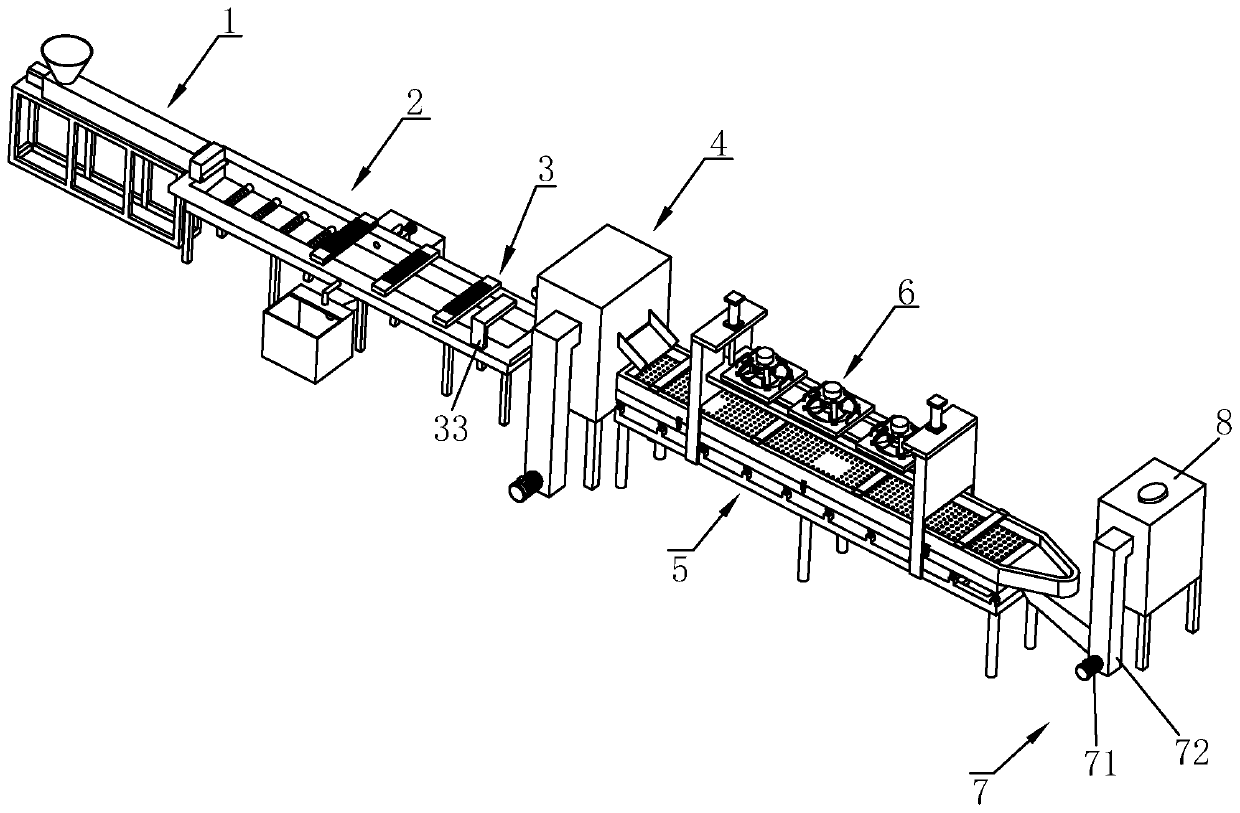

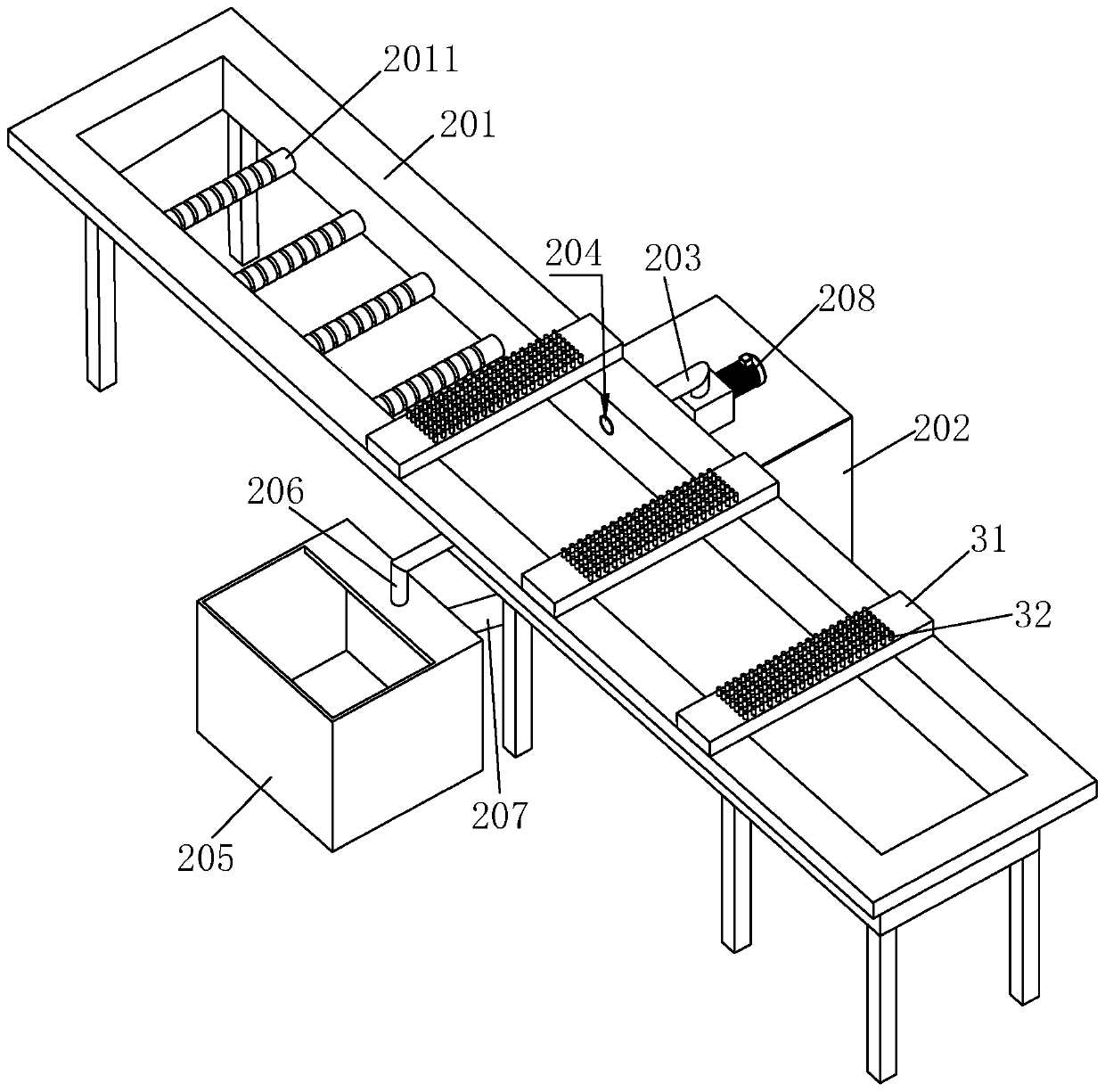

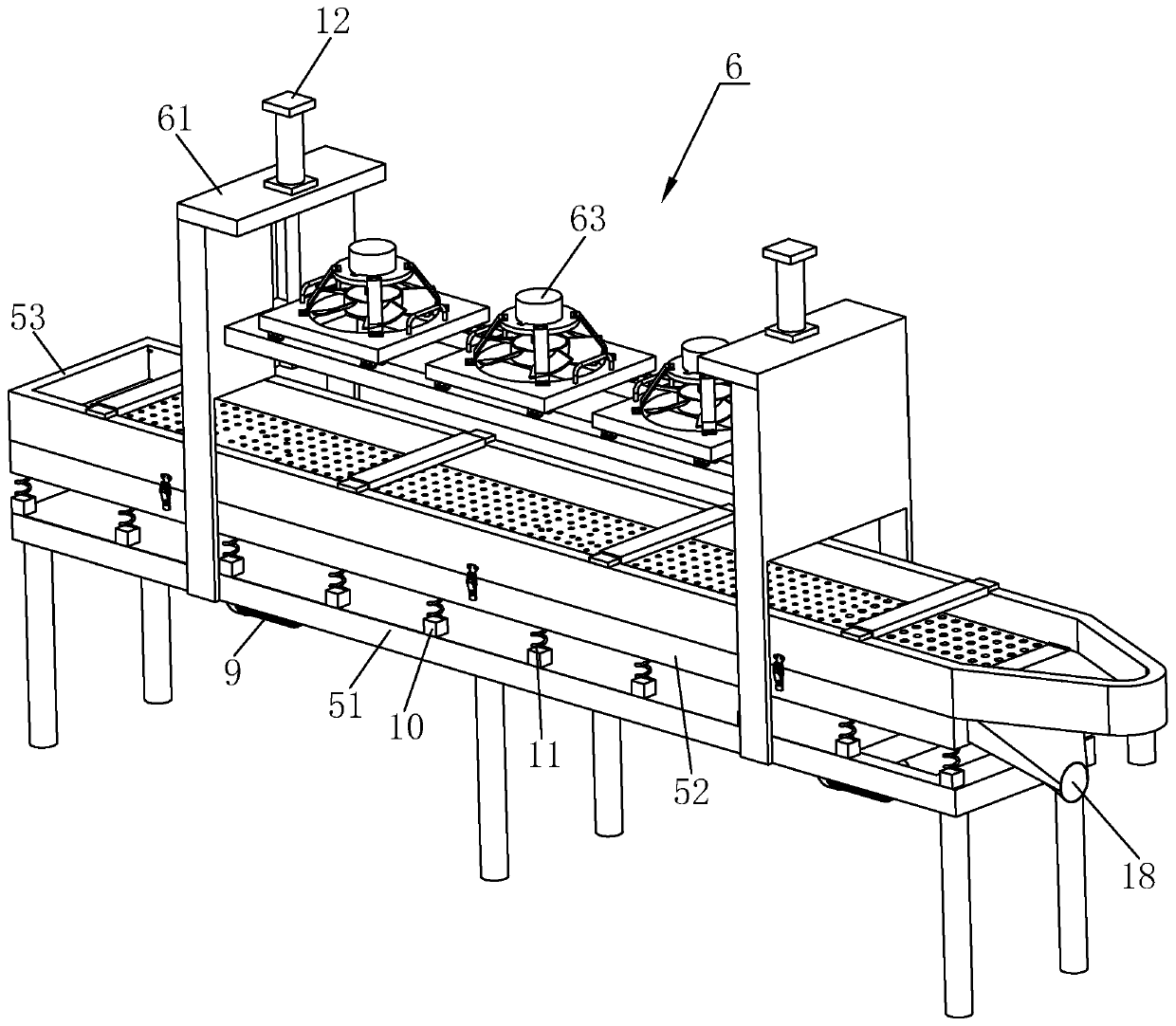

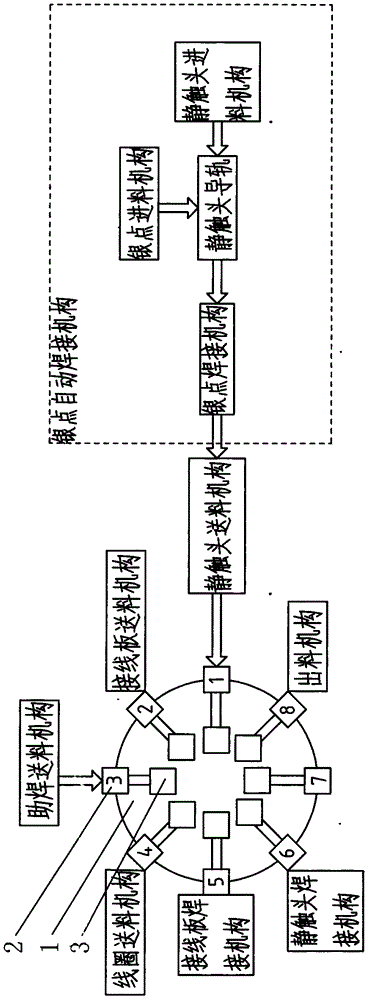

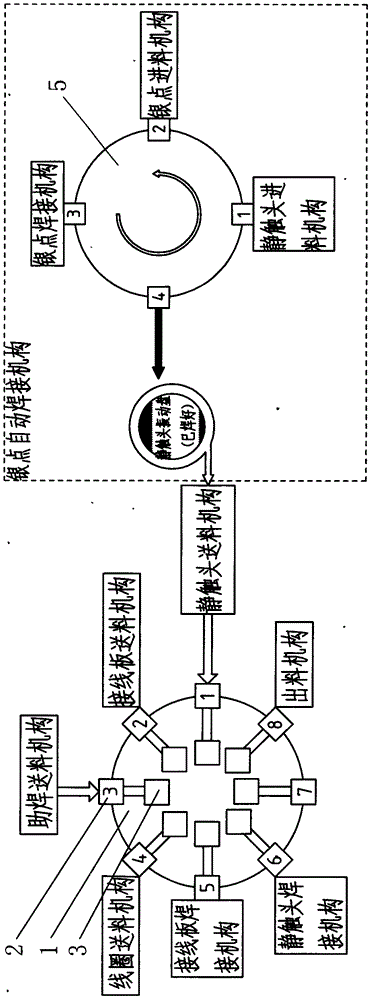

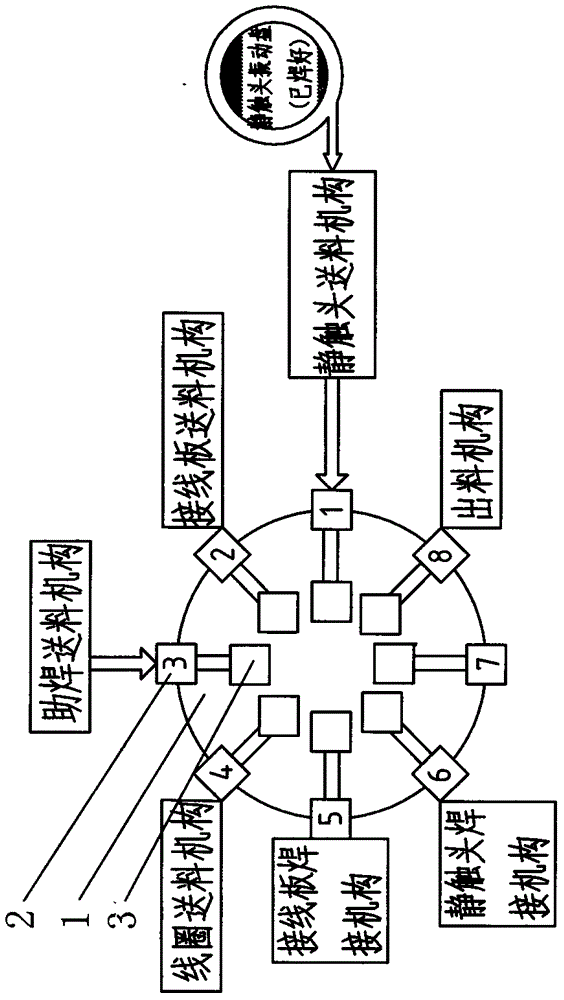

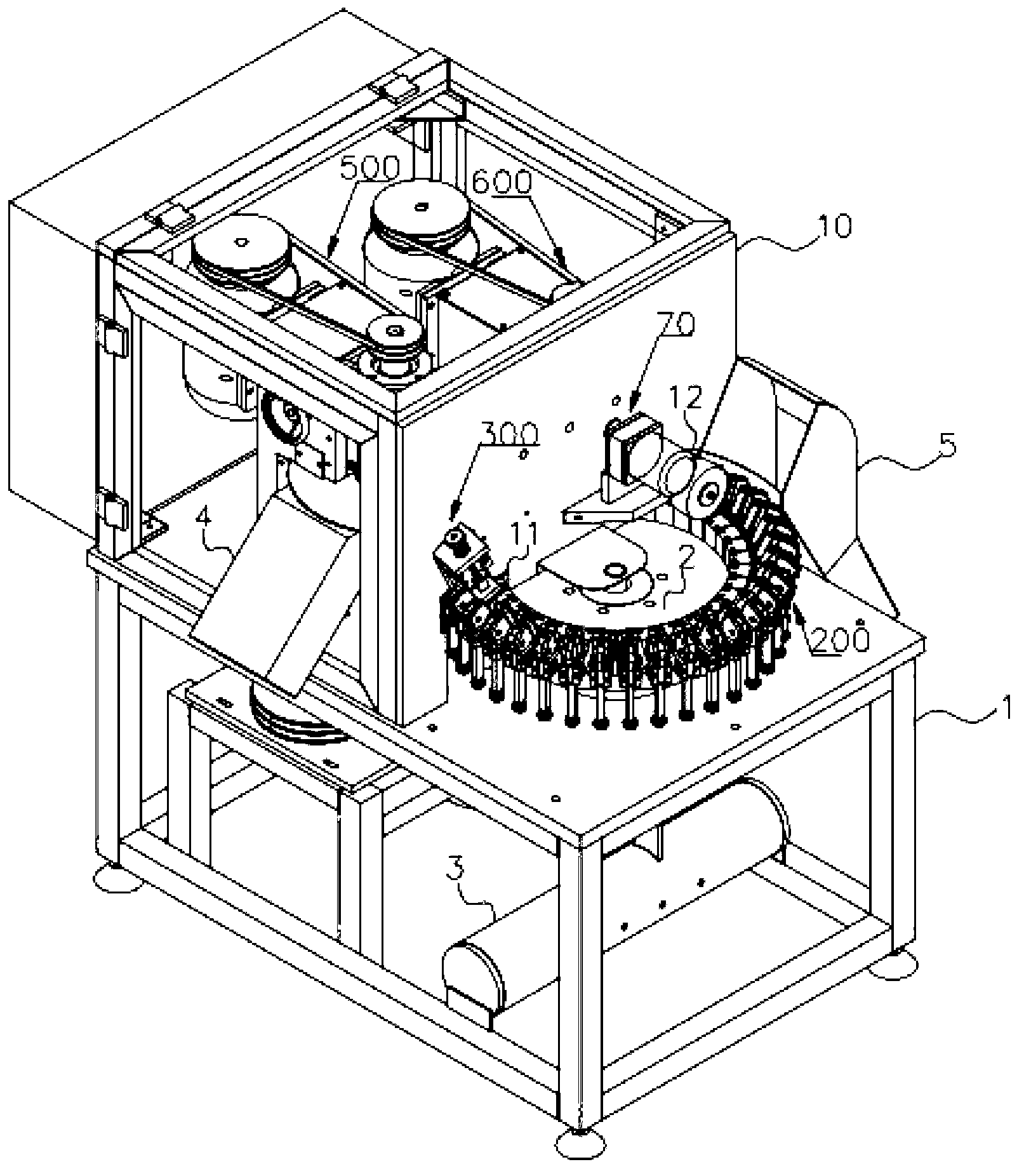

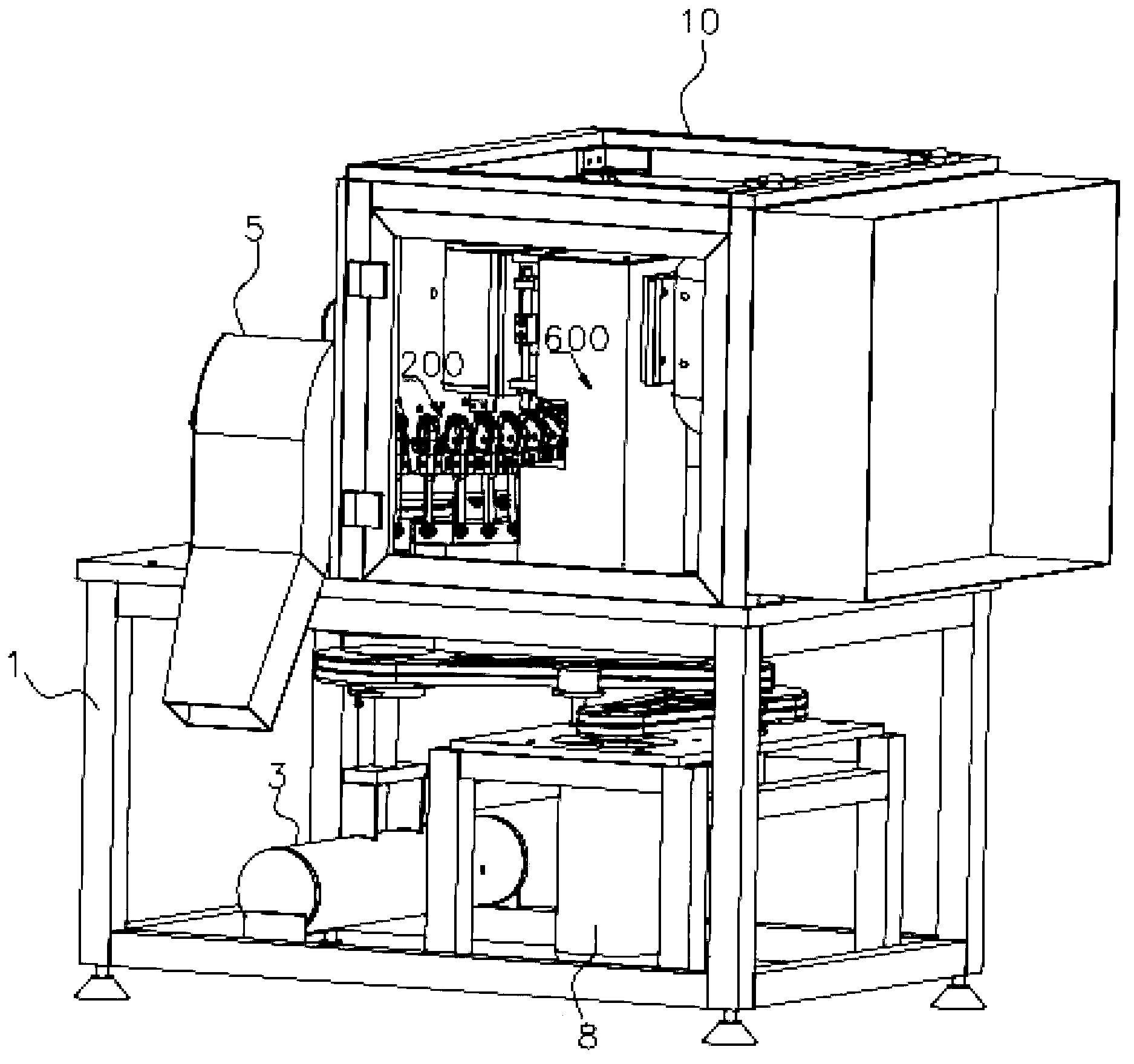

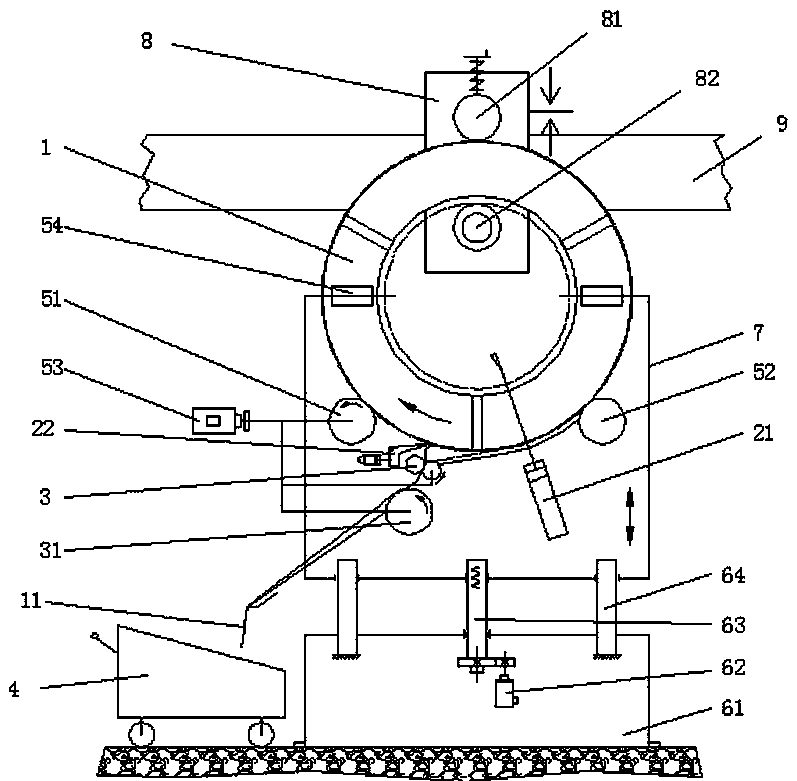

Electromagnetic system full-automatic welding machine and welding process thereof

InactiveCN106181085AImprove the degree of automated productionReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesWaste productIndustrial engineering

The invention discloses an electromagnetic system full-automatic welding machine and a welding process thereof. Turntable clamps are arranged on a slicer. The welding process of the electromagnetic system full-automatic welding machine comprises the following steps that (1) silver contacts are welded to fixed contacts, the fixed contacts are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (2) wiring boards are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (3) welding-assisting materials are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (4) coils are conveyed to the turntable clamps, and the slicer is automatically shifted to the next working station; (5) the coils are welded to the wiring boards through all welding mechanisms, the coils are welded to the fixed contacts through all the welding mechanisms, and the slicer is automatically shifted to the next working station after welding is completed; and (6) waste products and qualified products are screened at a discharging working station, and the slicer is automatically shifted to the next working station. According to the electromagnetic system full-automatic welding machine, the needed materials are clamped at the multiple working stations correspondingly and subjected to welding on the welding working station, electromagnetic system full-automatic welding is achieved, labor cost is greatly reduced, and the production efficiency is improved.

Owner:WENZHOU SHENKE DETECTION EQUIP

Miter cutting machine

ActiveCN103008763AReduce the burden onShorten the timeTube shearing machinesShearing machine accessoriesDrive motorRotating disc

The invention discloses a miter cutting machine, which comprises a frame for fixing a workpiece and a cutting device for cutting the workpiece, wherein a horizontal rotating disc and a driving motor for driving the horizontal rotating disc are arranged on the frame; and a plurality of jigs are arranged on the edge of the horizontal rotating disc in the circumferential direction. Compared with the prior art, the miter cutting machine has the advantages as follows: the jigs are mounted on the horizontal rotating disc, so that a plurality of workpieces can be fed at a time, and continuous conveying and cutting are realized; the workpieces are pressed tightly by a downward pressing device, clamped by the jigs and a lug boss and automatically discharged by a discharging device, and operators only need to feed the workpieces, so that the degree of automatic production of the miter cutting machine is increased, and the production efficiency is improved; the miter cutting machine can be adjusted in height, thereby meeting the requirements of products with different sizes; the miter cutting machine can perform precise cutting, so that the cut of an obtained product is smooth in cut and no burr exists at the periphery of the cut; and the miter cutting machine is convenient for size adjustment of the product.

Owner:ZHEJIANG AXILONE SHUNHUA ALUMINUM IND

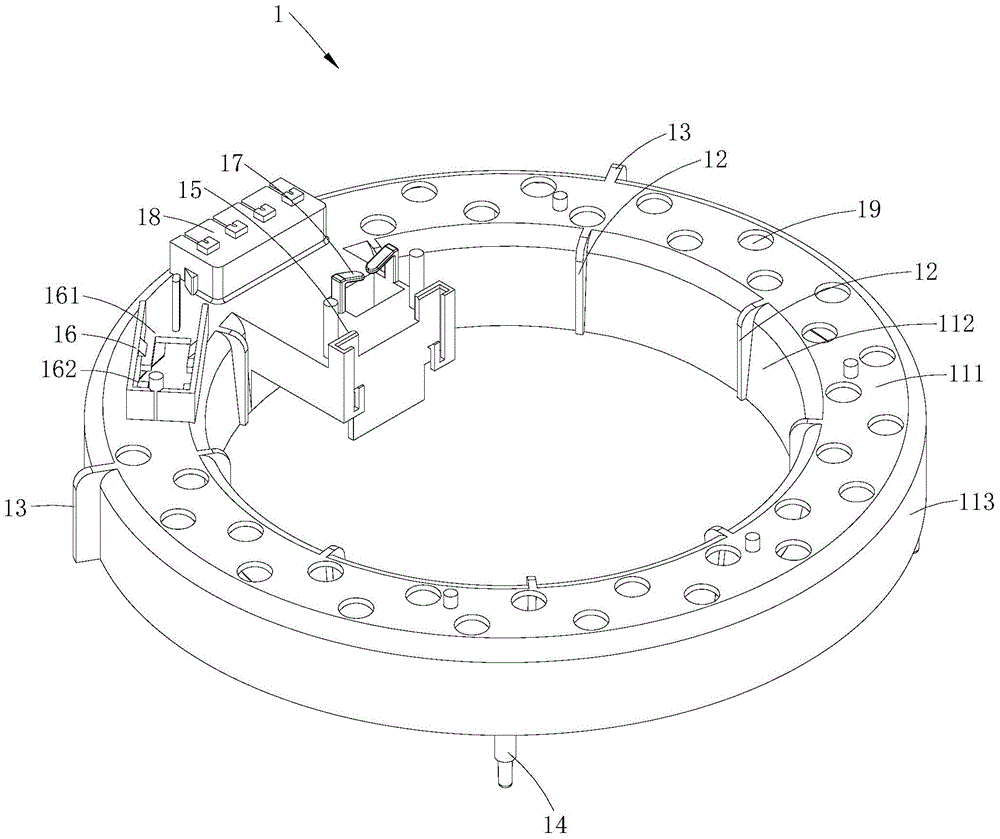

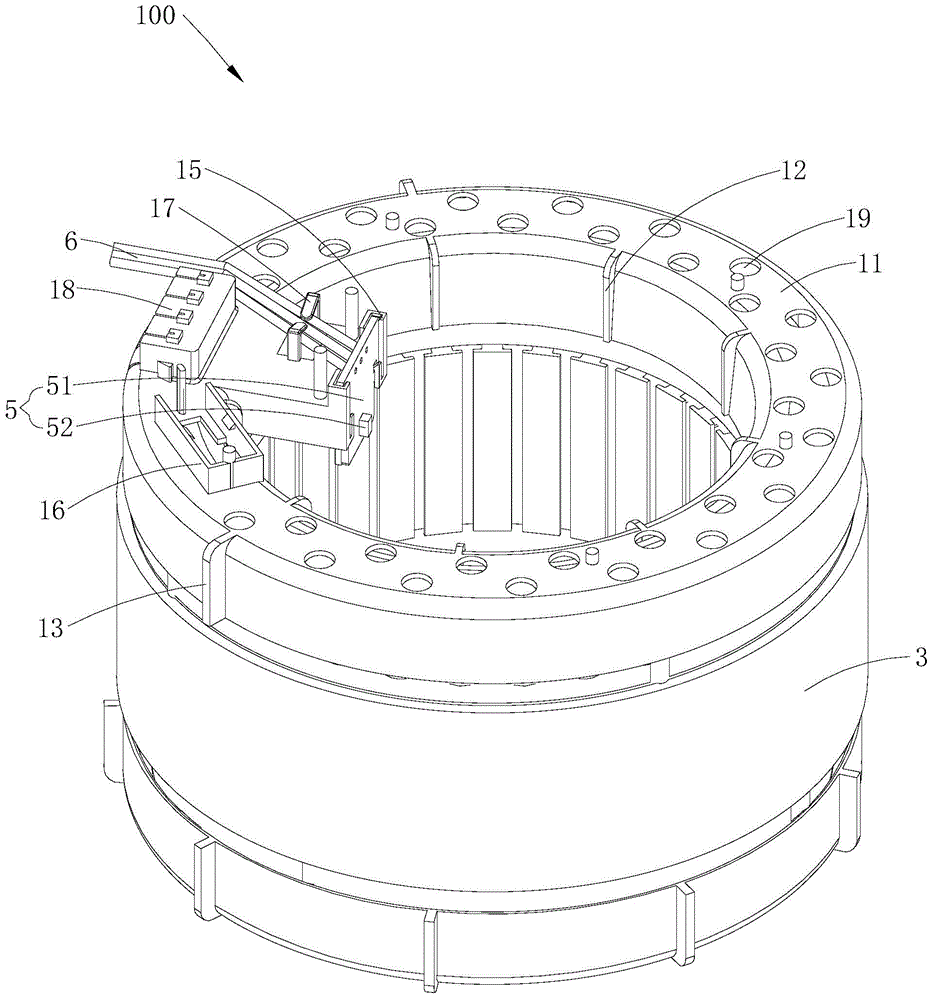

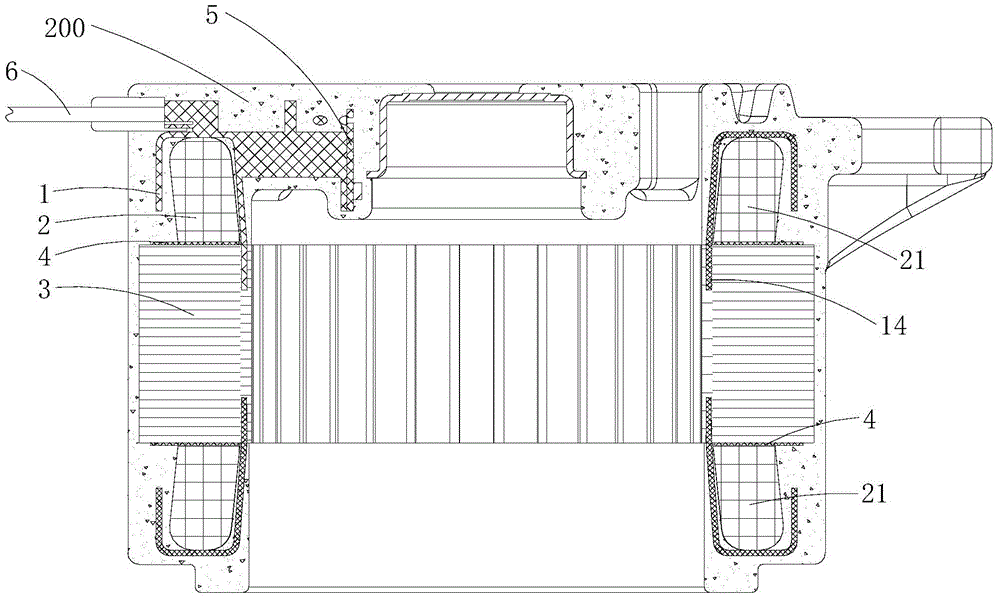

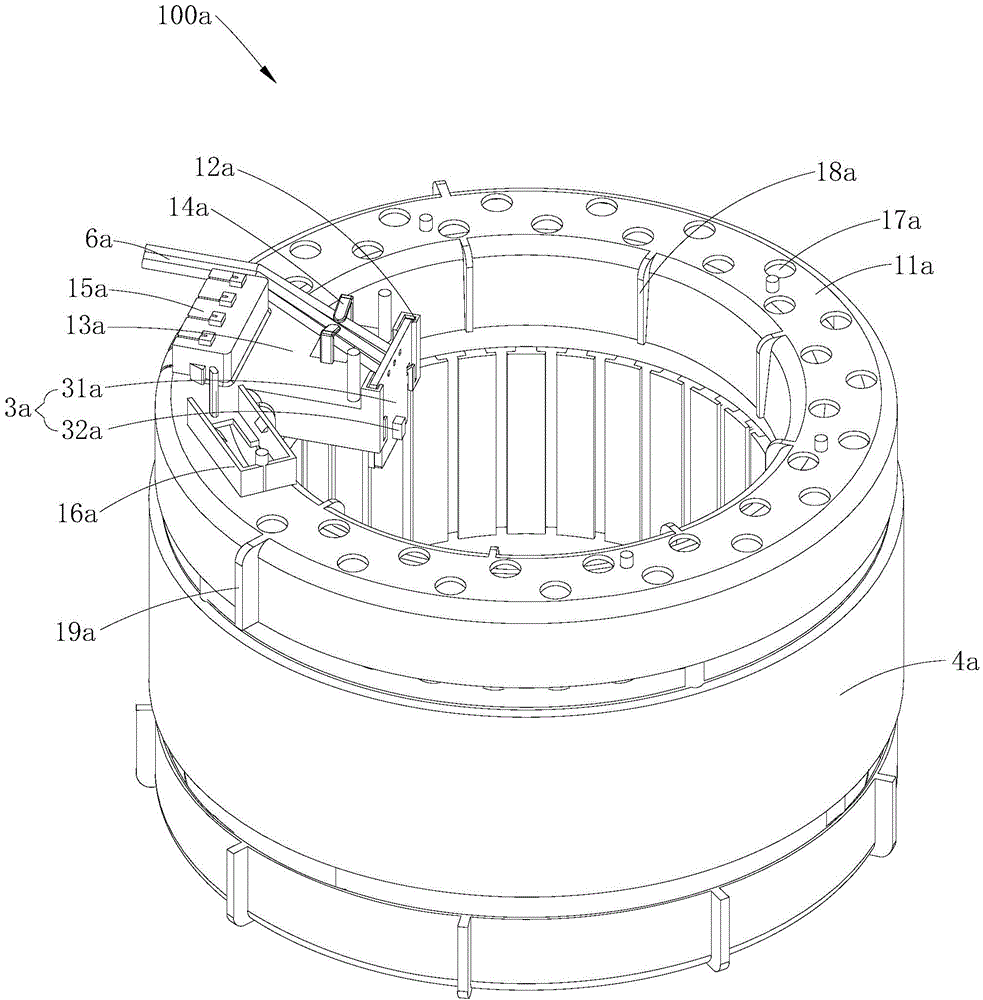

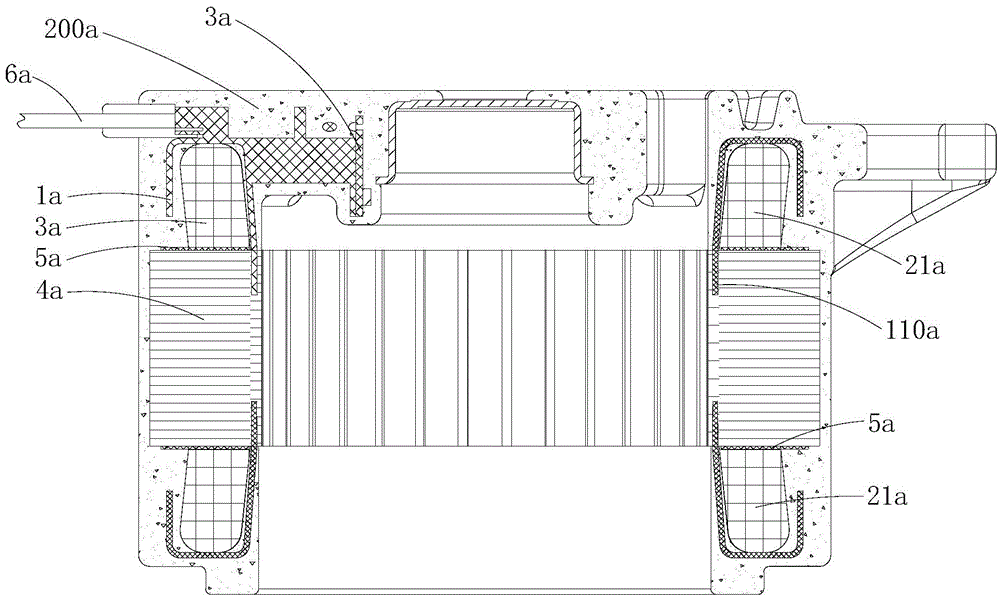

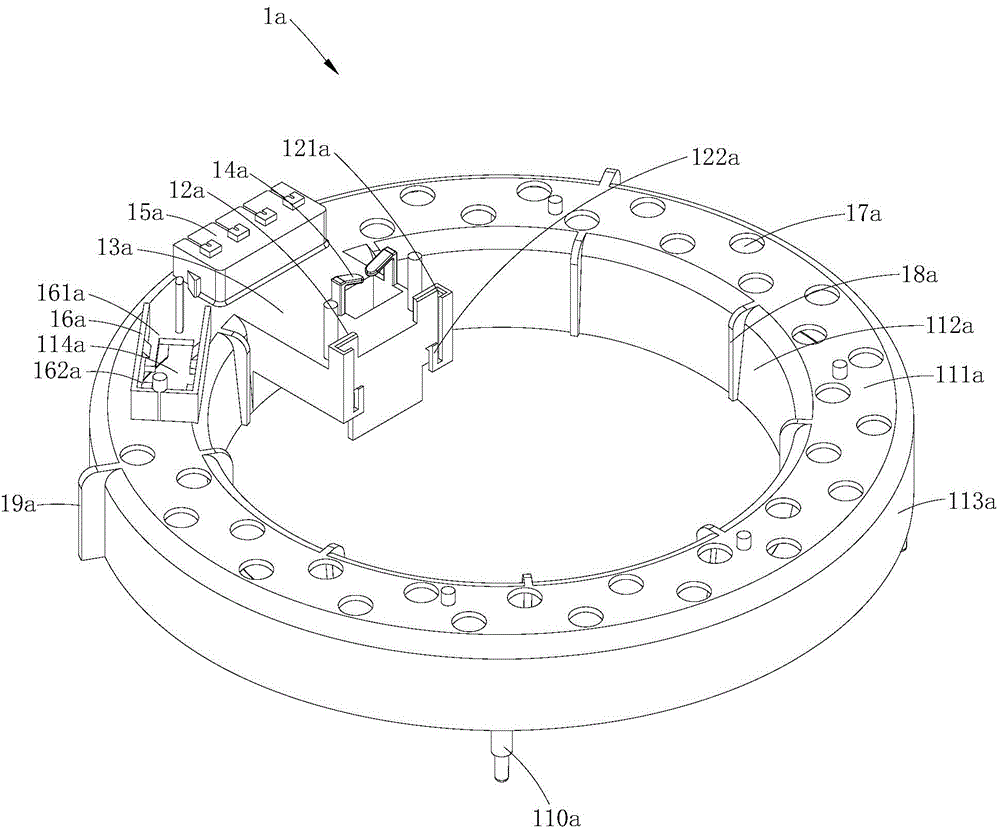

Stator winding end insulation frame, plastic-packaging stator assembly, and plastic-packaging motor

ActiveCN104836360APrevent radial displacement phenomenonRealize automated production and installationWindings insulation shape/form/constructionMagnetic circuit stationary partsPlastic packagingUltimate tensile strength

The invention is suitable for the field of motors, and discloses a stator winding end insulation frame, a plastic-packaging stator assembly, and a plastic-packaging motor. The insulation frame comprises an insulation frame body which is disposed at an axial end part of a stator winding along the axial direction of a motor in a sleeve manner. The insulation frame body comprises an annular panel, an inner side panel, and an outer side panel, wherein the inner side panel is provided with a plurality of inner side positioning convex blocks in a convex manner, and / or the outer side panel is provided with a plurality of outer side positioning convex blocks in a convex manner. According to the invention, the inner side positioning convex blocks and / or the outer side positioning convex blocks can abut against a plastic-packaging mold radially in a plastic-packaging process, thereby preventing the insulation frame from deflecting radially because of the injection molding pressure of plastic-packaging materials, preventing a large part of the insulation frame from being exposed after plastic packaging, further improving the bonding intensity of the plastic-packaging housing with the insulation frame, improving the beauty of a product, and finally improving the qualified rate of products.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Stator winding end insulation frame, plastic-packaging stator assembly, and plastic-packaging motor

ActiveCN104836358AAutomate installationGuaranteed reliabilityWindings insulation shape/form/constructionPlastic packagingEngineering

The invention is suitable for the field of motors, and discloses a stator winding end insulation frame, a plastic-packaging stator assembly, and a plastic-packaging motor. The insulation frame comprises an insulation frame body which is disposed at an axial end part of a stator winding along the axial direction of a motor in a sleeve manner. The insulation frame body is provided with a PG plate installation frame which is used for the installation and positioning of a PG plate member, wherein the PG plate installation frame is provided with a clamping groove which is used for the storage and positioning of the PG plate member. According to the invention, the insulation frame body is additionally provided with the PG plate installation frame, thereby achieving the installation and positioning of the PG plate member only if the PG plate member is slidingly clamped and inserted in the clamping groove of the PG plate installation frame during installation. The installation is very convenient, thereby facilitating the implementation of the automatic installation of the PG plate installation frame. Moreover, the PG plate member cannot be damaged by pressing in an installation process, thereby guaranteeing the reliability of motor performances. Meanwhile, the reduction design of the PG plate member is also facilitated, thereby avoiding the material waste, and reducing the cost of a motor.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Digital printing advertisement base material and preparation method thereof

ActiveCN105017548ASame protective effectImprove the degree of automated productionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesDigital printingHot-melt adhesive

The invention provides a digital printing advertisement base material and a preparation method thereof. The preparation method comprises the steps: preparing anti-ultraviolet hot melt glue for digital printing and putting a base layer on a coil-feeding rack of a coating machine for corona treatment; coating the anti-ultraviolet hot melt glue and drying the base layer at 60-120 DEG C, wherein the thickness of the cooled hot melt glue is 20-100 [mu]m; coating a 10-50 [mu]m thick ink-receptive coating on the cooled anti-ultraviolet hot melt glue, and printing a pattern; carrying out hot press, wherein the pressure is 1-5 kg, the temperature is 120-200 DEG C, the time is 2-50 seconds, and the anti-ultraviolet hot melt glue is melted and permeates among particles of the ink-receptive coating and the printed pattern and covers above and quickly congeals to a film to form a protective layer; and cooling and rolling. The advertisement base material prepared by the invention is bright in pattern, smooth and level, rainproof and sun-proof and strong in anti-ultraviolet ability, and is free of yellowing phenomenon if being used outdoors for one year.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

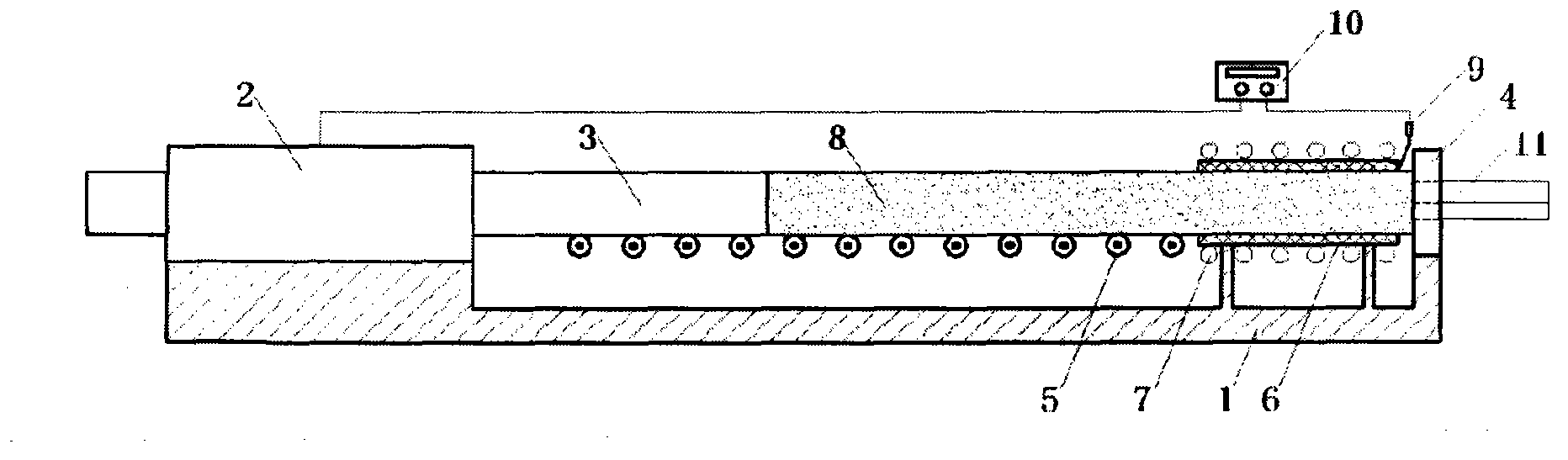

Aluminum profile extrusion production line

InactiveCN102935450AImprove the degree of automated productionQuality improvementExtrusion control devicesIntermediate frequencyThermal insulation

The present invention provides an aluminum profile extrusion production line, which is characterized in that the production line mainly comprises a base, a propulsion mechanism, a mold, a slide rail, a thermal insulation bush, an induction coil, a medium frequency power supply, a temperature detection member and a temperature controller, wherein a heating system and an extrusion system are integrated, an aluminum rod is pushed into the thermal insulation bush in front of the extrusion mold, and the induction coil wound on the periphery of the thermal insulation bush performs induction heating on the aluminum rod to achieve a synchronous heating and extrusion performing effect. According to the present invention, a space of the aluminum profile extrusion production line is substantially reduced; an automation production degree of aluminum profile extrusion is increased; quality of the produced aluminum profile can be effectively controlled; and the aluminum rod is uniform heated, and a heating time is short, such that heating efficiency is substantially increased, energy source is saved, no tail gas is discharged, and green environmental protection is provided.

Owner:ANHUI NEOFOUND TECH

Foldable three-dimensional double-opening iron core oil-immersed transformer

InactiveCN105513756AHigh mechanical strengthEasy to loosenTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerLow voltage

The invention discloses a foldable three-dimensional double-opening iron core oil-immersed transformer. The foldable three-dimensional double-opening iron core oil-immersed transformer comprises a double-opening transformer iron core having an L-shaped interlock structure, wherein the iron core is formed by splicing three single-frame double-opening iron cores at an center angle of 120 degrees, and the cross section of the spliced iron core is in an inscribed polygonal shape of a circle, an circular shape (R type) and a regular hexagonal shape; the iron core is arranged in an oil tank, three side surfaces of the oil tank are each provided with a heat radiation device, and the outer side of a core column is sequentially sleeved by a low-voltage coil and a high-voltage coil from inside to outside. The iron core of the foldable three-dimensional double-opening iron core oil-immersed transformer adopts a ferrite yoke and core column interlock structure, so that the foldable three-dimensional double-opening iron core oil-immersed transformer has the characteristics of low loss, small noise, high sudden short circuit resistance, high iron core mechanical strength and high production efficiency.

Owner:齐侠

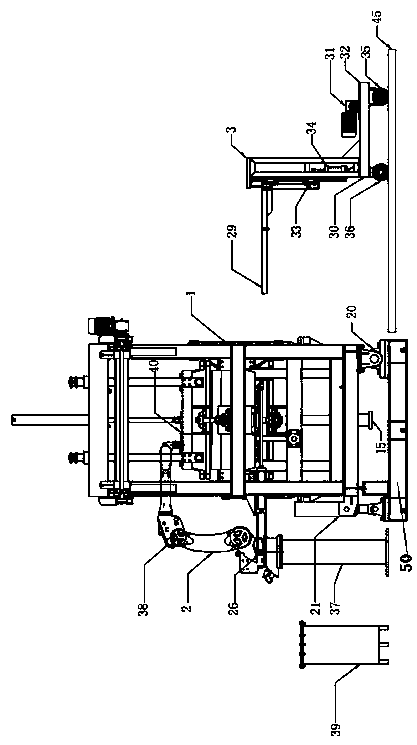

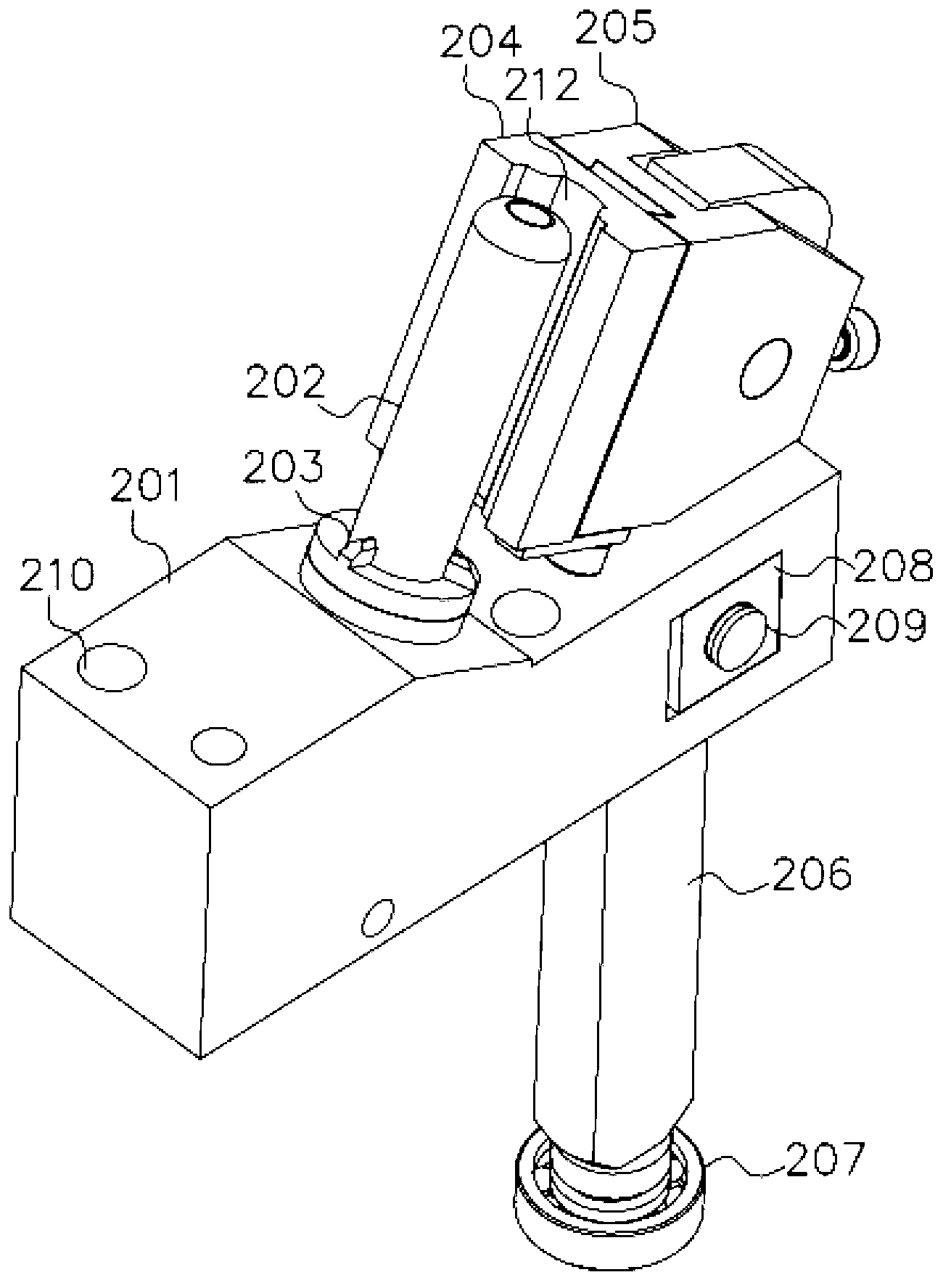

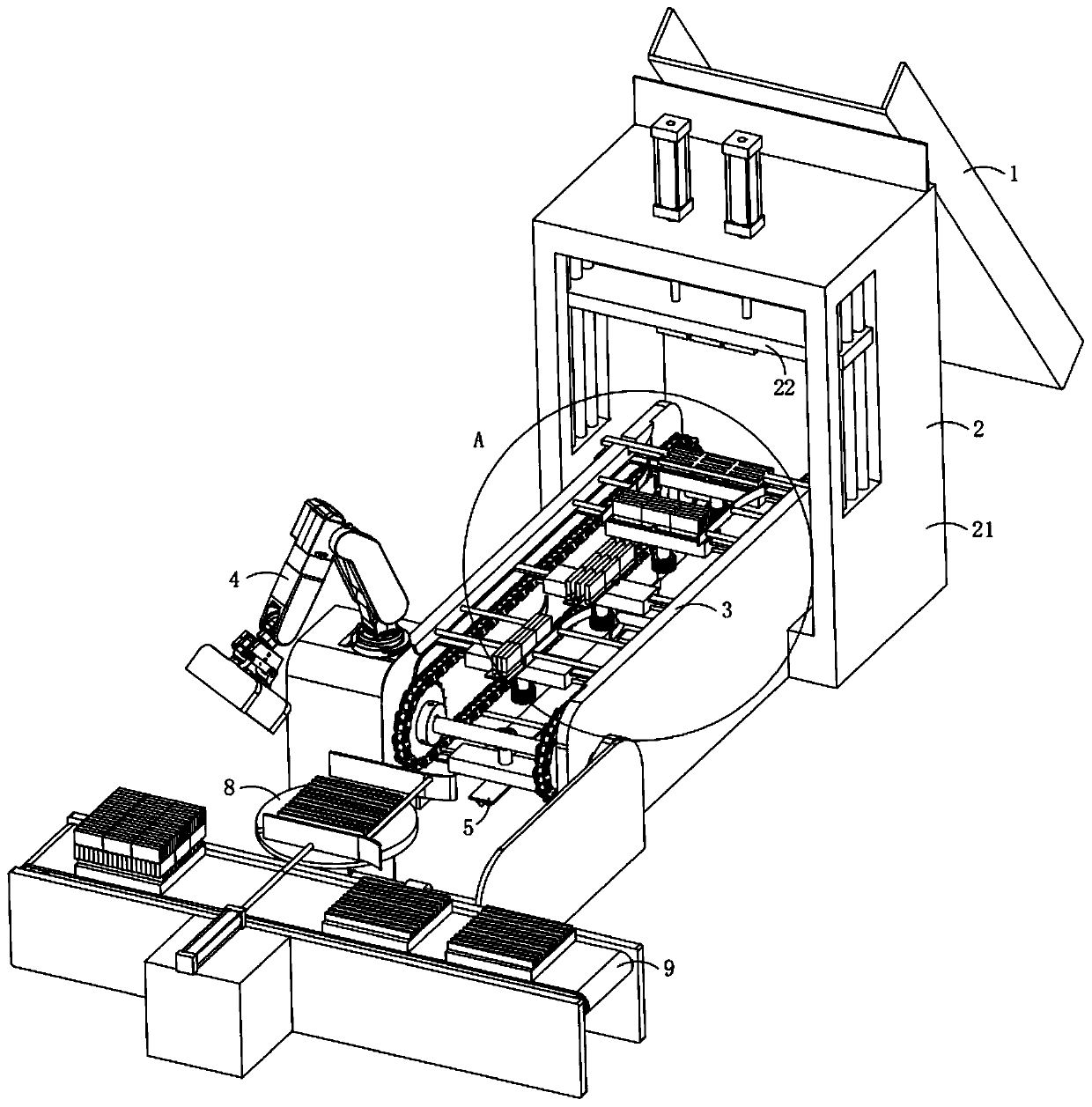

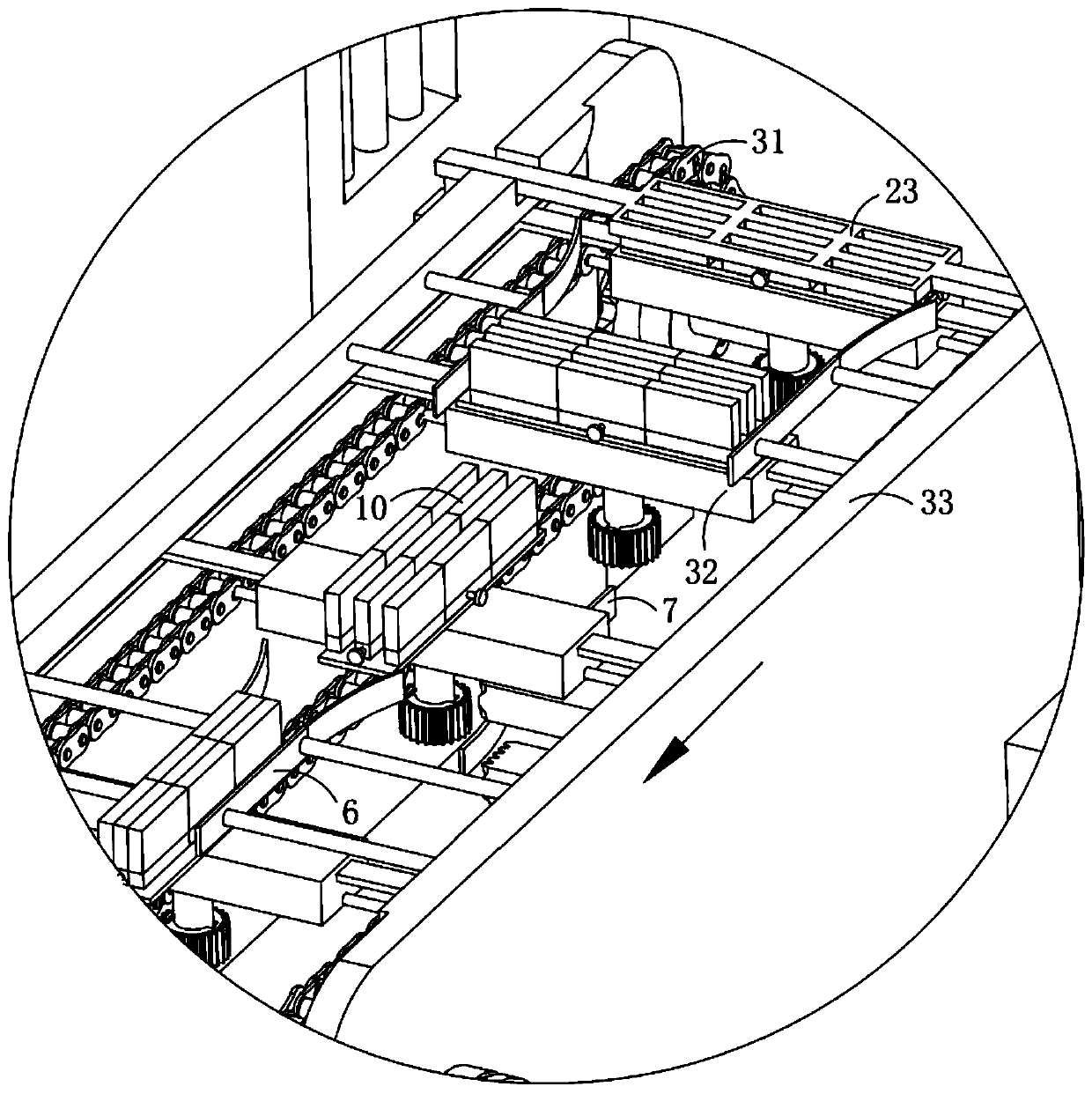

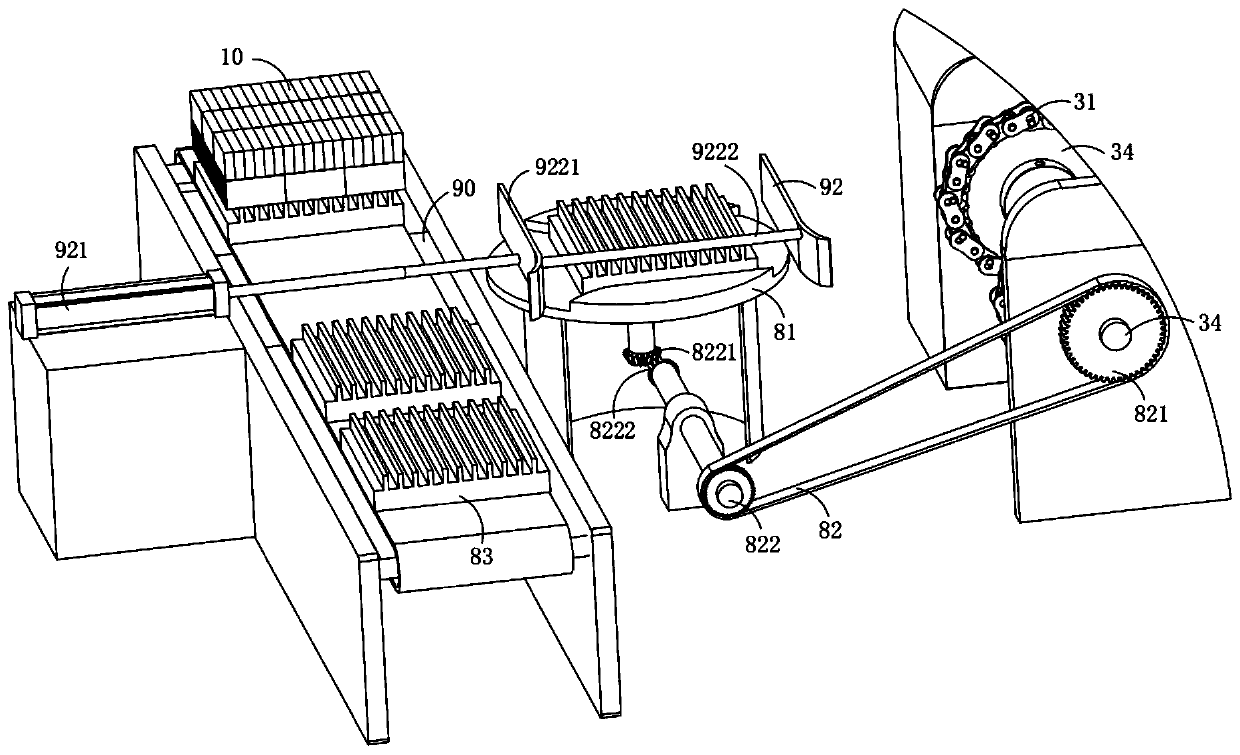

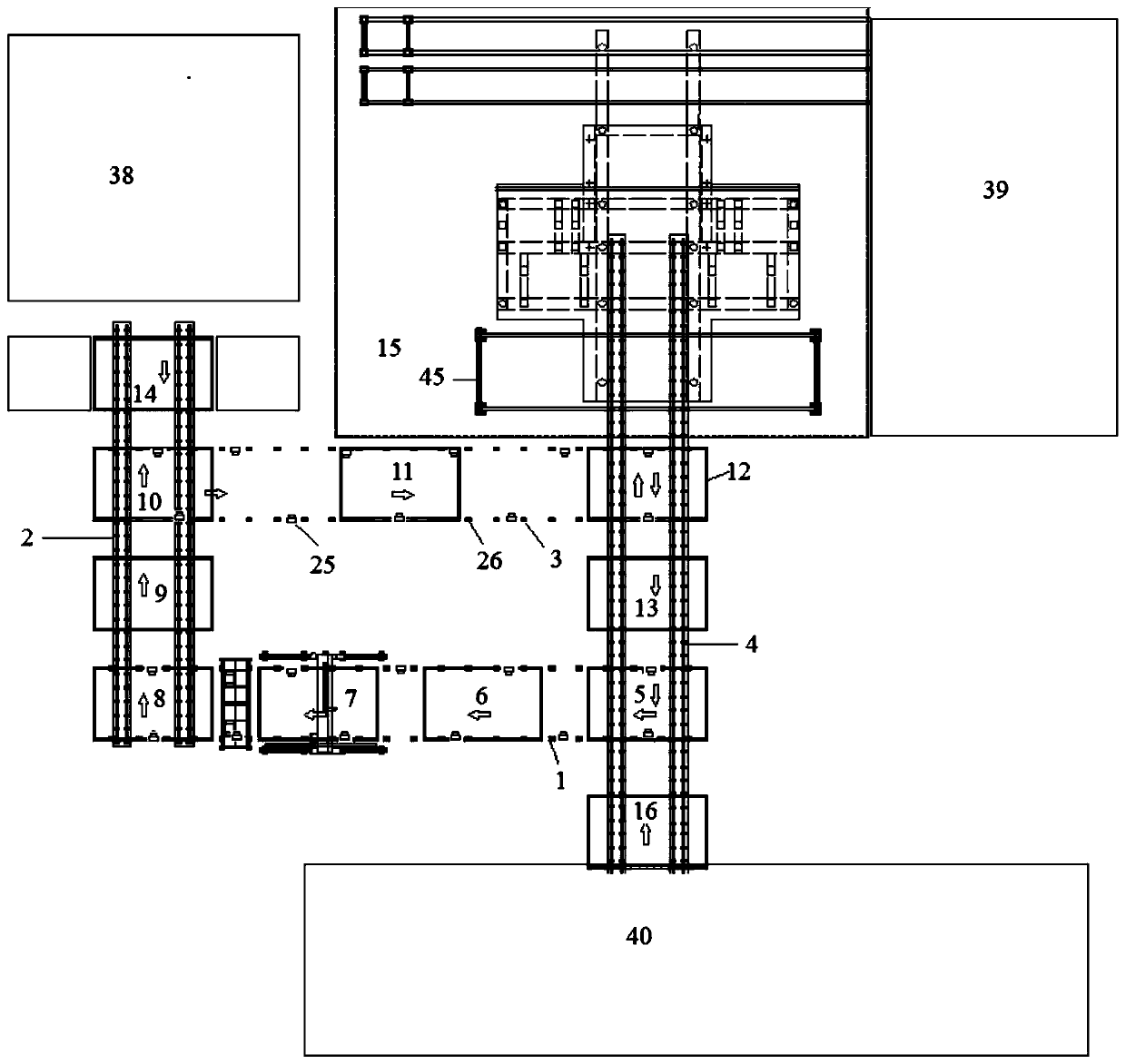

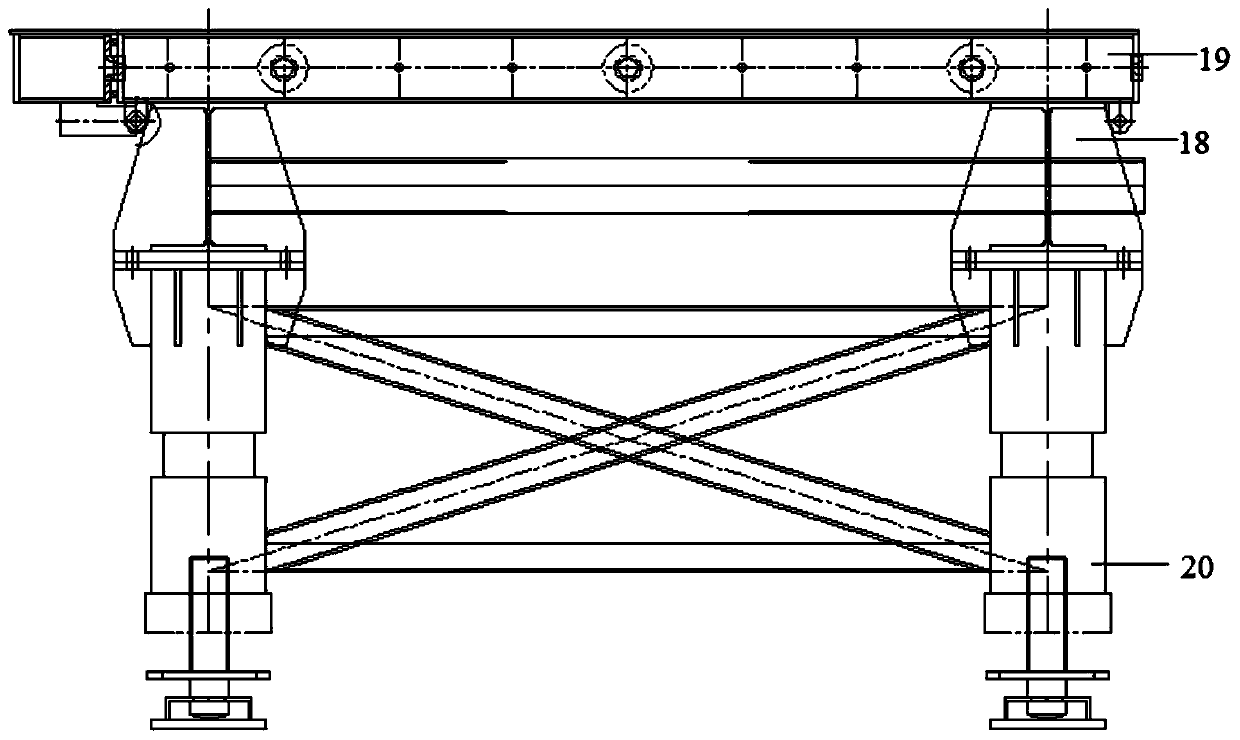

Automatic overturning and conveying device for high-pressure toilet bowl molding blank

PendingCN107322782AImprove the degree of automated productionReduce labor intensityAuxillary shaping apparatusAgainst vector-borne diseasesStructural engineeringMechanical engineering

The invention discloses an automatic overturning and conveying device for a high-pressure toilet bowl molding blank. The automatic overturning and conveying device comprises a host machine frame, and an overturning frame is arranged in the host machine frame and can be overturned relative to the host machine frame under driving of the host machine frame; the upper end and the lower end of the overturning frame are each provided with a conveying driving device, and the upper-end conveying driving device needs to fall or rise when installing is conducted. When the blank with a supporting plate enters the overturning frame, the lower-end conveying driving device stops moving, the supporting plate of the blank is clamped by supporting plate clamping devices arranged on the front side and the back side of the lower end of the overturning frame, the upper-end conveying driving device falls to be close to the blank, compressing devices compress the supporting plate and the blank in the vertical direction, an overturning driving device drives the overturning frame to overall rotate 180 degree, the blank with the supporting plate achieves overturning and then is overturned to the lower-end conveying driving device, and the overturned blank is driven to move out of the overturning frame. According to the automatic overturning and conveying device, automatic overturning and conveying functions on the blank with the supporting plate can be achieved.

Owner:TANGSHAN HEXIANG INDAL

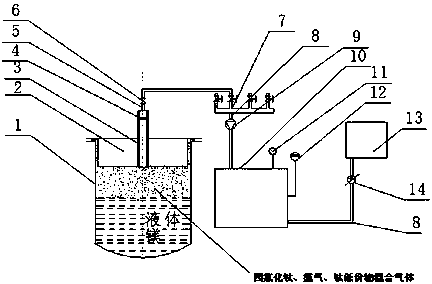

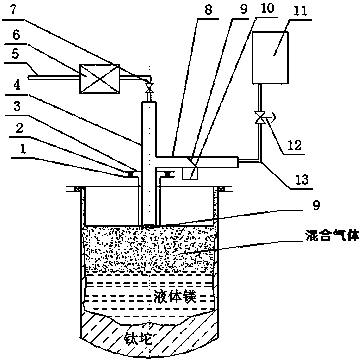

Reducing device for sponge titanium production process

PendingCN108396144AImprove the degree of automated productionAvoid direct dischargeProcess efficiency improvementTetrachlorideExhaust valve

The invention discloses a reducing device for a sponge titanium production process. The reducing device is composed of a reactor and a large cover arranged on the reactor. A vertical pipe is arrangedon the large cover, the vertical pipe passes through the large cover to form a gas channel, a filter screen is arranged in the vertical pipe, and the vertical pipe is connected with a valve group through a metal hose. The metal hose is provided with an automatic pressure relief valve. The valve group is connected with a titanium tetrachloride condenser through a metal pipe. A titanium fan is arranged between the valve group and the titanium tetrachloride condenser. An exhaust valve and a liquid level meter are correspondingly arranged at the top and the side wall of the titanium tetrachloridecondenser, and the lower part of one side of the titanium tetrachloride condenser is connected with a titanium tetrachloride storage tank through a metal pipe, and a magnetic force driving pump is arranged between the titanium tetrachloride condenser and the titanium tetrachloride storage tank. By the adoption of the reducing device, the automatic production degree of sponge titanium can be increased, direct emission of waste gas in the reducing process is avoided, the environment pollution of titanium tetrachloride is reduced, and the recycling of resources is realized.

Owner:ZUNYI TITANIUM

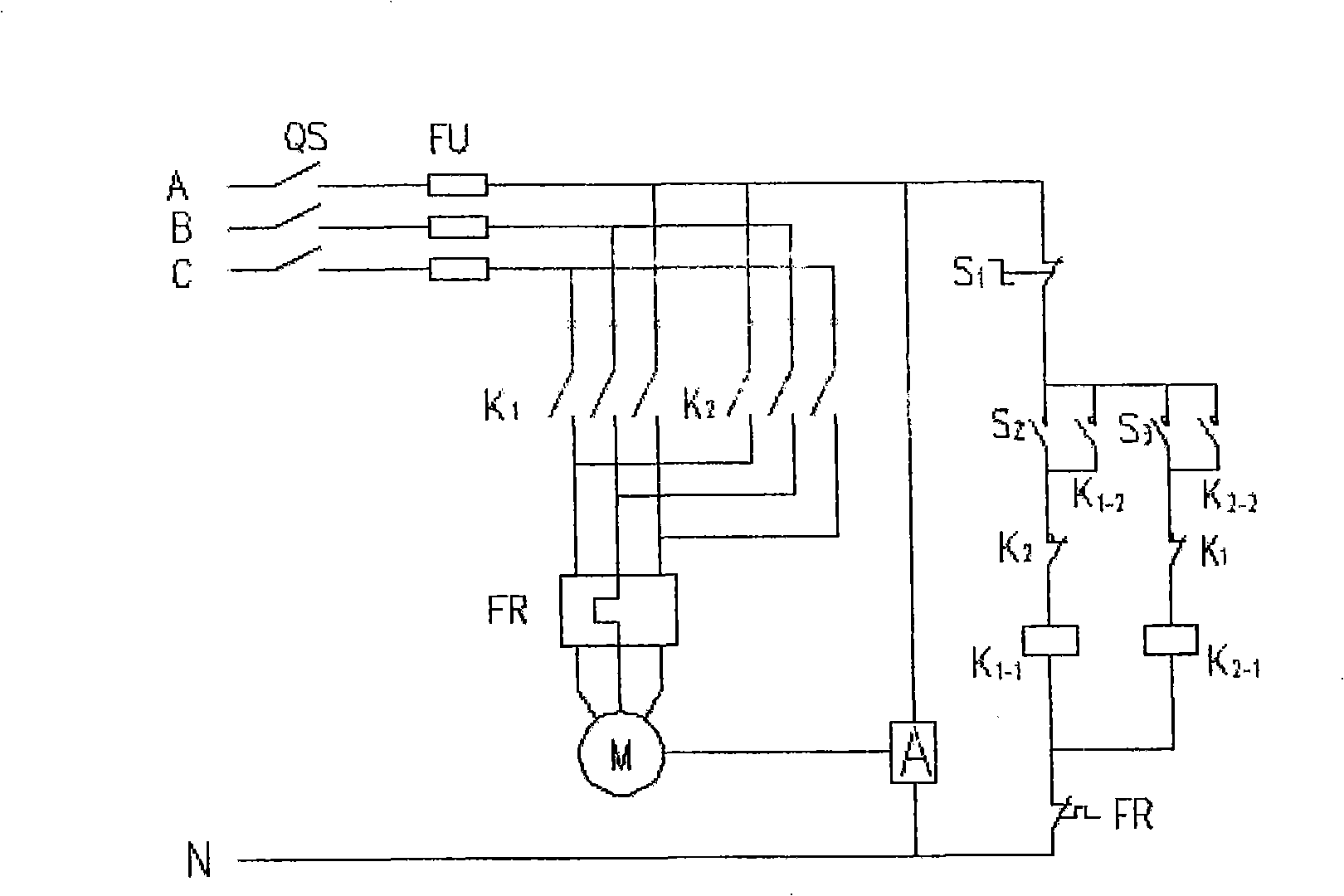

Automatic roller clutching disc bonding machine

InactiveCN101284340AImprove the degree of automated productionImprove quality and efficiencyWelding/cutting auxillary devicesAuxillary welding devicesTransmission beltElectrical control

The invention discloses an automated drum flange welder, which comprises a drum flange welder. A motor is arranged on the chassis and the bracket of the welder; a small belt wheel is fixed on the output shaft of the motor; a reducer is fixed on a flange plate; the output shaft of the reducer is fixed on the chuck of a workpiece; a big belt wheel is fixed on the input shaft of the reducer; a transmission belt is connected on the big belt wheel and the small wheel; an electric control cabinet is installed on one side of the chassis; an actiyator and a thermorelay are mounted inside the chassis; leads on the actiyator and the thermorelay are connected with the motor; two contactor switches, a corresponding SBF and an SBR, and a stop button are connected in parallel on the actiyator in the circuit between the actiyator and the thermorelay; and a three-way circuit breaker and the corresponding fuse protector are connected in parallel on the thermorelay. The welder has the advantages of high level of automation, high quality and high efficiency.

Owner:河南天隆输送装备有限公司

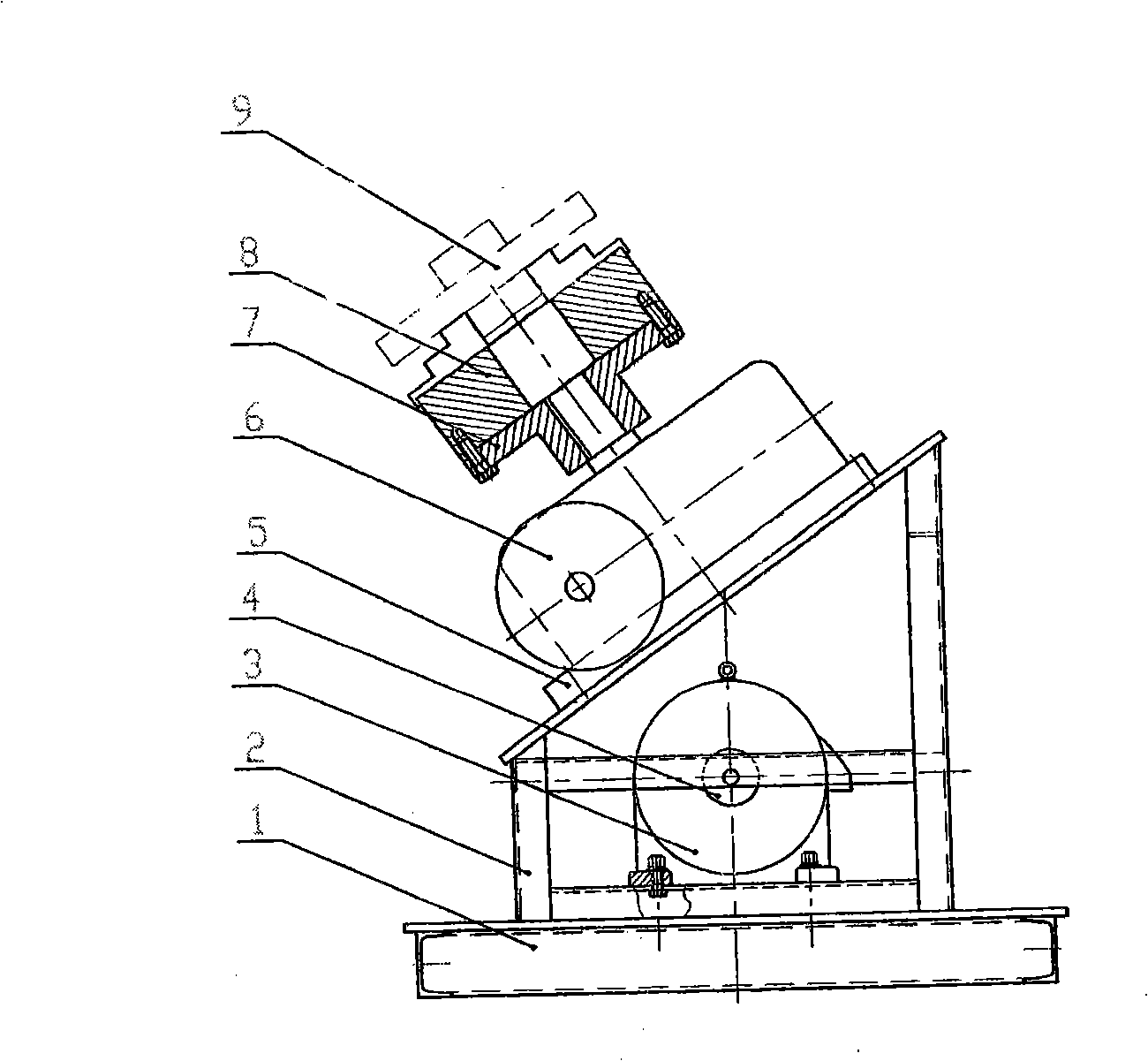

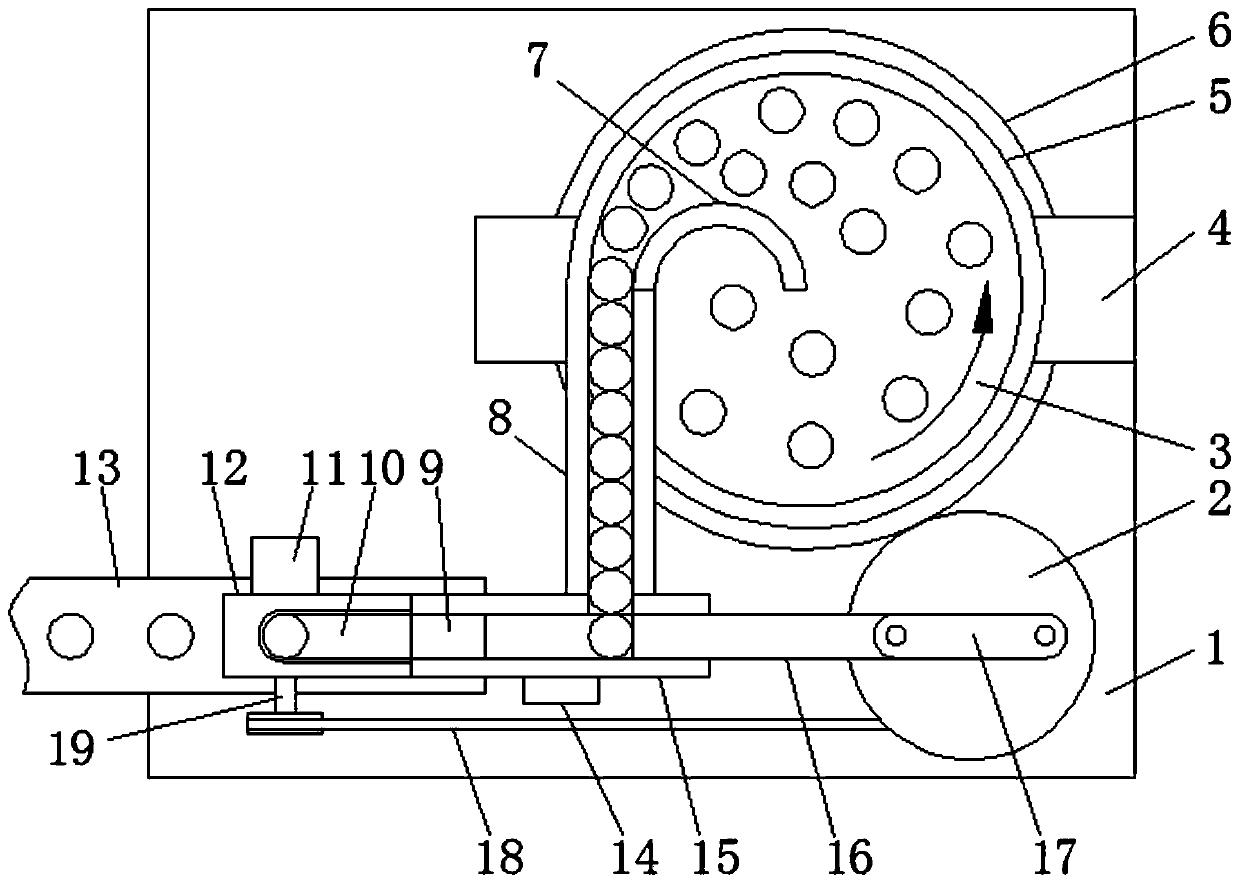

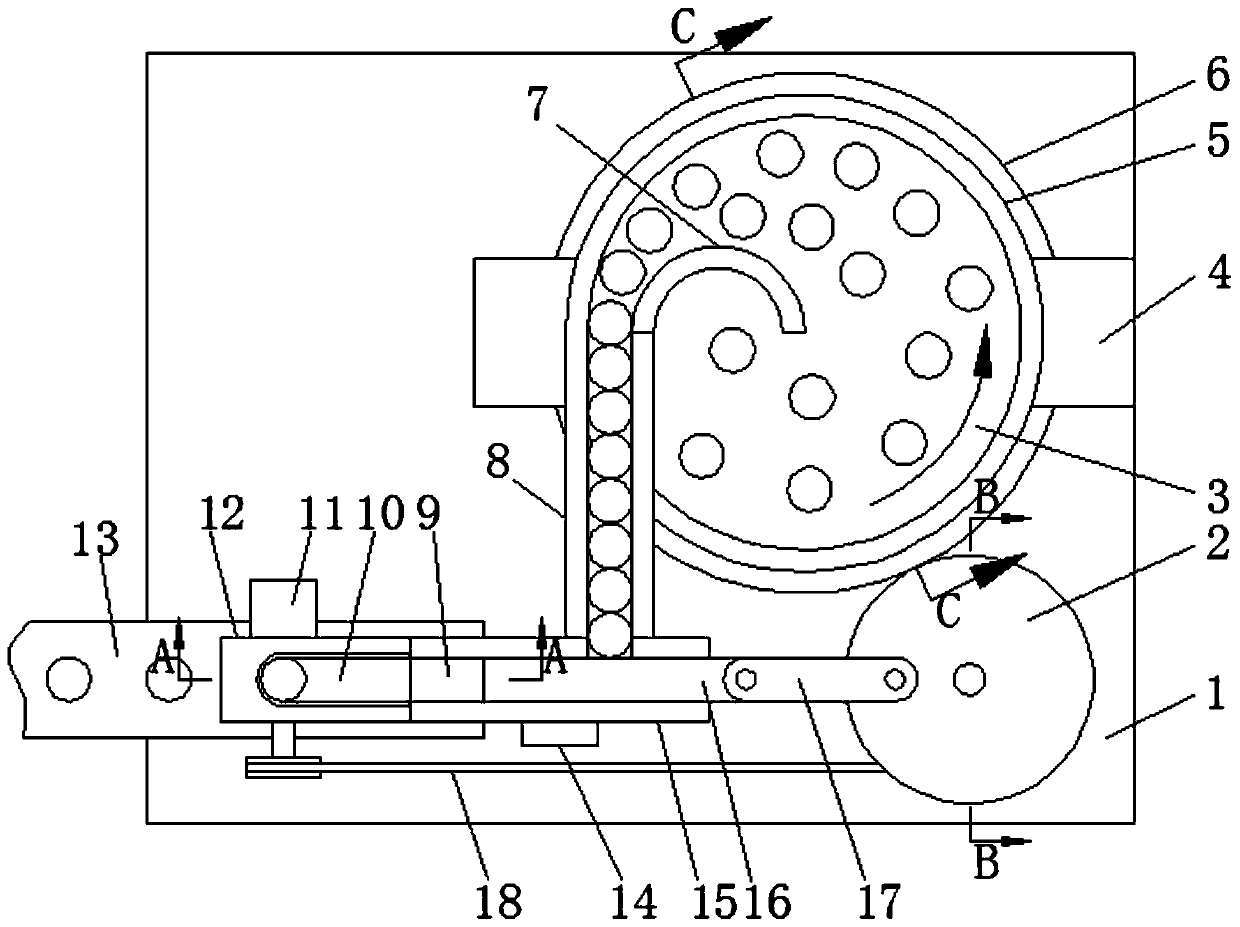

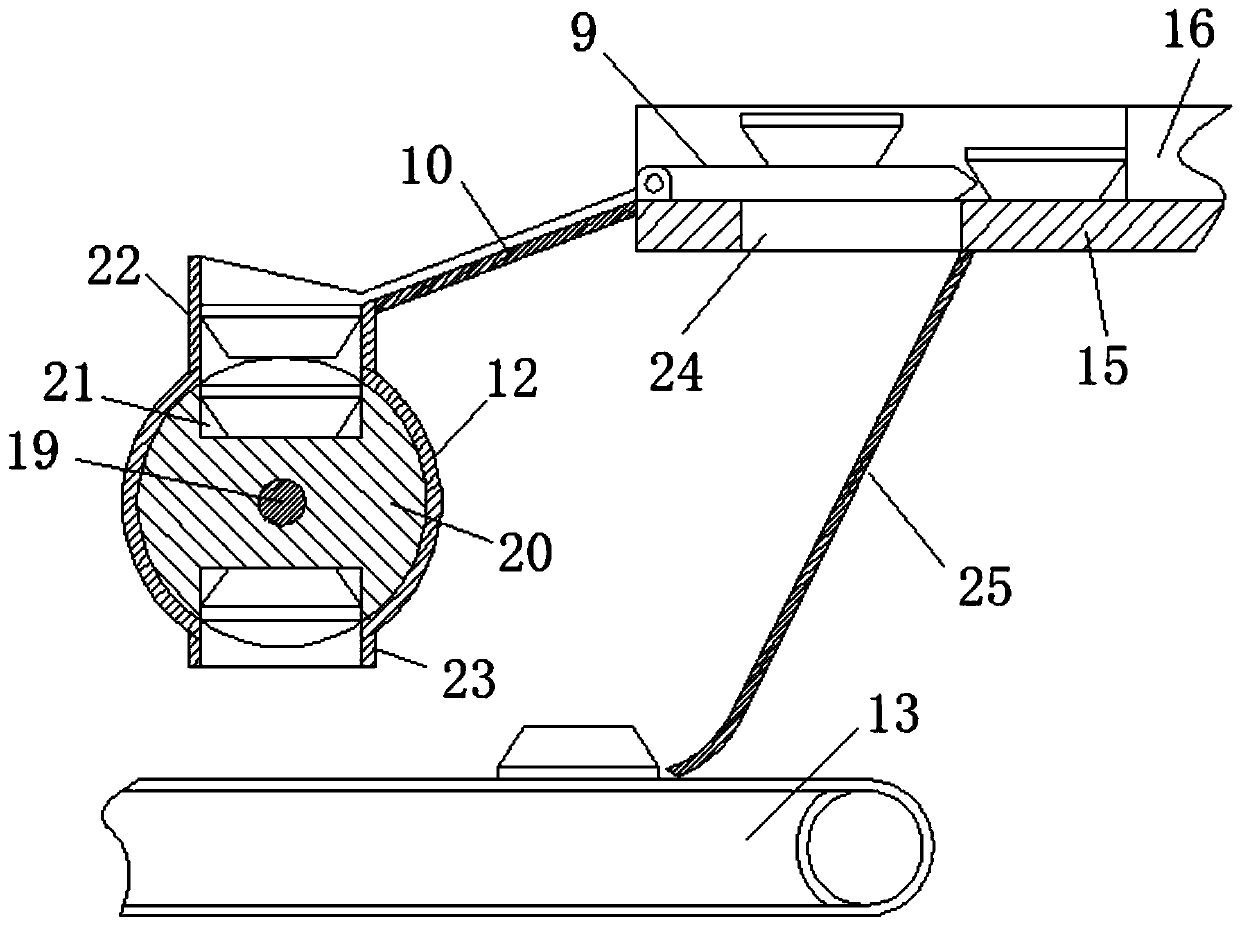

Automatic blanking wooden ball processing apparatus and method

InactiveCN104842263AImprove the degree of automated productionIncrease productivitySpherical surface grinding machinesGrinding feedersCamEngineering

The invention provides an automatic blanking wooden ball processing apparatus and method. A rolling mechanism, a large cam mechanism, a small cam mechanism, a wooden rod placing cabin, and a motor are arranged. The large cam mechanism and the small cam mechanism are arranged above the rolling mechanism and are driven by a shaft of the motor for operation. The wooden rod placing cabin is arranged in front of the large cam mechanism and the small cam mechanism. According to the invention, automatic embarking of wooden rods can be realized and manual control of embarking of wooden rods one by one is not needed. Therefore, the apparatus and method have advantages of high production efficiency, low production cost, high automation degree, and reduced operator fatigue.

Owner:林智坪

Foam sole pad milling machine tool

InactiveCN102069225AImprove the degree of automatic production of enterprisesImprove work efficiencyMilling equipment detailsEngineeringIndustrial Accident

The invention discloses a foam sole pad milling machine tool. The foam sole pad milling machine tool comprises a milling tool bit, a workbench, a supporting base and a feeding mechanism, wherein the milling tool bit is arranged above the workbench and is connected with a Z-axis motor consisting of a tool bit main motor and a tool bit transpositional motor; and the workbench is connected with a Y-axis motor and a X-axis motor, is arranged on the supporting base and can slide relative to the supporting base. The foam sole pad milling machine tool drives the workbench through the X-axis motor and the Y-axis motor to do curvilinear motion on the horizontal plane, and the Z-axis motor controls the inclination angle of a knife to cut out a relatively uniform and smooth beveled edge outline on the hard foam sole pad, so that the automatic production degree of an enterprise is improved, the working efficiency is improved, the time, the labour and the materials are saved, and the industrial accidents are reduced.

Owner:东莞市腾宇龙机械能源科技股份有限公司

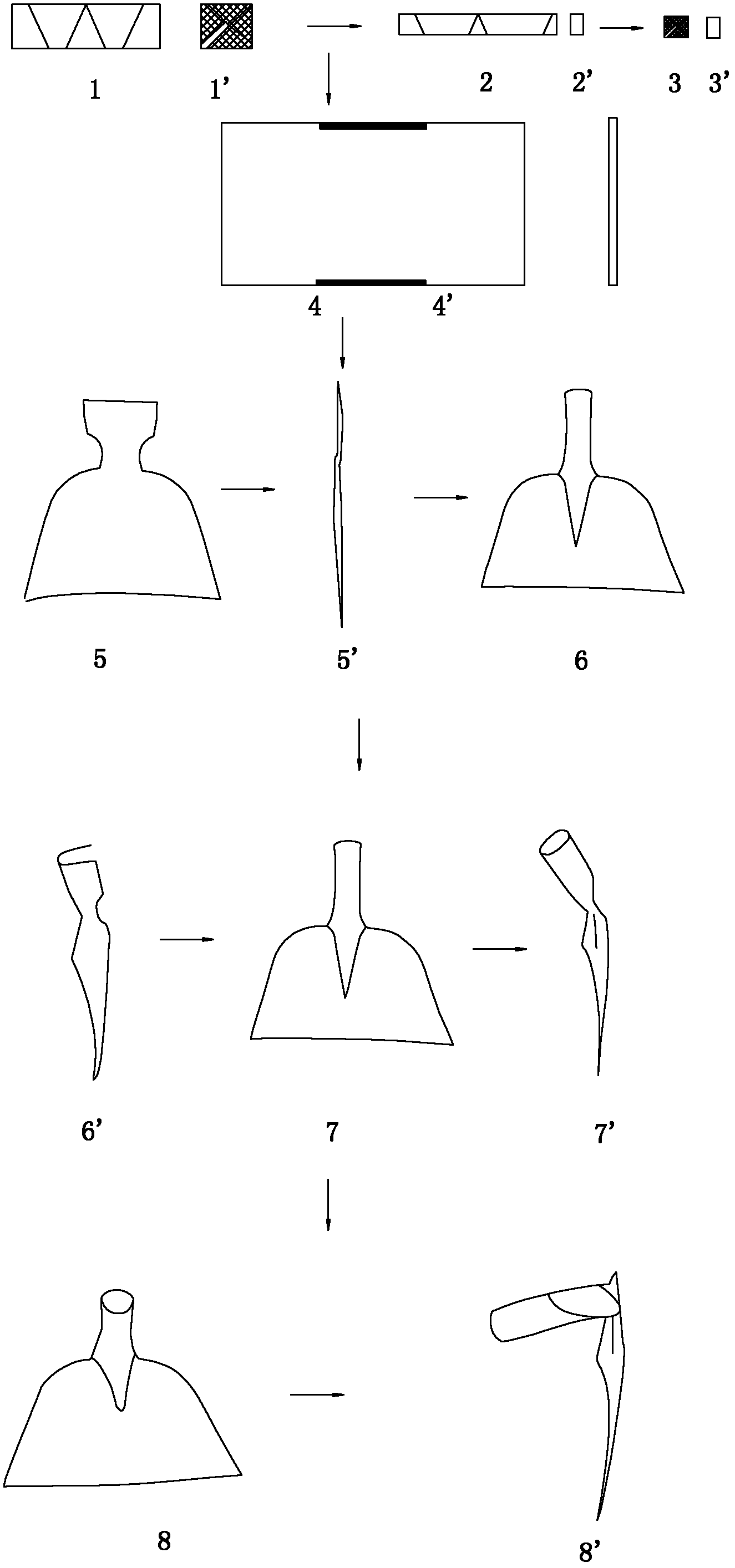

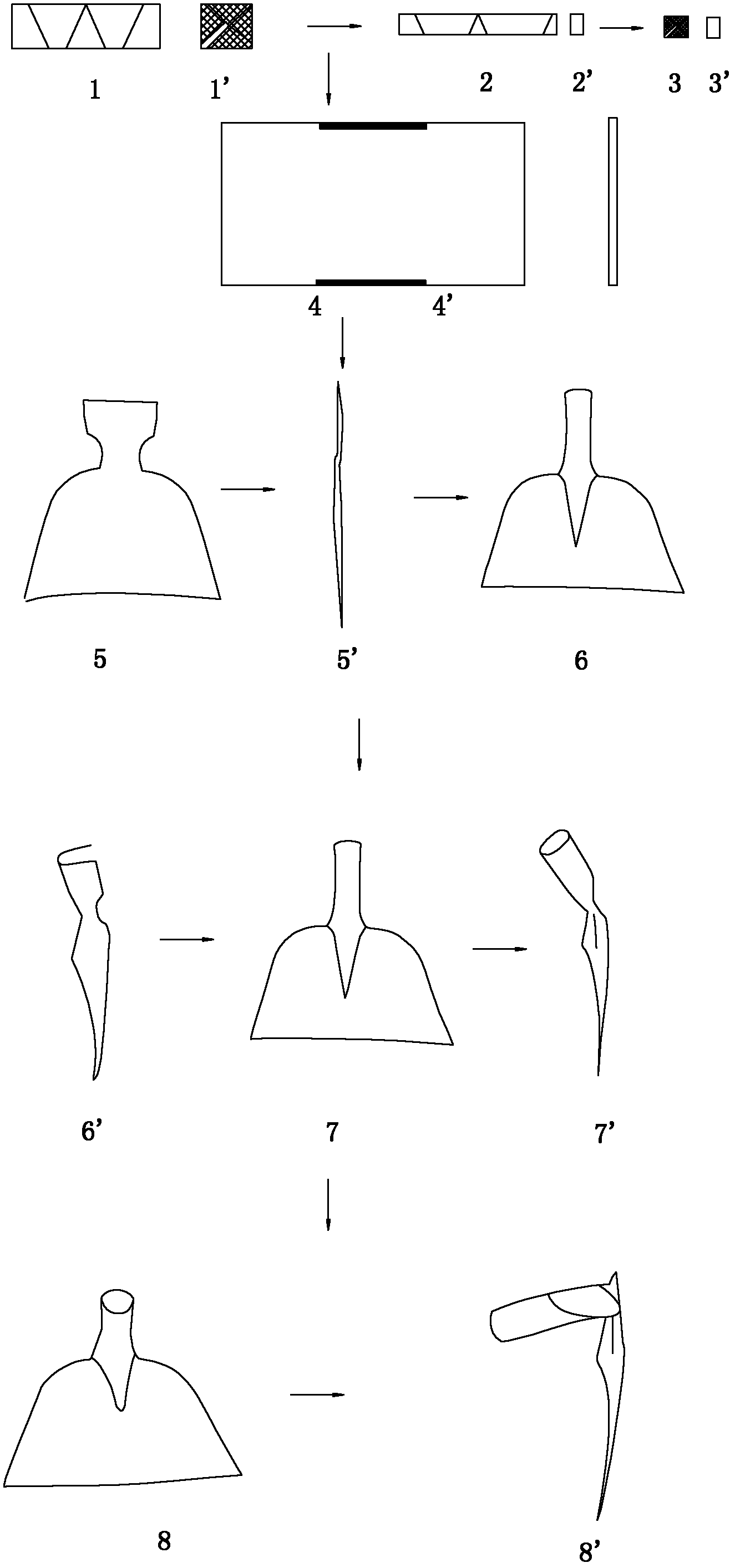

Method for processing steel plane hoe

The invention discloses a method for processing a steel plane hoe, which belongs to the technical field of agricultural machinery. The production technology of the steel plane hoe comprises the following steps of: using a 45# medium carbon steel billet, mechanically rolling a square steel into a flat steel, and adding a blank forming material; heating the blank forming material to 1200 degrees centigrade, mechanically rolling into a convex blank hoe plate material; using a punch die to punch the convex blank hoe plate material into a hoe plate with a steel plane hoe shape, and marking; using a friction pressure machine to press the hoe plate into an arc shape and to press out a triangular reinforced rib on the hoe plate; using the pressure machine to roll up a hoe cage, and bending the hoe cage to form the steel plane hoe; quenching by a chemical solution until the hardness reaches 45-50HRC; and polishing, painting, drying and packaging the steel plane hoe to obtain the steel plane hoe as a finished product. The method provided by the invention has the advantages of few working procedures, high automation level of production, durability, fuel source economy, beautiful appearance, few smoke wastes and less noise pollution, and is particularly suitable for industrial production.

Owner:会理县机具厂

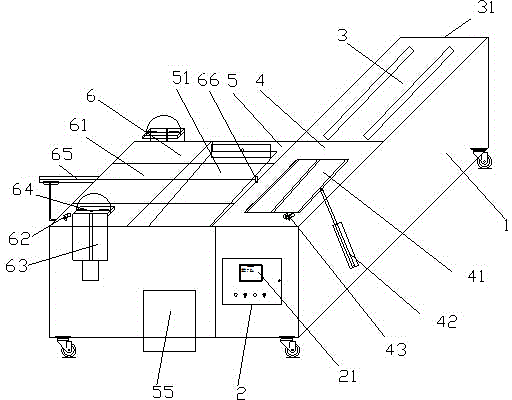

Sludge brick production equipment for hydrolysis and carbonization treatment

ActiveCN111113660ASmooth transferRealize layer by layer staggered stackingCeramic shaping plantsAuxillary shaping apparatusBrickSludge

The invention provides sludge brick production equipment for hydrolysis and carbonization treatment. According to the sludge brick production equipment, a stretchable brick receiving mechanism is arranged on a rotary conveying mechanism, and a folding mechanism and an unfolding mechanism are sequentially arranged on the conveying track of the brick receiving mechanism; the brick receiving mechanism bearing bricks is folded in the transverse direction and the longitudinal direction through the folding mechanism so that the bricks can be arranged in an attached mode, then the bricks are clampedin batches through a clamping mechanism, and layer-by-layer staggered stacking and transferring output of the bricks are completed through arranging a rotary stacking mechanism and a pushing and transferring mechanism in a matched mode; the unloaded brick receiving mechanism is unfolded in the transverse direction and the longitudinal direction through the unfolding mechanism so as to be matched with the next batch of brick receiving procedures; and full-process automation of brick pressing, conveying and stacking batch output is realized, and the technical problems that in the prior art, bricks cannot be transferred in batches, the automation degree is low, and the production efficiency is low are solved.

Owner:浙江合泽环境科技有限公司

Automatic press-in machine for gear and drive pin

PendingCN108480959AAutomate operationImprove work efficiencyMetal working apparatusGear wheelEngineering

The invention relates to the technical field of gear pin shaft press fitting, in particular to an automatic press-in machine for a gear and a drive pin. The automatic press-in machine comprises a base, an electric control box, a machining groove formed in the base, a first feed mechanism, a second feed mechanism, a press fitting mechanism and an ejection mechanism, wherein the first feed mechanism, the second feed mechanism, the press fitting mechanism and the ejection mechanism are electrically connected with the electric control box; the first feed mechanism comprises a steering assembly andis connected with the machining groove; and the second feed mechanism comprises a sliding block capable of moving in the horizontal direction, and the sliding block is provided with a feed through hole accommodating the drive pin moving in the vertical direction. The first feed mechanism and the second feed mechanism are adopted to convey the gear and the drive pin to a fixed plate, the drive pinis pressed into a size hole corresponding to the gear through the press fitting mechanism to realize automatic press-in, the work efficiency and the automated production degree are promoted, the production quality is guaranteed, and the manual labor intensity and the labor cost are reduced.

Owner:珠海大利刀具有限公司

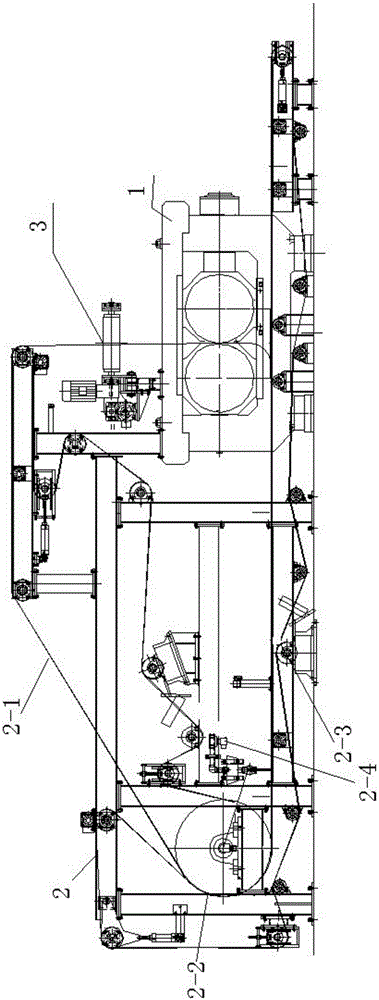

Short-line matching segmental beam circulating flow production line and production method thereof

PendingCN109773952AReasonable layoutImprove the degree of automated productionCeramic shaping plantsProduction lineCleaning station

The invention discloses a short-line matching segmental beam circulating flow production line and a production method thereof. The short-line matching segmental beam circulating flow production line comprises a first conveying channel, a first rail, a second conveying channel and a second rail, the heads and the tails of which are sequentially crossed to form a square circulation production line for circulation of a transmission bottom die; the first conveying channel is sequentially provided with a first transition station, a cleaning station, a marking station and a second transition stationin a production direction of an assembly line; the second transition station is arranged at the intersection of the first rail and the first conveying channel; the first rail is sequentially providedwith the second transition station, a checking station and a third transition station in the production direction of the assembly line; and the third transition station is arranged at the intersection of the first rail and the second conveying channel. The short-line matching segmental beam circulating flow production line has the advantages of capability of circulating production and small amount of hoisting equipment and can be widely applied to the technical field of prefabricating of short-line matching segmental beams.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

Device for automatic exhausting and argon filling of reduction distillation furnace in sponge titanium production

PendingCN108467952AImprove the degree of automated productionReduce labor intensityProcess efficiency improvementGas pipelineProcess engineering

The invention discloses a device for automatic exhausting and argon filling of a reduction distillation furnace in sponge titanium production. A three-way pipe sleeve is arranged on a reactor large cover, and a large cover sleeve flange is connected with a vertical pipe flange, a sealing gasket is arranged between the large cover sleeve flange and the vertical pipe flange, a filter screen is arranged at the bottom of a three-way pipe stand pipe, the three-way pipe stand pipe is connected with an argon gas pipeline, and a pneumatic high vacuum baffle valve and a check valve are arranged on theargon gas pipeline. A dust collecting tank is arranged directly below a filter screen arranged in a three-way cross pipe, the three-way cross pipe is connected with a gas recovery tank through a recovery pipeline, and an electromagnetic valve is arranged on the recovery pipeline. By using an automatic argon filling and exhausting device, the automatic production degree of sponge titanium can be improved, argon can be recycled, the labor intensity of operators can be reduced, and the production cost can be reduced.

Owner:ZUNYI TITANIUM

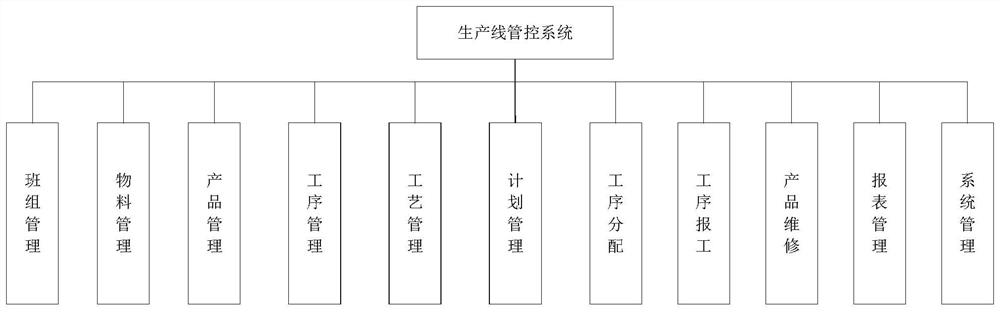

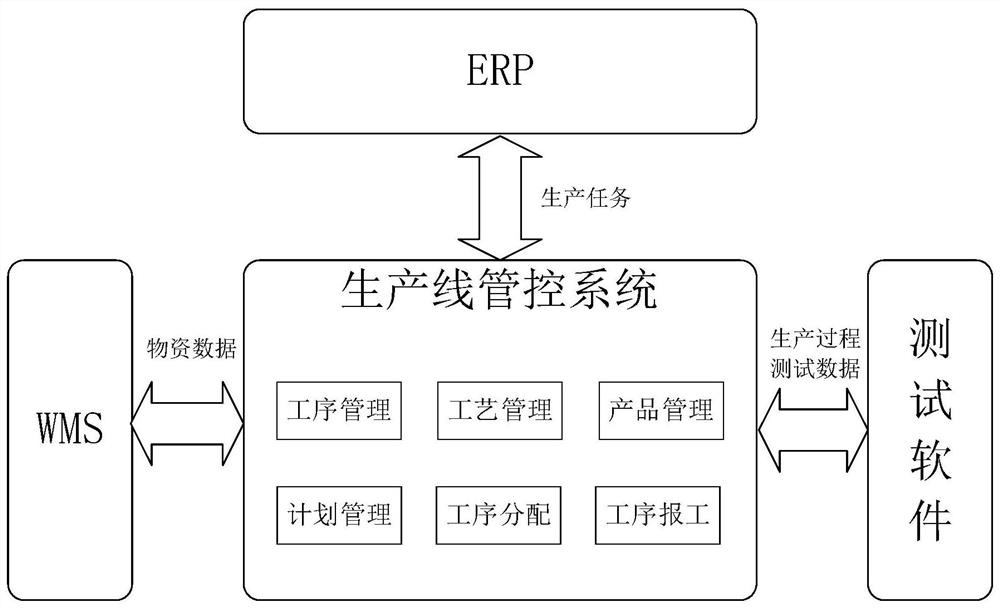

Production line management and control system based on test

PendingCN112785203AImprove real-time performanceRealize unified managementOffice automationResourcesControl systemBusiness enterprise

The invention discloses a production line management and control system based on the test. The system comprises a team management module, a material management module, a product management module, a procedure management module, a process management module, a plan management module, a process distribution module, a process work reporting module, a product maintenance module, a report management module and a system management module. The system can communicate with a plurality of systems, so that the real-time performance of data is enhanced, unified management of production lines by enterprises is realized, the automatic production degree and production efficiency of the enterprises are improved, the manufacturing process of the enterprises is greatly optimized, the labor cost of the enterprises is reduced, and the system is more beneficial to long-term development of the enterprises.

Owner:BEIJING INST OF COMP TECH & APPL

Conveyor for alarm workpiece production and using method thereof

InactiveCN111377215AOrderly rowsReduce labor intensityConveyor partsTransmission beltMaterial distribution

The invention relates to the field of alarm production equipment, in particular to a conveyor for alarm workpiece production and a using method thereof. The conveyor comprises a base, wherein a material arranging mechanism and a material pushing mechanism are arranged on the base, and the material pushing mechanism is in transmission connection with the material arranging mechanism; and a materialoverturning mechanism is arranged on the base, wherein the material overturning mechanism is located on the left side of the material pushing mechanism, and the pushing mechanism is in transmission connection with the overturning mechanism. According to the conveyor for alarm workpiece production and the using method thereof, top covers are orderly arranged through the material arranging mechanism, output is sequentially and orderly conducted through the material pushing mechanism, and materials in different directions are automatically distributed, so that the top covers in the needed directions are directly output, manual material distribution is not needed, time and labor are saved, the production efficiency is improved, the whole process does not need manpower interference, and the automatic production degree can be improved; and meanwhile, the material pushing mechanism drives the material overturning mechanism to overturn the materials in the opposite directions, the directionsof the top covers output by a conveying belt are consistent, manual overturning is not needed, and the production efficiency is further improved.

Owner:叶子路

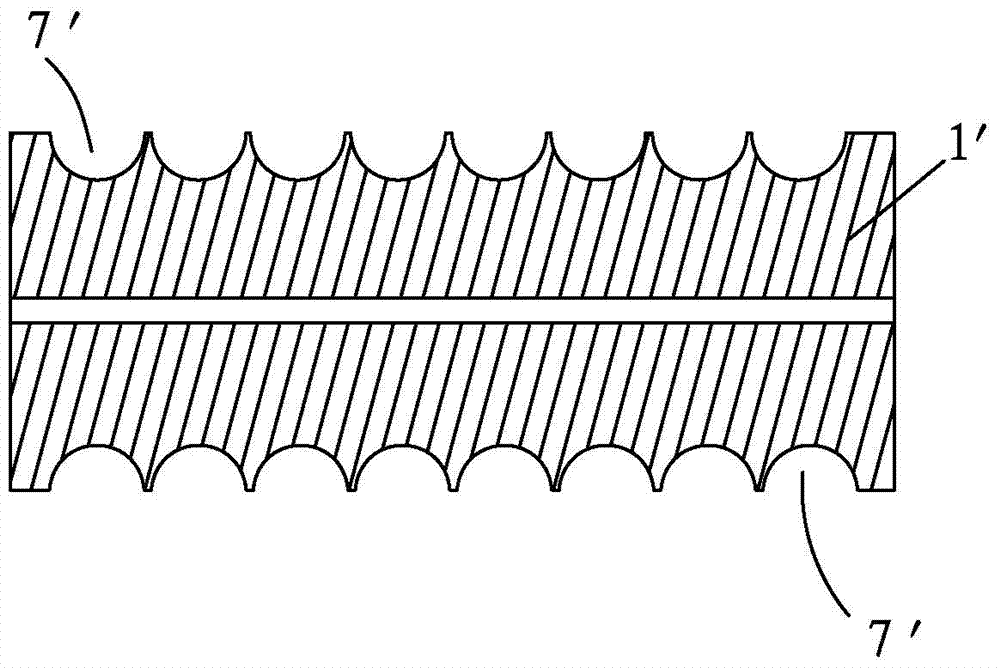

Anticorrosion layer protective structure of pipeline of directional drilling crossing section and method for manufacturing anticorrosion layer protective structure

ActiveCN104565677AImprove operational safetyImprove reliabilityPipe protection against damage/wearYarnViscose

The invention provides an anticorrosion layer protective structure of a pipeline of a directional drilling crossing section and a method for manufacturing the anticorrosion layer protective structure. The anticorrosion layer protective structure comprises a steel pipe and an anticorrosion layer. The anticorrosion layer covers the outer surface of the steel pipe, and a composite protective layer further covers the outer surface of the anticorrosion layer. The method for manufacturing the anticorrosion layer protective structure includes steps of (1), pretreating the anticorrosion layer of the pipeline; (2), distributing resin adhesive; (3), discharging yarns and dipping the yarns in the adhesive; (4), winding and forming the yarns; (5), trimming the yarns. The anticorrosion layer protective structure and the method have the advantages that the anticorrosion layer protective structure of the pipeline is excellent in abrasion-resistant and scratch-resistant performance, high-temperature resistance and corrosion resistance; the method for manufacturing the anticorrosion layer protective structure is high in mechanization and automation degree, the defect of easiness in generating bubbles due to the fact that glass fiber cloth is adhered on the surfaces of existing anticorrosion layers layer by layer and the shortcoming of degradation of the strength of products due to stress concentration at interlacing points of cloth marks and the tail ends of short glass fibers can be overcome, and the shear strength of the protective layer can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Installation structure of motor magnetic ring and motor

ActiveCN104300707AAxial space savingIncreased installation flexibilityMagnetic circuit rotating partsHall elementEngineering

The invention is applicable to the field of motors, and discloses an installation structure of a motor magnetic ring and a motor provided with the installation structure. The installation structure of the motor magnetic ring comprises a squirrel-cage rotor and a magnetic ring, wherein the squirrel-cage rotor comprises a rotor core and a first end ring arranged at one end of the rotor core, the first end ring is provided with a first axial end face back to the rotor core, the first axial end face is provided with an accommodating groove in a concave mode, and the magnetic ring is fixed in the accommodating groove. The installation structure disclosed by the invention reduces the axial space occupied by the magnetic ring inside the motor on the one hand, thereby providing a chance for additionally arranging parts convenient for automatic production on a stator winding, and being conducive to automatic production of an stator assembly; a Hall element is enabled to be placed in the motor horizontally or vertically on the other hand, thereby improving the installation flexibility of the Hall element; and on another aspect, a phenomenon that the machining process of a rotating shaft is caused to be complicated because the magnetic ring is fixed by processing edges on the rotating shaft and a phenomenon that the service life of a bearing is caused to be short because the magnetic ring is fixed by adding glue on the rotating shaft are avoided.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Hairpin permanent magnetic synchronous motor copper wire forming device and process

ActiveCN113441649AReduce the difficulty of productionIncrease productivitySynchronous motorCopper wire

The invention discloses a hairpin permanent magnetic synchronous motor copper wire forming device. The device comprises a bending mechanism used for feeding a copper wire and continuously bending the copper wire on a horizontal plane, a forming die, a copper wire conveying pneumatic claw, a forming die conveying line, a downward pressing air cylinder and a rack. The forming die is used for carrying out extrusion molding on the copper wire bent by the bending mechanism; the copper wire conveying pneumatic claw is used for placing the copper wire bent by the bending mechanism into the forming die; the forming die conveying line is used for supporting the forming die and driving the forming die to reciprocate on the forming die conveying line, the downward pressing air cylinder is used for pressing the forming die to extrude the copper wire, and the downward pressing air cylinder is located above the forming die conveying line; and the rack is used for bearing the bending mechanism, the copper wire conveying pneumatic claw, the forming die conveying line and the downward pressing air cylinder. Bending parameters of the bending mechanism and the forming die can be freely combined and exchanged, the production flexibility is high, the production difficulty of the copper wire is reduced, and the production efficiency of the copper wire is improved.

Owner:跃科智能制造(无锡)有限公司

Automatic waste embryo barreling machine for avian influenza vaccine production process

ActiveCN104310038AImprove the degree of automated productionReduce manual labor intensityStacking articlesConveyor partsVaccine ProductionAssembly line

The invention discloses an automatic waste embryo barreling machine for an avian influenza vaccine production process. The automatic waste embryo barreling machine for the avian influenza vaccine production process belongs to the field of avian influenza vaccine production equipment, and comprises a working table, wherein an electric cabinet is arranged right in front of the working table; a touch screen is arranged on the electric cabinet; an incubator tray conveying trough is arranged on the working table; the input end of the incubator tray conveying trough is connected with a harvester waste embryo outlet; the output end of the incubator tray conveying trough is connected with an incubator tray turnover device; a waste embryo discharge device is arranged on the left side of the incubator tray turnover device and is connected with a tray piling device. The automatic waste embryo barreling machine is matched with a chick embryo harvester for use, so that the chick embryos can be full-automatically harvested, the waste embryos can be full-automatically barreled, the automatic production degree is improved, the labor intensity of employees is greatly reduced, the health of the employees is ensured, meanwhile, the chick embryo harvest production line assembly line is realized, the work efficiency of the chick embryo harvest production line is improved by 50 percent, and a powerful guarantee is provided for expanding production.

Owner:ZHAOQING DAHUANONG BIOLOGIC PHARMA

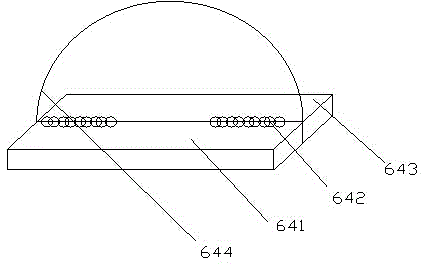

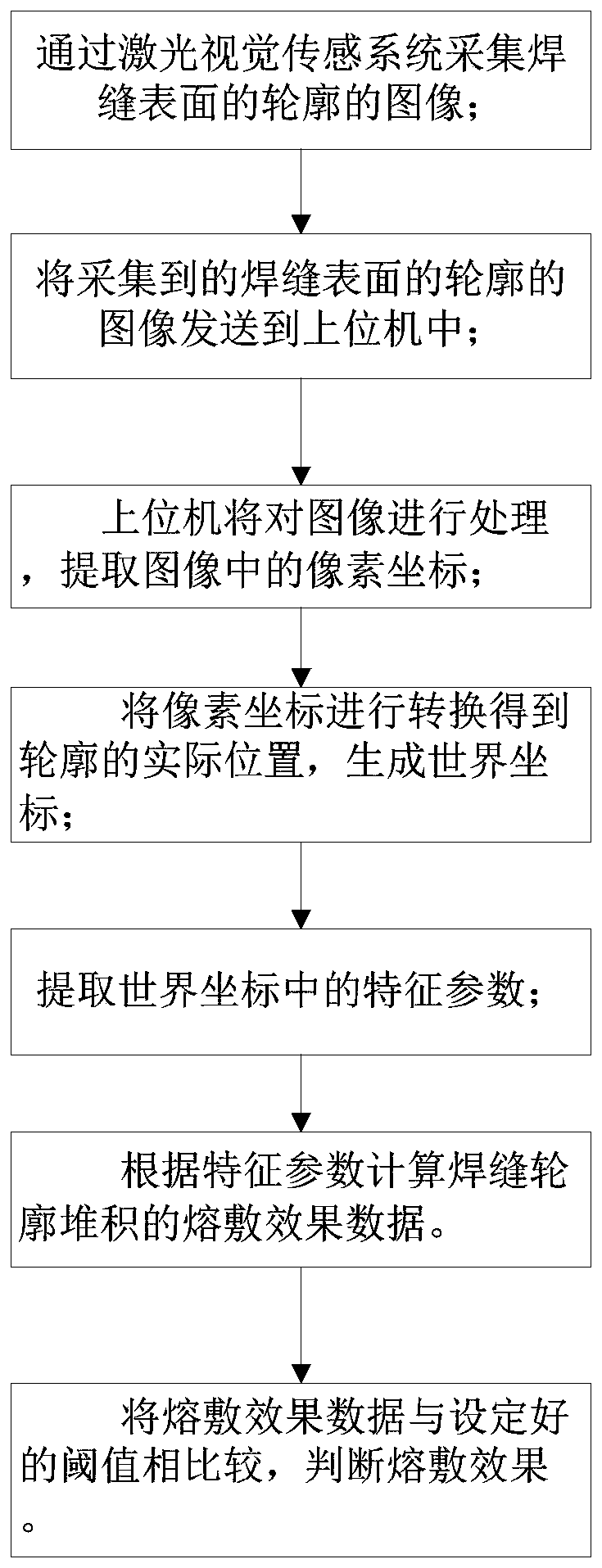

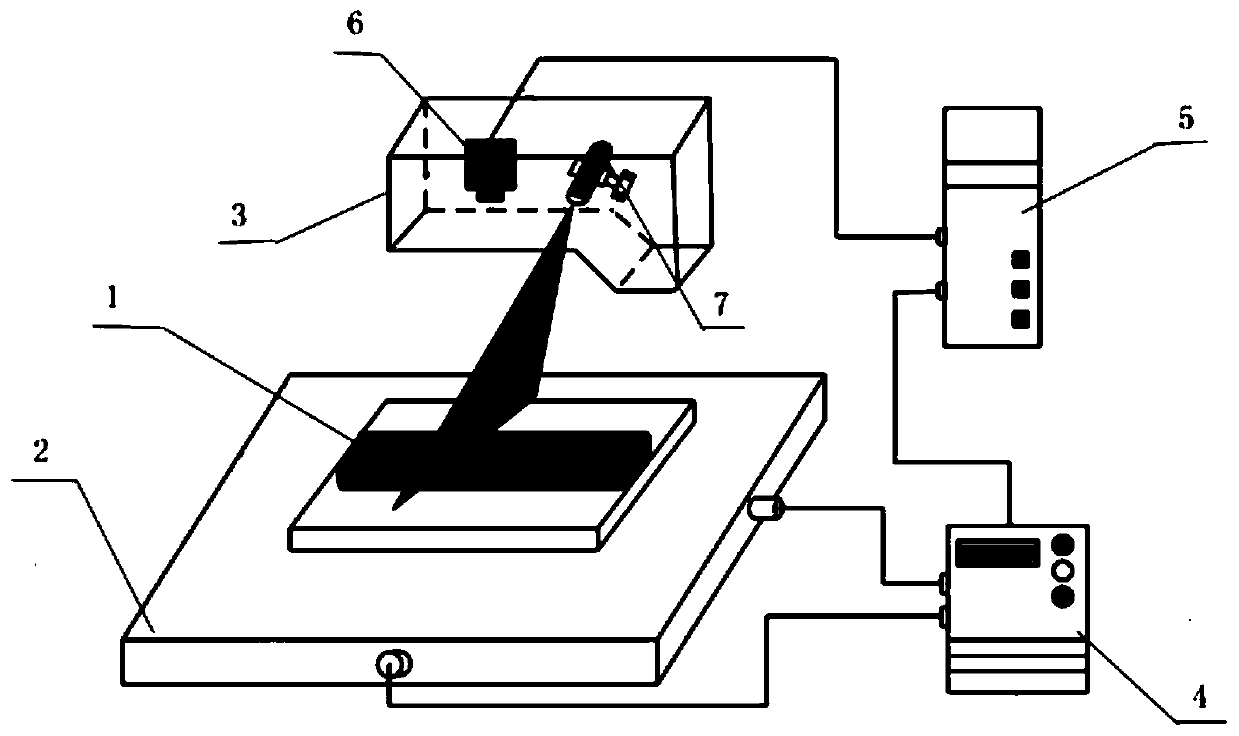

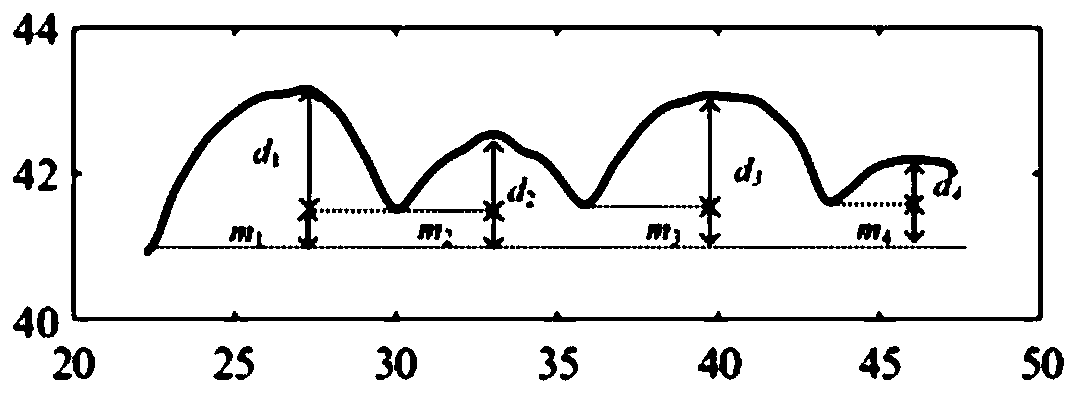

Single-layer multiple-pass weld stack deposition effect detection method and system

ActiveCN110608684AImprove the degree of automated productionUsing optical meansImaging processingTest object

The invention relates to the field of arc additive manufacturing and more specifically relates to a single-layer multiple-pass weld stack deposition effect detection method and system. According to the method and the system, on the basis of a laser vision sensing technology, profile information of a tested surface is obtained; and through collection of a profile of a surface of a tested object, through utilization of related image processing algorithms and through combination of a formula for judging a deposition effect, a single-layer multiple-pass weld stack deposition effect is detected. According to the method and the system, the defects of high artificial detection complexity, low efficiency and liable influence of subjective factors are overcome. Through utilization of an advanced efficient vision detection technology, automatic production degree is greatly improved.

Owner:GUANGDONG UNIV OF TECH

Equipment for removing packaging film of tire belt group

InactiveCN111392161AReduce labor intensityReduce labor costsUnpacking by cuttingIndustrial engineeringAutonomation

The invention discloses equipment for removing a packaging film of a tire belt group in the technical field of automatic production equipment, and aims to solve the technical problems that in the prior art, by means of a process for removing the packaging film of the tire belt group, the automation degree is low, the working efficiency of manual operation is low, and the labor intensity is high. According to the equipment, a driving roller and a supporting roller are rotationally connected with a support, the driving roller drives the tire belt group to rotate, a lateral cutter cuts off a sideface film of the tire belt group, a generatrix cutter cuts off the packaging film in the generatrix direction of the tire belt group, and a pulling roller mechanism is used for stripping the cut packaging film from the tire belt group. According to the equipment, the packaging film of the tire belt group is mechanically and automatically removed, the degree of automatic production is improved, large-scale production is facilitated, meanwhile, manpower is liberated, the labor intensity of workers is relieved, the production efficiency is improved, and the labor cost of enterprises is reduced.

Owner:HUBEI UNIV OF ARTS & SCI

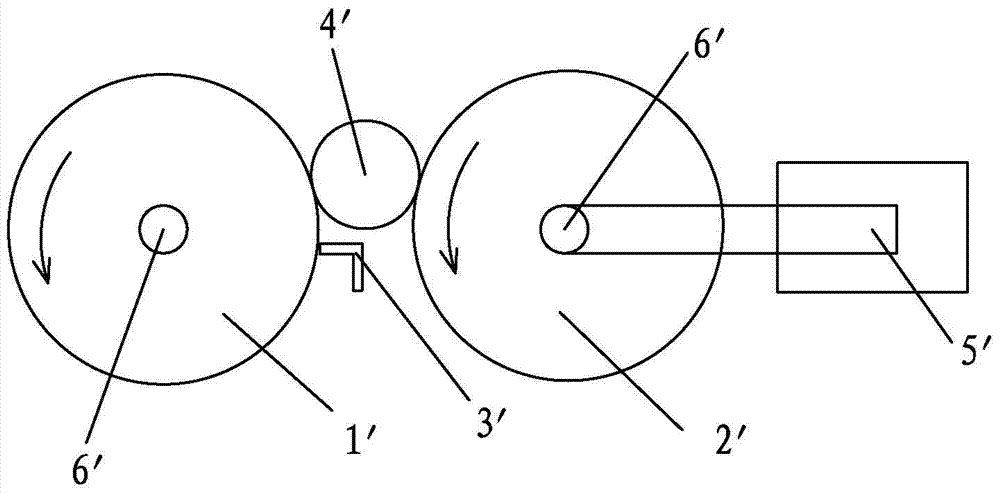

Automatic mixing device for open mill

InactiveCN105150400ARealize automatic multiple turning and mixing of rubberFulfill cooling needsEngineeringOperation safety

Disclosed is an automatic mixing device for an open mill. The automatic mixing device for the open mill is mainly composed of the open mill, an automatic rubber turning circulating device and an automatic rubber pounding device, wherein the automatic rubber pounding device is arranged on the upper portion of the open mill and can perform automatic rubber pounding on rubber. The automatic rubber turning circulating device is arranged to collect the rubber from the lower portion of the open mill, convey the rubber from the back side and then return to the upper portion of the open mill. The automatic rubber turning circulating device comprises a vertical rubber turning belt and achieves circular conveying of the rubber in the open mill through the circular rotation of the vertical rubber turning belt. By means of the device, the mixing process can be set according to the rubber characteristic, and functions of automatic rubber turning and uniform mixing of the open mill are achieved; the automatic production degree is improved, and accordingly human intervention factors are reduced, the uniformity of the rubber mixing process is guaranteed, the rubber performance stability is guaranteed, and the operation safety is improved; besides, by the cooperation of relevant equipment of spraying, cooling drums and automatic correction and the like, the temperature of rubber and the temperature of the equipment can be controlled effectively and conveniently, and the stable operation of the equipment and the stability of the quality of the rubber are further guaranteed.

Owner:特拓(青岛)轮胎技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com