Aluminum profile extrusion production line

A production line and aluminum profile technology, applied in the direction of metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problems of heat loss, energy waste, etc., achieve short heating time, improve the degree of automatic production, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

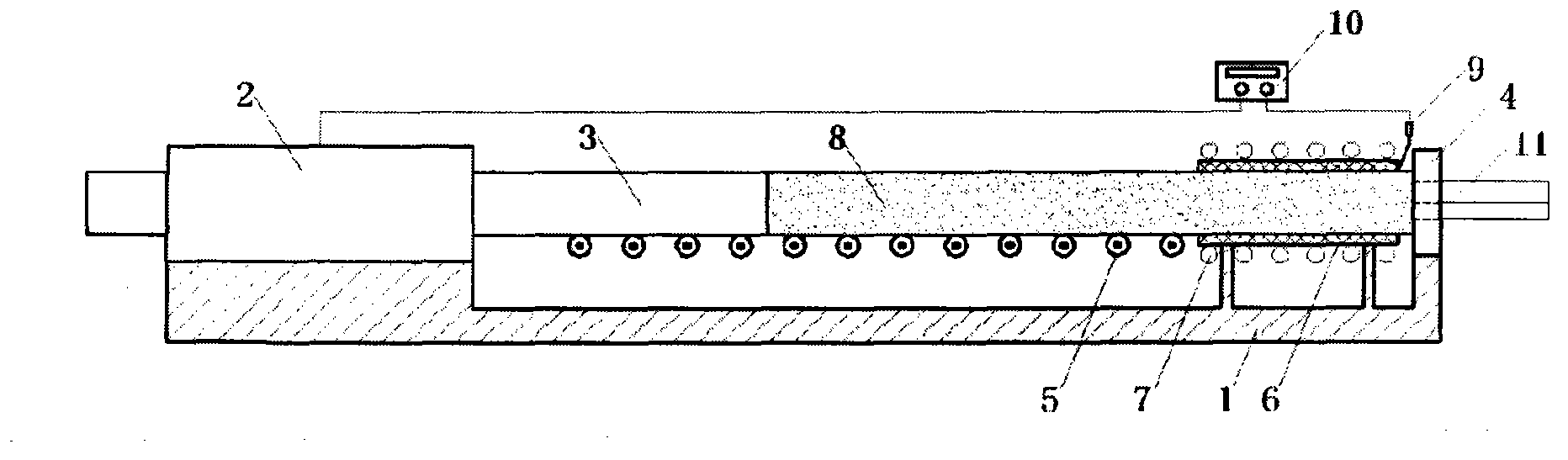

[0017] The following combination figure 1 The specific implementation of an aluminum profile extrusion production line provided by the present invention is described in detail.

[0018] The concrete device of a kind of aluminum extrusion production line that the present invention proposes is as follows:

[0019] The aluminum profile 11 extrusion machine mainly includes a base 1, a propulsion mechanism, a mold 4, a slide rail 5, a heat insulation sleeve 6, an induction coil 7, an intermediate frequency power supply, a temperature detection component 9 and a temperature controller 10, etc.

[0020] Propelling mechanism, mold 4, slide rail 5, heat insulation sleeve 6 are all installed on the same base 1. The heat insulating sleeve 6 is placed in front of the mold 4, and an induction coil 7 is wound around its periphery. The induction coil 7 is connected with the intermediate frequency power supply. An aluminum rod 8 can be placed on the slide rail 5 . The propulsion mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com