Single-layer multiple-pass weld stack deposition effect detection method and system

A multi-pass welding seam and detection method technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of relying on the effect of deposition, achieve the effect of improving the degree of automatic production and overcoming the high degree of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

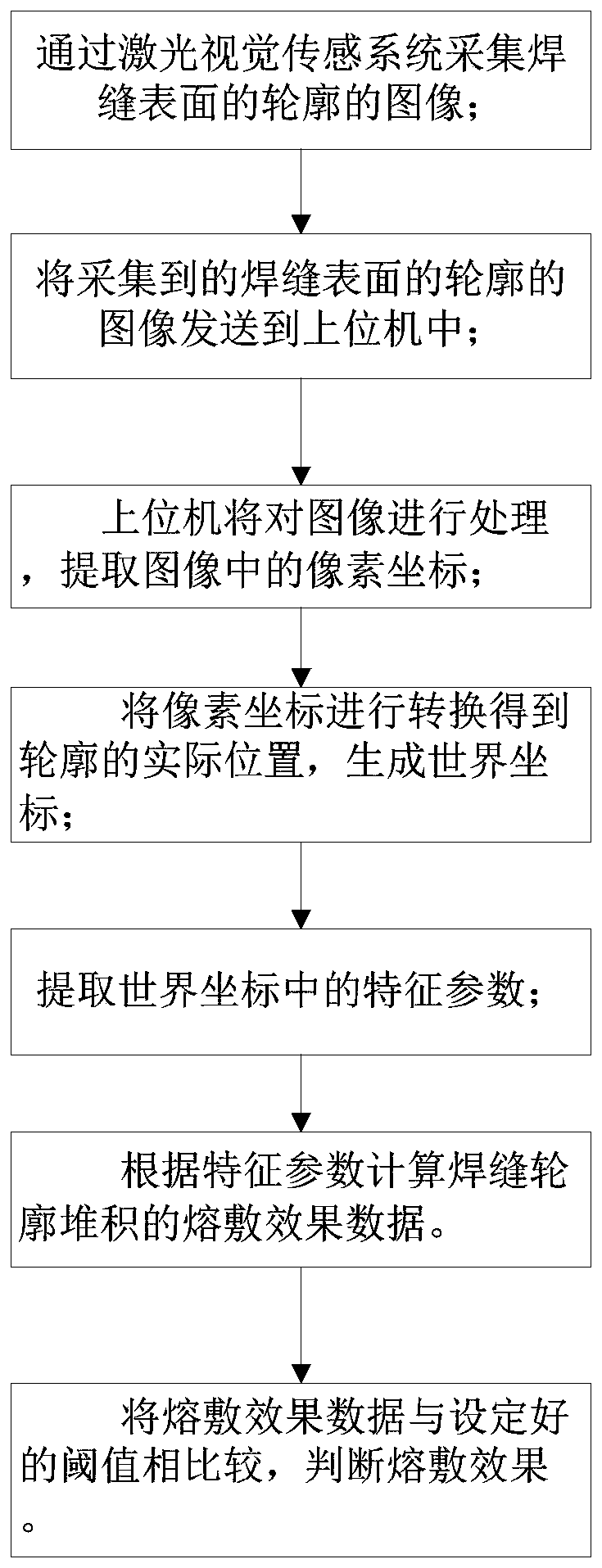

[0034] Such as figure 1 As shown, a single-layer multi-pass welding seam accumulation deposition effect detection method includes the following steps:

[0035] Step S1: collecting an image of the contour of the weld seam surface through a laser vision sensing system;

[0036] Step S2: Send the collected image of the contour of the weld surface to the host computer;

[0037] Step S3: The host computer will process the image and extract the pixel coordinates in the image;

[0038] Step S4: Convert the pixel coordinates to obtain the actual position of the outline, and generate world coordinates;

[0039] Step S5: extracting the characteristic parameters in the world coordinates;

[0040] Step S6: Calculating the deposition effect of the weld profile accumulation according to the characteristic parameters.

[0041] Preferably, the laser vision sensing system includes a laser emitter and a CMOS camera; the laser emitter and the CMOS camera are respectively connected to the hos...

Embodiment 2

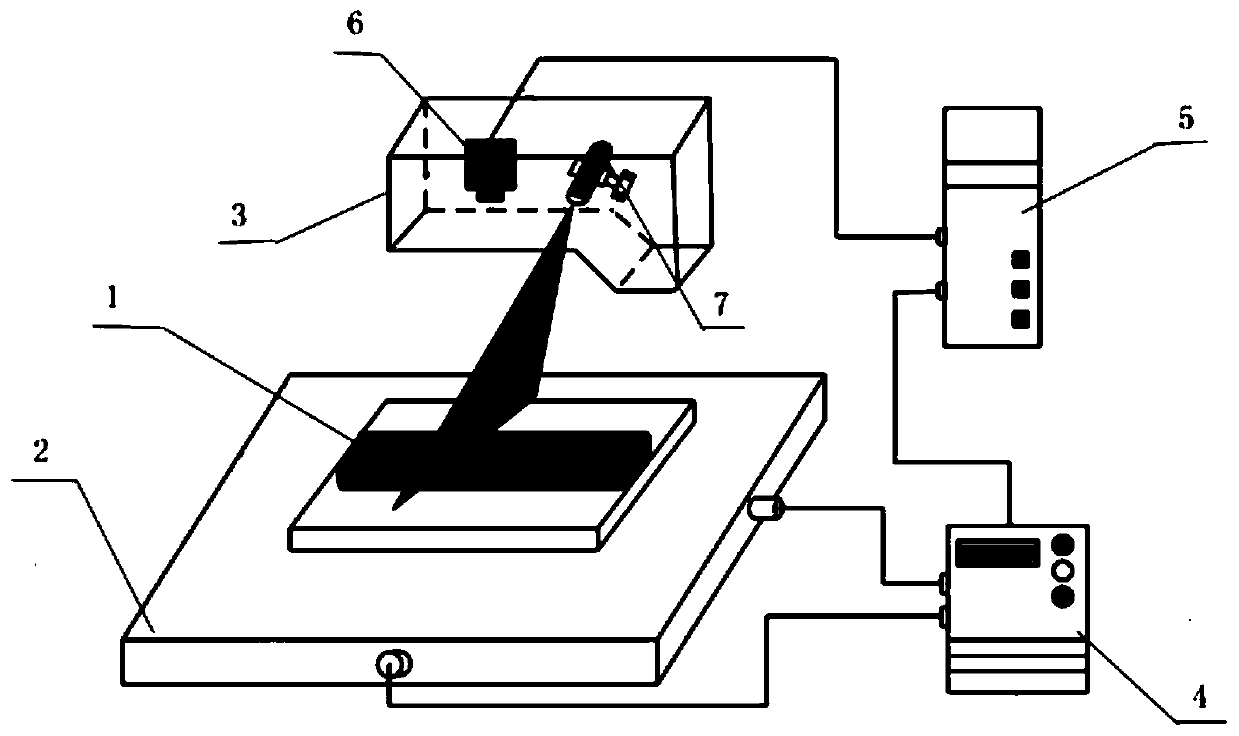

[0048] Such as image 3 As shown, this embodiment provides a single-layer multi-pass weld accumulation deposition effect detection system, the system is based on the method described above, including a surfacing substrate 1 and a moving platform 2, the surfacing substrate 1 Installed on the motion platform 2, the system also includes a laser vision sensing system 3, a host computer 5 and a control cabinet of the motion platform 2; Connection; the motion platform 2 control cabinet is connected with the motion platform 2.

[0049] The laser vision sensing system 3 is fixed above the motion platform 2 to emit laser light and collect laser stripe images on the weld surface. Under the control of the motion platform 2 control cabinet, the motion platform 2 makes the surface to be tested of the weldment within the measurable range of the laser vision sensing system 3, and then the upper computer 5 controls the laser vision sensing system 3 to scan the weld surface , the laser visio...

Embodiment 3

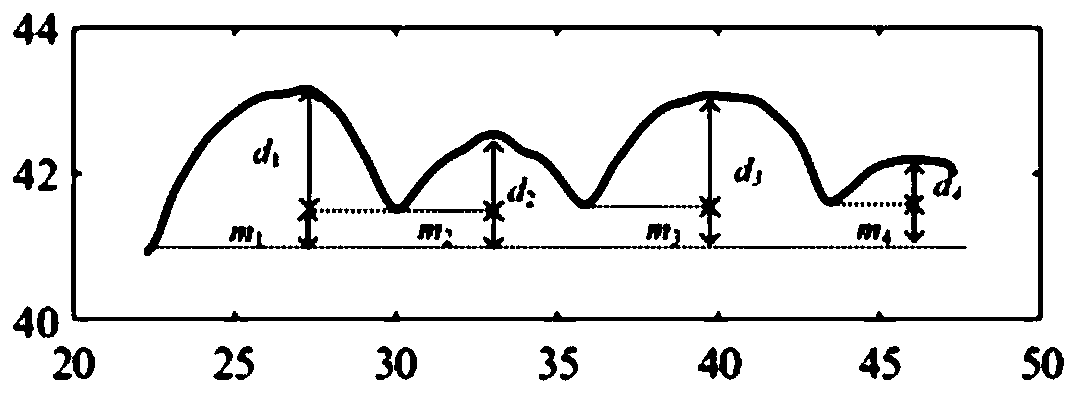

[0053] Such as Figure 1 to Figure 5 As shown, the process flow of the deposition detection method for multi-weld accumulation is as follows figure 1 As shown, put the weldment to be tested on the motion platform 2, adjust the position of the motion platform 2, make the laser vision sensing system 3 collect and scan the weld seam contour, select multiple frames of images and extract the pixel coordinates of the laser stripes, after coordinate conversion Get the actual position of the weld contour, extract as figure 2 The characteristic points shown in the figure obtain the corresponding characteristic parameters, which are substituted into the calculation formula of the degree of deposition to obtain the degree of deposition, and finally compared with the value of 1 / 2, too large or too small is not the best deposition effect, the closer to 1 / 2, it means The better the deposition quality.

[0054] Figure 4 It is the physical picture of arc additive material, and the real c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com