Installation structure of motor magnetic ring and motor

A technology of installation structure and magnetic ring, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of unfavorable automatic production of stator components, low installation flexibility of Hall elements, and complex shaft processing process , to achieve the effect of facilitating automated production, ensuring service life and improving the degree of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

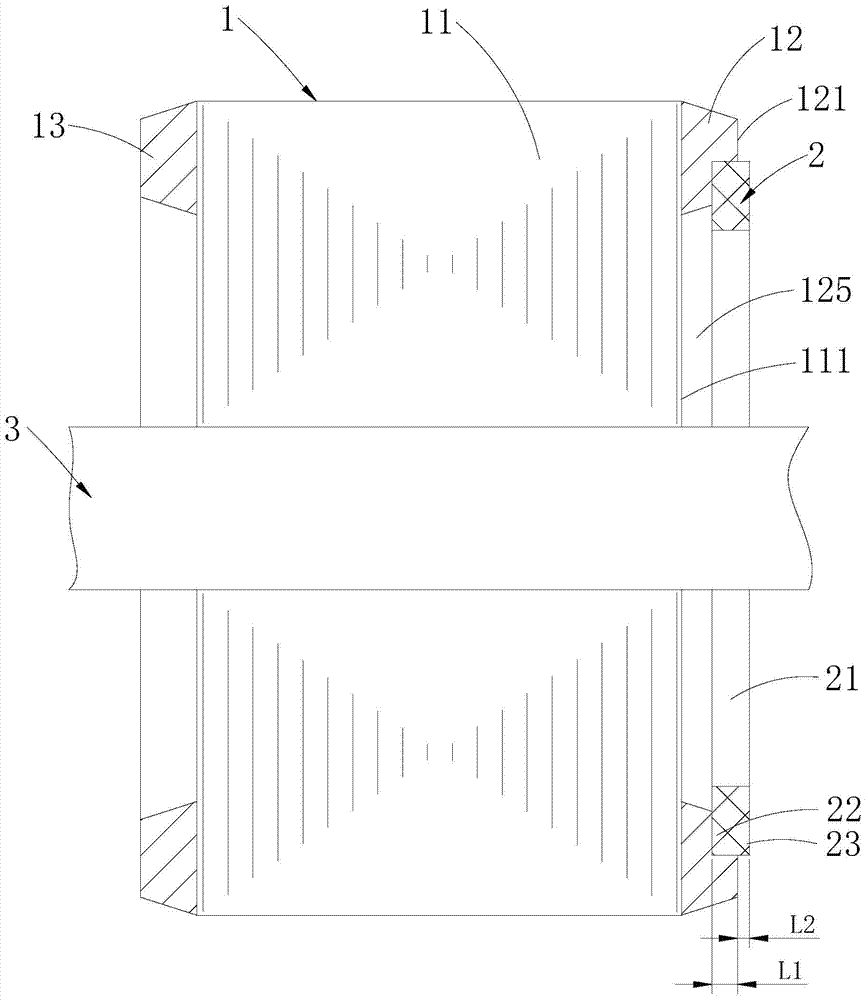

[0027] Such as Figure 1~3 As shown, the installation structure of the magnetic ring of the motor provided by Embodiment 1 of the present invention includes a squirrel-cage rotor 1 and a magnetic ring 2, and the squirrel-cage rotor 1 includes a rotor core 11 and a first end ring 12 disposed at one end of the rotor core 11 , the first end ring 12 has a first axial end face 121 facing away from the rotor core 11, a receiving groove 122 is recessed on the first axial end face 121 toward the side where the sub-core is located, and the magnetic ring 2 is fixed in the receiving Inside the slot 122. In this embodiment, the magnetic ring 2 is installed in the accommodating groove 122 of the squirrel cage rotor 1. On the one hand, it can effectively reduce the axial space occupied by the magnetic ring 2 inside the motor, and add other components to the stator winding (not shown). Parts that are convenient for automated production provide opportunities to facilitate the automated produ...

Embodiment 2

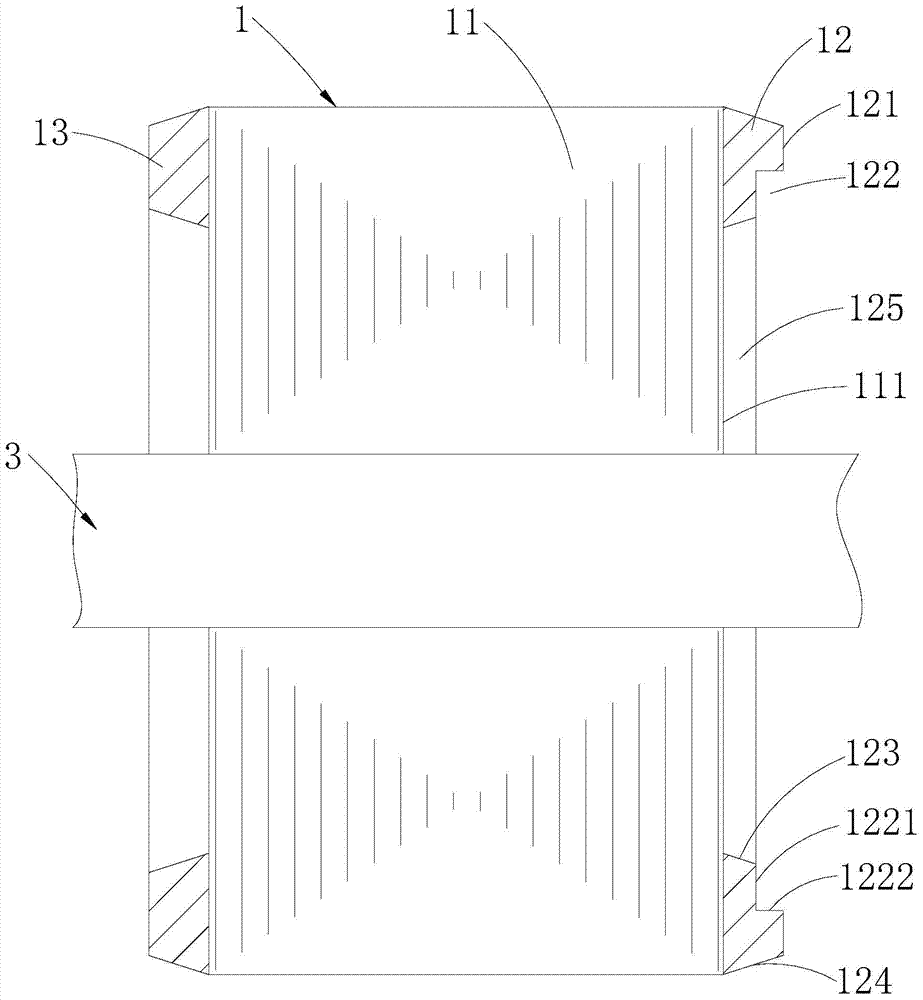

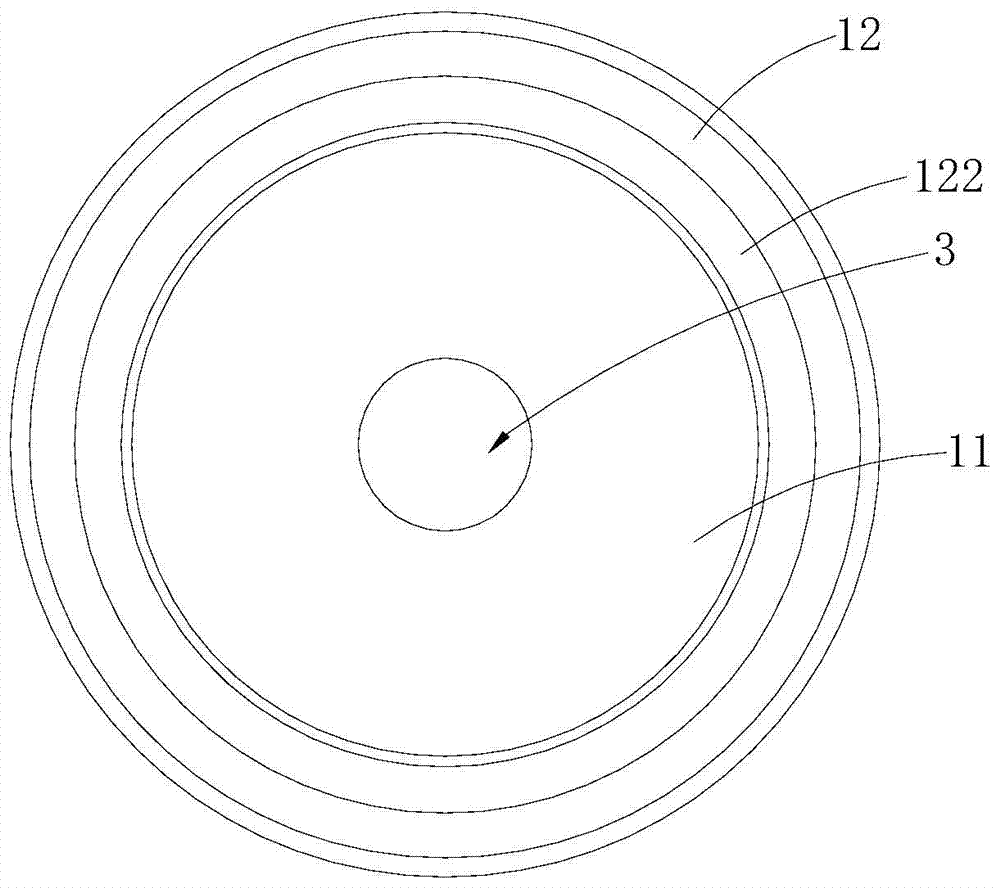

[0042] Such as Figure 4 and Figure 5 As shown, in the installation structure of the motor magnetic ring 2 provided in this embodiment, the rotor core 11 has a contact end surface 111 in contact with the first end ring 12, and the first end ring 12 has an inner ring wall 123 and an outer ring wall 124. The inner cavity 125 is enclosed by the ring wall 123 and the contact end surface 111 , and the accommodating groove 122 is disposed between the inner ring wall 123 and the outer ring wall 124 . The accommodating groove 122 is annular, and the cross-section of the one-side profile inside the accommodating groove 122 (the internal profile located on one side of the inner cavity 125) is roughly U-shaped, which consists of the bottom groove wall 1221 and the outside of the first end ring 12. The first side groove wall 1222 of the ring wall 124 is surrounded by the second side groove wall 1223 close to the inner ring wall 123 of the first end ring 12 . After the magnetic ring 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com