Brake cylinder

A brake cylinder and cylinder technology, which is applied in the field of brake cylinders, can solve the problems of brake cylinders with cumbersome structure, many connection activities, and large space structure, and achieve the effects of compact structure, reduced axial space, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to facilitate the understanding of those skilled in the art, the floor spring of the present invention will be further described below in conjunction with the drawings and specific embodiments:

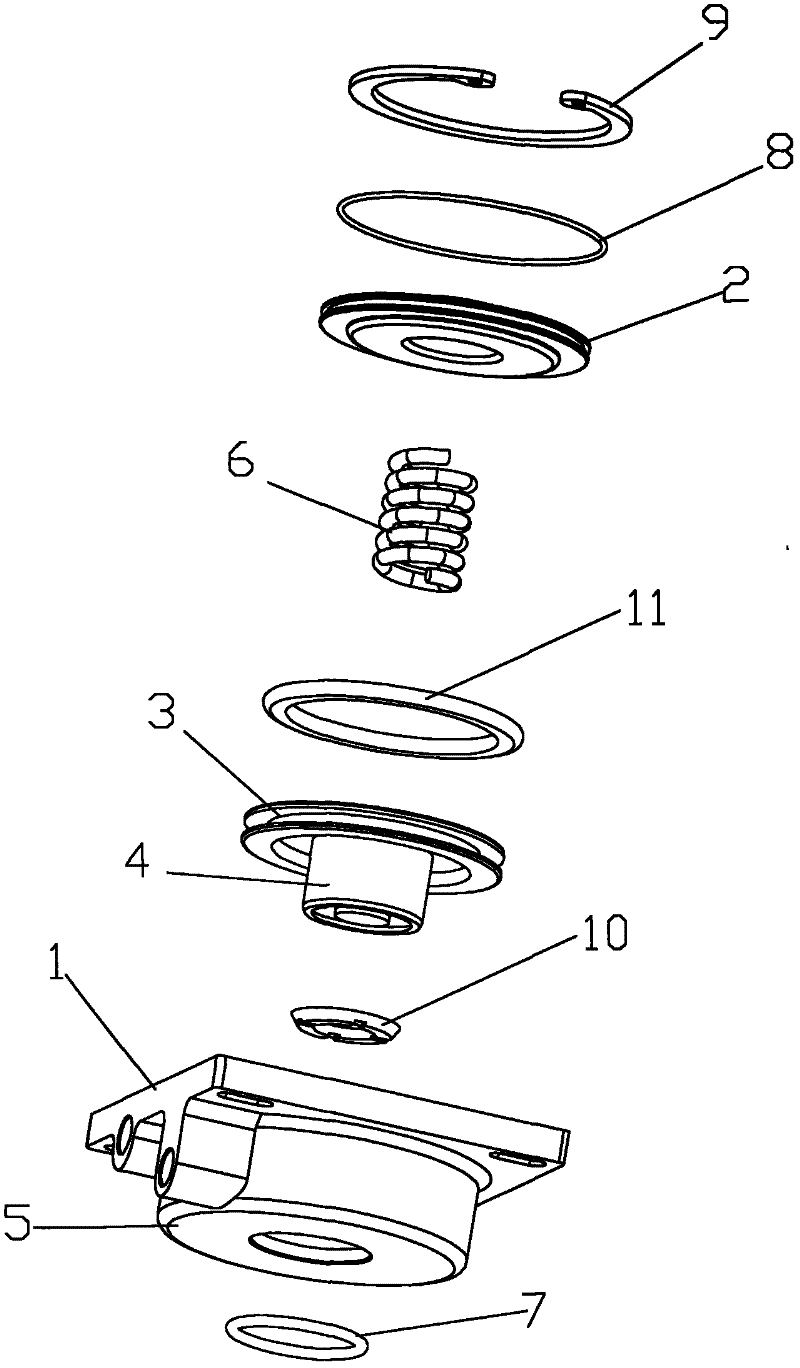

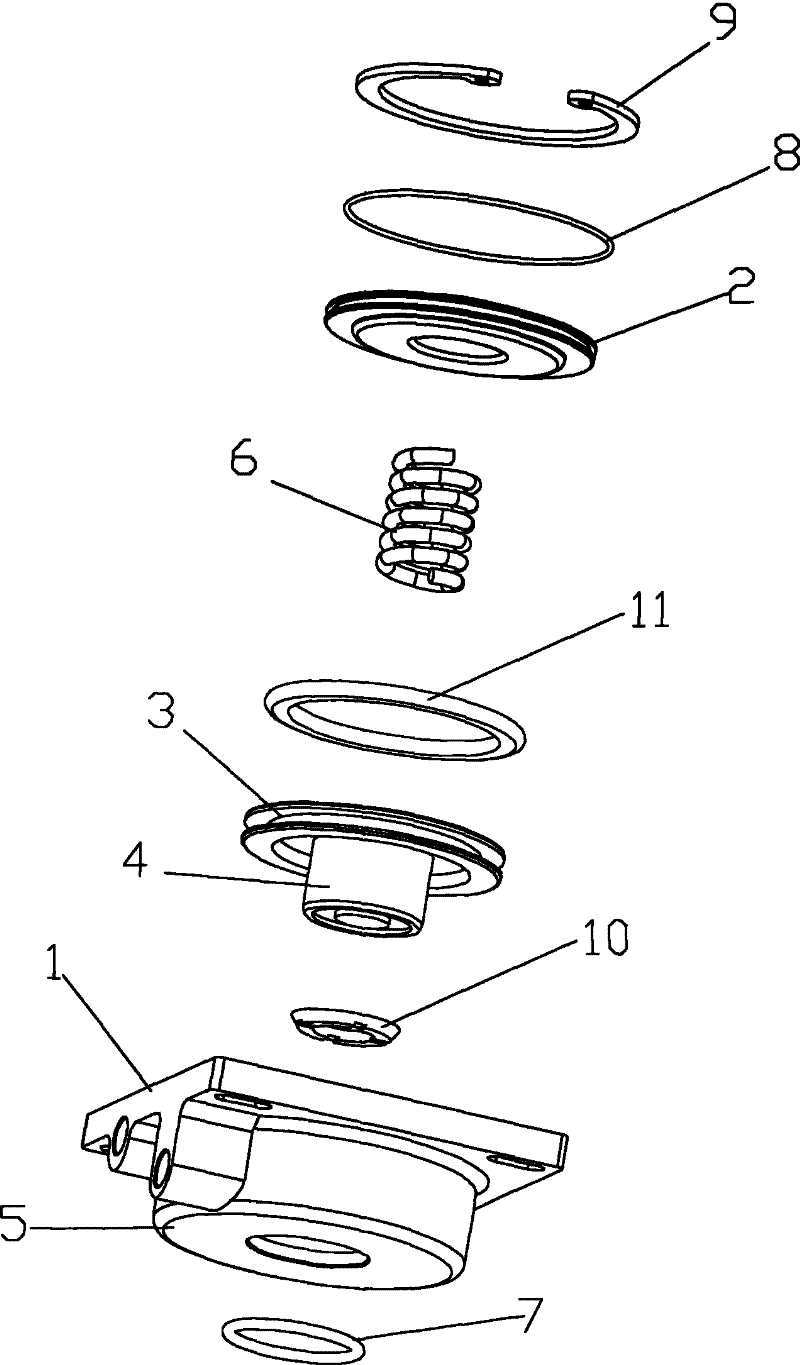

[0010] as attached figure 1 As shown, a brake cylinder includes a cylinder body 1 and a rear cover 2, and a cylinder core is provided in the cylinder body 1. The cylinder core includes a piston 3 and a piston rod 4, which is an integrated structure: the cylinder body 1 is a die-cast integrated structure including a front cover 5; the piston rod of the cylinder core is a hollow structure with a spring 6 inside. The front cover end of the cylinder block 1 is provided with an "O-shaped" rod ring 7 for sealing and guiding the piston rod, and a piston ring 11 for sealing the piston is provided on the piston 3 . The said rear cover 2 is provided with an "O" ring 8 and a snap ring 9 . The end of the piston rod 4 of the cylinder core is provided with a brake pad 10 made of n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com