Erectable arm assembly for use in boreholes

a technology of erectable arms and boreholes, which is applied in the direction of surveying, artificial islands, core removal, etc., can solve the problems of incorrectly determining various parameters, no one drilling method is satisfactory for all radii of curvature, etc., and achieve the effect of preventing jamming of the arm member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

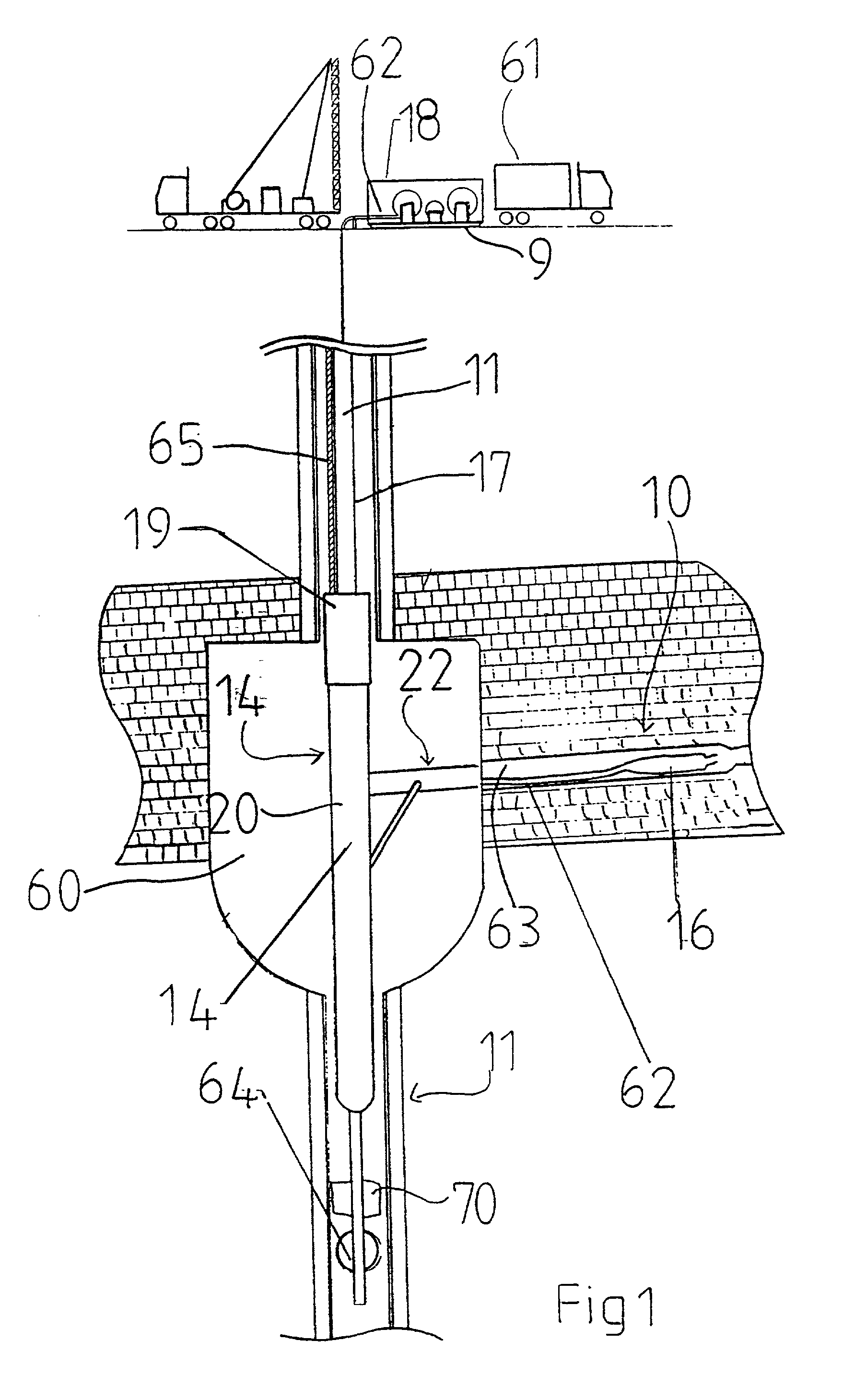

[0062] Referring to the figures, and initially to FIG. 1, there is shown diagrammatically an ultra-short-radius drilling method and assembly for cutting a substantially horizontal bore 63 into a coal seam 10 from an existing vertical borehole 11.

[0063] FIG. 1 shows a vertical bore 11 pre-drilled into the ground and extending through a coal seam 10.

[0064] An assembly 14 is shown in FIG. 1 and which is positioned in a pre-formed slot or cavity 60 in one side of vertical borehole 11.

[0065] A self-advancing steerable fluid cutting device 16 has been positioned substantially horizontally into coal seam 10 by virtue of the assembly 14.

[0066] The self-advancing cutting device 16 has a tubular steel body about 40-80 cm long and 5-15 cm in diameter. The body has a number of rearwardly facing high pressure retro jet thrusters which propel the cutting apparatus in a forward direction. The front face of the cutting device is provided with one or more high pressure water jet cutters to cut the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com