High-pressure automatic forming system of pedestal pan

A technology of automatic forming and high-pressure forming machine, which is applied in the direction of ceramic forming machines and manufacturing tools, which can solve the problems of unsuitable production rhythm, low space utilization rate, and low efficiency, so as to improve the degree of automatic production of the system, improve operating efficiency and Yield rate, effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] In summary, the present invention discloses an automatic high-pressure toilet molding system, which integrates the high-pressure molding machine for the toilet body and the high-pressure molding machine for the toilet ring into the same system, and realizes the toilet body and the toilet ring. Automated bonding and shifting can greatly improve operating efficiency and yield, and reduce labor intensity. The specific plan is as follows:

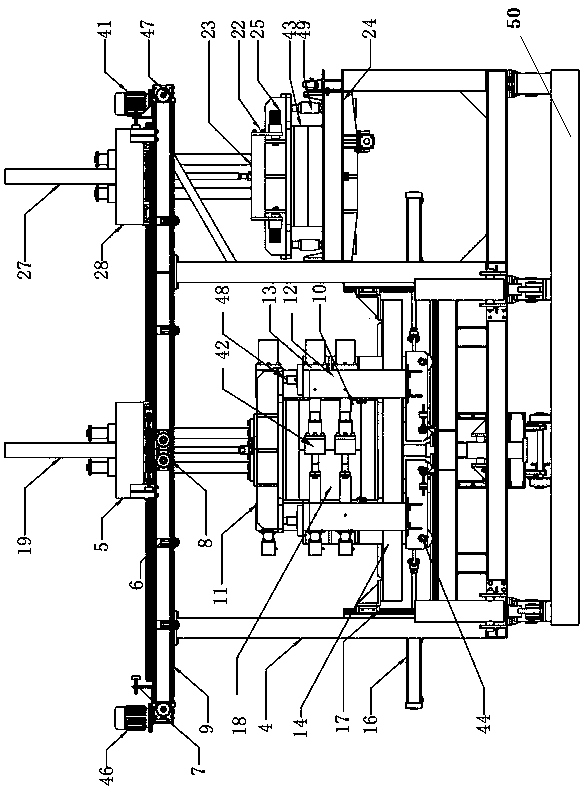

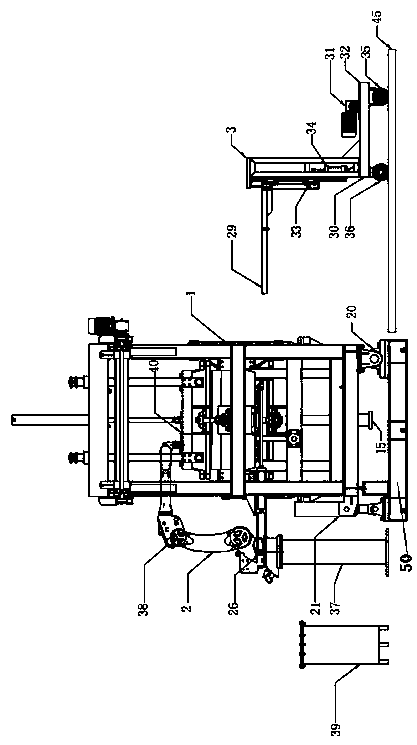

[0021] A kind of automatic forming system of high-pressure toilet (see attached figure 1 And attached figure 2 ), including a base 50, a door-shaped main frame 4, a mud spraying device 2, a toilet body high-pressure forming machine 10, a toilet ring body high-pressure forming machine 22 and a transfer machine 3, and two sides of the door-shaped main frame 4 one side One leg is hinged to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com