Accumulation body of ultrathin soft glass and manufacturing and processing method thereof

A processing method and soft glass technology, which are applied in glass manufacturing equipment, manufacturing tools, glass cutting devices, etc., can solve the problems of glass being fragile, unable to absorb impact force, and easily broken, so as to improve work efficiency and yield, and facilitate large-scale production. Mass production, enhanced anti-rupture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

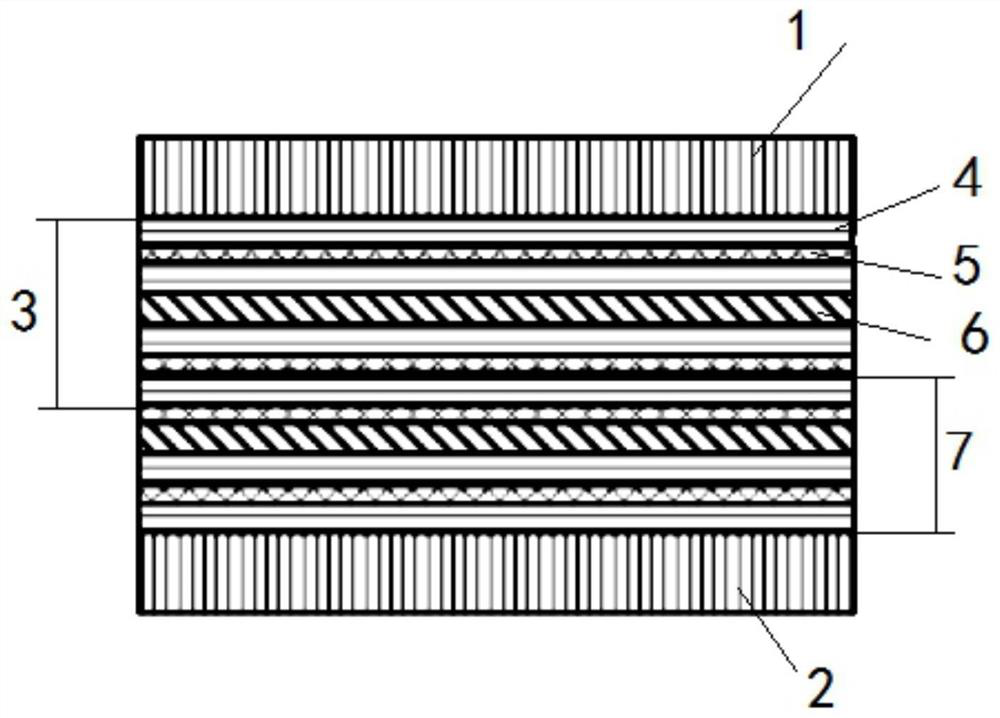

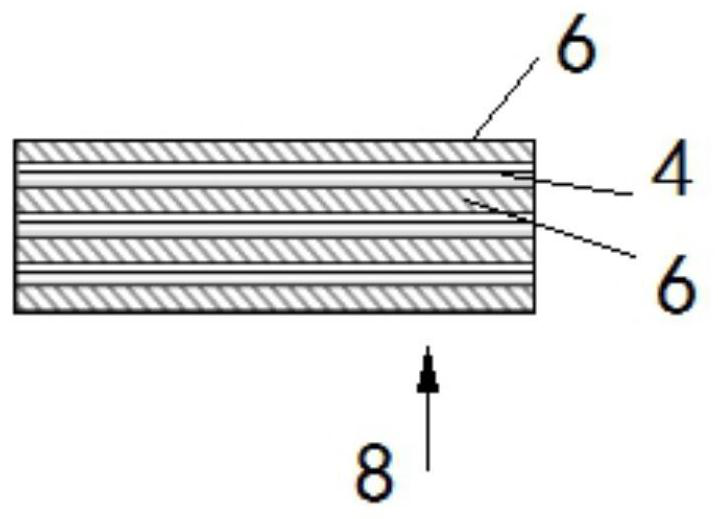

[0038] Example: see attached figure 1 , an accumulation body of ultra-thin soft glass, which has the upper bottom white glass 1 and the lower bottom white glass 2 as the base (in order to facilitate understanding, the upper bottom white glass 1 and the lower bottom white glass 2 are respectively marked with figure numbers) , between the upper bottom white glass 1 and the lower bottom white glass 2, there is at least one group of composite layers; there are two types of composite layers, the composition of the first type of composite layer 3 is glue layer 4-buffer film layer 5- Adhesive layer 4-ultra-thin film glass 6-adhesive layer 4-buffer film layer 5-adhesive layer 4; the composition of the second composite layer 7 is adhesive layer 4-buffer film layer 5-adhesive layer 4- Ultra-thin film glass 6-buffer film layer 5-glue layer 4. The number of groups of the composite layer is generally 2-20 groups according to the needs. In this embodiment, one group of the first type of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com