Dual-curing pressure-sensitive adhesive tape

A pressure-sensitive tape, dual-curing technology, used in pressure-sensitive films/sheets, adhesives, other rubber adhesives, etc. The effect of work efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A dual-cure pressure-sensitive adhesive tape, which takes the following raw materials:

[0027] Acrylic monomer 260g;

[0028] Rubber elastic body 100g;

[0029] Carboimide 80g;

[0030] Trimethylolpropane trimethacrylate 150g;

[0031] Tackifying resin 200g;

[0032] Dibenzoyl oxide 120g;

[0034] Modified polyacrylamide polymer A 300g.

[0035] A dual-cure pressure-sensitive adhesive, the preparation method of which is:

[0036] 1) Weigh a certain amount of dibenzoyl oxide and benzoin ethyl ether in a reaction kettle, heat to 65-75°C, and ultrasonically disperse to obtain a uniform heat-cured and light-cured mixed initiator solution.

[0037] 2) Add acrylate monomer, acrylic monomer, rubber elastomer, carboimide, trimethylolpropane trimethacrylate, tackifying resin and modified polyacrylamide polymer to the mixed initiator solution in phase step 1 A. Keep the temperature below 35°C and mix evenly to...

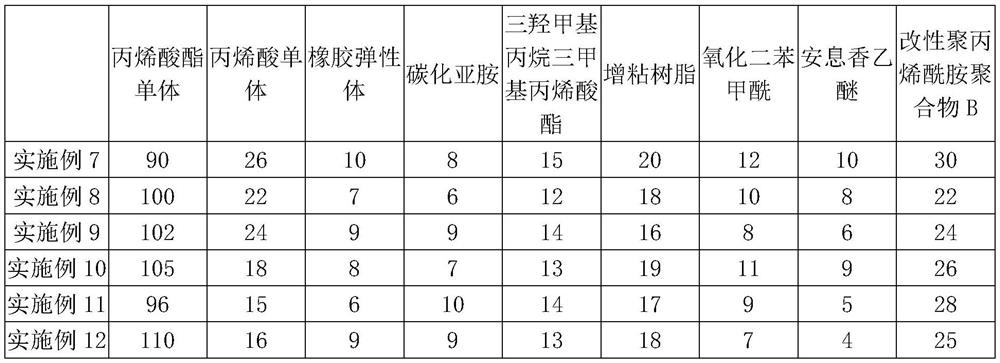

Embodiment 7-12

[0042] Embodiment 7-12 preparation method with reference to embodiment 1, concrete raw material is as follows table:

[0043]

[0044] the third part:

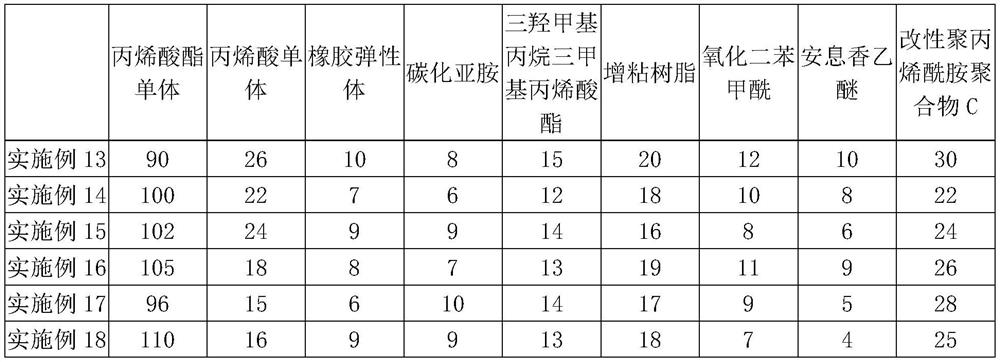

Embodiment 13-18

[0045] Embodiment 13-18 preparation method with reference to embodiment 1, concrete raw material is as follows:

[0046]

[0047] the fourth part:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com