Automatic material storing and conveying system for cooling copper pipe

A feeding system and automatic feeding technology, applied in the field of automation systems, can solve problems such as affecting the production speed, slowing down the production line speed, and increasing production costs, so as to improve work efficiency and yield, improve quality, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

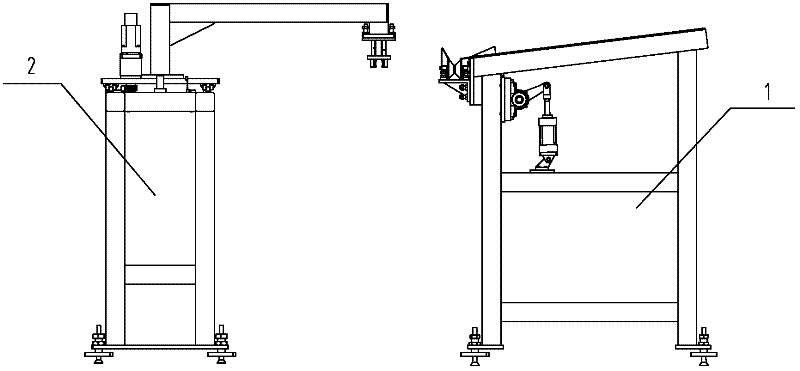

[0032] An automatic storage and delivery system for cooling copper tubes, which includes: a storage and distribution device 1 and an automatic feeding device 2;

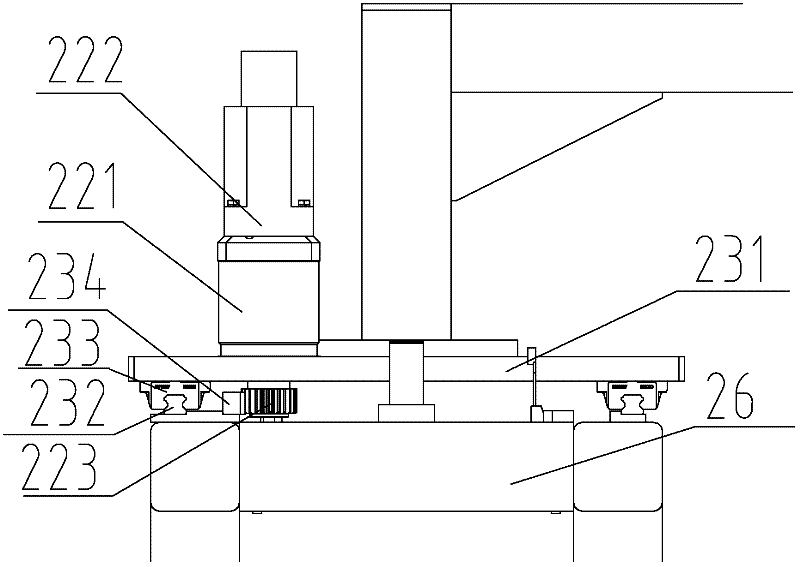

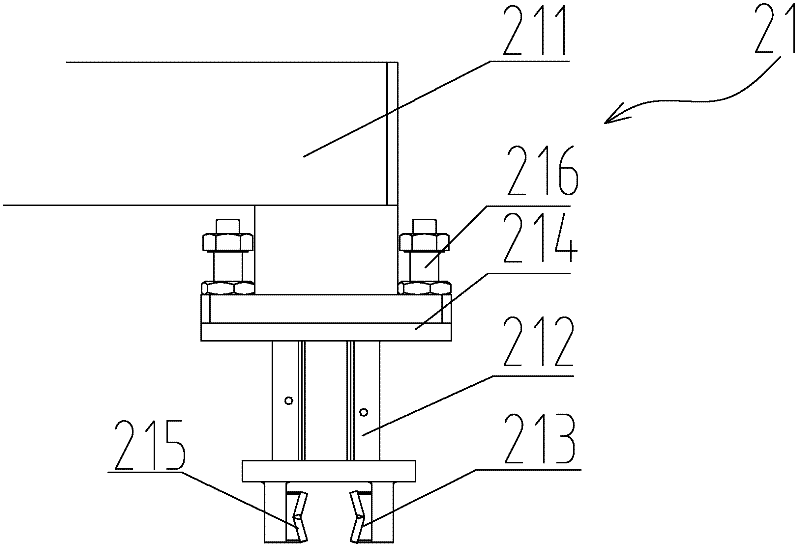

[0033] The material storage and distribution device 1 in this embodiment includes: a material distribution device, a V-shaped wheel assembly, and a material distribution frame 14, wherein the material distribution device includes: a double clevis seat 1101, a Y-shaped double rib plug 1102, a transmission rod 1103, a transmission Shaft 1104, cylinder 1105, guiding seat 1106, ejector rod 1107, connecting support 1108, locking seat 1109, connecting key 1110, fixed baffle 1111 and bearing seat 1112; V-shaped components include: V-shaped wheel 1201, V-shaped wheel seat 1202 , V-shaped wheel seat support 1203 , guide plate 1204 , rotating shaft 1205 and rotating bearing 1206 .

[0034] The connections of the above components are as follows:

[0035] One end of the cylinder 1105 in the material distribution device describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com