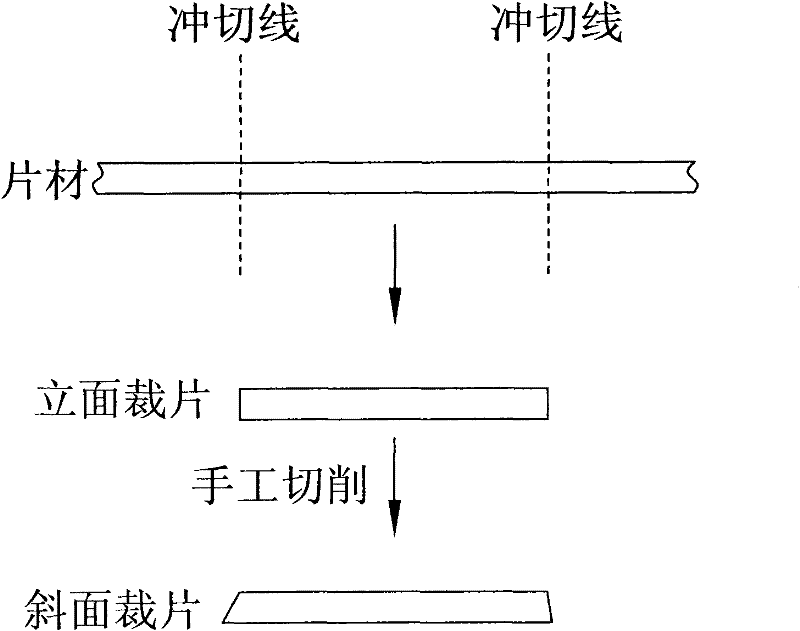

Method for once forming cut piece with slope

A one-time, piece-cutting technology, applied in metal processing and other directions, can solve problems such as unstable product quality, high manual labor intensity, and poor consistency of slopes, so as to improve work efficiency and yield, reduce production costs, and maintain slope consistency Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

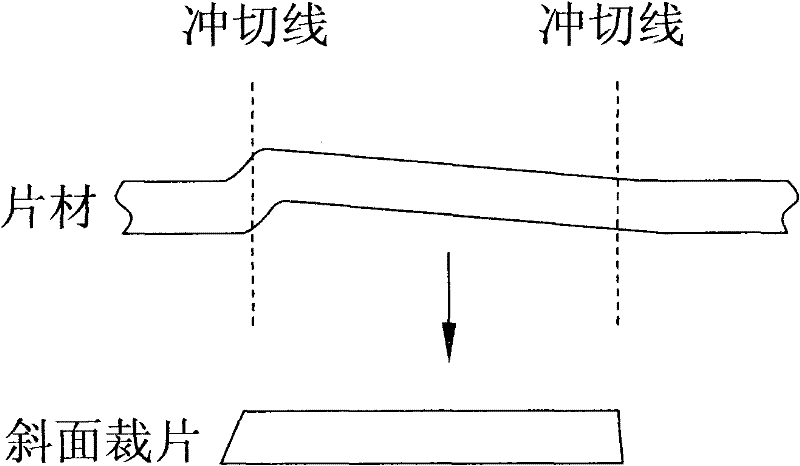

[0014] refer to figure 2 , to form a bevel on the insole, it is necessary to make the die and the sheet form an inclination during the punching process. The method of the present invention is to make the sheet along the bevel designed by the cut piece according to the position and inclination of the cut piece. The punching part is bent. After bending, the bending part of the sheet forms an inclination angle with the knife die. After punching, the punching surface of the bending part of the cut piece naturally forms an inclined surface, and the punching surface of the unbent part is a vertical surface, which can realize the slope The insole is molded at one time.

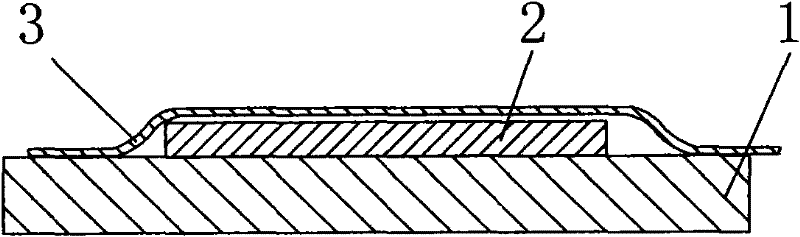

[0015] There are two methods for bending the sheet. see image 3 The first one is to set the punch 2 on the workbench 1. After the sheet 3 to be processed is placed on the workbench 1, the sheet will be bent naturally under the action of gravity at the suspended part around the punch 2.

[0016] see Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com