Method for processing steel plane hoe

A processing method and a technology of processing steps, which are applied in the field of agricultural machinery processing, can solve problems such as easy gaps in planing and hoeing, high labor intensity of workers, waste of raw materials, etc., achieve less smoke and dust waste and noise pollution, reduce labor intensity of workers, and automate The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

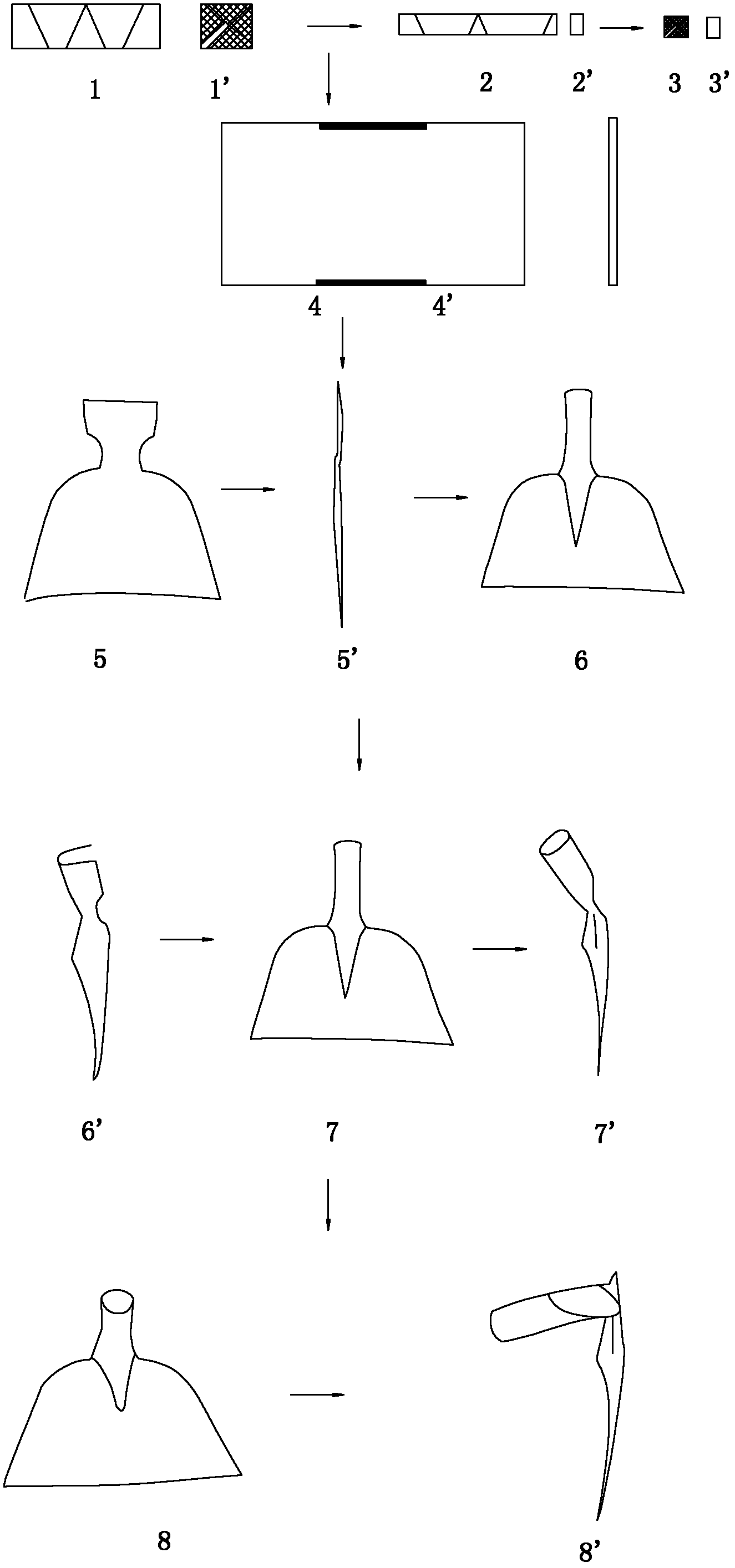

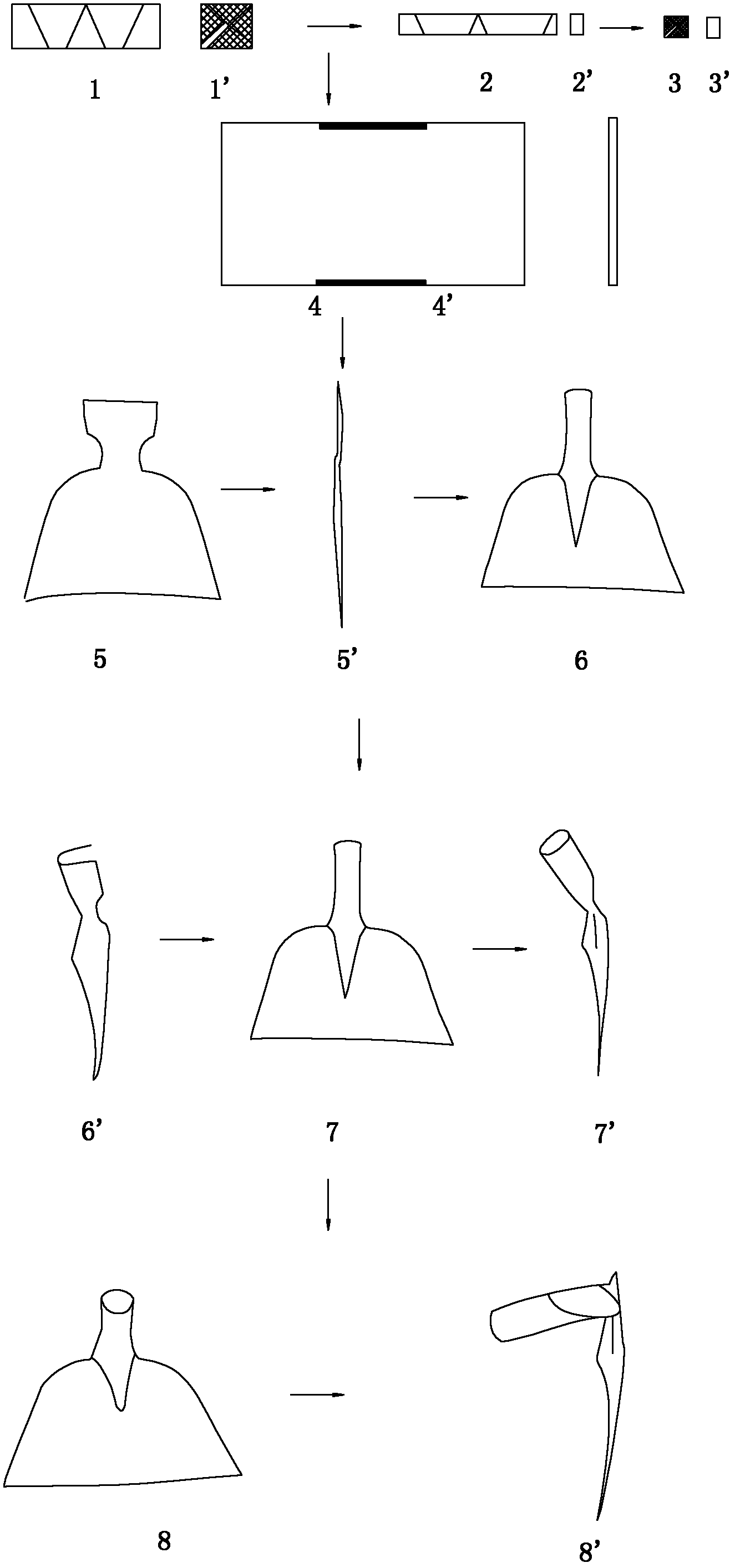

[0030] A processing method of a steel planer hoe, the technological process is as attached figure 1 Shown:

[0031] Step 1. Processing blank

[0032] Firstly, the 90×90 45# square steel 1 is mechanically rolled into a 16×100 flat steel 2, and then the required blank 3 can be pressed into the blank 3 by a stamping machine;

[0033] Step 2. Processing steel planer hoe

[0034] 1. Heat the blank 3 to 1200°C, and roll it into a convex blank hoe plate 4 by mechanical rolling;

[0035] 2. Use a stamping die to stamp the convex rough hoe plate 4 again, cut off the corners and corners, and make a hoe plate 5 with a steel planer hoe shape, and a trademark mark can be pressed on the stamped hoe plate 5;

[0036] 3. Then use a friction press to press the stamped hoe plate 5 into an arc shape, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com