Reducing device for sponge titanium production process

A production process and technology of sponge titanium, which is applied in the field of sponge titanium production equipment, can solve the problems of operators' physical hazards, excessive pressure, and no recycling, so as to prevent environmental pollution, realize recycling, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

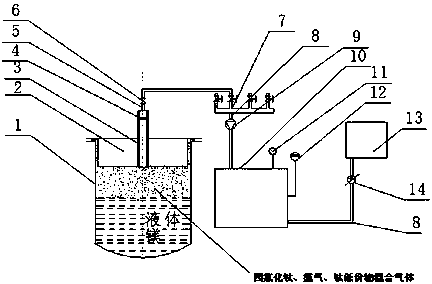

[0018] Such as figure 1 As shown, a reduction device used in the production process of sponge titanium is mainly composed of a reactor 1 and a large cover 2 arranged on it. A standpipe 3 is arranged on the large cover 2, and the standpipe 3 passes through the large cover 2. The cover 2 forms a gas channel, the standpipe 3 is provided with a filter 4, the standpipe 3 is connected to the valve group 7 through the metal hose 5, the metal hose 5 is provided with an automatic pressure relief valve 6, and the valve group 7 passes through the metal pipe 8 Connect with titanium tetrachloride condenser 10, be provided with titanium blower fan 9 therebetween, be respectively provided with exhaust valve 11 and liquid level gauge 12 at the top and side wall of titanium tetrachloride condenser 10, titanium tetrachloride condenser 10 The lower part of one side is connected with the titanium tetrachloride storage tank 13 through a metal pipe 8, and a magnetic drive pump 14 is arranged thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com