Miter cutting machine

A technology of oblique cutting machine and frame, applied in shearing device, pipe shearing device, attachment device of shearing machine, etc., can solve the problems of unstable product size and low efficiency of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

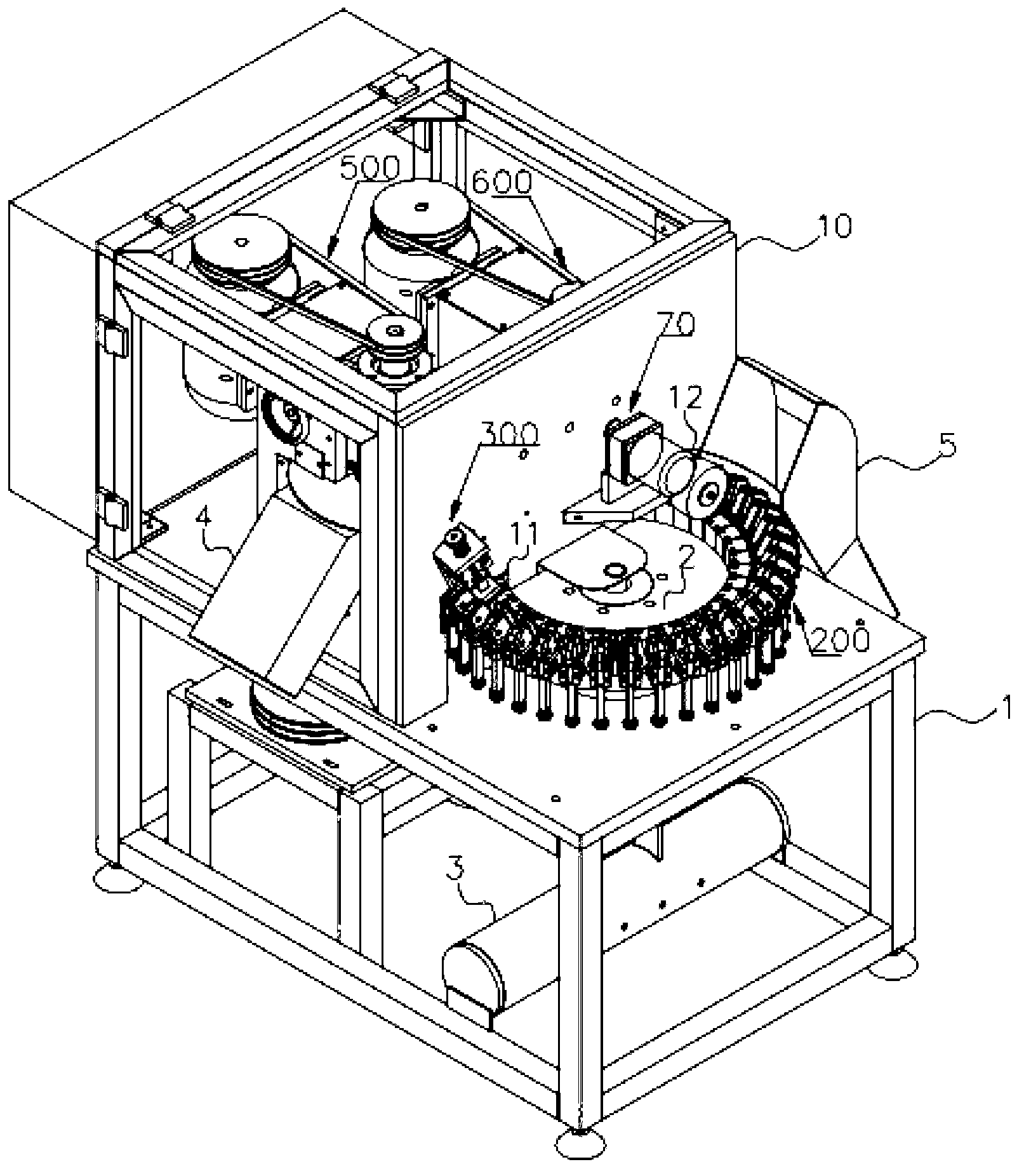

[0080] Such as figure 1 The bevel cutting machine shown includes: frame 1, horizontal turntable 2, compressed air source 3, protective box 10, jig 200, extrusion device 300, first rotary cutter 500, waste receiving groove 4, second rotary cutter 600, blanking device 70, workpiece receiving groove 5.

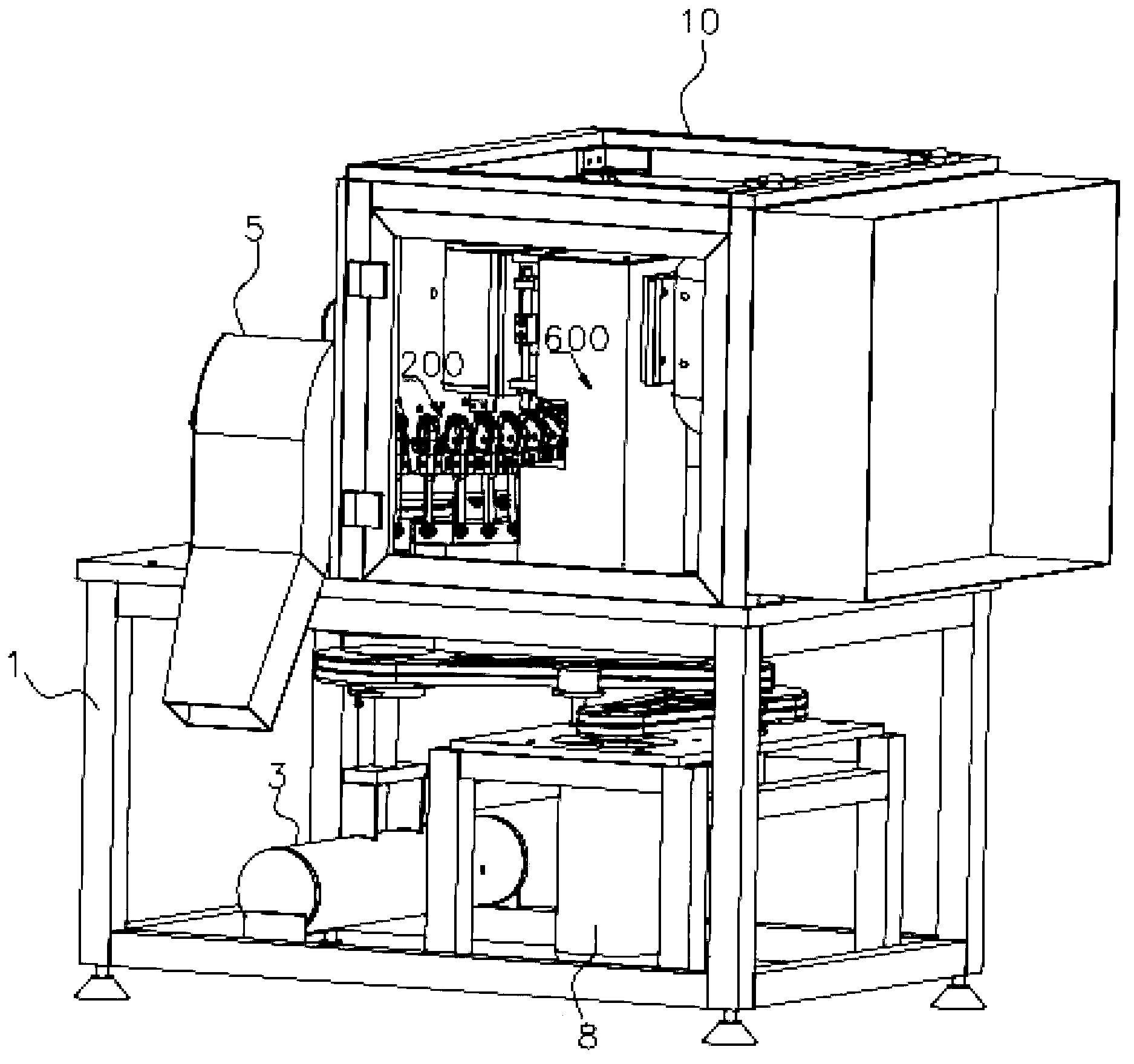

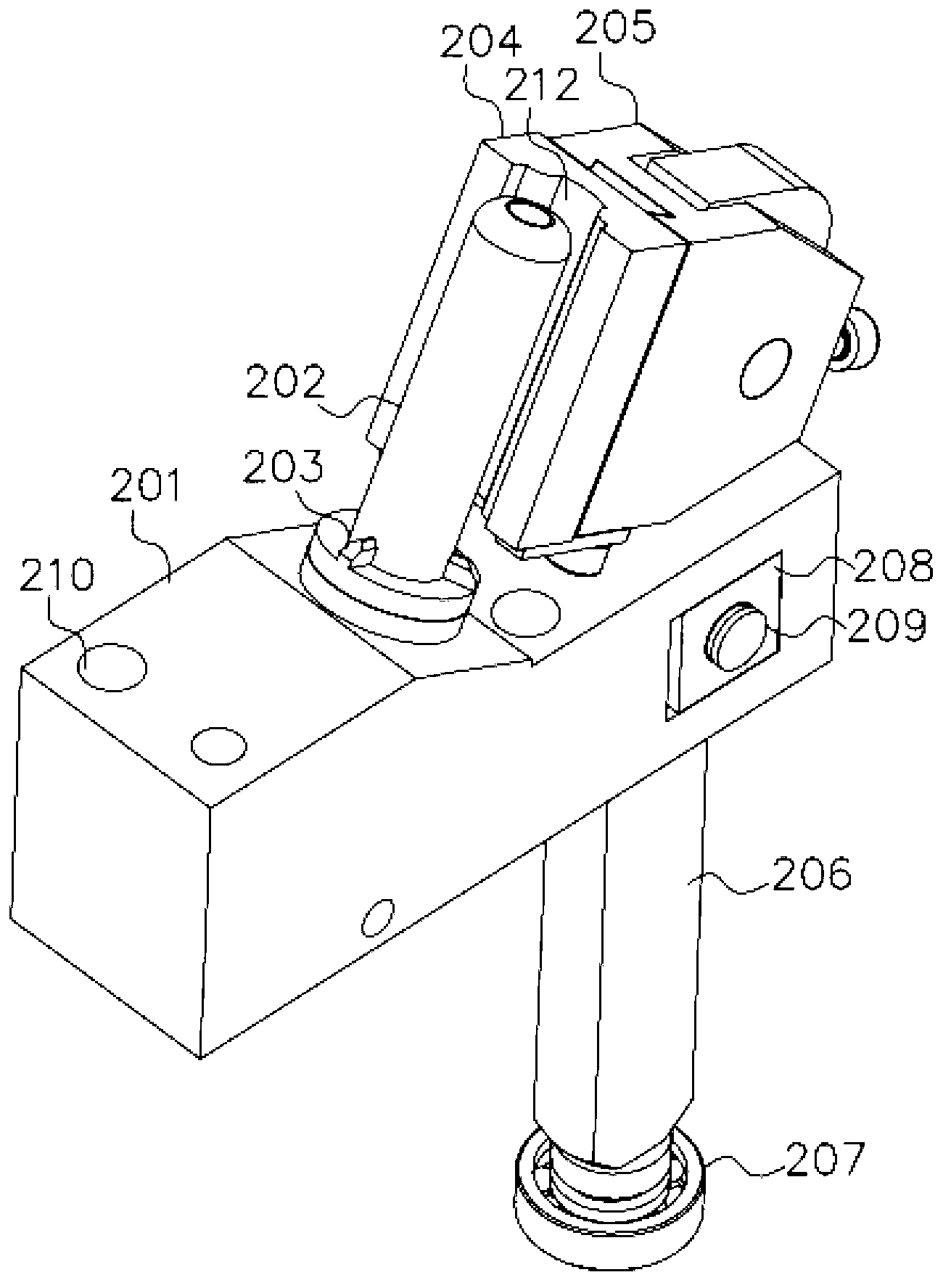

[0081] Depend on figure 1 and figure 2 It can be seen that the horizontal turntable 2 is installed on the frame 1, and the driving motor driving the rotation of the horizontal turntable 2 is installed under the frame 1. In this specific embodiment, a GV vertical three-phase gear reduction motor 8 is selected. On the edge of the horizontal turntable 2, a plurality of jigs 200 are installed along the circumference. The structure of each fixture 200 is as follows image 3 , 4 , 5, and 6.

[0082] combine figure 1 ,Dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com