Patents

Literature

55results about How to "Avoid sex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

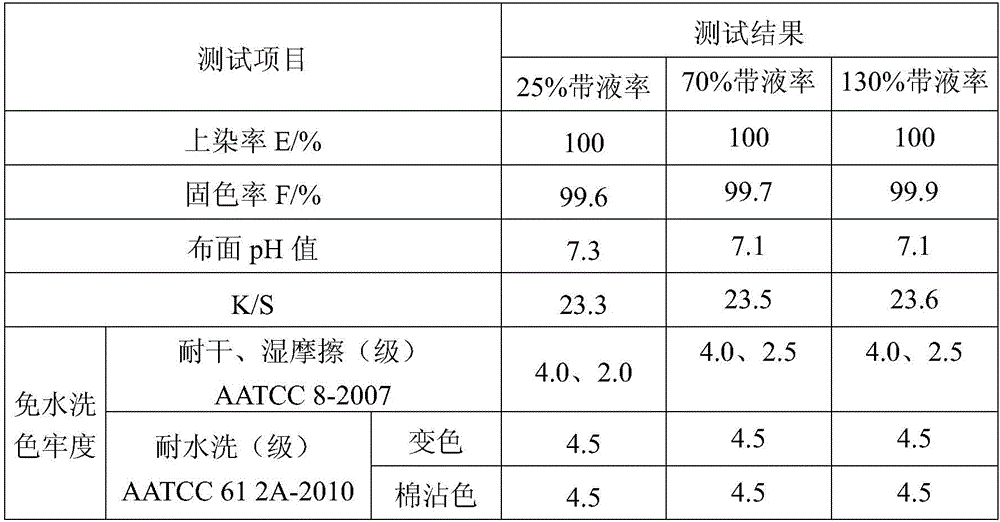

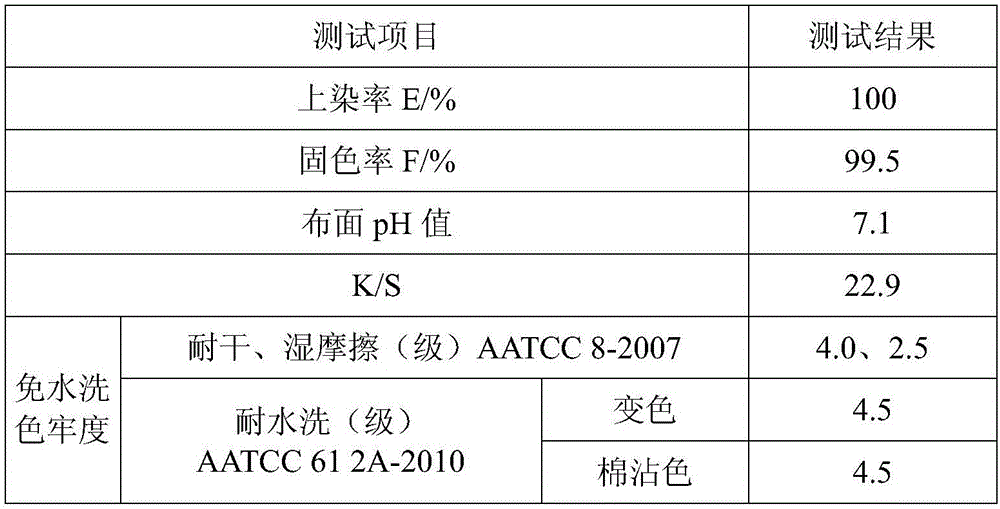

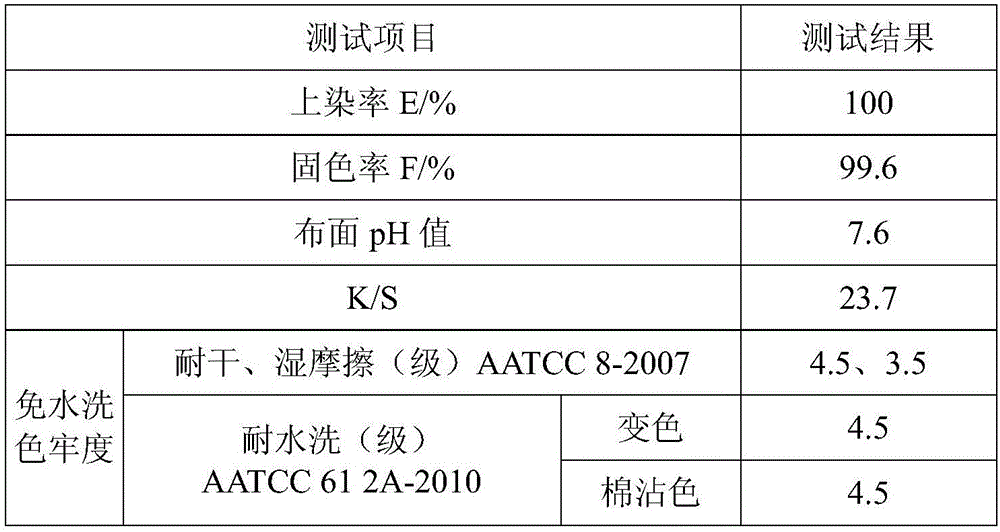

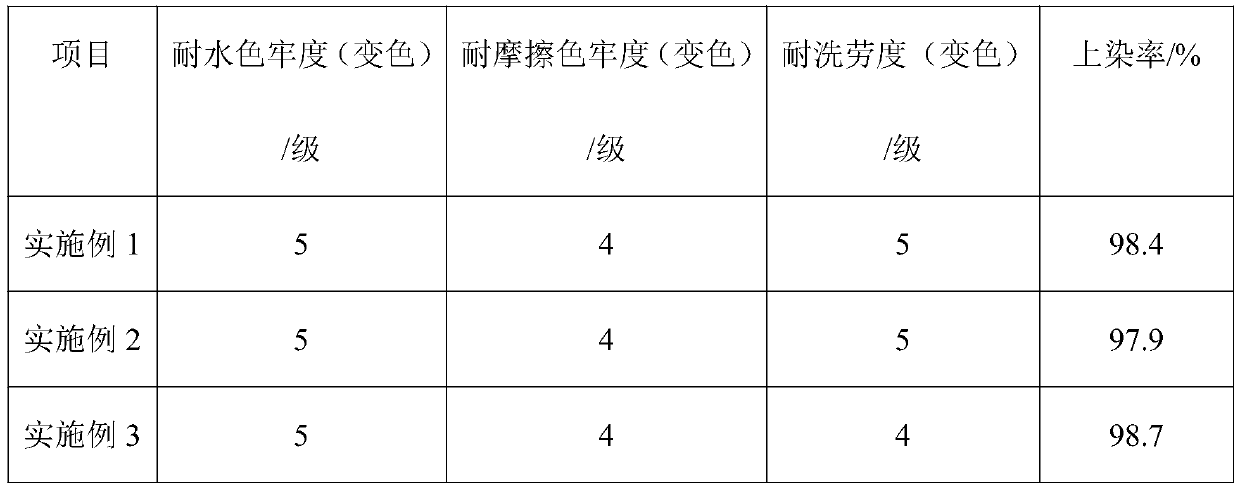

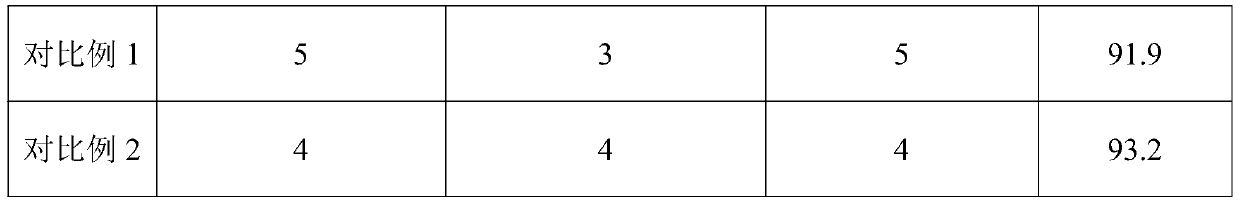

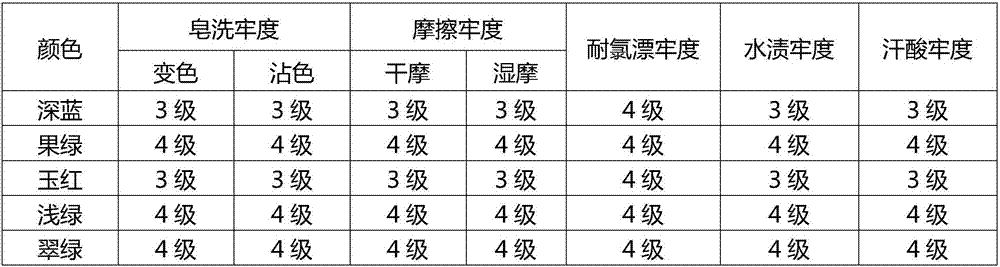

Non-aqueous-medium dyeing and washing-free color fixation method for reactive dye

The invention provides a method for non-aqueous medium dyeing and water-free color fixation of reactive dyes. The method includes: 1) placing the fabric or garment in an alkaline substance for swelling, controlling the liquid carrying rate, and drying; 2) mixing the fabric or garment with a reactive dye or a good solvent of the reactive dye and then heating it, before heating or During the heating process, add the poor solvent of the reactive dye, heat it up to the dyeing temperature, and then perform insulation dyeing. After the dyeing is completed, dry the fabric or garment; 3) Directly apply the color-fixing working solution evenly to the above-mentioned dryer by spraying or foaming. After drying both sides of the fabric or garment, control the liquid-carrying rate of the fabric or garment, and then bake to complete the non-aqueous medium dyeing of reactive dyes and water-free color fixation. The technical solution provided by the invention not only greatly improves the utilization rate and dye uptake rate of reactive dyes, but also effectively reduces the water consumption and wastewater discharge during the dyeing process.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

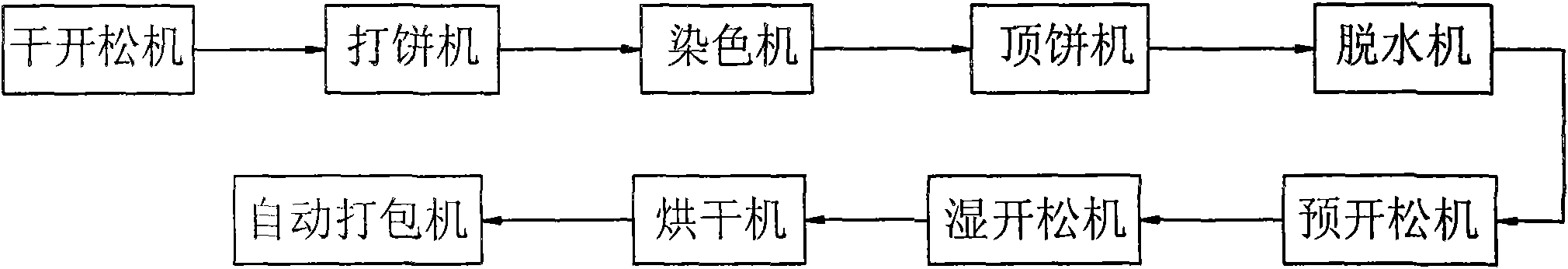

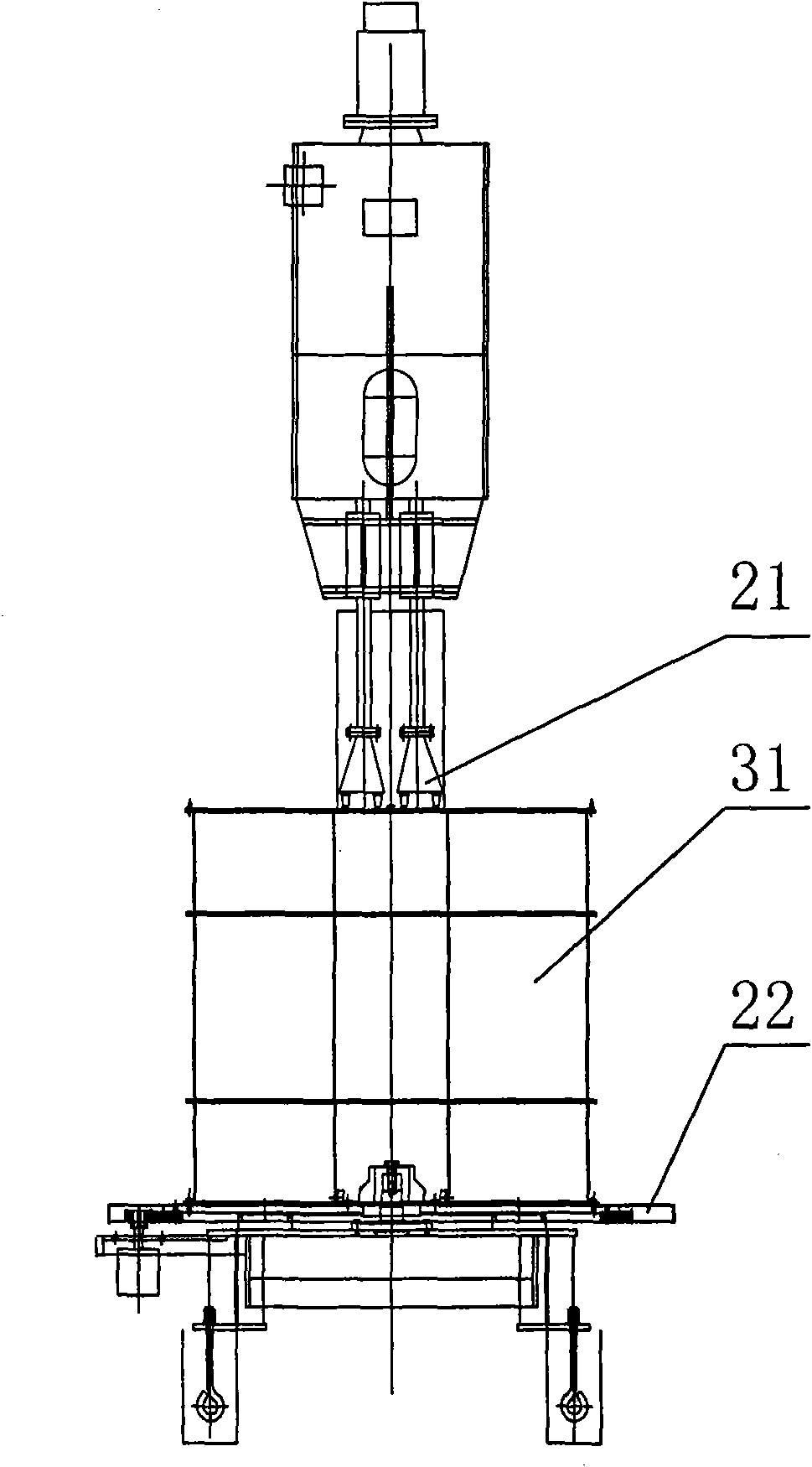

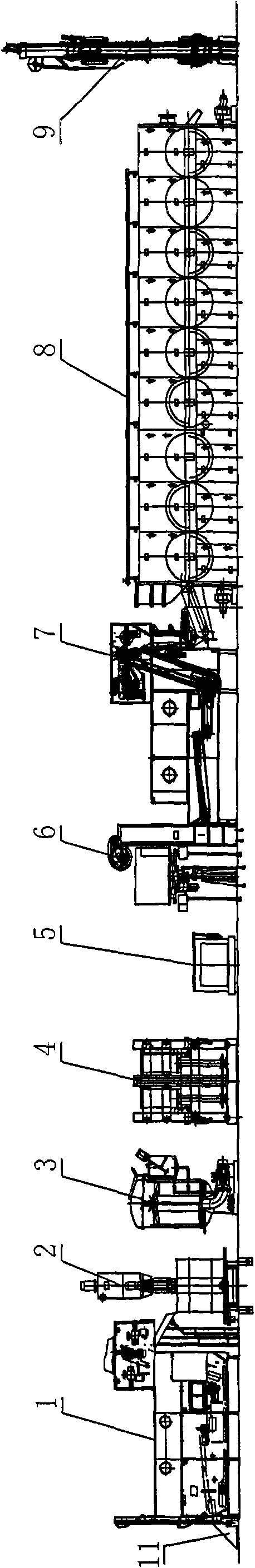

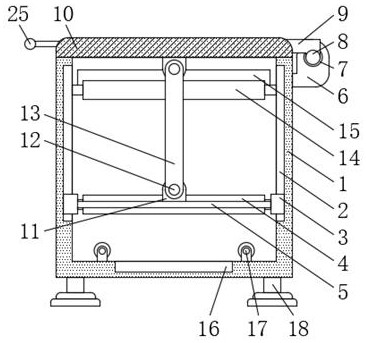

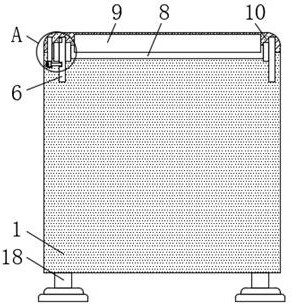

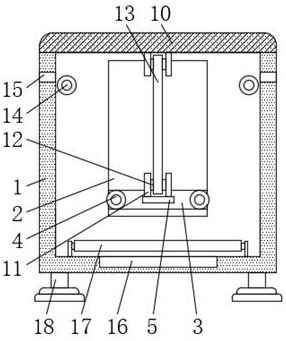

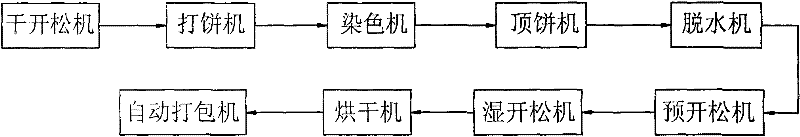

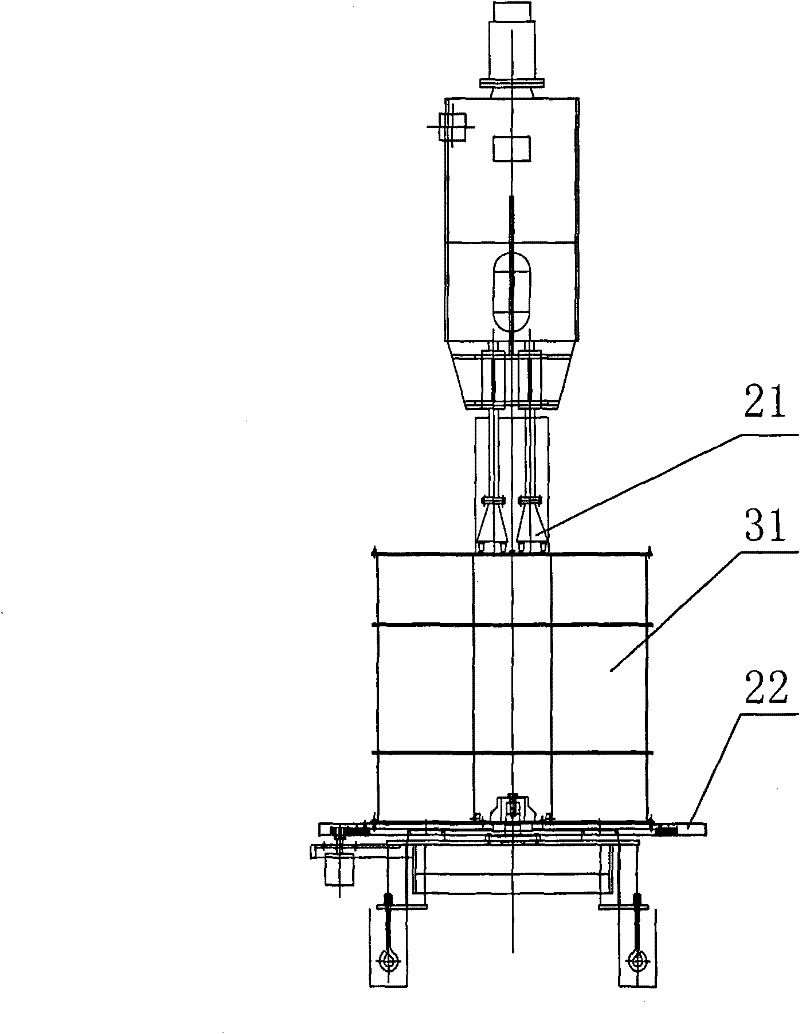

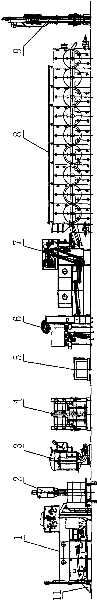

Automatic processing system for dyeing loose fibers

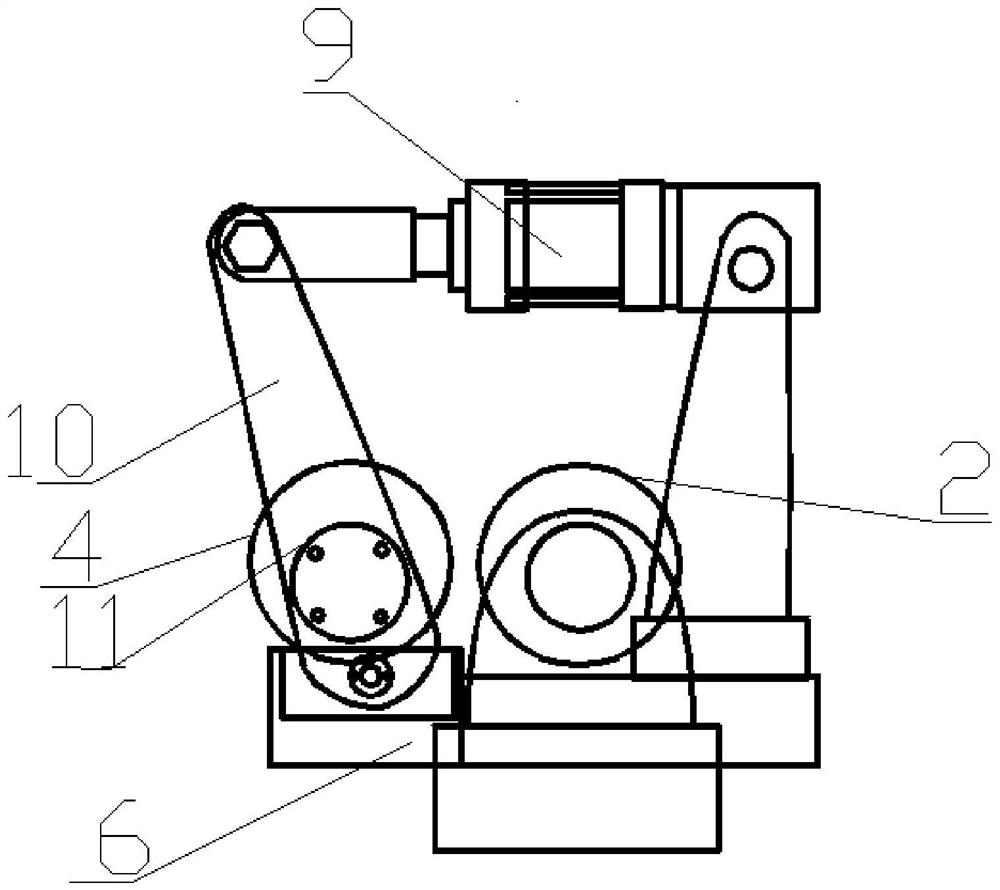

ActiveCN101629365AImprove the degree of automated productionIncrease productivityTextile treatment machine partsFibre cleaning/openingCircular discProduction line

The invention discloses an automatic processing system for dyeing loose fibers. The system comprises a dry opening machine, a disk forming machine, a dyeing machine, a dewatering machine, a wet opening machine, a drying machine and an automatic packing machine which are sequentially connected, wherein, a pre-opening machine is connected between the dewatering machine and the wet opening machine, the pre-opening machine comprises a rotatable disk, the disk is installed on a lifting rack, and a cotton peeling roller is arranged above the disk. A hydraulic disk jacking machine can also be arranged between the dyeing machine and the dewatering machine. The invention is the first automatic production line for dyeing the loose fibers, can be suitable for dyeing various fibers, and can increase the degree of automatic production, shortens the production period of entire dyeing processing, increases the production efficiency, reduces the intensity of labor production, and especially greatly increases safety.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

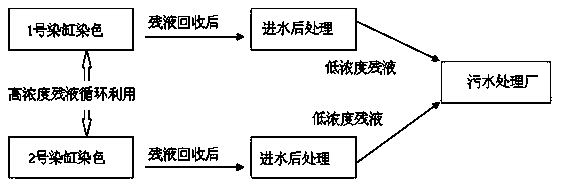

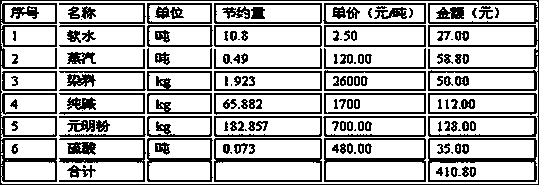

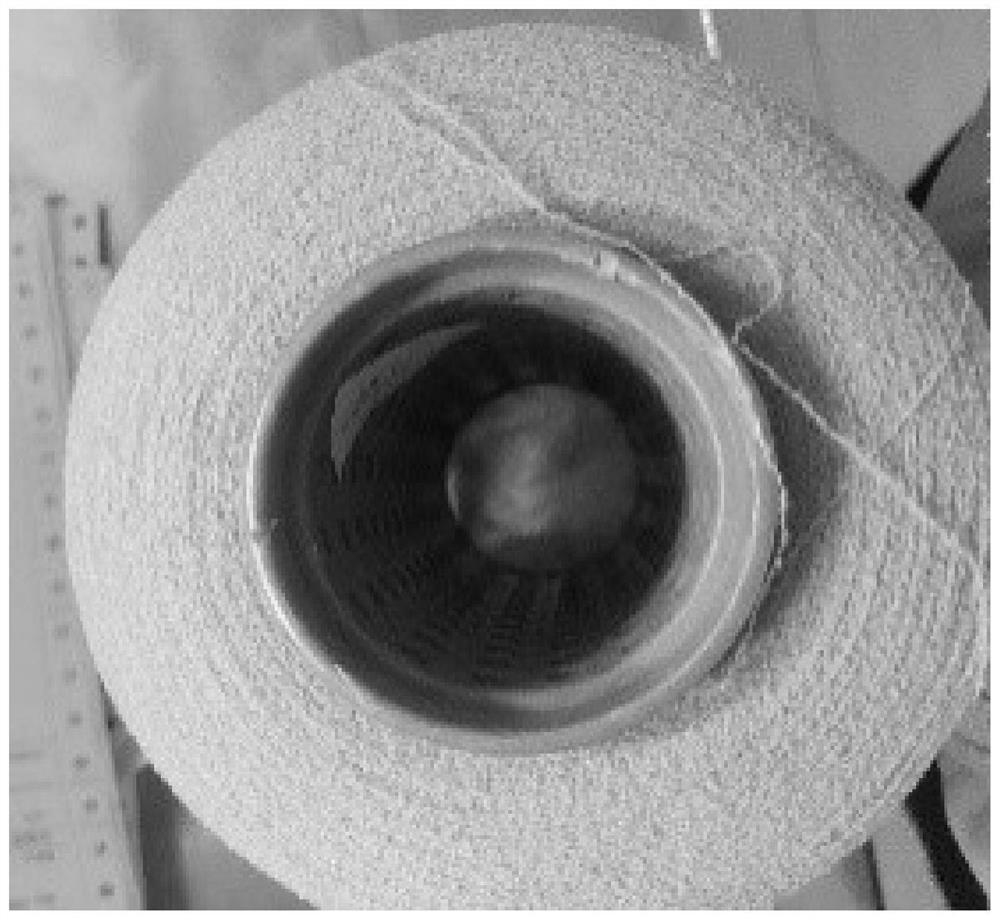

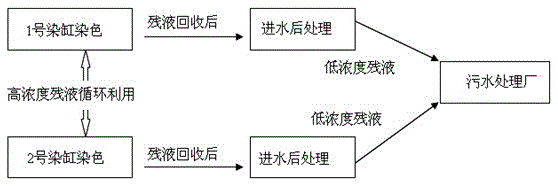

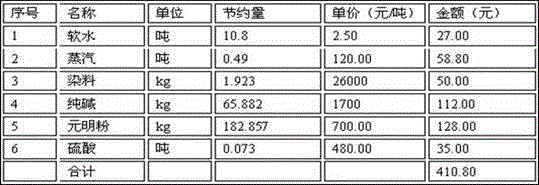

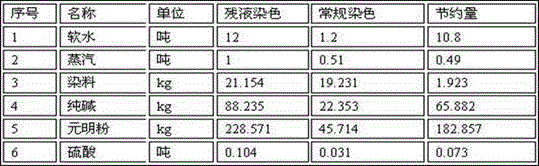

Residual liquid dyeing process of cheese

ActiveCN103741526AReduce consumptionEmission reductionTextile treatment machine arrangementsDyeing processYarnPulp and paper industry

The invention provides a residual liquid dyeing process of cheese in order to reduce the dye consumption for cheese dyeing. The residual liquid dyeing process is characterized in that a dye vat No.1 and a dye vat No.2 are connected through a pump, after yarns in the dye vat No.1 are dyed for the first time, a dyeing solution is pumped into the dye vat No.2, and after the yarns in the dye vat No.2 are dyed, the dyeing solution is returned to the dye vat No.1 to dye undyed yarns; the dyeing solution is recycled for dyeing between the dye vat No.1 and the dye vat No.2 according to the method; and after the dyeing solution is exhausted each time, a post-processing stage is entered, the dyed yarns are taken out after the post-processing is completed, and the undyed yarns are hung to wait for the import of the dyeing solution. According to the residual liquid dyeing process disclosed by the invention, the water consumption and sewage discharge are reduced from the source, resource consumption and environment pollution are reduced, and the cyclic utilization of resources and clean production are realized.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

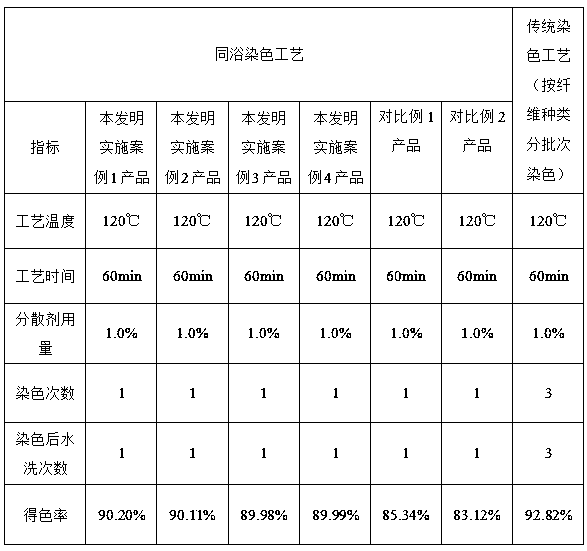

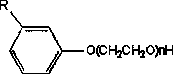

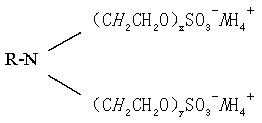

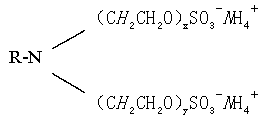

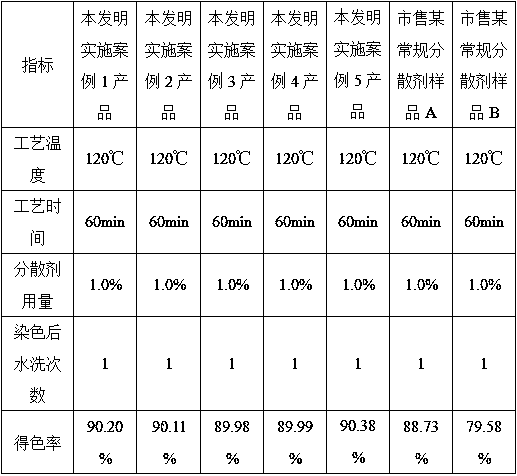

Environment-friendly dispersing agent for dyeing in one bath

The invention relates to environment-friendly dispersing agent for dyeing in one bath. The dispersing agent is applicable to pure chemical fiber fabric like polyester or blended fabric containing chemical fiber like polyester cotton, polyester chinlon, polyester acrylic cotton and wool polyester acrylic fiber. The dispersing agent has more protruding advantages for bathing and dyeing the blended fabric like polyester acrylic cotton and wool polyester acrylic fiber. The environment-friendly dispersing agent is characterized by being prepared from, by mass, 5%-20% of fatty alcohol-polyoxyethylene ether, 5%-20% of plant cardanol polyoxyethylene ether, 5%-10% of adsorption dispersing agent, 0.2%-1% of emulsifying thickening dispersing agent and the balance water. The environment-friendly dispersing agent for dyeing and bathing has high dispersing force on dyestuff and a high leveling property, can effectively solve the problems like color tone and color spots and solve the precipitation problem caused when the dyestuff has different kinds of iconicity at the same time. Besides, the environment-friendly dispersing agent also has a certain oil removing capability and the capability of washing a dye vat, so that multiple fiber and multiple dyestuff are smoothly subjected to one bath, time, water and power are saved, energy conservation and emission reduction are achieved, the economiceffect is effectively improved, and the energy conservation and environmental protection requirement is better met.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Process for producing hot-melting bonding double-point lining in production of low-elasticity cloth

InactiveCN102899842AAvoid sexAvoid stainsLiquid surface applicatorsFabric breaking/softeningPolyesterEngineering

The invention discloses a process for producing a hot-melting bonding double-point lining in the production of low-elasticity cloth. The process comprises the following steps of: weaving raw materials by an automatic air injection machine to form base cloth of the low-elasticity cloth; performing curling and end sewing on the base cloth of the low-elasticity cloth; softening, and washing; performing overflow dyeing, after dyeing, padding the base cloth, and drying; padding the dried base cloth, and conveying the base cloth to a drying room for arranging; after arranging, performing double-point coating treatment on the base cloth of the low-elasticity cloth; and performing quality inspection for packaging. According to the process, polyester silks are used as the raw materials and are subjected to softening, washing, overflow dyeing and the like, so that the problems of dyeing defects, color spots, flaws and the like in the process of producing lining cloth are solved, and the softness and planeness of the lining cloth are improved effectively; and by dyeing, drying, arranging and double-point coating, the initial stripping strength of the lining cloth is enhanced, the quality of the lining cloth is improved, the stability of products is improved, the production efficiency is improved, and the production cost is reduced.

Owner:温州鸿马科技有限公司

Degreasing agent used for dyeing in one bath and with multiple functions

The invention relates to a degreasing agent used for dyeing in one bath and with multiple functions. The degreasing agent is characterized by being composed of the following ingredients by mass percent: 5-20% of fatty alcohol polyoxyethylene ether, 5-20% of modified fatty amine polyoxyethylene ether, 2-10% of a dispersing agent, 5-10% of a solvent, 0.3-1% of polyether modified silyl ether ester and the balance of water. The degreasing agent used for dyeing in one bath and with multiple functions is easy in application and simplified in operation, and only one auxiliary is added. In the aspectof effect, dye dispersing and uniform dyeing effects are better during textile dyeing; besides, the degreasing agent has low foaming property and is easy to clean, degreasing is thorough during one-bath process dyeing of multiple fiber fabrics, removed grease stains are dispersed in dye liquor and can not touch a cloth cover and the inner wall of a dye vat, so that the problems of color tone, color spot, nonuniform dyeing and the like can be effectively avoided, deposition of cation and anion dyes also can be avoided, time, electricity and water are saved at the same time, energy conservationand emission reduction are realized, and economic benefit is effectively improved, so that energy-saving and environmental requirements can be better met.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

One-bath-process dyeing for PPT chinlon mucilage glue

The invention relates to the technical field of dyeing and especially relates to the one-bath-process dyeing for PPT chinlon mucilage glue. The dyeing method comprises the following steps: pretreatment: adding PPT chinlon mucilage glue and water into a dye vat, adding a degreasing agent, rising temperature to 90 DEG C, keeping temperature for 10min and cleaning; dyeing: rising temperature to 30 DEG C, adding auxiliaries, adding dyestuff and anhydrous sodium sulphate after 10min, rising temperature to 40 DEG C at the speed of 1 DEG C / min, keeping temperature for 10min, and then rising temperature to 98 DEG C at the speed of 0.5 DEG C / min, keeping temperature for 30-60min and reducing temperature to 80 DEG C; adding sodium carbonate, keeping temperature for 30-60min and cleaning; adding glacial acetic acid and soaping agent, quickly rising temperature to 80 DEG C, keeping temperature for 10min and cleaning; adding a softening agent, rising temperature to 40 DEG C, keeping temperature for 20min and then taking out of the vat. The one-bath-process dyeing for PPT chinlon mucilage glue according to the invention can effectively increase color fastness and prevent dyeing defects.

Owner:博森纺织科技股份有限公司

Dyeing technology of acrylon

InactiveCN104420337ASmooth conversion rateAvoid sexDry-cleaning apparatus for textilesDyeing processAcetic acidRoom temperature

The invention discloses a dyeing technology of acrylon. The dyeing technology comprises the steps of putting a to-be-dyed acrylic fabric into a working solution containing 1.5% anionic dye and a 0.3% retarding agent MOB at the room temperature; adjusting the pH value of dye bath to be 4-4.5 with acetic acid, heating up to 100 DEG C at the speed of 1.5 DEG C / min, carrying out heat-preservation dyeing for 40-60 minutes, then cooling to 60 DEG C from 100 DEG C at the speed of 1 DEG C / minute, and carrying out heat preservation for 30 minutes; soaking the acrylic fabric in a mixed solution of sodium carbonate and a detergent with the temperature of 100 DEG C, and carrying out heat preservation for 60 minutes; and washing, dewatering and drying. In the dyeing process, the switching rates of an auxiliary agent and dye are stable, so that the dyeing defect and dyeing blockage can be avoided; the dyeing can be smoothly carried out as long as the boiling dyeing time is well controlled, so that the dyeing technology is convenient to operate.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

Processing method for dyeing and finishing blended fabric with corn fiber and cotton fiber

ActiveCN104153221AStrong damageAvoid damageBleaching apparatusDyeing processPolymer scienceCotton fibre

The invention discloses a processing method for dyeing and finishing a blended fabric with corn fiber and cotton fiber. According to the processing method for dyeing and finishing the blended fabric, the dyeing pretreatment is carried out on the blended fabric before dyeing; the pretreatment comprises the steps of desizing, bleaching, singeing and mercerizing; and an active dye is used for carrying out foam dyeing. The blended fabric obtained by the processing method is small in fiber damage and high in dyeing homochromatism.

Owner:YANGZHOU YINJIANG CANVAS PRODS

Dyeing method for steaple reyon fabric in airflow cylinder with low bath ratio

The invention relates to a dyeing method for a steaple reyon fabric in an airflow cylinder with a low bath ratio. The dyeing method comprises the following steps: putting water into a dyeing cylinderof an airflow cylinder, putting the steaple reyon fabric in the dyeing cylinder, moving to completely soak cloth surfaces, and heating to 58-60 DEG C by controlling temperature increase speeds; feeding 10-20wt% of water back into a secondary cylinder, dissolving a one-bath deoiling agent and a permetant into the secondary cylinder, and sucking into the dyeing cylinder of the airflow cylinder to carry aids on clothe surfaces uniformly; feeding 10-20wt% of water back into the secondary cylinder, pulping and clarifying with active dyes and dispersants in the secondary cylinder, quantitatively pumping into the dyeing cylinder, enabling the airflow cylinder to operate continuously, and after complete pumping, enabling the airflow cylinder to operate continuously to soak the steaple reyon fabricinto the active dyes uniformly; feeding 10-20wt% of water back into the secondary cylinder for three times from the dyeing cylinder, adding anhydrous sodium sulfate and sodium carbonate at differenttimes, pulping and clarifying, sucking into the dyeing cylinder, keeping the temperature at 58-60 DEG C to operate so as to ensure uniform dyeing of the active dyes; cutting cloth, comparing colors, cleaning the cloth surfaces with clean water, and carrying out dyeing and shaping in aftertreatment. By adopting the dyeing method, the problems that a steaple reyon fabric has nonuniform dyeing, mixedcolors, long process time, excessive sewage and the like in an airflow cylinder with a low bath ratio can be solved.

Owner:浙江劲光纺织科技有限公司

Printing and dying process for improving easy dyeing property of polyester fabric

InactiveCN109295750AEnhanced stainabilityHigh color fastnessDyeing processColour fastnessDisperse dye

The invention discloses a printing and dying process for improving easy dyeing property of a polyester fabric. The dyeing prescription of the polyester fabric is composed of a disperse dye, glacial acetic acid and a dye leveller. The process comprises the following steps: checking whether the fabric appearance has smudginess or defects or not, after the inspection, placing the fabric for 12 to 24hours to eliminate the tension generated when the fabric is printed, when the fabric is placed for the required time, placing the polyester fabric in a washing machine, keeping the water temperature at 60 to 90 DEG C, and repeatedly cleaning the material for three times. The printing and dying process is characterized in that the disperse dye having small molecules, weak polarity, poor solubilityin water and good compatibility is used for dyeing polyester, the polyester fabric is more easily printed and dyed, and the easy dyeing property of the polyester fabric is improved, and the temperature and time of the reduction cleaning are strictly controlled, the color fastness of the polyester fabric after printing and dyeing is improved, and the problem that the polyester fabric is easily fading is avoided.

Owner:ZHEJIANG YINGFENG TECH CO LTD

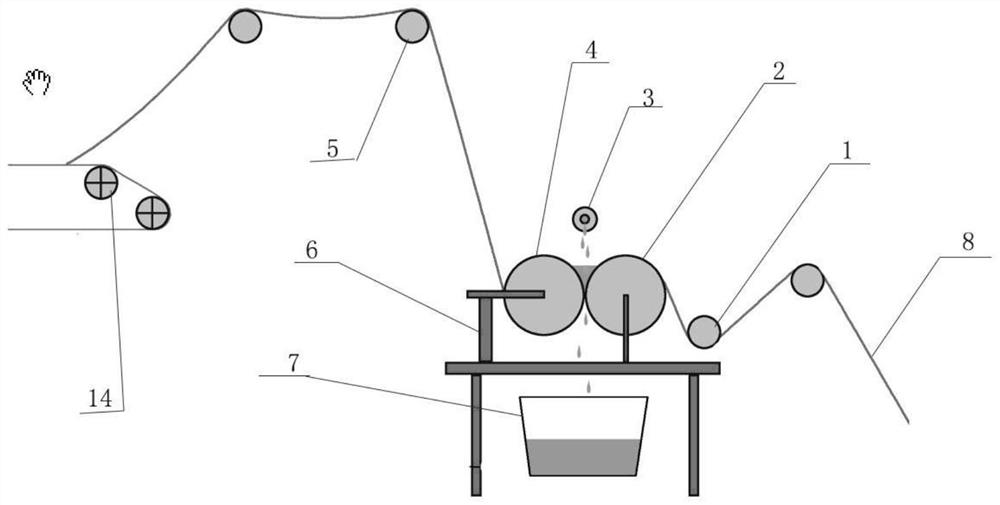

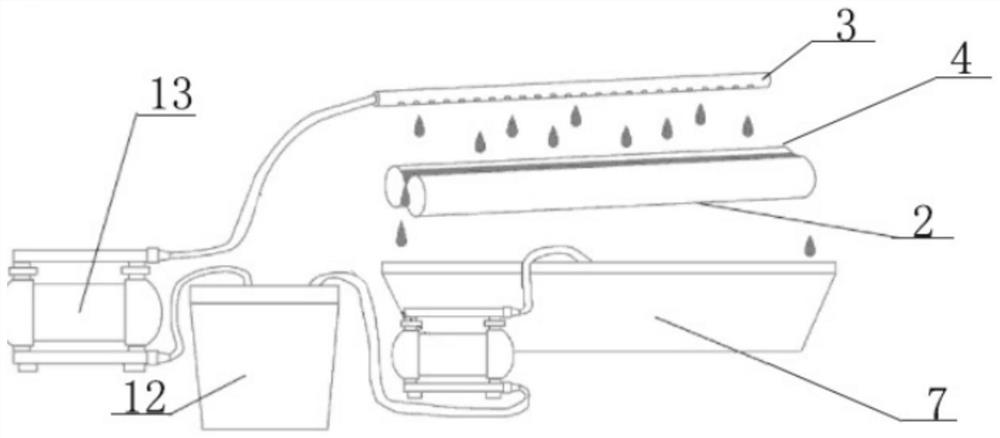

Blanket dyeing device and dyeing method

PendingCN112695473ASimple installationImprove operabilityTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentContinuous useSizing

The invention belongs to the technical field of blanket production, and particularly relates to a blanket dyeing device and dyeing method. The device comprises a size adding device and a size pressing device, wherein the paste pressing device comprises a driving roller and a pressure roller, the driving roller and the pressure roller are arranged in parallel, the driving roller is arranged on a rack, a rotating rod of the driving roller is connected with a motor, and a material receiving groove is formed below the driving roller and the pressure roller; squeezing sizing of grey cloth is realized through the size pressing device, so that the size carrying rate of the grey cloth is 80-120%; redundant size flows out from two ends of the groove and falls into a size tank below, and the size in the size tank is conveyed into a size barrel to be uniformly mixed with new size for continuous use. According to the blanket dyeing device and dyeing method, the dyeing defect caused by migration of dye in the color paste is effectively overcome, the blanket production quality and efficiency are greatly improved, and the device is simple, practical, high in operability and remarkable in effect.

Owner:LOFTEX INDS

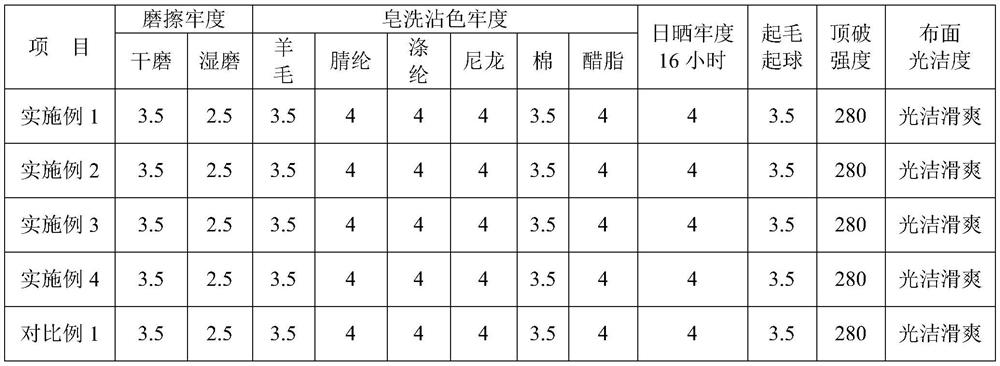

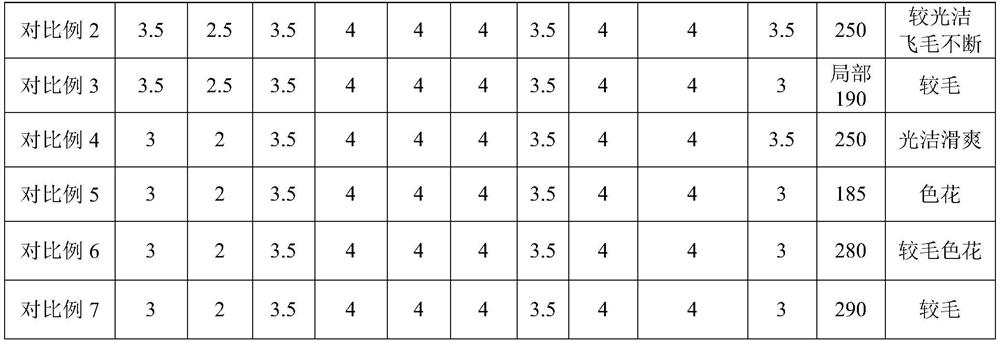

Energy-saving dyeing and finishing method for thin cotton spandex knitted fabric

ActiveCN111733590AOvercoming the severity of strength injuriesLittle strength damageMercerisingDyeing processAcetic acidCellulase

The invention discloses an energy-saving dyeing and finishing method for a thin cotton spandex knitted fabric. The energy-saving dyeing and finishing method comprises the following steps: firstly, mildly mercerizing; secondly, washing with water; thirdly, presetting; fourthly, bleaching the bottom; fifthly, dyeing cotton: first adding cellulase at the temperature of 55 to 60 DEG C; adding dyes inthe 15th to 25th minutes; adding anhydrous sodium sulphate in the 20th to 30th minutes, and maintaining the temperature for 15 to 25 minutes; adding sodium carbonate in the 40th to 50th minutes; raising the temperature to 60 to 65 DEG C, and maintaining the temperature for 25 to 35 minutes; draining, cleaning, then adding glacial acetic acid for acid pickling, and keeping the temperature for 10 to20 minutes; changing water once, adding an active soaping agent, raising the temperature to 90 to 95 DEG C, keeping the temperature for 15 to 25 minutes, cleaning with clear water and discharging thefabric out of a vat; sixthly, softening, fixing color and dehydrating; and seventhly, drying and setting. According to the energy-saving dyeing and finishing method disclosed by the invention, a grayfabric is first mildly mercerized, preset and dyed, and is subjected to one-bath and wool removal, so that the gray fabric reaches higher bursting strength while the smoothness of a fabric cover is met, and the dyeing and finishing cost is reduced.

Owner:ZHEJIANG YINHE PRINTING & DYEING

Dyeing method and device with anti-splashing structure for polyester chemical fiber cloth spinning

ActiveCN111749035AWon't breakAvoid sexTextile treatment machine arrangementsDyeing processPolyesterPolymer science

The invention discloses a dyeing method and device with an anti-splashing structure for polyester chemical fiber cloth spinning, and belongs to the technical field of spinning dyeing. The method comprises the following steps that pretreatment before dyeing is conducted, wherein polyester fabric needing to be dyed is put into a cleaning machine; when the water level reaches 13-17%, a laundry detergent and color bleaching powder are added; when the water level reaches 15-20%, heating is conducted to make the water temperature rise to 30-45 DEG C, the washing rotating speed of the cleaning machine is 30-40 r / min at the moment; and after cleaning is completed, the polyester fabric is dehydrated, the operation is repeated, and cleaning is conducted three times. According to the dyeing method with the anti-splashing structure for polyester chemical fiber cloth spinning, by arranging the pretreatment process before dyeing, oil dirt, dust and pigment generated on the surface of the polyester fabric in the production process can be treated thoroughly, therefore, the problem that when the polyester fabric is dyed, due to the fact that the polyester fabric is not cleaned thoroughly, dyeing defects such as various dyeing defects and color spots are generated in the dyeing process is avoided, and the normal dyeing quality of the polyester fabric is guaranteed.

Owner:江苏申久纺织科技有限公司

Dyeing nylon yarn, preparation method thereof and textile product

The invention relates to a dyed nylon yarn, a preparation method thereof and a textile product. According to the preparation method of the dyed nylon yarn, undyed nylon yarn is subjected to refining treatment and then sequentially subjected to dyeing treatment and soaping treatment, and the dyed nylon yarn is obtained; the dyeing treatment comprises the following steps: at 40-45 DEG C, soaking the refined nylon yarn in an aqueous solution of an ERIOFAST reactive dye to carry out first dyeing treatment for not less than 15 minutes, then adding calcium chloride to continue to carry out second dyeing treatment for not less than 5 minutes, then adding acetic acid and sodium acetate to continue to carry out third dyeing treatment for not less than 5 minutes, raising the temperature to 55-98 DEG C, and continuing to carry out fourth dyeing treatment for not less than 50 minutes; and the OWF of the ERIOFAST reactive dye is less than 1.0 percent. Therefore, under specific conditions, dyeing defects can be avoided while the nylon yarns are dyed with light colors.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Temperature-control knitted underwear fabric and preparing method thereof

ActiveCN110106716AAccelerate evaporationImprove cooling effectWeft knittingWarp knittingTemperature controlTest requirements

The invention relates to a temperature-control knitted underwear fabric and a preparing method thereof, and belongs to the technical field of the textile dyeing and finishing process. The preparing method of the temperature-control knitted underwear fabric includes the steps of weaving, primary sizing, preprocessing, dyeing, soaping, drying, sizing and the like. The sizing step specifically includes the substeps of sizing dried color cloth and adding a temperature control aid with the concentration of 48-52 g / L and silicone oil T718 with the concentration of 18-22 g / L according to the water yield during sizing. All interior qualities of the obtained temperature-control knitted underwear fabric all meet the national textile test requirements, and the temperature-control effect of the fabricis remarkably better than that of similar temperature-control materials. The fabric is simple in production process, low in cost and high in additional value, only the temperature-control treatment needs to be conducted in the sizing process, and operation is simple and convenient.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

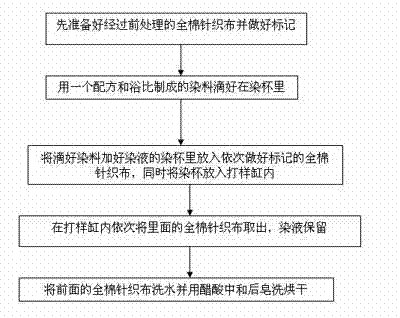

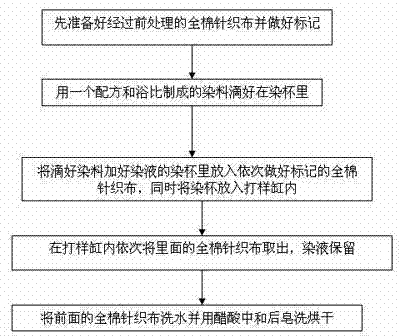

Stepped coloring process of reactive dye

InactiveCN102409563AAvoid sexPrevent abnormal problems such as chromatic aberration in the edgeDyeing processAcetic acidChemistry

The invention discloses a stepped coloring process of a reactive dye. The process comprises the following steps of: (1) firstly, preparing the pre-processed all-cotton knitted fabric, and marking; (2) dripping the dye prepared according to a formula and a bath ratio into a dyeing cup; (3) putting the dyeing cup with the dye and the dyeing liquid in the all-cotton knitted fabric marked in turn, and putting the dyeing cup in a proofing jar; (4) taking the all-cotton knitted fabric out of the proofing jar in turn, and maintaining the dyeing liquid; and (5) washing the all-cotton knitted fabric with water, neutralizing with acetic acid, and then soaping and drying. Through the stepped coloring process of the reactive dye disclosed by the invention, abnormal situations such as dyeing defect, edge-middle color difference and the like can be prevented in advance, the product quality can be effectively ensured and improved, and the cost of maintaining due to the abnormal situations is lowered.

Owner:JIANGSU JINCHENZHEN TEXTILE

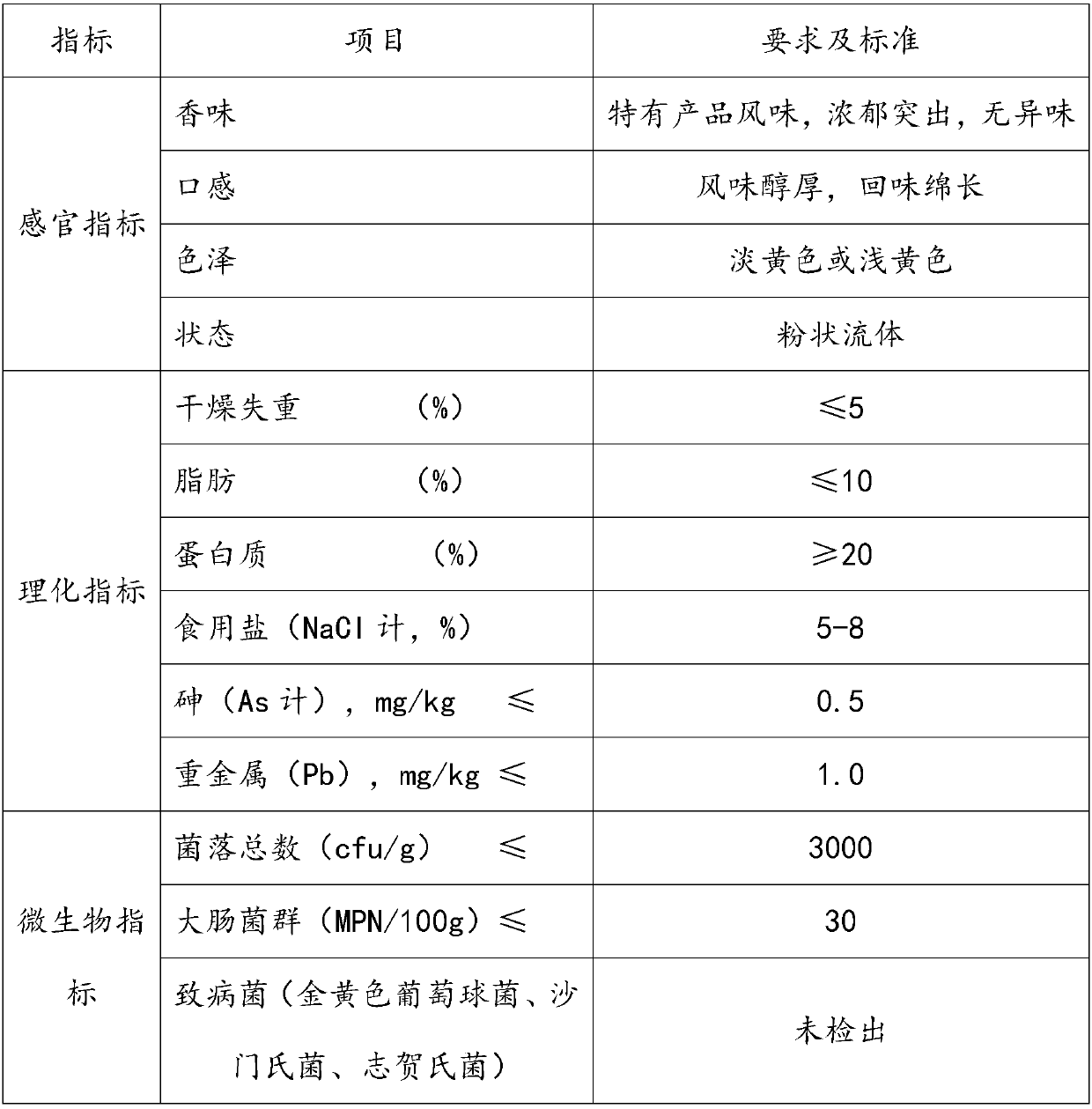

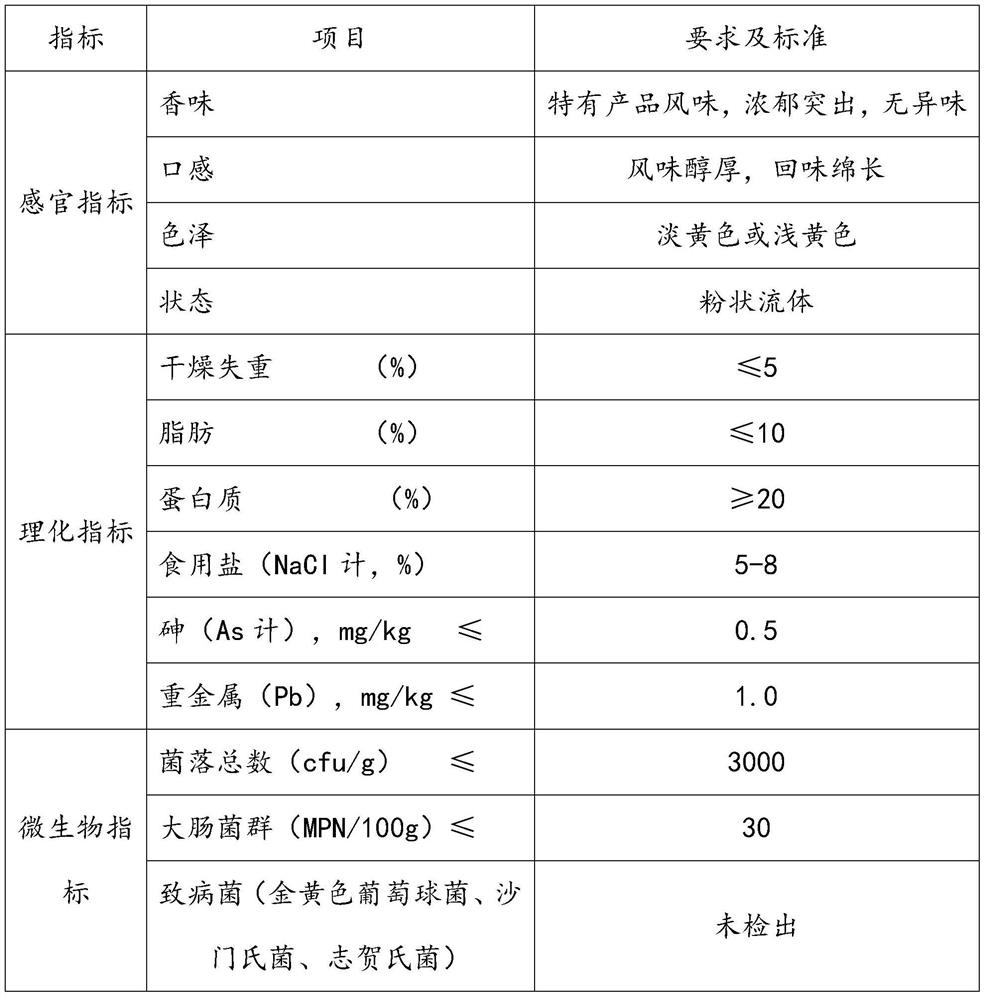

Tibetan chicken soup drink and preparation method thereof

The invention discloses a Tibetan chicken soup drink and a preparation method thereof. The Tibetan chicken soup drink is prepared from the following materials: a raw material of a chicken grown in Tibetan valleys and cut into a plurality of chicken pieces of 50-80 g; chicken oil in a weight 6% of the total weight of the chicken pieces; a deodorant substance; cooking wine in an addition amount of 0.3% of the total weight of the chicken pieces; papain; a Novozyme flavourzyme; a seasoning substance; and water. The Tibetan chicken soup drink and the preparation method thereof can solve the problemof the prior art that true chicken soup product with combination of nutrition and convenience does not exist.

Owner:江苏特味浓食品股份有限公司

A kind of residue dyeing process of cheese yarn

ActiveCN103741526BReduce consumptionEmission reductionTextile treatment machine arrangementsDyeing processYarnPulp and paper industry

The invention provides a residual liquid dyeing process of cheese in order to reduce the dye consumption for cheese dyeing. The residual liquid dyeing process is characterized in that a dye vat No.1 and a dye vat No.2 are connected through a pump, after yarns in the dye vat No.1 are dyed for the first time, a dyeing solution is pumped into the dye vat No.2, and after the yarns in the dye vat No.2 are dyed, the dyeing solution is returned to the dye vat No.1 to dye undyed yarns; the dyeing solution is recycled for dyeing between the dye vat No.1 and the dye vat No.2 according to the method; and after the dyeing solution is exhausted each time, a post-processing stage is entered, the dyed yarns are taken out after the post-processing is completed, and the undyed yarns are hung to wait for the import of the dyeing solution. According to the residual liquid dyeing process disclosed by the invention, the water consumption and sewage discharge are reduced from the source, resource consumption and environment pollution are reduced, and the cyclic utilization of resources and clean production are realized.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

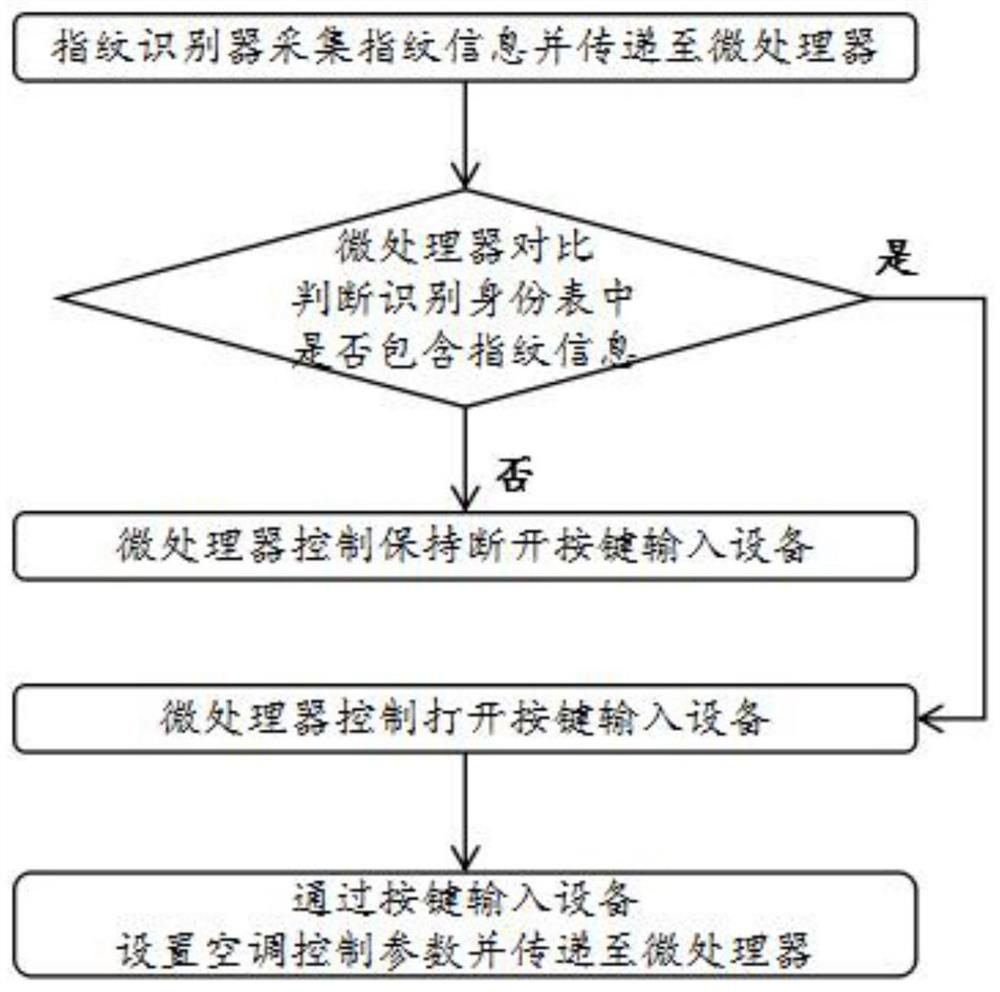

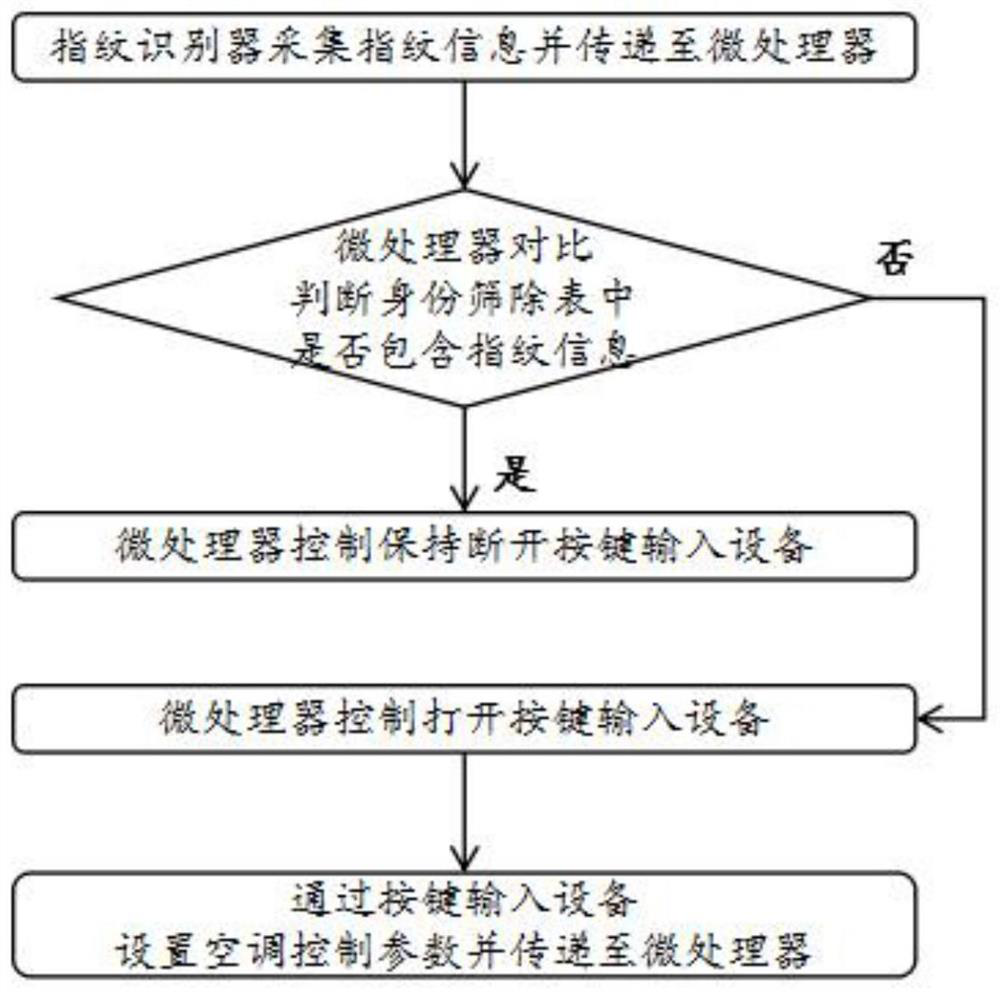

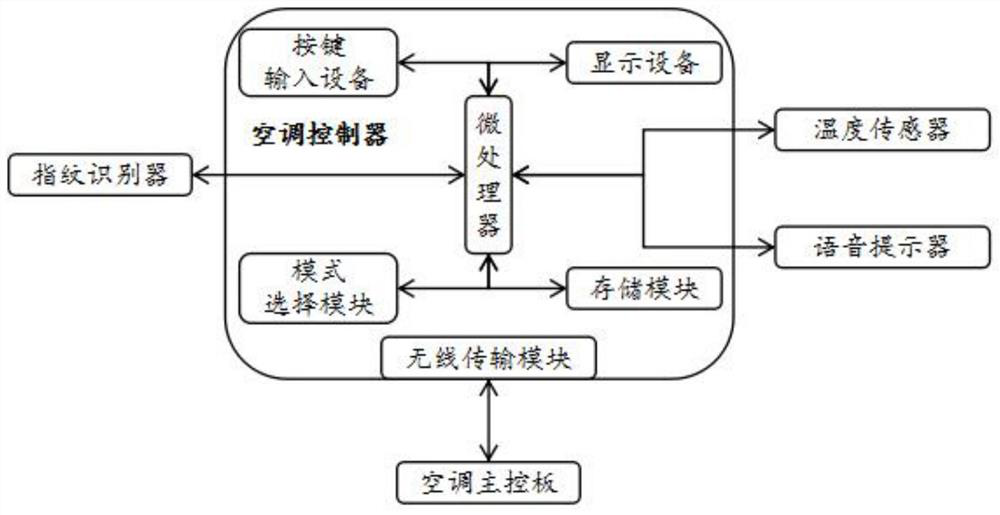

Air conditioner control method and controller thereof

ActiveCN112432334AAvoid sexQuality improvementMechanical apparatusSpace heating and ventilation safety systemsKey pressingControl engineering

The invention discloses an air conditioner control method and a controller thereof and relates to the technical field of air conditioner control. A fingerprint identification mode or a fingerprint filtering mode is selected through a mode selection module of the air conditioner controller; in the fingerprint identification mode, after a microprocessor receives an identification result of a fingerprint identifier, the microprocessor compares the identification result with an identification identity table in a fingerprint database to control key input equipment to be opened or kept disconnected;and in the fingerprint filtering mode, after the microprocessor receives the identification result of fingerprint identification, the microprocessor compares the identification result with an identity screening table in the fingerprint database to control the key input equipment to be opened or kept disconnected. According to the air conditioner control method and the controller thereof, after fingerprint information of a child is collected through the fingerprint identifier, the microprocessor compares the fingerprint information and judges whether the identity screening table contains the fingerprint information of the child or not; and the key input equipment is kept disconnected, the child is prevented from pressing the air conditioner controller randomly, the air conditioner controlquality and efficiency are improved, and waste is avoided.

Owner:合肥迅驰电子科技有限责任公司

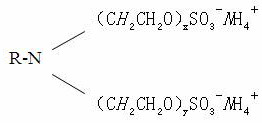

Multifunctional degreasing agent for one-bath dyeing and preparation method thereof

InactiveCN112553907AEffective dissolutionGood dispersionFibre typesDyeing processDiethylene glycol monobutyl etherDisperse dye

The invention relates to a multifunctional degreasing agent for one-bath dyeing. The multifunctional degreasing agent is characterized by comprising the following components of fatty alcohol-polyoxyethylene ether, modified fatty amine polyoxyethylene ether, glyceryl ether oleate, fatty alcohol-polyoxyethylene ether, iso-tridecanol polyoxyethylene ether, phenol ether ammonium sulfate, polyether modified silyl ether ester, ethylene glycol monobutyl ether or diethylene glycol monobutyl ether and water. The multifunctional degreasing agent for one-bath dyeing is convenient to apply and simple to operate, and only one auxiliary agent is added. In the aspect of effect, the multifunctional degreasing agent has relatively good disperse dye and level dyeing effects during fabric dyeing, also has low-foaming property, is easy to clean, and can remove oil cleanly when used for dyeing multi-fiber fabrics by a one-bath method, and the removed oil stain is dispersed in dye liquor and does not stickto the cloth surface and the inner wall of a dye vat, therefore, the problems of dyeing defects, color spots, uneven dyeing and the like can be effectively avoided, and the energy-saving and environment-friendly requirements are met.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Finishing method capable of effectively reducing nylon dyeing difference

InactiveCN111996822ADoes not affect the feelEasy to operateLiquid/gas/vapor treatment of propelled fabricsDyeing processPolymer scienceAcid dye

The invention provides a finishing method capable of effectively reducing the nylon dyeing difference. According to the finishing method, oil is removed by an oil remover DM-1119N, an oil-removed fabric is dyed with a mixed working solution of a dye, a diluent and an acid dye leveling agent, and in the fabric dying process, reworking is carried out in the case of vat difference, cloth difference and color difference between left and right parts of the same piece of cloth. Through the combined process of oil removal and dyeing, dyeing difference of the nylon fabric in the dyeing process is prevented, and color tones, color dots and color spots occurring in the dyeing process of the nylon fabric are prevented.

Owner:DYMATIC CHEM

Mucilage glue emission-reduction type one-bath dyeing process

InactiveCN109736070AMild conditionsSolve processing disadvantagesBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile technologyThermal insulation

The invention provides a mucilage glue emission-reduction type one-bath dyeing process, belonging to the technical field of spinning. The process comprises the steps of preparing composite desizing enzyme, preparing a substrate solution, preparing a desizing agent, dipping, carrying out thermal insulation desizing, washing, and the like. According to the mucilage glue emission-reduction type one-bath dyeing process, the desizing and one-bath dyeing purposes are achieved by virtue of a biological enzyme desizing method, so that the energy saving and theemission reduction are realized.

Owner:LANGXI YUANHUA TEXTILE

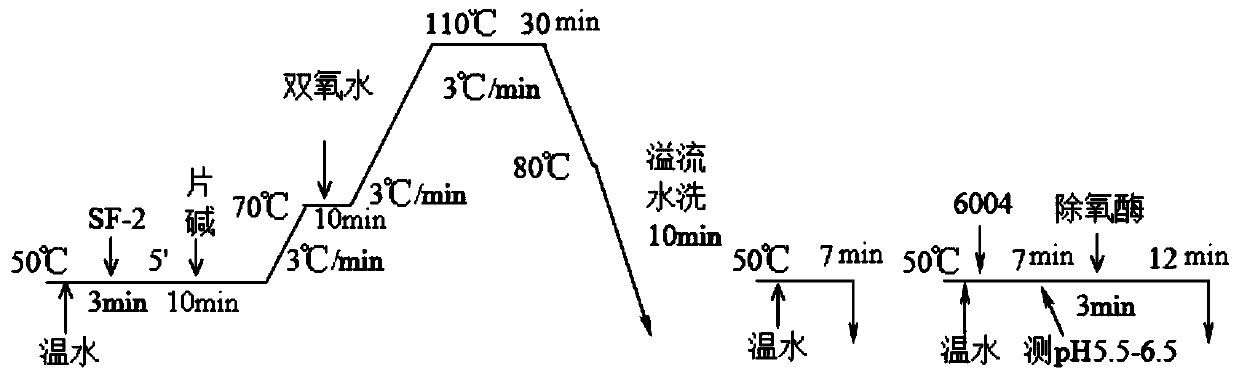

Continuous dyeing-finishing process for Xinlun T3000/polyester low-elasticity yarn interwoven and tatted cloth

The invention discloses continuous dyeing-finishing process for Xinlun T3000 / polyester low-elasticity yarn interwoven and tatted cloth. The continuous dyeing-finishing process sequentially comprises the following steps: cloth turning, head sewing, desizing, steaming, formation, dyeing, reduction cleaning and finishing tentering, wherein a desizing solution prepared in the desizing step contains 15g / L-20g / L of caustic soda, 6g / L-8g / L of a scouring agent and 4.5g / L-6g / L of a penetrant, and the immersion cleaning is carried out in hot water of 88-95 DEG C after rolling and stacking; a steaming solution prepared in the steaming contains 9.2g / L-11g / L of caustic soda, 1.5g / L-2.8g / L of a scouring agent and 1.6g / L-2.6g / L of the penetrant, the solution temperature is 88-91 DEG C, the steaming temperature is 99-104 DEG C, the steaming time is 80-100 seconds, immersion cleaning is carried out in hot water of 88-91 DEG C. The finished cloth is uniformly dyed, low in chromatic aberration, good in luster, stable in elasticity, high in color fastness and stable in product quality and suitable for large-scale production.

Owner:四川意龙科纺集团股份有限公司

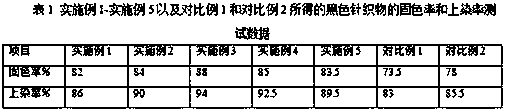

Black knitted fabric vat-replenishing dyeing process

ActiveCN110616574AAvoid sexTo achieve the effect of energy saving and emission reductionDyeing processEngineeringRise rate

The invention discloses a black knitted fabric vat-replenishing dyeing process and belongs to the technical field of knitted fabric dyeing processes. The dyeing process includes following steps: fullysoaking knitted fabric after being pretreated into a dyeing machine, rising temperature to first set temperature at a temperature rising rate of 3 DEG C / min, adding salt with concentration identicalwith starting bath dye liquid, a promoter and a leveling agent, and running for 15-20min; adding black active dye into the dyeing machine, running for 10-25min, rising the temperature of the dyeing machine to second set temperature at a temperature rising rate of 1 DEG C / min, holding the temperature for 30-45min, adding starting bath water after being supplemented for redyeing in a standing vat, rising temperature in the standing vat to 58 DEG C at a temperature rising rate of 2 DEG C / min, holding the temperature for 30-45min, and taking cloth out. The dyeing process has the advantages of highdyeing rate, strong color fastness and capability of realizing energy conservation and emission reduction.

Owner:花法科技有限公司

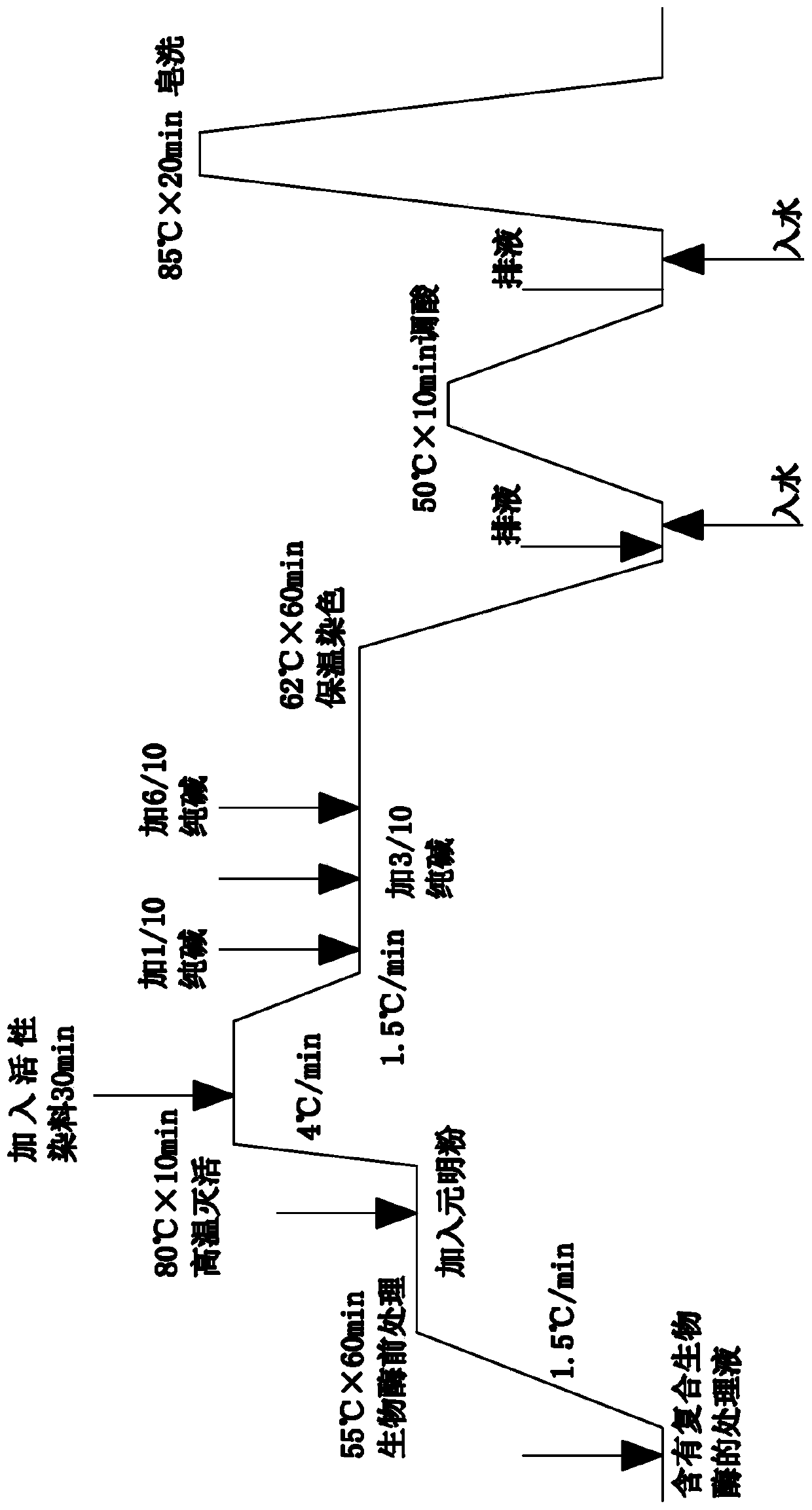

Cotton fabric scouring and dyeing one-bath dyeing process

ActiveCN111270537ACompatibility is reasonableImprove removal efficiencyDyeing processFiberPulp and paper industry

The invention discloses a cotton fabric scouring and dyeing one-bath dyeing process. The cotton fabric scouring and dyeing one-bath dyeing process comprises the following steps of: immersing the cotton fabric in a treatment solution containing compound biological enzymes, raising the temperature to 50 degrees centigrade to 58 degrees centigrade, and performing biological enzyme pretreatment for 30min to 60 min; then adding anhydrous sodium sulphate directly to the treatment solution, heating up to 75 degrees centigrade to 85 degrees centigrade and treating for 5 min to 10 min, and performinghyperthermia inactivation on the compound biological enzymes; then adding dissolved reactive dyestuff to the treatment solution at a uniform speed, wherein the feeding time is 20 min to 40 min, reducing the temperature to 60 degrees centigrade to 70 degrees centigrade, adding soda ash in 2 times to 3 times, wherein each adding time is 15 min to 30 min, and performing insulation dyeing for 40 min to 60 min after the adding is finished; and draining solution, performing water washing, adjusting acid, drain solution and soaping after dyeing. By using the cotton fabric scouring and dyeing one-bathdyeing process, not only the whiteness and capillary effect are higher, the fiber damage is less, no color flower is on the cloth, but also the level dyeing is better.

Owner:CHANGZHOU NEW WIDE KNITTING & DYEING

Automatic processing system for dyeing loose fibers

ActiveCN101629365BImprove the degree of automated productionIncrease productivityTextile treatment machine partsFibre cleaning/openingCircular discProduction line

The invention discloses an automatic processing system for dyeing loose fibers. The system comprises a dry opening machine, a disk forming machine, a dyeing machine, a dewatering machine, a wet opening machine, a drying machine and an automatic packing machine which are sequentially connected, wherein, a pre-opening machine is connected between the dewatering machine and the wet opening machine, the pre-opening machine comprises a rotatable disk, the disk is installed on a lifting rack, and a cotton peeling roller is arranged above the disk. A hydraulic disk jacking machine can also be arranged between the dyeing machine and the dewatering machine. The invention is the first automatic production line for dyeing the loose fibers, can be suitable for dyeing various fibers, and can increase the degree of automatic production, shortens the production period of entire dyeing processing, increases the production efficiency, reduces the intensity of labor production, and especially greatly increases safety.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Tibetan chicken soup drink and preparation method thereof

The invention discloses a Tibetan chicken soup drink and a preparation method thereof. The Tibetan chicken soup drink is prepared from the following materials: raw materials, the raw materials are Tibetan chicken grown in river valleys in Tibet, and cut into multiple chicken pieces of 50-80g; Chicken oil, the weight of the chicken oil is 6% of the total weight of the chicken nuggets; odor-removing substances; cooking wine, the addition of the cooking wine is 0.3% of the total weight of the chicken nuggets; papain; Novozymes flavored protease; seasoning substances; and water. The invention can solve the problem that there is no real chicken soup product combining nutrition and convenience in the prior art.

Owner:江苏特味浓食品股份有限公司

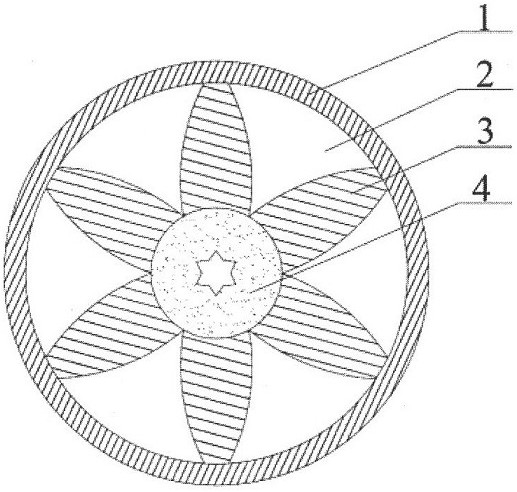

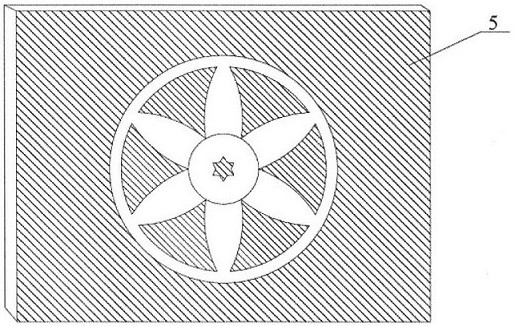

Double-yarn air-spliced high-color-fastness polyester staple fiber and preparation method

ActiveCN113445147AIncrease elasticityIncrease contact areaHollow filament manufactureFilament/thread formingPolyesterYarn

The invention relates to double-yarn air-spliced high-color-fastness polyester staple fiber and a preparation method. The double-yarn air-spliced high-color-fastness polyester staple fiber comprises an outer layer, a core layer and a leaf part for connecting the outer layer and the core layer; the cross section of the outer layer is in a circular ring shape; the leaf part is composed of six leaf-shaped connecting pieces; the connecting pieces are distributed on the outer side of the core layer in an annular array mode; and the center of the core layer is a hexagonal cavity. High-color-fastness polyester staple fiber is prepared from dimethyl terephthalate, ethylene glycol, potassium hydroxide, dipropylene glycol isophthalate-5-sodium sulfonate and other raw materials; double-yarn air splicing operation is carried out through an air splicer; bicarbonate, ammonium salt and distilled water are mixed and stirred; dye and a complexing agent are added, a mixture is stirred uniformly to form a standby dye liquor; and a fabric and the dye liquor are put into a dye cup with a sealing effect to obtain the double-yarn air-spliced high-color-fastness polyester staple fiber. The method has an obvious dyeing accelerating effect on polyester and blended fabrics thereof, has high color fastness, and is low in toxicity and environment-friendly.

Owner:浙江光乾纺织有限公司

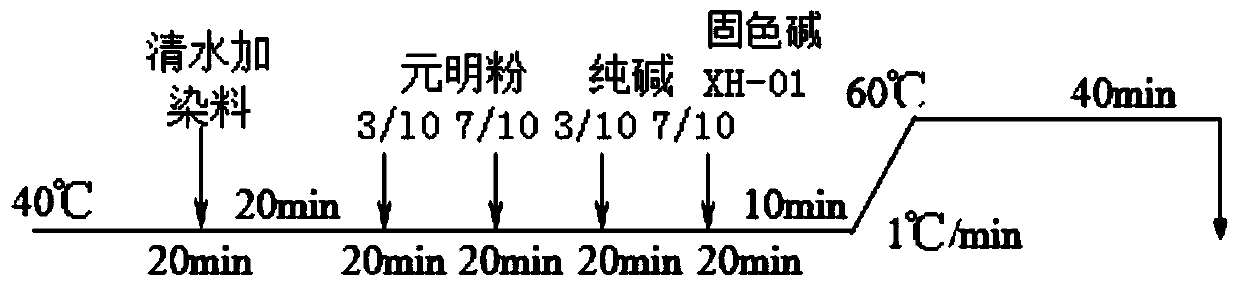

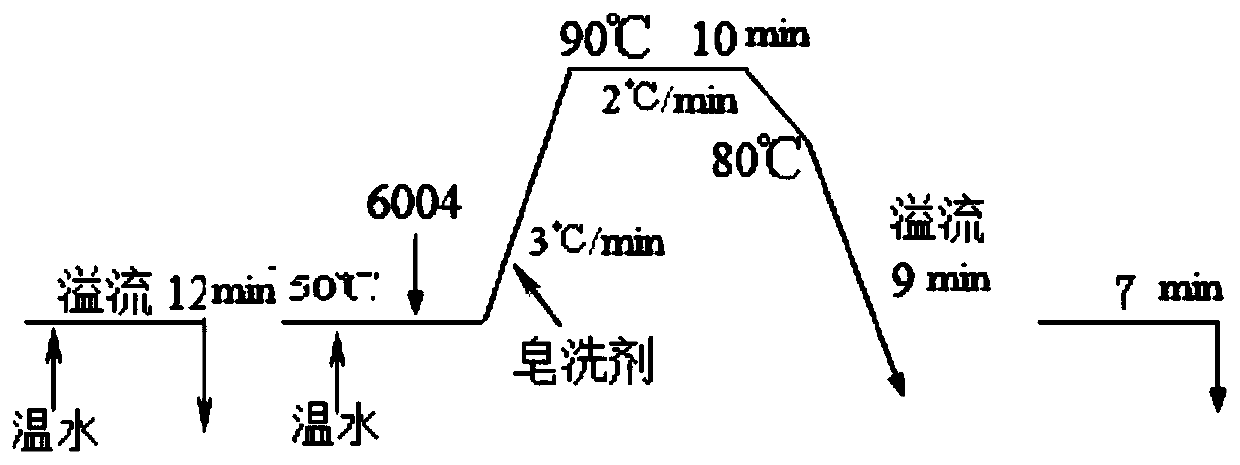

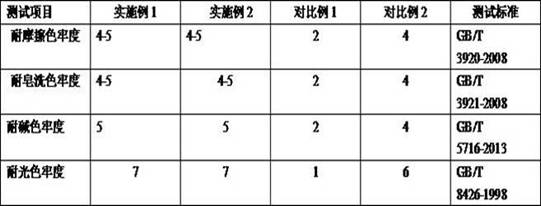

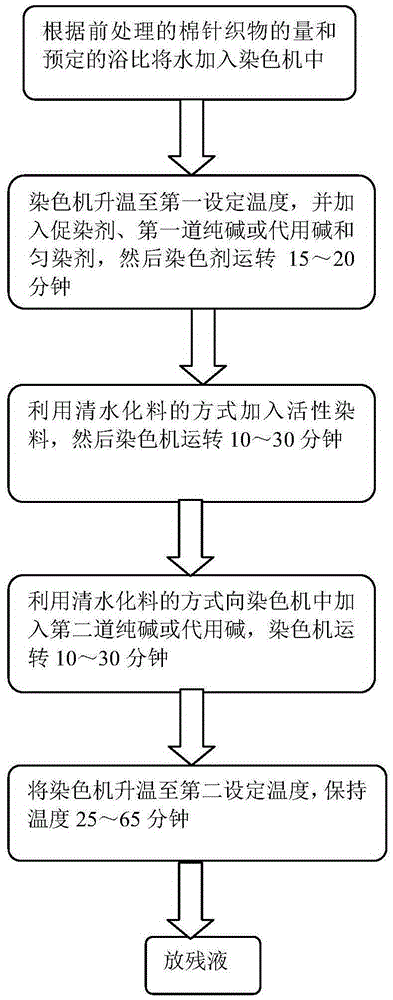

Dyeing Technology of Cotton Knitted Fabric

ActiveCN103924461BGood extensibilityImprove dyeing first time successDyeing processCOTTON WOOLProcedure time

The invention discloses a dyeing process for cotton knitted fabric. The dyeing process mainly aims to improve the one-time success probability of dyeing. The dyeing process at least comprises the steps that dyeing accelerating agents, first sodium carbonate or substitution alkali and levelling agents are added to a dyeing machine; reactive dyes and second sodium carbonate or substitution alkali are added to the dyeing machine in the mode of dissolving materials with clear water; the dyeing machine is heated to a second set temperature, and the second set temperature is kept for 25 to 65 minutes. Before the dyes are added, the dyeing accelerating agents of anhydrous sodium sulphate and the sodium carbonate or the substitution alkali for fixing colors are added, the mode of dissolving the materials with the clear water is adopted twice to add the dyes and the second sodium carbonate or substitution alkali for subsection heating, the general character and the specific characters of the reactive dyes are comprehensively considered, such as proaporphine, temperature types and salt types, the dye yield and levelling property of the process are improved, the number of the adopted dyes is reduced, dyeing defects are overcome, the color phase is stable, the number of the steps is small, the operation is simple and easy to control, the procedure time is short, and the one-time success probability of dyeing is comprehensively improved.

Owner:JIHUA 3543 KNITTING CLOTHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com