Temperature-control knitted underwear fabric and preparing method thereof

A technology of underwear fabric and production method, applied in knitting, weft knitting, warp knitting, etc., can solve the problem of single comfort of underwear, achieve the effect of reducing the occurrence of common diseases and protecting human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for manufacturing a temperature-controlled knitted underwear fabric, comprising the following steps:

[0050] Step 1, weaving: use combed cotton 40S yarn and 20D spandex to weave gray fabric;

[0051] Step 2, Preliminary determination: Preliminary setting of the gray cloth, the temperature during the preliminary setting is 198°C, the speed of the vehicle is 26m / min, and the upper and lower overfeeds are 45% / 6%;

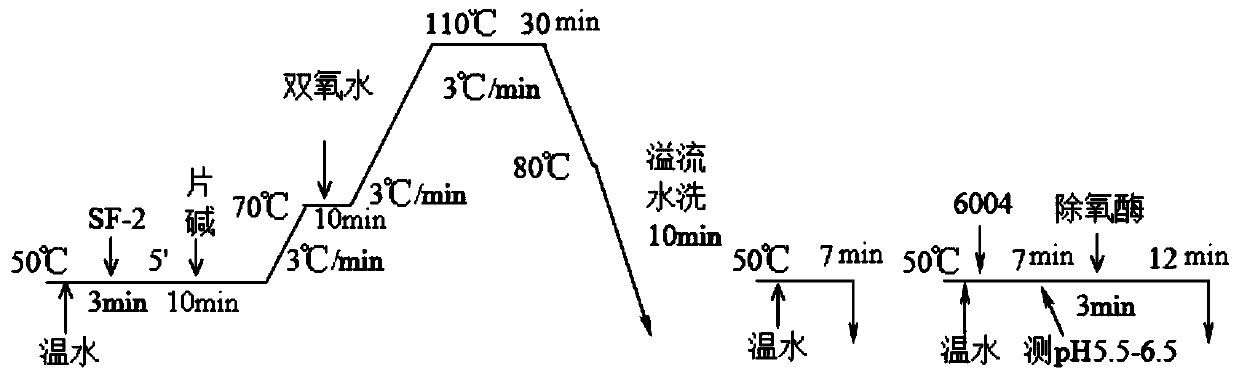

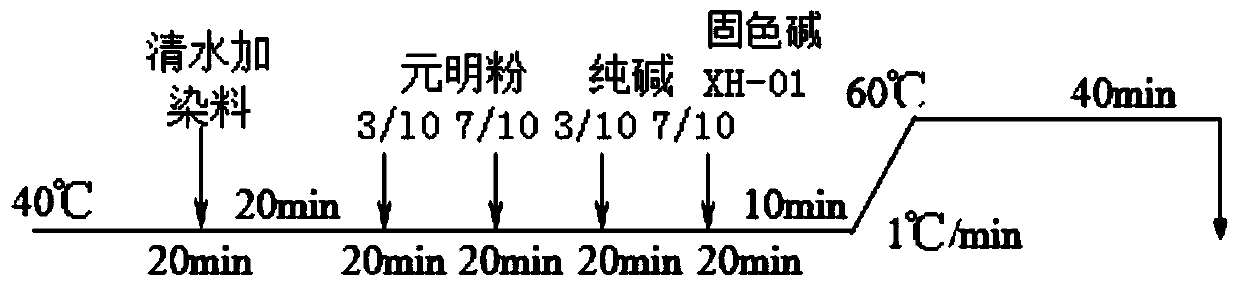

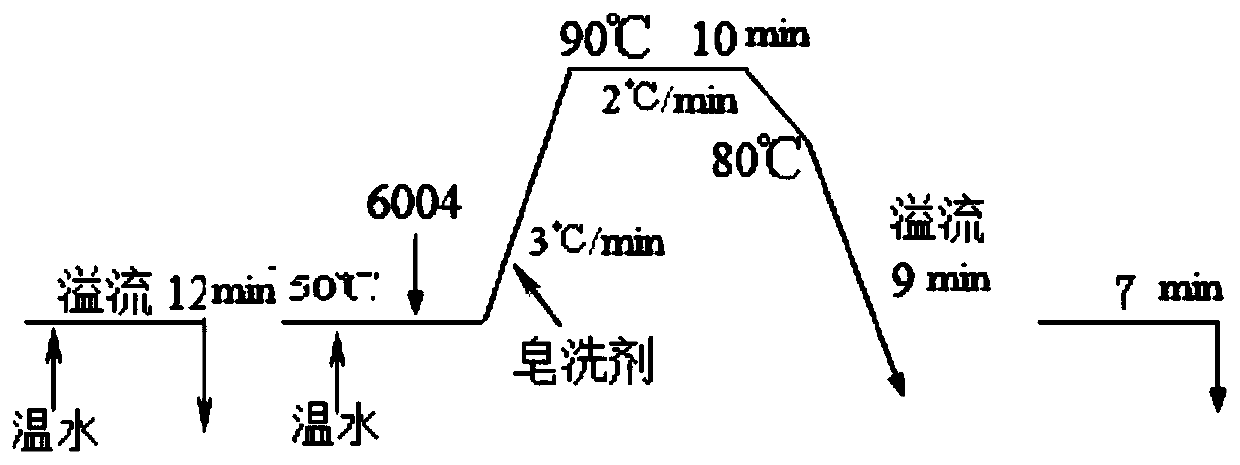

[0052] Step 3, pre-treatment: pre-treat the pre-set gray cloth in the pre-treatment liquid, the pre-treatment liquid includes the following components in terms of water volume: 0.8g / L low-foam refining degreasing agent SF-2, 2.8 g / L caustic soda, 7.8g / L hydrogen peroxide, 0.3g / L neutralizing acid 6004, 0.13g / L deoxygenase DM-8618; the pretreatment is as follows: put the gray cloth into the tank, add warm water at 45°C, and add low-foaming scouring Degreasing agent SF-2, add time 2min, after running for 4min, add caustic soda, add time 8min, heat up to...

Embodiment 2

[0058] A method for manufacturing a temperature-controlled knitted underwear fabric, comprising the following steps:

[0059] Step 1, weaving: use combed cotton 40S yarn and 20D spandex to weave gray fabric;

[0060] Step 2, Preliminary determination: Preliminary setting of the gray cloth, the temperature during the preliminary setting is 198°C, the speed of the vehicle is 26m / min, and the upper and lower overfeeds are 45% / 6%;

[0061] Step 3, pre-treatment: pre-treat the pre-set gray cloth in the pre-treatment liquid, the pre-treatment liquid includes the following components in terms of water volume: 1.2g / L low-foam refining degreasing agent SF-2, 3.2 g / L caustic soda, 8.2g / L hydrogen peroxide, 0.7g / L neutralizing acid 6004, 0.17g / L deoxygenase DM-8618; the pretreatment is as follows: put the gray cloth into the tank, add warm water at 55℃, add low foam scouring Degreasing agent SF-2, add time 4min, after running for 6min, add caustic soda, add time 12min, heat up to 75°C a...

Embodiment 3

[0067] A method for manufacturing a temperature-controlled knitted underwear fabric, comprising the following steps:

[0068] Step 1, weaving: use combed cotton 40S yarn and 20D spandex to weave gray fabric;

[0069] Step 2, Preliminary determination: Preliminary setting of the gray cloth, the temperature during the preliminary setting is 198°C, the speed of the vehicle is 26m / min, and the upper and lower overfeeds are 45% / 6%;

[0070] Step 3, pre-treatment: pre-treat the pre-set gray cloth in the pre-treatment liquid, the pre-treatment liquid includes the following components in terms of water volume: 1.0g / L low-foam refining degreaser SF-2, 3.0 g / L caustic soda, 8.0g / L hydrogen peroxide, 0.5g / L neutralizing acid 6004, 0.15g / L deoxygenase DM-8618; the pretreatment is as follows: put the gray cloth into the tank, add 50℃ warm water, add low foam scouring Degreasing agent SF-2, add time 3min, after running for 5min, add caustic soda, add time 10min, heat up to 70°C at a heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com