Patents

Literature

47results about How to "Optimize the dyeing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

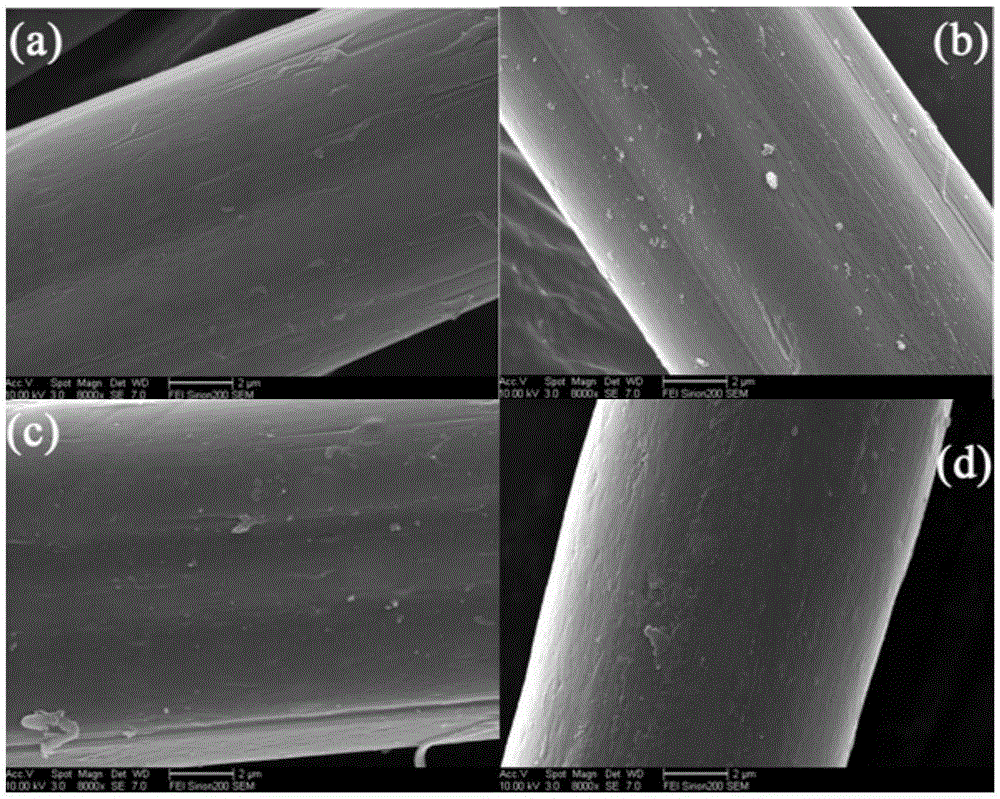

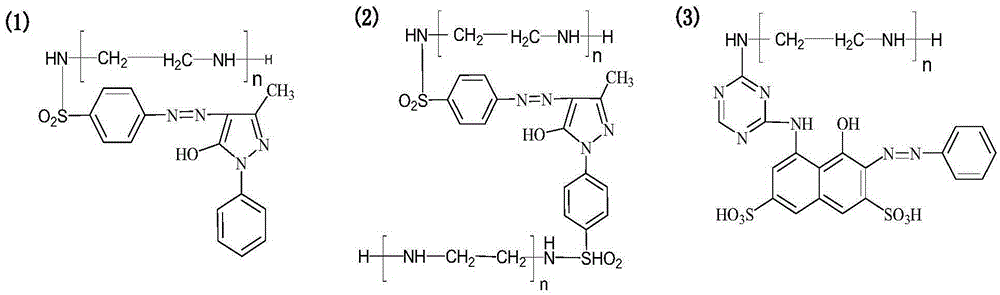

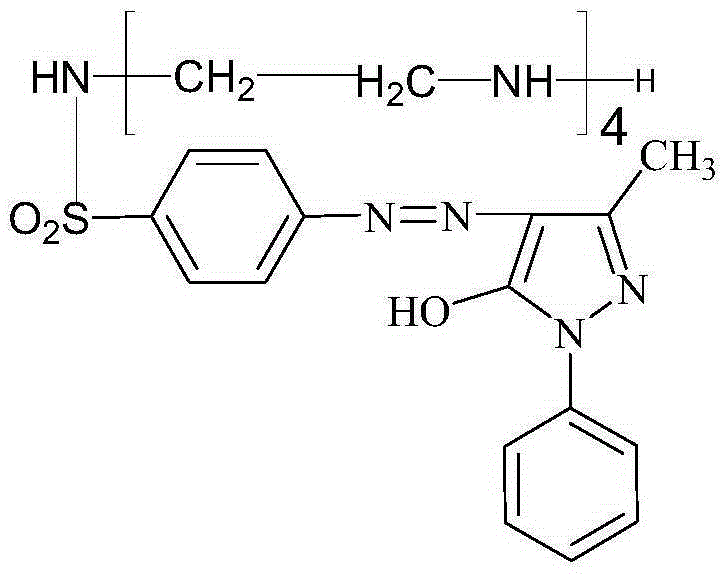

Dyeing method for calcium alginate fibers

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

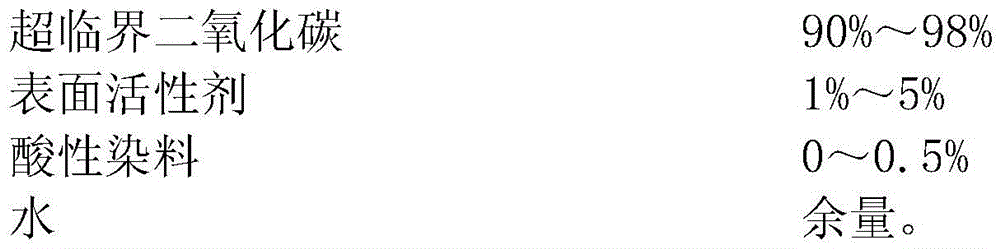

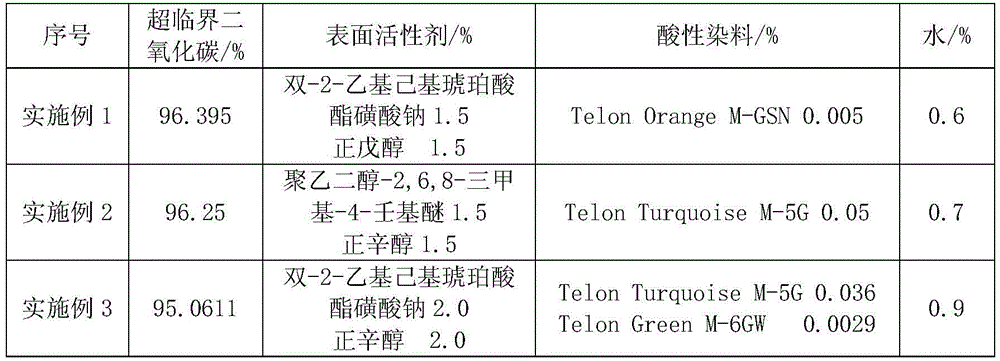

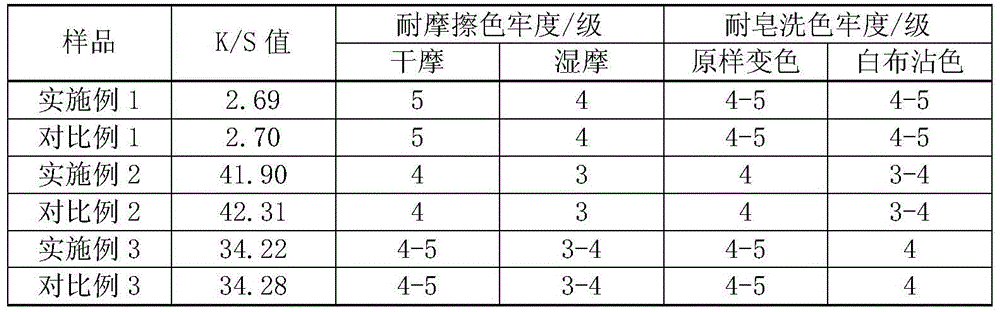

Reverse micelle system and application thereof in acid dye dyeing

InactiveCN105484071AMake up for the inability to dissolve polar substancesReduce dosageDyeing processOrganic solventSolvent

The invention discloses a reverse micelle system and an application thereof in acid dye dyeing. The reverse micelle system is characterized by comprising the following components in percentage by weight: 90%-98% of supercritical carbon dioxide, 1%-5% of a surfactant, 0-0.5% of an acid dye and the balance of water. Supercritical carbon dioxide dyeing is organically combined with reverse micelle dyeing; the supercritical carbon dioxide is taken as a non-polar organic solvent in reverse micelle dyeing due to the fact that the supercritical carbon dioxide is nontoxic, tasteless and not easy to combust and is an environment-friendly chemical solvent; in addition, the system only contains very little water of a reverse micelle-coated soluble dye; the amount of water can be greatly reduced; meanwhile, the carbon dioxide is recovered in the form of gas under the supercritical condition; the non-polar organic solvent, the surfactant and water can be easily separated; and recovery and cyclic utilization are achieved.

Owner:中国纺织科学研究院江南分院 +1

Foam spraying dyeing method adopting reactive dyes

ActiveCN102650097AReduce dosageIncrease profitTextile treatment with treating outlet contectReactive dyeEnvironmental geology

The invention relates to a foam spraying dyeing method adopting reactive dyes, which comprises the following steps: mixing a reactive dye liquor and a color fixing liquid; applying the mixed liquor to a fabric; and carrying out water washing after fixing the color of the fabric. The method is characterized in that the mixed liquor is foamed before being applied to the fabric, and is applied to the fabric in a foamed manner. The foam spraying dyeing method has the advantages that the stability for controlling the dyeing process is improved; the process flow is short; energy and dye utilization ratios are improved; table salt, glauber salt or urea is not required; and unfixed dyes and the pollution discharge during the dyeing process are reduced.

Owner:上海虹馨管理咨询有限公司

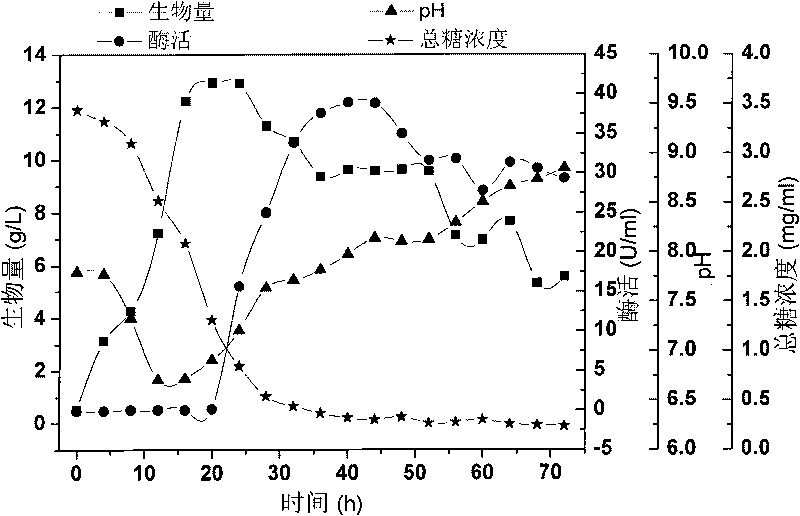

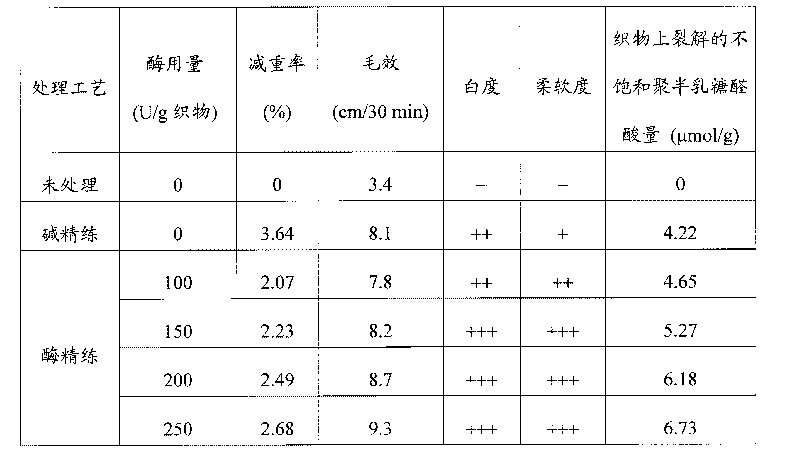

Compound enzyme preparation for textile fabrics and applications thereof

ActiveCN101713150AReduce processing costsReduce salt contentBacteriaBiochemical fibre treatmentPectinaseSolvent

The invention provides a high-efficiency compound enzyme preparation used for a pretreatment process of textile fabrics, particularly cotton fabrics, and application thereof. The compound enzyme preparation mainly comprises the following components by final concentration: 50 to 100g / L of polysiloxane, 50 to 100g / L of fatty alcohol-polyoxyethylene ether, 80 to 150g / L of Tween 20 to 80 series, 80 to 150g / L of Span 20 to 80 series, 30 to 80g / L of sorbitol, 3 to 10g / L of calcium chloride, 5 to 15g / L of sodium benzoate, 800 to 1,000U / mL of alkaline pectinase, 1,000 to 1,200U / nL of cellulase, and water serving as a solvent. The compound enzyme preparation is applied to the pretreatment of the textile fabrics to replace the conventional alkali boiling off process, can effectively reduce production cost, reduce labor intensity and enable the quality of the product to be obviously improved, can also reduce the salt content and BOD, COD and the like in the water discharged into the environment and obviously reduce the pollution to the environment, and is a green process route which accords with the sustainable development.

Owner:ZHEJIANG UNIV OF TECH

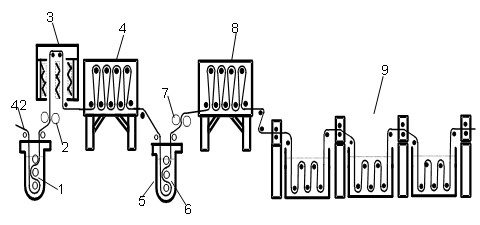

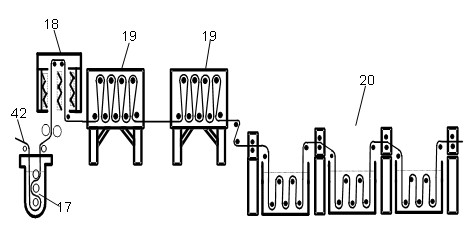

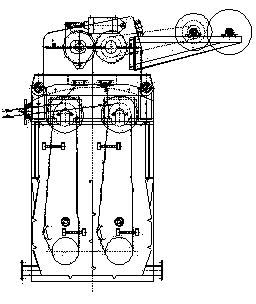

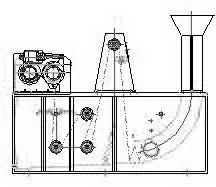

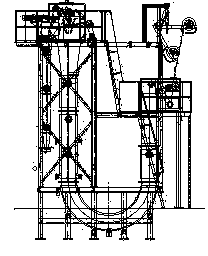

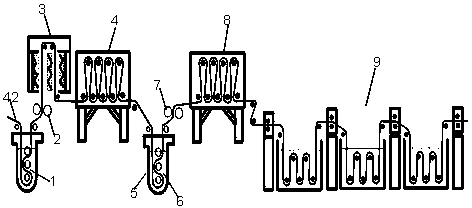

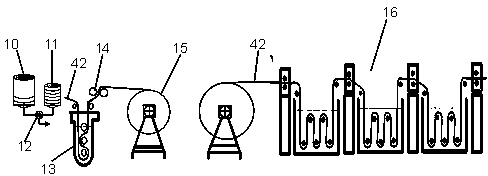

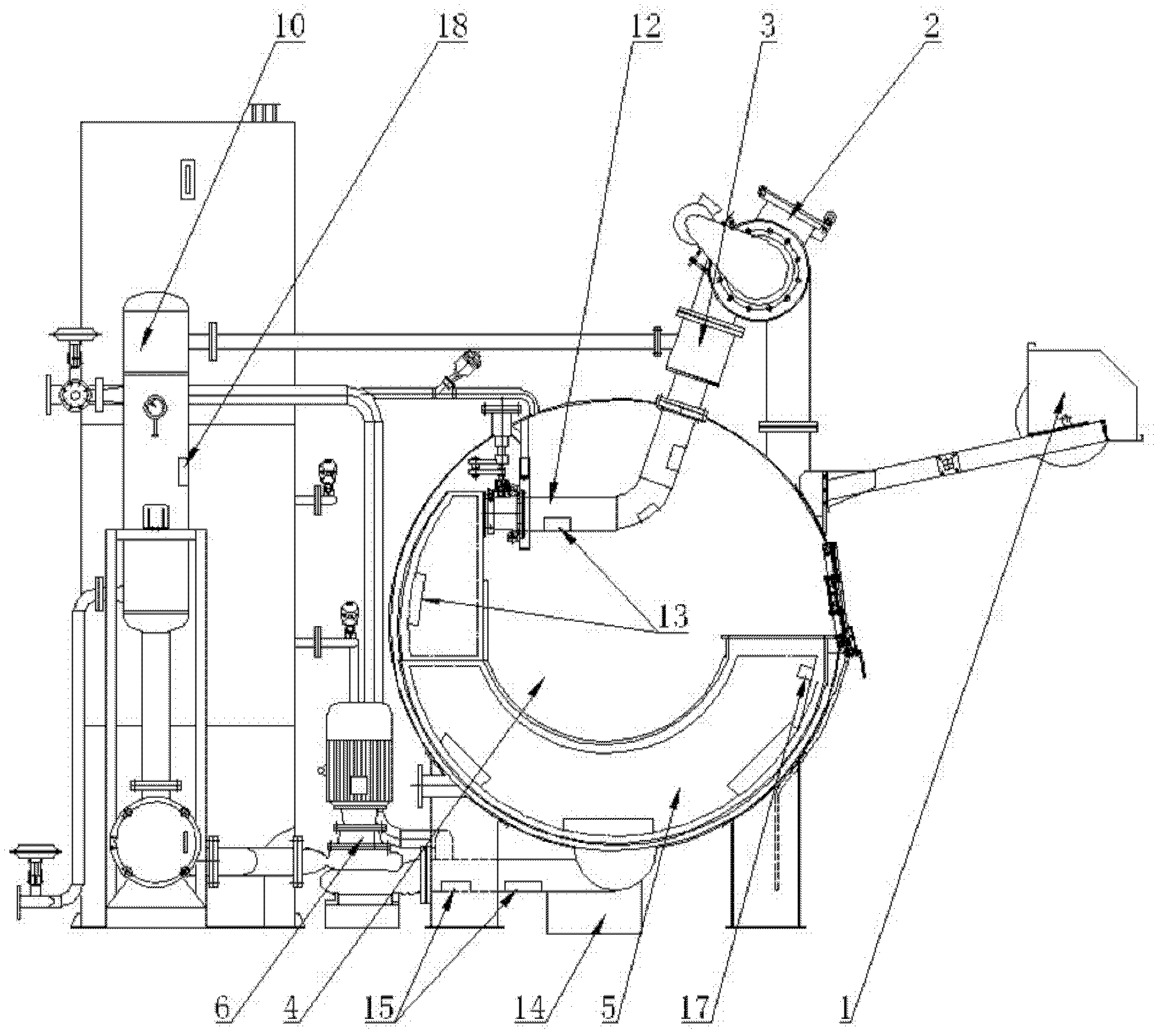

Rope-shaped desizing, scouring and bleaching combination machine

ActiveCN104328616AReduce energy consumptionImprove wettabilitySucessive textile treatmentsTextile treatment containersProcess engineeringDesizing

The invention belongs to the field of technical equipment in the fabric pre-treatment procedure in the printing and dyeing industry, and in particular relates to a rope-shaped desizing, scouring and bleaching combination machine. The rope-shaped desizing, scouring and bleaching combination machine comprises water washing tanks, rolling washing machines, scouring tanks, a J-shaped tank after acid rolling, and a J-shaped tank after hypochlorous acid rolling. The rope-shaped desizing, scouring and bleaching combination machine is characterized by being formed by connecting the water washing tank I, the rolling washing machine I, the scouring tank I, the scouring tank II, the water washing tank II, the water washing tank III, the water washing tank IV, the washing tank V, the rolling washing machine II, the J-shaped tank after the acid rolling, the water washing tank VI, the rolling washing machine III, the J-shaped tank after the hypochlorous acid rolling, the water washing tank VII and the water washing tank VIII in sequence. According to the rope-shaped desizing, scouring and bleaching combination machine, technical flow steps are simple, the operation is reliable, the maintenance is convenient, 3 persons are saved, the energy consumption is reduced by one time, the desizing effect is good, the damage to cloth is lightened, and the operation efficiency is improved by 2.5 times.

Owner:HUAFANG

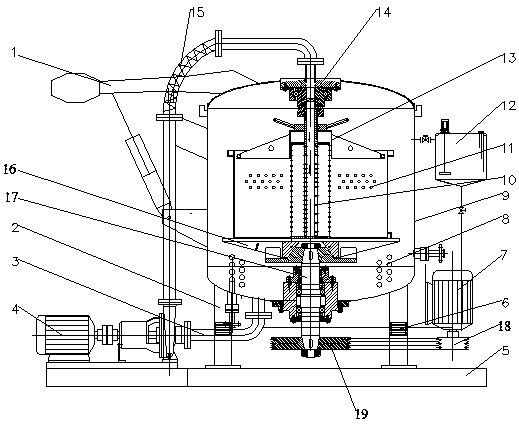

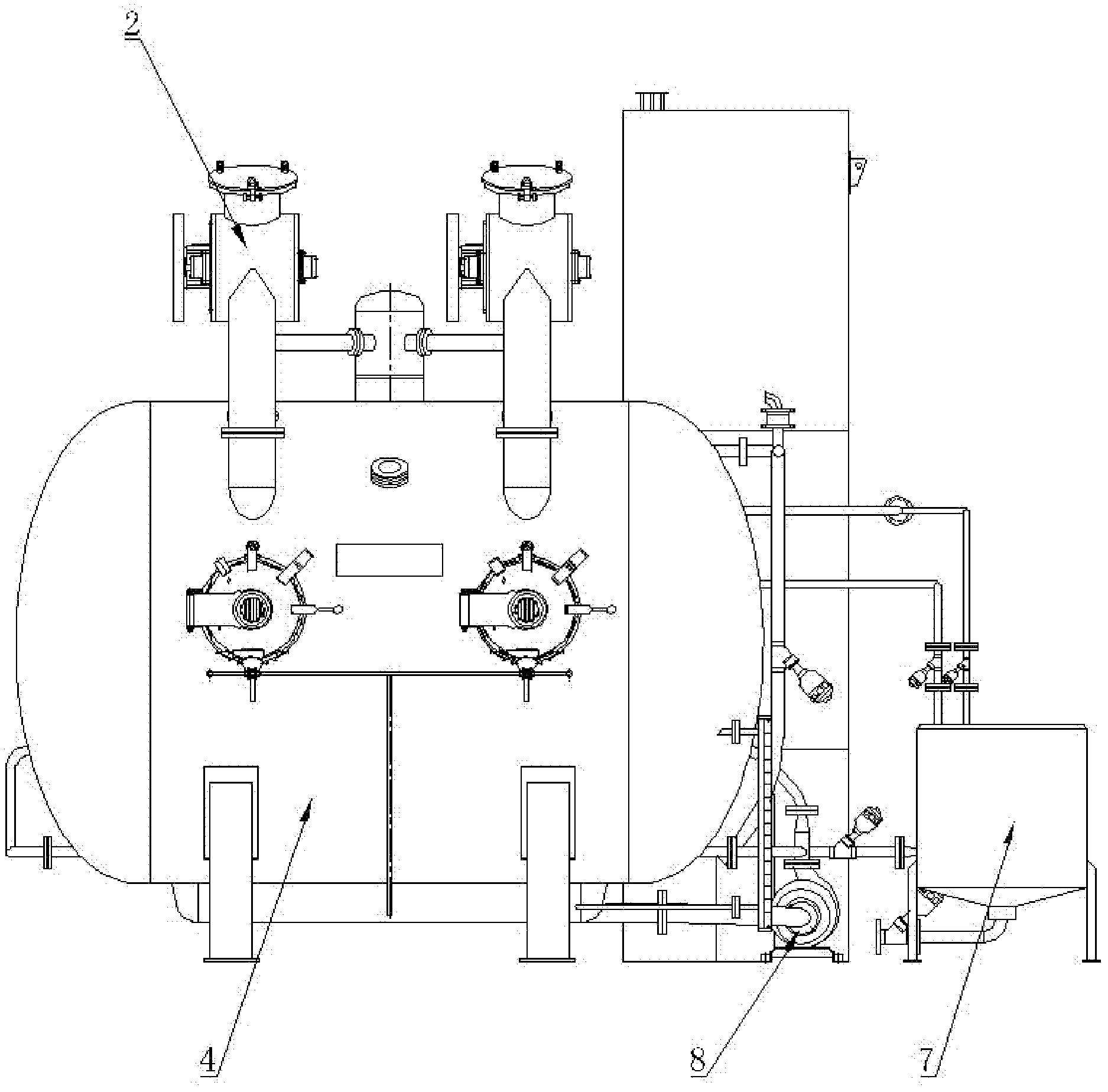

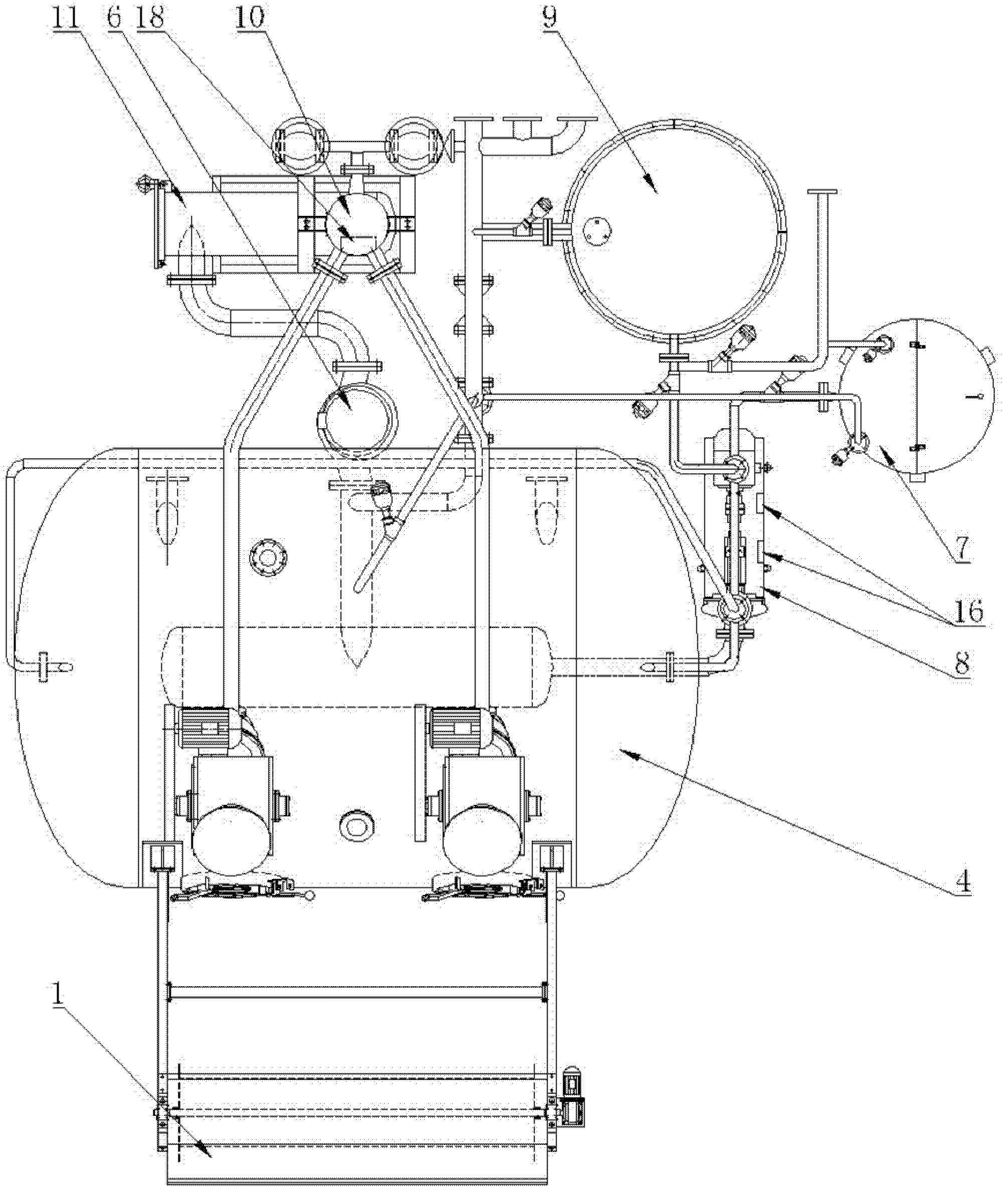

Environment-friendly energy-saving loose-wool dyeing and dehydrating all-in-one machine

ActiveCN108978070AOptimize the dyeing processSimple processSucessive textile treatmentsTextile treatment machine arrangementsFiberMaster cylinder

The invention discloses an environment-friendly energy-saving loose-wool dyeing and dehydrating all-in-one machine, and the machine comprises a pedestal. The pedestal is provided with a dye liquor circulating pump and a main cylinder body. The main cylinder body is fixed on the pedestal through a support connection system, and a dehydrating motor is connected below the main cylinder body. The interior of the main cylinder body is provided with a loose-wool cage and a dye liquor heating system. The main cylinder body is also provided with a charging system, and the top of the main cylinder bodyis provided with a dye liquor spraying nozzle. The all-in-one machine can optimize the water circulation, improve efficiency, reduce the waste of water resources, save water and energy, and reduce the number of water cleaning times. The all-in-one machine is better in stability and balance for the processing of loose fibers (more than 150kg). Dyeing equipment and dehydrating equipment are perfectly combined into the all-in-one machine, thereby shortening the technological process, reducing the labor intensity, reducing the equipment investment, alleviating the environment protection pressure,achieving the low-investment and high yield purpose, and maximizing the benefits.

Owner:ZHONGYUAN ENGINEERING COLLEGE

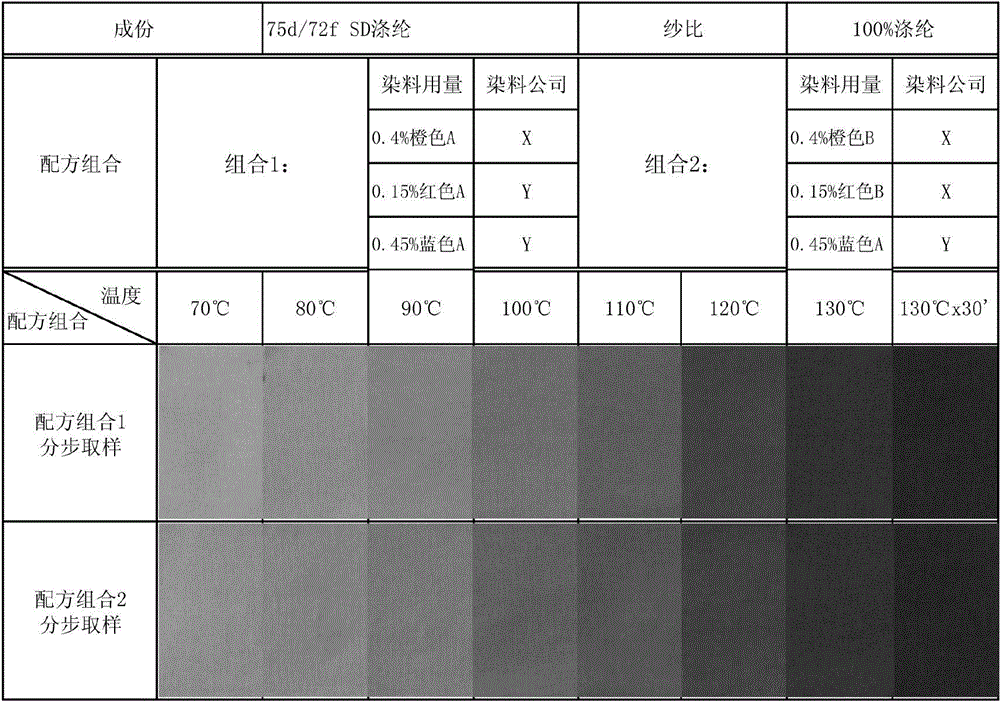

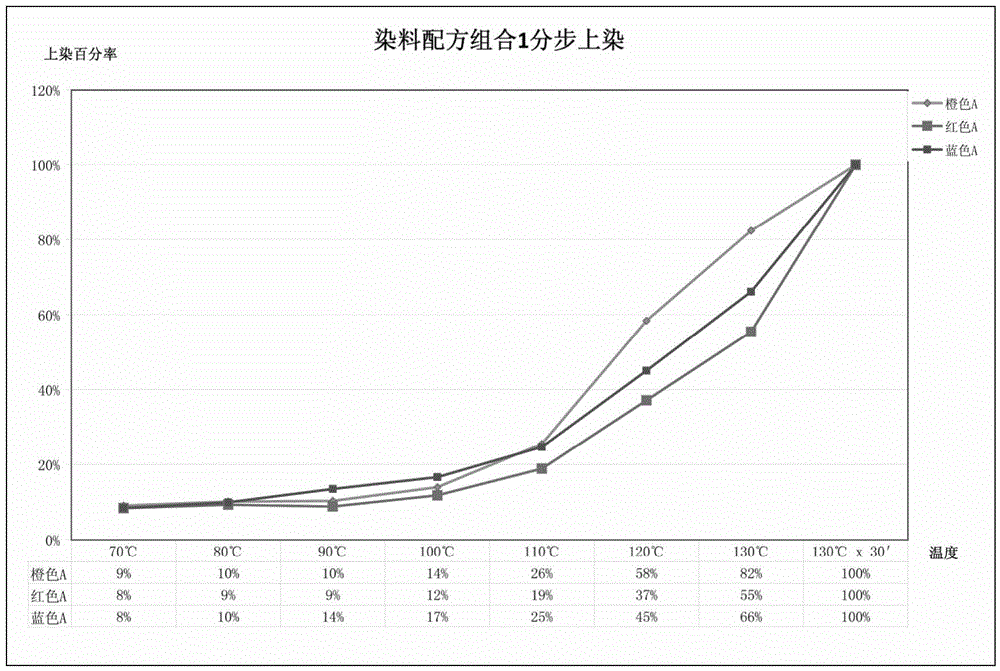

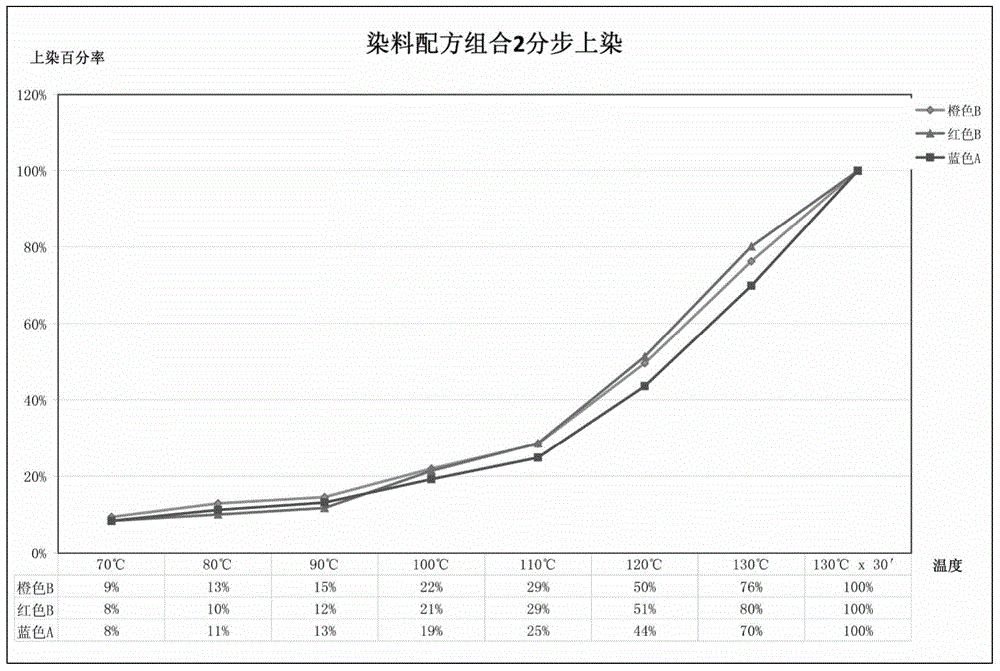

A method of digitized analysis of compatibility of a dye composition by adoption of a spectrometer

InactiveCN104614319AThe result is objective and reasonableEasy to optimizeColor/spectral properties measurementsSpectral analysisDigitization

A method of digitized analysis of compatibility of a dye composition by adoption of a spectrometer is disclosed. The method includes: subjecting cloth samples in different heating stages of the dye composition to color measuring and matching by a datacolor spectrometer, acquiring different formula concentrations of the dye composition by color measuring and matching, sorting out corresponding dye uptakes in different dyeing heating stages of each dye in the dye composition, and showing all the dye uptakes of each dye in one chart, then the compatibility of the dye composition can be clearly determined. At present, manners of evaluating dye uptakes and compatibility by spectral analysis of dye solutions do not consider influence factors of dye hydrolysis in dyeing processes, while the method provided by the invention relates to evaluation of the dye uptakes and the compatibility for the actual colors of fabrics after dyeing, so that results of the method are more reasonable and impersonal, the method can show actual dyeing performance of fabrics at present dyeing conditions well, and the method facilitates optimization of dyeing processes and improvement of formulas.

Owner:福建宇邦纺织科技有限公司

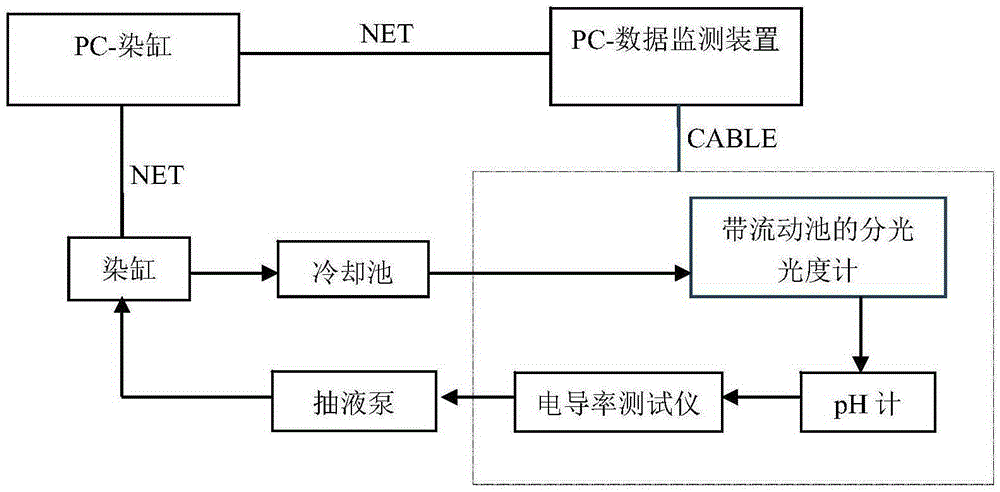

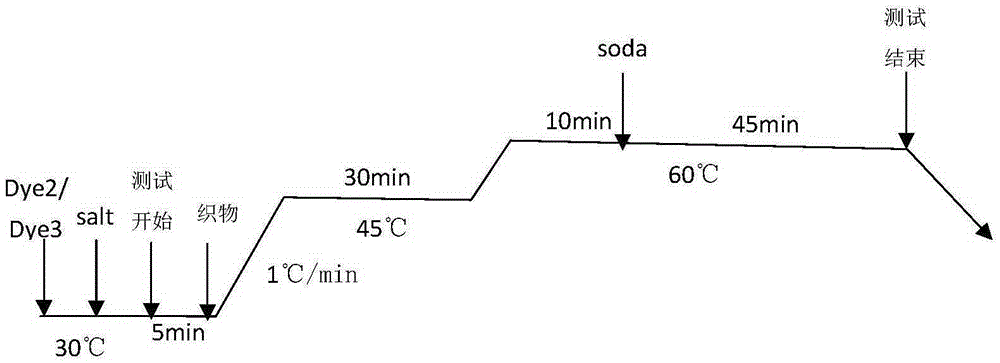

Dyeing process monitoring method

ActiveCN105386263AOptimize the dyeing processImprove dyeing qualityTextile treatment machine partsEngineeringComputer terminal

The invention relates to a dyeing process monitoring method. The method includes the following steps of firstly, sequentially connecting a dyeing vat, a dyeing liquid cooling pool, a data monitoring device and a liquid suction pump through pipelines to form a loop, and making a computer terminal in communication with the dyeing vat and the data monitoring device, wherein the data monitoring device comprises one or more of a spectrophotometer with a flowing pool, a pH meter and a conductivity tester; secondly, starting the liquid suction pump when dyeing starts, making dyeing liquid continuously circulate and flow between the dyeing vat, the dyeing liquid cooling pool and the data monitoring device; thirdly, collecting data of the dyeing vat and data obtained through monitoring of the data monitoring device in the dyeing process at the set time moment, and recording the collecting time. By means of the method, the whole dyeing process can be reflected through real-time, accurate and objective parameters, the basis is provided for accurately judging the dye combination of dyeing and reasonability of the process, the dyeing process is improved more scientifically, and the dyeing quality is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

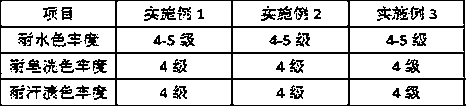

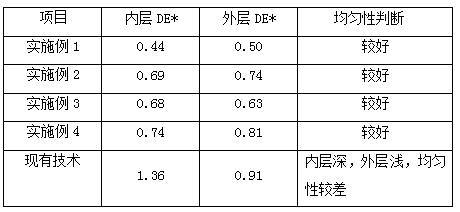

Comfortable silk fabric and dyeing method thereof

InactiveCN108085836AImprove uneven colorHigh saturationDyeing processWoven fabricsYarnBiomedical engineering

The invention belongs to the field of textiles and relates to a comfortable silk fabric and a dyeing method thereof. The fabric is characterized in that silk yarns and modal yarns are interwoven by satin weaves to expose the silk yarns on the front surface of the fabric and expose the modal yarns on a skin contacting surface of the fabric, and accordingly comfort and glossiness can be kept and highlighted to the greatest extent. By the dyeing method of the comfortable silk fabric, the problem of poor color uniformity in double-component silk fabric dyeing is effectively solved, dyeing saturability is improved, and color purity is enhanced.

Owner:LILANG CHINA

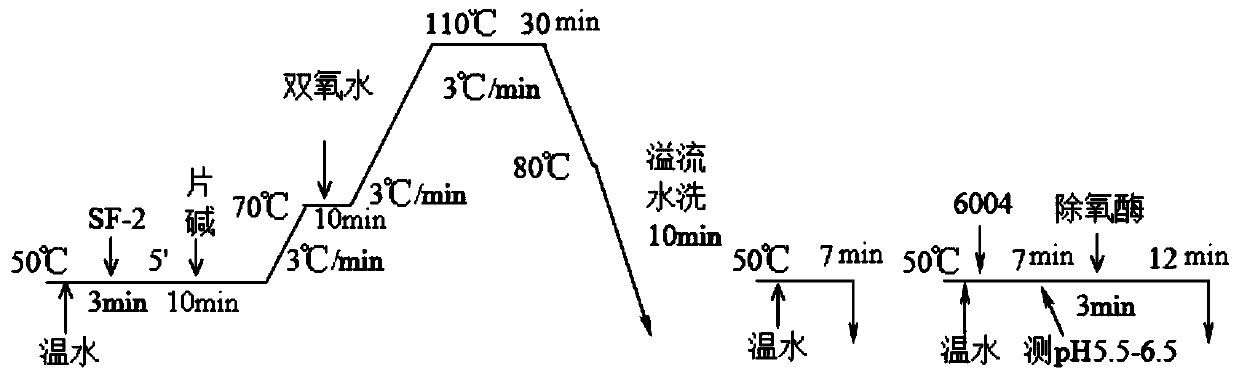

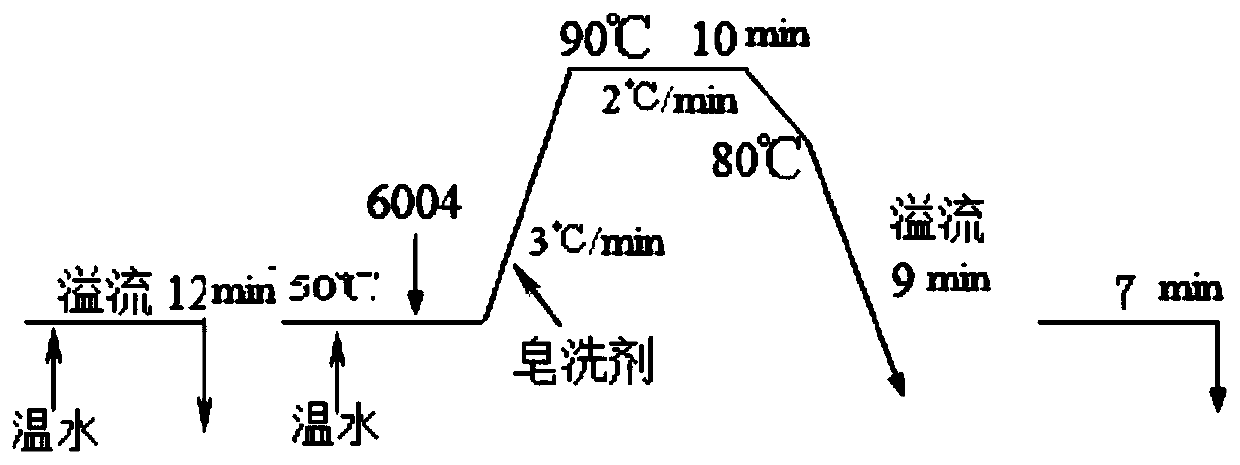

Dyeing process of chinlon and cotton lace

InactiveCN107740260AImprove gross effectSolve the problem that if the dye is not transparent, it will be whiteDyeing processYarnNeutral ph

The invention discloses a dyeing process of a chinlon and cotton lace. The dyeing process of the chinlon and cotton lace is mainly characterized in that a cotton pretreatment process, PH before activedyeing, a high-temperature migration temperature and time and soda ash adding time are controlled, the using amount of an auxiliary is selected, and the temperature of a dyeing bath and temperature keeping time are selected, so that a reasonable dyeing process is optimized, the problem of exposure of coarse folded yarns of the chinlon and cotton lace is solved, and a new idea and a new directionare provided for the type of products. According to the dyeing process of the chinlon and cotton lace, tea saponin, flake alkali, hydrogen peroxide and a refining agent are used for improving the wooleffect of cotton in a pretreatment process of cotton, so that the permeability of reactive dyes is enhanced. By adopting the dyeing process of the chinlon and cotton lace, the active dyeing temperature is raised to 95 to 98 DEG C, and the dye diffusion time is prolonged. After high-temperature migration, the temperature is lowered and soda ash is added fractionally to fix the dyes, so that migration of the dyes is facilitated, the permeability of the dyes is enhanced, and the problem of folded yarn exposure during dyeing is solved; moreover, high-temperature migration under a neutral PH condition does not cause hydrolysis of the reactive dyes, so that the color depth does not decline.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

Method for dyeing rayon fiber by using reduced dye

The invention discloses a method for dyeing rayon fiber by using reduced dye, and belongs to the technical field of fiber dyeing. The method comprises the following steps: A, pretreating: conveying rayon yarns into a bathtub, adding water, the dye and peregal o, keeping for 9min, then adding caustic soda, then adding bone glue, triethanolamine and water, keeping for 9min, and adding sodium hydrosulfite; B, dyeing: raising the temperature of the bathtub to 60 DEG C, preserving heat for 45 minutes, then adding 5% of the total amount of the sodium hydrosulfite in the step A, and continuing keeping for 15 minutes; C, washing by using water: washing the dyed fiber by using water for 9min each time; D, oxidizing: adding glacial acetic acid and hydrogen peroxide into the bathtub, keeping for 27min, and washing by using water; E, soaping; F, posttreating. By the method, a series of problems which appear in the dyeing process using the vat dye in the prior art are solved; the method is designedfor rayon fiber dyeing, and has the advantages of uniform dyeing and no white core.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

High-color-fastness flannel fabric

InactiveCN105420891AImprove physical performanceGood coloring effectOrnamental textile articlesDyeing processFiberColour fastness

The invention discloses a high-color-fastness flannel fabric. The flannel fabric is prepared by weaving surface yarn and bottom yarn. The surface yarn and the bottom yarn are blended yarn of cotton fiber and polyester fiber, 16.7 tex ultra-fine denier polyester fiber is adopted as the polyester fiber in the surface yarn, 11.1 tex polyester fiber is adopted as the polyester fiber in the bottom yarn, the surface yarn and the bottom yarn are formed by conducting weaving after dyeing, dispersion dye and active dye are added during dyeing, and dip dyeing is conducted in a dyeing vat at the temperature of 40 DEG C for 35-40 min. In this way, the physical performance and dyeing effect of the yarn can be improved, the yarn has excellent dyeing performance, and therefore the color fastness and washing fastness of the fabric are improved.

Owner:常熟市梅李镇赵市盛欣纺织制品厂

Temperature-control knitted underwear fabric and preparing method thereof

ActiveCN110106716AAccelerate evaporationImprove cooling effectWeft knittingWarp knittingTemperature controlTest requirements

The invention relates to a temperature-control knitted underwear fabric and a preparing method thereof, and belongs to the technical field of the textile dyeing and finishing process. The preparing method of the temperature-control knitted underwear fabric includes the steps of weaving, primary sizing, preprocessing, dyeing, soaping, drying, sizing and the like. The sizing step specifically includes the substeps of sizing dried color cloth and adding a temperature control aid with the concentration of 48-52 g / L and silicone oil T718 with the concentration of 18-22 g / L according to the water yield during sizing. All interior qualities of the obtained temperature-control knitted underwear fabric all meet the national textile test requirements, and the temperature-control effect of the fabricis remarkably better than that of similar temperature-control materials. The fabric is simple in production process, low in cost and high in additional value, only the temperature-control treatment needs to be conducted in the sizing process, and operation is simple and convenient.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Foam spraying dyeing method adopting reactive dyes

ActiveCN102650097BReduce dosageIncrease profitTextile treatment with treating outlet contectEngineeringReactive dye

The invention relates to a foam spraying dyeing method adopting reactive dyes, which comprises the following steps: mixing a reactive dye liquor and a color fixing liquid; applying the mixed liquor to a fabric; and carrying out water washing after fixing the color of the fabric. The method is characterized in that the mixed liquor is foamed before being applied to the fabric, and is applied to the fabric in a foamed manner. The foam spraying dyeing method has the advantages that the stability for controlling the dyeing process is improved; the process flow is short; energy and dye utilization ratios are improved; table salt, glauber salt or urea is not required; and unfixed dyes and the pollution discharge during the dyeing process are reduced.

Owner:上海虹馨管理咨询有限公司

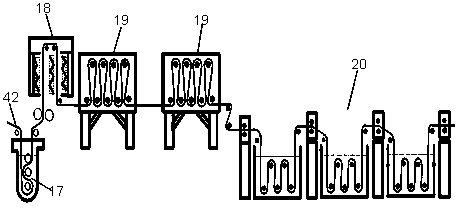

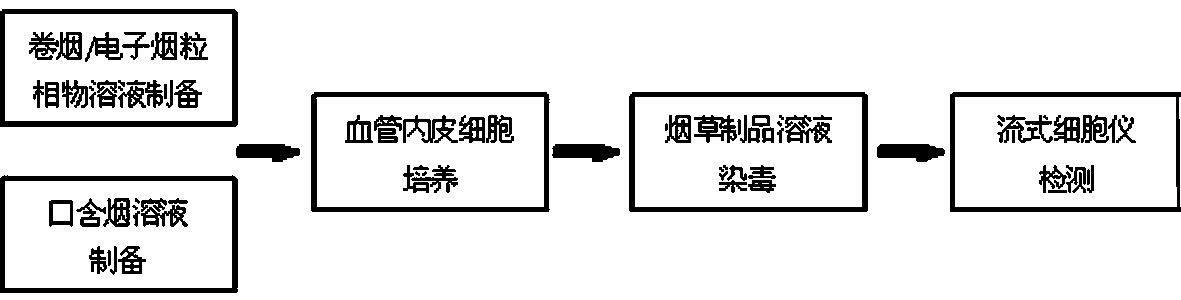

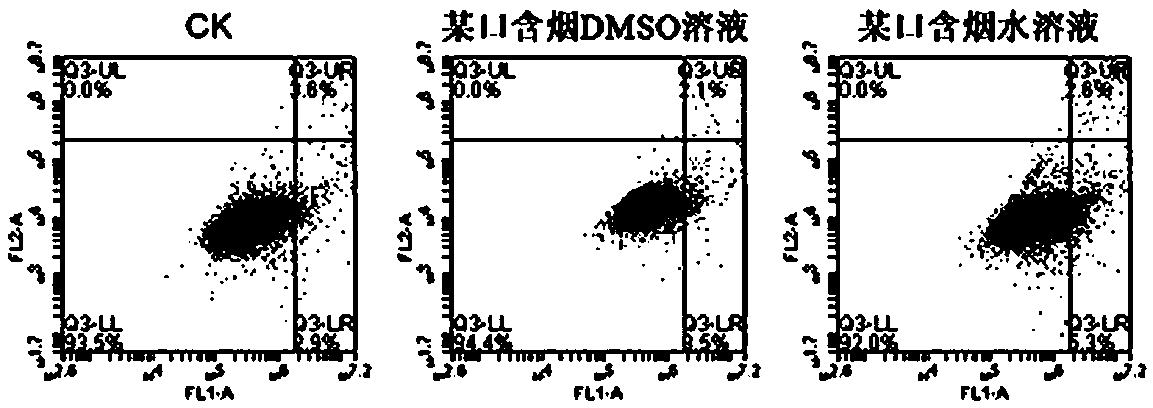

Method for testing induction of tobacco products on vascular endothelial cell apoptosis

InactiveCN107727840AHigh sensitivityClear exposure timePreparing sample for investigationIndividual particle analysisFiltration membraneCentrifugation

The invention discloses a method for testing induction of tobacco products on vascular endothelial cell apoptosis. The method is characterized in that tobacco product solutions are prepared and then are subjected to centrifugation and purification of filtration membranes, poisoning and exposure on human vascular endothelial cells with appropriate density which are inoculated and are cultured overnight are carried out, then Annexin V-FITC and PI dyeing on cell suspensions prepared through digestive cells can be carried out, and finally, cells are detected by using a flow-type cytometer so as toquickly analyze a cell apoptosis condition. The method has the advantages of simpleness and convenience in operation, high sensitivity, reliability in results and the like, and can accurately detectan induction condition of tobacco products of different types on the human vascular endothelial cell apoptosis.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

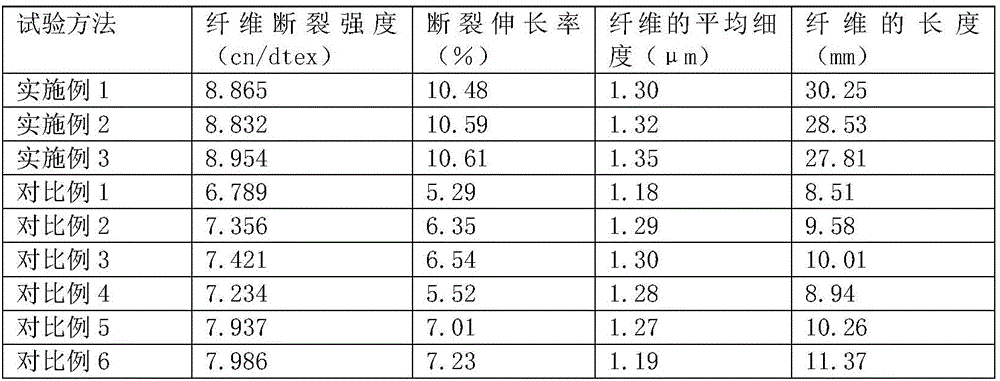

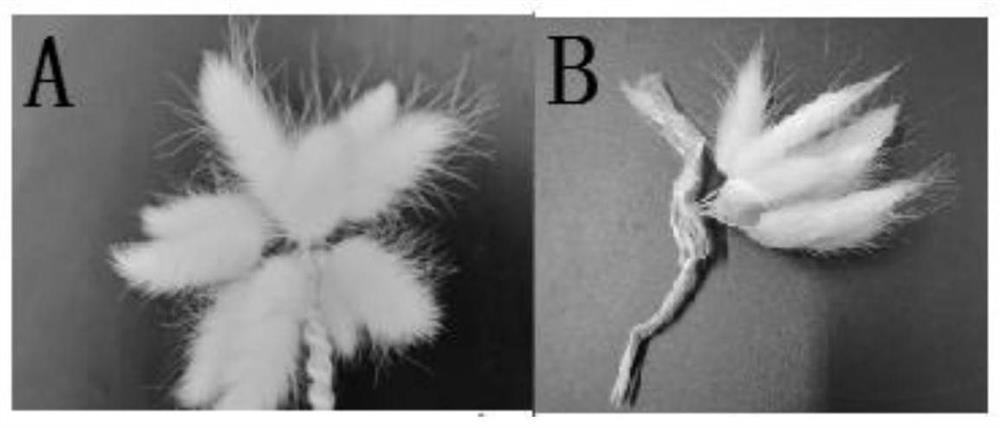

Method for preparing garlic bolt leaf fibers

ActiveCN105908263AHigh degumming rateShort degumming timeVegetable materialMechanical fibre separationFiberMicrowave

The invention provides a method for preparing garlic bolt leaf fibers. The method comprises the steps of compound acid pretreatment, low-temperature plasma treatment, microwave radiation and complex enzyme alternate treatment, water washing, soap washing, dewatering, shaking to be loose, oil feeding and drying. According to the method for preparing the garlic bolt leaf fibers, fiber degumming time can be shortened, attachments on the surfaces of the garlic bolt leaf fibers can be reduced, spinnability can be improved, and the garlic bolt leaf fibers prepared through the method for preparing the garlic bolt leaf fibers have high strength and elongation at break and large length.

Owner:南通隆特家纺有限公司

Environment-friendly reactive red disazo dye and preparation method thereof

InactiveCN104479403AWeakly alkalineImprove protectionOrganic chemistryOrganic compound preparationChemical structureBisazomethine dye

The invention relates to an environment-friendly reactive red disazo dye and a preparation method thereof. The chemical structure general formula is disclosed as Formula (I), wherein X is selected from Na, K or Li; R1 is -H, -CH3(CH2)n-1, -CH3(CH2)n-1O, -COOH or -SO3H; R2 is -CH3(CH2)n-1O; R3 is -(CH2)n-; and n is a whole number, and 1<=n<=4. The disazo dye contains hydroxy, amino and sulfo groups, and thus, is weakly alkaline, thereby being beneficial to lowering the strict preparation conditions and further beneficial to the subsequent dyeing technique. The functional groups are combined with the disazo group to enhance the fixation rate and deep dyeing property.

Owner:吴江桃源染料有限公司

Dyeing process capable of effectively improving white spots of elastic fabric

ActiveCN108560240AOptimize the dyeing processSolve the problem of easily forming white spots in dyeingDry-cleaning apparatus for textilesDyeing processEmulsionEngineering

The invention relates to the technical field of textile dyeing, in particular to a dyeing process capable of effectively improving white spots of an elastic fabric. The invention provides a dyeing process capable of effectively improving the white spots of the elastic fabric. On the basis of the conventional dyeing process, after the basic desizing step, the desizing treatment way in a cylinder isperformed again, in the desizing step and the in-cylinder desizing step, a desizing solution of a specific constitution and content is adopted, the emulsion breaking and back-dipping phenomenon of the silicone oil can be effectively improved, the white spot problem easy to form when in dyeing can be greatly avoided, the success rate of the elastic fabric dyeing process is increased from less than30 percent to 95 percent or above, the production efficiency is greatly improved, and the production cost is effectively reduced.

Owner:SHISHI SANYI WEAVING DYEING & FINISHING

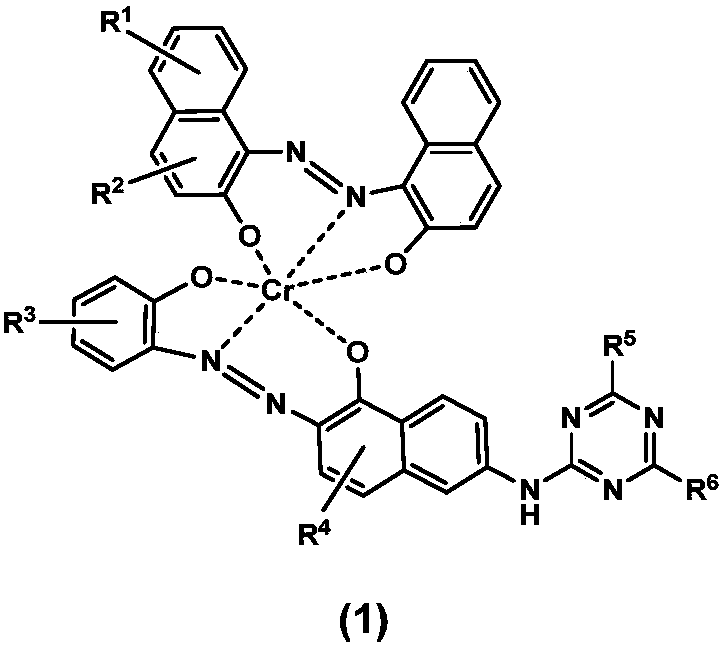

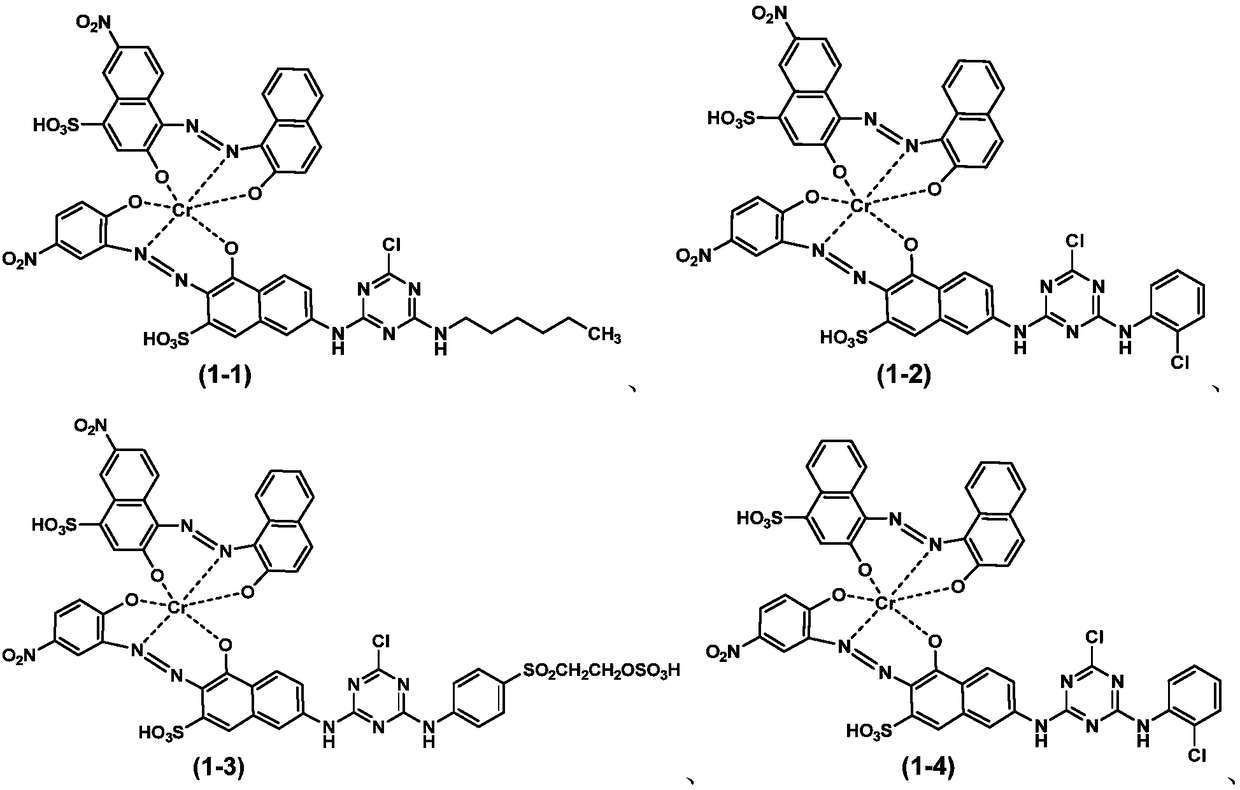

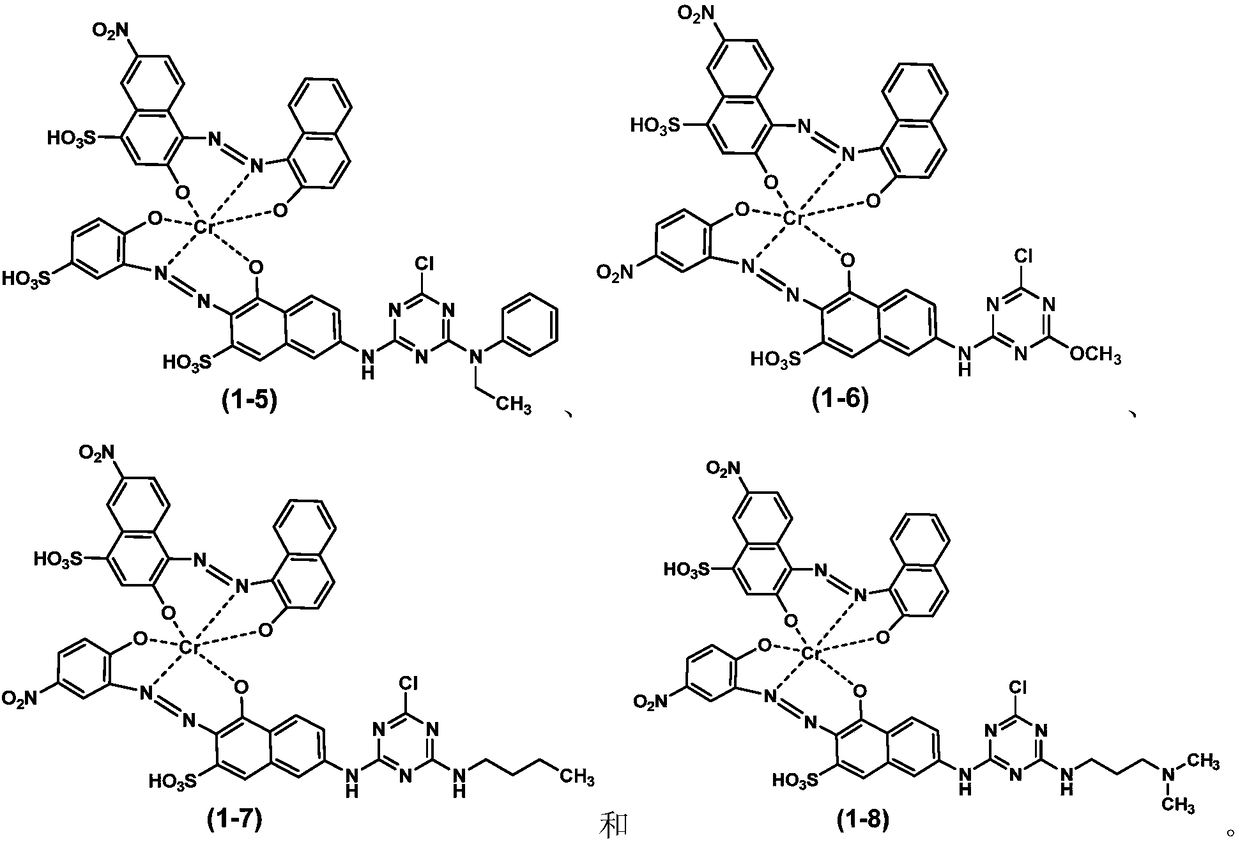

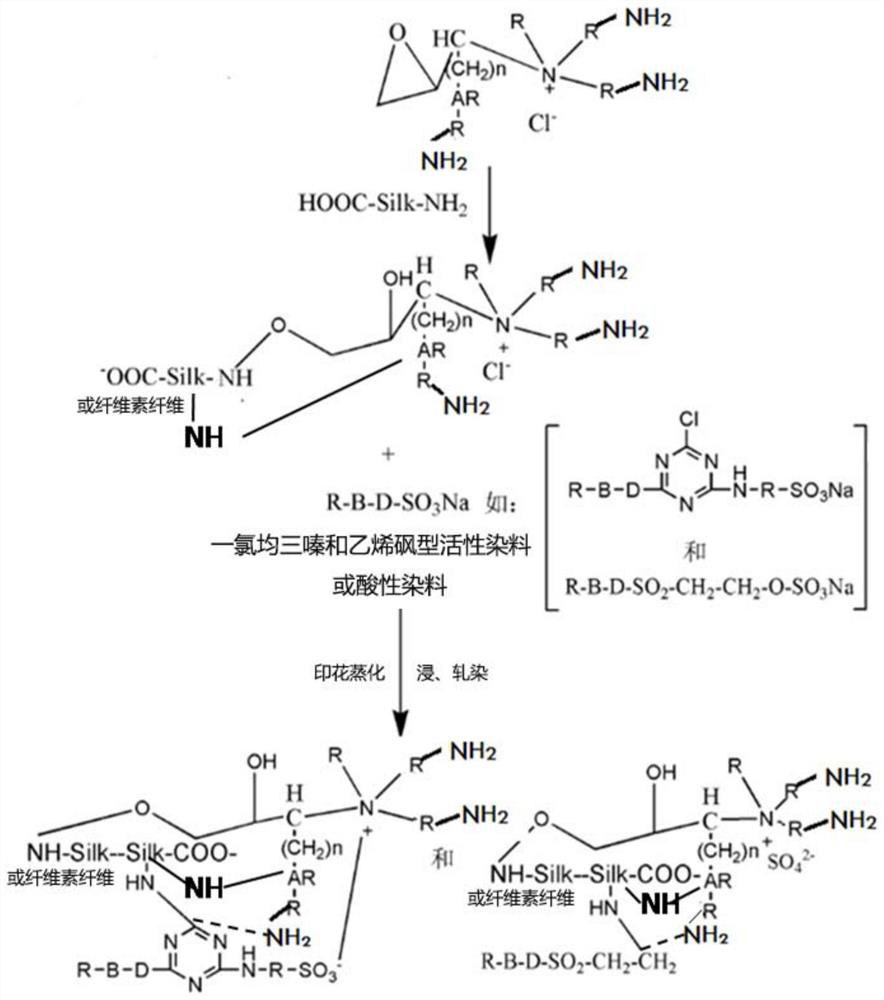

Asymmetric metal complex black dye and preparation method thereof

ActiveCN108912724AHigh fastnessOptimize the dyeing processDyeing processComplex metal azo dyesFiberAcid dye

The invention relates to an asymmetric metal complex black dye and a preparation method thereof. Specifically, the asymmetric metal complex black dye has a structure represented by the following formula (1). The dye combines the advantages of acid dyes and reactive dyes, and is suitable for printing dyeing of fiber materials containing hydroxyl or amino groups. The dyeing process is simple, stableand reliable, and the dyeing effect is excellent. The material dyed by the dye has good fastness to wet and fastness to daylight.

Owner:上海青石化学有限公司

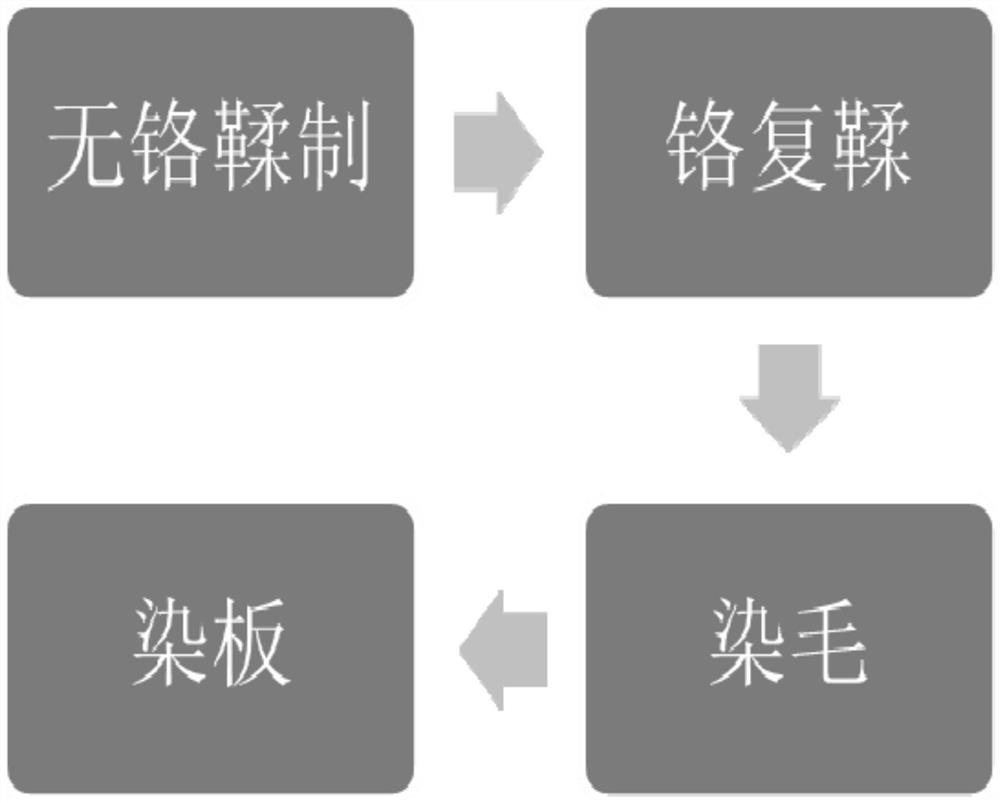

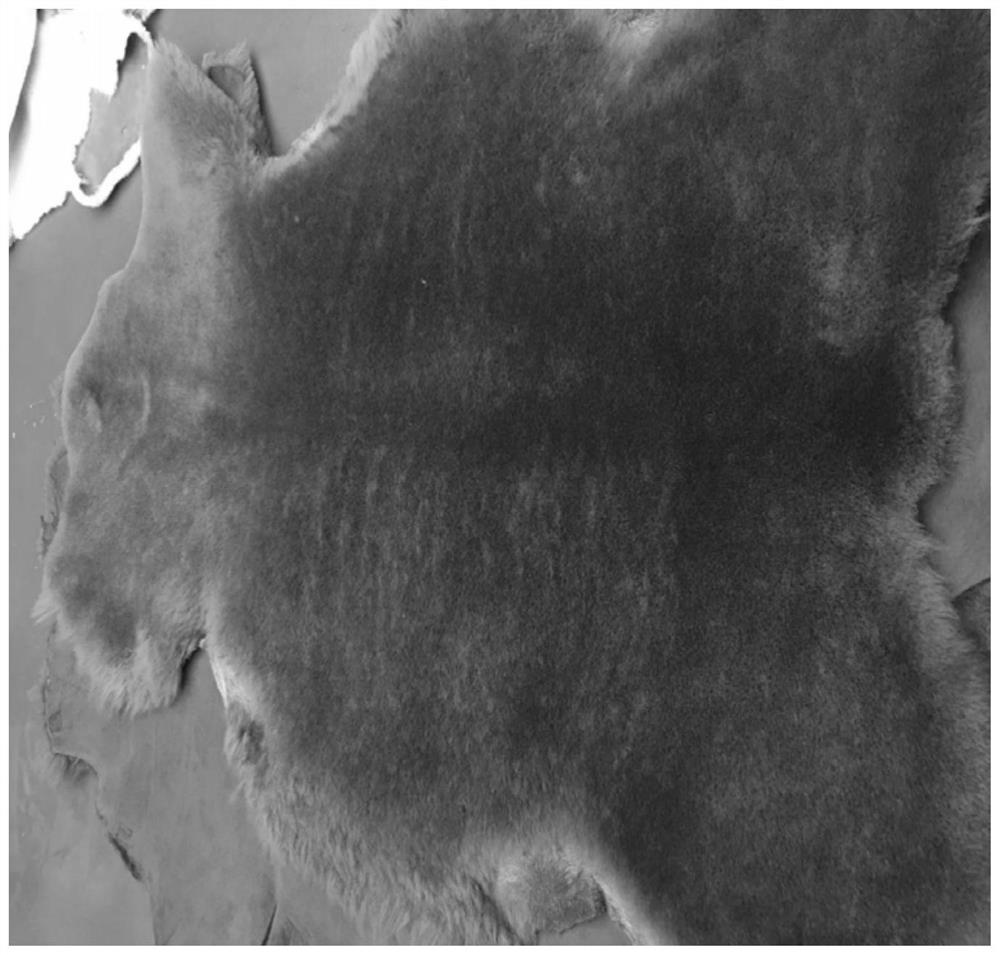

Dyeing process for improving level dyeing property of sheared fine-wool leather

ActiveCN112391857AShorter rotation timeImprove uniformityTanning treatmentTextile/flexible product manufacturePerformance indexEngineering

The invention provides a woolen leather dyeing process which comprises the following step of carrying out wool dyeing and plate dyeing on a retanned woolen leather material so as to obtain dyed woolenleather, wherein a wool dyeing agent used in the wool dyeing step comprises an alkyl phosphate dyeing auxiliary agent; and in the plate dyeing step, a fatting agent is added firstly, and then dye isadded. According to the dyeing process for improving the level dyeing property of the sheared fine-wool leather provided by the invention, the combination of the dye and a wool quilt is greatly improved, the level dyeing property is improved, the combination of the plate dyeing dye and the wool quilt is reduced, the uniformity of wool color is finally improved, the convenience in operation is realized, the production cost is low, the dyeing process is suitable for mass production, the product is environment-friendly and safe, and various safety performance indexes are qualified.

Owner:隆丰革乐美时尚有限公司

Ultrasonic dyeing machine

ActiveCN102535064BIncrease speedHigh color yieldVibration treatmentCirculating pumpUltrasonic generator

The invention discloses an ultrasonic dyeing machine. The machine comprises a cloth feeding and discharging component, a cloth lifting component, a nozzle component, a main cylinder, a net cage component, a main pump component, a circulating pump component, a barrel component, a water preparing bucket component, a heat exchanger component and a filter component, wherein a plurality of ultrasonic transducers are respectively arranged in the net cage component and on the pipe wall of a cloth guide pipe and are connected in parallel with the same ultrasonic generator; the ultrasonic generator is connected with a control panel through a signal wire; and a computer chip and analog-to-digital (A / D) and digital-to-analog (D / A) conversion circuits are arranged on the control panel. The ultrasonic dyeing machine is relatively low in cost and can be suitable for dyeing and finishing various fabrics, ultrasonic frequency and intensity are easy to adjust, dye-uptake can be improved, dyes are saved, dyeing time is shortened, the sewage discharge capacity is reduced, and the requirements of energy conservation, emission reduction, low carbon and environment friendliness are met.

Owner:ZHEJIANG ZHONGTE INTELLIGENT EQUIP CO LTD

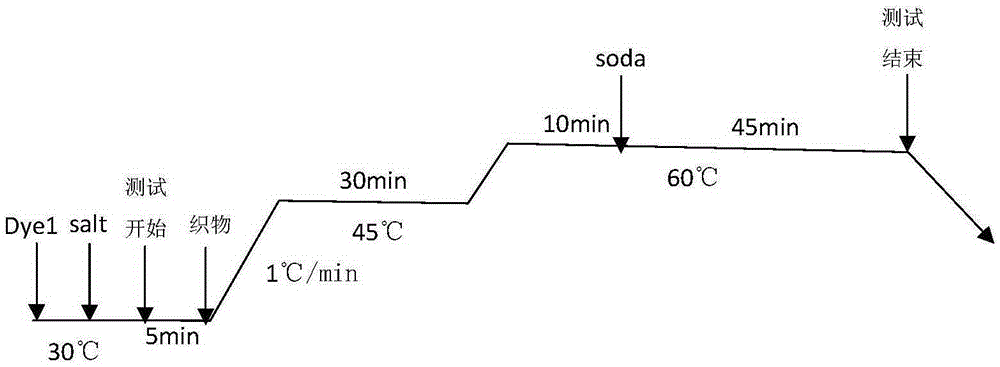

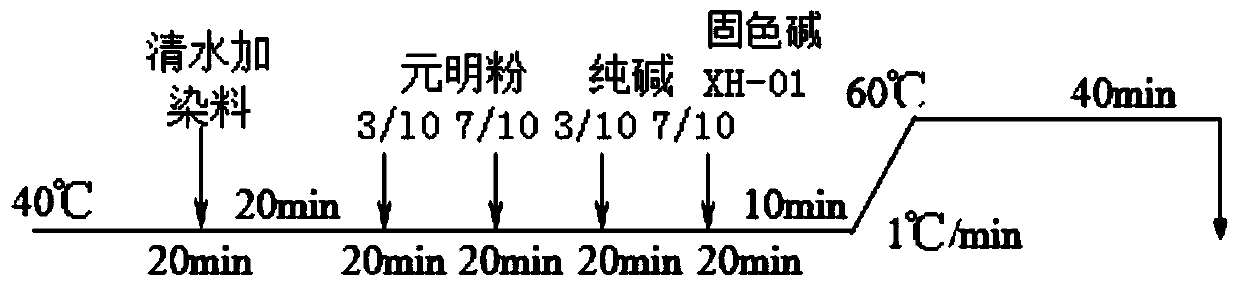

Reactive dye dyeing technology improvement

The invention discloses a reactive dye dyeing technology improvement. The adopted salt and alkali technology is good in levelling property, high in color yield, and short in dyeing time, after being added into a dyeing machine at normal temperature, salt and one third pure alkali are evenly adsorbed by a dyed article under the condition of no dyes, so as to eliminate negative charges on fibers and ionize partial hydroxyls in the fibers, then dyes are slowly added to generate adsorption, diffusion, dye uptake and bonding color fixation; due to the low temperature and pH value, the initial dyeing rate and the color fixation speed are low, the color fixation is performed while dye uptake so as to achieve the levelling effect, the dye uptake percentage and the color fixation increased can be improved by heating, and after the dye uptake and the color fixation are greatly improved, the alkali is secondarily added for color fixation, the pH value of dye bath can be increased, the color fixation percentage is increased, the step-by-step heating and the twice alkali addition are adopted during the whole dyeing process, so that the hydrolysis of the dyes can be reduced, the color yield can be increased, the salt is relatively conveniently added relative to thick and deep color products with the relatively high amount of the salt and the alkali, and the technology control is facilitated.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

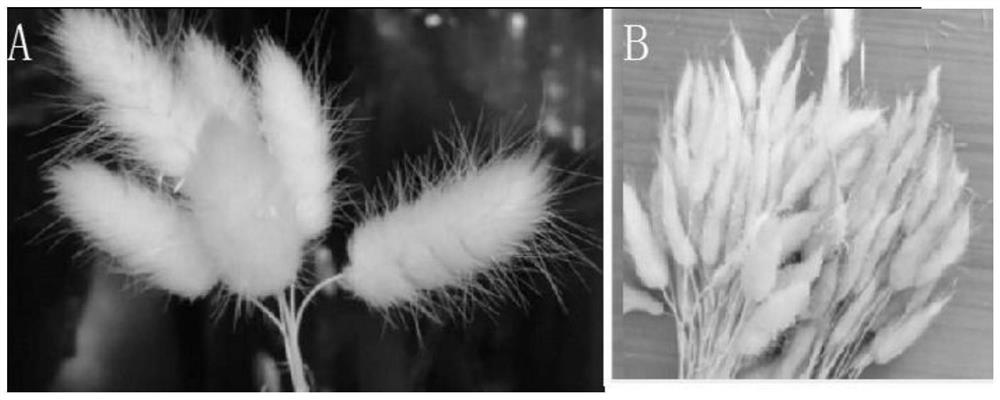

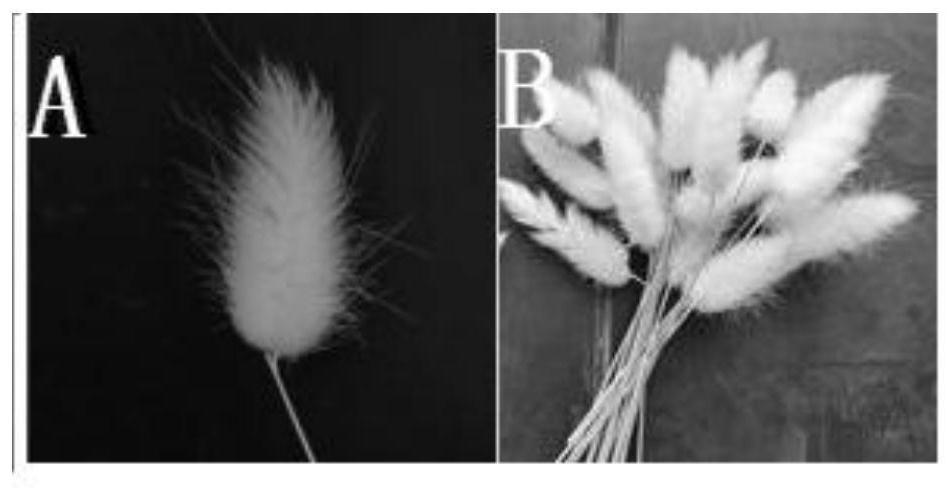

Bleaching method for improving fluffy degree of cyclamen grass

InactiveCN111775250ASolve problems such as adhesionImprove bleaching effectWood treatment detailsReed/straw treatmentSodium chlorateSodium chlorite

The invention discloses a bleaching method for improving fluffy degree of cyclamen grass , and belongs to the technical field of dry flower bleaching preparation. The method disclosed by the inventioncomprises the following steps: randomly selecting cyclamen grass, soaking the cyclamen grass in a mixed solution of sodium chlorite and concentrated hydrochloric acid, heating in a water bath to 40-60 DEG C, and soaking for 2.8-3.2 hours; cleaning the cyclamen grass with water, soaking the cleaned cyclamen grass in a hydrogen peroxide solution, and heating the soaked cyclamen grass in a water bath to 40-60 DEG C for 1.8-2.2 hours; and cleaning and quickly blow-drying by using hot air to obtain the cyclamen grass. The cyclamen grass prepared by the method is good in fluffy degree and uniform in color, and hair does not fall off in the bleaching process.

Owner:YUXI NORMAL UNIV

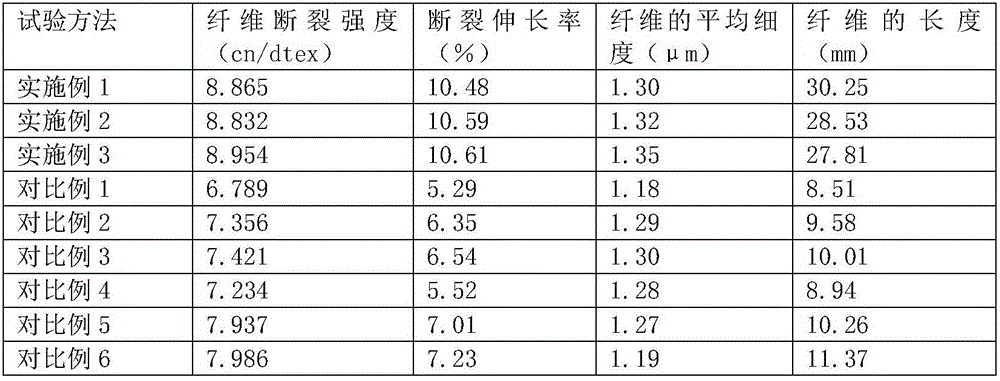

Garlic sprout leaf fiber

ActiveCN105839417AHigh degumming rateShort degumming timeUltrasonic/sonic fibre treatmentBiochemical treatment with enzymes/microorganismsEnzymeMicrowave

The invention provides garlic sprout leaf fiber with the fracture intensity being 8.5 to 9cn / dtex, the fracture elongation rate being 10 to 11 percent and the fiber length being 20 to 40mm. Preparation steps of the garlic sprout leaf fiber include composite acid pretreatment, low-temperature plasma treatment, microwave radiation and complex enzyme alternate treatment, water washing, soaping, dewatering, fluffing, oiling and drying. The preparation method has the advantages that the fiber degumming time can be shortened; garlic sprout leaf surface attachments can be reduced; the spinning performance can be improved.

Owner:朱兰英

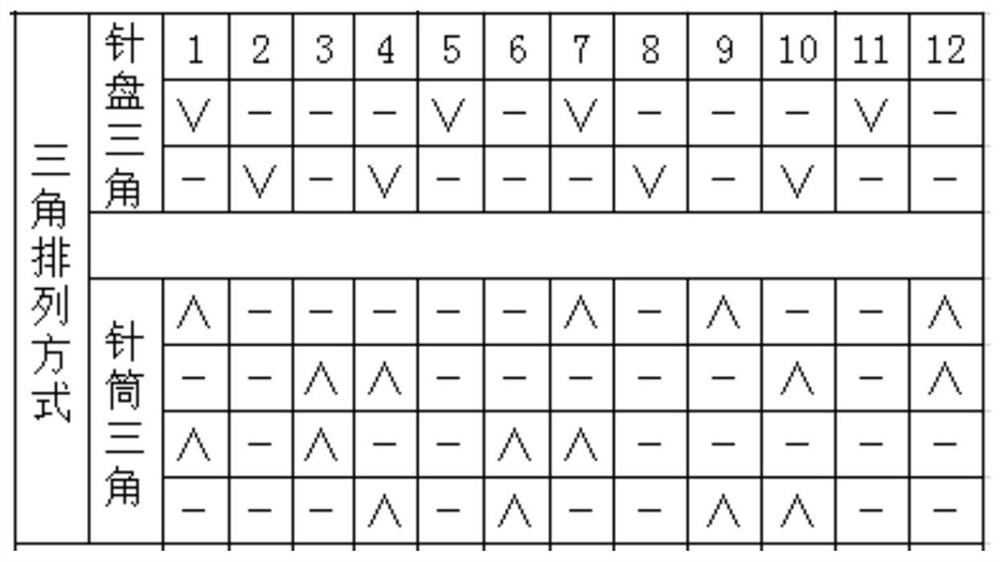

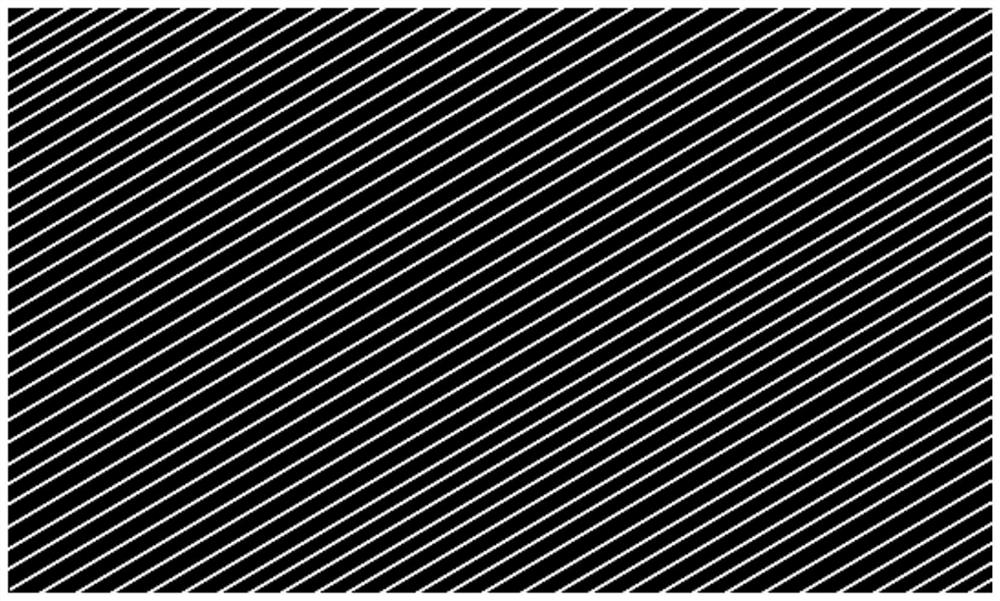

Production method of weft knitted suede fabric with double-color inclined stripe appearance

PendingCN112779655ASoft and delicate touchSoft and elegant lusterWeft knittingHeating/cooling textile fabricsPolyesterWoven fabric

The invention discloses a production method of a weft knitted suede fabric with a double-color inclined stripe appearance. The production method comprises the following steps of providing a double-sided machine, and arranging triangles and knitting needles according to fabric design requirements; providing yarns, wherein the yarns comprise sea-island filaments, polyester low stretch yarns and spandex; and weaving by using the double-sided machine and adopting 12 paths as a cycle to obtain a fabric with two kinds of twill, and sequentially performing pretreatment, pre-shaping, splitting, dyeing, raising and shaping processes on the woven fabric to obtain the weft-knitted suede fabric with the double-color inclined stripe appearance. The spandex, the polyester low stretch yarn and the sea-island low stretch yarn are ingeniously combined, a reasonable knitting technology is matched, and then a dyeing technology is matched, so that the fabric is endowed with a delicate and fashionable appearance effect with double-color inclined stripes, soft and fine touch feeling and soft and elegant luster. Moreover, the production method disclosed by the invention is short in process flow and low in production cost, and the obtained product is stable in quality and convenient to popularize and apply.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

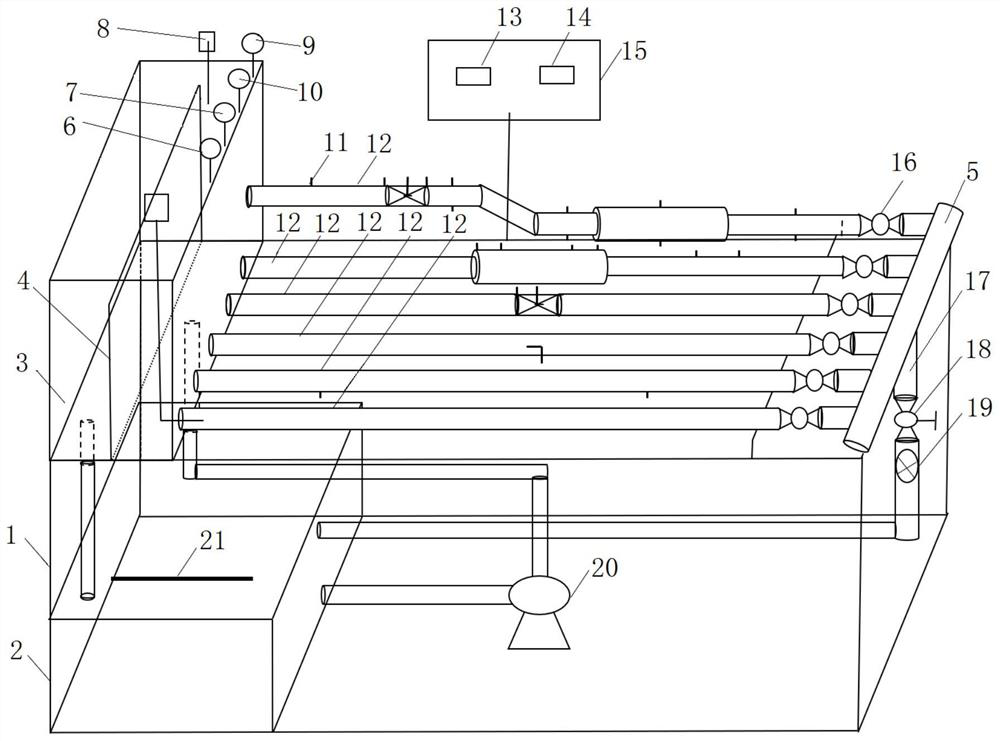

Multi-flow-state dyeing medium mechanical measurement system

PendingCN113588009AEasy, quick and efficient operationOptimize the dyeing processHydrodynamic testingPH meterLiquid storage tank

The invention relates to a multi-flow-state dyeing medium mechanical measurement system which comprises a plurality of measuring pipes, one end of each measuring pipe is communicated with a pressure stabilizing water tank, the other end of each measuring pipe is communicated with a liquid storage tank through a return pipe, the liquid storage tank is connected with the pressure stabilizing water tank through a water pump, and the liquid storage tank is used for storing a dyeing medium. The water pump is used for pumping the dyeing medium in the liquid storage tank to the pressure stabilizing water tank, each measuring pipe is provided with an electromagnetic valve, the return pipe is provided with a proportional valve and a flow meter, a measuring device is connected in the pressure stabilizing water tank, and the measuring device comprises a temperature sensor, a chloride ion concentration meter, a sodium ion concentration meter, a pH meter and a conductivity meter. According to the invention, the chloride ion concentration, the sodium ion concentration, the pH value, the conductivity, the temperature and other parameters in the multi-flow-state dyeing medium can be accurately measured and monitored, the motion state of dye particles in the dyeing medium can be analyzed, and the dyeing process can be optimized.

Owner:SUZHOU UNIV

Linen fiber warping and slashing process

InactiveCN110923874AShorten the weaving processShorten the production cycleYarnVegetal fibresProcess engineeringFlax fiber

The invention discloses a linen fiber warping and slashing process, which comprises the following steps of (1) pretreatment, (2) warping process, and (3) slashing process. Through above modes, the weaving process can be greatly shortened, the production period is shortened, and the production efficiency is improved. And a dyeing process is optimized.

Owner:CHANGSHU CHANGHONG TEXTILE

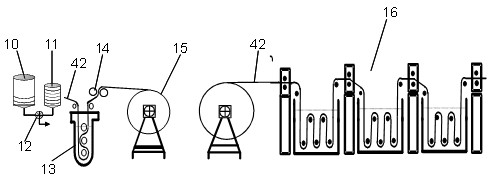

A double-width linkage pretreatment method for pure cotton fabric

ActiveCN103696223BReduce energy consumptionShorten the timeDry-cleaning apparatus for textilesBleaching apparatusPretreatment methodPulp and paper industry

The invention belongs to the technical field of fabric pretreatment technology in the printing and dyeing industry, and in particular relates to a double-width linkage pretreatment method for pure cotton fabrics. That is, a process of double-width desizing, scouring, bleaching, and double-width mercerizing, especially the process of double-width desizing, double-width scouring and double-width bleaching of fabrics, including double-width desizing, double-width scouring, double-width bleaching, and double-width mercerization. The cloth feeding method is double-width feeding Cloth, the steps are as follows: add surfactant HF-A01: 1-4g / L, surfactant HF-JL4: 2-6g / L, caustic soda 45-50g / L, perform double-width padding, and then put the fabric at 90 Steam at -94°C for 2 hours; then wash in hot water, cold water, and squeeze water in sequence; then perform the second double-width padding bleaching solution 2-2.5g / L, then sequentially wash in cold water, squeeze water; Padding with sulfuric acid 1-1.5g / L three times, followed by cold water washing and double-width mercerizing, the treatment is completed. The process steps are simple, the energy consumption is reduced by 1 time, the desizing effect is good, the damage to the cloth surface is reduced, and the production efficiency is improved by 1 time.

Owner:HUAFANG

Salt-free alkali-free washing-free dyeing method for all-cotton and regenerated cellulose fabric

InactiveCN111996722AEmission reductionSaving dyeSucessive textile treatmentsHeating/cooling textile fabricsProcess engineeringBatch reaction

The invention discloses a salt-free alkali-free washing-free dyeing method for an all-cotton and regenerated cellulose fabric. The salt-free alkali-free washing-free dyeing method comprises the following steps that 1, fixation synergistic no-clean amine is rolled, a semi-finished fabric is placed on padding equipment, the fabric is soaked in the fixation synergistic no-clean amine through a plurality of guide rollers, the fabric is uniformly rolled through a double-roller padder, the fabric is flatly rolled on an A-shaped frame, rotary cold batch is carried out for 1 to 48 hours; after the cold-batch reaction, washing with a continuous washing machine for the first time and drying are carried out; 2, dyeing is carried out, the fabric is put into the double-roller padder again, the fabric is soaked in the dyeing solution by virtue of the plurality of uniform guide rollers, the fabric is rolled by virtue of a roller, the fabric is rolled on an A-shaped frame in a wet manner, and rotary cold batch is carried out for 1-24 hours to react and fix the color; the fabric is directly dried without washing, the drying temperature ranges from 80 DEG C to 180 DEG C, padding is conducted througha setting machine, a fabric softening agent is added, the PH value is adjusted, other after-finishing auxiliaries are used for tentering and shaping, the shaping temperature ranges from 100 DEG C to180 DEG C; and final preshrinking, calendaring and other processes are carried out, and a finished product is inspected and packaged. The method II comprises the following steps that 1, the fixation synergistic no-clean amine is rolled, the semi-finished fabric is put on the padding equipment, the fabric is soaked in the fixation synergistic no-clean amine by virtue of the plurality of guide rollers, uniform rolling and direct drying at 80-180 DEG C for later use are carried out, the fabric is subjected to dip dyeing in a dye vat or uniform pad dyeing through the double-roller padder and thenis dried, softened and shaped, the shaping temperature ranges from 100 DEG C to 180 DEG C; and the final preshrinking, calendaring and other processes are carried out, and the finished product is inspected and packaged.

Owner:杭州帛阳新材料科技有限公司

A kind of production process of tr four-way stretch blended blanket

ActiveCN106223068BIncrease profitActive realizationSucessive textile treatmentsLiquid/gas/vapor removalDisperse dyeProcess engineering

The invention relates to a production process of a T / R (polyester / rayon) four-way stretch blended blanket, comprising the steps of selecting a material, spinning, warp knitting, cutting, repairing, sizing and setting, pre-shearing and coiling, printing and dyeing, decating, washing with water, tentering, inspecting, opening, napping, polishing and shearing, and tailoring, wherein the material is T / R four-way stretch composite fabric. The dyeing process in conventional blended blanket production is modified, strong-alkali-tolerant high-salinity-tolerant disperse dyes and high-temperature-resistant active dyes are screened in connection with special leveling agent and a color fixing agent, the dyeing process is optimized, one-bath dyeing with active and disperse dyes for T / R fabric is achieved, and dye utilization rate is increased; the process has the advantages of high integrity, stable production quality, low energy consumption and the like, the produced T / R four-way stretch product has good color-light control precision and good surface flatness, and production energy consumption and pollutant emission are effectively reduced.

Owner:ZHEJIANG TRUELOVE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com