Foam spraying dyeing method adopting reactive dyes

A reactive dye and dyeing method technology, applied in the field of textile dyeing, can solve the problems of difficulty in controlling the stability of low-humidity baking conditions, difficulty in controlling humidity and temperature fluctuations of baking devices, and difficulty in controlling temperature and humidity, so as to improve energy efficiency. , the effect of reducing pollution discharge and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

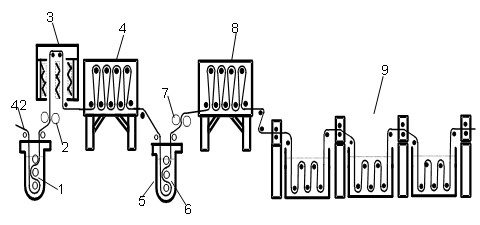

[0032] Such as Figure 6 As shown, it is a schematic diagram of a textile spray dyeing device using reactive dyes that adopts baking and color fixing. For the baking device 36, the output side of the color fixing device is provided with a washing device 37, and the input side of the color fixing device is provided with a foam applicator 35, and the foam applicator 35 is connected to the foam generator 33 through a pipeline 44, and the foam generator 33 is connected to the ratio The outlet of the pump 32 and the inlet of the proportional pump 32 are connected to the reactive dye solution tank 31 and the fixing solution tank 30 . The foam applicator 35 has a slit-shaped outlet 43 arranged transversely on the fabric 42 . The width of the slit-shaped outlet 43 is 1 mm, and the foam generator 33 is connected to the PLC34.

[0033] The method for dyeing and producing orange cotton woven fabric by using the above-mentioned device: comprising mixing the reactive dye solution...

Embodiment 2

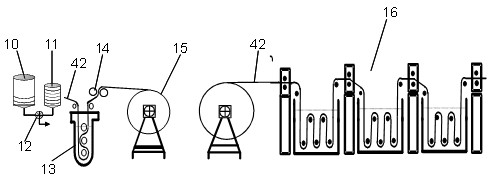

[0059] Such as Figure 7 As shown, it is a schematic diagram of a textile spray dyeing device using reactive dyes that adopts steaming and color fixing, and the described textile spray dyeing device that uses reactive dyes that uses baking and color fixing includes a color fixing device, and the color fixing device It is a steaming device 38, the output side of the color fixing device is provided with a water washing device 39, and the input side of the color fixing device is provided with a foam applicator 35, and the foam applicator 35 is connected to the foam generator 33 through a pipeline 44, and the foam generator 33 is connected to the ratio The outlet of the pump 32 and the inlet of the proportional pump 32 are connected to the reactive dye solution tank 31 and the fixing solution tank 30 . The foam applicator 35 has a slit-shaped outlet 43 arranged transversely on the fabric 42 . The width of the slit-shaped outlet 43 is 8 millimeters, and the foam generator 33 i...

Embodiment 3

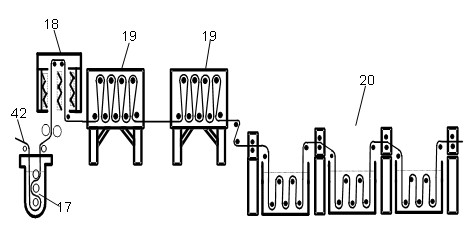

[0086] Such as Figure 8 As shown, it is a schematic diagram of a textile spray dyeing device using reactive dyes that adopts cold stack color fixing, and the described textile spray dyeing device that uses reactive dyes that uses baking and color fixing includes a color fixing device, and the color fixing device It is a cold pile device 40, the output side of the color fixing device is provided with a water washing device 41, and the input side of the color fixing device is provided with a foam applicator 35, and the foam applicator 35 is connected to the foam generator 33 through a pipeline 44, and the foam generator 33 is connected to the ratio The outlet of the pump 32 and the inlet of the proportional pump 32 are connected to the reactive dye solution tank 31 and the fixing solution tank 30 . The foam applicator 35 has a slit-shaped outlet 43 arranged transversely on the fabric 42 . The width of the slit-shaped outlet 43 is 4 millimeters, and the foam generator 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com