Comfortable silk fabric and dyeing method thereof

A dyeing method and technology for real silk, applied to comfortable real silk fabrics and the field of dyeing, can solve the problems of poor homochromaticity, cumbersome production process, long processing time, etc., and achieve enhanced color purity, improved color unevenness, and improved saturation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

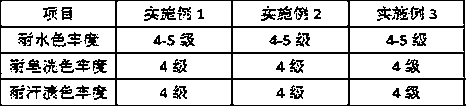

Embodiment 1

[0018] A comfortable silk fabric, the warp is made of 20 / 22D silk, the weft is made of 40S Lenzing Modal, and five pieces of three-flying satin weave are used. The front side mainly reveals the silk yarn, and the back side mainly reveals the modal yarn.

[0019] A dyeing method for comfortable silk fabrics: Dyeing with reactive dyes and one-bath one-step dip-dyeing process, low-temperature dyeing, adding anti-dyeing agent at 30°C, adding dye after the dyeing vat runs for 20 minutes, and then adding NaCl in 3 times, each interval 7min, continue to run for 30min, then add soda ash in 3 times, each interval is 7min, slowly heat up to 90°C, heating rate 1.5°C / min; keep warm and dip for 40min, drain, add water and heat up to 90°C, soap for 15min, drain , to complete the dyeing process;

[0020] Further, the dyes are Cohuasu G Black, Cohuasu 3BS Red and Cohuasu 3RS Yellow;

[0021] Further, the dosage of the dyes is 60g / L of Kehuasu G black, 8.5g / L of Kehuasu 3BS red, and 2.8g / L of...

Embodiment 2

[0026] A comfortable silk fabric, the warp is made of 20 / 22D silk, the weft is made of 50S Lenzing Modal, and five pieces of three-flying satin weave are used. The front side mainly reveals silk yarn, and the back side mainly reveals modal yarn.

[0027] A dyeing method for comfortable silk fabrics: Dye the fabric with reactive dyes and one-bath one-step dip-dyeing process, enter the dyeing at low temperature, add anti-dyeing agent at 30°C, add dye after the dyeing vat runs for 25 minutes, and then add NaCl in 4 times, Each interval is 8 minutes, continue to run for 5 minutes, add soda ash in 45 times, each interval is 8 minutes, slowly heat up to 90°C, heating rate is 2°C / min, keep warm and dip for 45 minutes, drain, add water, heat up to 90°C, and soap for 15 minutes , Drainage, complete the dyeing process.

[0028] Further, the dyes are Cordair G black, Cordair 3BS red and Cordair 3RS yellow.

[0029] Further, the dosage of the dyes is 60 g / L of Kehuasu G Black, 8.5 g / L of...

Embodiment 3

[0034] A comfortable silk fabric, the warp is made of 20 / 22D silk, the weft is made of 60S Lenzing Modal, and five pieces of three-flying satin weave are used. The front side mainly reveals the silk yarn, and the back side mainly reveals the modal yarn.

[0035] Another object of the present invention is to provide a dyeing method for comfortable silk fabrics: use reactive dyes and one-bath one-step dip-dyeing process to dye the fabrics, enter dyeing at low temperature, add anti-dyeing agent at 30°C, and add dyes after the dyeing vat runs for 20 minutes , and then add NaCl in 5 times, with an interval of 10 minutes each time, continue to run for 30 minutes, then add soda ash in 5 times, with an interval of 10 minutes each time, slowly raise the temperature to 90 ° C, the heating rate is 1.5 ° C / min, keep warm and dip for 50 min, drain, and then add water Raise the temperature to 90°C, soap for 15 minutes, and drain the liquid to complete the dyeing process.

[0036] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com