Wavelength conversion element and its preparation method, illumination source

A technology of wavelength conversion element and laser light source, which is applied in the direction of light source, lighting device, lighting and heating equipment, etc., can solve the problems of uneven mixing of blue light and yellow light, large difference in etendue, single luminous wavelength, etc., and achieve improvement The effects of uneven color, good optical performance, and high color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

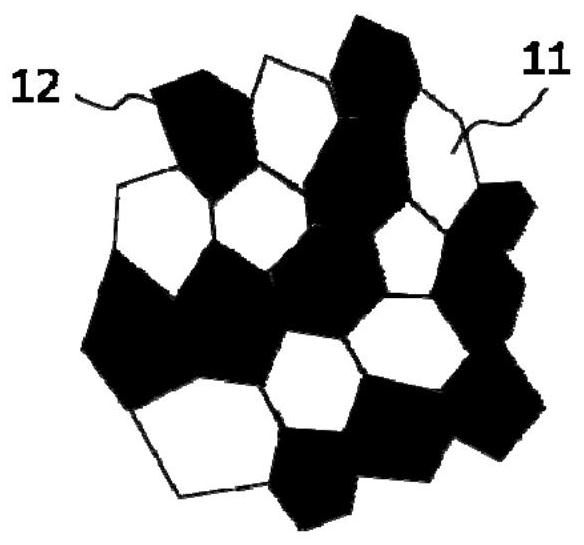

[0029] In this embodiment, the RE is Ce, that is, the first phase RE 3+ :Al 2 o 3 The crystal phase is the first phase Ce 3+ :Al 2 o 3 crystal phase, the wavelength conversion element is Ce 3+ :YAG and Ce 3+ :Al 2 o 3 Composed of multiphase ceramics, where the first phase Ce 3+ :Al 2 o 3 The molar ratio of Ce to (Ce+Al) in the crystal phase is 0.02-0.1, the second phase Ce 3+ : the mol ratio of Ce and (Ce+Al) in the YAG crystal phase is 0.001-0.1, and the Ce 3+ :Al 2 o 3 and Ce 3+ : The molar ratio of YAG is 0.2-5.

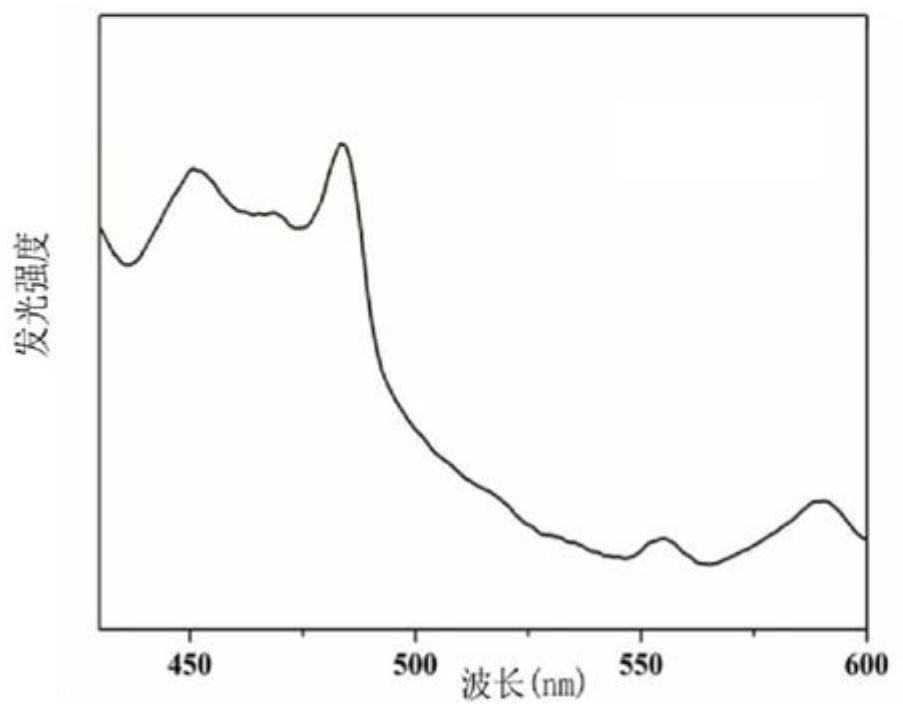

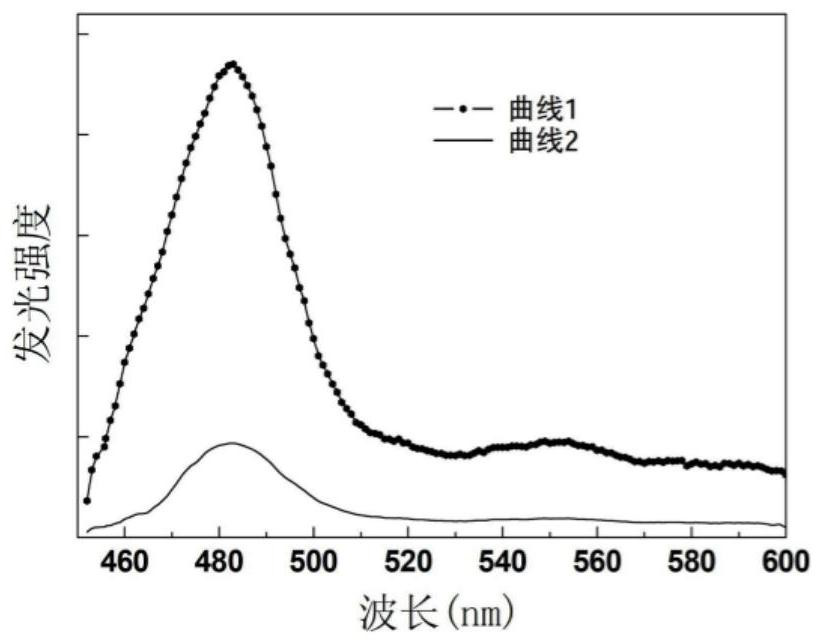

[0030] figure 2 It is the emission spectrum of the first phase under the excitation of 375nm excitation light in Example 1 of the present invention. Such as figure 2 As shown, the excitation light source is selected as a 375nm ultraviolet laser, and the laser light source emits excitation light with a first wavelength of 375nm and is incident on the wavelength conversion element, which is absorbed by the first phase Ce in the wavelength convers...

Embodiment 2

[0038] In this embodiment, the RE is Yb and / or Yb+Nd, that is, the first phase RE 3+ :Al 2 o 3 The crystal phase is the first phase Yb 3+ :Al 2 o 3 crystal phase, or the first phase Nd 3+ ,Yb 3+ :Al 2 o 3 crystal phase, or Yb 3+ :Al 2 o 3 with Nd 3+ ,Yb 3+ :Al 2 o 3 common crystalline phases. where, when the first phase RE 3+ :Al 2 o3 The crystal phase is the first phase Yb 3+ :Al 2 o 3 Crystal phase, the molar ratio of Yb and (Yb+Al) is preferably 0.01-0.1; when the first phase RE 3+ :Al 2 o 3 The crystal phase is the first phase Nd 3+ ,Yb 3+ :Al 2 o 3 crystal phase, or Yb 3+ :Al 2 o 3 with Nd 3+ ,Yb 3+ :Al 2 o 3 When the crystal phase is composed together, the molar ratio of Nd and (Nd+Yb+Al) is 0.01-0.08, and the molar ratio of Yb and (Nd+Yb+Al) is 0.01-0.1, the second phase Ce 3+ : the molar ratio of Ce and (Ce+Al) in the YAG crystal phase is 0.001-0.1, and the RE 3+ :Al 2 o 3 and Ce 3+ :Al 2 o 3 The molar ratio is 0.5-10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com