Patents

Literature

179results about How to "Saving dye" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of easy-dyeing microfiber leather

InactiveCN105803816AStrong skeletonStrong environmental protectionDyeing processMicrofiberWoven fabric

The invention discloses a preparation method of easy-dyeing microfiber leather.The preparation method comprises the steps that 1, sea-island fibers are spun; 2, a non-woven fabric is made from the sea-island fibers; 3, heat setting is conducted on the non-woven fabric; 4, a polyurethane sizing agent is impregnated and cured, and then semi-finished synthetic leather is prepared; 5, decrement is conducted on the unfigured sea-island fibers through a methylbenzene stripping technology or decrement is conducted on the figured sea-island fibers through an alkali decrement stripping technology, and superfine fiber synthetic leather can be prepared; 6, softening treatment and sueding treatment are conducted, and then synthetic leather to be dyed can be prepared after treatment is finished; 7, the synthetic leather to be dyed is dyed with dispersed dye liquid or cationic dye liquid, and after dyeing is finished, the easy-dyeing microfiber leather is obtained.The easy-dyeing microfiber leather product prepared through the method has the advantages of being high in fiber content, skeleton sense and environmental friendliness, excellent in drapability and high in dyeing fastness.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

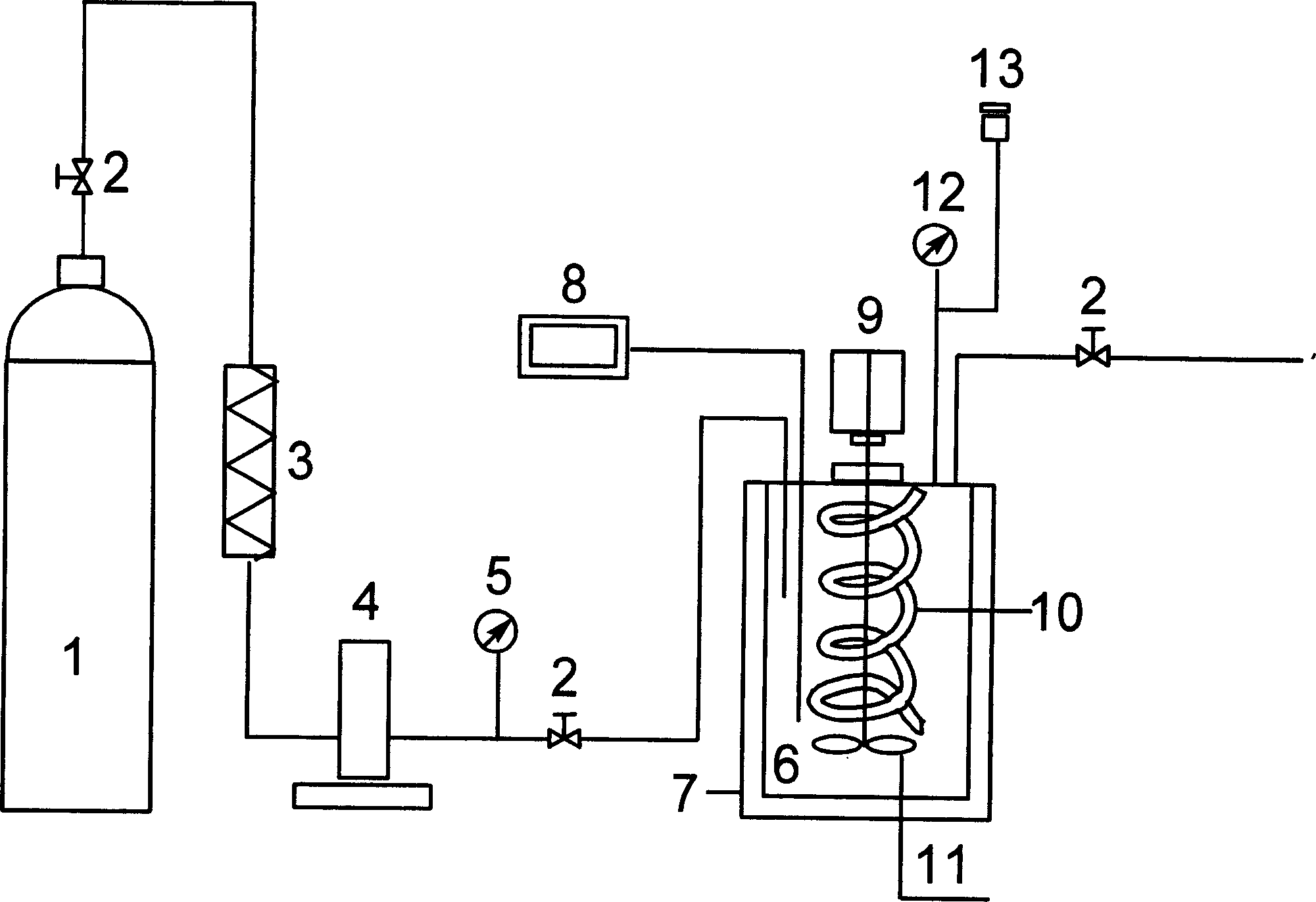

Technology for dyeing ramie fiber with overcritical carbon dioxide method

The invention relates to a new process of supercritical CO2 dyeing of ramie fiber, using ramie fiber as raw material, swelling by NaOH solution and modifying by benzoyl chloride, and dyeing with dispersive dye in supercritical CO2 medium by supercritical fluid technique. And its advantages: it is a clean producing process; the dyed ramie fiber has characters of bright color, short dyeing flow, dyeing uniformity, good color intensity, low synthetic cost, and remarkable economic and environmental protection benefits. And it also reveals a process device implementing the dyeing method, suitable to spread and apply in spinning and weaving, and printing and dyeing enterprises.

Owner:SHAANXI NORMAL UNIV

Sodium alga acid printing paste and preparation process thereof

The invention relates to sodium alga acid printing paste, comprising the following components in percent by weight: 60-90% of sodium alga acid, 5-15% of sodium hexametaphosphate and 5-25% of anhydrous sodium sulphate. The preparation method of the sodium alga acid printing paste comprises the following steps of: (1) weighing sodium alga acid, sodium hexametaphosphate and anhydrous sodium sulphate in the proportion of a formula; (2) smashing the sodium alga acid to 30-40 meshes; (3) placing smashed sodium alga acid, sodium hexametaphosphate and anhydrous sodium sulphate into a mixing tank to be stirred; and (4) stirring to be completely uniform, thus the sodium alga acid printing paste finished product is obtained. The sodium alga acid printing paste disclosed by the invention has the beneficial effects that (1) sodium carboxymethyl starch having adverse effects on colouring is removed, and anhydrous sodium sulphate which can activate active groups in dye and has high colouring rate is adopted; and (2) sodium hexametaphosphate can cause calcium ions or magnesium ions in water to enter into sodium hexametaphosphate molecules to be changed into stable soluble complex, thus permeability of the printing paste is improved, colour fastness is improved, and the dye can be saved.

Owner:青岛聚大洋藻业集团有限公司

Moisture-absorbing quick-drying yarn as well as production and manufacturing method thereof

The invention discloses a moisture-absorbing quick-drying yarn as well as a production and manufacturing method thereof. The yarn is manufactured by the blending of 65 to 80% of anti-pilling hollow highcount-type wool fiber and 20 to 35% of combed cotton or viscose in percentage by weight. By combining the high moisture thermal insulation of the Porel fiber and the hydrophilic moisture absorption of the cotton fiber and the viscose, the yarn of the invention can absorb the sweat completely and release the sweat to the air quickly to realize the dry and comfortable skin. The raw materials of the yarn are easy to obtain, the cost is low and the manufacture is convenient.

Owner:JIANGSU DASHENG GROUP

Urea-free active dye printing color paste and printing technology thereof

InactiveCN106192465AGood moisture absorptionGood hygroscopicityDyeing processSodium bicarbonateHigh concentration

The invention discloses urea-free active dye printing color paste and a printing technology thereof. The printing color paste is prepared from, by weight, 1%-10% of active dye, 0.5%-3% of PEG 200, 0.5%-3% of glycerol, 2%-5% of sodium bicarbonate, 0%-1% of sodium carbonate, 1% of reserve salt S, 3%-6% of a thickening agent PTF-RT and the balance water. A cotton fabric is printed through the printing color paste according to the processes of printing, drying, steaming and aftertreating, and the printed fabric is bright in color and luster and good in color fastness; urea is replaced with glycerol and PEG 200 for active dye printing, and therefore the problem that water eutrophication is caused by ammonia nitrogen compounds in wastewater can be thoroughly solved. The thickening agent PTF-RT is a high-concentration and high-quality synthetic thickening agent which is specially developed for active dye printing of the fabric, and the production cost is reduced by replacing sodium alginate with the thickening agent PTF-RT for active dye printing.

Owner:HENAN INST OF ENG

Neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics

ActiveCN102154230AReduce pollutionImprove water absorptionBiochemical fibre treatmentEnzymesPectinaseCellulose

The invention relates to a neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics. The neutral low-temperature refining enzyme comprises 15 to 50 weight parts of neutral cellulose, 30 to 70 weight parts of pectinase, 10 to 30 weight parts of xylanase, 5 to 30 weight parts of lipase and 10 to 15 parts of laccase. When the neutral low-temperature refining enzyme is used, cotton seed hulls, pectic substances, waxiness and the like can be removed effectively, the water absorptivity, fiber strength and dyeing property of cotton fabrics can be improved, dye can be saved, process time can be reduced and the production efficiency can be improved. A green processing method which is low in carbon content, environment-friendly and energy-efficient can be realized actually in the fabric dyeing industry.

Owner:沧州夏盛酶生物技术有限公司

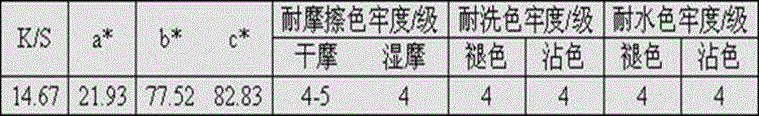

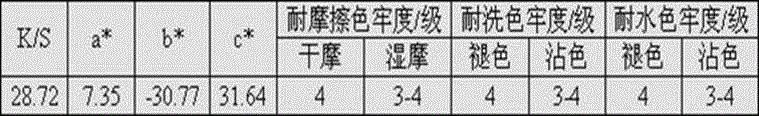

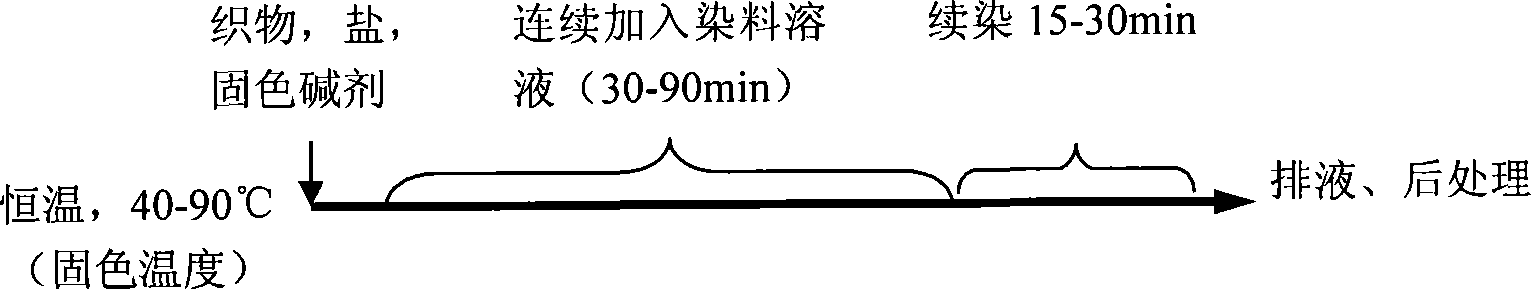

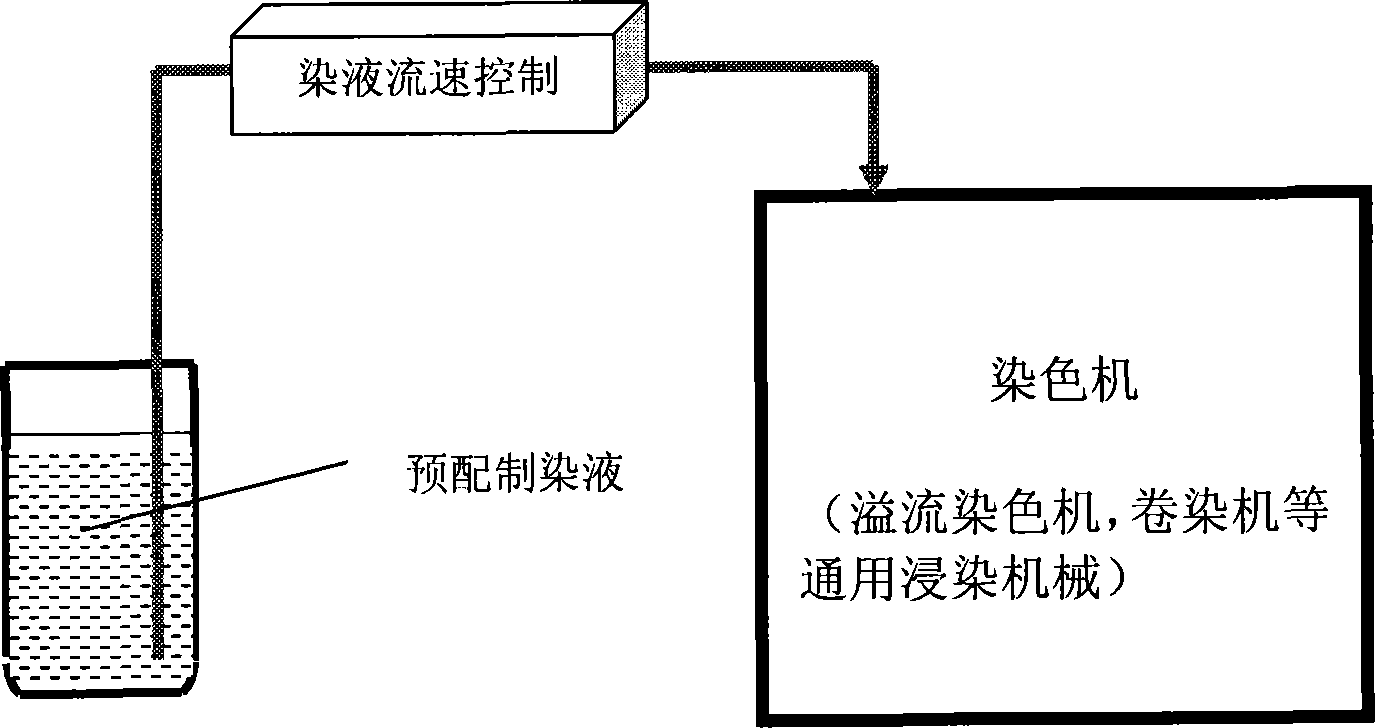

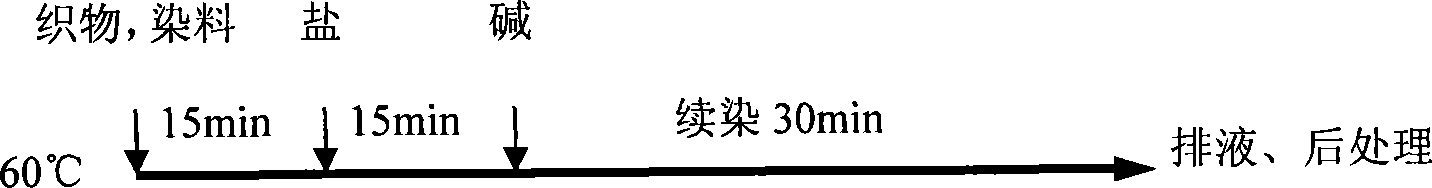

Dyeing method for improving reactive dye fabric tray dyeing color strength

The invention relates to a dyeing method for improving the dip-dye color depth of an active dye fabric, which includes: (1) when dyeing is started, adding the fabric, salt and a fixing agent, alkali, into a dye bath at the constant temperature of 40 to 90 DEG C to be operated for 10 to 30 minutes to lead the fabric to uniformly absorb the salt and alkali agent; (2) then using a continuous liquid adding device to add the dye slowly for 30 to 90 minutes, then continuously dying for 15 to 30 minutes; (3) after dyeing is finished, the fabric is washed by water, washed by soap, washed by water and then dried. The invention can acquire the color deeper than that of a normal technique, can remarkably save the dye, reduce the discharging of contaminations and is suitable for the developing direction of ecological energy-saving dyeing technique. The dyeing method is suitable for the dyeing of the fiber woven fabric and the knitting of fibrin such as cotton poplin, khaki and knitting, etc. The effect is extremely remarkable when dyeing a dark color.

Owner:DONGHUA UNIV

Melt-Coated Dosage Forms

InactiveUS20110217289A1High active ingredient loadingGood stabilityBiocidePretreated surfacesSolventFoam Dosage Form

Formulations of sparingly water-soluble active ingredientscomprising carrier particles provided with active ingredient-containing coatings, the sparingly soluble active ingredients being embedded in coatings composed of amphiphilic copolymers, and the coatings being applied in the form of a solvent-free melt.

Owner:BASF SE

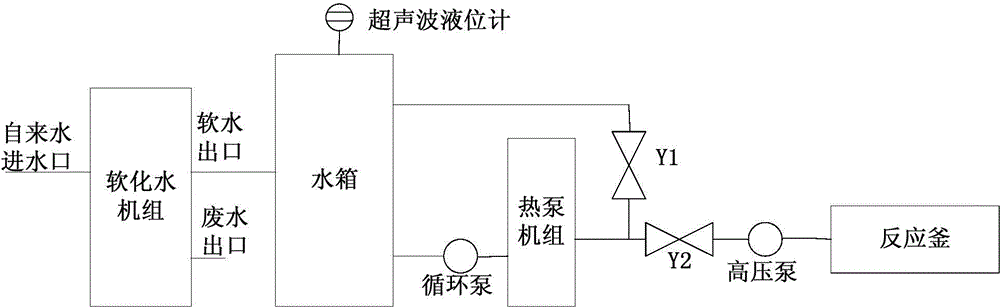

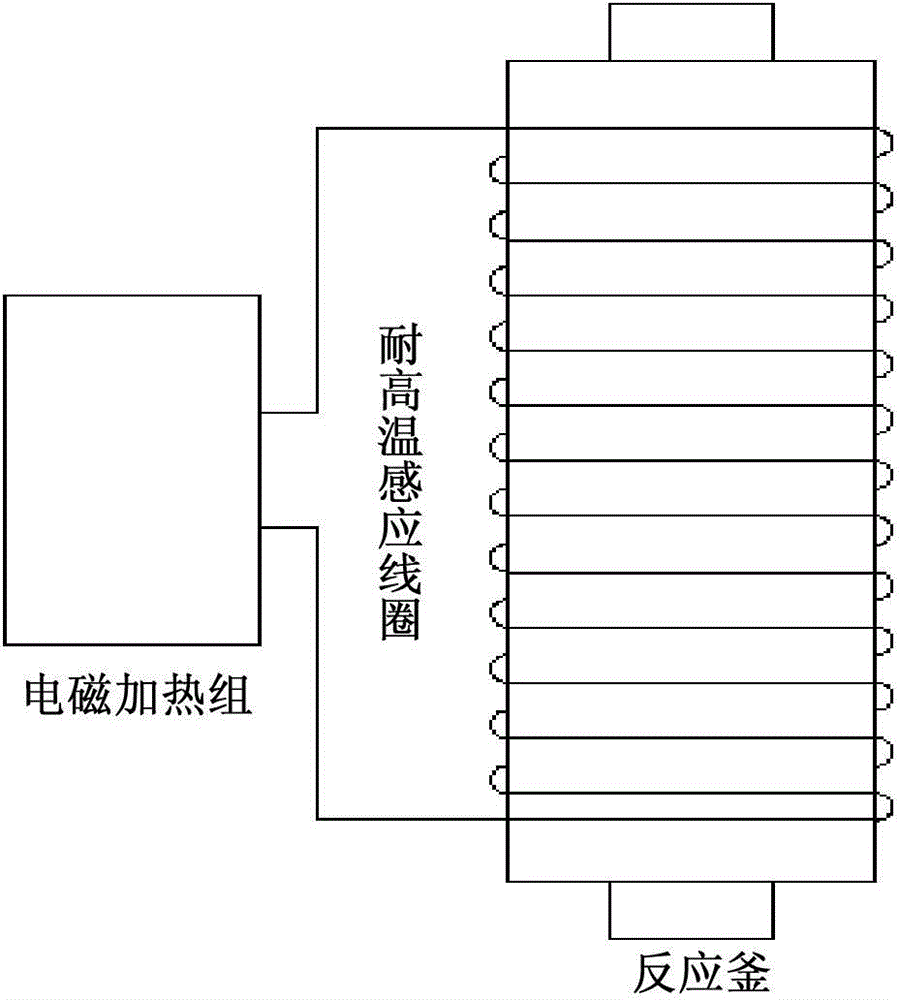

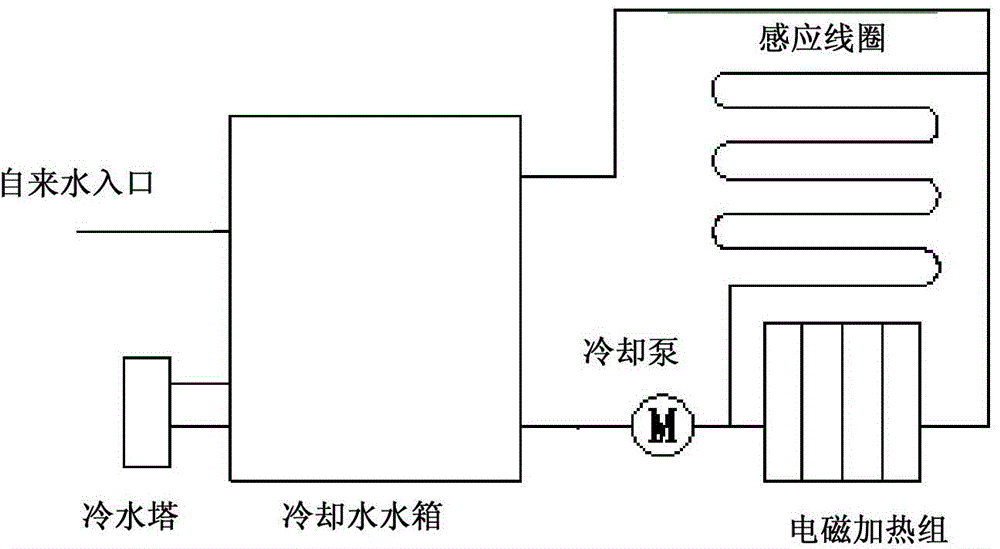

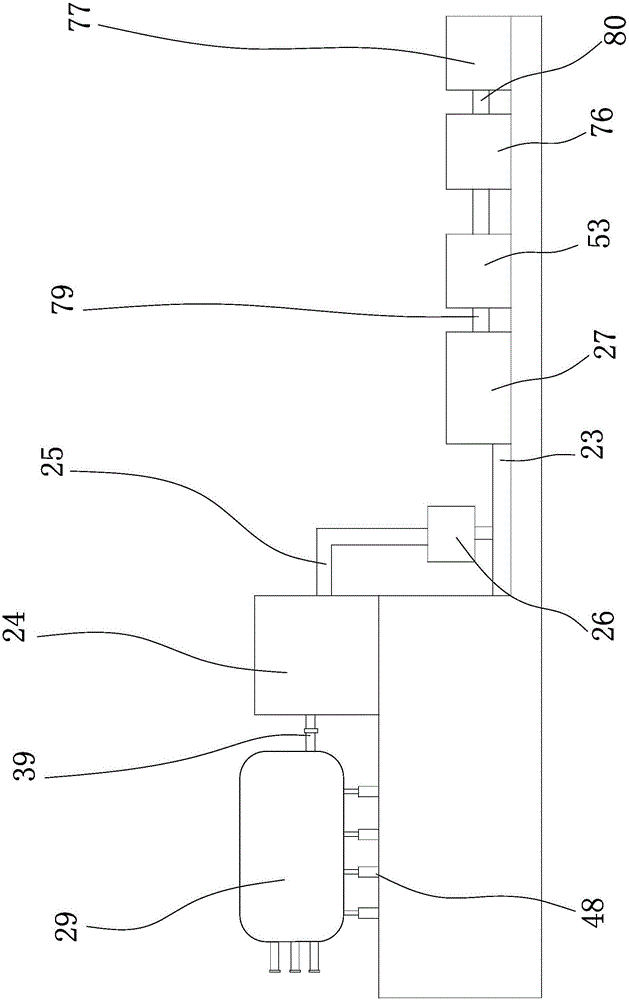

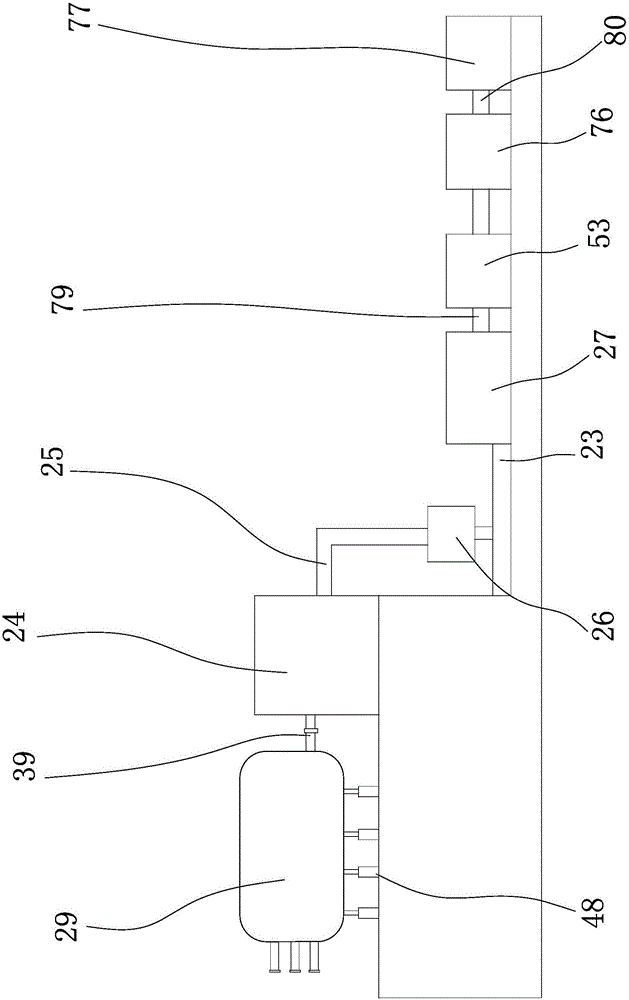

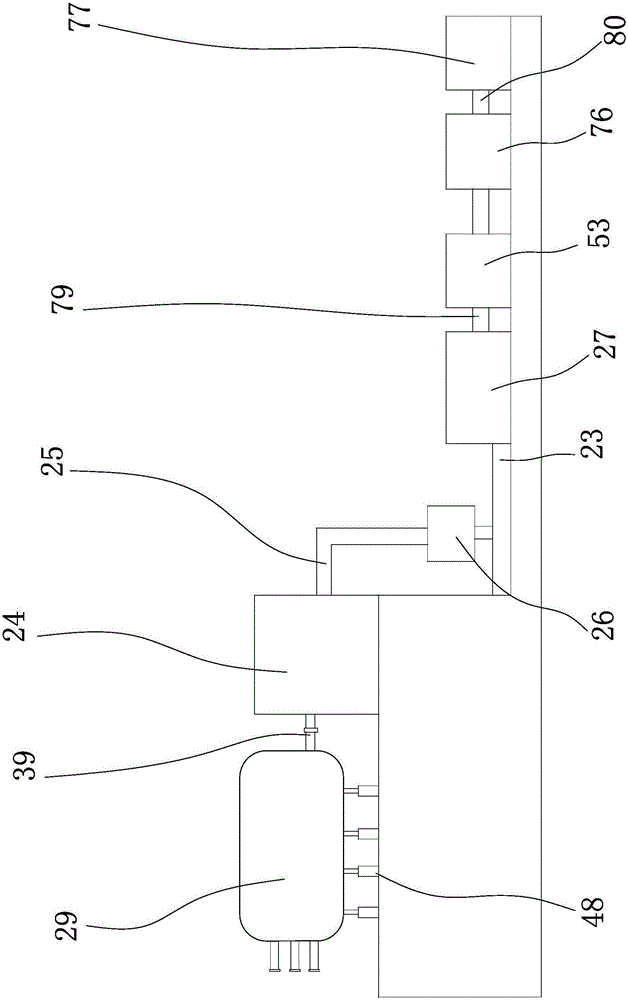

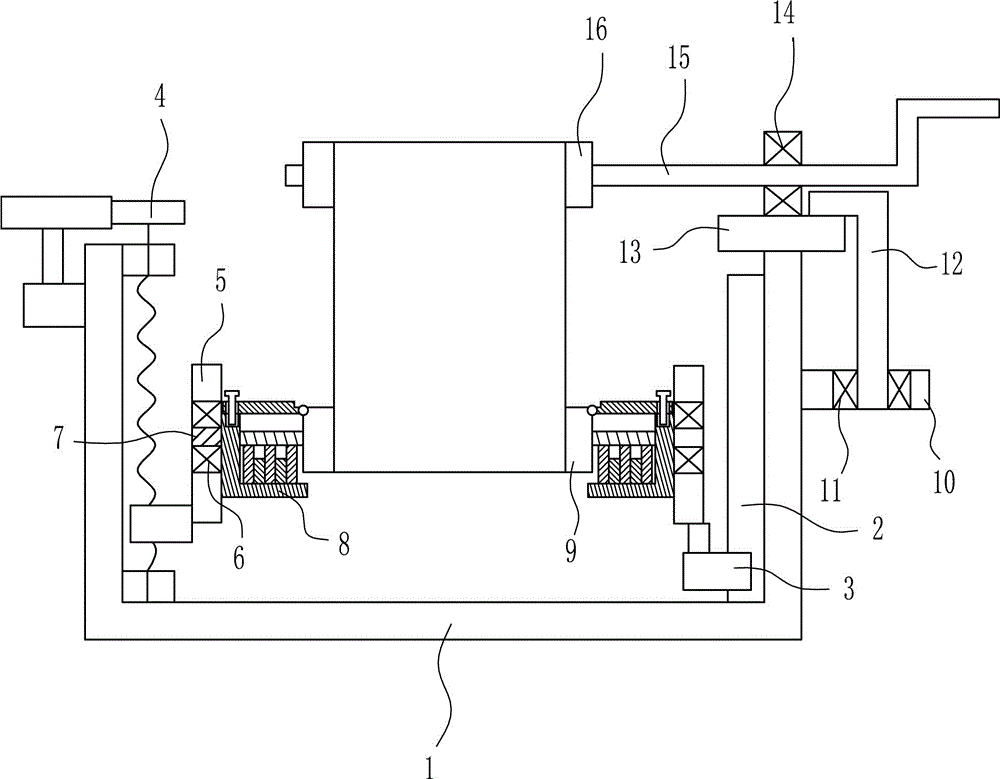

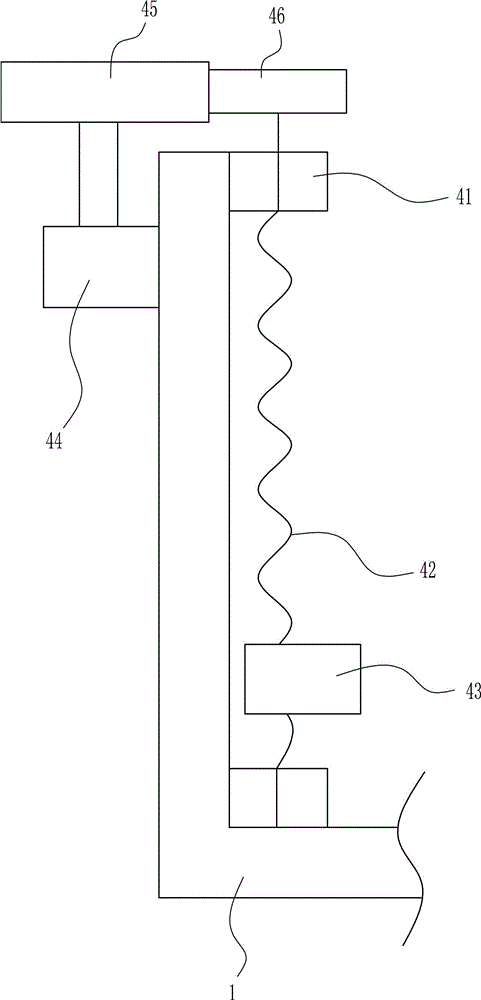

Electric steam generator and steam generator control system

InactiveCN104359096AZero emissionHigh efficiency and energy saving outputSteam generation heating methodsBoiler controlWater softeningElectricity

The invention discloses an electric steam generator and a steam generator control system. The electric steam generator comprises a water softening machine set used for softening tap water, a water tank used for storing soft water, a heat pump machine set used for heating the soft water, a high-pressure pump used for atomizing water, a reaction kettle used for producing steam, a circulating pump used for circulating the soft water, and an electromagnetic heater used for heating the heat pump machine set and the reaction kettle, wherein the heat pump machine set is an air energy heat pump machine set, the steam outlet port of the reaction kettle is parallelly connected with a gas storing tank through a pipe network. By virtue of the technical scheme, the electric steam generator and the steam generator control system can be used for realizing zero pollution, zero release, and efficient energy-saving gas supply and heat supply, and realizing remote centralized management under an unattended operation condition.

Owner:TAICANG DENASEN MECHANICAL & ELECTRICAL ENG CO LTD

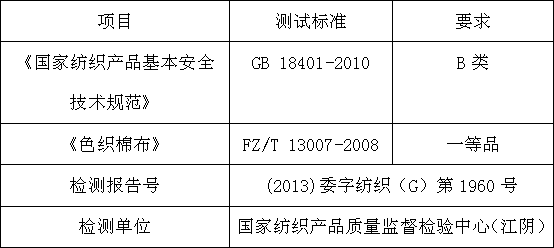

High-grade environment protection type knitted elastic face fabric and production process thereof

The invention relates to a top grade environmental protection knitting resilience outside material and the technology to manufacture. The invention adopts contexture that is made up from urethane elastic fiber thread and environmental protection fiber yarn, and the content of urethane elastic fiber is over 4%. The manufacturing process is the following steps: urethane elastic fiber transmitting machine and great circle machine weaving, dry split opening, Santex typesetting machine original forming, inhalator dyeing, high frequency oscillating drying process, and Santex typesetting machine final forming. The outside material has advantage of good elasticity, thin grain, and soft handle.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

Super cotton-like cashmere double-side fabric and production process thereof

InactiveCN103276500AMaintain propertiesConvenient careFibre treatmentMulti-ply fabricsYarnPolymer science

The invention relates to super cotton-like cashmere double-side fabric. The super cotton-like cashmere double-side fabric is characterized by being made of supercool / cotton blended yarn, cotton / cashmerino blended yarn, and mercerized gassed woolen yarn. The super cotton-like cashmere double-side fabric is in double-side weave; warps are made of 7.3tex Supercool / cotton blended yarn; and accordingly the whole cover of the fabric reveals no warp but weft, the weft front side of the fabric is made of 18.2tex mercerized gassed woolen yarn, and the weft reverse side is made of 18.2tex cotton / cashmerino blended yarn. Super cotton-like fiber is high in strength, wear-resistant, highly breathable, antistatic, wrinkle-resistant, and as warm as cashmerino. With perfect combination of wefts and warps by the special double-side weave, the fabric looks and feels different on two sides.

Owner:江苏保丹服饰有限公司

Non-aqueous solvent cold pad batch dyeing method of reactive dye

The invention provides a non-aqueous solvent cold pad batch dyeing method of reactive dye. The method comprises the steps of curing and drying the pad batch alkali liquor of the textile; pad dyeing the textile; yarding the pad dyed textile products in the saturated vapor atmosphere of reactive dye poor solvent; curing and drying the yarded textile products, and finishing the non-aqueous solvent cold pad batch dyeing of the reactive dye; or, conducting cationicm odification to the textile; curing and drying the pad batch alkali liquor of the textile; pad dyeing the textile; yarding the pad dyed textile products; curing and drying the yarded textile products; and finishing the non-aqueous solvent cold pad batch dyeing of the reactive dye. The method can achieve the salt free shade dyeing for the reactive dye, the dyeing fixation rate is high, the use amount of the organic solvent and water is low, the energy consumption is low, and the amount of discharged waste water is less.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

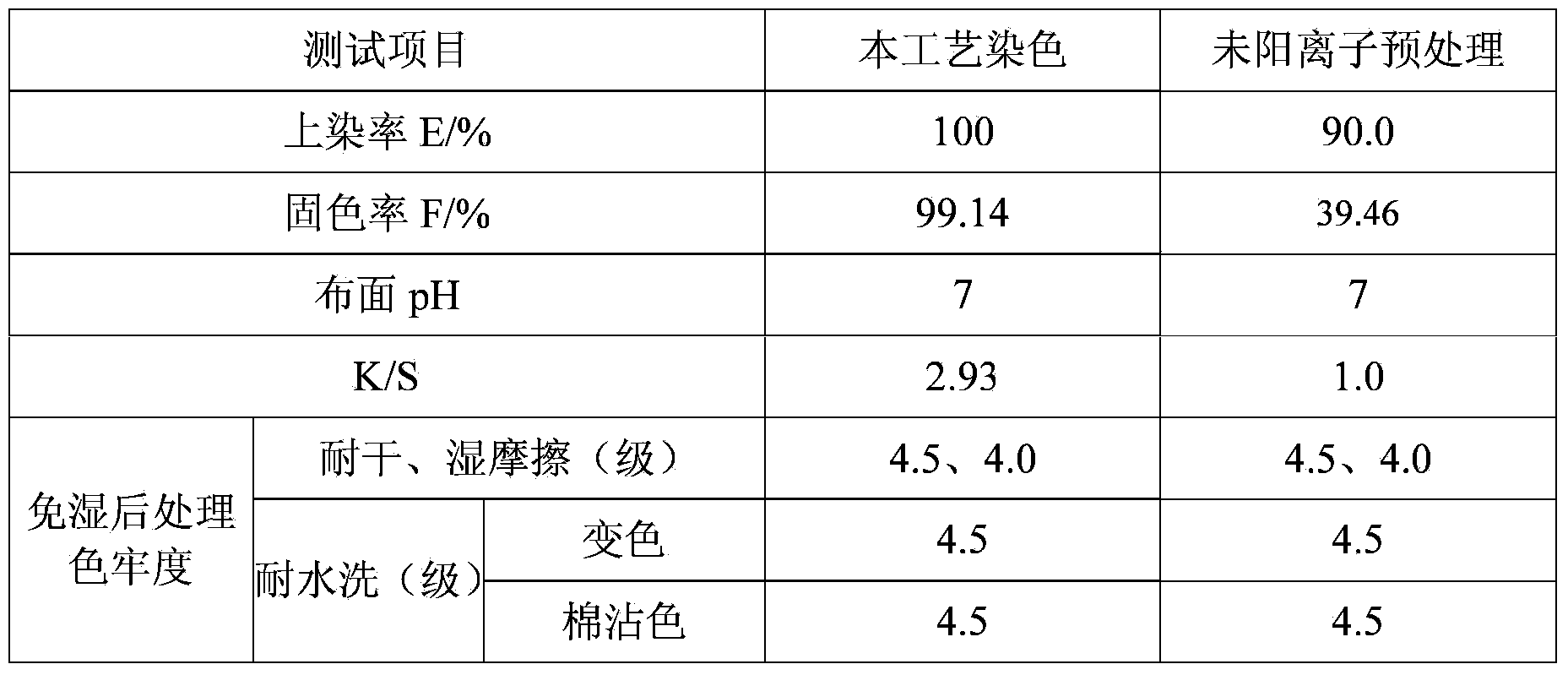

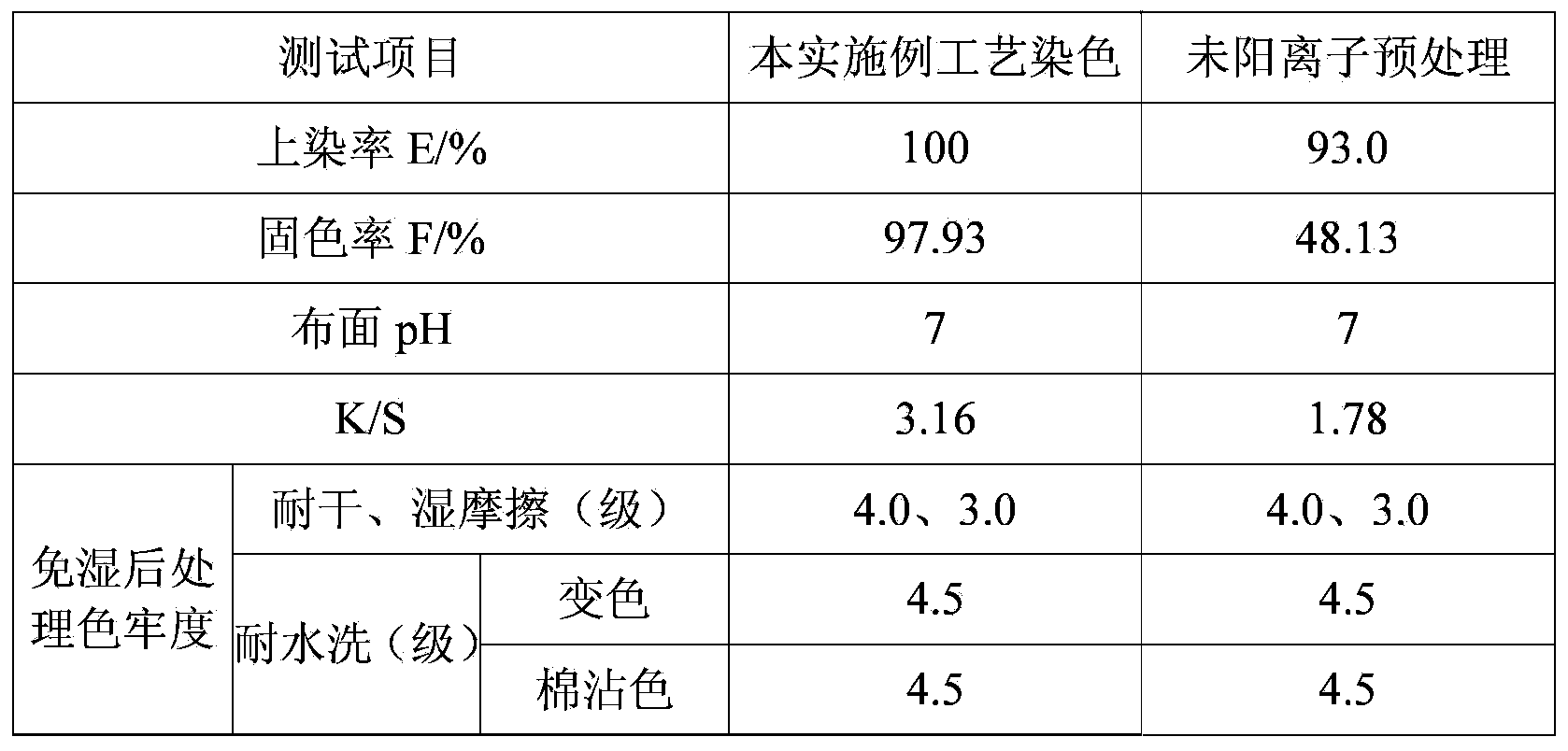

Active dye non-aqueous solvent dyeing method without wet post-treatment

The invention provides an active dye non-aqueous solvent dyeing method without wet post-treatment. The method comprises the following steps: carrying out cation modification on a cotton textile; mixing the modified cotton textile with an active dye and a good solvent of the active dye; heating to a dyeing temperature at a speed of 1 DEG C / min and dyeing; adding a poor solvent of the active dye in the heating process and preserving heat for a period of time, wherein the volume ratio of the good solvent of the active dye to the poor solvent of the active dye is 1 to (3-20) and the mass ratio of the good solvent of the active dye to the cotton textile is (2-50) to 1; and drying the cotton textile to finish dyeing, wherein the good solvent of the active dye is a non-aqueous solvent which can be used for dissolving the active dye but is not subjected to a chemical reaction with the active dye, and the poor solvent of the active dye is a non-aqueous solvent which cannot be used for dissolving the active dye and is not subjected to a chemical reaction with the active dye. The active dye non-aqueous solvent dyeing method provided by the invention has a high fixation rate and does not need a wet post-treatment step.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Printed and embroidered seamless wall fabric and manufacturing method thereof

ActiveCN105804345ALow viscosityEvenly dispersedCovering/liningsDyeing processBiochemical engineeringMembranous layer

The invention belongs to the technical field of facing decoration materials and particularly relates to printed and embroidered seamless wall fabric and a manufacturing method thereof. The wall fabric comprises a cloth layer, a glue film layer and a raw paper layer or non-woven layer, wherein the glue film layer is located between the cloth layer and the raw paper layer; the surface, making contact with the glue film layer, of the cloth layer is a smooth surface, and the other surface of the cloth layer is provided with printed patterns; and embroidered patterns are arranged on the cloth layer, and the cloth layer is soaked or coated with a waterproof and mouldproof agent. The wall fabric is formed by conducting printing and embroidering on base cloth and then conducting shaping. The wall fabric manufactured through the manufacturing method has the advantages of being easy to stick, not prone to wrinkles, various in style and long in service life.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

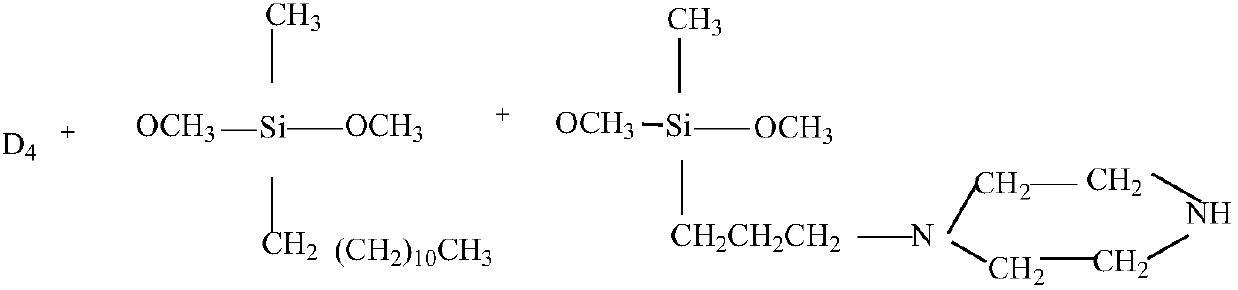

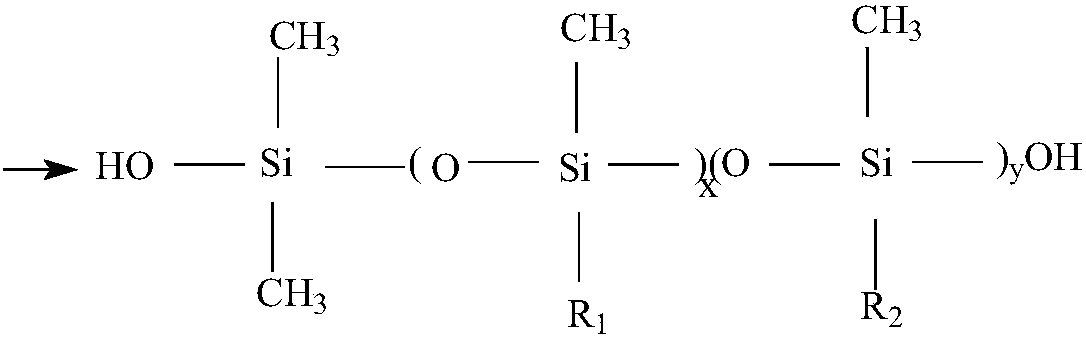

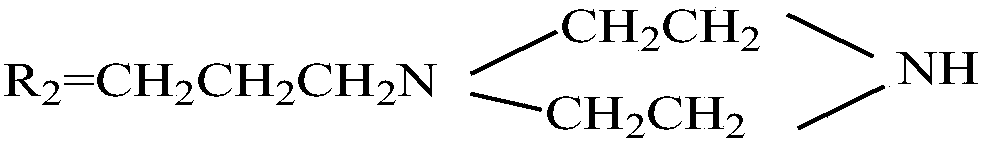

Preparation method of smoothing, stiffening and color deepening silicone oil

The invention discloses a preparation method of smoothing, stiffening and color deepening silicone oil. The method comprises steps as follows: (1) synthesis of the smoothing, stiffening and color deepening silicone oil: the smoothing, stiffening and color deepening silicone oil is prepared from certain amounts of octamethylcyclotetrasiloxane, dodecyl methyldimethoxysilane and gamma-piperazinylpropylmethyldimethoxysilane under the catalysis of a certain quantity of catalysts at certain polymerization temperature for a certain time; (2) emulsification of the smoothing, stiffening and color deepening silicone oil: 10% of 2-phenoxyethanol as a special emulsifier is added to a silicone oil emulsifier to emulsify the smoothing, stiffening and color deepening silicone oil, and milky-white smoothing, stiffening and color deepening silicone oil emulsion which has the content of 40% and has slight blue light is obtained. The smoothing, stiffening and color deepening silicone oil emulsion realizes the color deepening effect by reducing the surface refractive index of fabric and is an organosilicon finishing agent, and the hand feel finishing and color deepening of the fabric are performed simultaneously, so that energy conservation, environmental protection, color deepening, dye saving and cost reduction are realized.

Owner:HEIGHTCHEM FINE CHEM CO LTD

Cotton yarn dyeing process

ActiveCN106283448AStir wellWell mixedTextile treatment machine arrangementsTextile treatment cleaning apparatusYarnPulp and paper industry

The invention provides a cotton yarn dyeing process, and belongs to the technical field of dyeing treatment. A method for dyeing cotton yarns used for weaving a jean fabric comprises the following steps: a, preparing the cotton yarns; b, performing surface treatment on the cotton yarns; c, rinsing the cotton yarns for the first time; d, rinsing the cotton yarns for the second time; e, dyeing the cotton yarns; f, drying the cotton yarns; and g, rolling up the cotton yarns. The cotton yarn dyeing process disclosed by the invention has the advantage of capability of dyeing the cotton yarns used for weaving the jean fabric more effectively.

Owner:HAINING DENIM WEAVING CO LTD

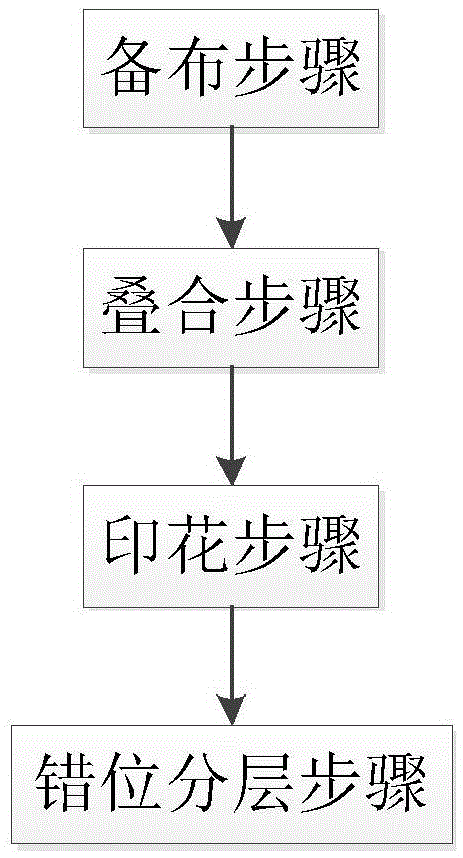

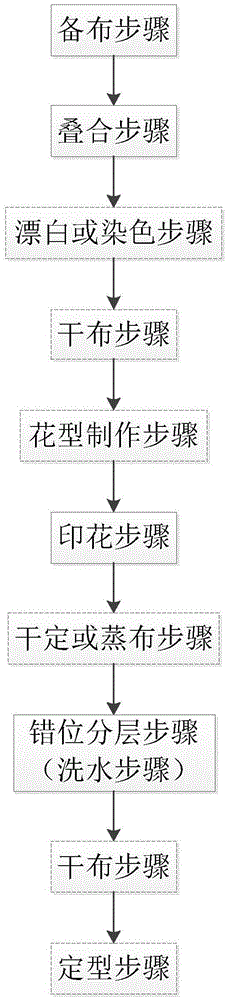

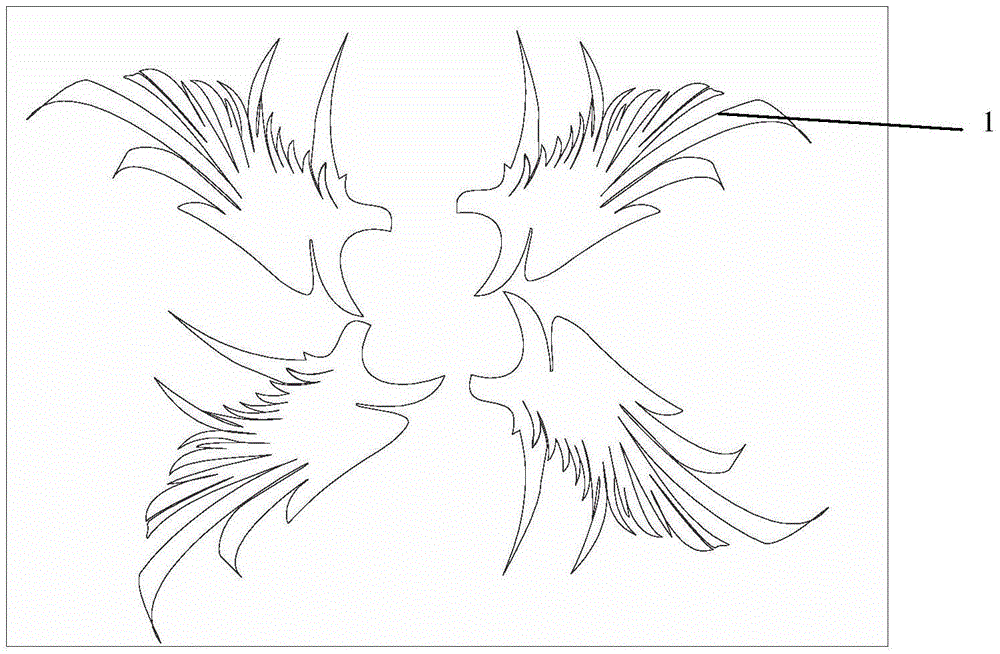

Novel 3D stereo printing process

InactiveCN105484061AImprove the level of cleaner productionSolve chromatic aberrationLayered productsTransfer printing processSuperimpositionEngineering

The invention discloses a novel 3D stereo printing process. The 3D stereo printing process comprises the steps of cloth preparation, superimposition, printing and misplaced laying, wherein the printing steps adopts a one-time printing and dyeing process, printing of compound-layer fabrics can be completed through one-time printing and dyeing, and then printed compound-layer fabrics are separated and misplaced, namely the patterns can show multiple-layer overlapped stereo layering sense and the 3D stereo printing effect which can be seen by naked eyes. By the adoption of the printing process, dyes can be saved in production, the cost can be reduced, the technological process can be simplified, and the cleaning production level of enterprises can be improved. In the printing effect, the chromatic aberration problem caused by different temperatures and pressures of different printing batches is avoided due to one-time printing, printing colors can be unified, and the visual effect is good. The process enables the 3D stereo printing effect to be also achieved under the condition of naked eyes, and the costs for 3D stereo glasses are reduced.

Owner:COSMO LADY (CHINA) HOLDINGS

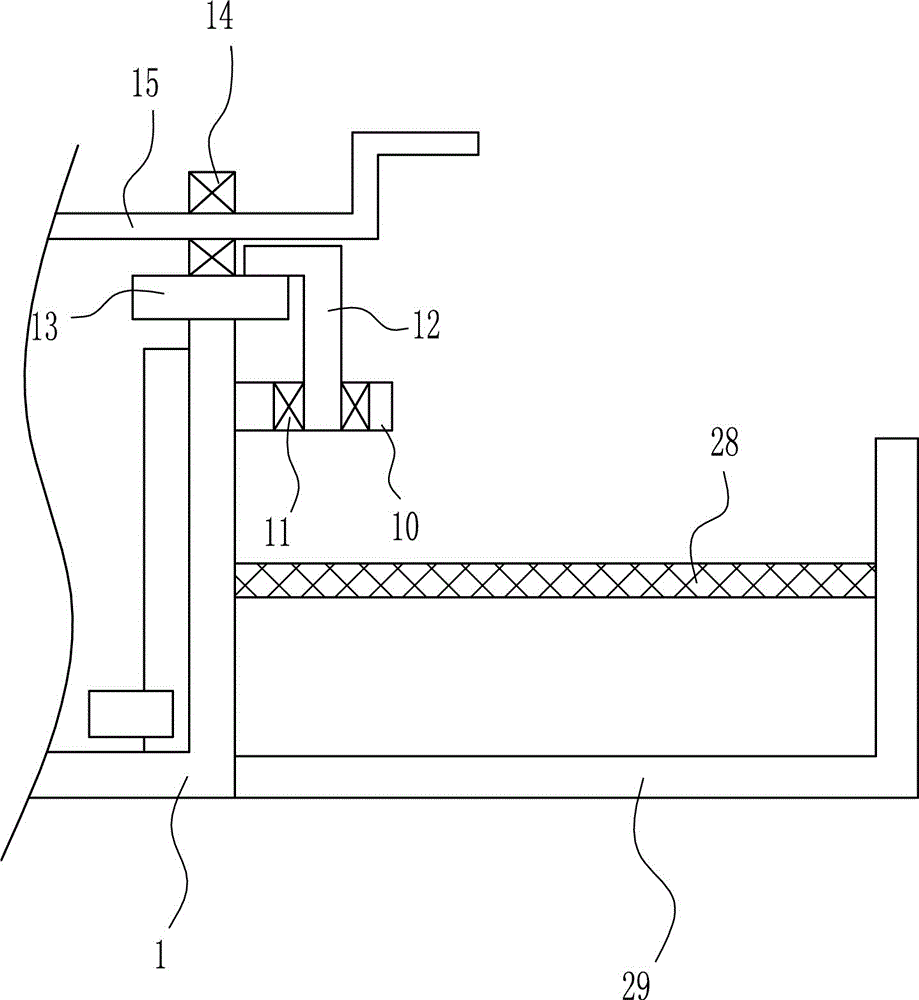

Dye vat with waste liquid treatment device

ActiveCN106400360AStir wellWell mixedTextile treatment containersTextile treatment machine arrangementsLiquid wastePulp and paper industry

The invention provides a dye vat with a waste liquid treatment device. The dye vat with a waste liquid treatment device comprises a rack and a vat body; the vat body comprises an inner vat and an outer vat; the inner vat is covered with an inner cover, and the outer vat is covered with an outer cover; a cycling containing chamber is formed between the inner vat and the outer vat; the bottom of the cycling containing chamber is provided with a cycling water pump; the side wall of the outer vat is connected with a water inlet pipe; a heat exchanger is placed inside the inner vat; the heat exchanger is connected with a cycling heat exchange system through a pipeline; a vibration disk is installed under the outer vat; the vibration disk is provided with multiple vibration poles; the vibration poles are provided with compression springs therein; vibration balls are supported on the tops of the compression springs; the vibration balls are exposed from the top openings of the vibration poles; the tops of the vibration balls are in touch with the bottom of the outer vat; a rotating seat is installed under the outer vat; the inner vat is also connected with a waste liquid treatment device. By means of the dye vat with a waste liquid treatment device, dying can be carried out more efficiently and waste water produced from dying can be treated.

Owner:HAINING DENIM WEAVING CO LTD

Dyeing method of cotton yarn for weaving jean fabric

ActiveCN106319805AIncreased turbulenceHigh activityTextile treatment containersDry-cleaning apparatus for textilesYarnEngineering

The invention provides a dyeing method of cotton yarn for weaving jean fabric, and belongs to the field of dyeing processing. The method includes the following steps of a, preparing the cotton yarn; b, processing the surface of the cotton yarn; c, conducting primary water washing; d, conducting secondary water washing; e, conducting dyeing; f, conducting sizing; g, conducting drying; h, conducting rolling. The dyeing method has the advantages that the cotton yarn for weaving the jean fabric can be more effectively dyed.

Owner:HAINING DENIM WEAVING CO LTD

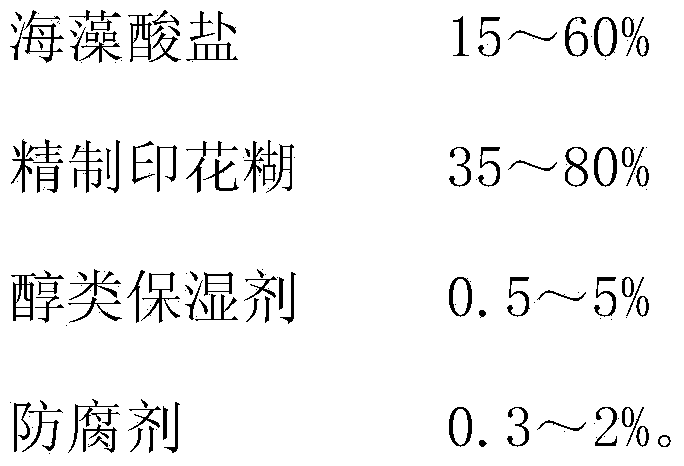

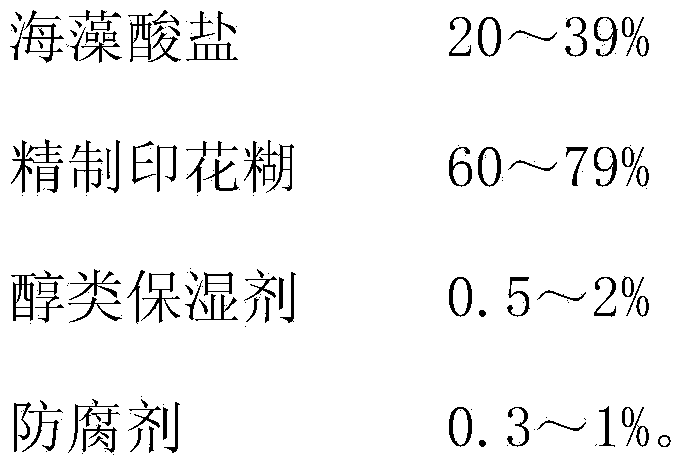

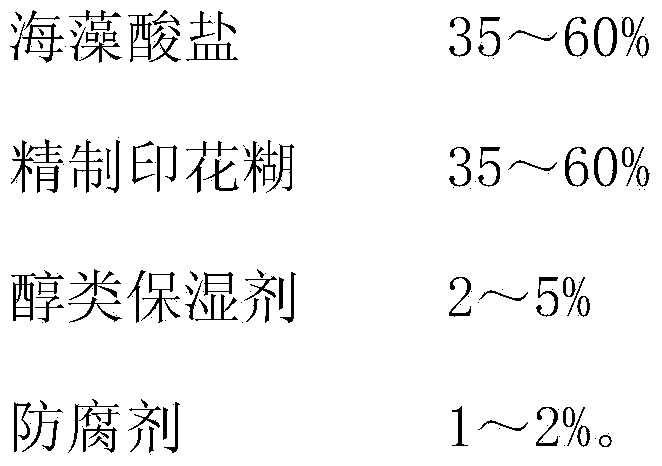

Reactive printing paste and production method thereof

The invention relates to the technical field of production methods and particularly relates to reactive printing paste and a production method thereof. The reactive printing paste comprises the following raw materials in percentage by mass: 15-60% of alginate, 35-80% of refined printing paste, 0.5-5% of an alcohol wetting agent and 0.3-2% of a preservative. According to the reactive printing paste, the raw material is less in consumption and low in cost, and the reactive printing paste is resistant to electrolyte and biodegradation, capable of increasing the color yield by 30% and greatly reducing the dye used later, beneficial to the reduction of three wastes and low in production and use costs. The preparation method of the reactive printing paste provided by the invention is simple in process, convenient to operate and beneficial to the scaled production.

Owner:DONGGUAN MILLSING CHEM SCI & TECH CO LTD

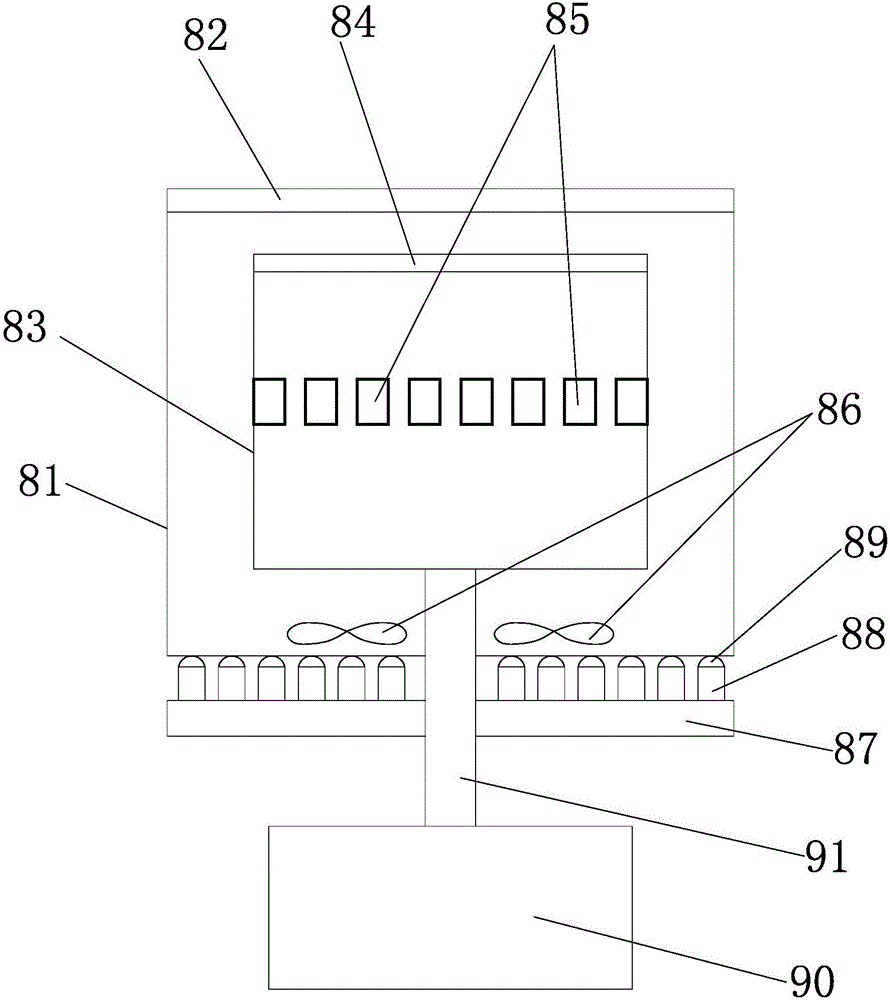

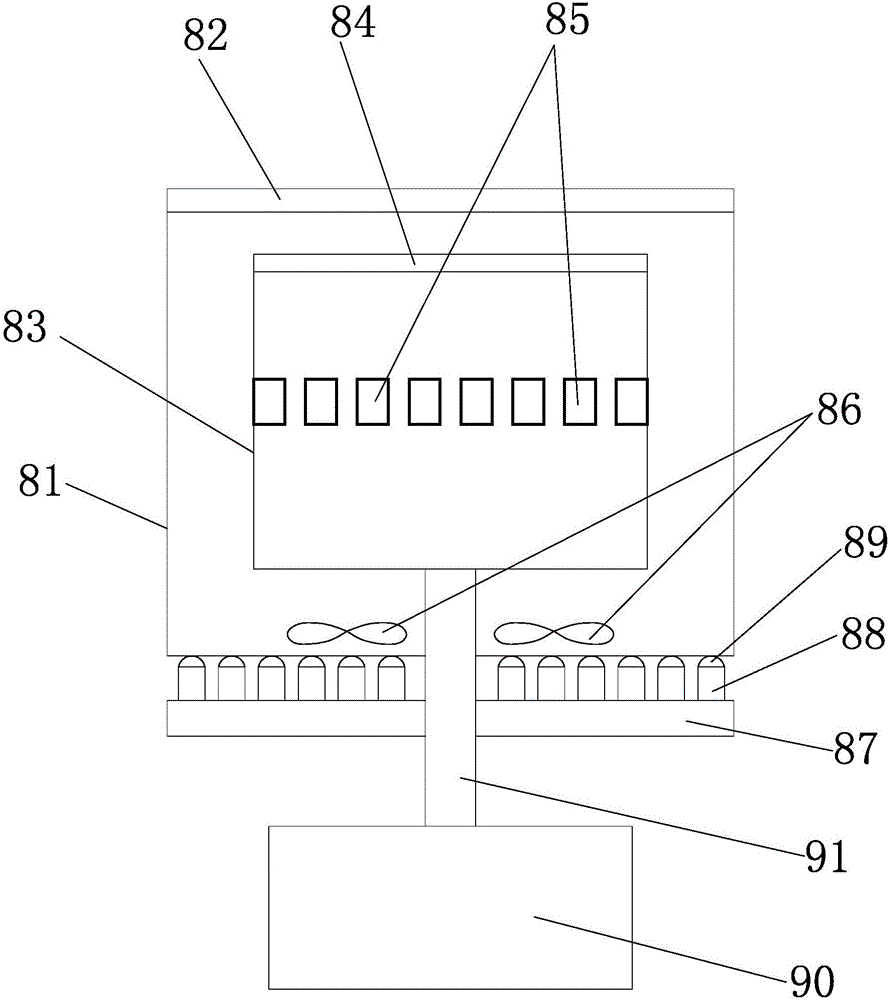

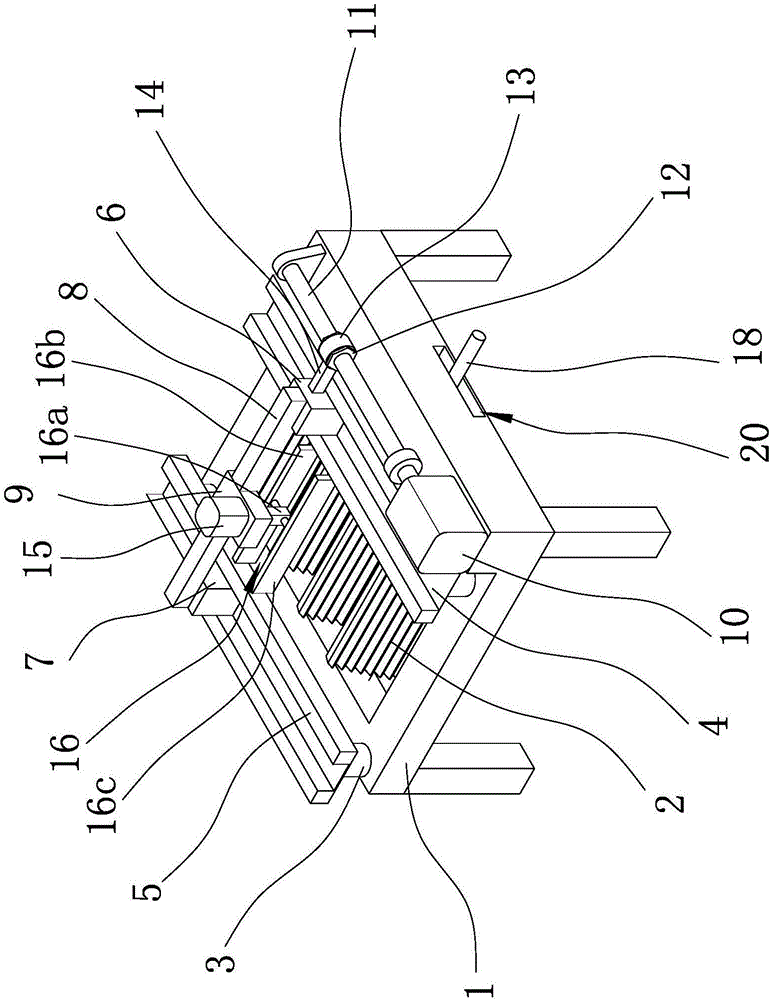

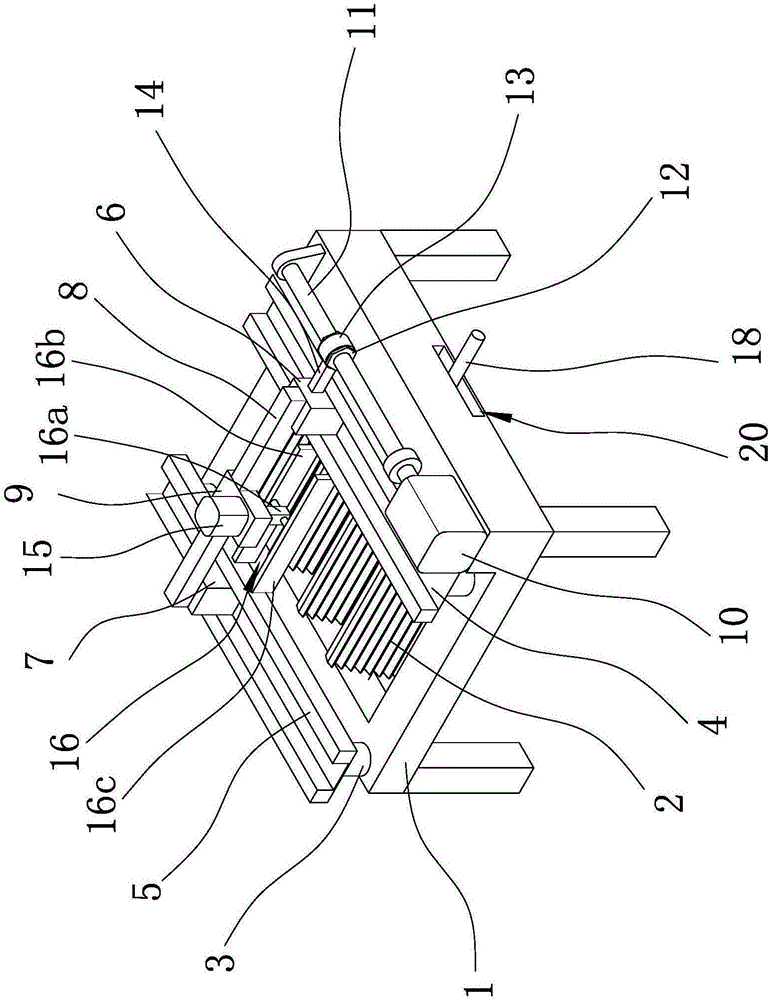

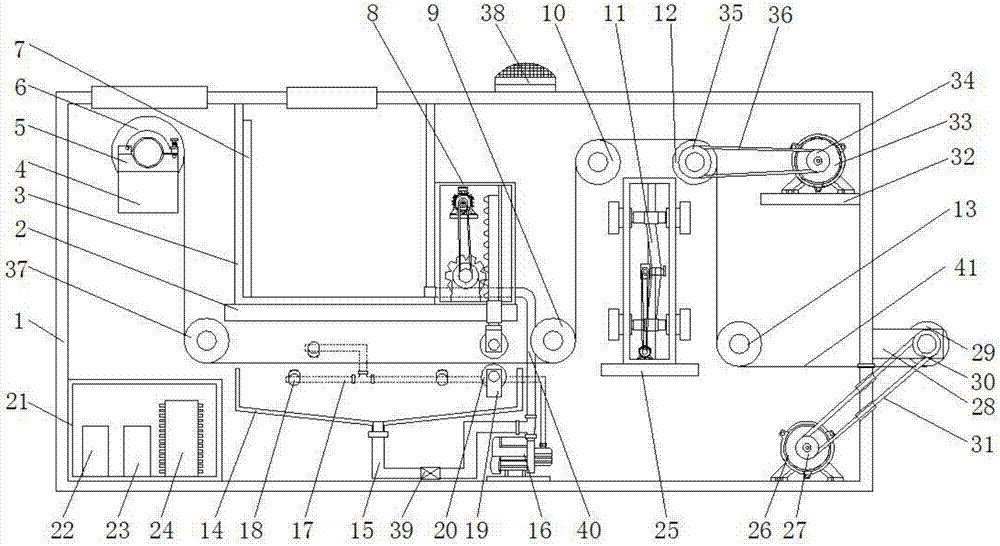

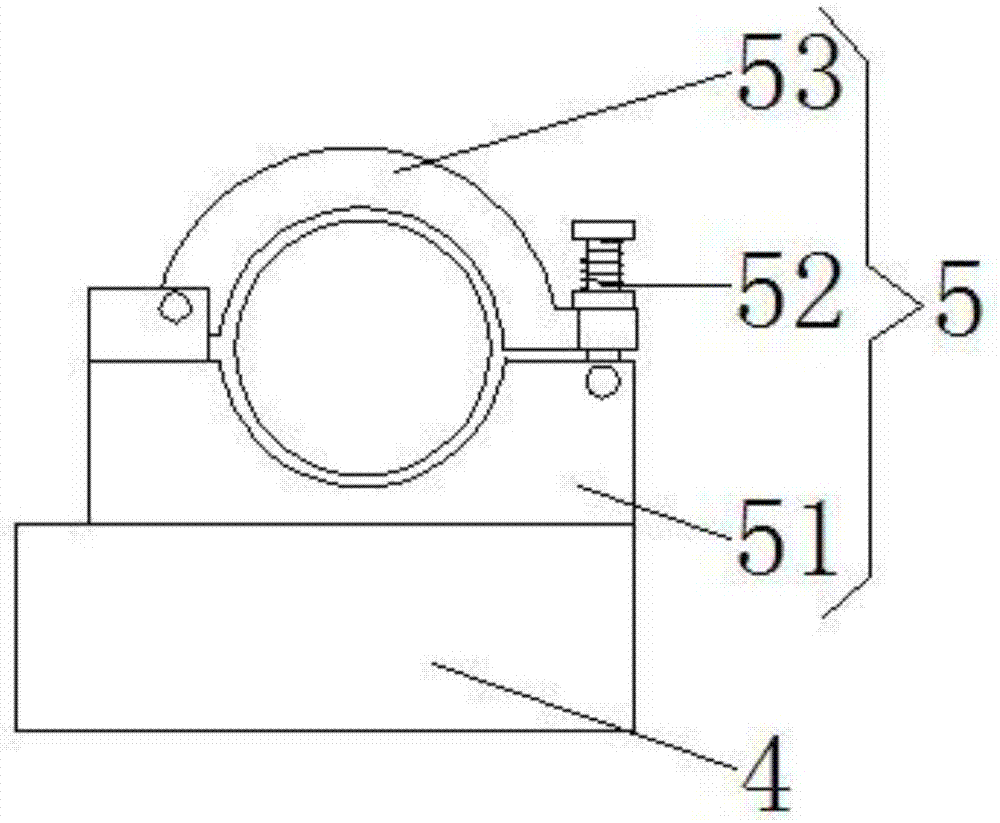

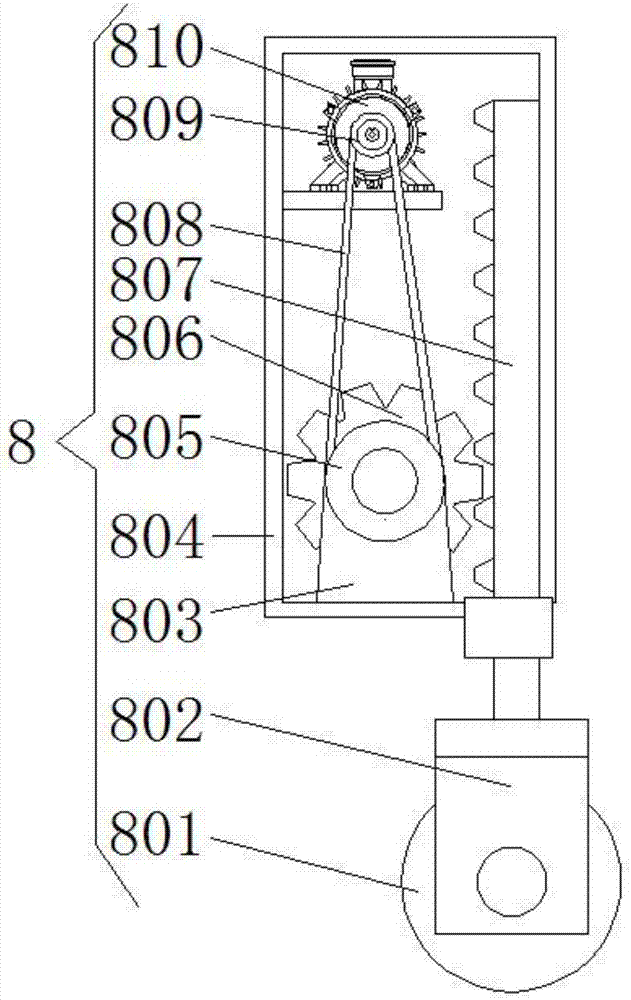

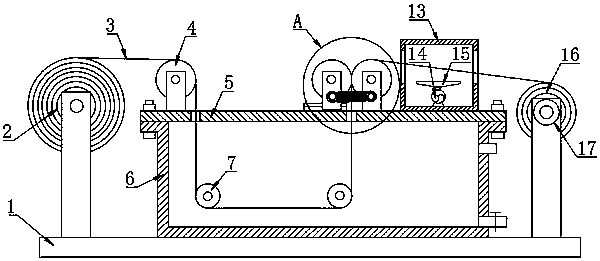

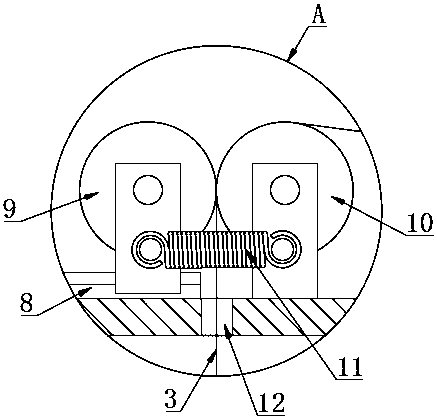

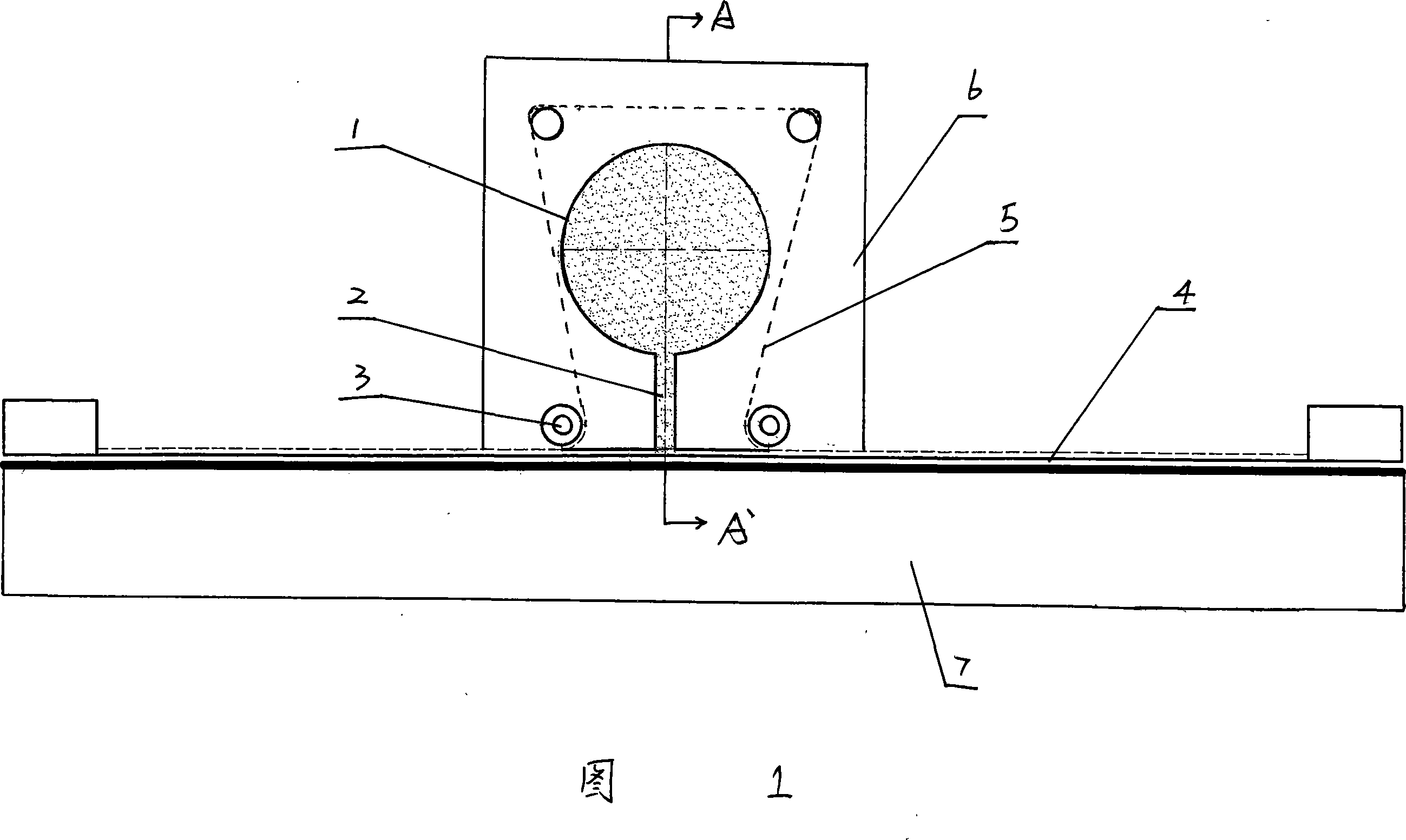

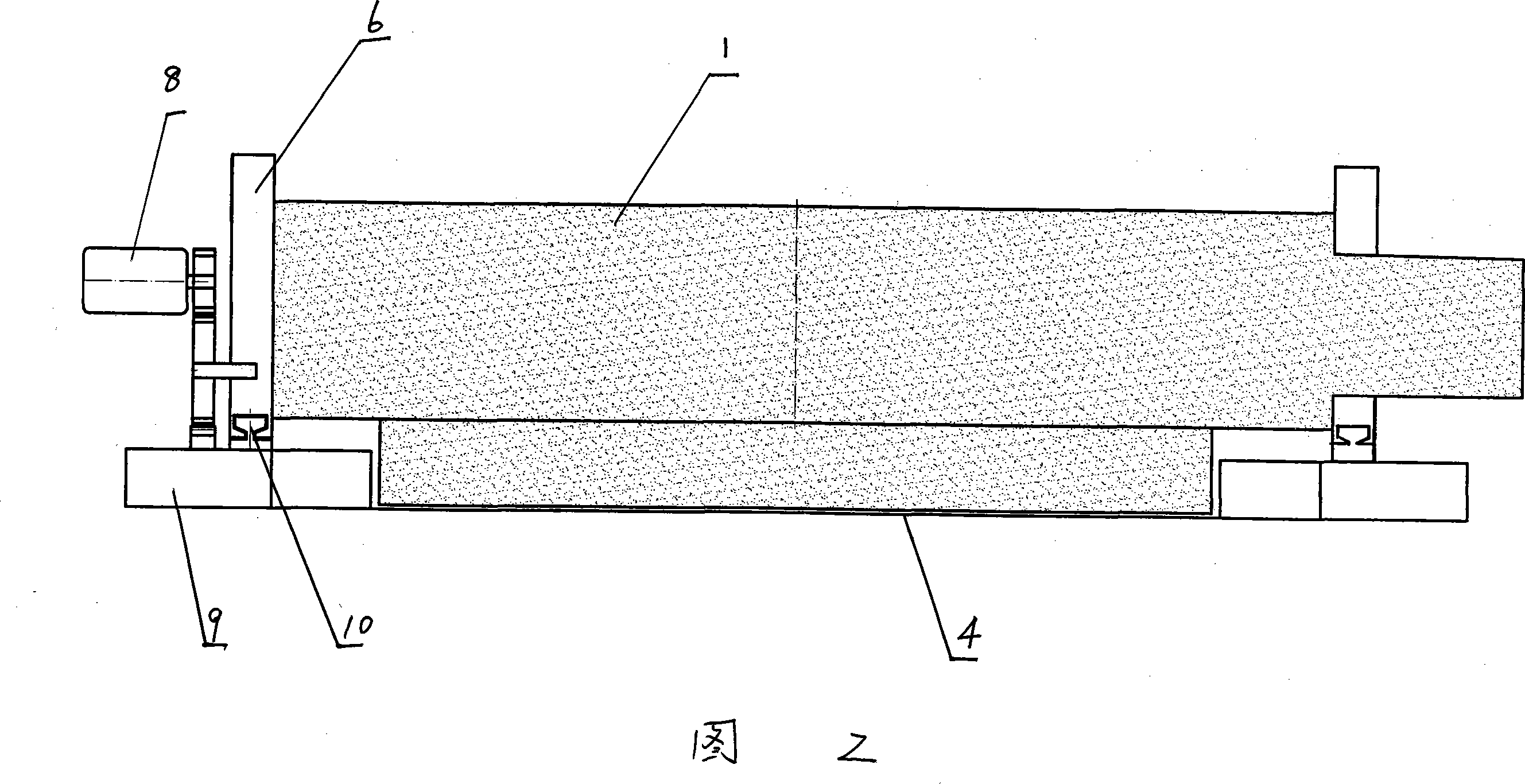

Textile dyeing device capable of saving dyes

InactiveCN107488959ARealize deliveryAvoid damageLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringDrying time

The invention discloses a textile dyeing device capable of saving dyes. The textile dyeing device comprises a box body, a dye box is fixedly connected between two opposite sides of the inner wall of the box body through a supporting plate, the two opposite sides of the inner wall of the box body are fixedly connected with a fixing device through fixing blocks, one side of the top of the supporting plate is fixedly connected with a pressing device, a leaky bucket is fixedly connected between two opposite sides of the inner wall of the box body, the bottom of the leaky bucket communicates with a first dye tube, one end of the first dye tube communicates with a water pump, the outlet end of the water pump is connected with a spray dyeing tube through a second dye tube, the two opposite sides of the inner wall of the box boy are fixedly connected with a pair of cushioning devices, the centers of the cushioning devices are rotatably connected with pressed roller wheels, and a drying device is fixedly connected between the two opposite sides of the inner wall of the box body through a fixing plate. The invention relates to the technical field of textile processing. The textile dyeing device capable of saving the dyes improves the dyeing efficiency, shortens the drying time, saves the dyes, reduces the labor intensity and improves the work efficiency.

Owner:李文艳

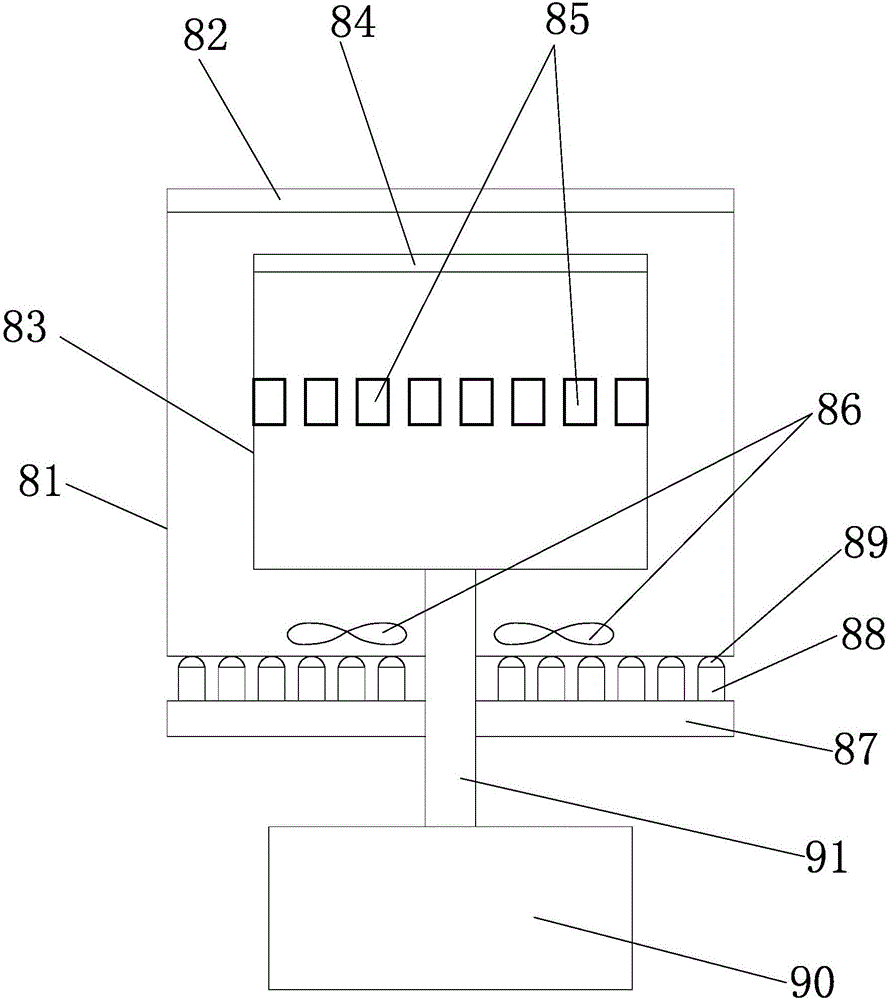

Non-woven fabric dyeing device for garment production

InactiveCN106811887AEasy to addEasy to take outTextile treatment machine arrangementsTextile treatment carriersEngineeringNonwoven fabric

The invention relates to a non-woven fabric dyeing device, in particular to a non-woven fabric dyeing device for garment production. The technical problem to be solved by the invention is to provide a non-woven fabric which is convenient to take and dye and the non-woven fabric dyeing device for garment production which enables the woven-woven fabric to be dyed uniformly. In order to solve the problem, the non-woven fabric dyeing device for garment production provided by the invention comprises a dyeing box, a first sliding rail, a first sliding block, a lifting mechanism, first connecting rods and the like; the inner right wall of the dyeing box is connected with the first sliding rail, the first sliding rail is connected with the first sliding block; the inner left wall of the dyeing box is connected with the lifting mechanism, the lifting mechanism and the first sliding block are respectively connected with the first connecting rods, and each first connecting rod is connected with a first bearing seat. According to the non-woven fabric dyeing device for garment production designed in the invention, the device is provided with the lifting mechanism, so that a roller can move up and down, undyed non-woven fabric is conveniently to add and dyed non-woven fabric is convenient to take.

Owner:广州腾宏纺织服装有限公司

Fixation crosslinking agent, and producing method

InactiveCN101003953AHigh alkalinityTo overcome high temperatureDyeing processHexamethylenediamineEpichlorohydrin

The present invention relates to a fixation coupling agent. It is made up by using trimethylamine, hydrochloric acid, epichlorohydrin, and cyanuric chloride and hexamethylene diamine through the processes of neutralization, quaternization and polymerization.

Owner:LIAONING FIXED STAR FINE CHEM

Cloth printing, dyeing and drying device for textile

InactiveCN108486807AImprove flatnessShorten drying timeLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by gas jetsEngineeringMechanical engineering

The invention discloses a cloth printing, dyeing and drying device for textile. The cloth printing, dyeing and drying device for textile comprises a base and cloth, wherein a cloth outlet roll and a cloth feeding roll are rotatably arranged on the left side and the right side of the top of the base through supports separately; the cloth feeding roll is driven by a gear motor which is positioned onthe front side of the cloth feeding roll; a printing and dyeing box is further fixedly arranged on the top of the base and is positioned between the cloth outlet roll and the cloth feeding roll; a cover plate is fixedly arranged on the top of the printing and dyeing box through bolts and nuts; a first guiding roll is rotatably arranged on the left side of the top of the cover plate through a support; a third guiding roll is further rotatably arranged on the top of the cover plate through a support; a left second guiding roll and a right second guiding roll are rotatably arranged in the printing and dyeing box in the front-back direction; two ends of the cloth are separately wound on the cloth outlet roll and the cloth feeding roll; the cloth is wound through the first guiding roll, the second guiding roll and the third guiding roll separately; and a cloth opening for cloth to penetrate through is formed in the cover plate. In a printing and dyeing process, cloth cannot be messy; afterprinting and dyeing, the cloth is reeled directly; and the smoothness of the cloth is good.

Owner:PINGHU YIFANJIA LUGGAGE CO LTD

Process for cotton reactive dye applying in silk broadcloth dying

The invention relates to a technique for dyeing silk fabrics by a cotton reactive dye. The technical problem to be solved is that the technique needs to dye silk fabrics by the cotton reactive dye effectively, has the characteristics that the dye uptake is high, the fixation ratio is high, the color depth of the product is increased greatly, the coloring matter is saved and the dyeing quality is high; moreover, the residual liquid discharge concentration is decreased and the environment is protected. The technical proposal is to adopt the cotton reactive dye for dyeing silk fabrics and has the following steps that: 1) the silk broadcloth after the pre-treatment is placed into a dye vat, a dye solution is prepared and is added into the dye vat to dye, the dye solution has a pH value ranging from 6.5 to 7.5, the dye temperature ranges from 85 to 98 DEG C, the dye time lasts one to two hours; 2) the dye residual solution is discharge partially or completely, clear water is added, the temperature is adjusted to 50 to 60 DEG C; 3) certain amount of ammonium polycarylate is added to fix the color, the pH value is kept to be 9 to 10, the fixation time lasts one to two hours, the temperature of the clear water ranges from 4 to 20 DEG C.

Owner:HIGH FASHION CHINA CO LTD

Exhaust dyeing cold pad-batch process with small bath ratio

The invention discloses a process for dyeing cellulose fiber and fabrics blended by the cellulose fiber by using reactive dye, which adopts small bath ratio, multiple impregnation, and batch feeding to achieve the effect of even dyeing, mildly adds alkali for color fixation at low temperature, then uses a cold pad-batch mode to remedy the disadvantage of color fixation in a machine, fully ensures that the reactive dye is bonded with fiber, and greatly reduces hydrolysis reactions of the dye. The process has the advantages of reducing the pollution, saving energy sources and improving the benefit.

Owner:吴道平

Slurry-free woven fabric with cotton single yarn or cotton blend single yarn as warp and processing method thereof

ActiveCN102926091AAvoid changeImprove spinnabilityMercerising of yarns/threads/filamentsWoven fabricsYarnFiber

The invention relates to a slurry-free woven fabric with a cotton single yarn or a cotton blend single yarn as a warp and a processing method of the slurry-free woven fabric with the cotton single yarn or the cotton blend single yarn as the warp. The processing method comprises steps of fabric mercerization, mercerizing fabric spinning, weaving and after-finishing, wherein the fabric mercerization comprises fabric slivering, rope braid weaving, tension mercerization and rope braid degradation. The mercerizing fabric spinning means that pure manufactured mercerizing fabric spin or other fabricblending is woven into a single yarn. The weaving means that single yarn is woven into a fabric after warping. The after-finishing means that the fabric after weaving is organized to form a slurry-free woven fabric. The slurry-free woven fabric with the cotton single yarn or the cotton blend single yarn as the warp and the processing method of the slurry-free woven fabric with the cotton single yarn or the cotton blend single yarn as the warp solves an industry problem that the single yarn or the cotton blend yarn can be directly used for woven weaving as a warp without slurry-filling, eliminates complex processes like a slurry-filling process and a slurry-degradation process during a woven fabric production process, guarantees that no slurry residue exists in a finished product fabric, and achieves the effect of reducing production equipment and energy expenditures.

Owner:无锡市鳌尊生态科技有限公司

Method for patterned polychrome printing through four separated colors

A method for printing multi-color pattern on fabric includes such steps as splitting the color of an original pattern into red, yellow, blue and black colors by computer, outputting their negative films, choosing screen, installing it on frame, exposing to preparing 4 plates, preparing the pigment slurries for said 4 colors, scrape printing four times, steaming, and water washing.

Owner:杭州喜得宝集团有限公司

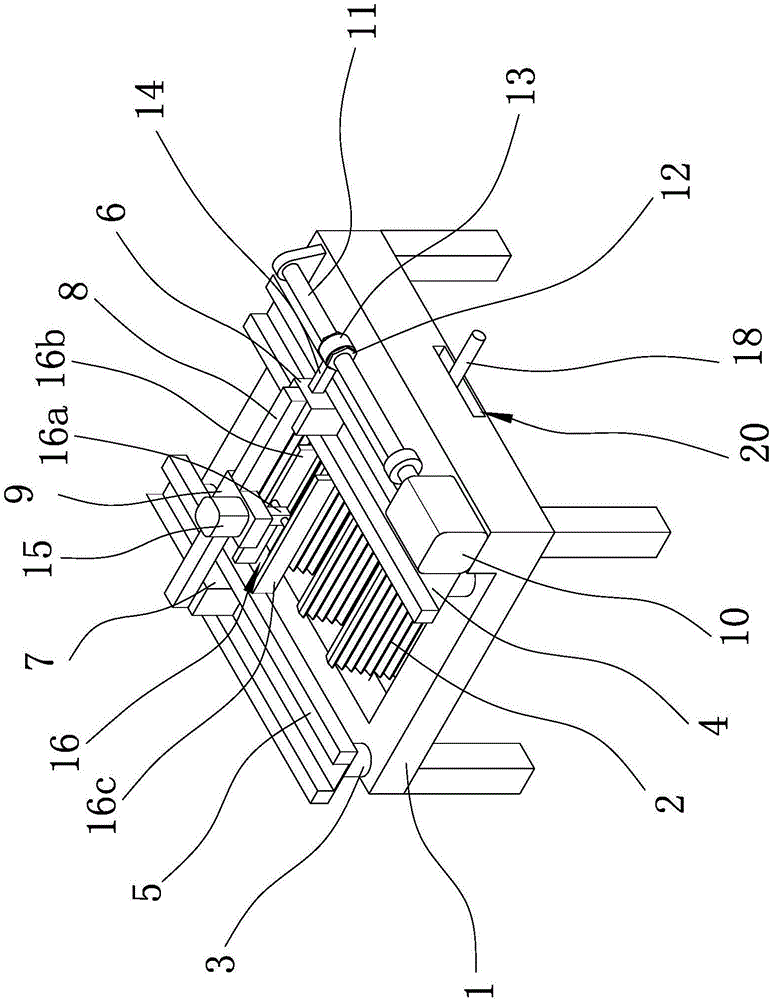

Fabric dyeing and printing device

InactiveCN101245537AImprove printing and dyeing effectUniform and beautiful colorTextile treatment by spraying/projectingTextile treatment carriersEngineeringControllability

The invention relates to a fabric printing and dyeing device which includes a machine frame, a power system and a transmission system. The device is characterized in that: a fabric supporting piece is arranged on the machine frame or the transmission system. The fabric supporting piece is made by ventilating materials or is provided with a ventilating hole. The upward side and the downward side of the fabric supporting piece are respectively provided with a vacuum absorption cavity and an atomizing system. The vacuum absorption cavity is connected with a vacuum pipeline. A vacuum pump is arranged on the vacuum pipeline. The atomizing system includes an atomizer and a dye channel. A pattern templet is fixedly on the machine frame below the outlet of the dye channel. The atomizing system moves opposite to the pattern templet under the drive of the power system and the transmission system. The device of the invention utilizes vacuum subpressure absorption to print and dye atomized dyes on the fabric and has the advantages of simple and reasonable structure, low dyeing cost, high controllability on operation and high dyeing efficiency, being beneficial to improving the dyeing effect of the fabric. The color of the fabric after printing and dyeing is uniform and beautiful.

Owner:浙江宝通环保印染设备科技有限公司

Production technology of low-twist yarn

The invention discloses a production technology of low-twist yarn. The production technology comprises the steps of cotton selection, fore-spinning and post-spinning, wherein the fore-spinning processcomprises the steps of blowing, carding, drawing and roving, and the post-spinning process comprises the steps of spinning and winding. According to the production technology of the low-twist yarn, through selection control on raw materials, optimized configuration on the fore-spinning process, false twist treatment on the spinning step and vacuum low-temperature steam yarn shaping treatment on yarn fruits, the problems of more broken ends in weaving, deterioration of quality indicators, difficulty in spinning and the like caused by reduction of yarn twist in the prior art can be effectivelysolved.

Owner:ZHONGHUA GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com