Active dye non-aqueous solvent dyeing method without wet post-treatment

A technology of reactive dyes and non-aqueous solvents, applied in the field of textile dyeing and finishing, can solve problems such as low color fixation rate, loss of non-aqueous solvents, waste of resources, etc., achieve high dye utilization rate, simple dyeing process, and save dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a kind of non-aqueous solvent dyeing method of reactive dyes after moisture-free post-treatment, comprising the following steps:

[0031] Immerse 10g of knitted fabric in cationic reagent A with a concentration of 10g / L to 100% liquid retention rate, dipping twice and rolling twice, drying at 60°C for 10min, and then baking at 130°C for 10min;

[0032] Put the cationically modified knitted fabric in the dyeing cup, add 0.05g (0.5% o.m.f) Argazd Yellow NF-GR dye, 50mL of dimethyl sulfoxide, dye at 50°C, and heat up at 1°C / min Slowly raise the temperature, slowly add 300mL of tetrachlorethylene during the heating process, raise the temperature to 130°C and keep it for 2h;

[0033] The knitted fabric was taken out and dried directly to complete the dyeing; the solvent was recovered and the color fastness was tested, and the dye fixation rate was tested by soaping. The test results are shown in Table 1.

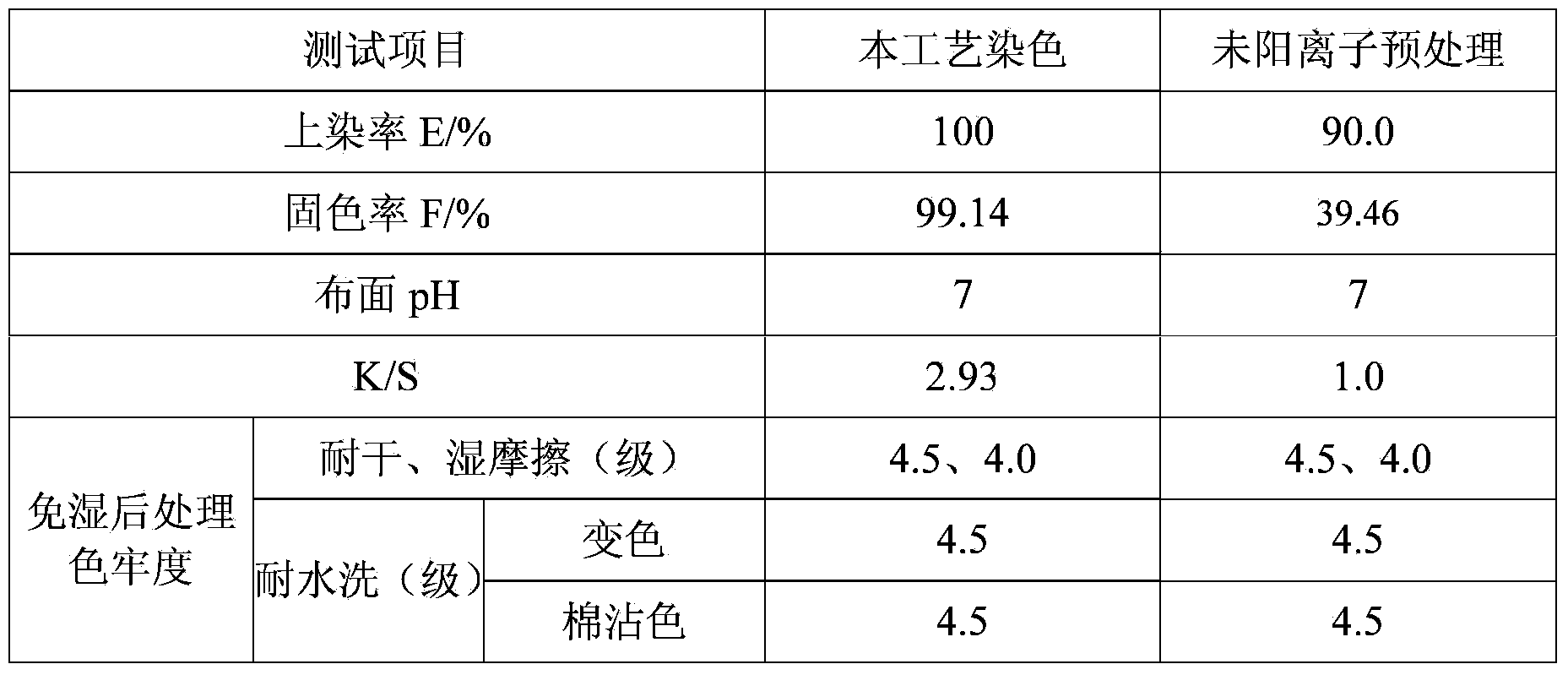

[0034] Table 1 is through the performance t...

Embodiment 2

[0037] This embodiment provides a kind of non-aqueous solvent dyeing method of reactive dyes after moisture-free post-treatment, comprising the following steps:

[0038] First configure the solution of cationic modifier: the aqueous solution of cationic reagent B with a concentration of 26g / L and the NaOH with a concentration of 8g / L are mixed;

[0039] Heat the knitted fabric in the solution of cationic modifier to 80°C for 60 minutes, take out the knitted fabric, wash it, and dry it;

[0040] Put the cationically modified knitted fabric in the dyeing cup, add 0.05g (0.5% o.m.f) Argazd Red N-SB dye, 50mL of dimethyl sulfoxide, dye at 50°C, and heat up at 1°C / min Slowly raise the temperature, slowly add 300mL of tetrachlorethylene during the heating process, raise the temperature to 130°C and keep it for 2h;

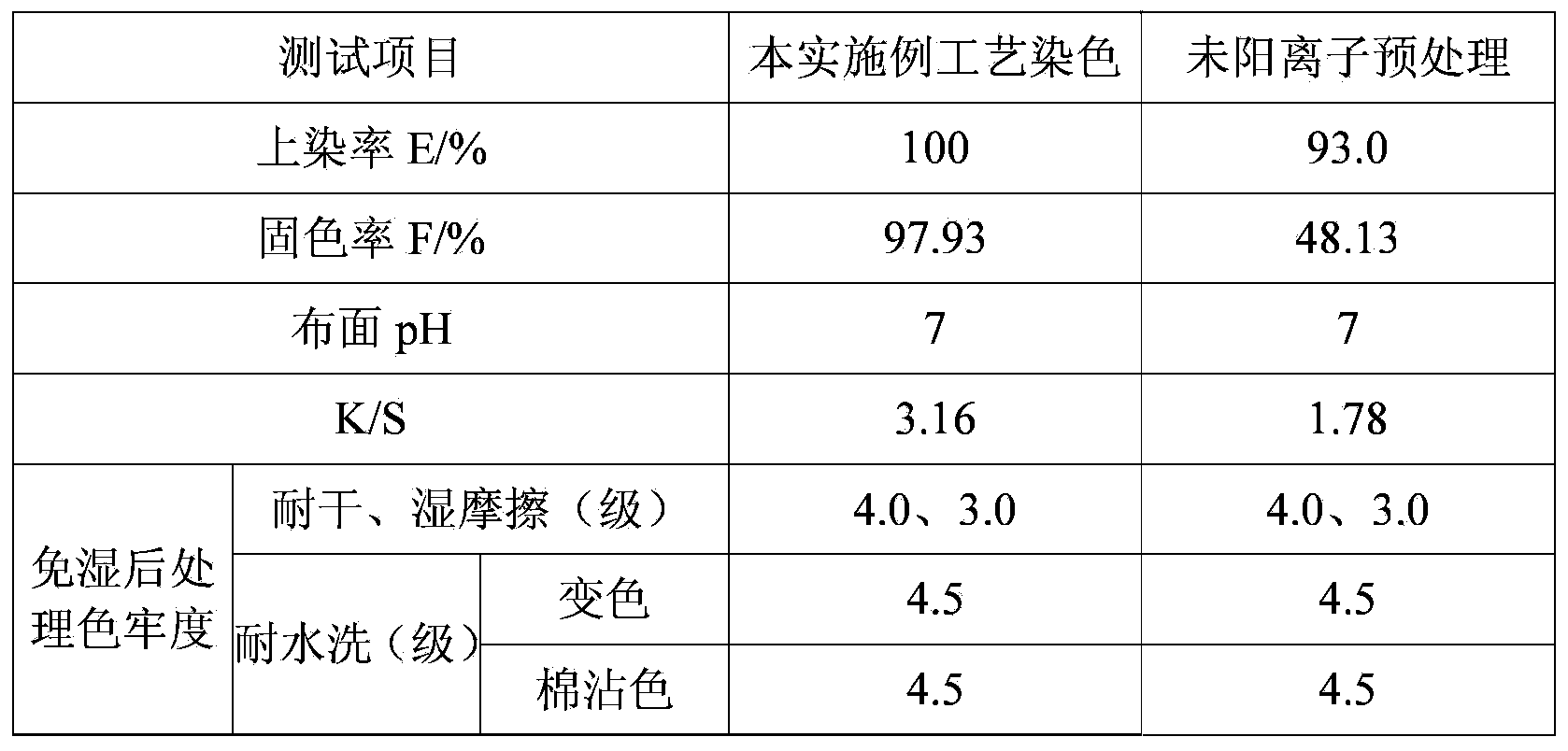

[0041] The knitted fabric was taken out and dried directly to complete the dyeing; the solvent was recovered and the color fastness was tested, and the dye fixation rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com