Preparation method of smoothing, stiffening and color deepening silicone oil

A technology of deep silicon and crude oil, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of increasing costs, wasting energy, and not being able to improve the fabric handle, etc., and achieve the effect of deepening color, reducing costs, and deepening handle finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

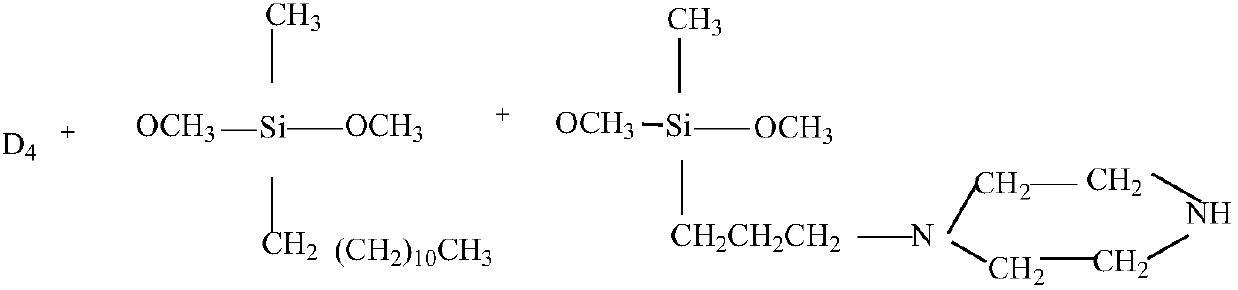

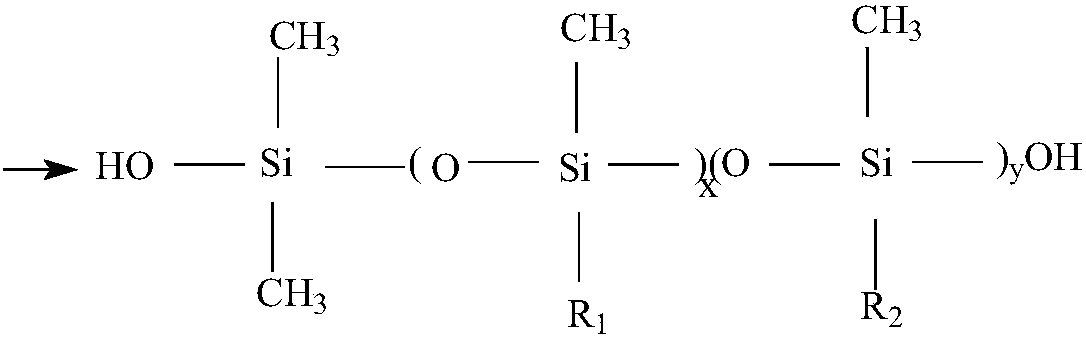

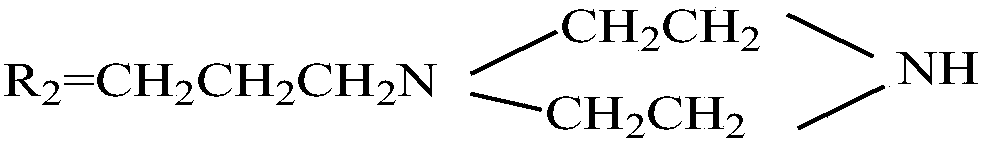

[0014] A method for preparing smooth and darkening silicone oil, the sources or specifications of the reagents used are as follows: Octamethylcyclotetrasiloxane D 4 (CAS No. 556-67-2, Bluestar Silicone Materials Co., Ltd.), dodecylmethyldimethoxysilane HD-109 (CAS No. 163131-89-3, Hangzhou Dadi Chemical Co., Ltd.), γ- Piperazinylpropylmethyldimethoxysilane GP-108 (CAS No. 128996-12-3, Shanghai Sipu Chemical Co., Ltd.), carboxylated chitosan (Shanghai Ziyi Reagent Factory), silicone oil emulsifier GR -300 (Shanghai Gerunning Chemical Technology Co., Ltd.), ethylene glycol phenyl ether E109370 (CAS No. 122-99-6, Shanghai Aladdin Biochemical Technology Co., Ltd.) acid agent, glacial acetic acid, sulfuric acid, hydrochloric acid, formic acid, alkali The base catalyst, tetramethylammonium hydroxide, potassium hydroxide, lithium hydroxide, sodium hydroxide, etc. are analytically pure, and dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethyl Oxysilanes are commonly use...

Embodiment 1

[0029](1) Synthesis of smooth and deep silicone oil crude oil: a certain amount of octamethylcyclotetrasiloxane, dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethoxy Silane was sequentially added to a three-necked flask equipped with a stirrer and a thermometer, the amount of octamethylcyclotetrasiloxane and dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethoxy The ratio of the combined amount of silane is 100:5, wherein the amount of dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethoxysilane is 3:1, start stirring and Raise the temperature to 80°C, then add 0.02% tetramethylammonium hydroxide in the amount of octamethylcyclotetrasiloxane, stir for 20 minutes, raise the temperature to 135-140°C, keep it warm for 4 hours, add carboxylation After the chitosan, the heat preservation reaction was continued for 2 hours. The concentration of the carboxylated chitosan was 1.0% of the total amount of smoothing and darkening silicone oil crud...

Embodiment 2

[0032] (1) Synthesis of smooth and deep silicone oil crude oil: a certain amount of octamethylcyclotetrasiloxane, dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethoxy Silane was sequentially added to a three-necked flask equipped with a stirrer and a thermometer, the amount of octamethylcyclotetrasiloxane and dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethoxy The ratio of the combined amount of silane is 100:6, wherein the amount of dodecylmethyldimethoxysilane and γ-piperazinylpropylmethyldimethoxysilane is 2:1, start stirring and Raise the temperature to 80°C, then add 0.04% tetramethylammonium hydroxide in the amount of octamethylcyclotetrasiloxane, stir for 20 minutes, raise the temperature to 135-140°C, keep it warm for 6 hours, add carboxylation After the chitosan, the heat preservation reaction was continued for 2 hours. The concentration of the carboxylated chitosan was 2.0% of the total amount of smoothing and darkening silicone oil cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com