Novel 3D stereo printing process

A three-dimensional printing and 3D technology, applied in the field of textile printing, can solve the problems that the printing effect is easily affected by temperature and pressure, the cost of pigments is high, and it is easy to cause dizziness, etc., so as to improve the level of clean production, reduce costs, and have excellent visual effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

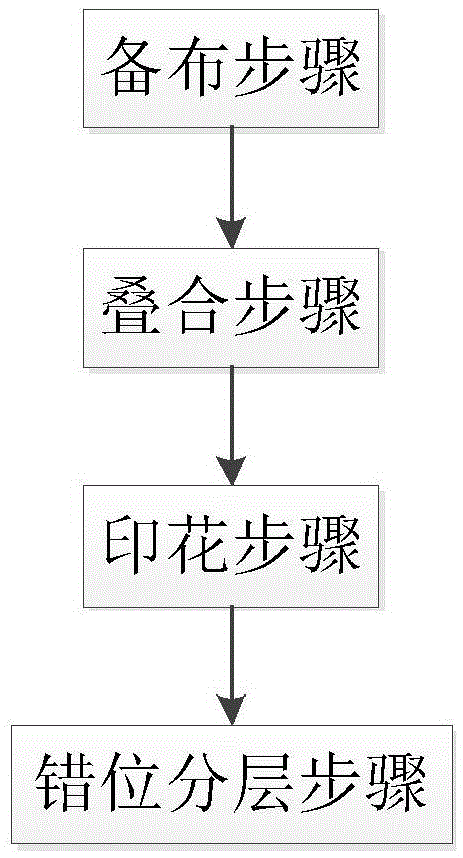

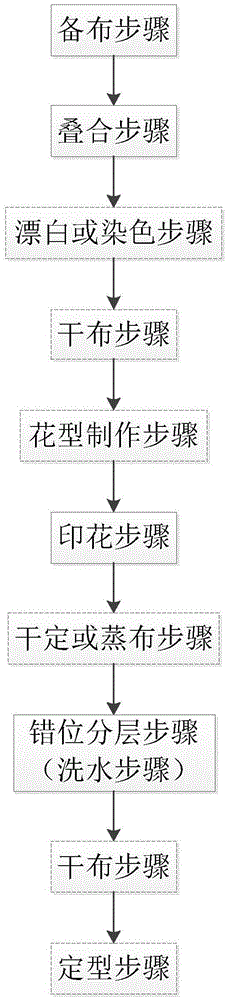

[0045] Step 1, cloth preparation step: prepare mesh cloth and chiffon cloth required for printing;

[0046] Step 2, stacking step: the mesh cloth and chiffon cloth obtained in the cloth preparation step are overlapped and bonded by an adhesive to form a composite layer fabric;

[0047] Step 3, bleaching or dyeing step: bleaching or dyeing the cloth;

[0048] Step 4, dry cloth step: carry out dry cloth treatment to the cloth that has been bleached or dyed;

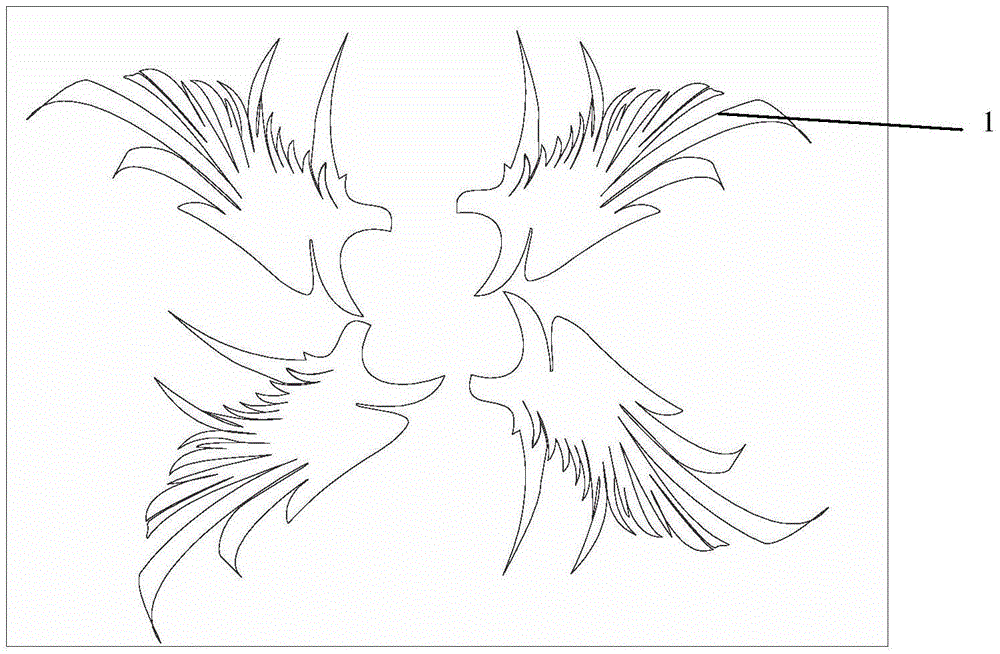

[0049] Step 5, pattern making step: arrange and make the patterns that need to be printed and dyed;

[0050] Step 6. Printing step: Use disperse dyes with a molecular weight of 250-400 and a particle diameter of 0.2-2 microns, a water-soluble carrier or an alcohol-soluble carrier, and an oil-soluble resin to make an ink, and then use the ink to print the pattern required for printing and dyeing onto the thermal transfer paper, and then process the thermal transfer paper and fabric through a transfer printing machine at a ...

Embodiment 2

[0056] The printing process of embodiment 2 is basically the same as that of the above embodiment 1, the difference is the printing step in step 6, the printing step in embodiment 2 is: first select the ink according to the properties of the cloth, and then use the ink to print and dye the required Print the pattern on the thermal transfer paper, then pad the composite layer fabric through the mixed solution including color fixing aid and paste, and then transfer it by hot pressing in a wet state. During the transfer process , the ink on the thermal transfer paper is first printed and dyed on the permeable layer of the composite layer fabric, and then the ink passes through the permeable layer fabric and printed on the dyed layer fabric, completing the transfer and fixation of the ink from the thermal transfer paper to the composite layer fabric;

Embodiment 3

[0058] The printing process of embodiment 3 is basically the same as that of the above embodiment 1, the difference is the printing step in step 6, the printing step in embodiment 3 is: first prepare the ink with dye and wax as the basic components, and then use the prepared The ink prints the pattern to be printed and dyed on the thermal transfer paper, and then melts and presses the ink on the thermal transfer paper to be printed on the permeable layer of the composite layer fabric, and then the ink passes through the permeable layer fabric and is printed and dyed On the printing and dyeing layer fabric, complete the transfer and fixation of the ink from the thermal transfer paper to the composite layer fabric;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com