A kind of preparation method of water-based black natural dye inkjet printing ink

A natural dye and inkjet printing technology, applied in natural dyes, dyeing methods, azo dyes, etc., can solve the problems of natural dye inks such as lack of black color, poor stability, uneven color spectrum, etc., and achieve the effect of improving the level of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of water-based black natural dye ink-jet printing ink, comprising:

[0021] Step 1: preparation of black natural dye raw material;

[0022] In one embodiment, this step can be specifically performed as follows: respectively dissolving tannic acid and hematoxylin in an acidic aqueous solution with a pH value of 2 to 4 to prepare a dye solution with a concentration of 5 to 10% by mass, and mixing evenly. Under stirring, add ferrous sulfate solution with a mass percentage concentration of 5-10% dropwise within 1-2 hours, heat up to 50-90°C, and react at a constant temperature for 10-30 hours. After the reaction, salt out, filter, and dry to obtain black Natural dye raw material, wherein, the mass percentages of the three components in the reaction system are: 10-20% of tannic acid, 30-60% of hematoxylin, 20-60% of ferrous sulfate, and the tannic acid is extracted from Galla gall Obtained by extraction, and the hematoxyli...

Embodiment 1

[0028] The preparation method of water-based black natural dye inkjet printing ink comprises the following steps:

[0029] (1) Preparation of black natural dye raw material:

[0030] The mass percentages of the three reactants are: 15% of tannic acid, 45% of hematoxylin, and 40% of ferrous sulfate.

[0031] Dissolve tannic acid and hematoxylin in an acidic aqueous solution with a pH value of 3.2 to prepare a dye solution with a mass percentage concentration of 7%, and mix evenly; under stirring, add dropwise a mass percentage concentration of 8% within 1.5h. The ferrous sulfate solution was heated up to 75°C and reacted at constant temperature for 21 hours. After the reaction, salt out, filter and dry to obtain black natural dye raw materials.

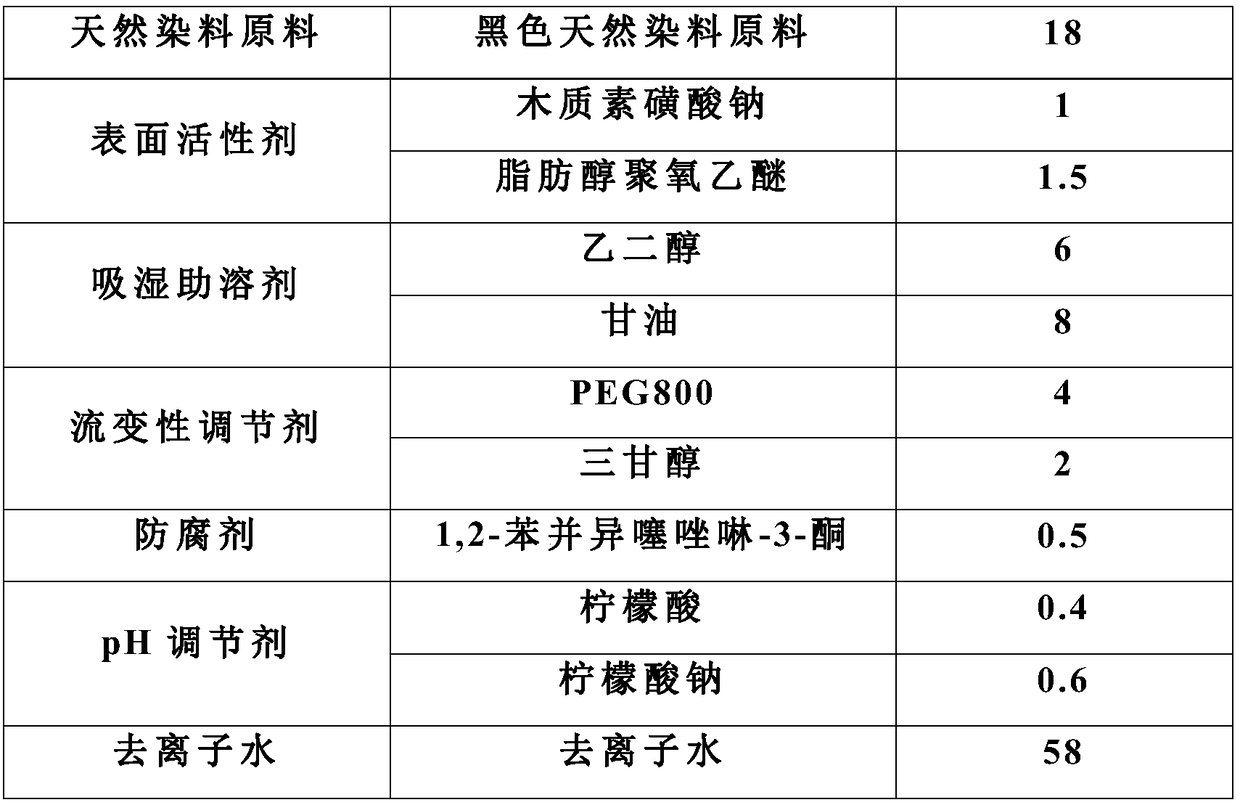

[0032] (2) Preparation of water-based black natural dye inkjet printing ink:

[0033] The mass percentage of water-based black natural dye inkjet printing ink components is as follows:

[0034]

[0035]

[0036] Put each comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com