Patents

Literature

96results about How to "Improve shift efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

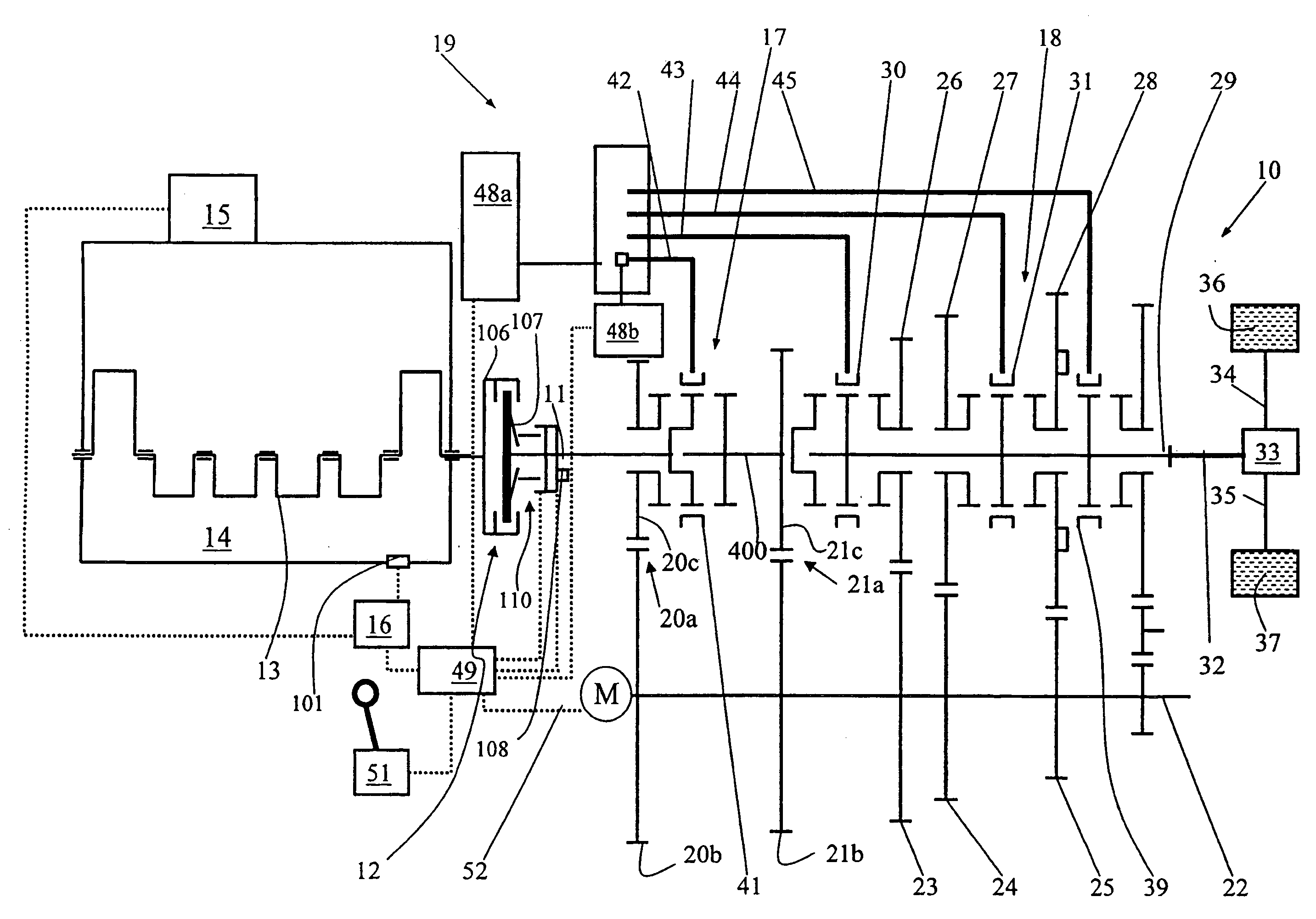

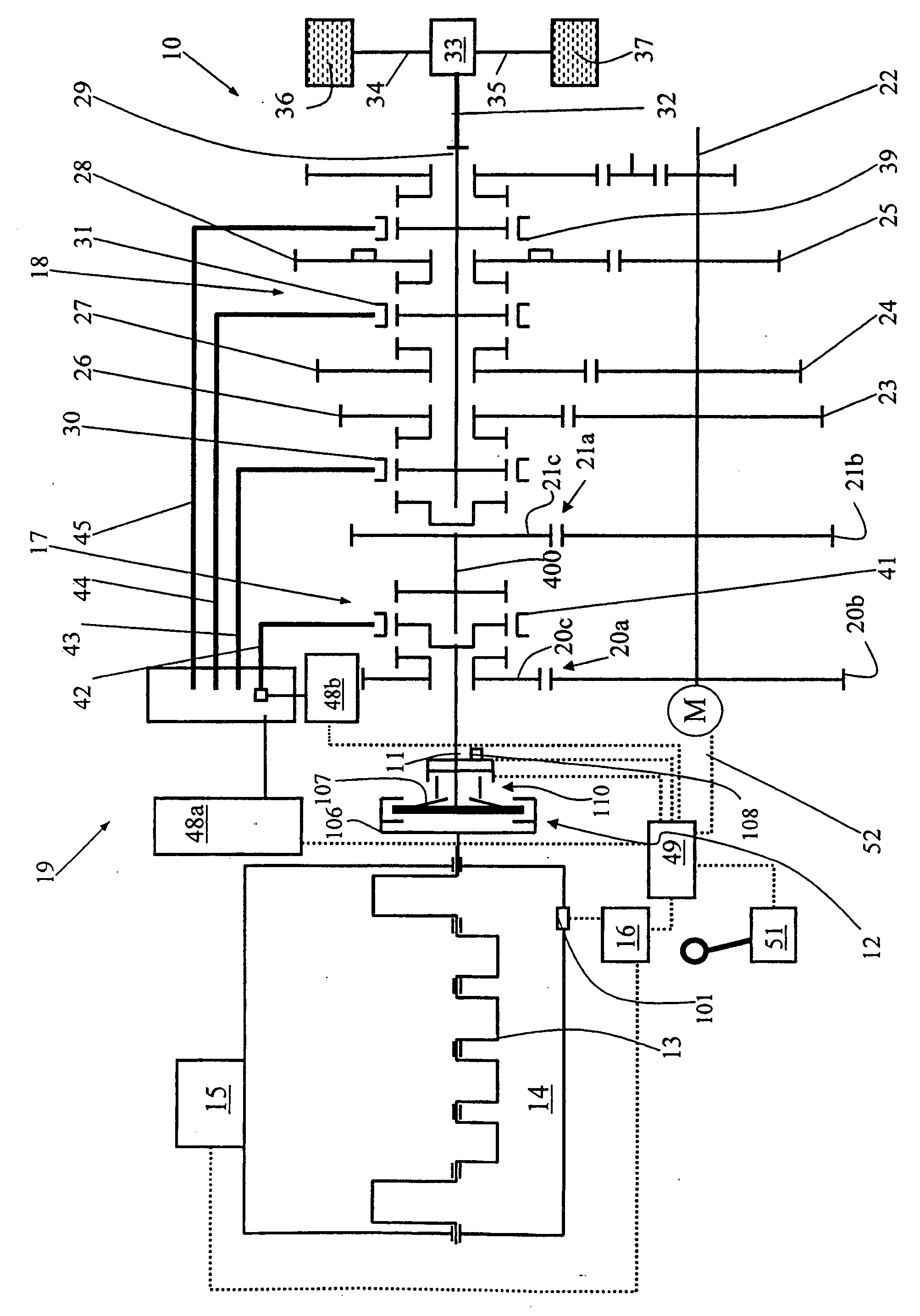

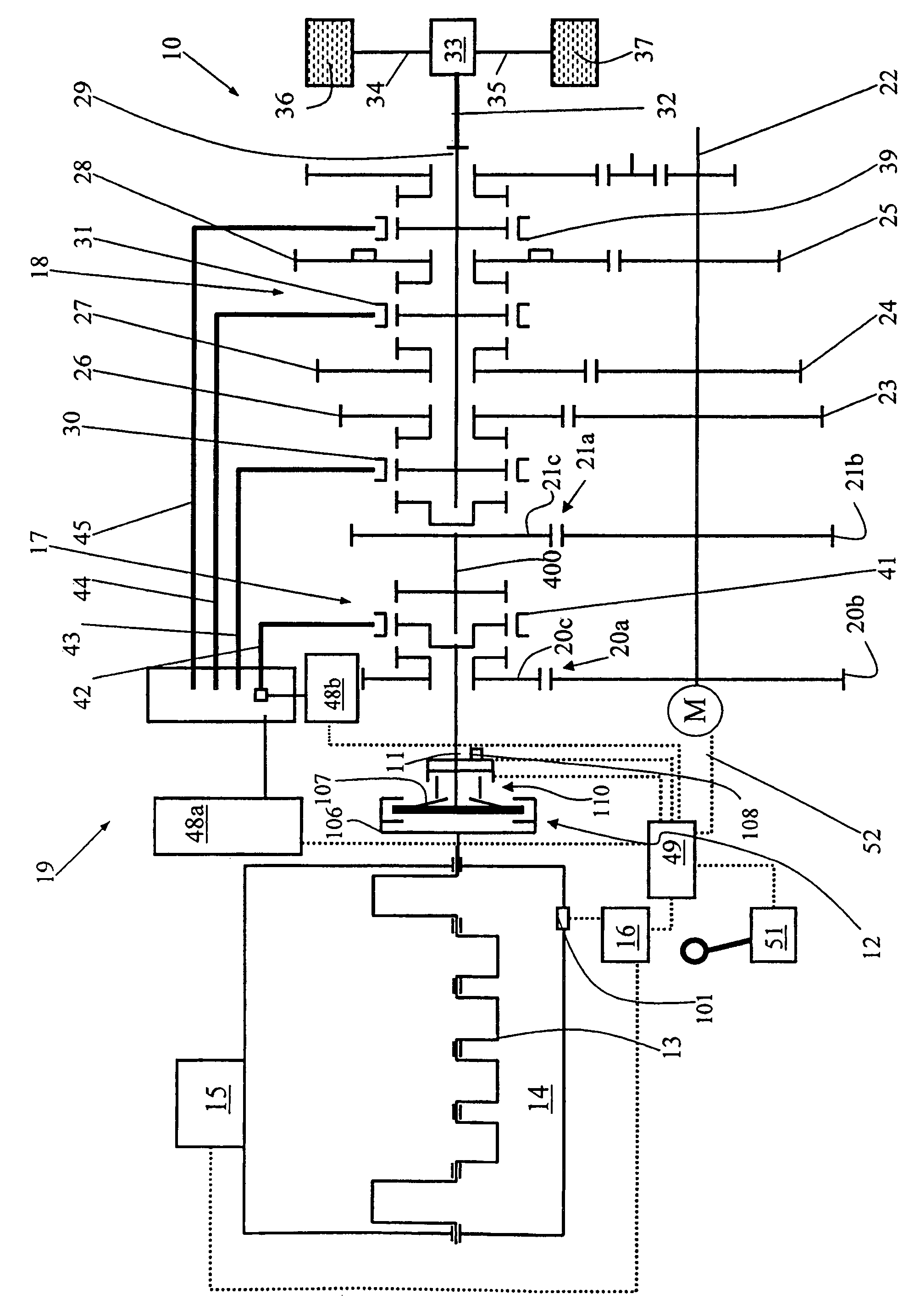

Shifting claw transmission and shifting method therefor

InactiveUS20080314176A1Easy transferAvoid problemsToothed gearingsGearing controlFree rotationGear wheel

In a shifting claw transmission for a motor vehicle including a main shaft and a countershaft and an electric motor for rotating the countershaft or being rotated thereby with freely rotatable gear wheels supported on the counter shaft and engageable with the countershaft by claw engagement structures, the speed of the countershaft is adjustable by the electric motor to be close to, but somewhat different from, the speed of the freely rotatable gear wheels to be engaged in order to facilitate shifting but avoid a tooth-on-tooth problem which would inhibit shifting.

Owner:DAIMLER AG

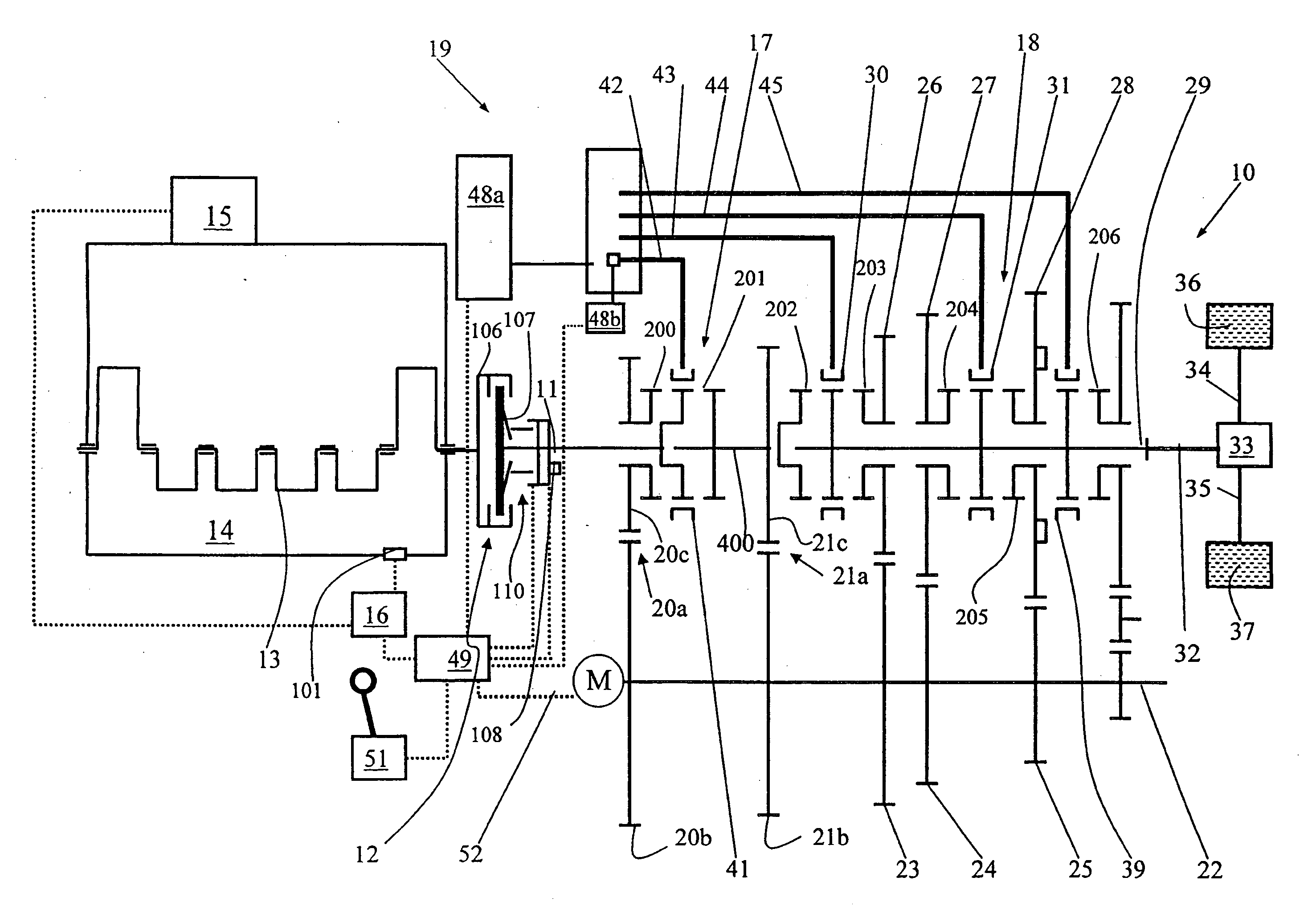

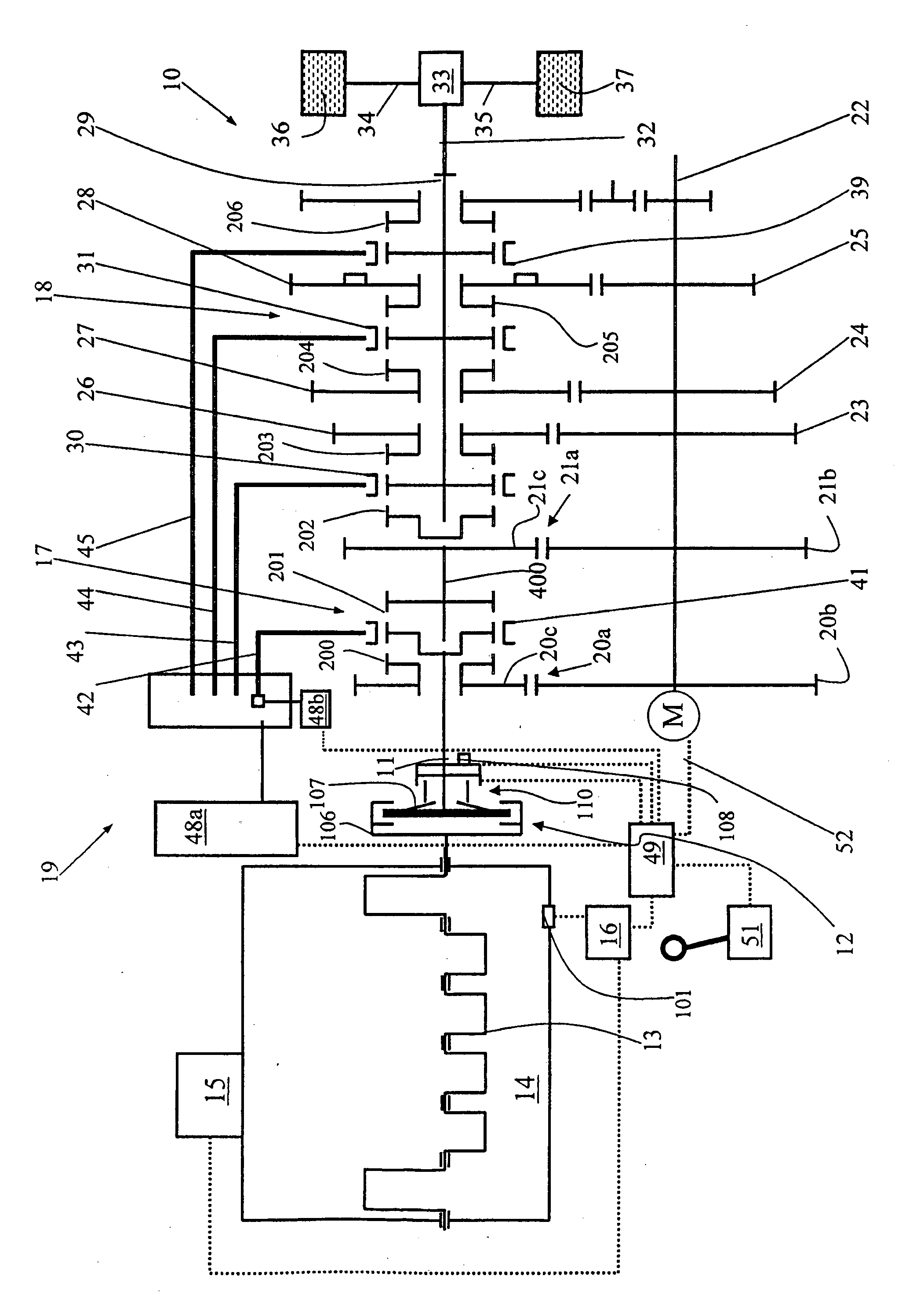

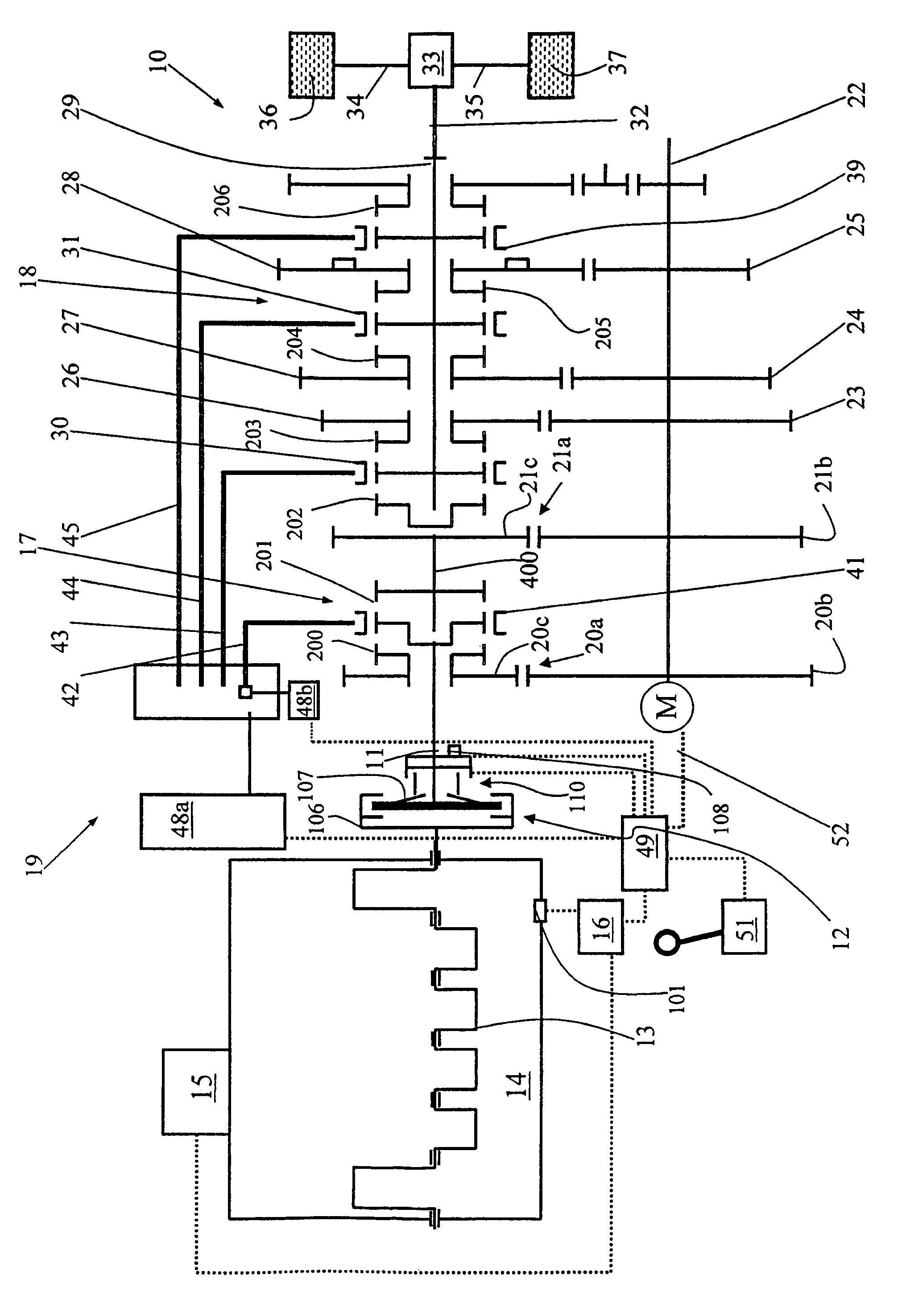

Utility vehicle having a drive motor and a shifting claw transmission with an electric motor

InactiveUS20090107270A1Fast brakingEasy to adjustToothed gearingsGearing controlMobile vehicleGear wheel

In a motor vehicle, in particular a utility vehicle, having a shifting claw transmission and an electric motor connected to a countershaft of the transmission to facilitate central synchronization for gear speed changes, a transmission controller is connected to the electric motor for sensing the electric motor speed and, together therewith the rotational speed of the countershaft based on the induction values present in at the electric motor and sensed by the transmission controller for use in adjusting the energization of the electric motor.

Owner:DAIMLER AG

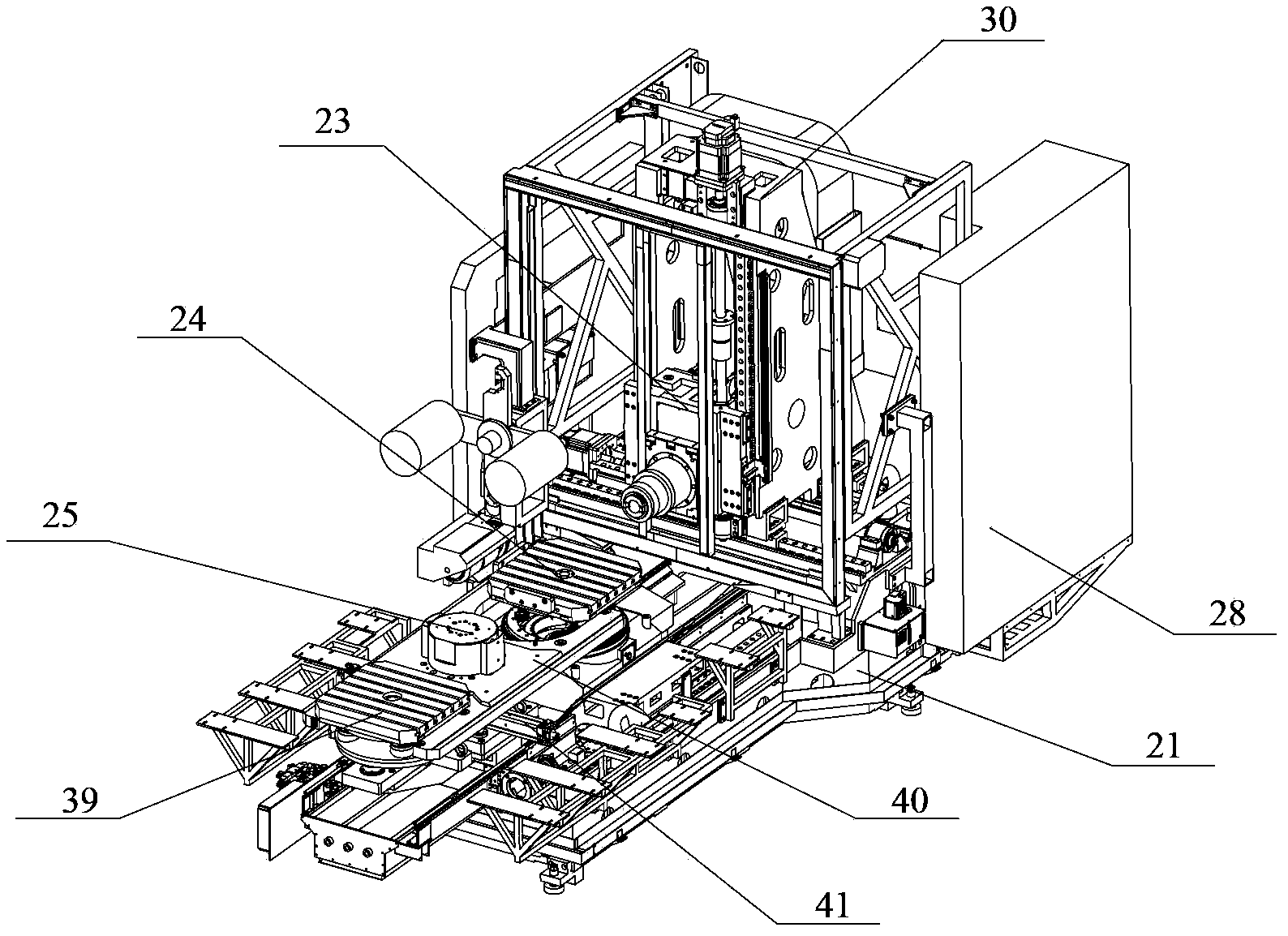

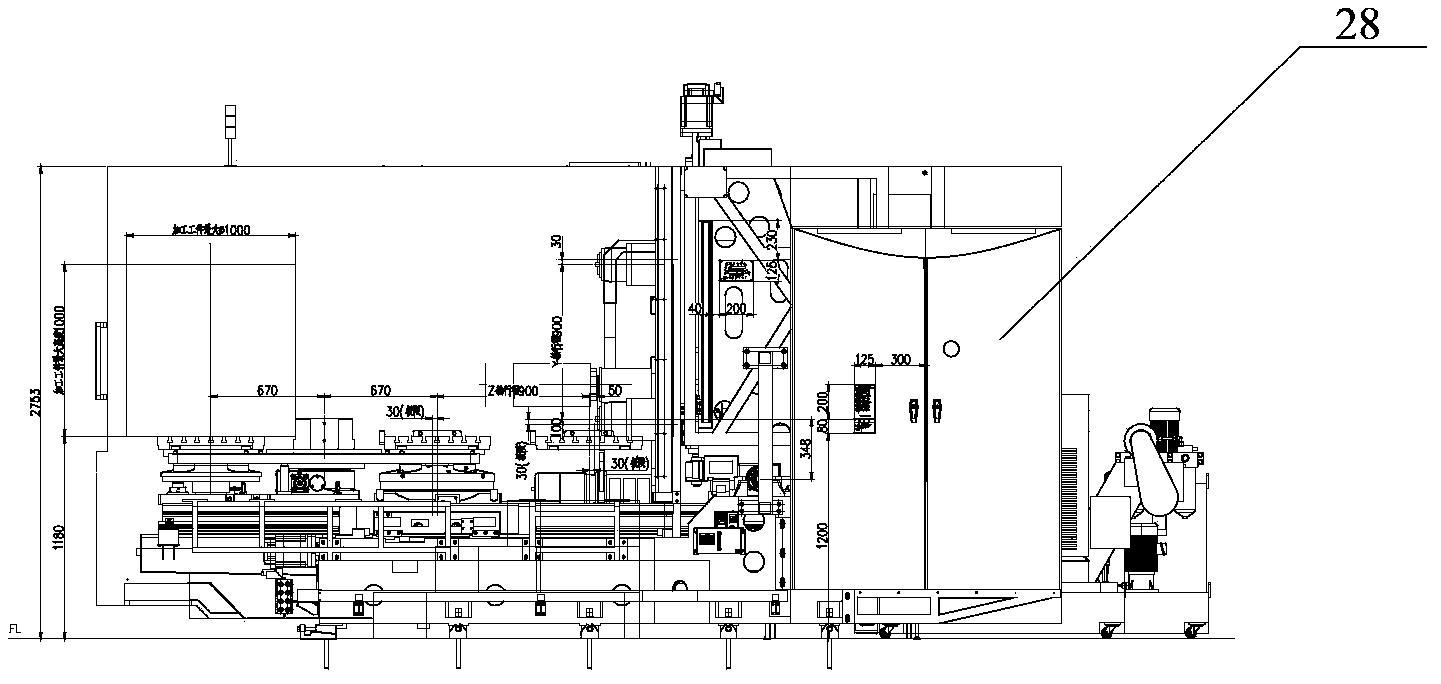

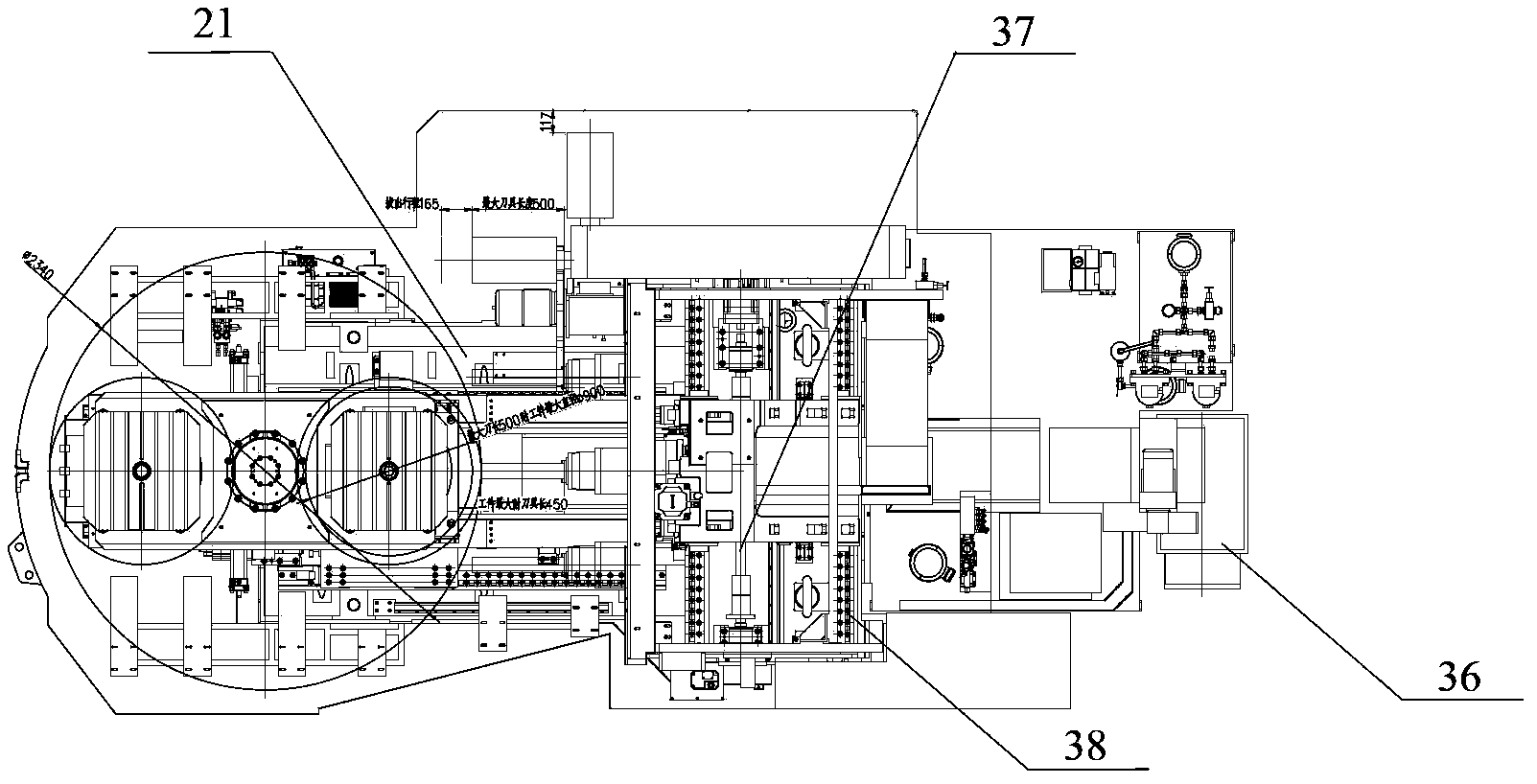

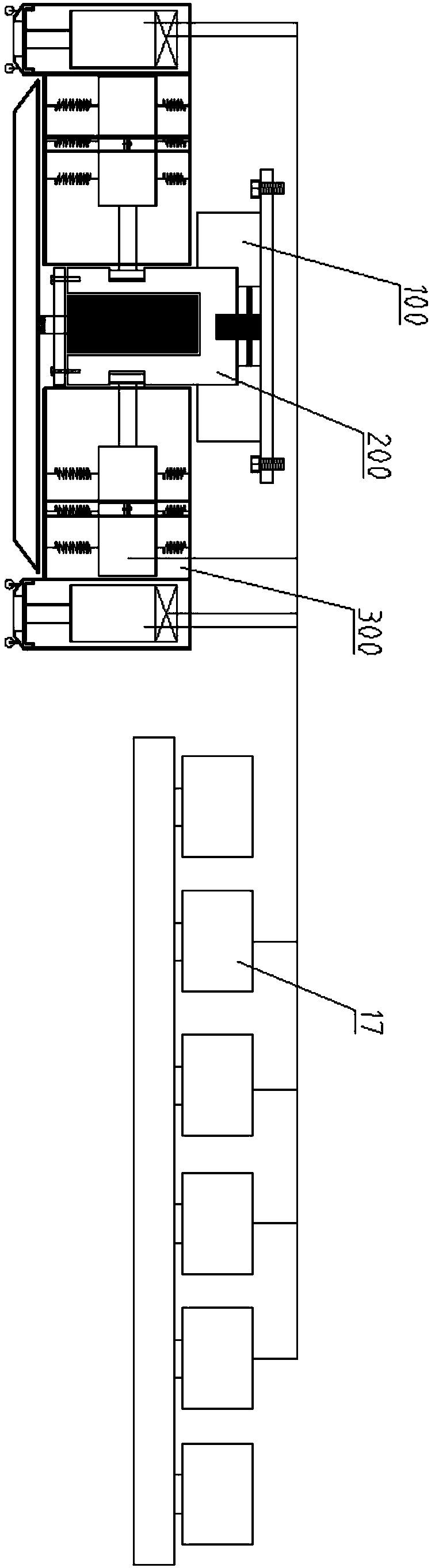

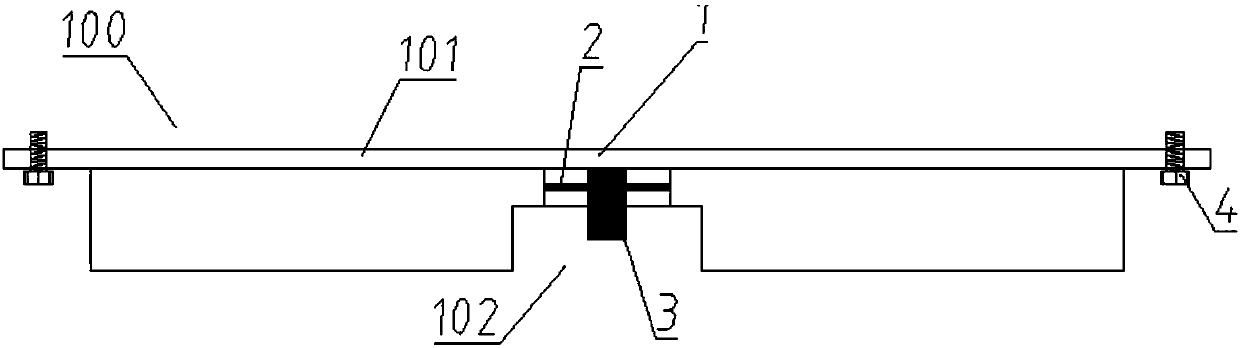

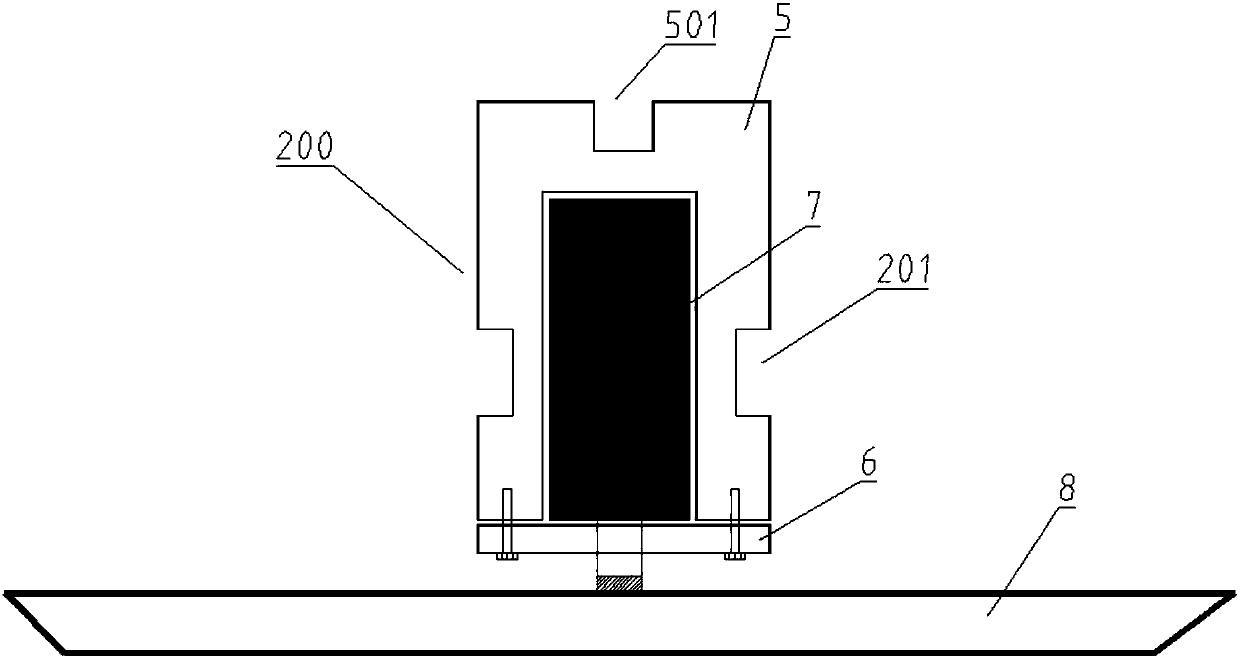

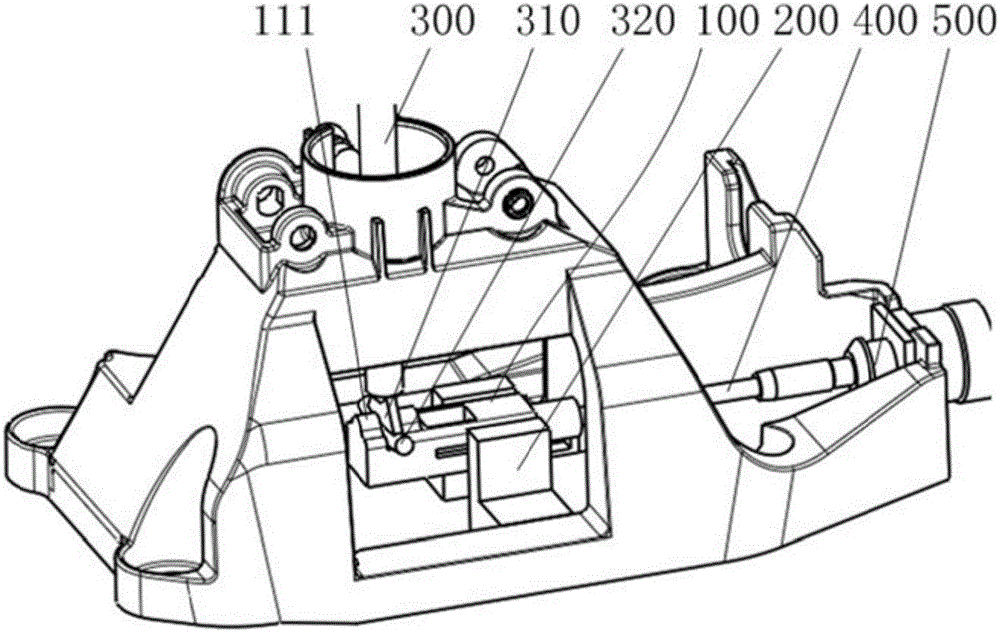

Efficient complete machine structure for horizontal machining center and manufacturing method thereof

ActiveCN103358186AResidue reductionAvoid harmFeeding apparatusLarge fixed membersManufacturing technologyTransmitted power

The invention relates to the field of machine manufacturing equipment, in particular to an efficient complete machine structure for a horizontal machining center and a manufacturing method thereof, and belongs to the design of a numerically controlled machining center of a machine tool and manufacturing technique. The complete machine structure comprises a lathe bed, a column, a headstock, a tool magazine and the like, wherein backwater holes are formed in the declined surface of the rigidity lathe bed; the gantry framework type column which moves horizontally on the lathe bed adopts a *-shaped rib arrangement; a motor directly connected ZF reduction gearbox on a headstock which moves vertically on the column transmits power to a spindle through the belt; a loosely clamped knife adopts a gas-liquid conversion pressurized cylinder; a swivel table that moves along the lathe bed forwards and backwards adopts a modularized design; a variable-frequency ATC (Air Traffic Control) at the left side of the lathe bed is in rigid connection with a square tool magazine body; an L-shaped electrical cabinet is arranged at the right side of the lathe bed; a structure of combing a large-flow cutting fluid fling mechanism with a chain plate chip cleaner is adopted in the middle of the lathe bed; a function setting interface, a maintenance plan function and an energy saving function are possessed. The structure provided by the invention solves the problems that a common horizontal machining center is large in size, high in energy consumption, complex in maintenance in the prior art.

Owner:SHENYANG MASCH TOOL CO LTD

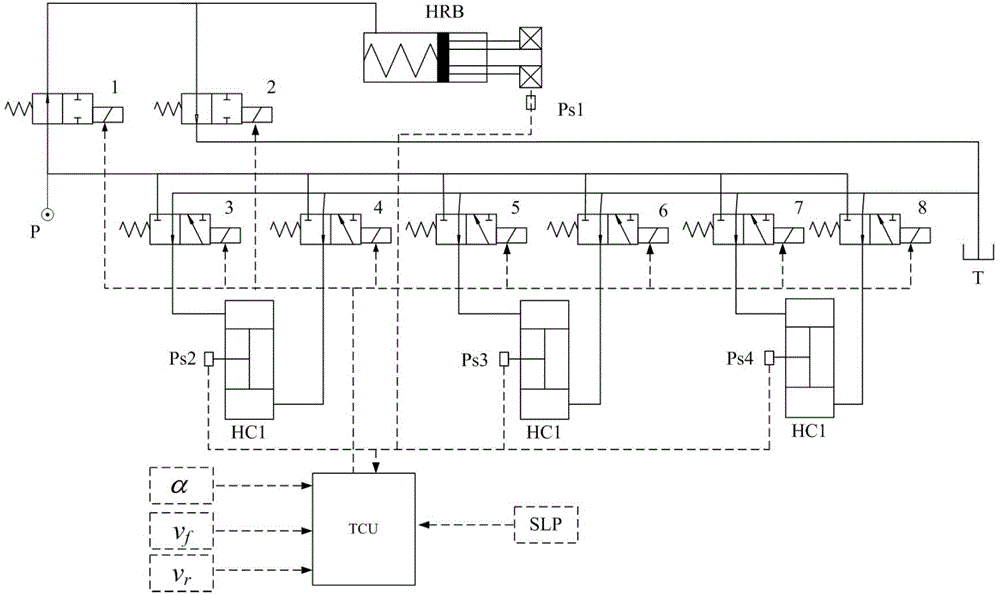

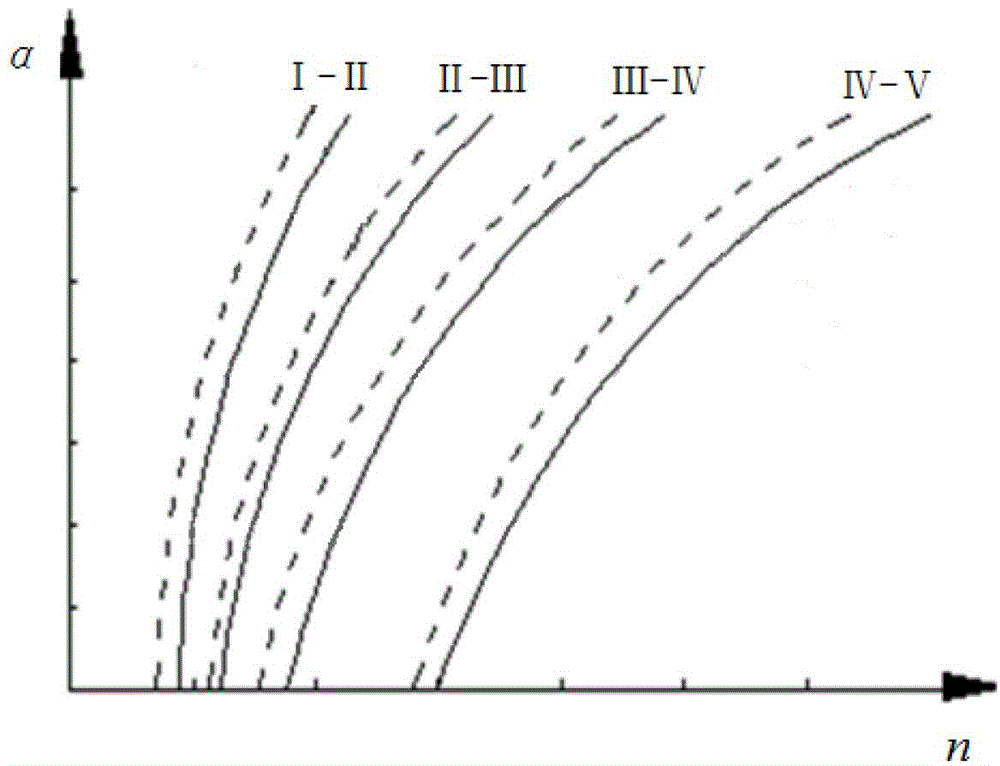

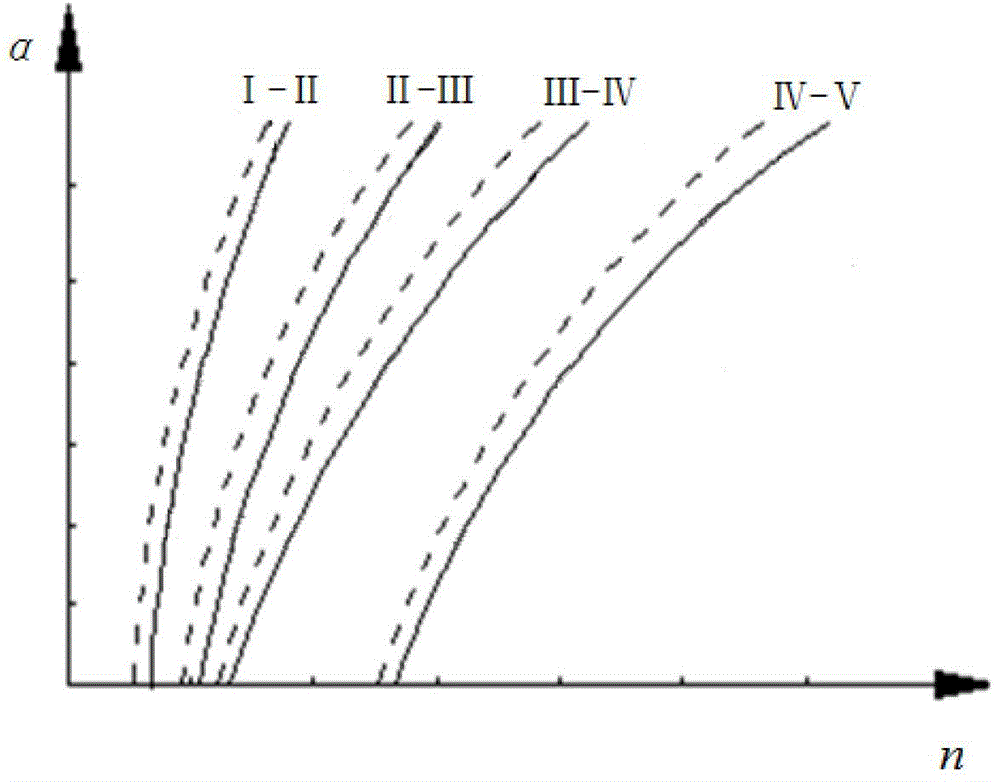

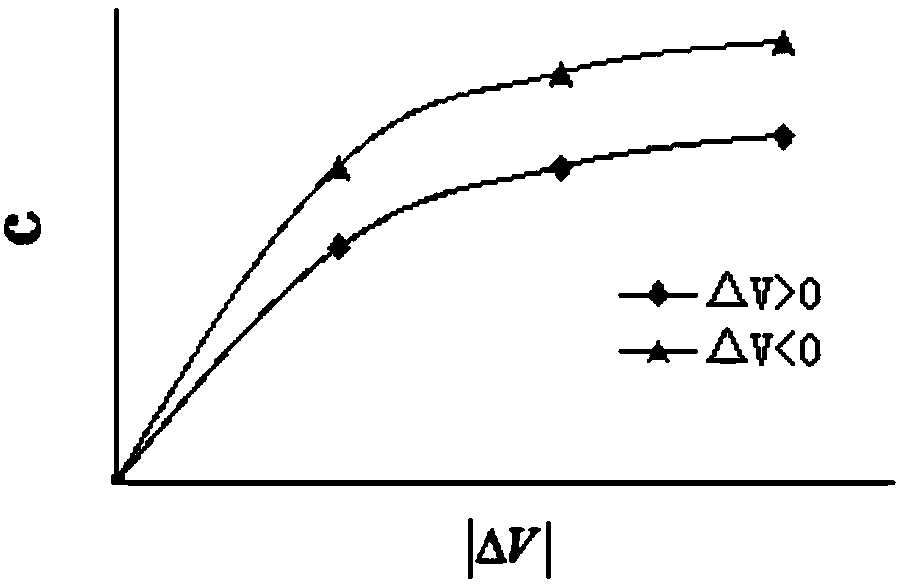

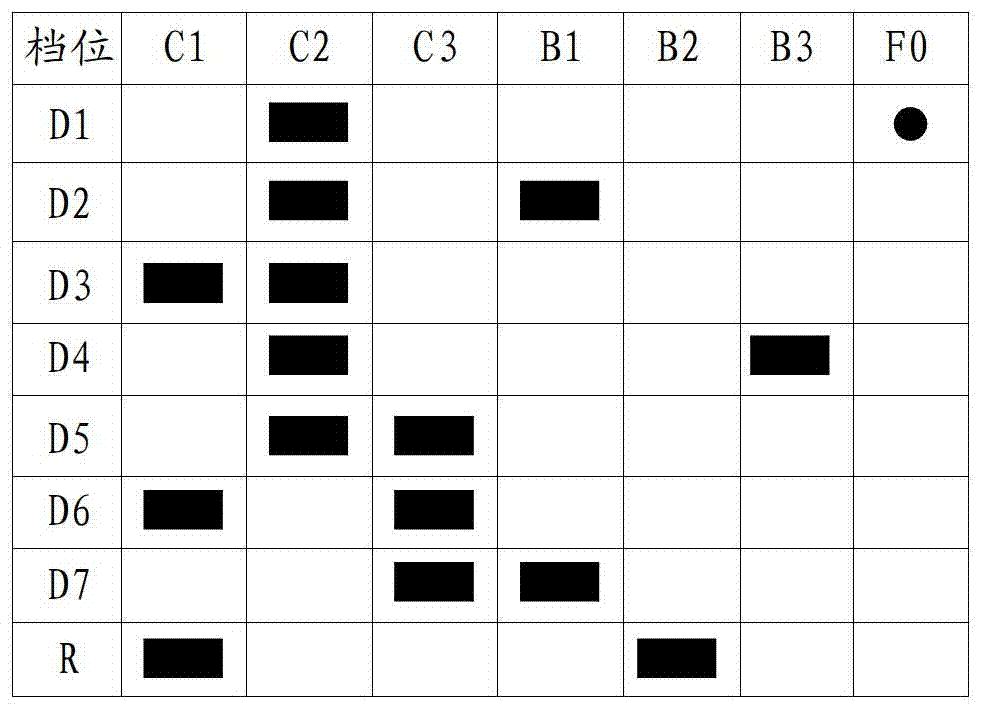

Gear-shifting schedule curve measuring method and corresponding gear-shifting control method for off-road vehicles

The invention relates to a gear-shifting schedule curve measuring method and a corresponding gear-shifting control method for off-road vehicles, and belongs to the technical field of automatic variable speed control of the off-road vehicles. According to the methods, a gear-shifting schedule curve equation of an AMT (automated mechanical transmission) of an off-road vehicle is calculated firstly; a corresponding gear-shifting schedule curve is drawn; the current practical vehicle speed, the slip ratio and the throttle opening degree are collected, and corresponding target gears are determined; control signals for electromagnetic valves of actuating mechanisms are output through an logical operation; therefore, the electromagnetic valves of the actuating mechanisms are enabled to perform corresponding actions, and the automatic gear shifting is achieved. The gear-shifting schedule curve measuring method and the corresponding gear-shifting control method can guarantee the tractive efficiency and the fuel oil economic efficiency of the AMT of the off-road vehicles, reduces the work intensity of a driver, and enables the vehicles to travel more smoothly; meanwhile the gear-shifting actuating mechanisms are improved, a gear selecting process is omitted, the gear-shifting time is reduced and the gear-shifting efficiency is improved due to the direct gear shifting; and the methods can be used for AMT of off-road engineering vehicles, agricultural vehicles and military motor vehicles.

Owner:HENAN UNIV OF SCI & TECH

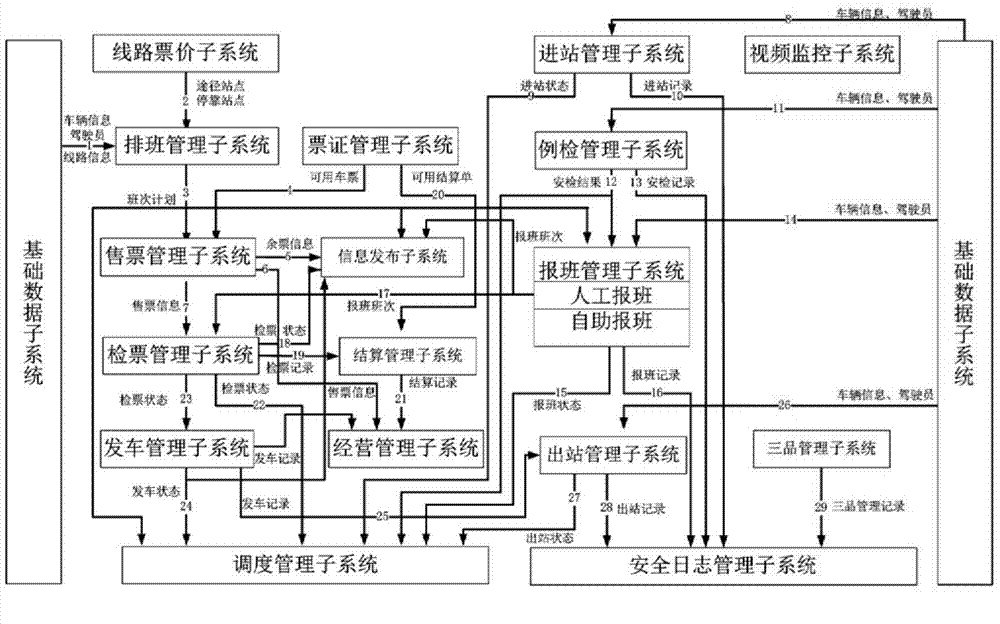

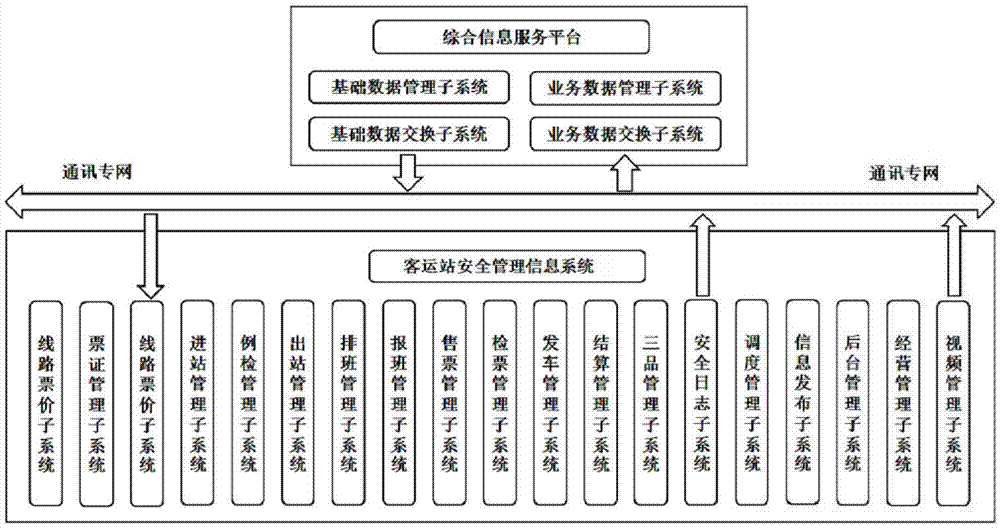

Passenger station safety management information system and method

InactiveCN104850928AImprove safety supervisionImprove pit stop efficiencyResourcesPassenger transportSecurity management

Provided is a passenger station safety information management system. The system employs a B / S structure, makes full use of technologies such as the Internet of Things, cloud calculation, and big data etc., and the standardization, process, normalization, and intelligence of commercial vehicles and station-yard operation can be promoted. The passenger station safety information management system comprises a comprehensive information service platform connected via a communication special network and a passenger station safety information management subsystem.

Owner:北京壹卡行科技有限公司

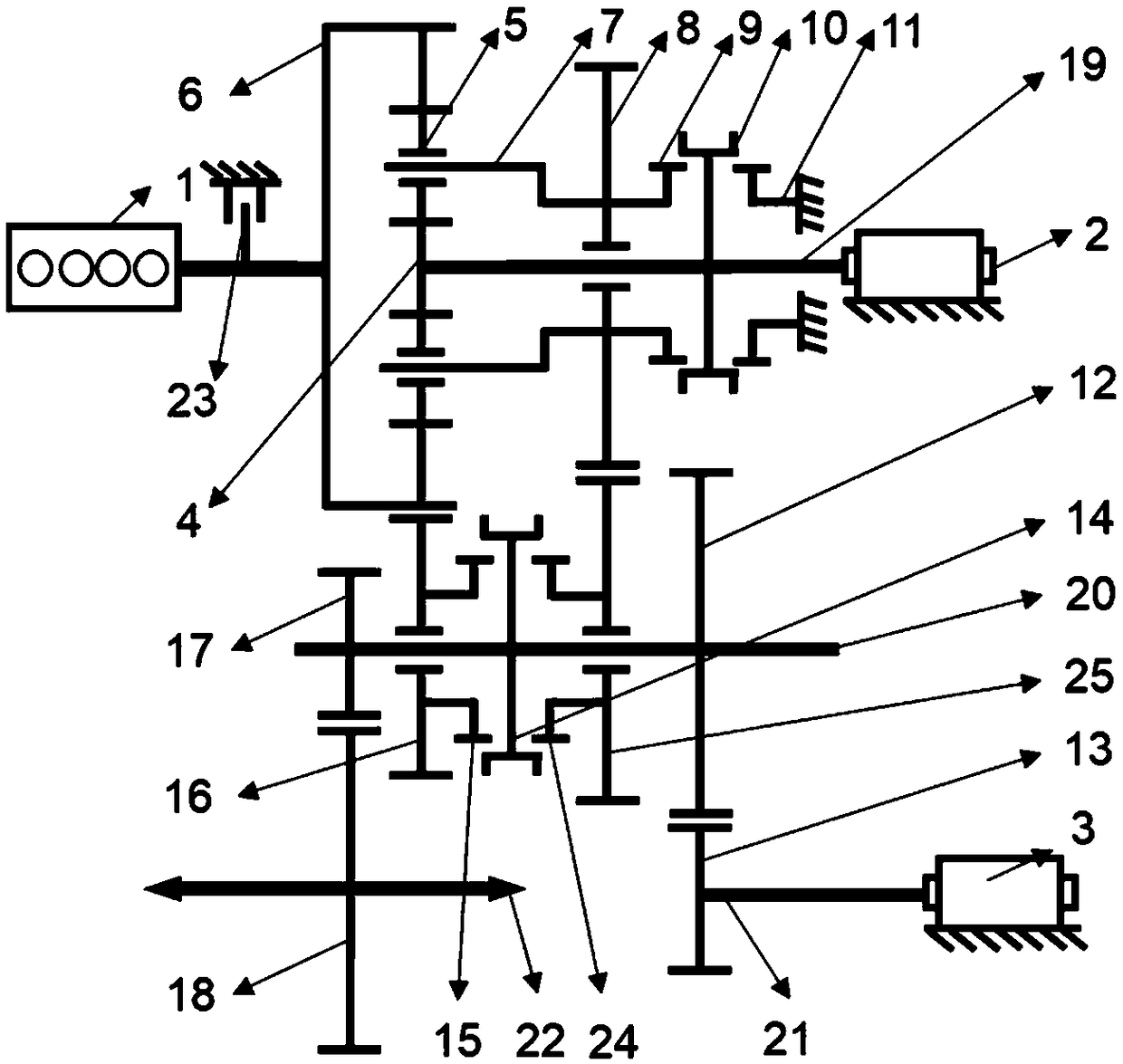

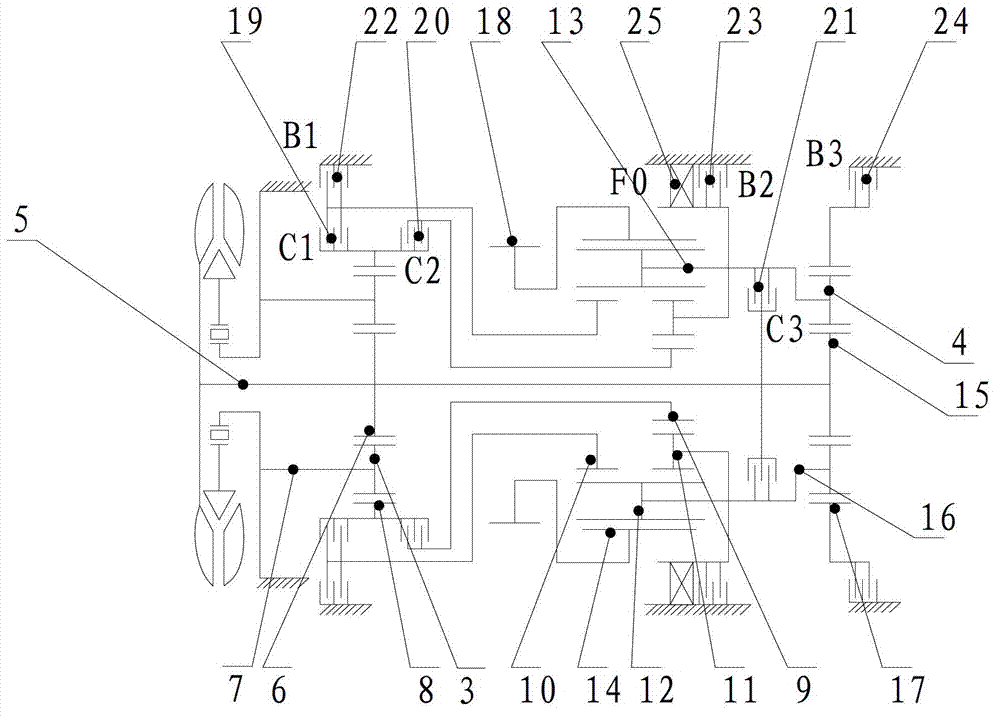

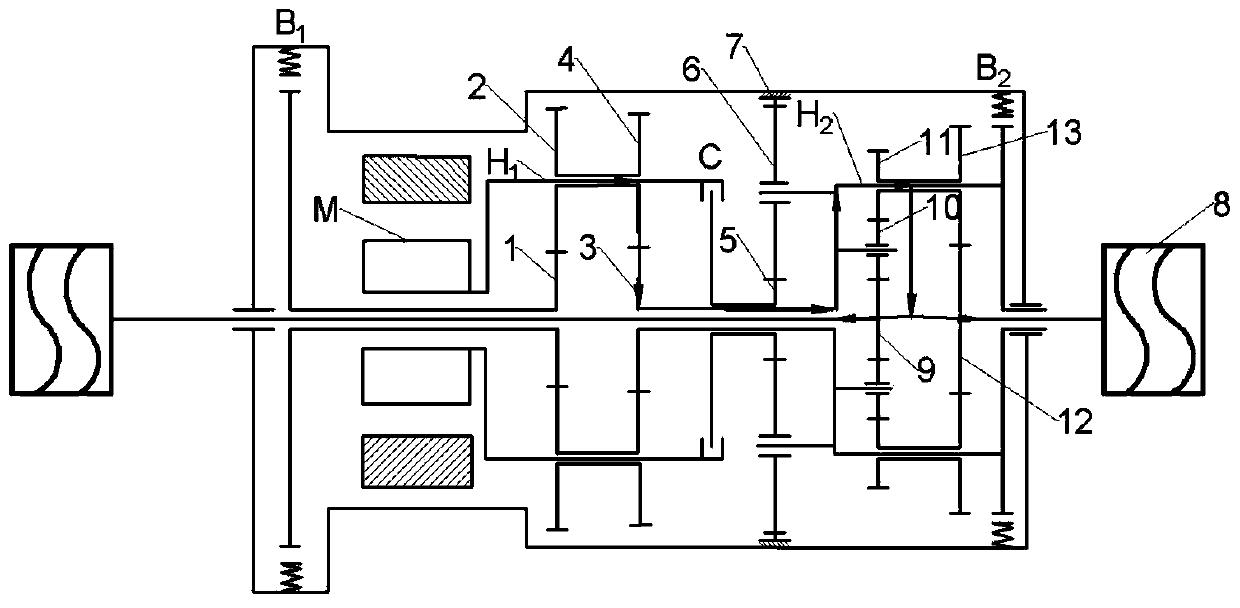

Single planetary gear multi-mode hybrid power transmission

PendingCN108725178AImprove shift efficiencyExtend your lifeHybrid vehiclesGas pressure propulsion mountingClutchVariator

The present invention relates to a single planetary gear multi-mode hybrid power transmission for respectively connecting an engine, single or double number of motors, the single planetary gear multi-mode hybrid power transmission comprises a single planetary row, a gear shift element, a one-way clutch or a common brake, and a common gear, the single planetary row comprises a sun gear, a planetarygear, an outer gear ring and a planetary frame, wherein the planetary gear is meshed with the outer gear ring and the sun gear respectively; the single planetary row has two freedom of rotation, andcan be used to determine the rotation speed of each component; the common gear is meshed with the single planetary row; the gear shift element comprises a meshing component and a synchronous component, wherein the meshing component is connected to the common gear, and the synchronous component is connected to the drive shaft of a motor; the one-way clutch or the common brake is connected to an engine and the outer gear ring gear respectively. Compared with the prior art, the single planetary gear multi-mode hybrid power transmission has the advantages of longer service life, low mechanical complexity, low cost, low control difficulty, more smooth gear shift and the like.

Owner:陈海军

Utility vehicle having a drive motor and a shifting claw transmission with an electric motor

InactiveUS7992458B2Easy to useImprove reliabilityToothed gearingsGearing controlMobile vehicleDrive motor

In a motor vehicle, in particular a utility vehicle, having a shifting claw transmission and an electric motor connected to a countershaft of the transmission to facilitate central synchronization for gear speed changes, a transmission controller is connected to the electric motor for sensing the electric motor speed and, together therewith the rotational speed of the countershaft based on the induction values present in at the electric motor and sensed by the transmission controller for use in adjusting the energization of the electric motor.

Owner:DAIMLER AG

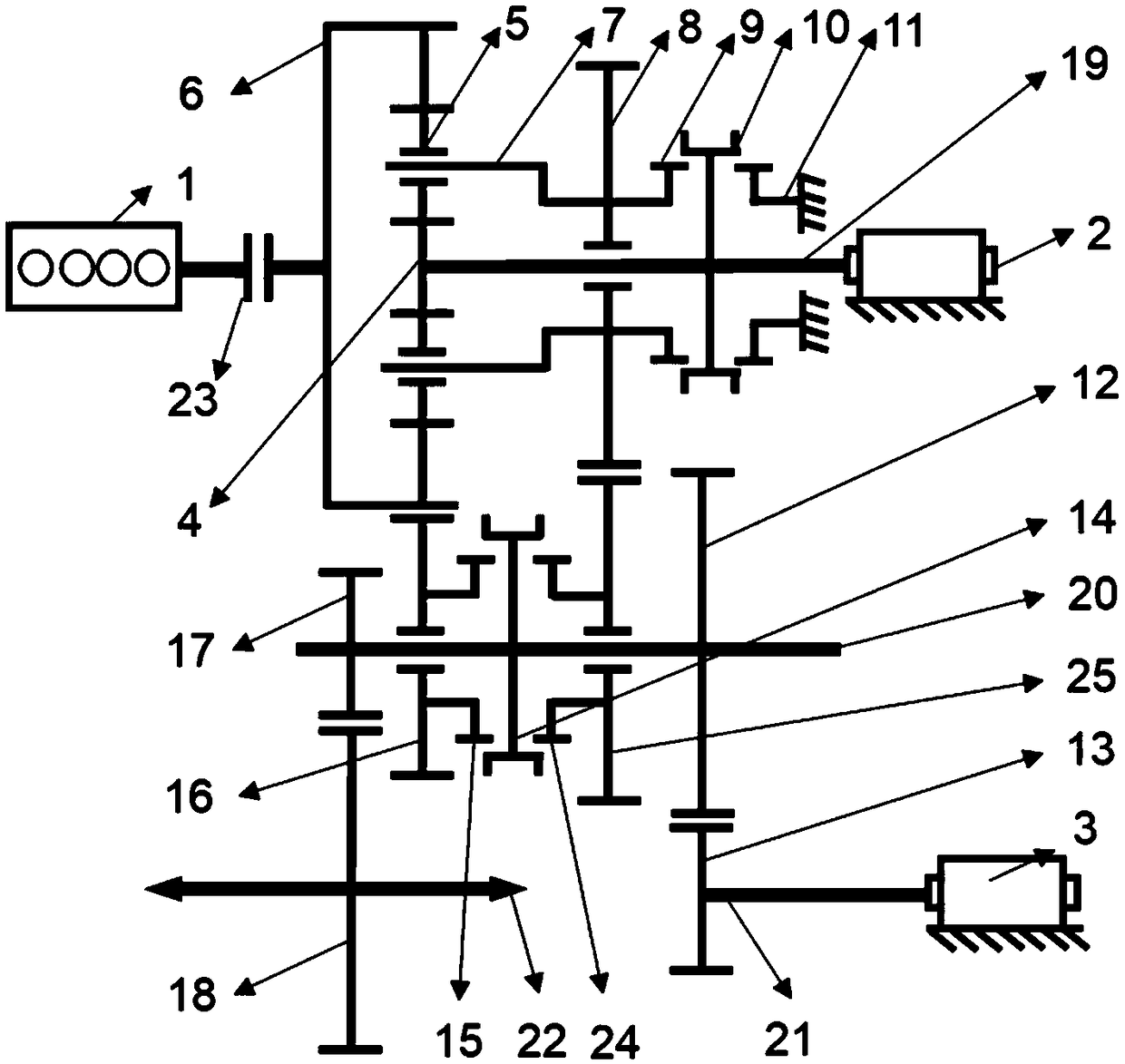

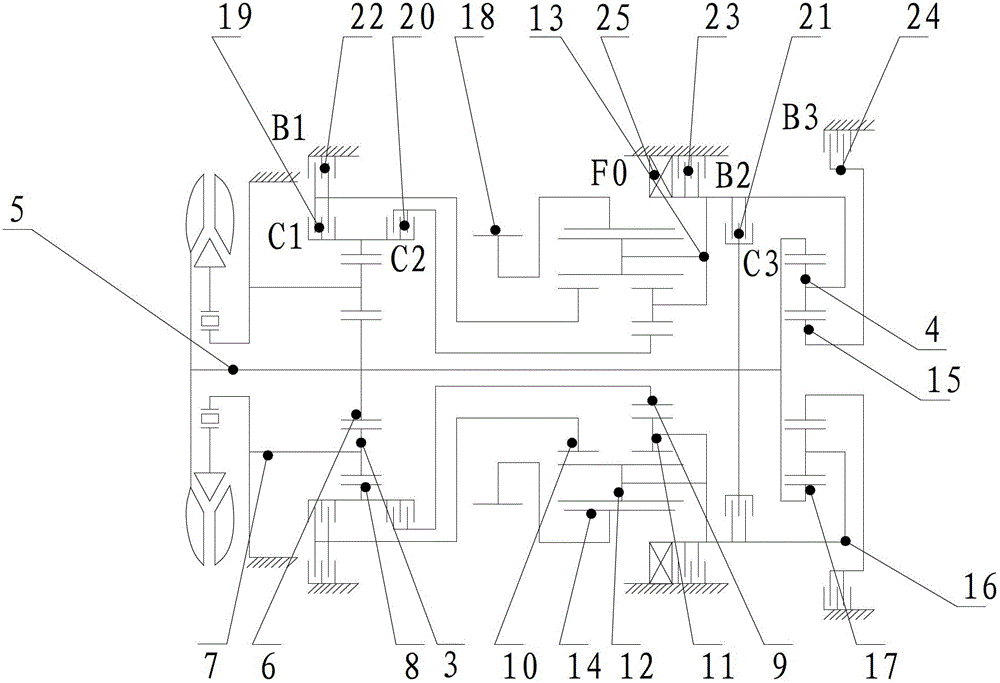

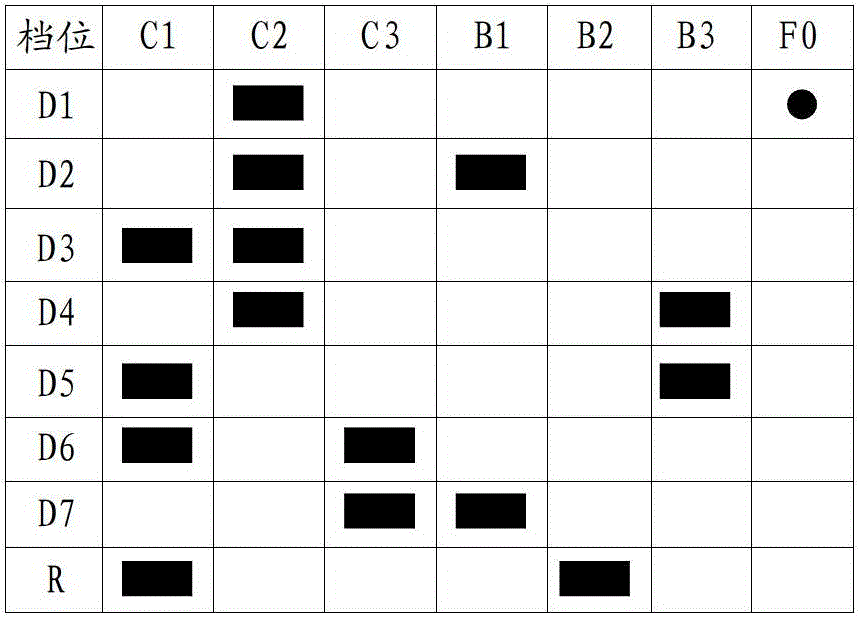

Automobile and speed changer thereof

InactiveCN103148182ACompact structureAxial dimension shortGearboxesToothed gearingsSingle stageEngineering

The invention discloses an automobile and a speed changer thereof. The speed changer comprises a shell, an input shaft, a Ravigneaux planet gear mechanism, and first and second single-row and single-stage planet gear mechanisms, wherein the first single-row and single-stage planet gear mechanism comprise a first sun gear, a first planet gear, a first planet carrier and a first inner gear which are sleeved on the input shaft; the Ravigneaux planet gear mechanism comprises a larger sun gear, a smaller sun gear, a longer planet gear, a shorter planet gear, a planet carrier and an inner gear ring; the larger and smaller sun gears, the first inner gear ring, the planet carrier are connected separably with the input shaft; the second single-row and single-stage planet gear mechanism comprises a second sun gear, a second planet gear, a second planet carrier, a second inner gear ring, a first brake, a second brake and a third brake; the second inner gear ring is connected with the input shaft; the second planet carrier is fixed on the planet carrier; the first brake is used for braking the larger sun gear; the second brake is used for braking the planet carrier; and the third brake is used for braking the second sung gear. According to the speed changer, seven forward gears are designed; and the speed changer is simple in structure, and has high shifting efficiency.

Owner:GREAT WALL MOTOR CO LTD

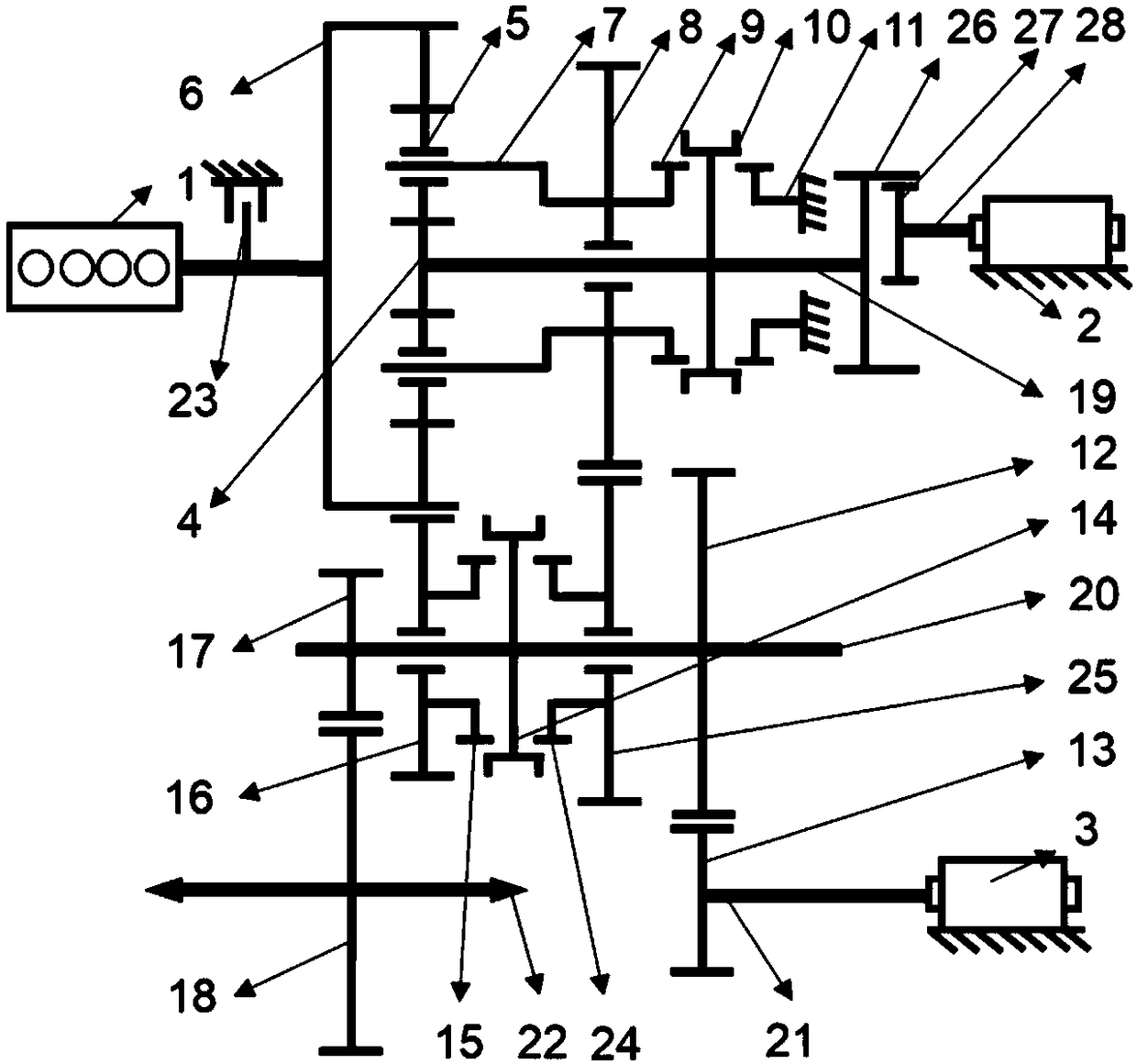

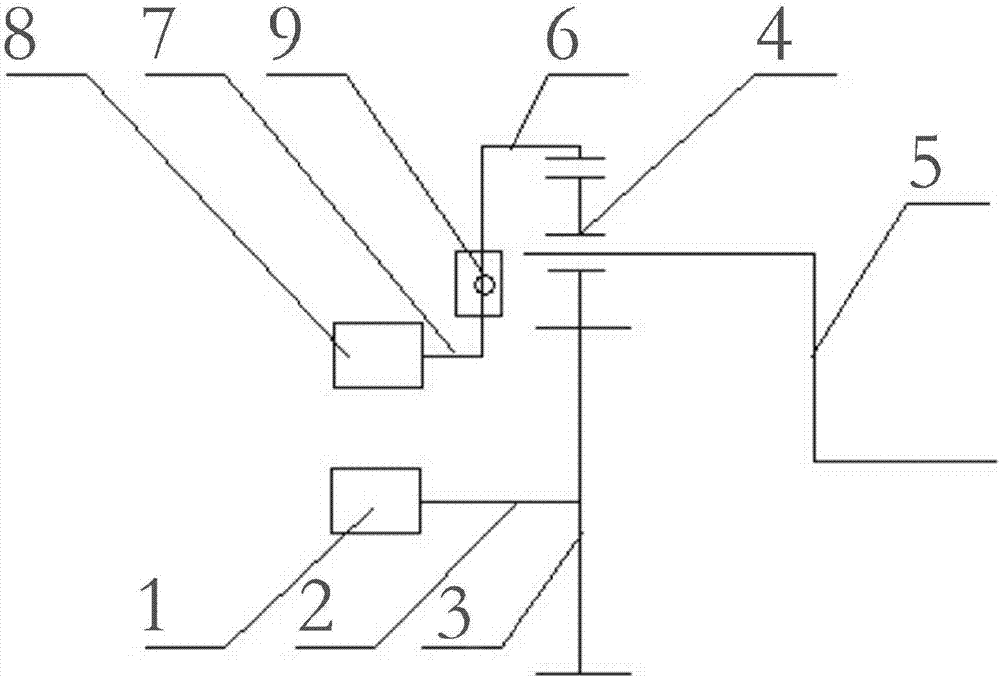

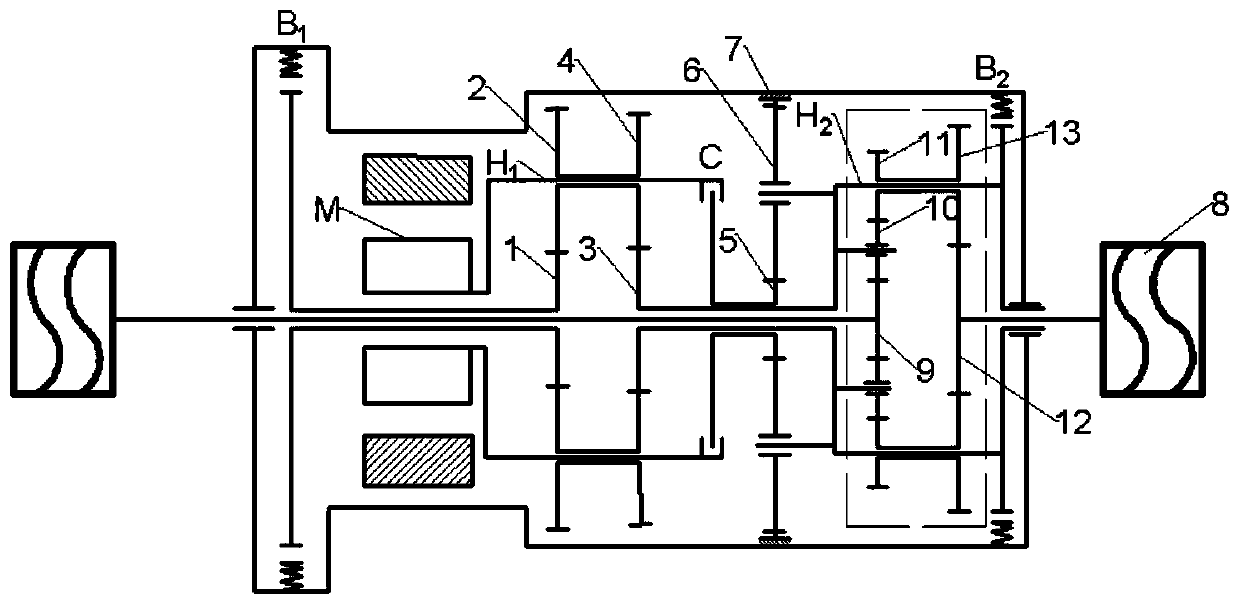

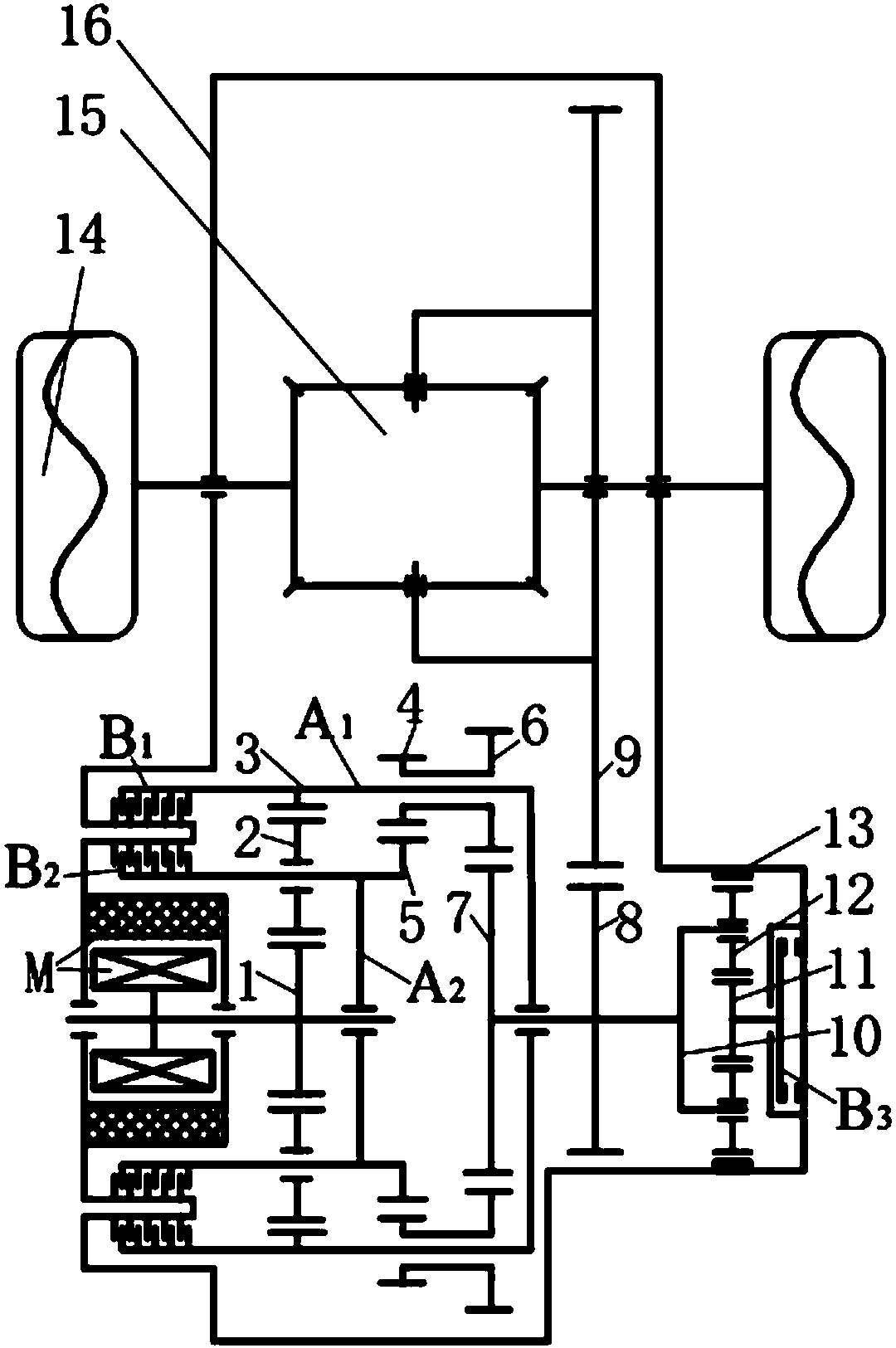

Double-motor planetary transmission

PendingCN106949203AImprove efficiencyImprove shift efficiencyToothed gearingsGearing controlSpur gearPlanet

The invention discloses a double-motor planetary transmission. The double-motor planetary transmission comprises a first motor, a first input shaft, a sun gear, a planet gear set, a planet rack, a gear ring, a second input shaft and a second motor; the first motor is connected to the first input shaft; the first input shaft is connected with the sun gear; the sun gear is matched with the planet gear set; the planet gear set is engaged to the gear ring; the gear ring is connected to the second input shaft; the second input shaft is matched with the second motor; and the planet rack is matched with the planet gear set.

Owner:NANJING YUEBOO POWER SYST CO LTD

Shifting device and method of existing building

ActiveCN107939064AShift continuesUninterrupted shiftBuilding repairsArchitectural engineeringJackscrew

Owner:SHANGHAI NO 4 CONSTR

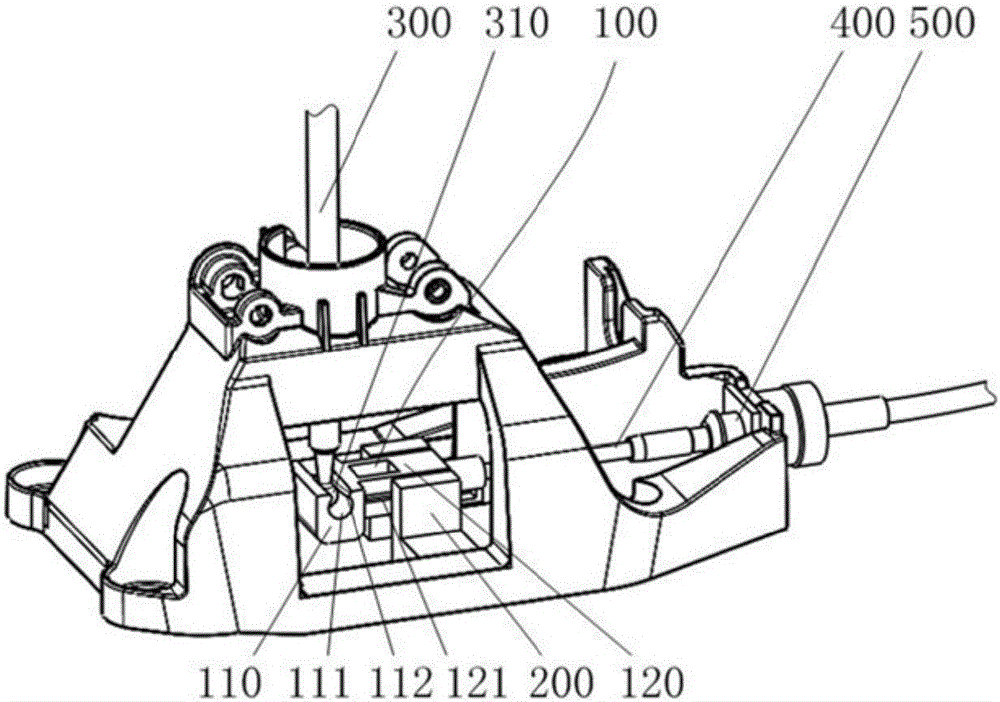

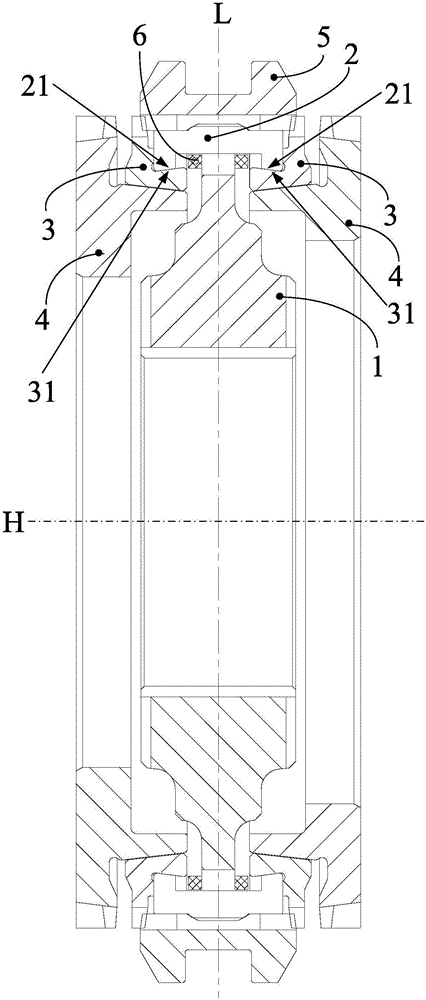

Gear shifting wire drawing joint assembly and wire drawing assembly

InactiveCN106402368AReduce frictionImprove shift efficiencyGearing controlShaft for linear movementEngineeringFriction force

The invention discloses a gear shifting wire drawing joint assembly and a wire drawing assembly. The gear shifting wire drawing joint assembly comprises a wire drawing joint and guide rails; the wire drawing joint comprises a control part and a guide part; a sliding groove is formed in the control part, and is matched with a ball head on the gear shifting rod; the guide rails abut against the two side faces of the guide part; according to the gear shifting wire drawing joint assembly and the wire drawing assembly, through the sliding groove and the guide rails, in the gear selecting and shifting process, a drawn wire can move in the axial direction, friction force between the drawn wire and a protection sleeve is reduced, and the gear shifting efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Shifting claw transmission and shifting method therefor

InactiveUS7992459B2Easy transferImprove shift efficiencyToothed gearingsGearing controlEngineeringTooth problem

In a shifting claw transmission for a motor vehicle including a main shaft and a countershaft and an electric motor for rotating the countershaft or being rotated thereby with freely rotatable gear wheels supported on the counter shaft and engageable with the countershaft by claw engagement structures, the speed of the countershaft is adjustable by the electric motor to be close to, but somewhat different from, the speed of the freely rotatable gear wheels to be engaged in order to facilitate shifting but avoid a tooth-on-tooth problem which would inhibit shifting.

Owner:DAIMLER AG

Electromobile transmission

InactiveCN103836161AImprove shift efficiencyImprove climbing abilityGearing detailsElectromagnetic clutchDrive shaft

The invention discloses an electromobile transmission. The electromobile transmission comprises a transmission body, wherein an input shaft and a driven shaft are arranged in the transmission body, a first driving gear and a second driving gear are arranged on the input shaft, a synchronizer is arranged between the first driving gear and the second driving gear in a sliding mode, a left blocking ring is arranged on the portion, on one side of the first driving gear, of the input shaft, a left electromagnetic clutch matched with the first driving gear is fixedly arranged on the left blocking ring, a right blocking ring is arranged on the portion, on one side of the second driving gear, of the input shaft, a right electromagnetic clutch matched with the second driving gear is fixedly arranged on the right blocking ring, a first driven gear and a second driven gear are arranged on the driven shaft, a transition shaft is arranged on the portion, between the first driven gear and the second driven gear, of the transmission body, a transition gear is arranged on the transition shaft, the transition gear is meshed with both the first driving gear and the first driven gear, and the second driven gear is meshed with the second driving gear.

Owner:盐城市金洲机械制造有限公司

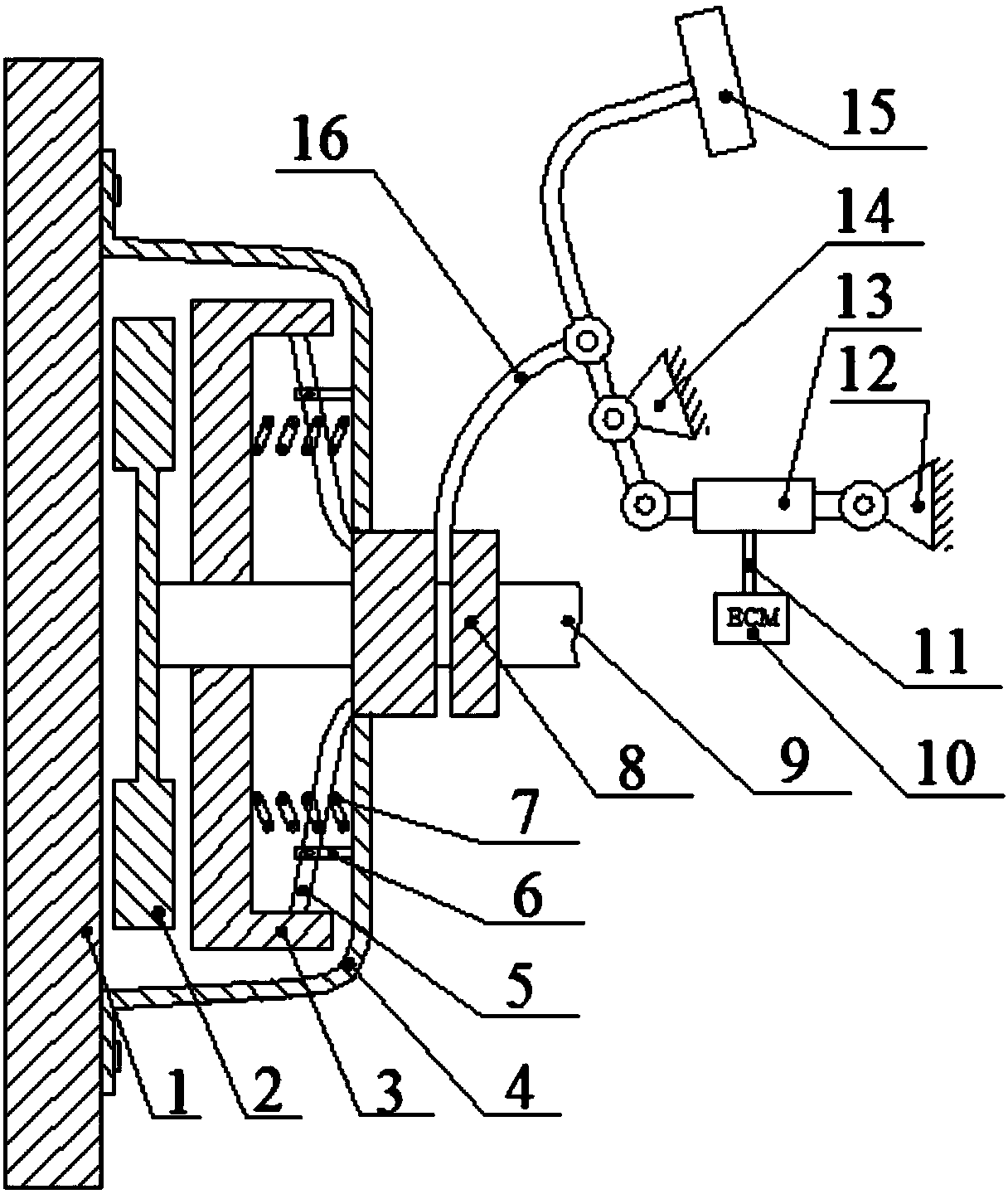

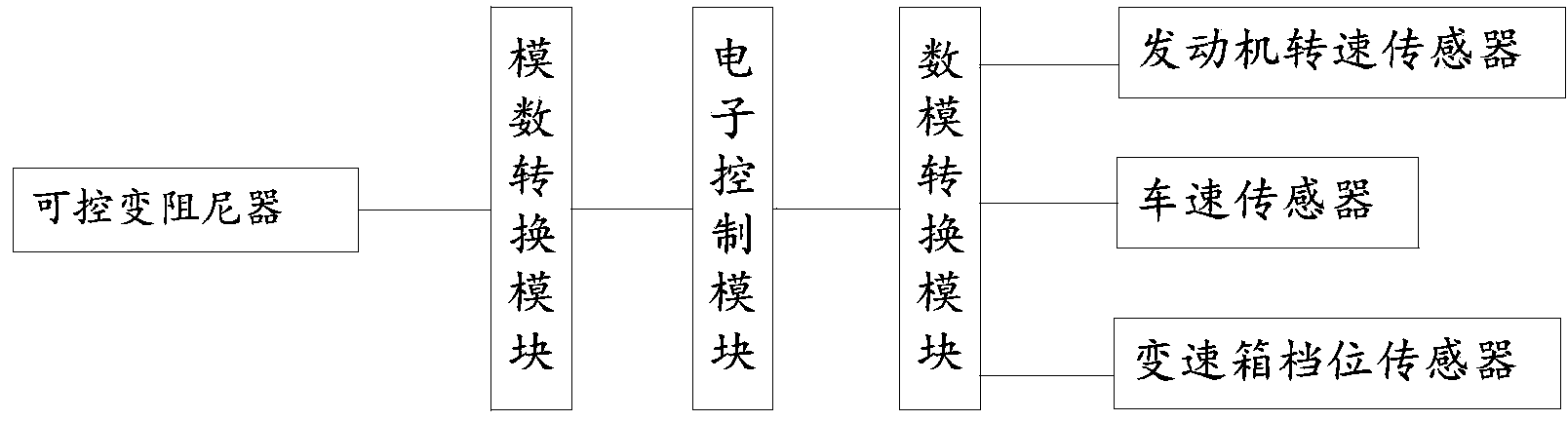

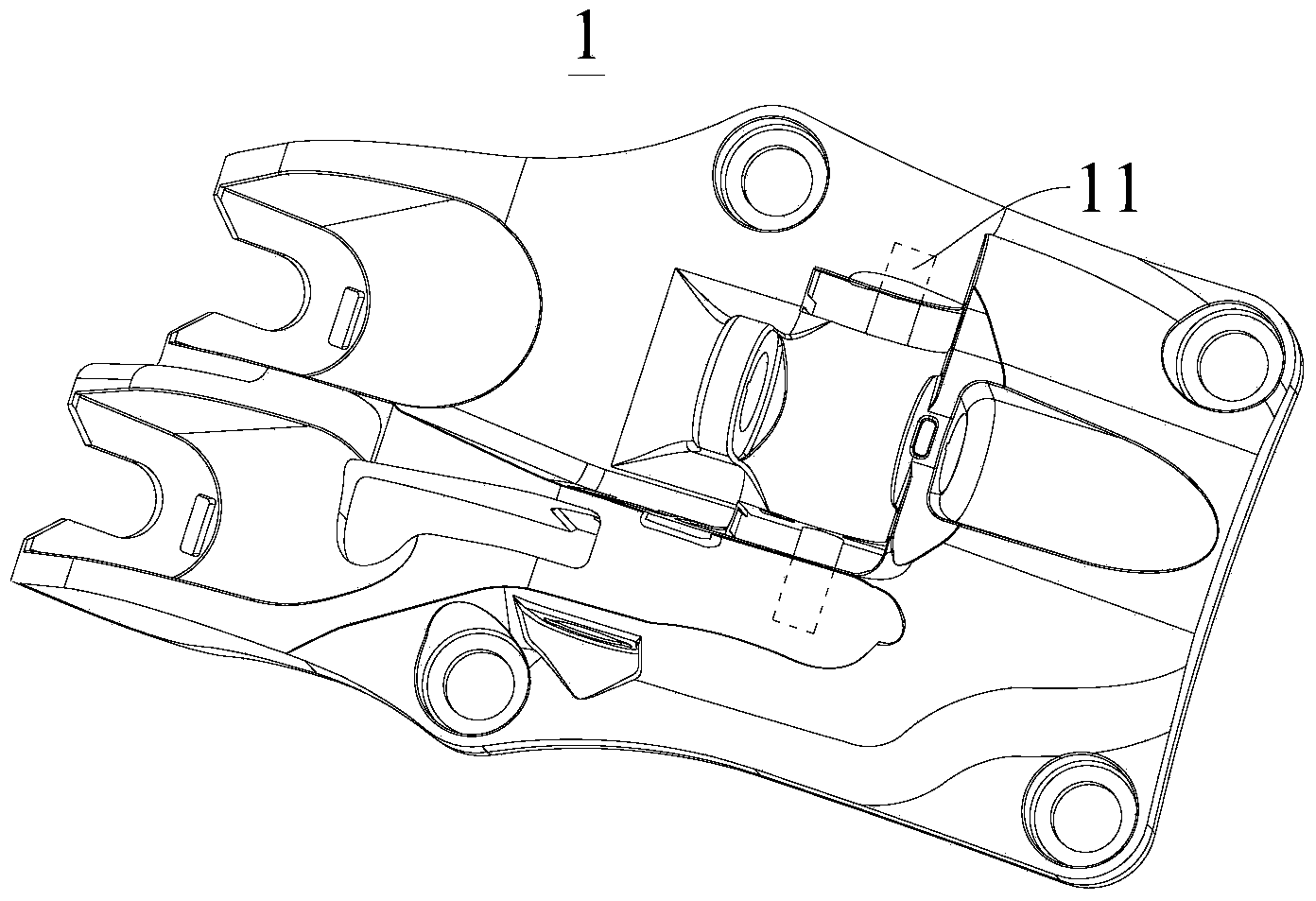

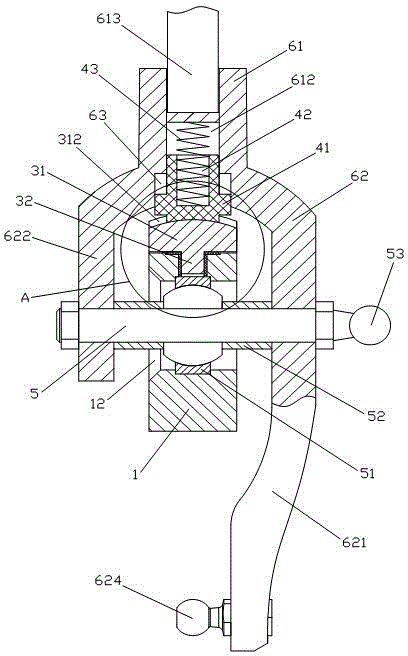

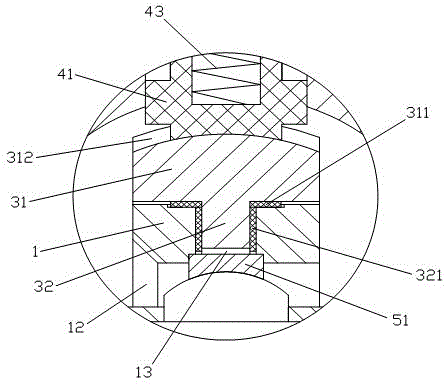

Control mechanism for clutch and control method of control mechanism

InactiveCN103967970ASave design modification costsReduce control requirementsMechanical actuated clutchesShock absorberClutch

The invention discloses a control mechanism for a clutch. The control mechanism comprises a clutch pedal and a pedal rod connected with the clutch pedal. The pedal rod is hinged to a pedal rod fixing support. A lever mechanism is formed, a first lever arm of the lever mechanism is hinged to a separation shifting fork, a second lever arm of the lever mechanism is hinged to one end of a controllable variable damper, and the other end of the controllable variable damper is hinged to a damper fixing support. The controllable variable damper is controlled by an electronic control module. According to the control mechanism for the clutch, an original structure of the clutch is not greatly changed, the design cost and the improvement cost are saved, the control requirement of a driver for the clutch is reduced, and the operation strength of the driver is reduced. When an existing clutch is designed, a free stroke is reserved, and the driver does not easily control the clutch due to the existence of the free stroke. However, the control process of actively controlling the control mechanism is not affected by the free stroke of the pedal.

Owner:XIHUA UNIV

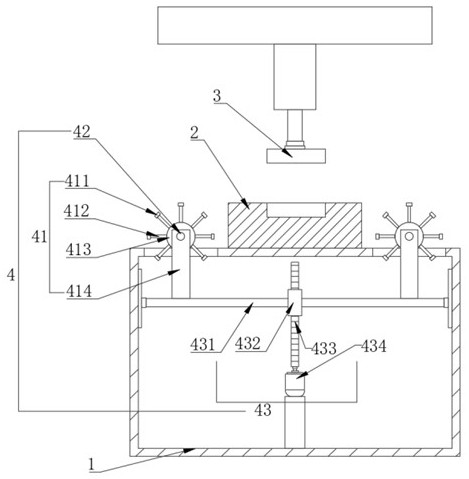

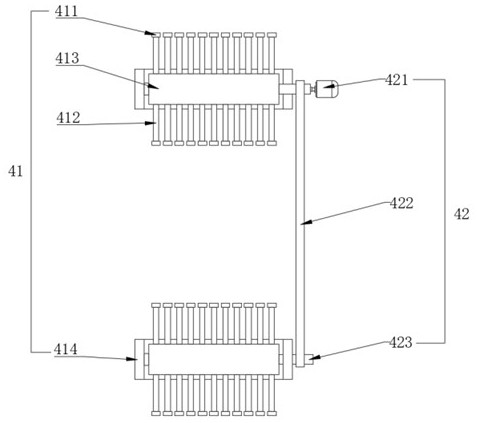

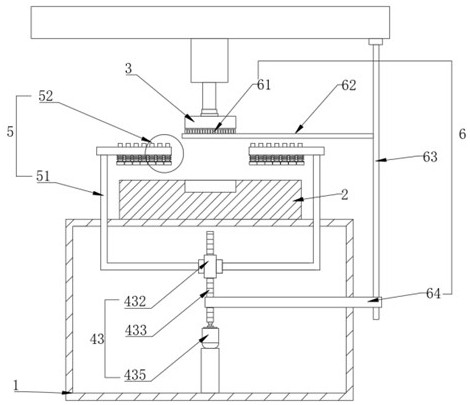

Stamping device for plate processing

InactiveCN113290115AImprove shift efficiencyMetal-working feeding devicesCleaning using toolsMechanical engineeringPhysics

The invention is applicable to the technical field of metal plate stamping equipment, and particularly relates to a stamping device for plate processing. The stamping device comprises a workbench, a stamping die holder and a stamping head, wherein the stamping die holder is installed on the workbench; a die cavity is formed in the surface of the stamping die holder; the stamping device for plate processing further comprises a plate conveying structure; and the plate conveying structure is installed on the workbench and used for jacking the plate to enable the plate to be separated from the stamping die holder after the stamping head stamps the plate on the stamping die holder, and then driving the jacked plate to enable the sunken plate to be moved away from the interior of the die cavity of the stamping die holder. By arranging the plate conveying structure, after the plate on the stamping die holder is stamped by the stamping head, the plate is firstly jacked, so that the plate can be separated from the stamping die holder, and then the jacked plate is driven, so that the sunken plate can be moved away from the interior of the die cavity of the stamping die holder, and the displacement efficiency of the plate is improved.

Owner:XUZHOU SHENGHE WOOD

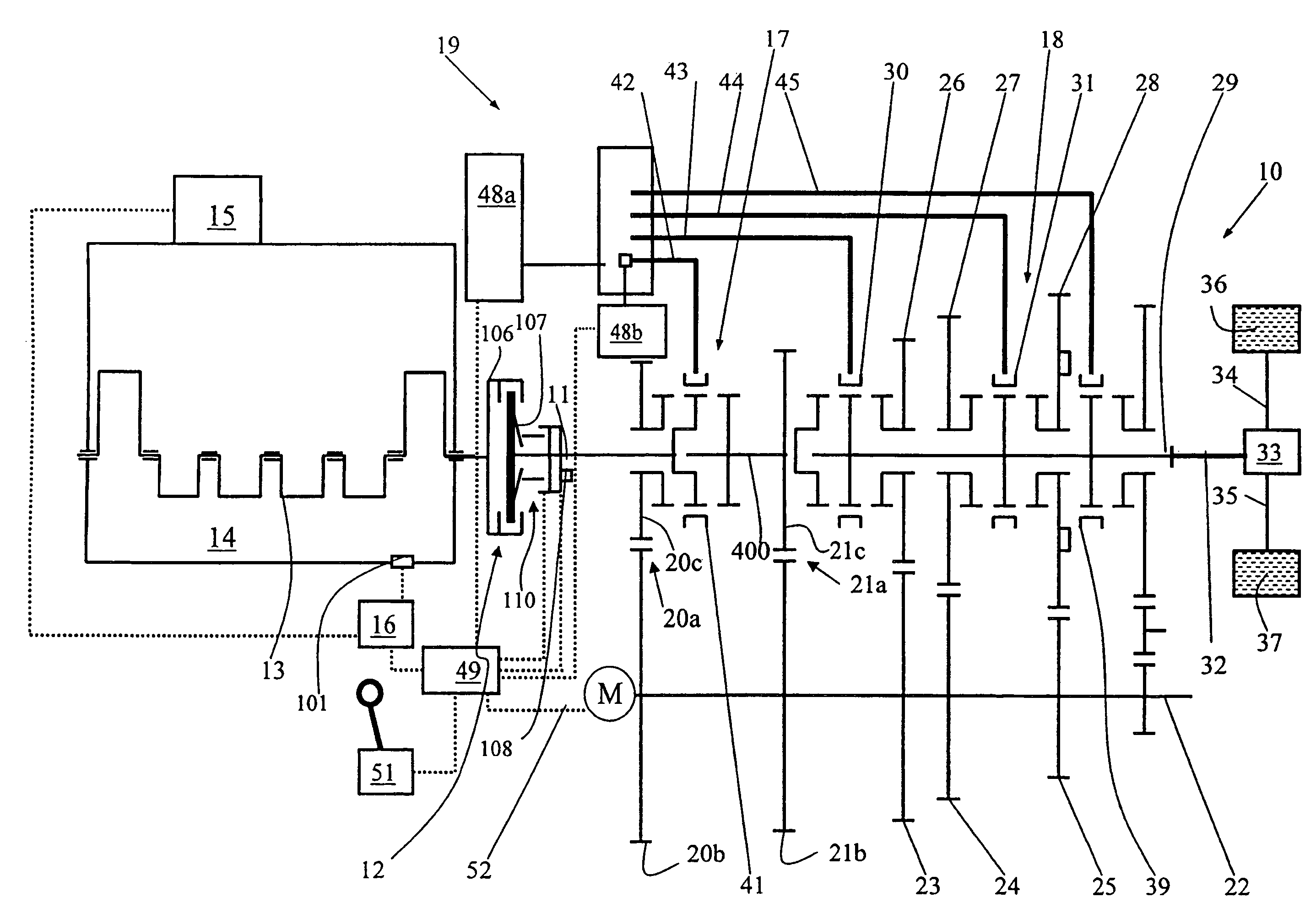

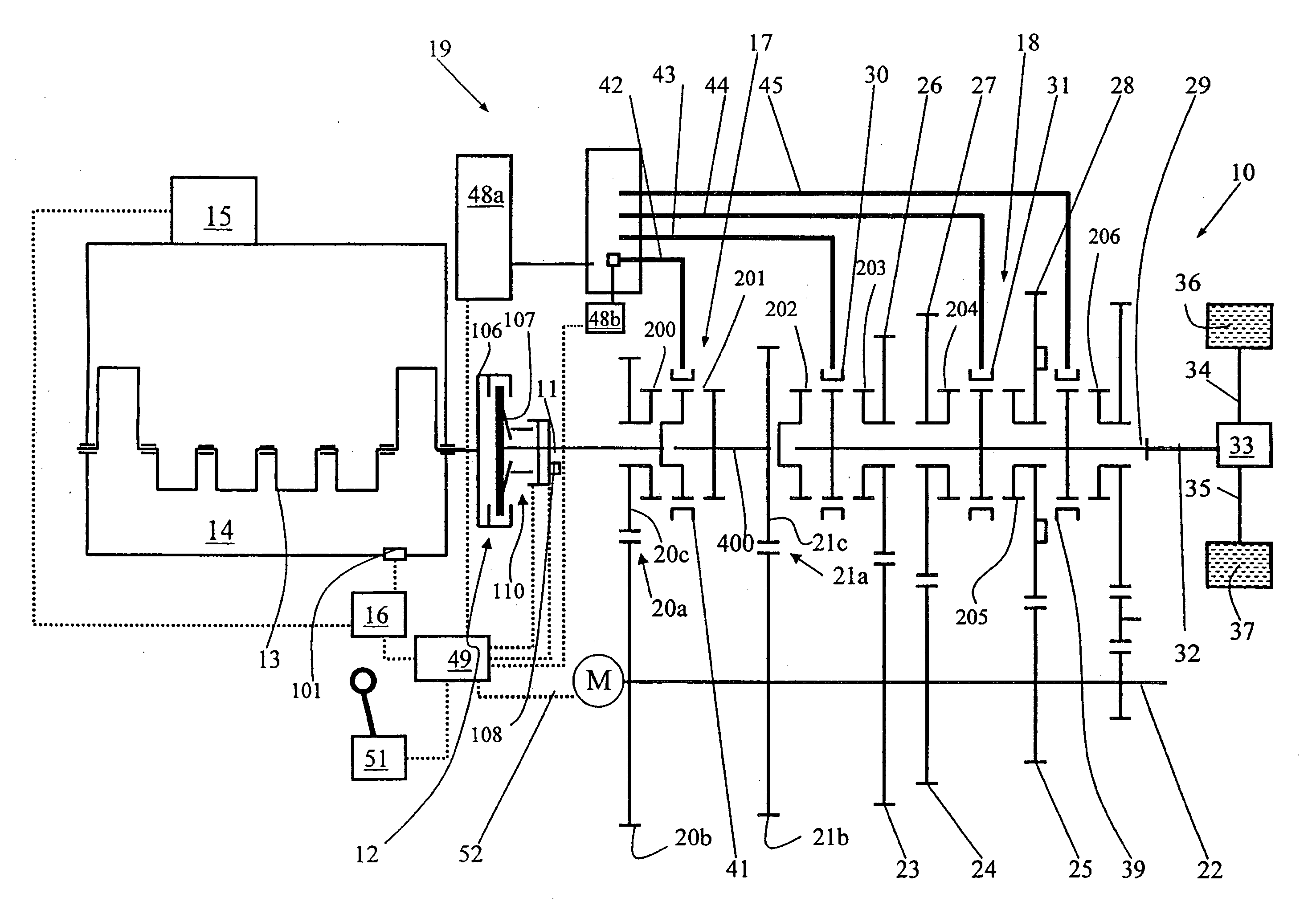

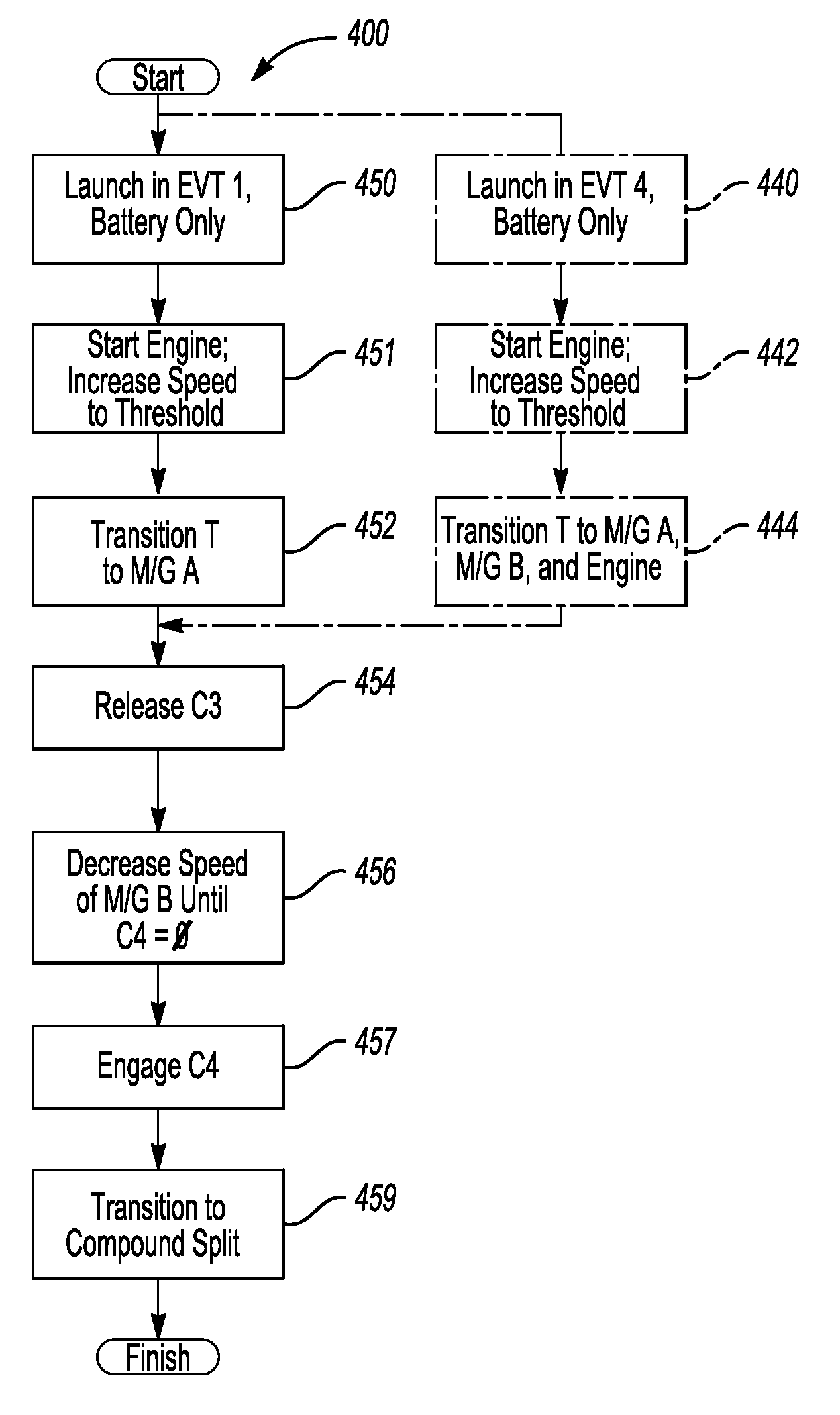

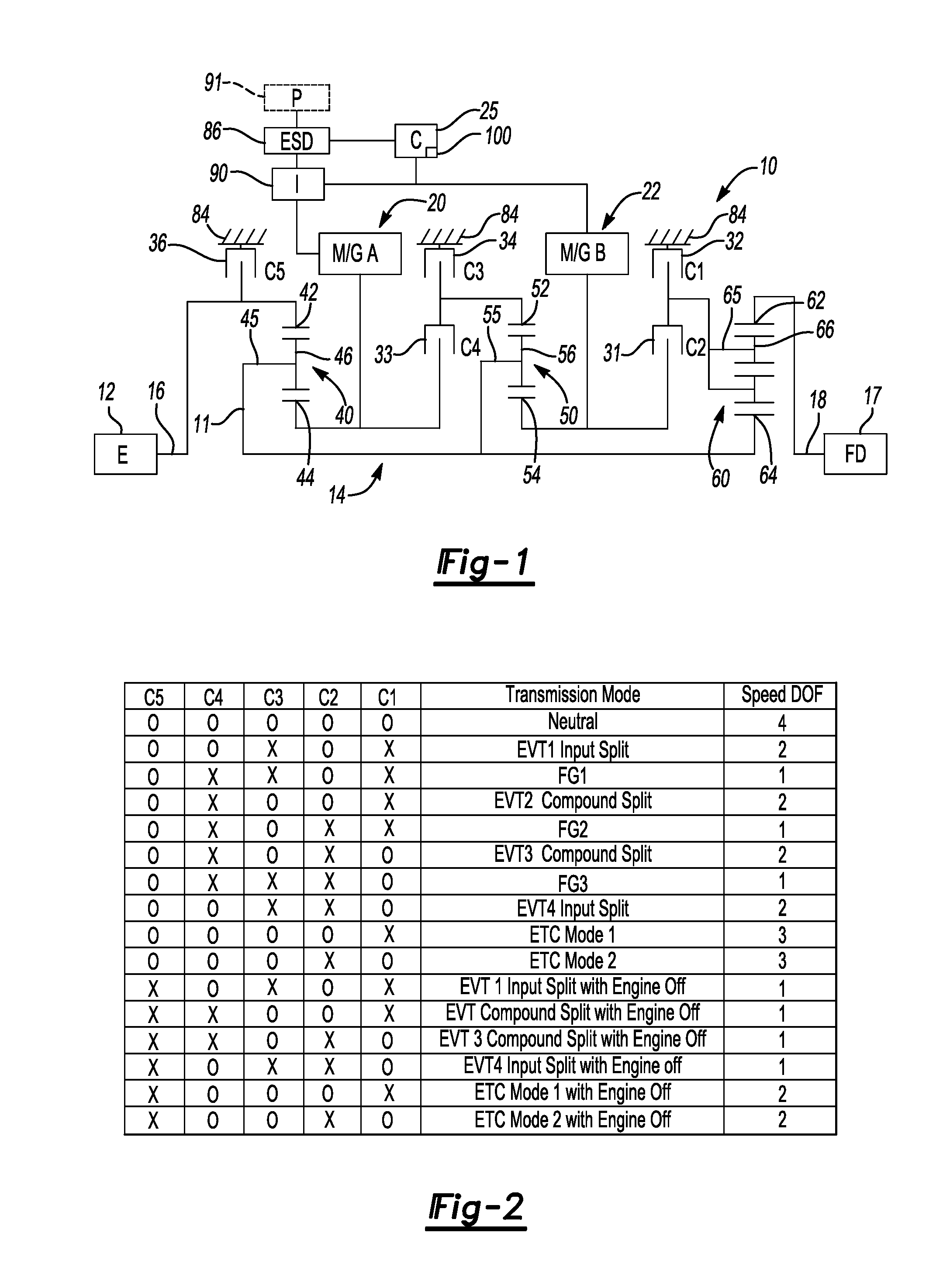

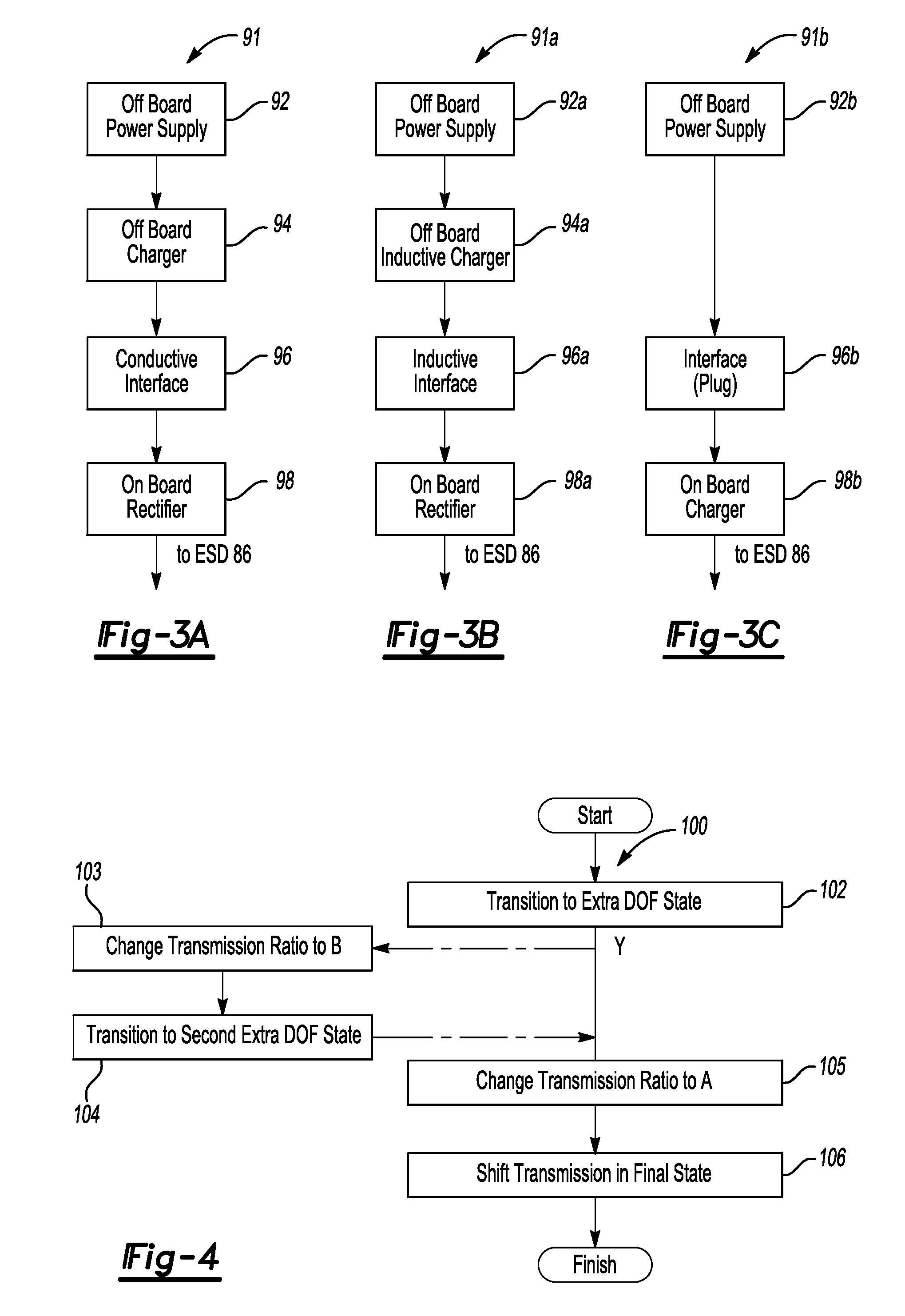

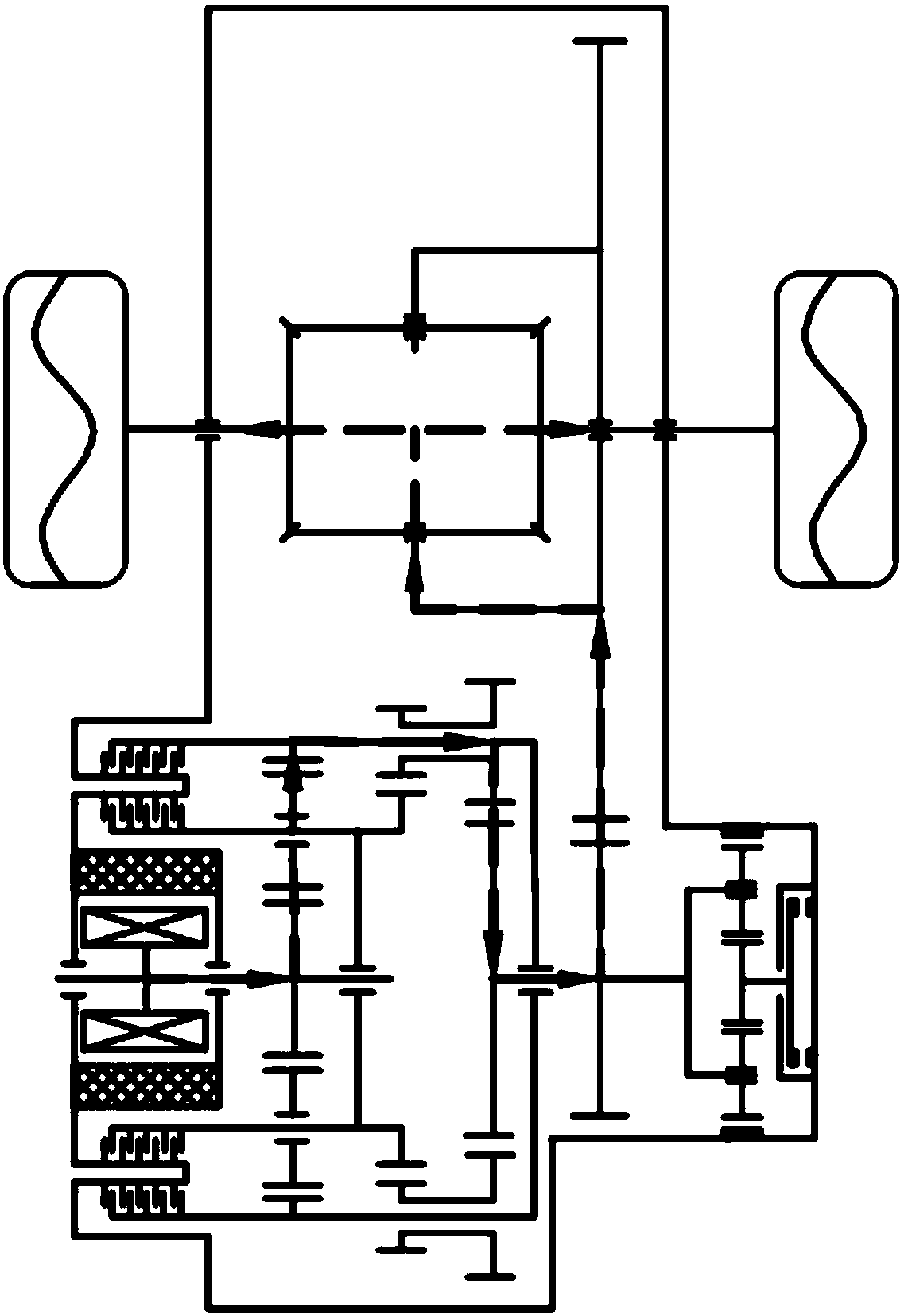

Method and apparatus for transitioning an electrically variable transmission

InactiveUS8000865B2Improve shift efficiencyReduce disruption and disruptionHybrid vehiclesAnalogue computers for trafficDegrees of freedomEngineering

A method is provided for transitioning from an initial to a final transmission mode in an electrically variable transmission (EVT), and includes transitioning to an intermediate mode having an additional speed degree of freedom (DOF), changing a transmission ratio, and engaging a clutch to shift to the final mode. The modes include input and compound split, fixed gear ratio, and electric torque converter (ETC), with and without input from an engine. Output torque is maintained by adjusting a charge on an energy storage device. A brake grounds an input member of the EVT. The EVT has the input member, an output member, a stationary member, and first and second motor / generators. An algorithm transitions between modes by releasing at least one clutch to transition to a mode having an extra speed degree of freedom (DOF), and utilizing the extra speed DOF to change the ratio of the EVT.

Owner:GM GLOBAL TECH OPERATIONS LLC

Gear shifter and vehicle comprising same

ActiveCN104179961AImprove driving experienceImprove shift efficiencyGearing controlEngineeringRocker arm

The invention discloses a gear shifter and a vehicle comprising the same. The gear shifter comprises a base, a shifting rocker arm, a cross shaft, a shifting selection rod and a gear selection rocker arm; the shifting rocker arm comprises a first base portion and a rocker arm portion which is fixedly arranged on the first base portion; the first base portion is arranged on the base through a base rotating shaft in a rotatable mode; the cross shaft comprises a front and back shaft and a left and right shaft, wherein an included angle is formed between the front and back shaft and the left and right shaft; the shifting selection rod is arranged on the first base portion so as to push the first base portion to rotate around the base rotating shaft; the shifting selection rod sleeves the left and right shaft; one end of the gear selection rocker arm sleeves the end portion of the left and right shaft; the first base portion is driven by the shifting selection rod during front and back swing to rotate around the base rotating shaft; the gear selection rocker arm is driven by the shifting selection rod through the cross shaft during lateral movement to move vertically. According to the gear shifter which is applied to the vehicle, the shifting rocker arm cannot be affected by the gear selection of the shifting selection rod and accordingly the working efficiency of the gear shifter is improved and the driving experience of a driver is improved.

Owner:GREAT WALL MOTOR CO LTD

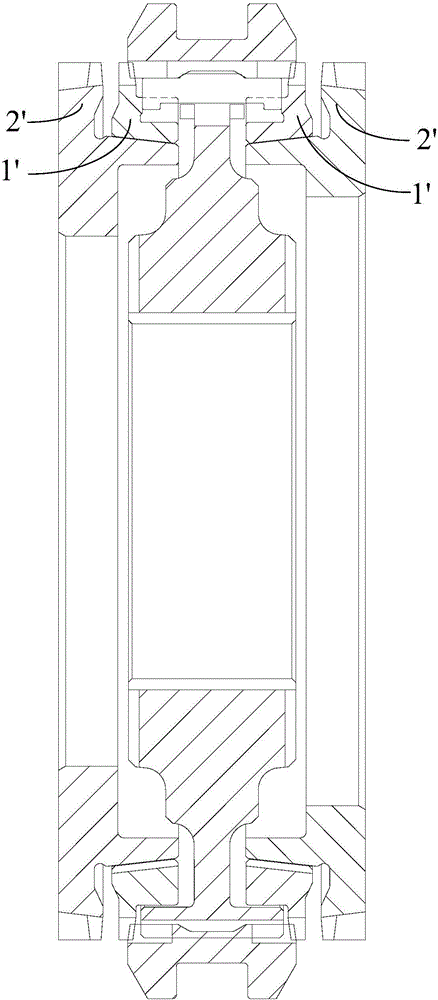

Synchronizer and gearbox

ActiveCN105822689AReasonable structureEasy to processMechanical actuated clutchesMechanical engineeringSynchronizing

The invention provides a synchronizer and a gearbox. The synchronizer comprises toothholders, sliding blocks arranged on the outer ring face of the toothholders and provided with first limiting parts, connecting teeth provided with outer conical faces, synchronizing rings capable of moving in the axial direction relative to the connecting teeth and provided with conical holes capable of being matched with the outer conical faces and containing grooves capable of being matched with the sliding blocks, and tooth sleeves capable of being engaged with the connecting teeth and the synchronizing rings, wherein the sliding blocks can slide in the circumferential direction relative to the containing grooves, and the groove walls of the containing grooves are provided with second limiting parts. In the technical scheme, free movement spaces of the synchronizing rings in the axial direction are eliminated through matching of the first limiting parts and the second limiting parts, the axial synchronous movement of the synchronizing rings and the sliding blocks during gear shifting is achieved, the synchronizing rings are prevented from attaching to the connecting teeth uncontrollably, and the problem of large-area friction of the friction conical faces of the synchronizing rings and the friction conical faces of the connecting teeth is avoided, so that the gear-shifting efficiency of the gearbox is improved, abrasion to the synchronizing rings is reduced, and the service life of the synchronizing rings is prolonged.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

Automobile and transmission thereof

The invention discloses an automobile and a transmission thereof. The transmission comprises a casing, an input shaft, a Ravigneaux's planetary gear train, a first single-row single-stage planetary gear train and a second single-row single-stage planetary gear train. The first single-row single-stage planetary gear train comprises a first sun wheel sleeved on the input shaft, a first planet wheel, a first planet carrier and a first inner gear ring. The Ravigneaux's planetary gear train comprises a large sun wheel, a small sun wheel, a long planet wheel, a short planet wheel, a planet carrier and an inner gear ring. The large sun wheel, the small sun wheel, the first inner gear ring, the planet carrier and the input shaft are connected respectively in separating mode. The second single-row single-stage planetary gear train comprises a second sun wheel sleeved on the input shaft, a second planet wheel, a second planet carrier and a second inner gear ring, and the second planet carrier is fixed on the planet carrier. A first brake is used for braking the large sun wheel, a second brake is used for braking the planet carrier, and a third brake is used for braking the second inner gear ring. The transmission achieves design of seven forward gears, is simple in structure and high in gear shifting efficiency.

Owner:GREAT WALL MOTOR CO LTD

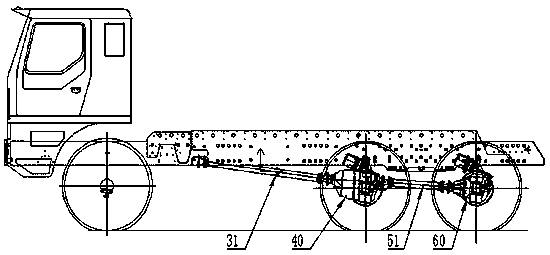

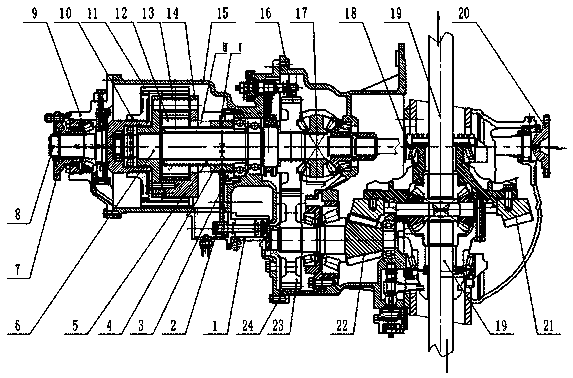

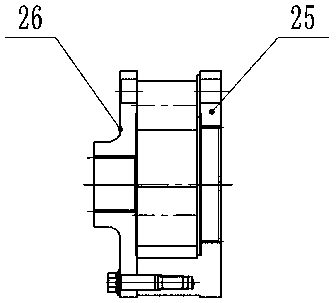

Heavy truck duplex driving axle capable of achieving double speeds

PendingCN109334348AHighlight shifting functionWith variable speed functionAxle unitsControl devicesDrive shaftControl system

The invention discloses a heavy truck duplex driving axle capable of achieving double speeds. The driving axle is composed of a middle axle assembly and a rear axle assembly, and is characterized in that a power transmission system of the middle axle assembly is composed of an input flange, an input shaft, an end cover, a box body, a planetary speed reducing device, a spline sleeve, a sliding meshing sleeve, a fixed support, an output shaft, an inter-axle differential assembly of the duplex driving axle, a driving cylindrical gear, a driven cylindrical gear, a driving bevel gear, a driven bevel gear pair, an inter-wheel differential assembly, a half shaft (19), a through shaft, an inter-axle transmission shaft and the rear axle assembly; a control system of the middle axle assembly is composed of a spline sleeve, a sliding meshing sleeve, a fixed support, a shifting fork and a reversing valve assembly. The driving axle has a speed change function, the use range of a truck is wider, andthe driving axle has the advantages of being simple and compact in structure, having few reversing elements, being high in transmission efficiency and the like.

Owner:SHANDONG PENGXIANG AUTOMOBILE

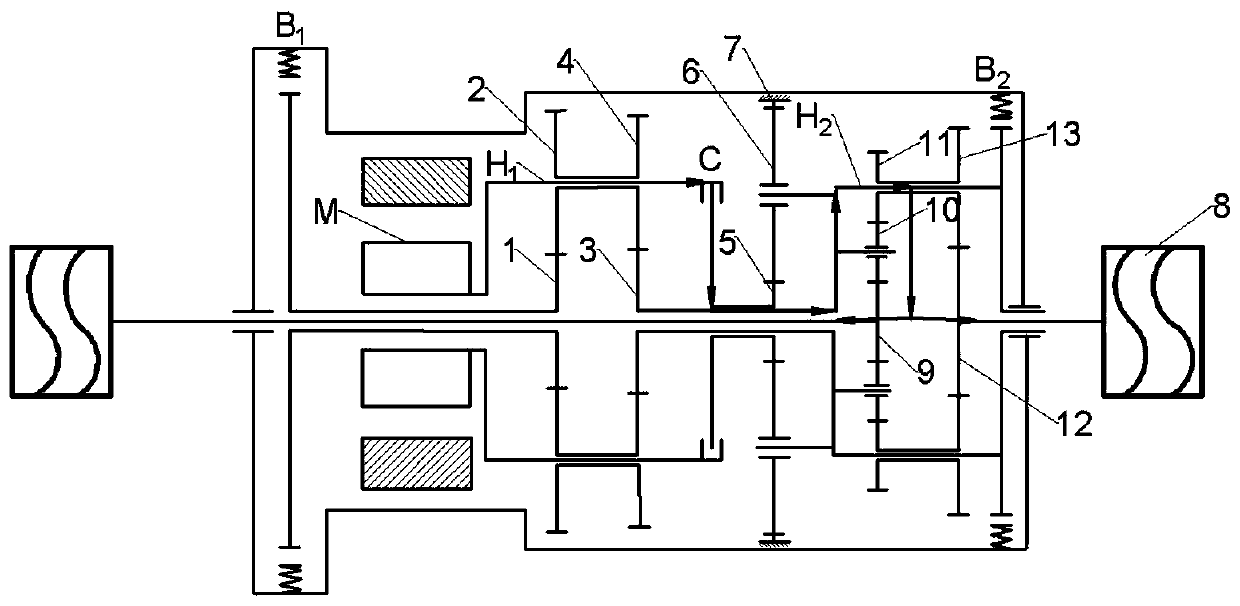

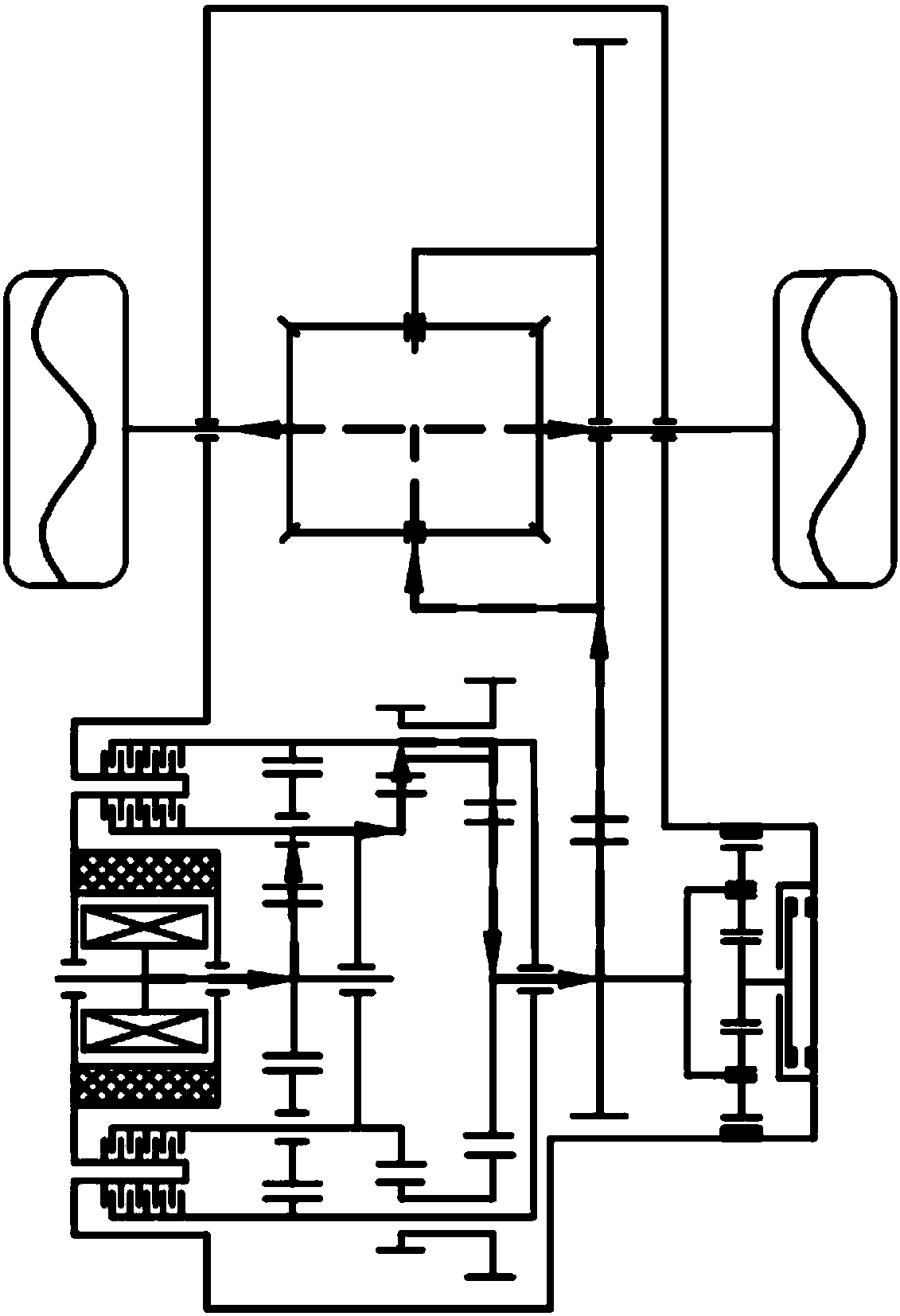

Integrated multi-gear automatic transmission of motor and non-bevel-gear differential mechanism

ActiveCN110056616ACompact structureExtended service lifeToothed gearingsTransmission elementsAutomatic transmissionDrivetrain

The invention relates to an integrated multi-gear automatic transmission of a motor and a non-bevel-gear differential mechanism. The integrated multi-gear automatic transmission of the motor and the non-bevel-gear differential mechanism is characterized by being mainly composed of the motor, a first planetary gear row, a second planetary gear row, a first brake device, a second brake device, the differential mechanism and a shell body, wherein the first planetary gear row and the second planetary gear row are connected through a planetary carrier, and the advantage of close transmission connection is achieved; and a brake part adopts a left-right parallel structure of the first brake device and the second brake device, and gear conversion is realized through a combined clutch. The integrated multi-gear automatic transmission of the motor and the non-bevel-gear differential mechanism is provided with two forward gears, one neutral gear and one parking gear, and is high in transmission efficiency, compact in structure and simple in gearshift manner; a new scheme reference is provided for an existing power transmission system structure for an electric automobile; and high use value and a good application prospect are achieved.

Owner:HEFEI UNIV OF TECH

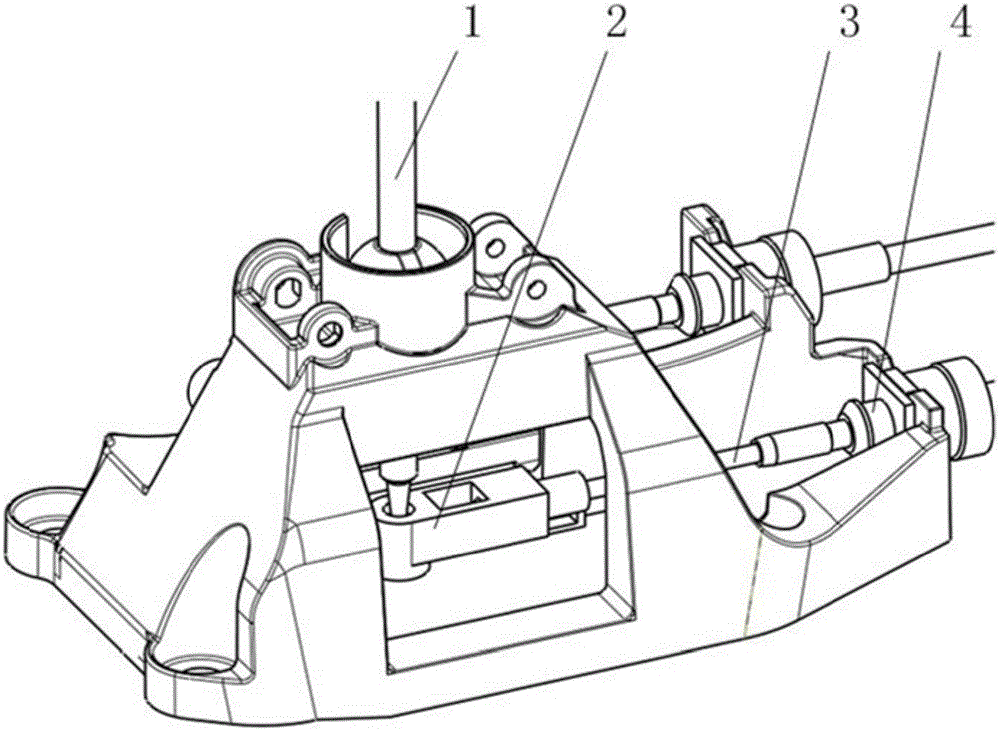

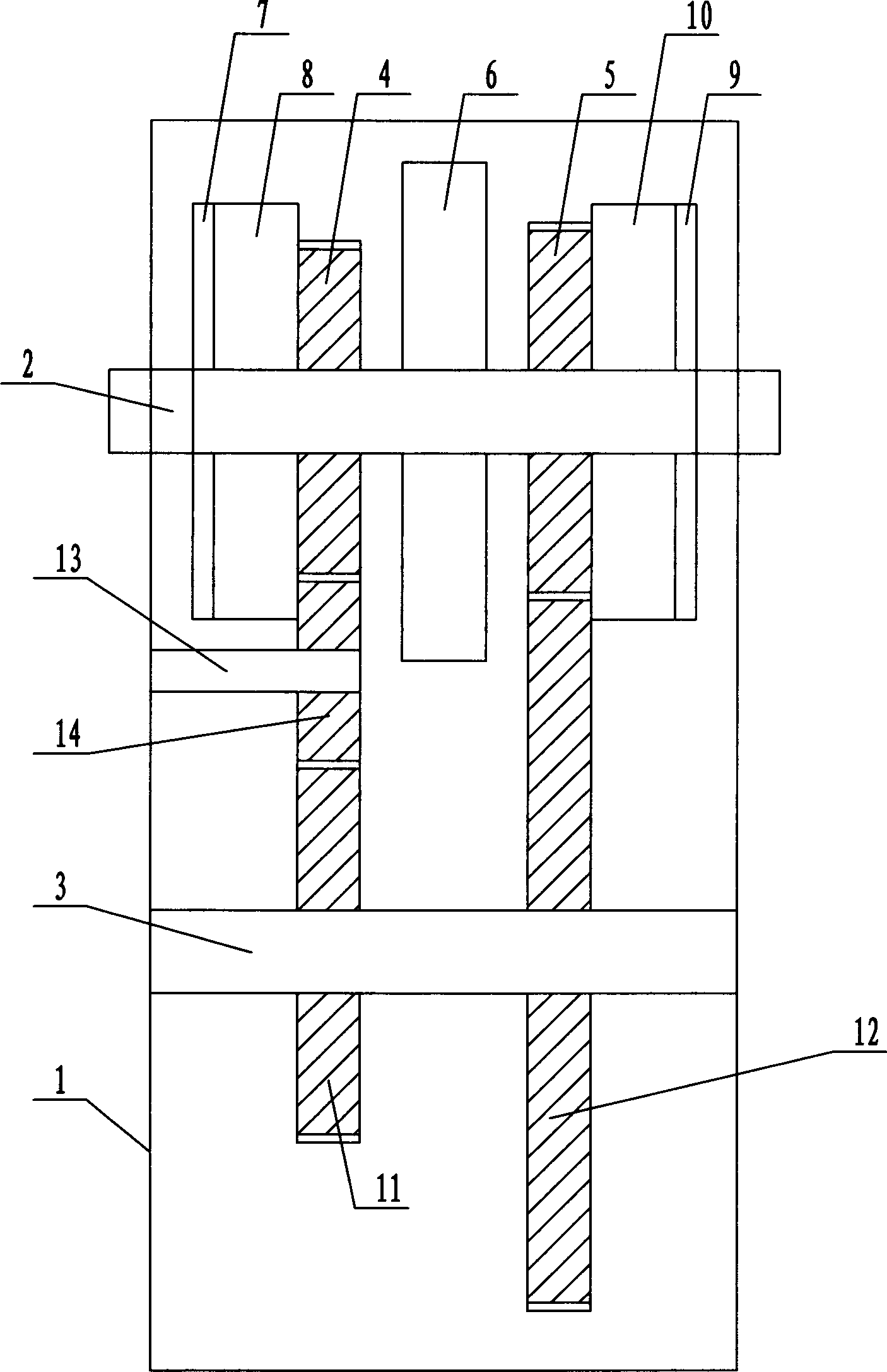

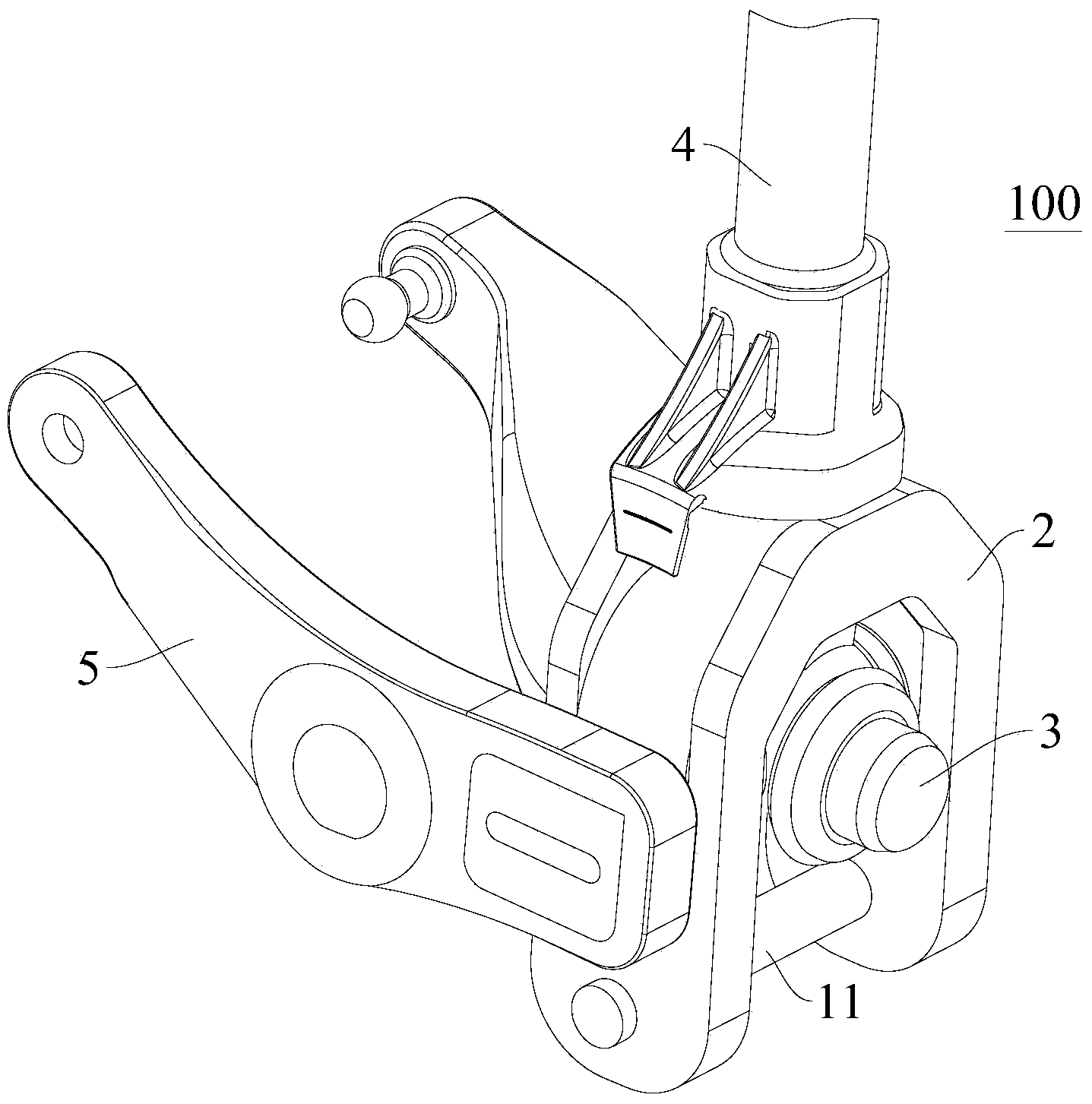

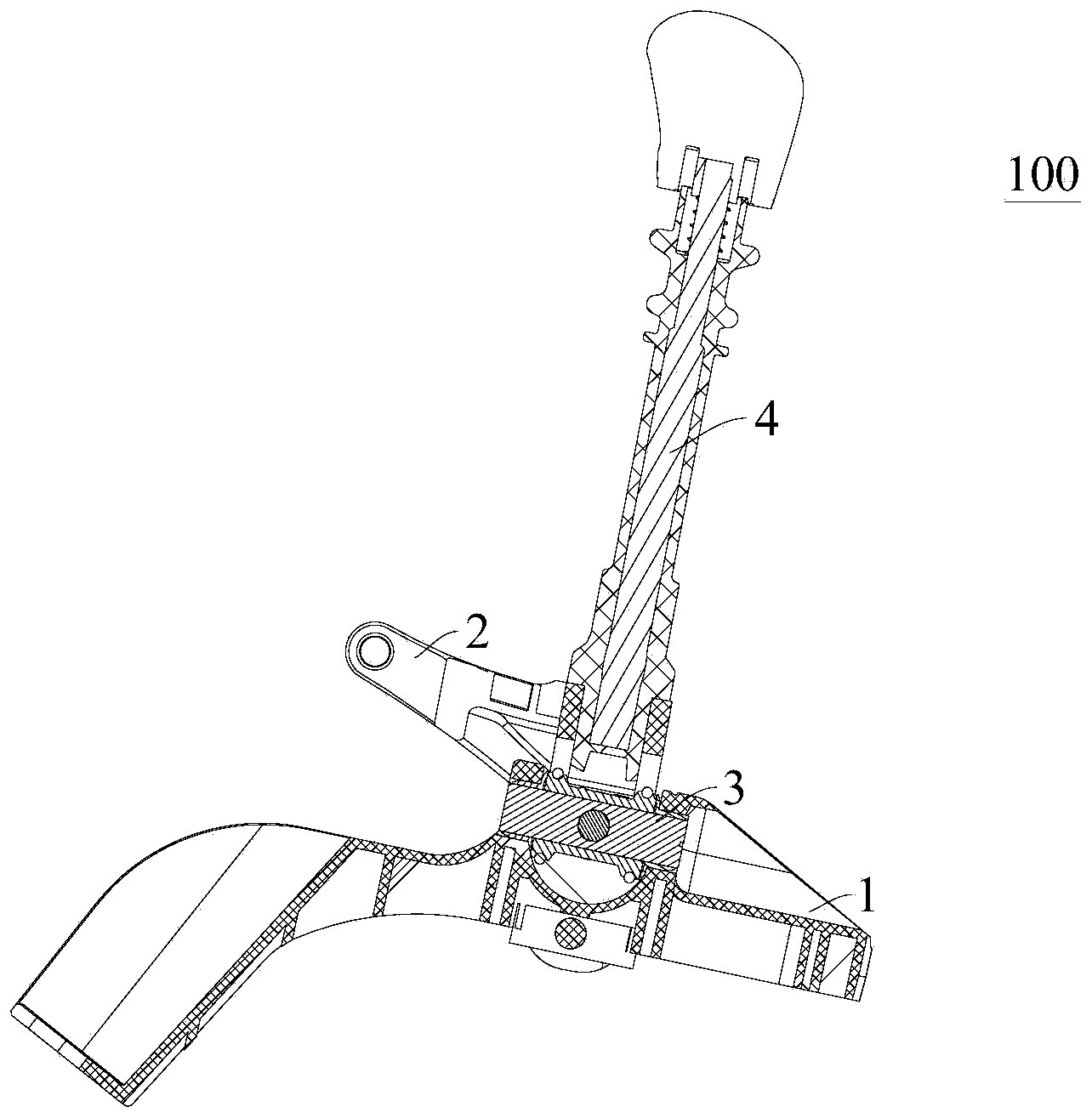

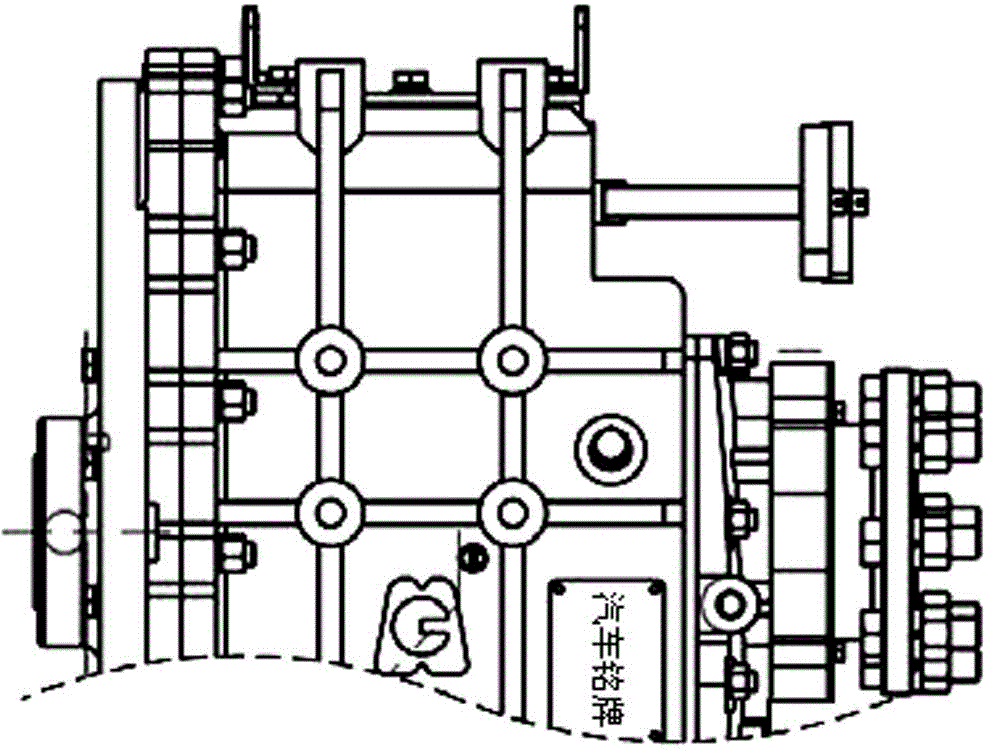

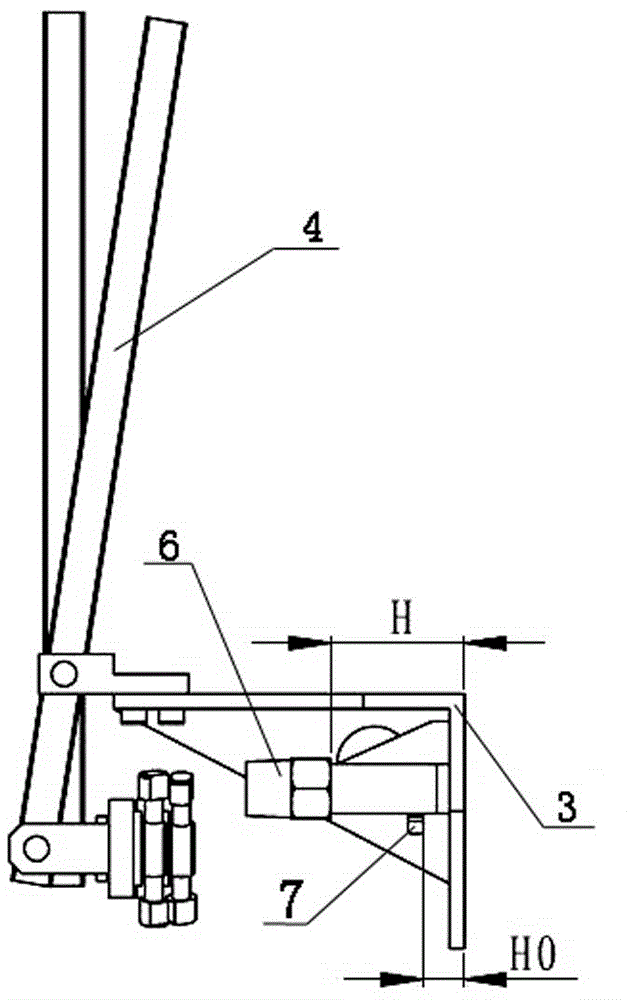

Mechanism for gear shifting and stroke detection of gearbox

InactiveCN104596763AReduce labor intensityImprove test run efficiencyMachine gearing/transmission testingEngineeringMechanical engineering

Disclosed is a mechanism for gear shifting and stroke detection of a gearbox. The mechanism mainly comprises a gear shifting body and a stroke detection assembly. The gear shifting body comprises an L-shaped support, wherein the L-shaped support is fixedly installed on a box body side wall, a gear shifting shaft stretches out of the box body side wall, a gear shifting lever is hinged to the outer end of the L-shaped support, and the lower end of the gear shifting lever is connected to the gear shifting shaft through a hinged connecting rod. The stroke detection assembly comprises a base, wherein the base is installed on the box body side wall on the side of the gear shifting shaft, a signal lamp switch is installed outside the base, and a trigger rod is allocated. The L-shaped support is fixed on the box body side wall through a bolt, the connecting rod is connected with the gear shifting shaft through a rotating body component, and a rotating sleeve is fixed to the connecting rod; the distance H between the plane of the signal lamp switch installed on the base of the stroke detection assembly and the box body side wall with the L-shaped support is obtained from the negative allowance. The mechanism has the advantages of being simple in structure and convenient to use and operate, reducing the accident risk and the labor intensity, increasing the product percent of pass, and improving the working efficiency.

Owner:HANGZHOU ADVANCE GEARBOX GRP

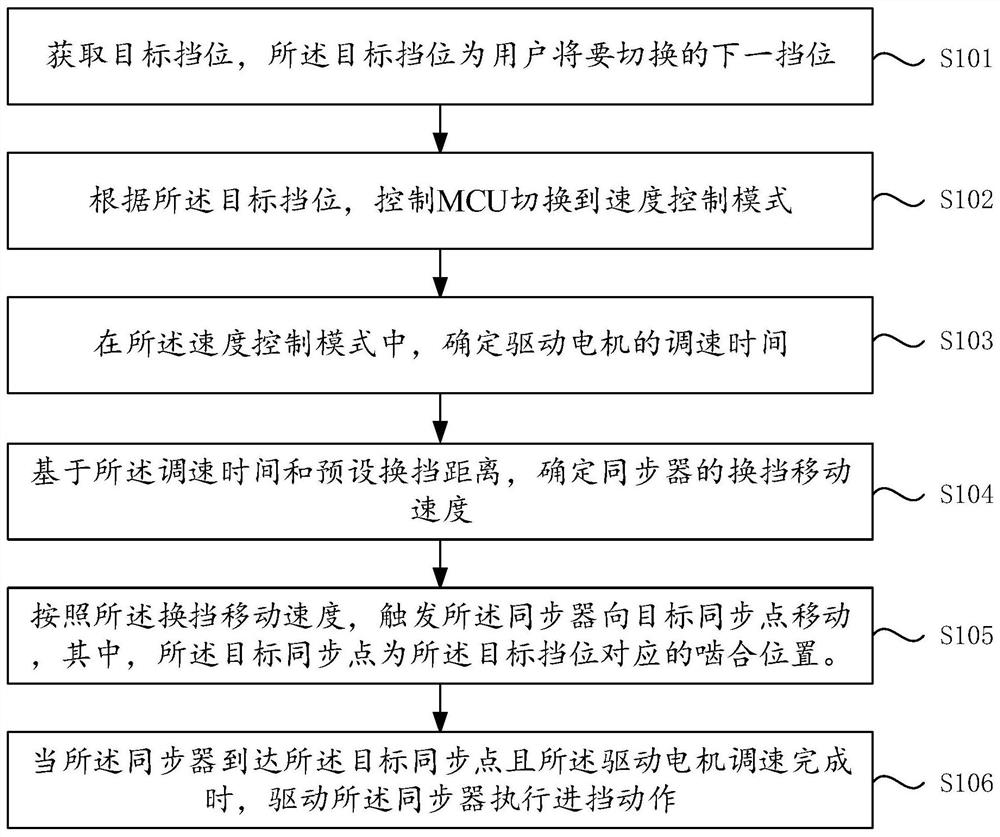

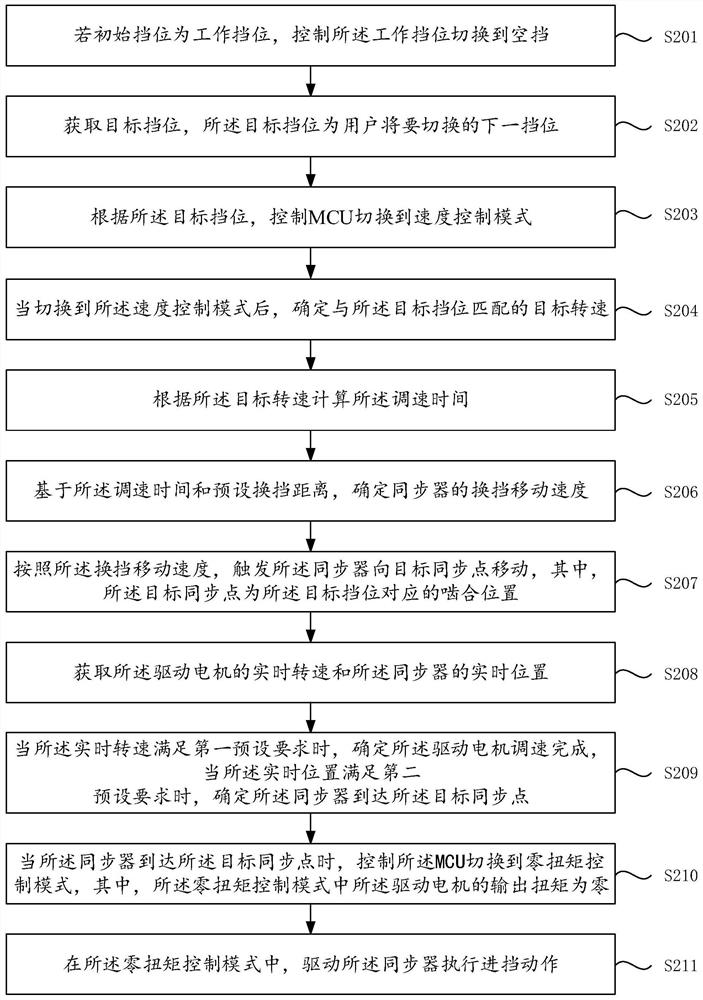

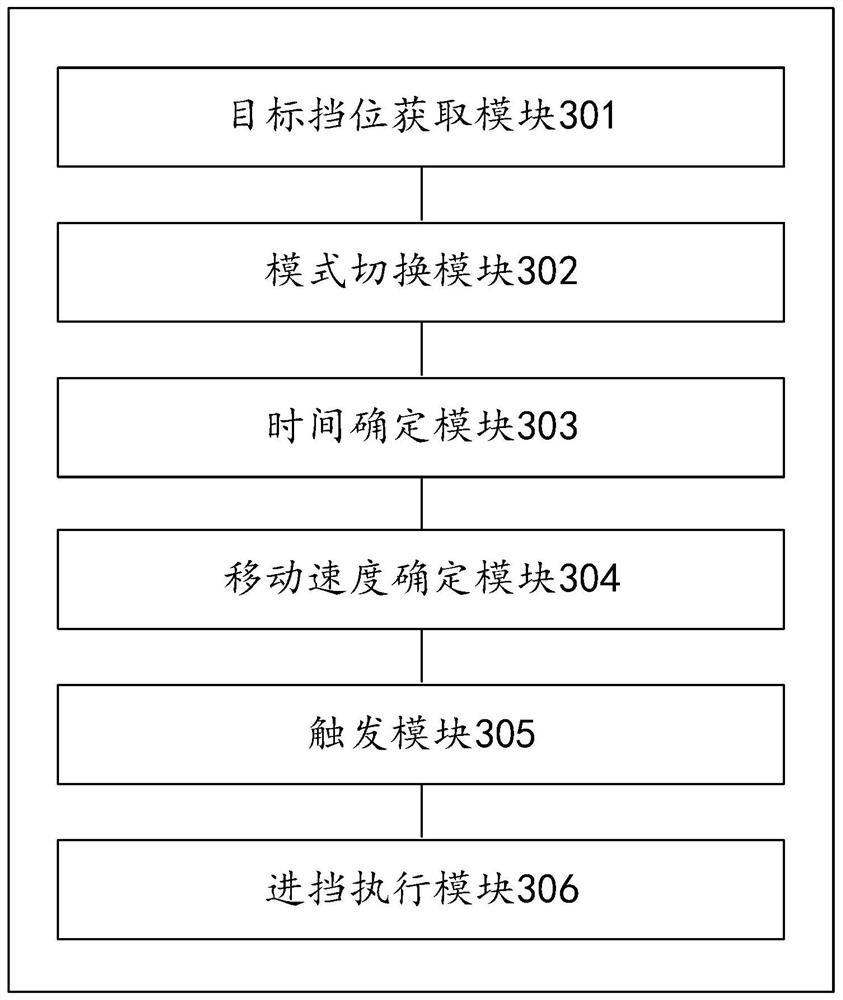

Gear shifting control method and device

ActiveCN112013106AShorten the timeImprove accuracyGearing controlControl engineeringElectric machinery

The invention provides a gear shifting control method and device. The method comprises the steps: obtaining a target gear which is the next gear to be switched by a user; controlling an MCU to switchto a speed control mode according to the target gear; in the speed control mode, determining the speed regulation time of a driving motor; based on the speed regulation time and a preset gear shiftingdistance, determining the gear shifting moving speed of a synchronizer; according to the gear shifting moving speed, triggering the synchronizer to move to a target synchronization point within the speed adjusting time, wherein the target synchronization point is the meshing position corresponding to the target gear; and when the synchronizer reaches the target synchronization point and the speedregulation of the driving motor is completed, driving the synchronizer to execute a gear advancing action so as to be switched to the target gear. According to the gear shifting control method, the speed regulating time for regulating the speed of the driving motor to the target rotating speed can be calculated, and then the movement speed of the synchronizer is calculated according to the time,so that the speed regulation and the movement of the synchronizer are completed at the same time, and the gear shifting accuracy and stability can be improved.

Owner:GREAT WALL MOTOR CO LTD

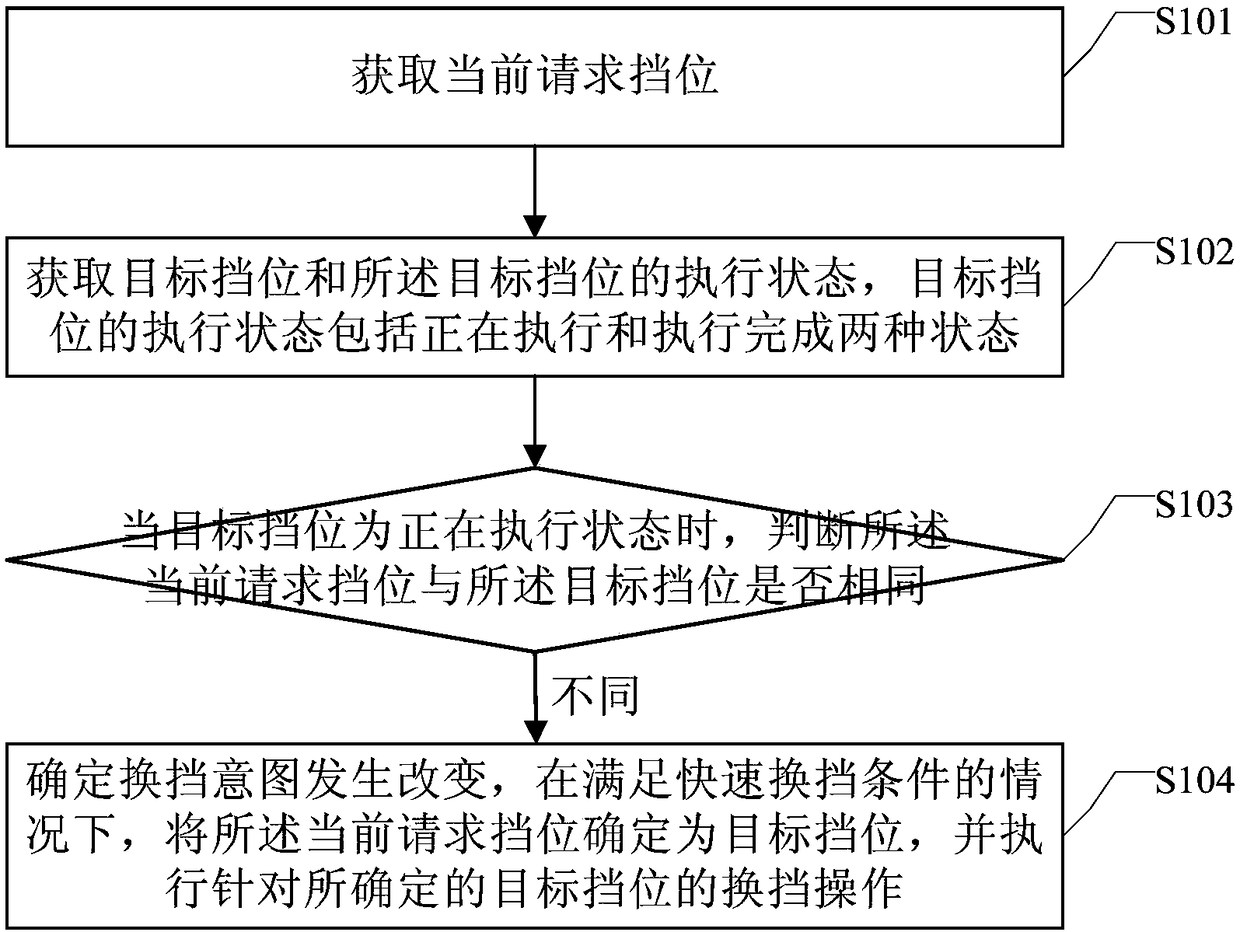

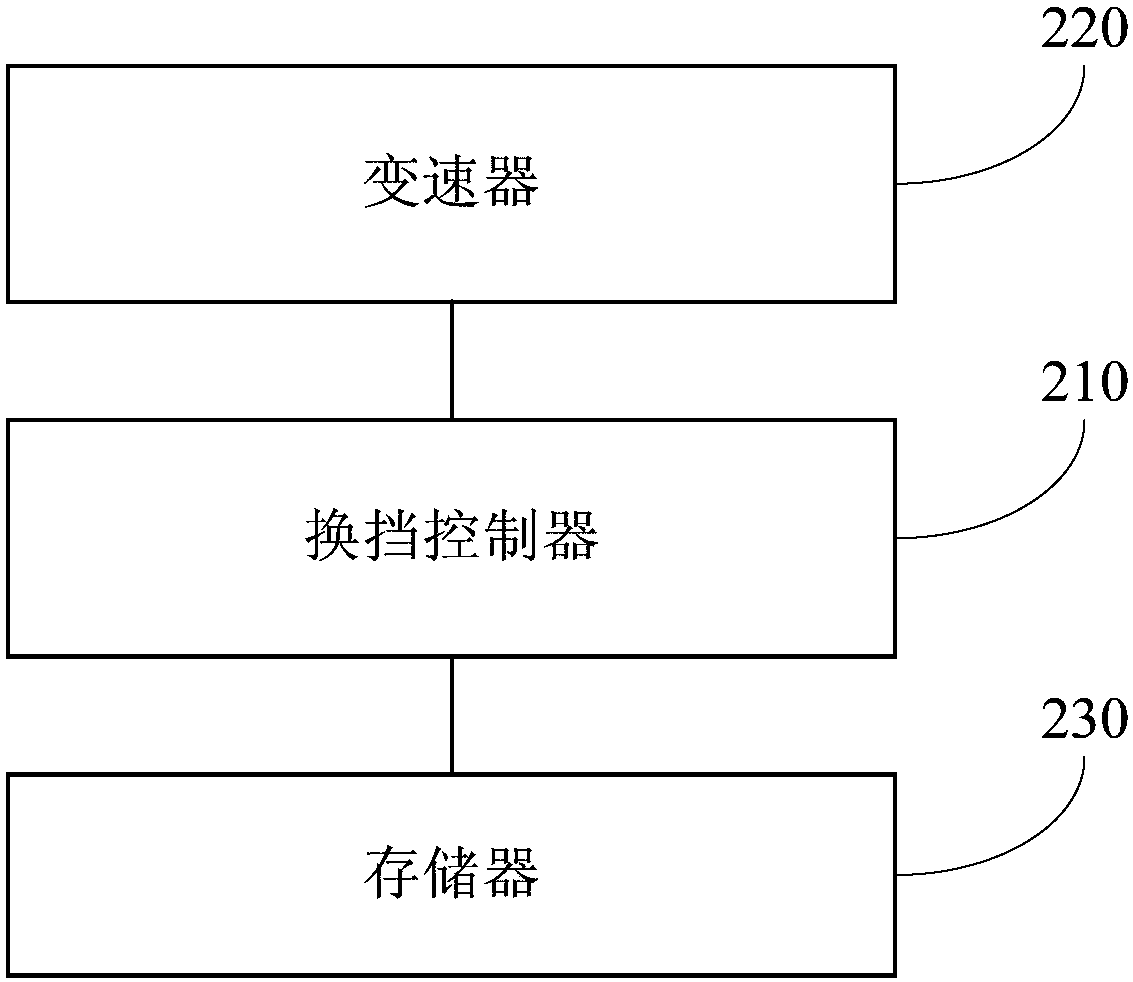

Gear-shifting control method and system

ActiveCN108374888AShorten shift timeImprove shift efficiencyControlled membersGearing controlDriver/operatorReal-time computing

An embodiment of the invention relates to the technical field of automobile transmissions and provides a gear-shifting control method and system. The gear-shifting control method includes: acquiring acurrent request gear position; acquiring a target gear position and execution states thereof, wherein the execution states of the target gear position include an executing state and an executed state; when the target gear position is in the executing state, judging whether the request gear position is identical to the target gear position or not; if not, determining changing of gear-shifting intention, and under the condition that quick gear-shifting conditions are met, determining the current request gear position as the target gear position, and executing gear-shifting operation aiming at the target gear position. By adoption of the method for gear-shifting control, when a driver changes gear-shifting intention in a driving process, as for a circumstance allowing direct skipping of a last gear-shifting request, the gear-shifting operation corresponding to the current gear-shifting request is carried out when meeting of the quick gear-shifting conditions is determined, and accordingly gear shifting efficiency under the circumstance is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

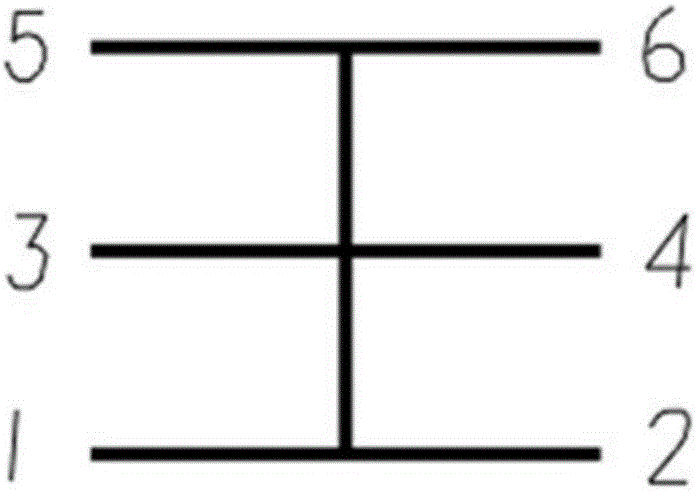

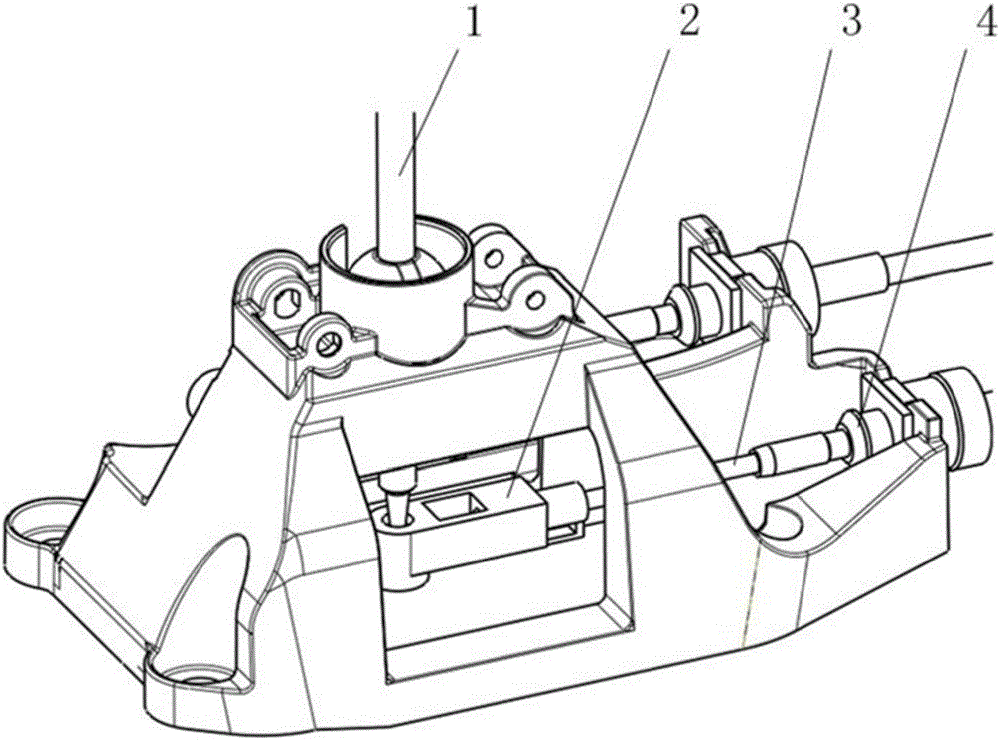

Gear selecting and shifting device

The invention discloses a gear selection and shifting device, which includes a shift lever, a drawing joint, a guide rail and a drawing; wherein, the end of the shifting lever is provided with a contact; the drawing joint includes a control part and a guide part, and the control part is provided with a There is a chute, and the chute cooperates with the contact; the guide rail is against the two sides of the guide part; one end of the wire drawing is fixedly arranged on the transmission bracket through the sheath, and the other end of the wire drawing is fixedly arranged on the guide part. The gear selection and shifting device provided by the present invention realizes that the wire can only move in the axial direction of the wire during the gear selection and shift process through the cooperation of the contact and the chute, and through the restriction of the guide rail to the Y-axis direction, thereby reducing the The friction between the wire drawing and the sheath is improved, and the shifting efficiency is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Electric drive system of double-gear electric car

ActiveCN108050222ACompact structureExtended service lifeGearingControl devicesDrivetrainElectric cars

The invention relates to an electric drive system of a double-gear electric car. The electric drive system is characterized by mainly consisting of an electromotor, a first planet gear row, a second planet gear row, a first brake, a second brake, a duplicate gear, a main reducing pinion, a main reducing big gear, a parking brake part, a differential mechanism and a shell; and the first duplicate gear row and the second duplicate gear row are connected through the duplicate gear. The electric drive system has the advantage that the transmission ratio adjustment range is large; the brake part adopts a structure that the first brake and the second brake are nested from inside to outside; gear switching is realized by alternating braking; besides, the parking brake part adopts a differential gear train for parking, so locking of the car can be realized by virtue of a relatively small torque. The electric drive system provided by the invention has two forward gears, two reverse gears and one neutral gear, is also high in transmission efficiency, compact in structure and simple in a gear switching method, provides a new reference scheme for an existing power transmission system structureof the electric car and realizes a relatively good use value and application prospects.

Owner:HEFEI UNIV OF TECH

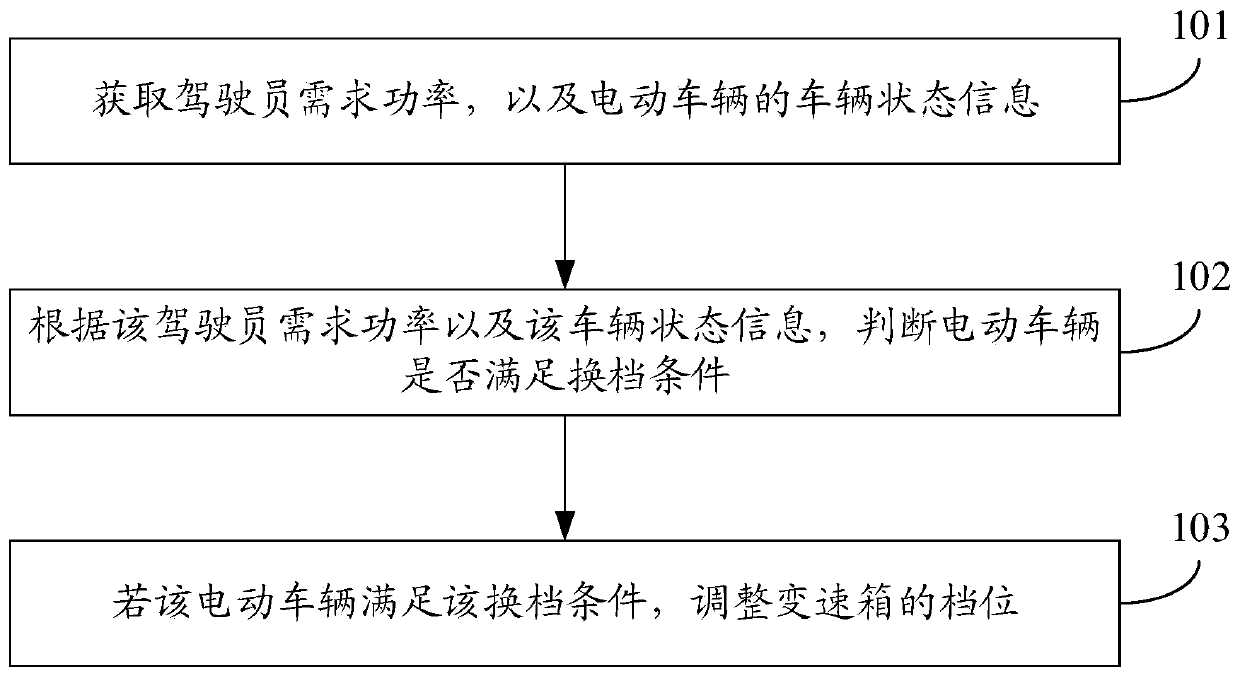

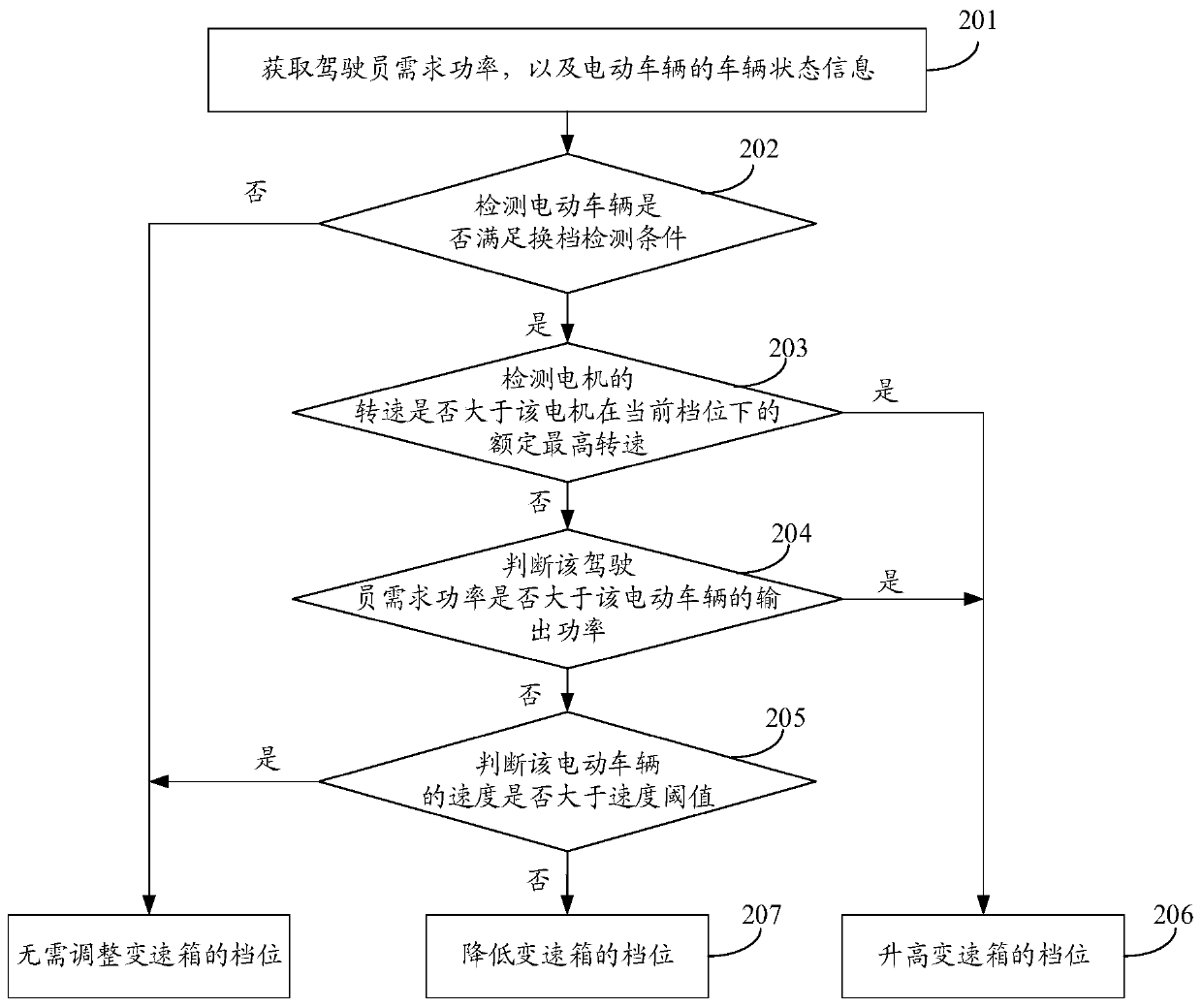

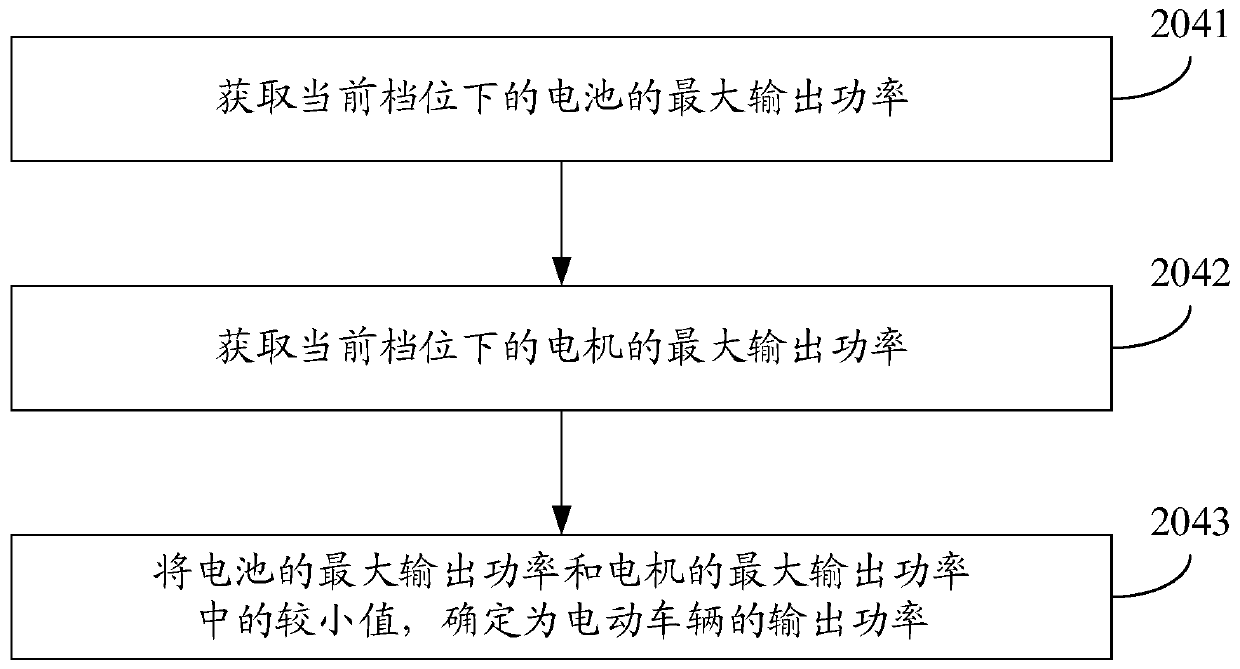

Shift control method and device for electric vehicle

ActiveCN110053603ARealize automatic switchingImprove shift efficiencyElectric vehicleAutomotive engineering

The invention discloses a shift control method and device for an electric vehicle, and relates to the field of vehicles. According to the shift control method and device for the electric vehicle, whether the electric vehicle meets the shift condition or not can be judged according to the acquired driver demand power and the vehicle state information of the electric vehicle, and gears of a gearboxare adjusted if the shift condition is met. According to the shift control method of the electric vehicle, automatic switching of the gearbox of the electric vehicle between a plurality of gears can be conveniently realized, and the shift efficiency is improved.

Owner:CHERY AUTOMOBILE CO LTD

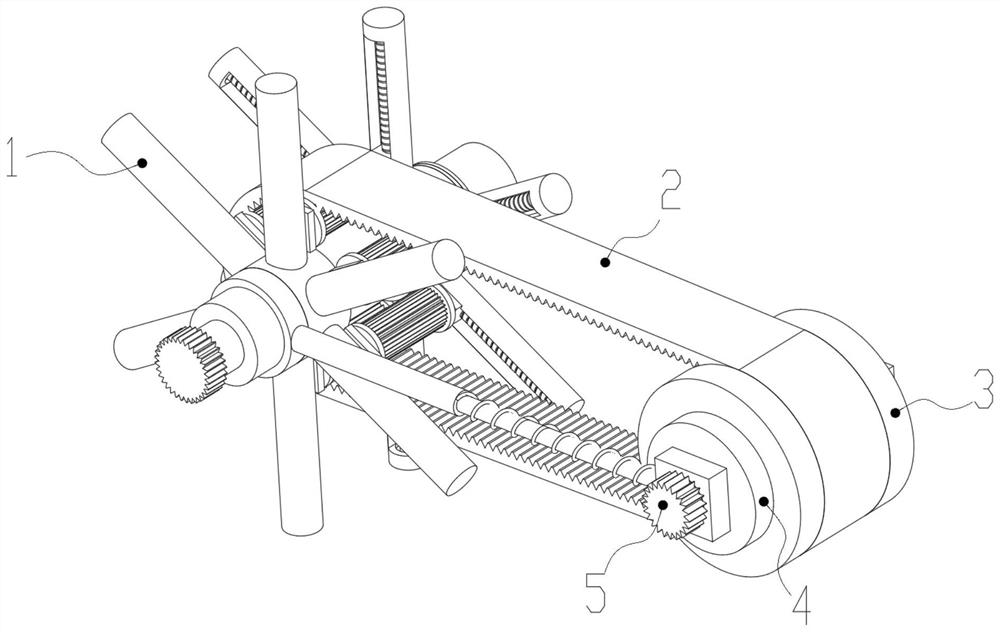

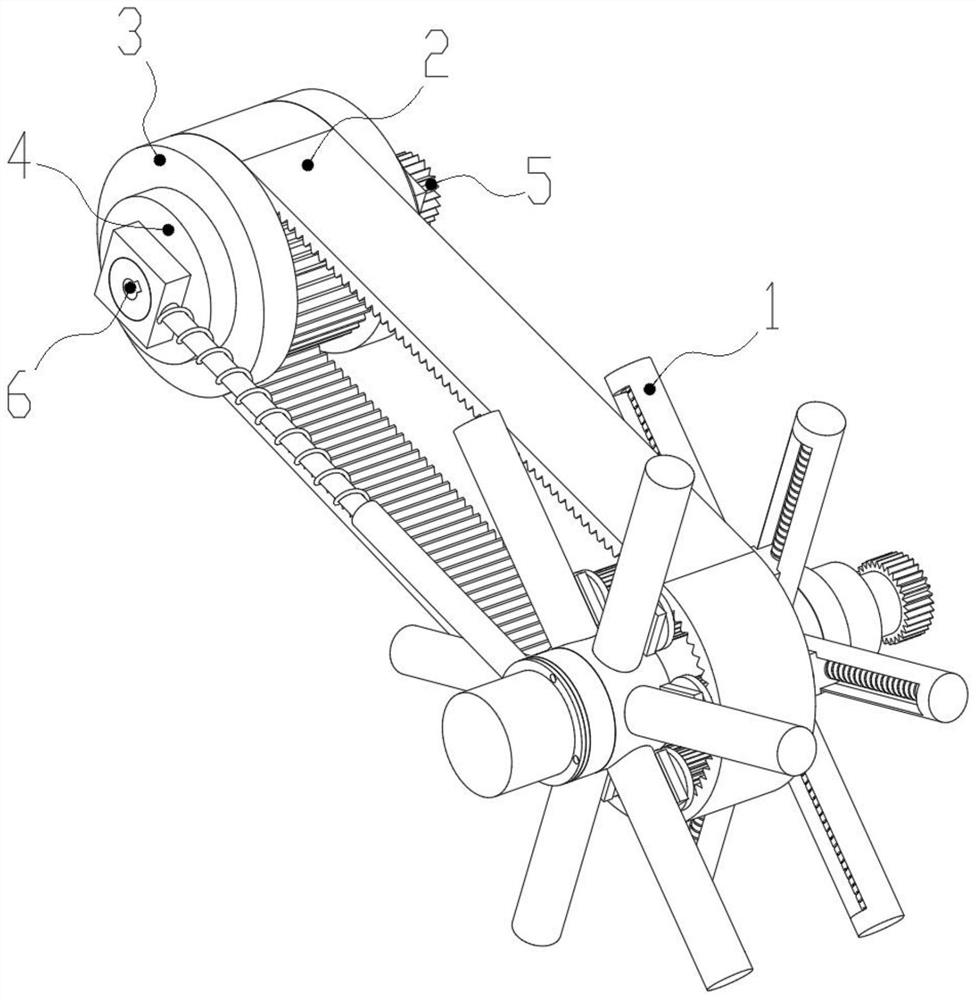

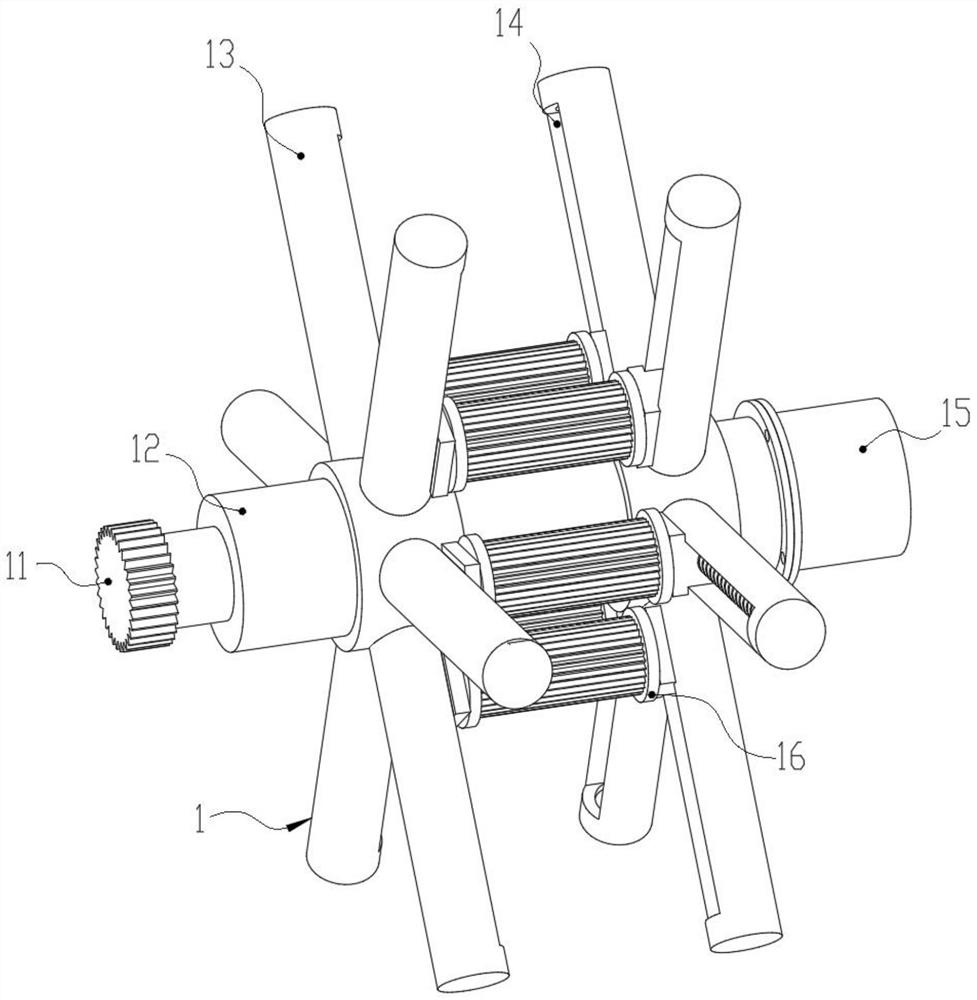

Speed change mechanism capable of realizing large-range regulation and control and used for machining

The invention discloses a speed change mechanism capable of realizing large-range regulation and control and used for machining. The speed change mechanism comprises an adjusting mechanism, a tooth-shaped belt, a tooth-shaped belt wheel, limiting mechanisms, a transmission gear and an inserting groove, and the limiting mechanisms used for supporting are symmetrically and rotationally clamped to the outer end surface of the adjusting mechanism. The adjusting mechanism is arranged, when speed change is carried out, a gear rotating plate and guide gears are arranged, so that when the gear rotating plate rotates, power can be uniformly conveyed to the six sets of guide gears, and then the guide gears can drive a threaded shaft to rotate through connecting supporting rods; a positioning sliding block is arranged at the outer part of the threaded shaft in a threaded mode, through the threaded displacement mode, the accuracy and stability of displacement of the positioning sliding block outside the threaded shaft can be effectively improved, after the radius of the positioning belt wheel is adjusted, the transmission stability and accuracy can be improved to the maximum degree, and thus the follow-up speed change efficiency is improved.

Owner:孙萱泽

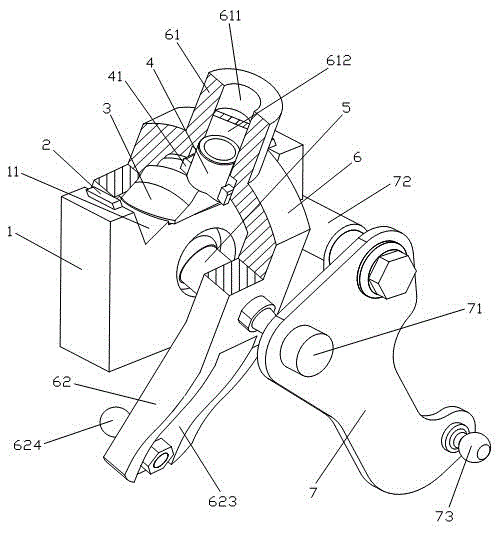

Gear shifting manipulator

ActiveCN104696506AAvoid problems that cannot be correctedAvoid interferenceGearing controlManipulatorRocker arm

The invention relates to a gear shifting manipulator. The gear shifting manipulator comprises a manipulator support, a gear-shifting limit block, a limit bolt, a gear shifting shaft, a gear-shifting rocker arm and a shift-selecting rocker arm, wherein the gear-shifting limit block is movably mounted at the top end of the manipulator support, and consists of a transverse limit part and a longitudinal limit shaft; the gear-shifting rocker arm comprises a basis part and a connecting arm; a gear lever is arranged at the top end of the basis part in a penetrating manner; a bolt clamping groove is formed in the connection position of the basis part and the connecting arm; the limit bolt is provided with a cylindrical cavity, and the other end of the limit bolt is in contact connection with a neutral limit groove in a movable manner; a spring is embedded in the cylindrical cavity; one or more pairs of anti-rotation blocks are arranged on the limit bolt; the gear-shifting limit block collides with a gear-shifting limit blocking pad during forward shifting and backward shifting; one side of the upper end of the shift-selecting rocker arm is connected with a shaft body at one end of the gear shifting shaft in an assembled manner, and a rotating shaft of the gear-selecting rocker arm is fixedly arranged on the other side of the upper end of the shift-selecting rocker arm. The gear shifting manipulator disclosed by the invention has the advantages that the structural design is reasonable, the operation and the use are simple, the feeling of manipulation is good, gear selection and shifting are convenient and reliable, the out-of-gear problem after engagement of gears can be effectively avoided.

Owner:SHIYAN DAFENG FLEXIBLE CONTROL CABLES

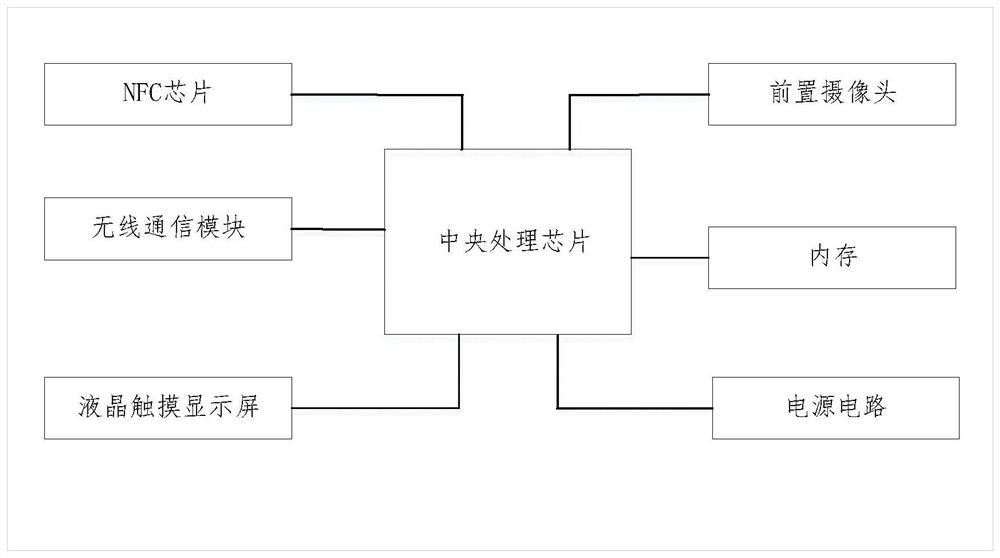

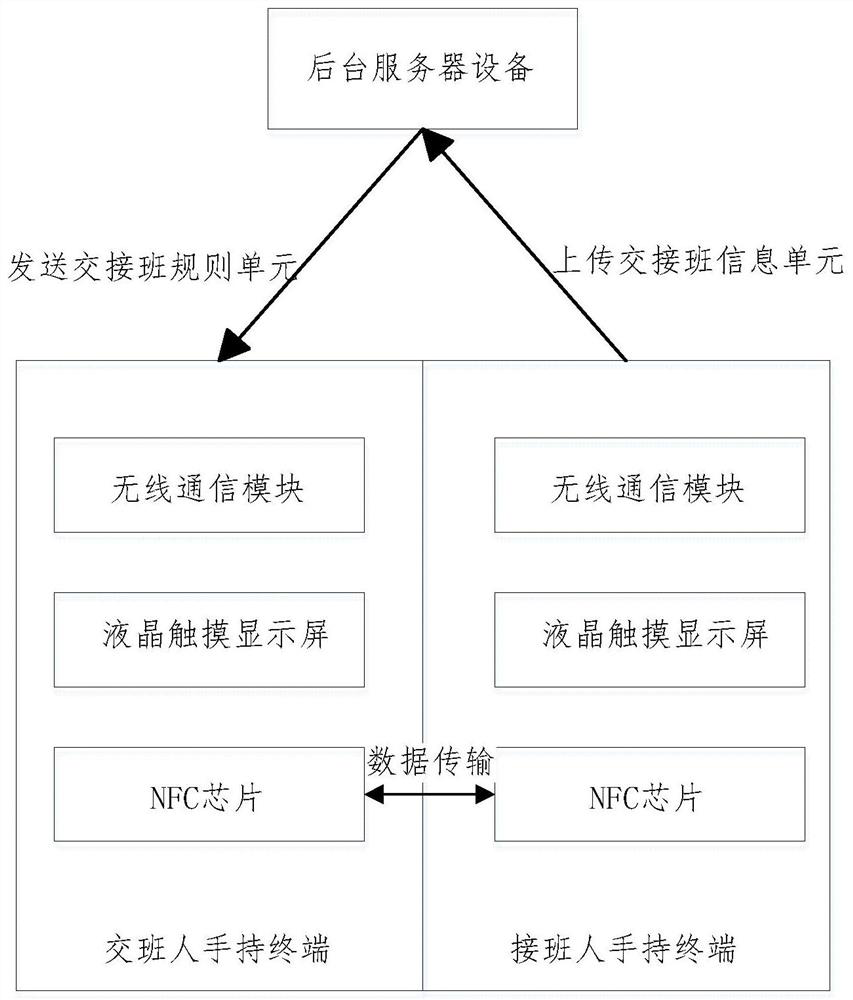

Handover system based on handheld terminal

PendingCN114093048AEnsure on-site handoverFast transferRegistering/indicating time of eventsConnection managementInformation transmissionJob number

The invention discloses a handover system based on a handheld terminal, and the system comprises a handheld terminal device which is used for downloading a handover rule, recording the on-duty content, verifying the information of a handover person, completing the transmission of the handover information, and uploading the handover data; a background server device which is used for storing and managing the handover rules, including the names, job numbers and handover time limits of the personnel of each handover, sending the handover rule data to the hand held terminal through a network, and meanwhile, receiving the handover related data information uploaded by the hand held terminal after the handover succeeds, comprising the on-duty records, the handover personnel information, the handover personnel photos and the handover time. According to the invention, the point-to-point data transmission function of an NFC chip in the handheld terminal is utilized, so that the on-duty record and the handover of the work content can be quickly completed, and the handover efficiency is improved; and the on-site handover of the shift-shifting personnel and the shift-receiving personnel is ensured, the alternative handover by others is prevented, and the handover management is standardized.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com