Shifting device and method of existing building

A shifting device and technology for existing buildings, applied in construction, building maintenance, building construction, etc., can solve the problems of low construction efficiency, time-consuming, cumbersome process, etc., to alleviate the impact of horizontal jacks, facilitate installation or The effect of adjusting and simplifying the process of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

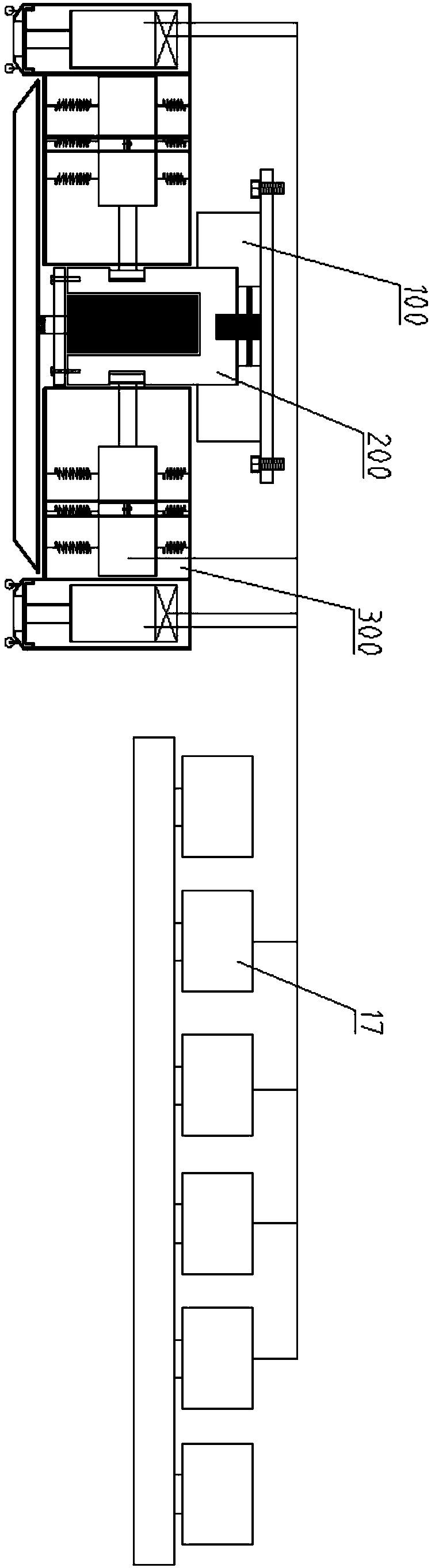

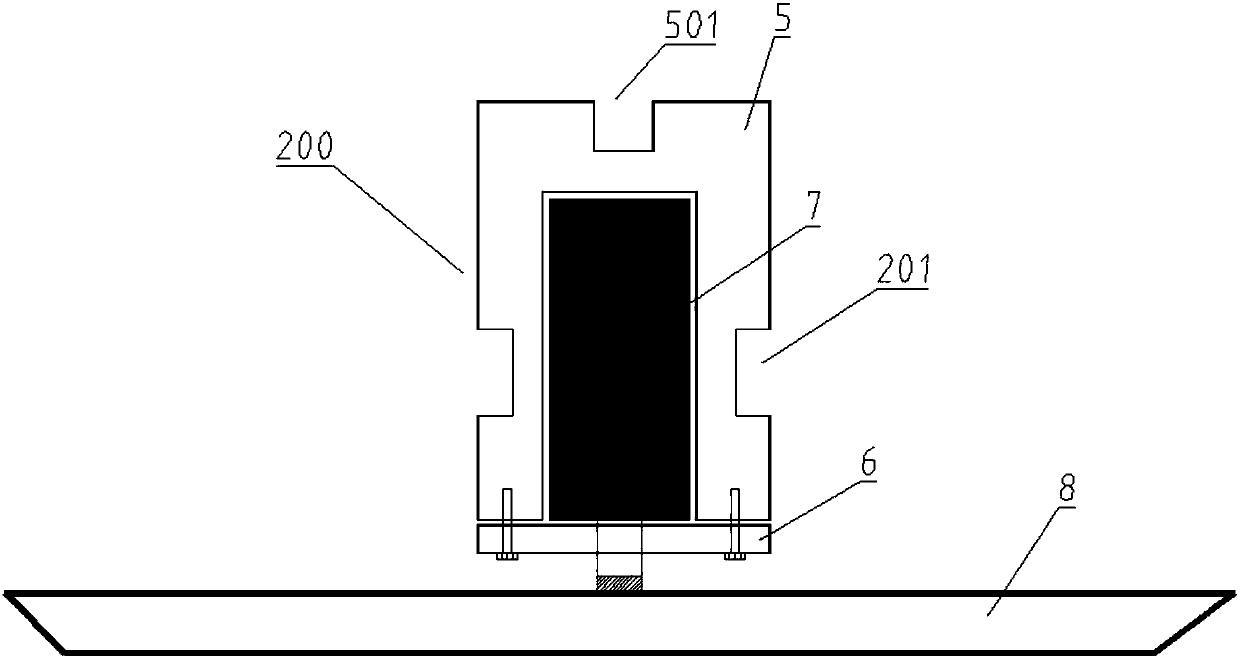

[0048] This embodiment provides a displacement device for existing buildings, such as Figure 1-15As shown, it includes a connection mechanism 100 connected to the bottom of an existing building, a displacement drive mechanism 300 for driving the connection mechanism 100 to move, and a jacking mechanism 200 for connecting the connection mechanism 100 and the displacement drive mechanism 300 .

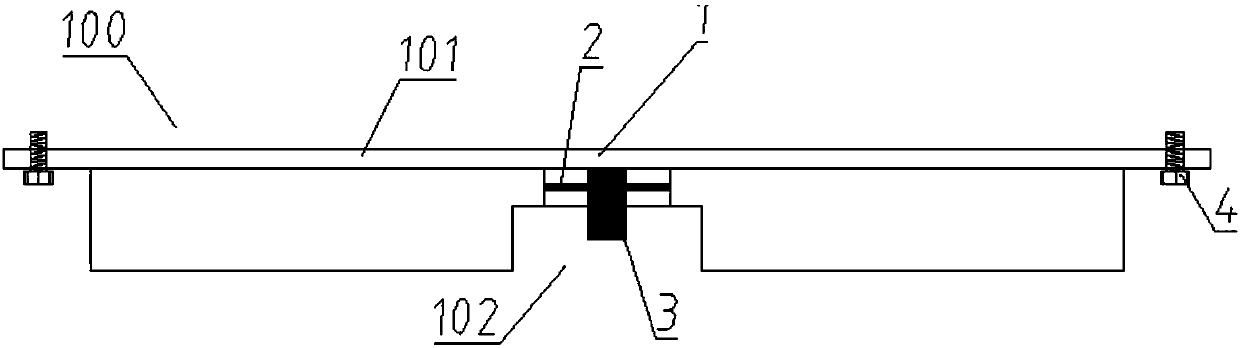

[0049] The connection mechanism 100 includes a base 1, a flange 101 is provided on the side of the base 1 close to the existing building, and a connecting bolt 4 is provided on the flange 101 to fix the base 1 to the bottom of the existing building.

[0050] In the middle of the base 1 is rotatably provided a rotating disk 2 whose axis extends vertically, and a rotating shaft 3 is coaxially fixed on the rotating disk 2. The rotation of the rotating disk 2 is driven by a motor connected to a computer control system 17. , and furthermore, the rotation and rotation angle of the rotation sh...

Embodiment 2

[0066] Embodiment 2 is directed at the use method of the shifting device in Embodiment 1, which specifically includes the following steps:

[0067] Step 1: Underpinning construction is required before the existing building is moved to place the existing building on the pallet, and set the anchor plate on the lower side of the pallet;

[0068] Step 2: leveling the shifting site of the existing building, and laying steel plates on the leveled site, the steel plate is a stainless steel plate to reduce the friction with the shifting shoe 8;

[0069] Step 3: Determine the displacement route of the existing building according to the starting point and end point of the displacement, and determine the position of the lock hole 22 according to the maximum stroke of the horizontal jack 12, and bury the lock hole 22 in the site; The coordinates are input into the computer control system;

[0070] Step 4: Install a plurality of shifting devices as required. The installation sequence of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com