Mechanism for gear shifting and stroke detection of gearbox

A technology for stroke detection and gearbox, which is applied in the direction of machine gear/transmission mechanism testing, measuring devices, instruments, etc. It can solve the problems of unable to find the production rhythm, low test run efficiency, and unqualified conditions, so as to improve the efficiency of gear shifting and detection , reduce the rate of returning to the factory, and improve the effect of the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

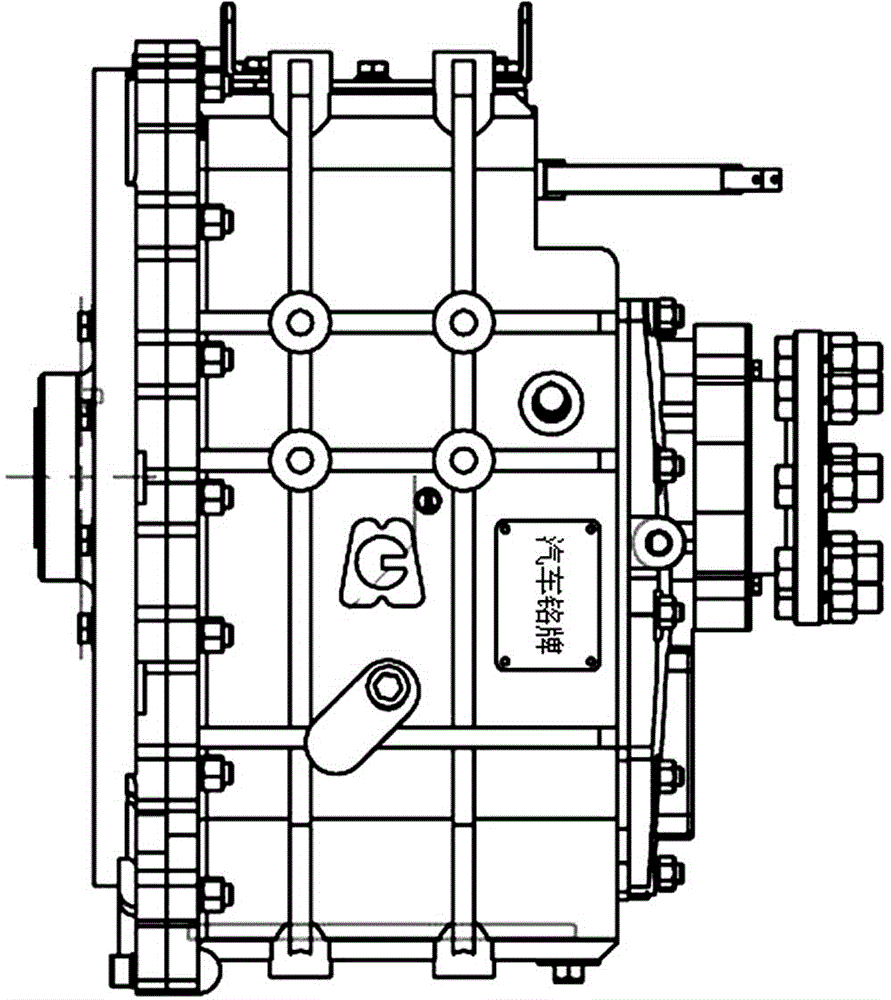

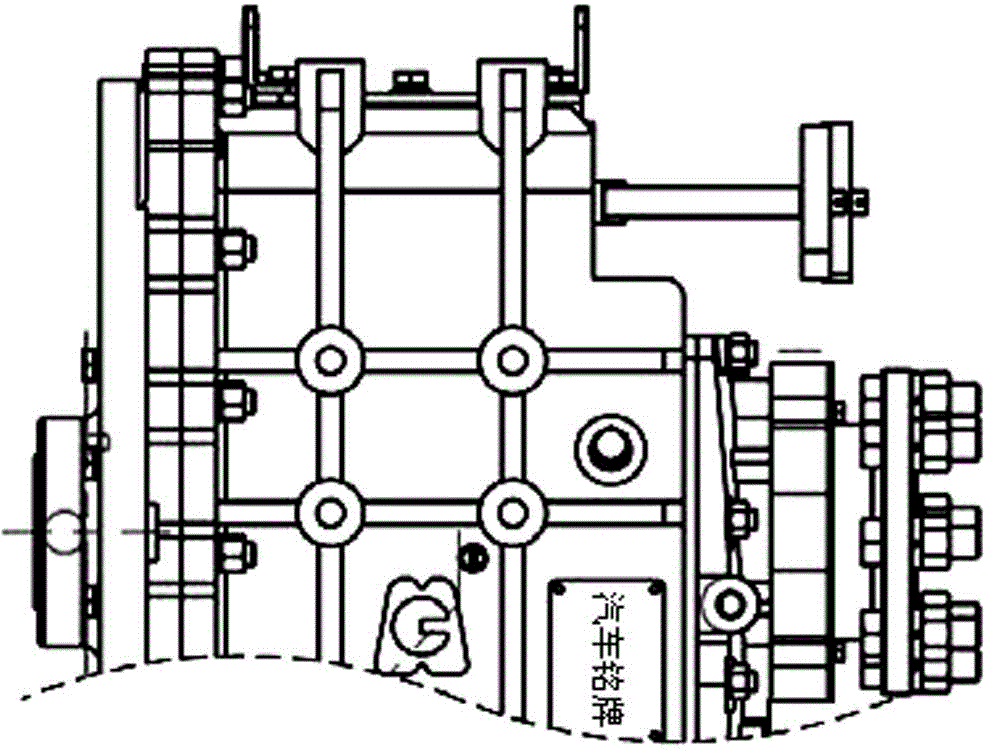

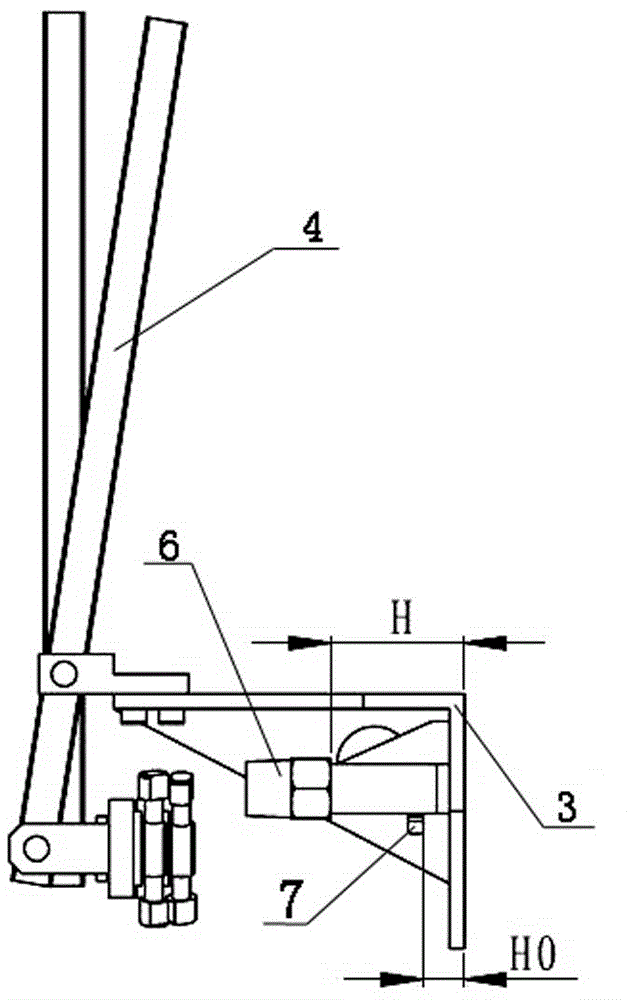

[0023] Embodiment: The present invention can also be called a kind of tooling, which is composed of tooling main body and stroke detection. The shifting wheelbase of the tooling body is determined by the gearing wheelbase of the gearbox. The position of the shifting lever is designed so that The shift lever is vertical in the neutral position. The fixing holes of the main body of the tooling correspond to the positions of the threaded holes of the box body. The rotating body part A on the tooling adopts a half-hole and half-thread design, which can make it play a guiding role when combined with the shift shaft, and facilitate the screwing of the threads. A certain ratio is selected at both ends of the fulcrum of the shift lever to reduce the shifting force. The light hole of the fixed rotating sleeve B on the shift lever is designed with a long slot to offset the dimensional change along the direction of the lever when shifting gears. The distance H between the plane of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com