Heavy truck duplex driving axle capable of achieving double speeds

A technology of double drive axles and heavy trucks, which is applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of less transmission gears and small transmission range of automatic transmissions, and achieves less reversing components, high transmission efficiency, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

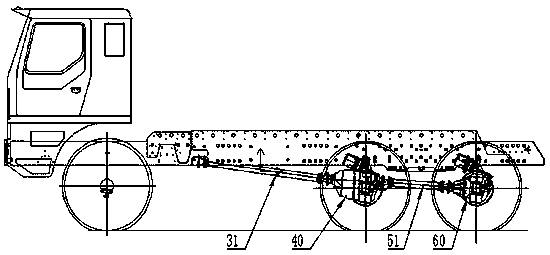

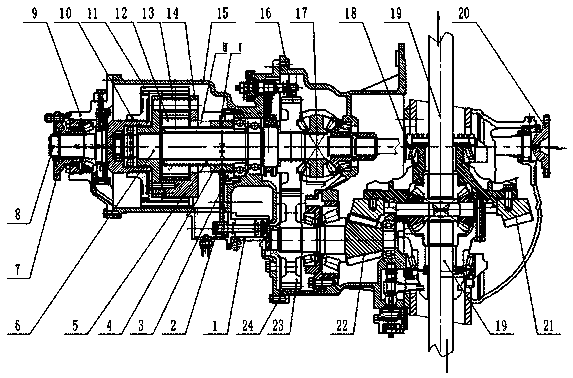

[0017] Example 1, see figure 1 , 2 3. According to the design requirements, the relevant components of the middle axle assembly 40 and the rear axle assembly 60 are processed;

[0018] The driving cylindrical gear 16 and the output shaft 6 are loosely matched, and the differential rotation is realized through the inter-shaft differential assembly 17 and the output shaft 6, or after being locked by the inter-shaft differential lock, they rotate rigidly together; the driving cylindrical gear 16 and the The driven cylindrical gear 23 is meshed, the driven cylindrical gear 23 and the driving bevel gear 22 are spline connected, and the driving bevel gear 22 and the driven bevel gear 21 are meshed to form a bevel gear pair; The transmission assembly 18 is connected; the half shaft 19 and the half shaft gear of the inter-wheel differential assembly 18 are splined; then the input flange 7 and the input shaft 8 are connected by splines, and the input shaft 8 and the planetary reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com