A non-contact torque measuring device with variable speed function

A non-contact, torque measurement technology, used in measurement devices, torque measurement, power measurement, etc., can solve the problems of cumbersome mechanical alignment, easy damage to strain gauges, easy fatigue damage, etc., and achieves simple and convenient installation and maintenance. No need for lubrication and cooling, the effect of preventing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

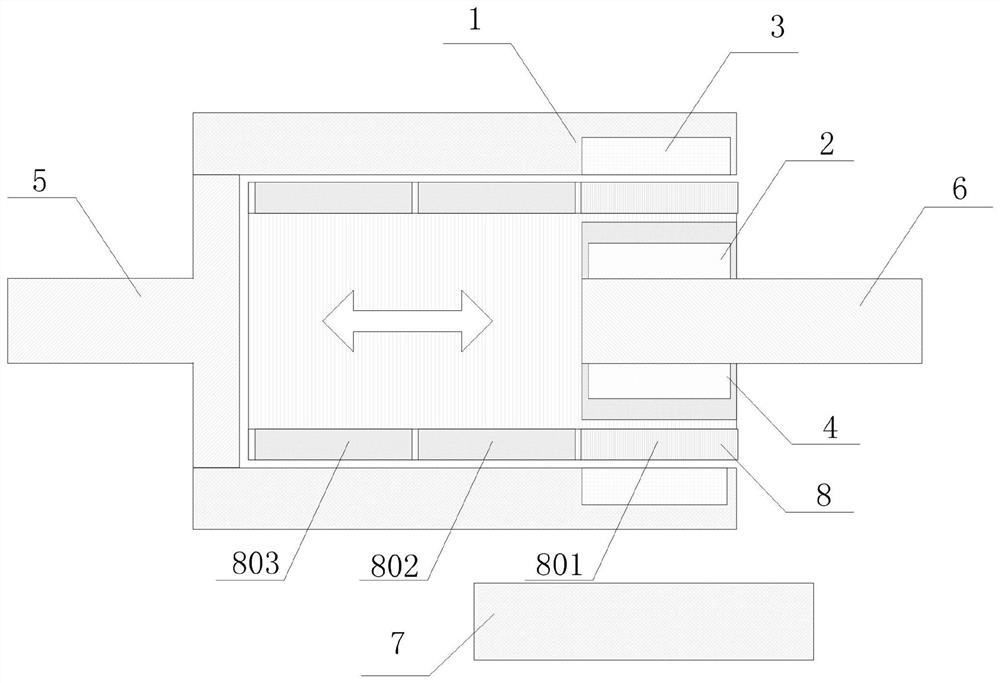

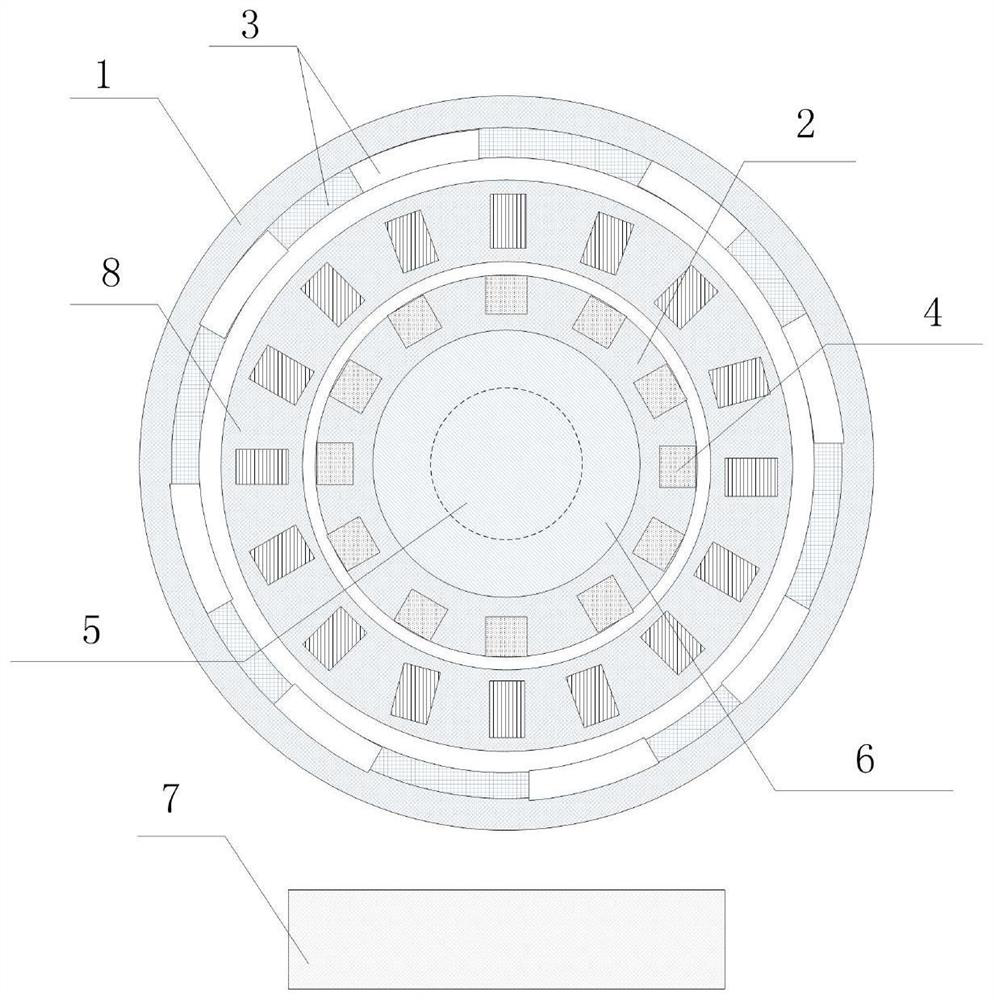

[0054] Such as figure 1 , figure 2 , Image 6 with Figure 7As shown, a non-contact torque measurement device with variable speed function, the measurement device includes: a measurement module 7, a permanent magnet rotor, a squirrel cage rotor, a magnetic field modulation ring 8, a driving end 5 and a driven end 6;

[0055] The permanent magnet rotor is connected to the driving end 5, the squirrel cage rotor is connected to the driven end 6, and the torque change of the permanent magnet rotor is transmitted to the squirrel cage rotor;

[0056] The permanent magnet rotor, the magnetic field modulation ring 8 and the squirrel cage rotor are sequentially nested from outside to inside and fixed on the same axis;

[0057] The magnetic field modulation ring includes a multi-section modulation iron core, the multi-section modulation iron cores are placed side by side, the multi-section modulation iron cores are all provided with slots, and the slot numbers of the multi-section m...

Embodiment 2

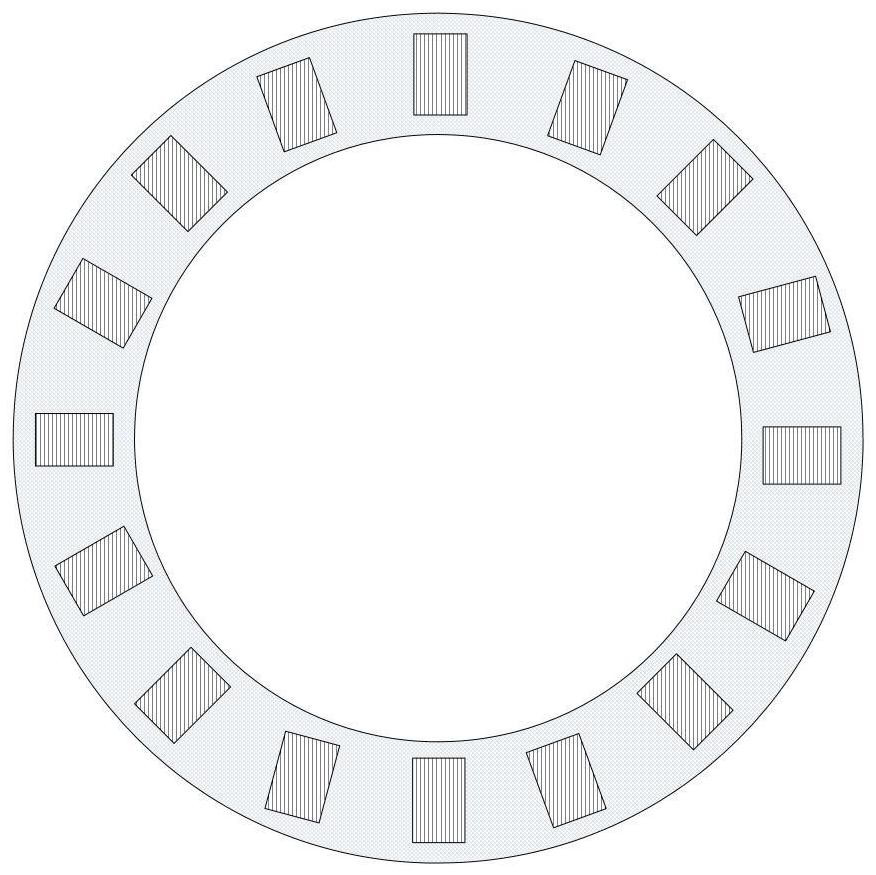

[0080] Figure 8 It shows a non-contact torque measuring device with variable speed function according to the second embodiment of the present invention, the torque measuring device includes a permanent magnet rotor, a magnetic field modulation ring 8 and a squirrel cage rotor, the squirrel cage rotor is a cylindrical structure and The inner diameter of the squirrel cage rotor is greater than the outer diameter of the magnetic field modulation ring 8, and the inner diameter of the magnetic field modulation ring 8 is greater than the outer diameter of the permanent magnet rotor; the permanent magnet rotor is composed of a permanent magnet rotor core 1 and a permanent magnet 3, and the permanent magnet core 1 can be composed of Silicon steel sheets or other soft magnetic materials are stacked to form a cylindrical structure, which can also be made of magnetically conductive materials such as amorphous. The N and S poles of the permanent magnet 3 face the center of the circle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com