Efficient complete machine structure for horizontal machining center and manufacturing method thereof

A technology of machining center and complete machine structure, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing, etc., can solve the problems of ordinary horizontal machining centers, such as large volume, small footprint, complicated maintenance, etc., and reduce the width of the machine tool and machine tool footprint, reduce weight, and ensure the effect of transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

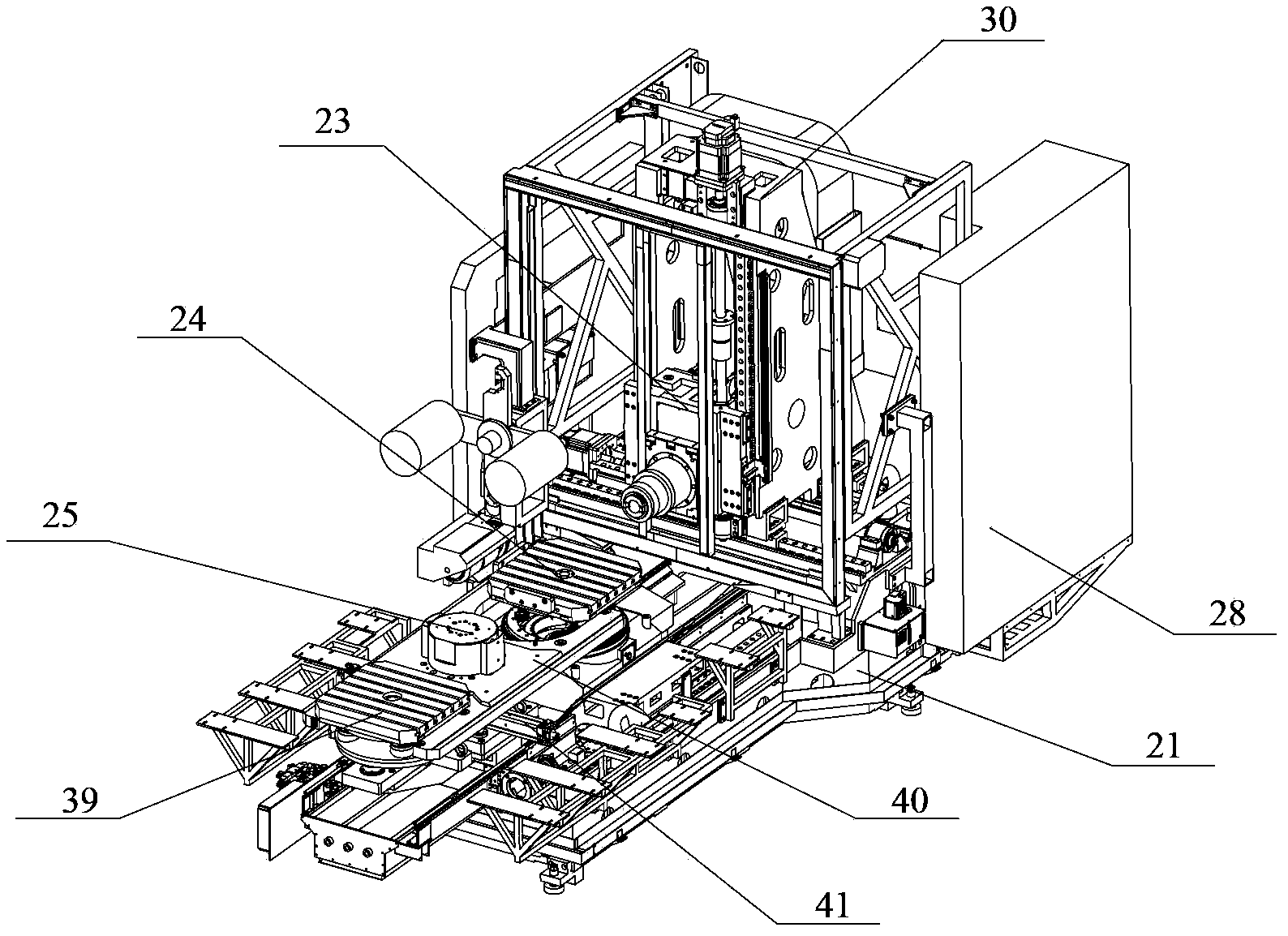

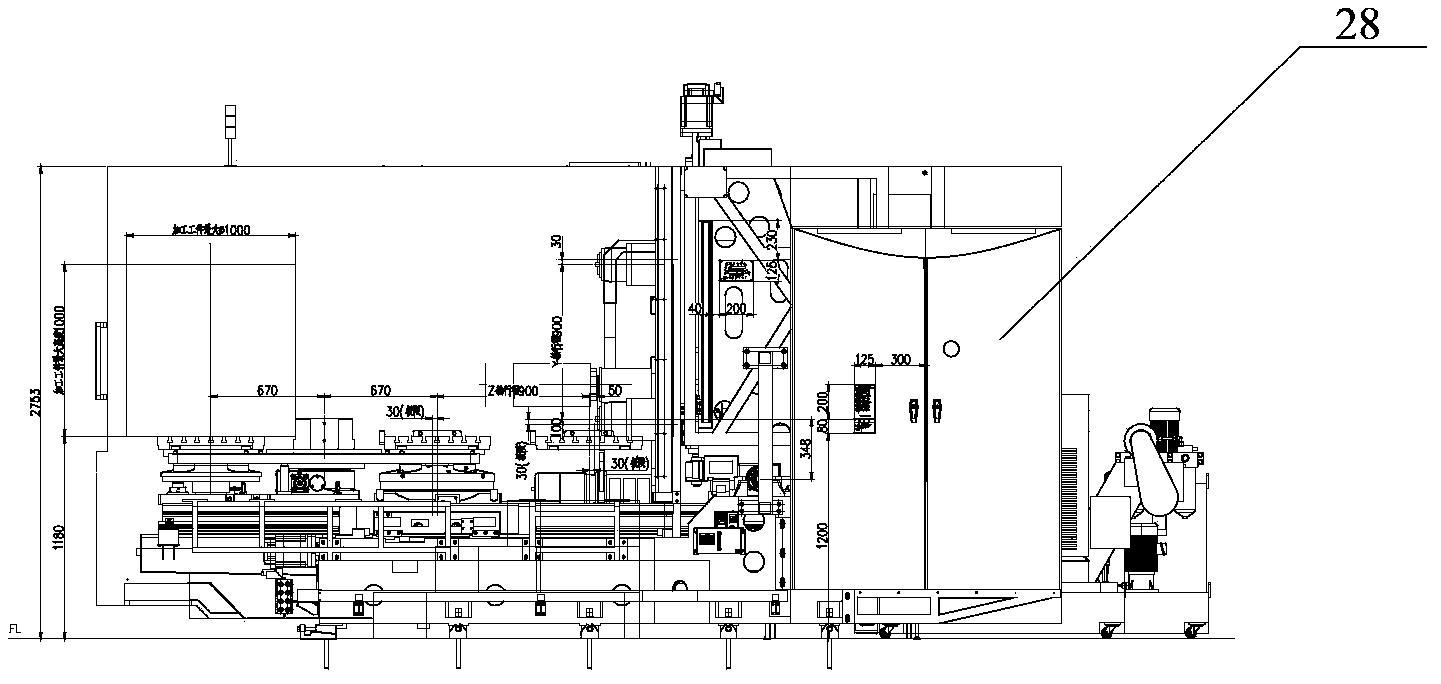

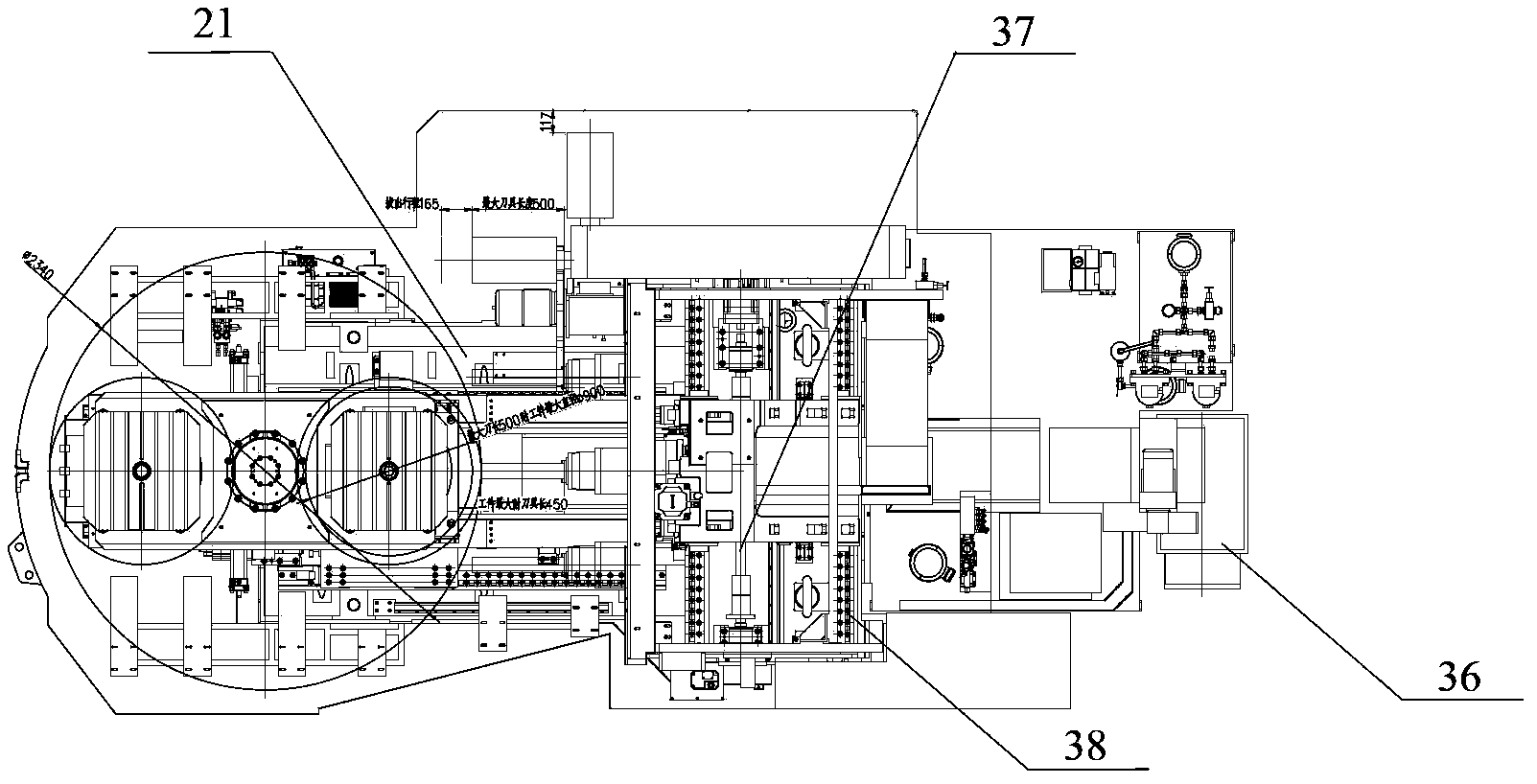

[0047] like Figure 1-Figure 13 As shown, the whole machine structure and manufacturing method of the high-efficiency horizontal machining center of the present invention, the whole machine includes a bed 21, a spindle box 23, a rotary table 24, an exchange station 25, a tool magazine 27, a column 30, etc., and the rigid bed 21 is inclined The surface is provided with return holes 32 ( Figure 12 ), the gantry frame column 30 moving left and right on the bed 21 adopts the rice-shaped rib 31 on the frame ( Figure 13 ) layout, on the spindle box 23 that moves up and down on the column 30, the motor is directly connected to the ZF reducer 1 to transmit the power to the spindle 3 through the reinforced toothed belt 2, and the loose clamping knife adopts a gas-liquid conversion booster cylinder (cutter cylinder) 34 , the rotary table 24 and the three-axis transmission mechanism 33 that move forward and backward along the bed 21 adopt a modular design, the L-shaped electrical cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com