Control mechanism for clutch and control method of control mechanism

A control mechanism and clutch technology, which is applied to clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of vehicle power loss, poor driving comfort, and poor shifting smoothness, so as to save design and modification costs and improve shifting performance. Ride comfort and the effect of improving vehicle economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

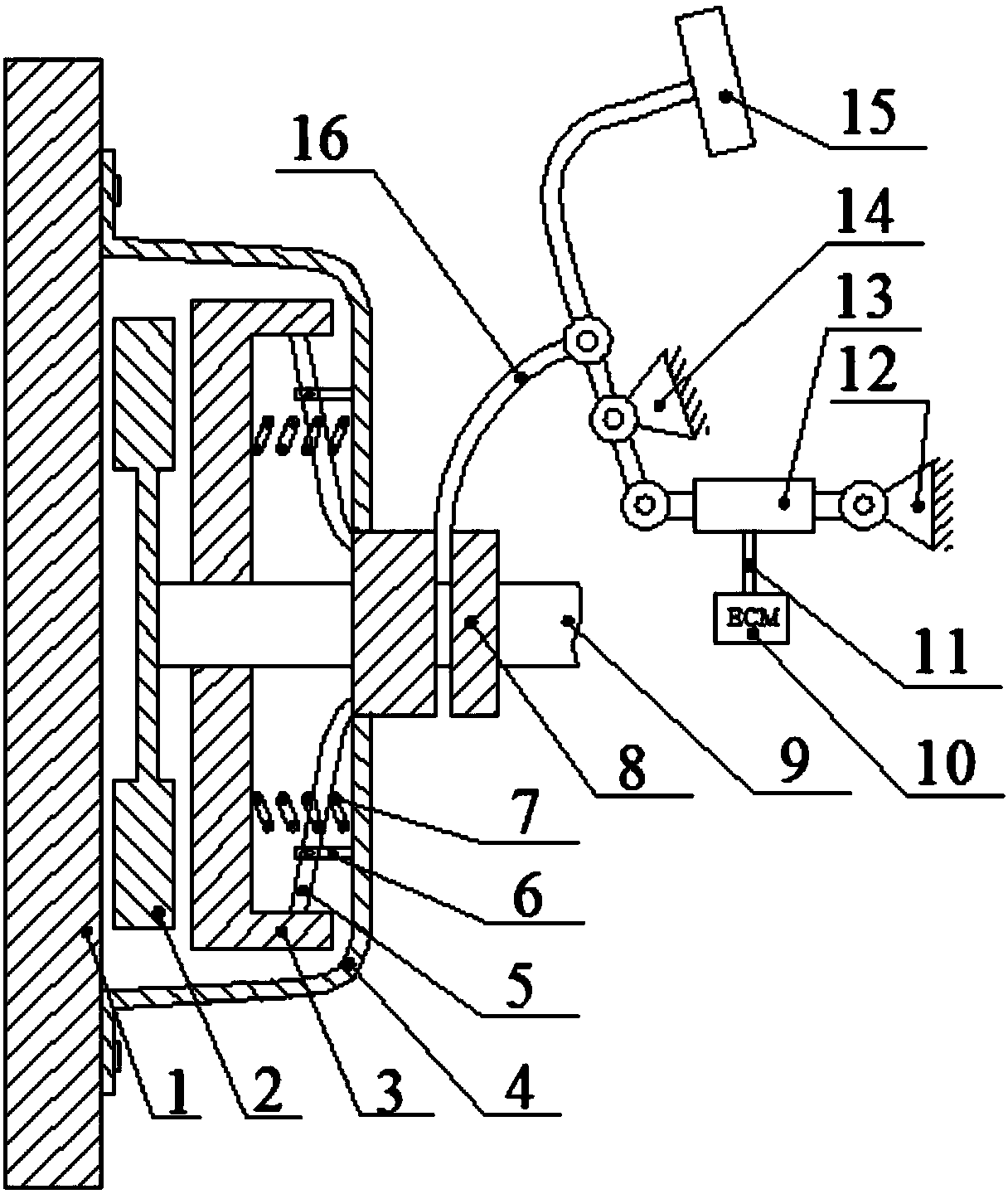

[0022] The following will be described in conjunction with the accompanying drawings and a specific embodiment.

[0023] see figure 1 . The clutch cover 4 is fixed on the flywheel 1 of the engine. One end of the diaphragm spring 5 is fixed to the clutch pressure plate 3, the other end of the diaphragm spring 5 is in contact with the release bearing 8, and the middle part of the diaphragm spring 5 is fixed to the clutch cover 4 by the diaphragm spring support 6 and forms a lever. The two ends of the return spring 7 are fixed on the driven disc 2 and the clutch cover 4 respectively. The driven disk 2 is fixed to the output shaft 9. The pressure plate 3 and the release bearing 8 can slide axially on the output shaft 9 .

[0024] Clutch pedal 15 is connected with pedal lever, and pedal lever is hinged with pedal lever fixed support 14, and forms a lever mechanism, and its first lever arm is hinged with separation fork 16, and the second lever arm is hinged with one end of cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com