Patents

Literature

30results about How to "Winding method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

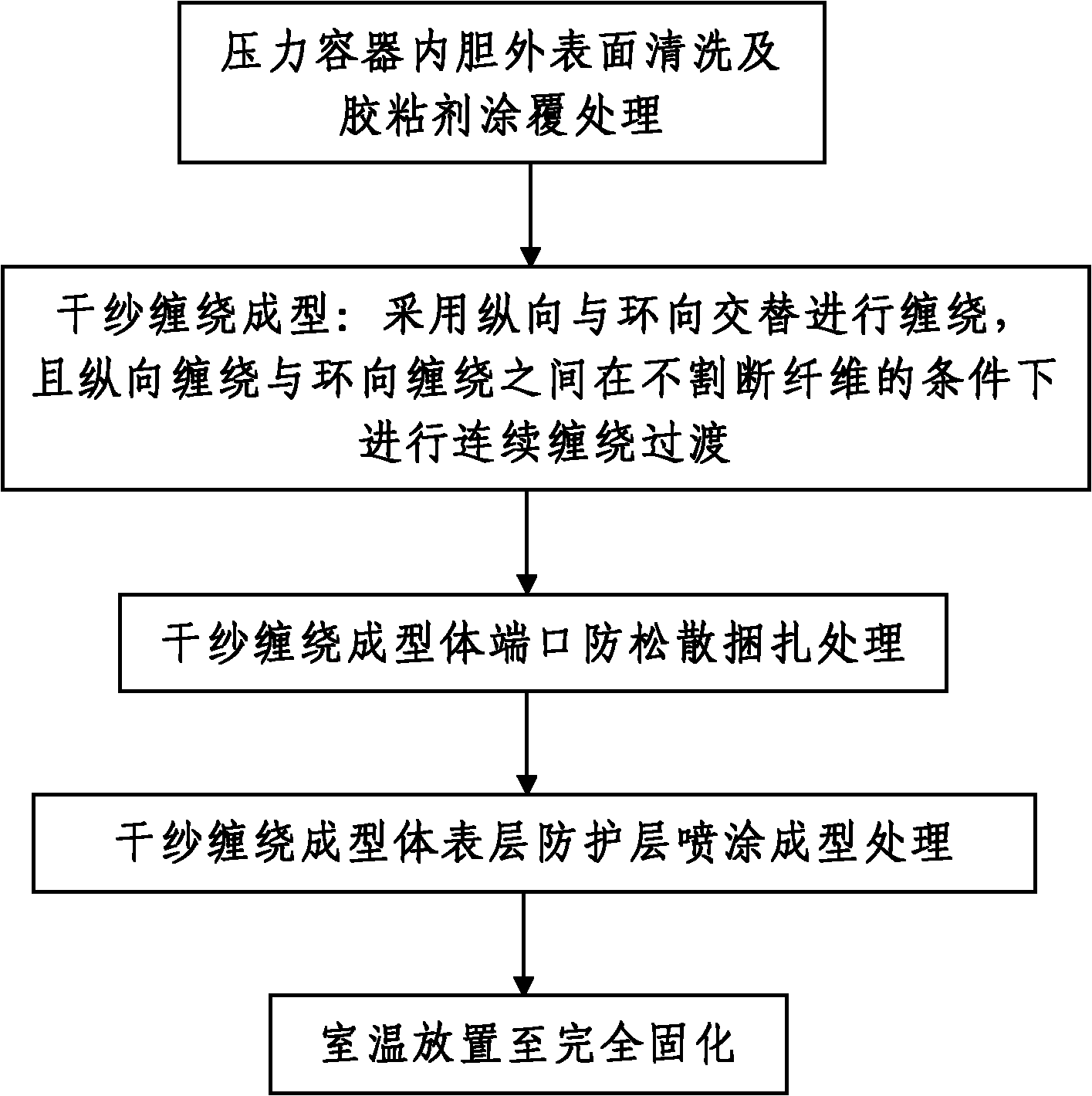

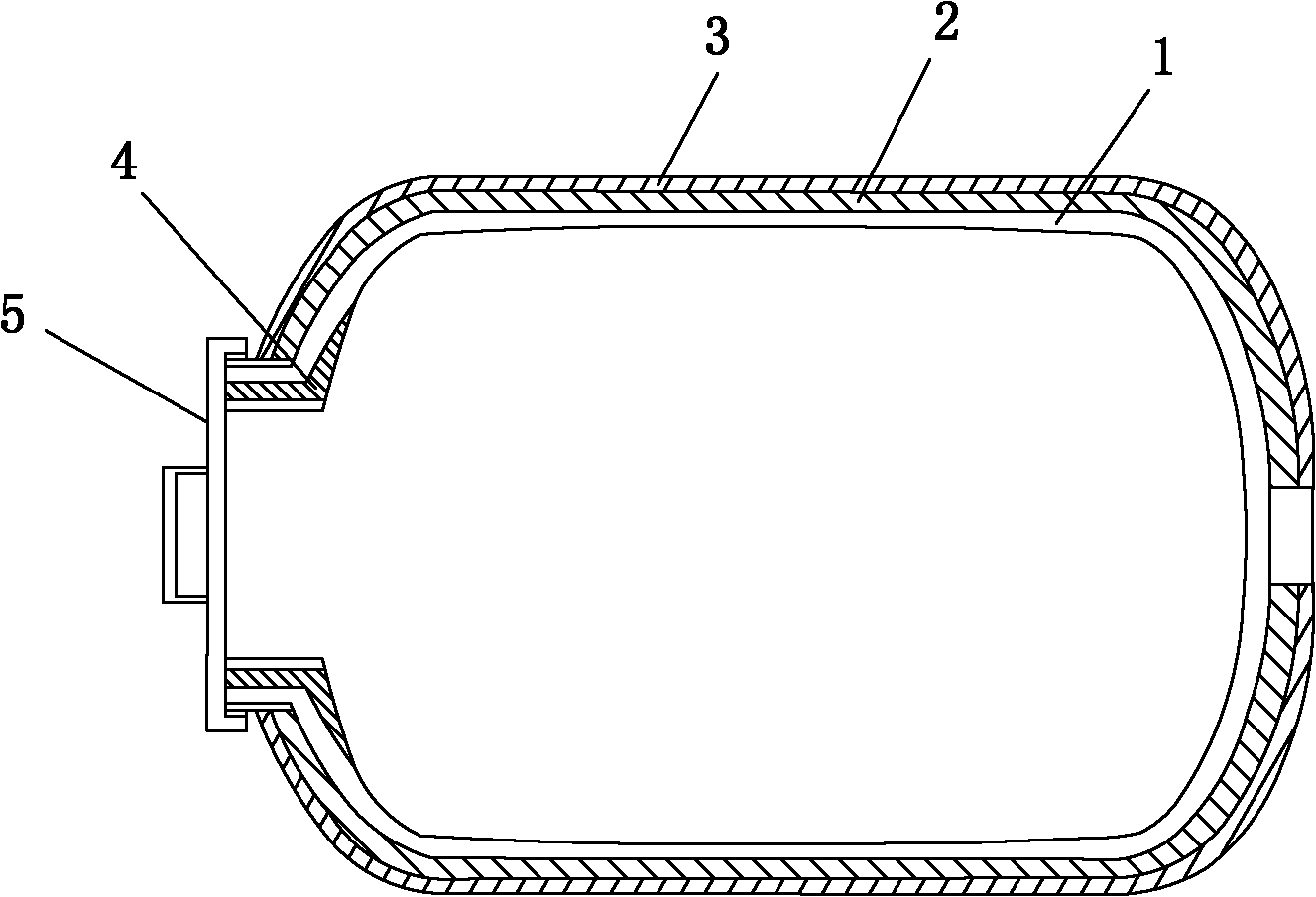

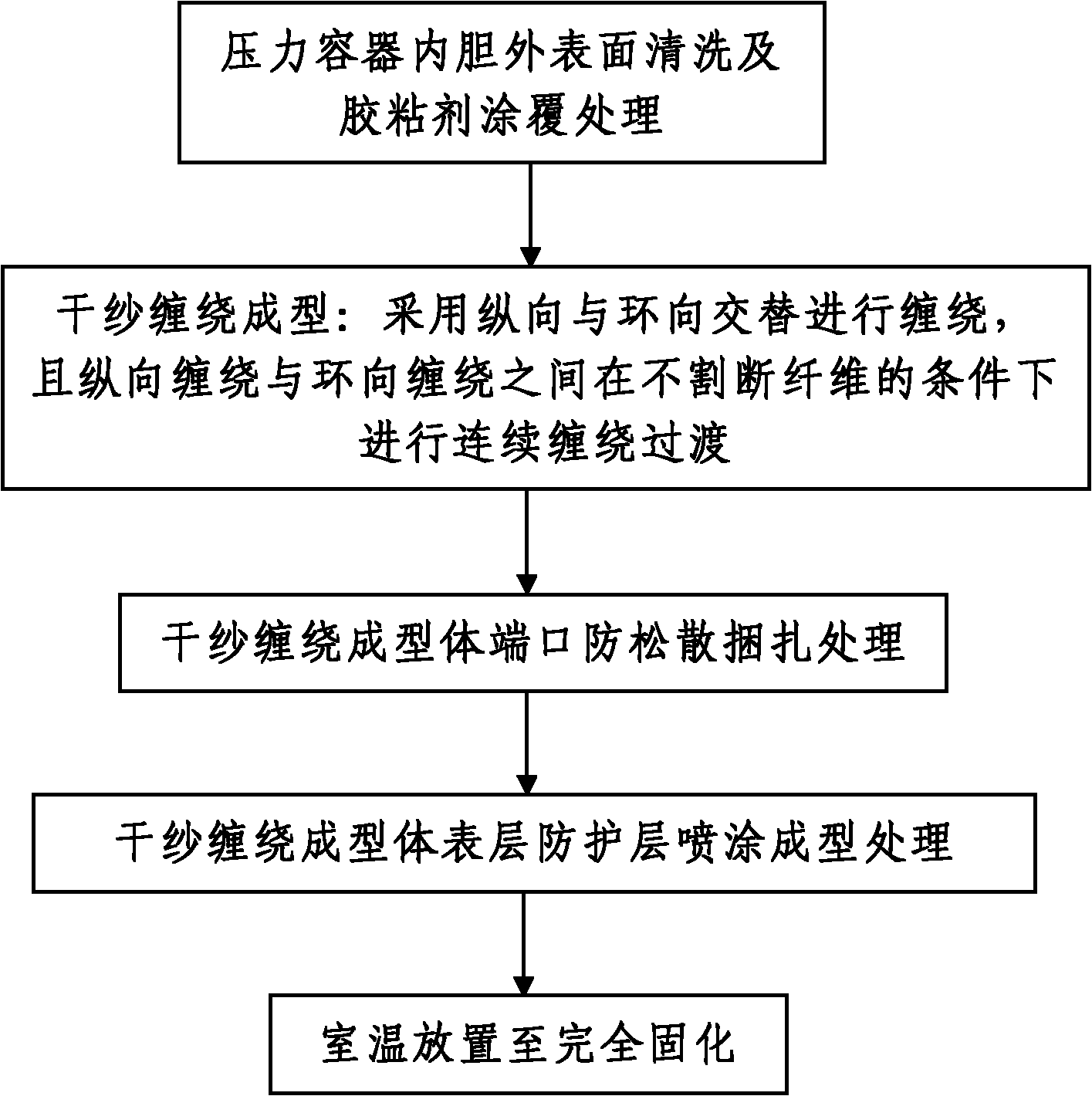

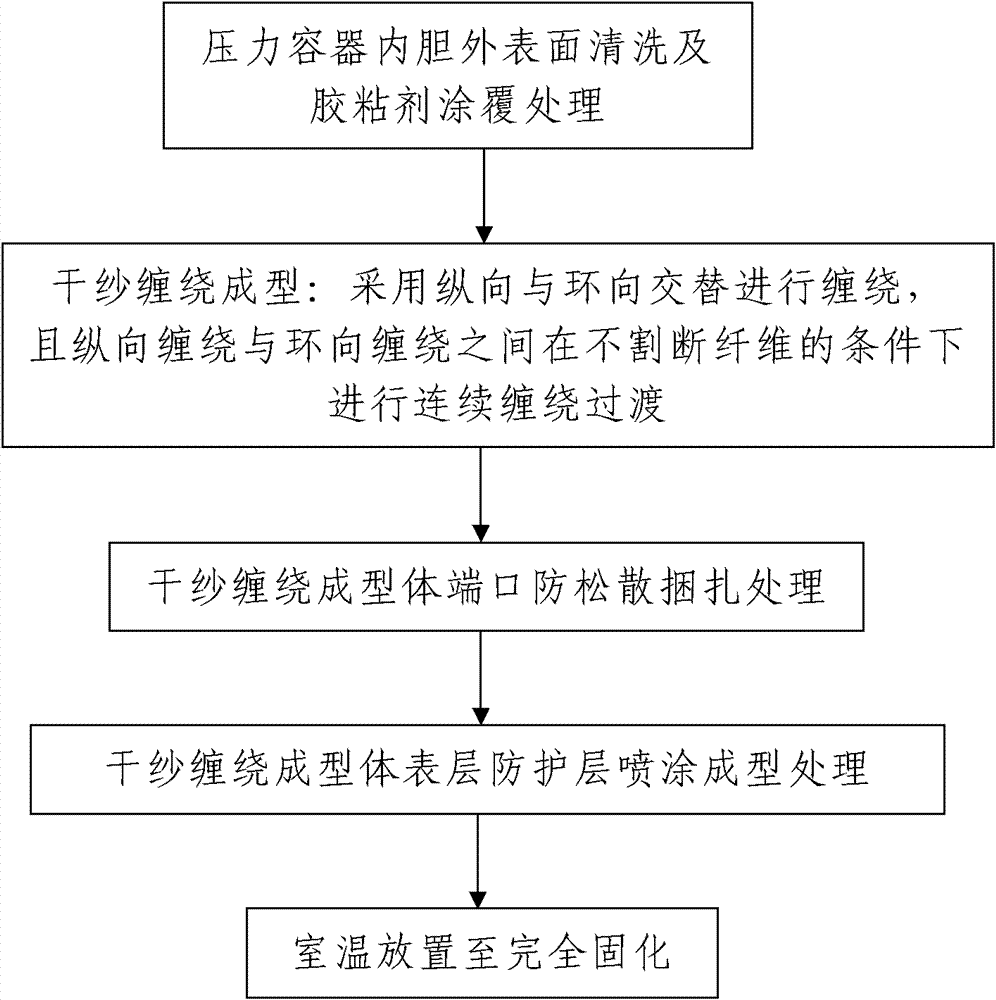

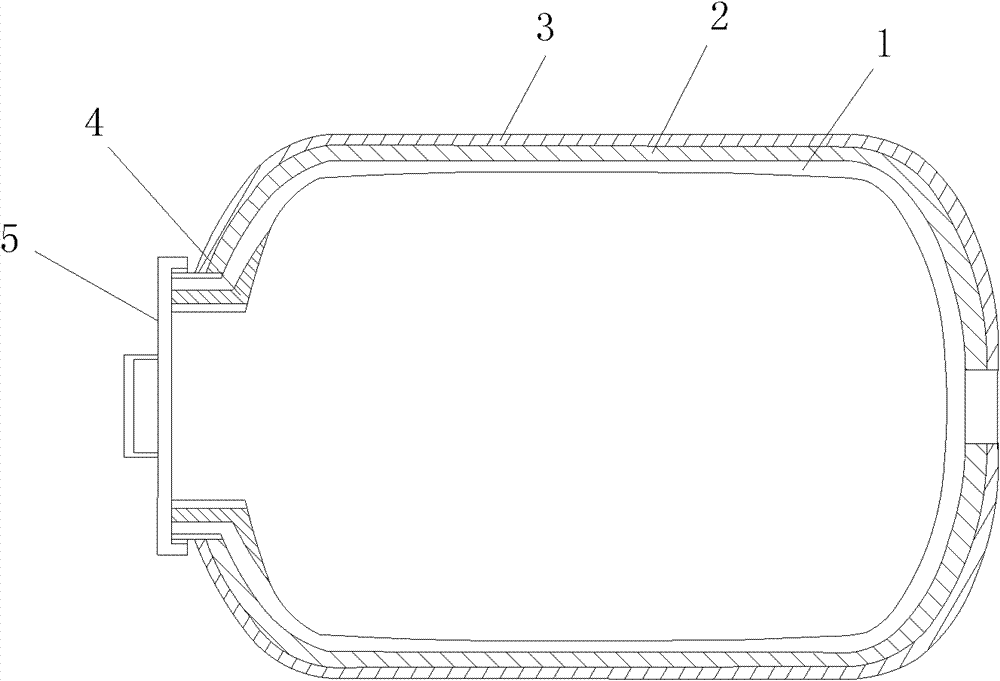

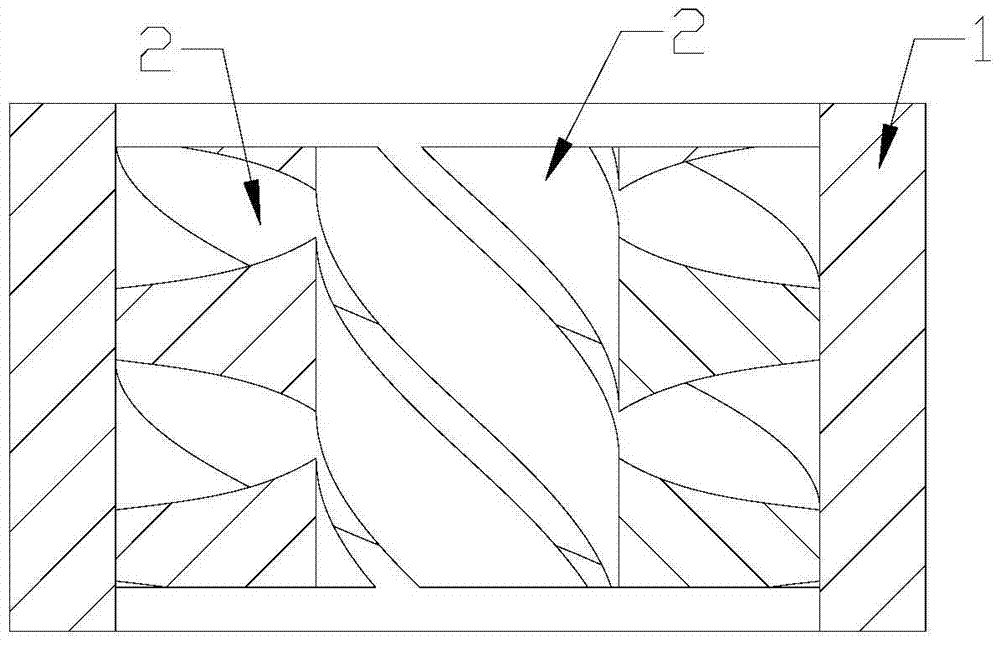

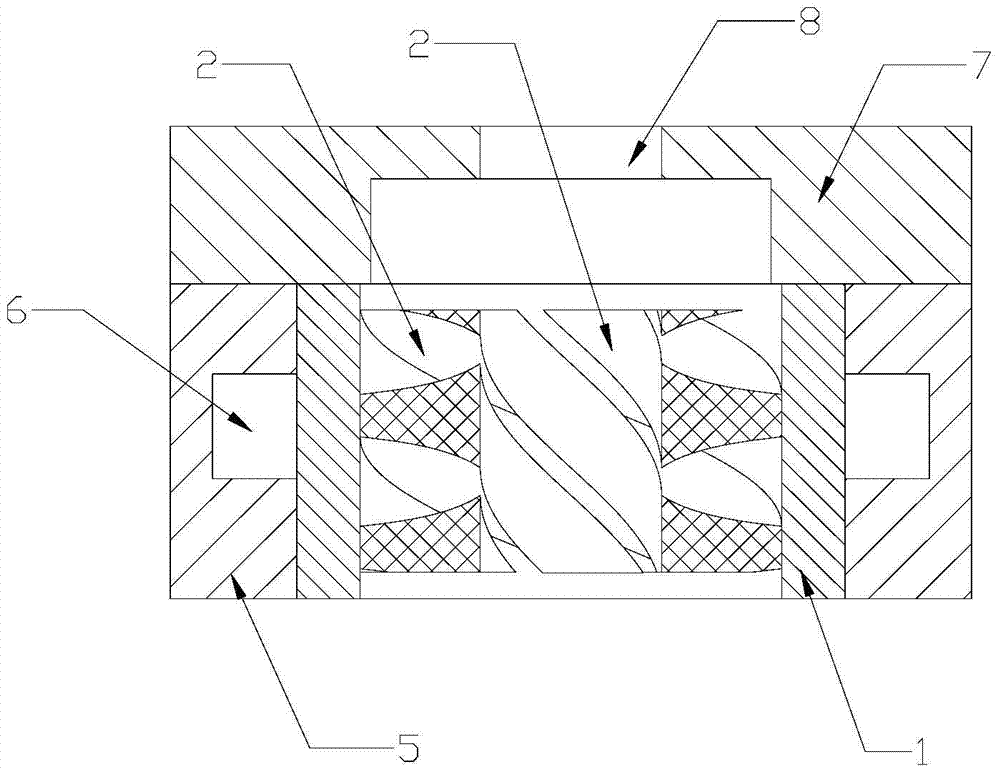

Dry yarn winding forming method for pressure container

The invention discloses a dry yarn winding forming method for a pressure container. The method comprises the following steps: 1. carrying out outer surface treatment on an inner container of the pressure container, namely coating an adhesive uniformly on the outer surface of the inner container of the cleaned pressure container; 2. carrying out dry yarn winding forming, namely winding on the outer surface of the inner container of the pressure container in a winding mode of alternative longitudinal winding and hoop winding, and carrying out continuous transition between the longitudinal winding and hoop winding under the condition that fibers are not cut off; 3. carrying out loose-proof strapping treatment on the port of a dry yarn winding forming body; 4. carrying out spraying forming treatment on a protective layer at the surface layer of the dry yarn winding forming body; and 5. placing and solidifying at room temperature. The dry yarn winding forming method for the pressure container provided by the invention has the advantages of reasonable design, simplicity and convenience in operation, convenience in control and good winding forming effect; and because an impregnation process and a solidifying process link are omitted, a plurality of practical problems, such as complex forming technology, longer production cycle, higher cost, no large scale of industrial production andthe like, of the existing winding forming process can be solved effectively.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

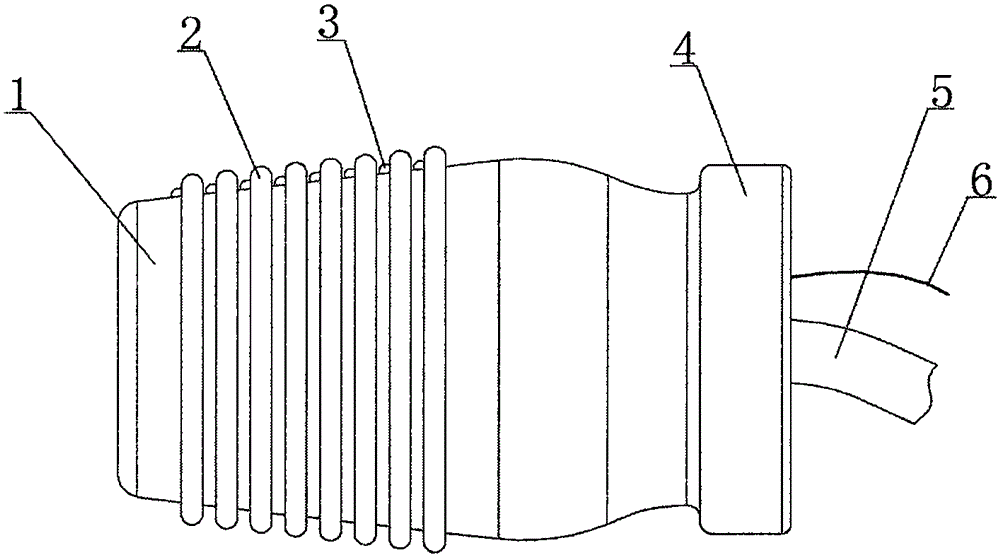

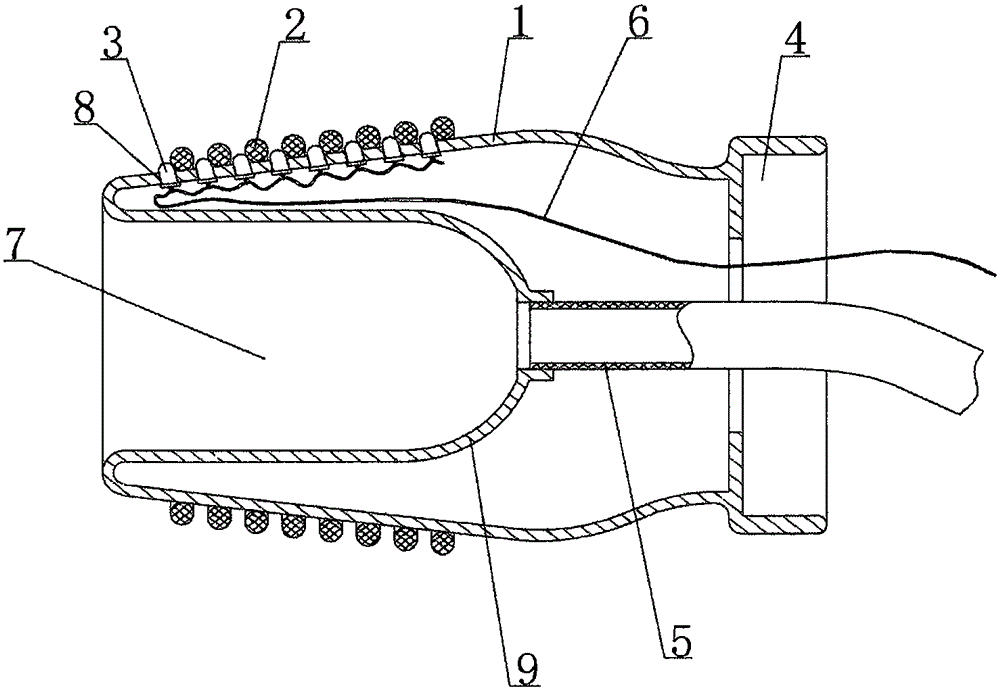

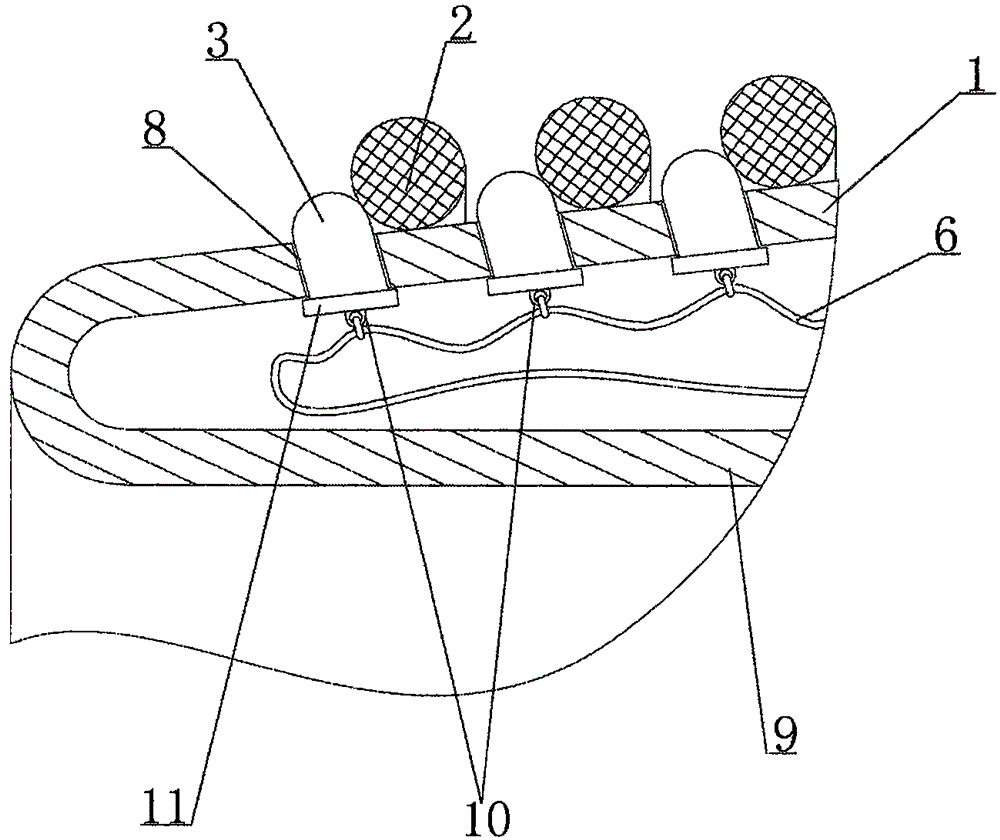

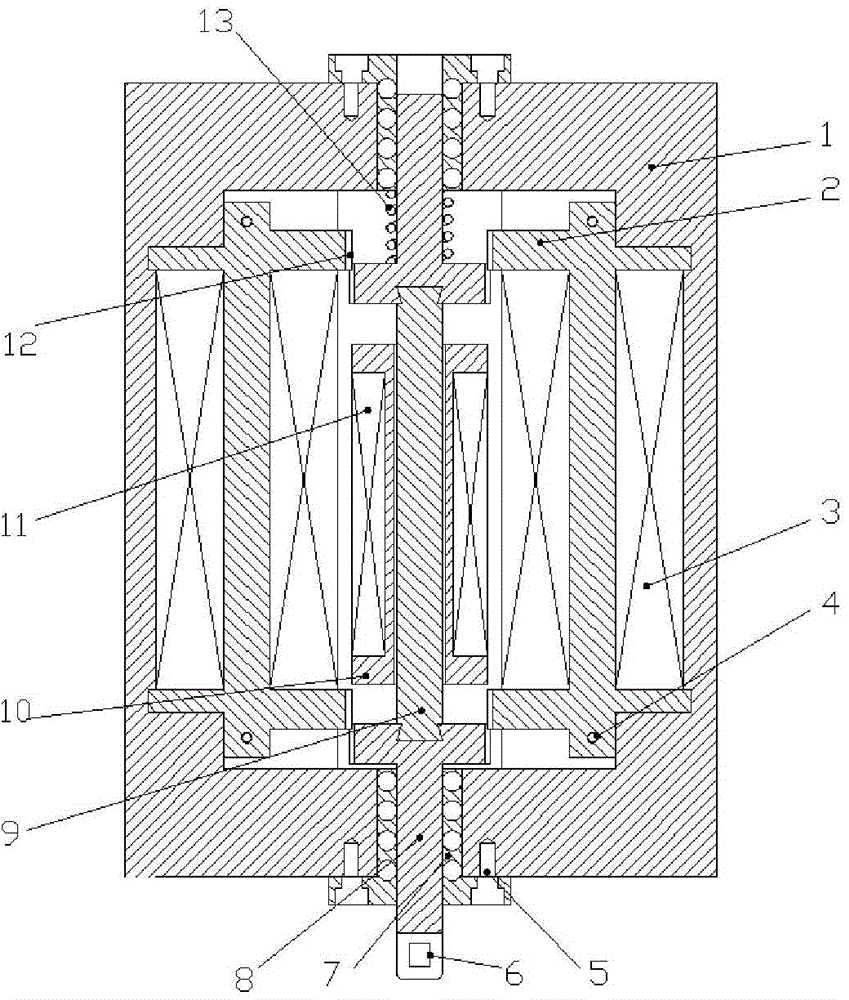

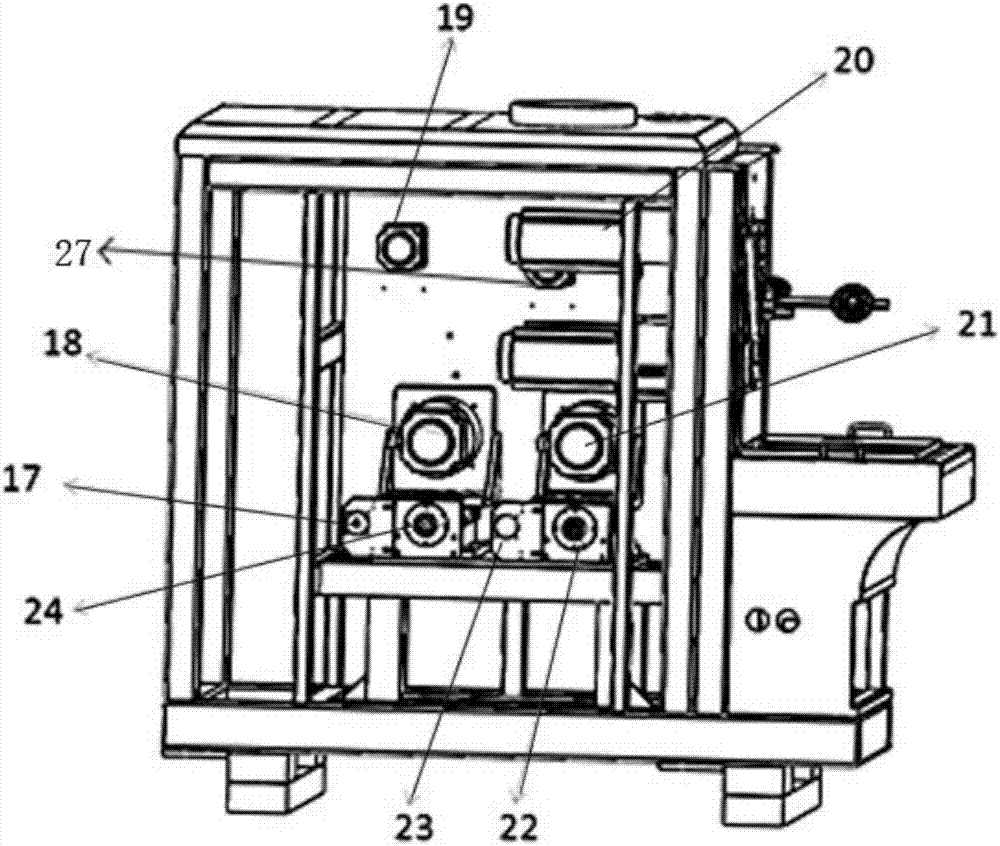

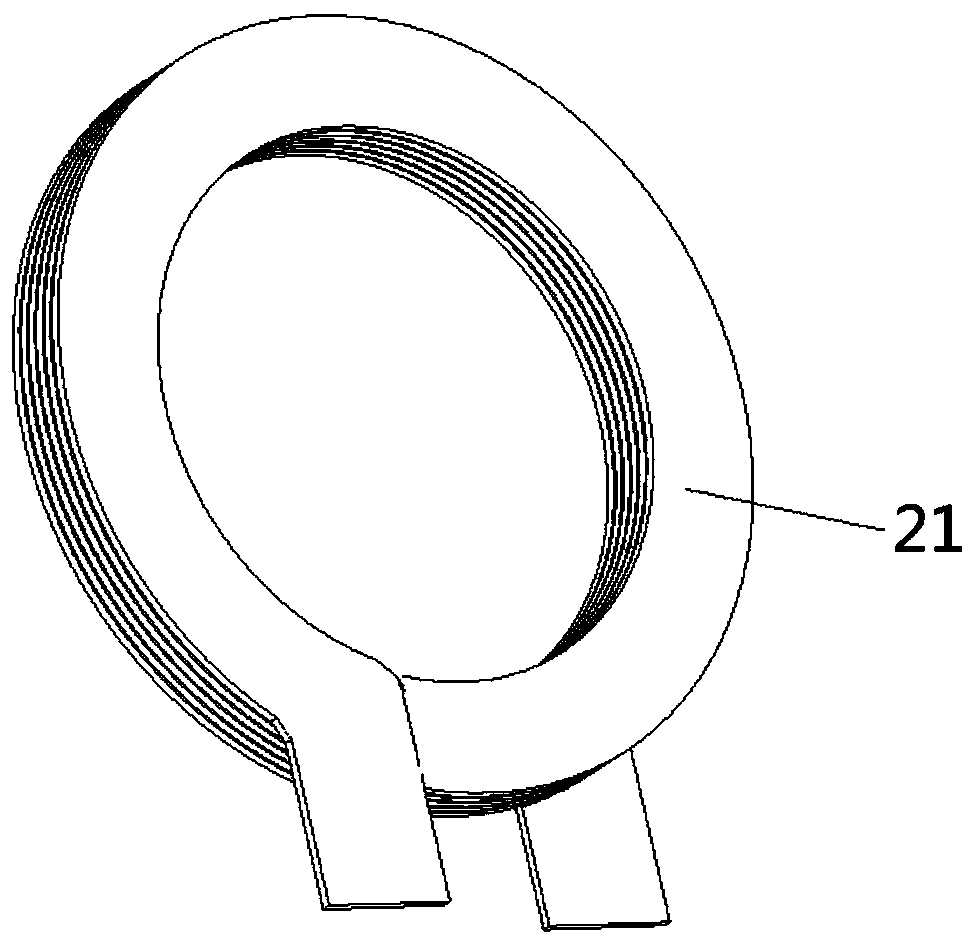

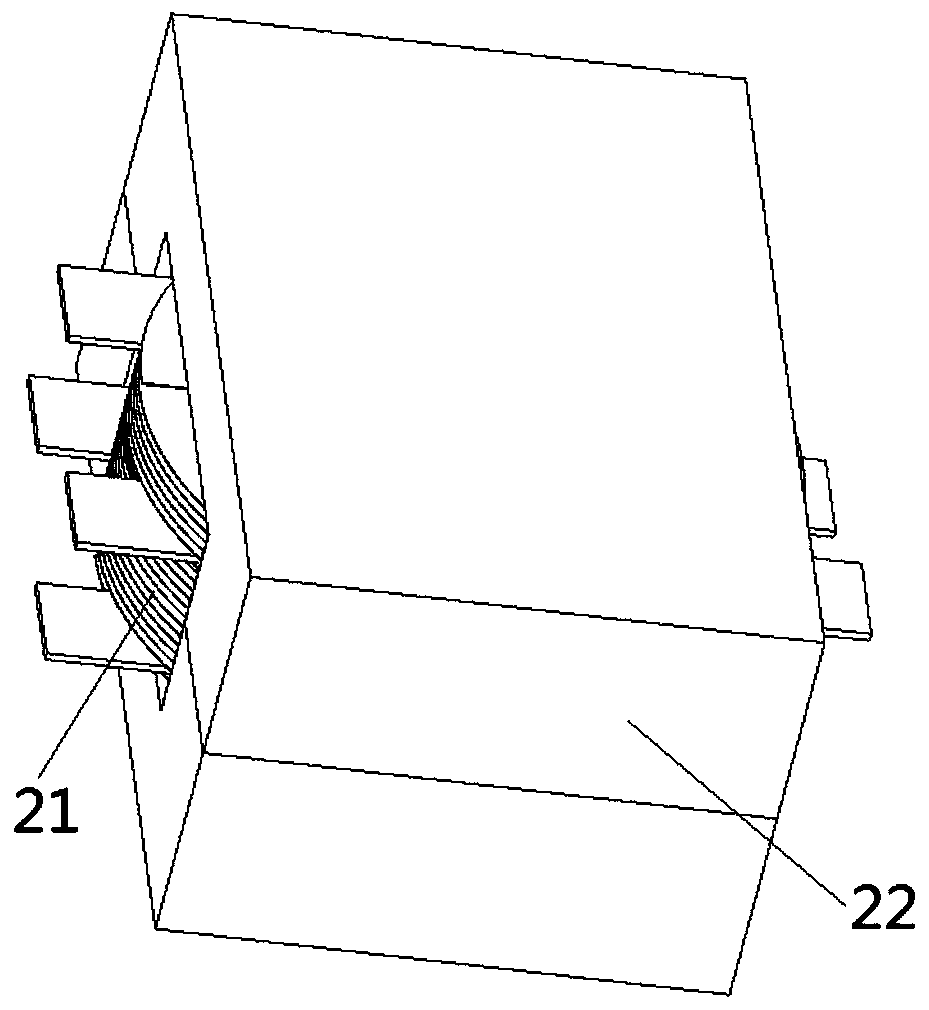

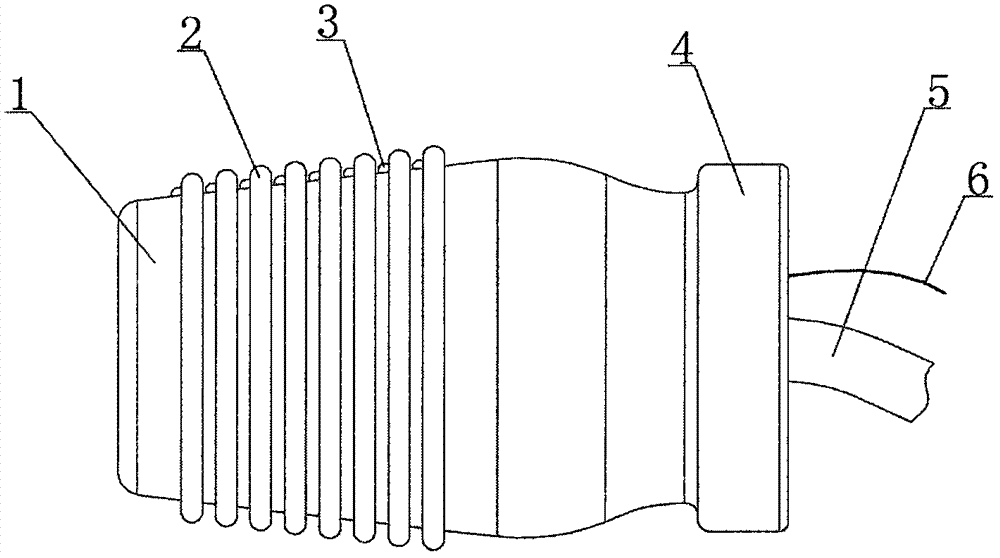

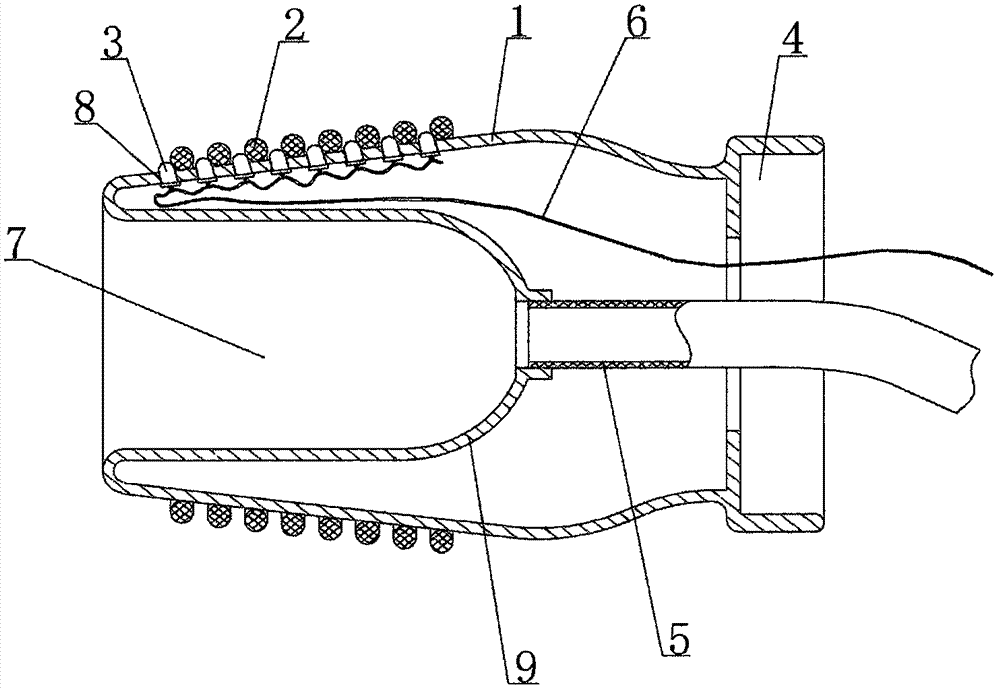

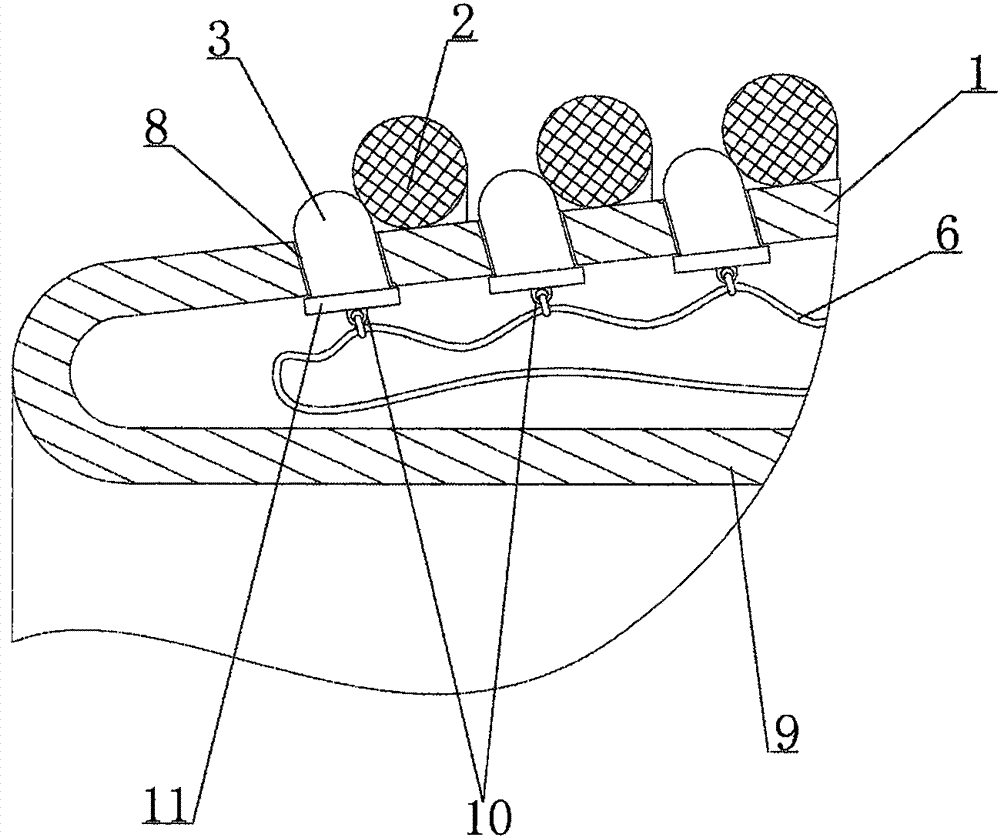

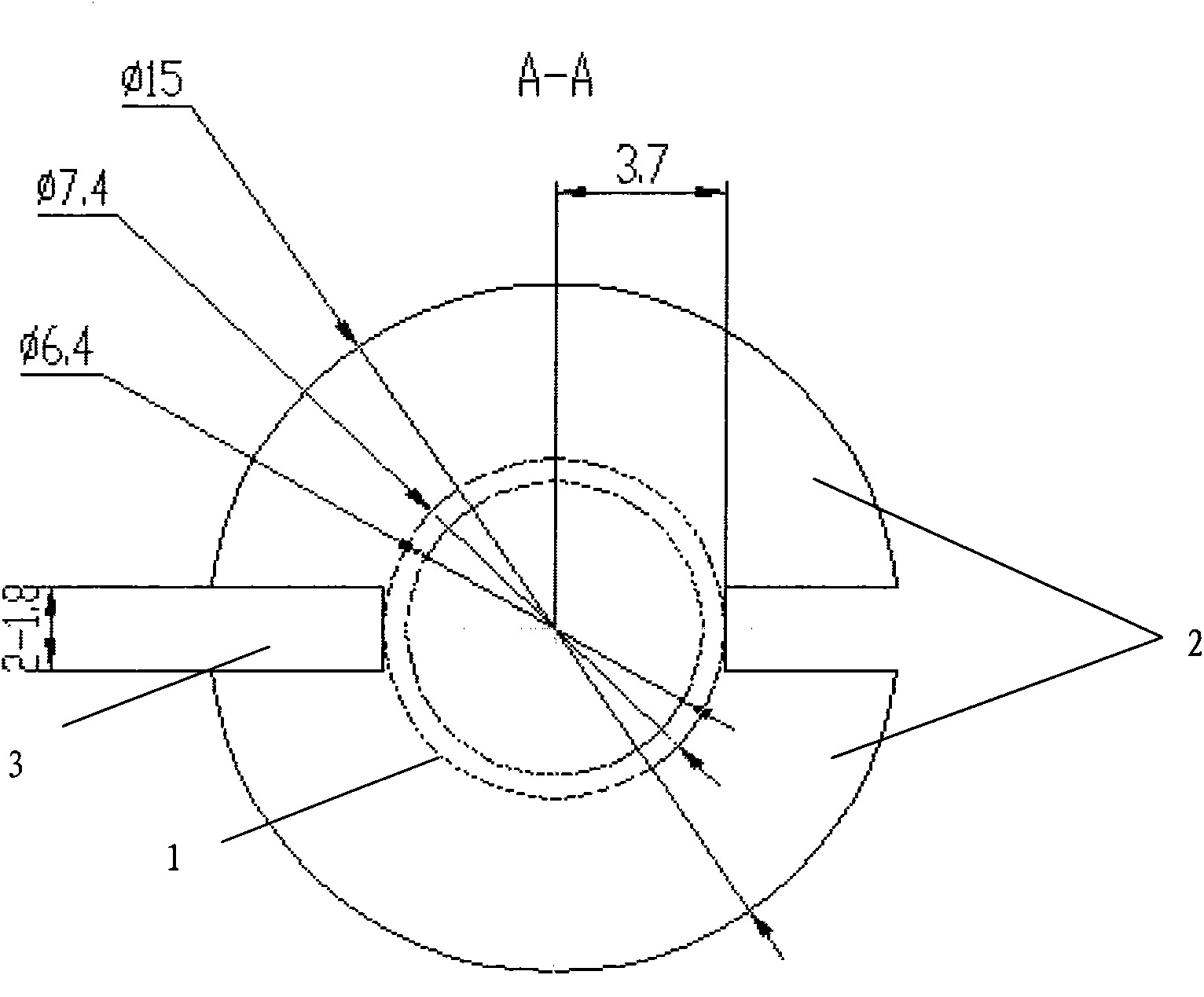

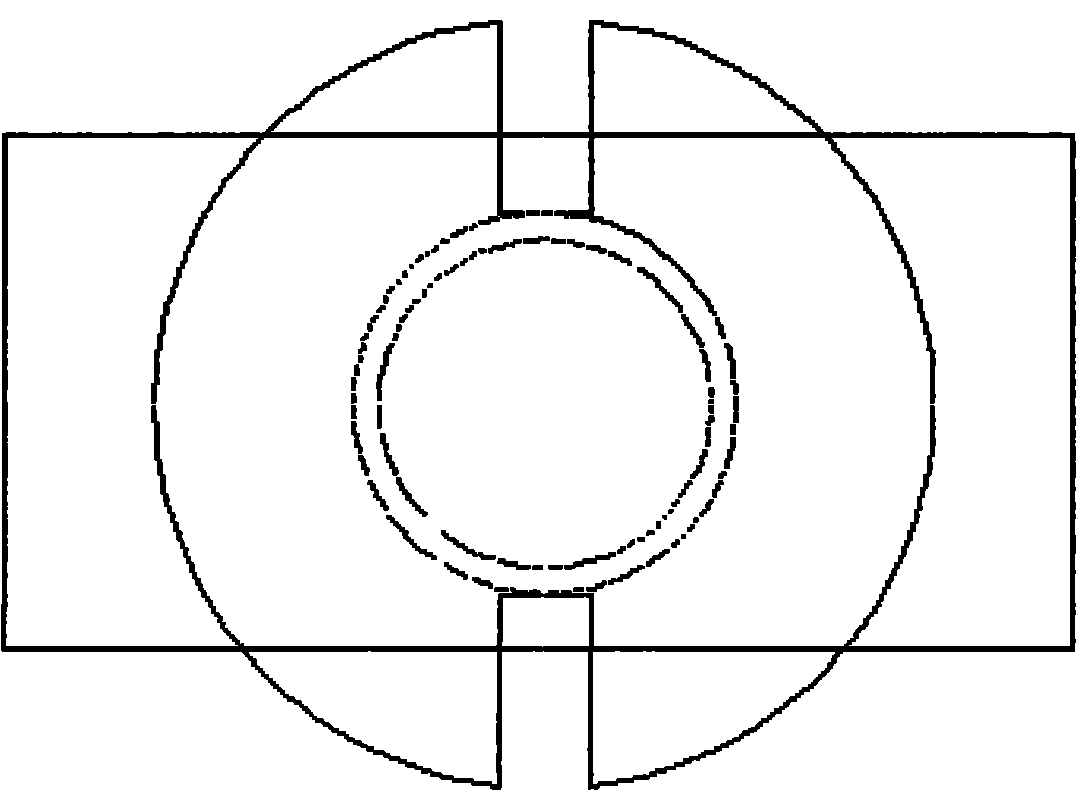

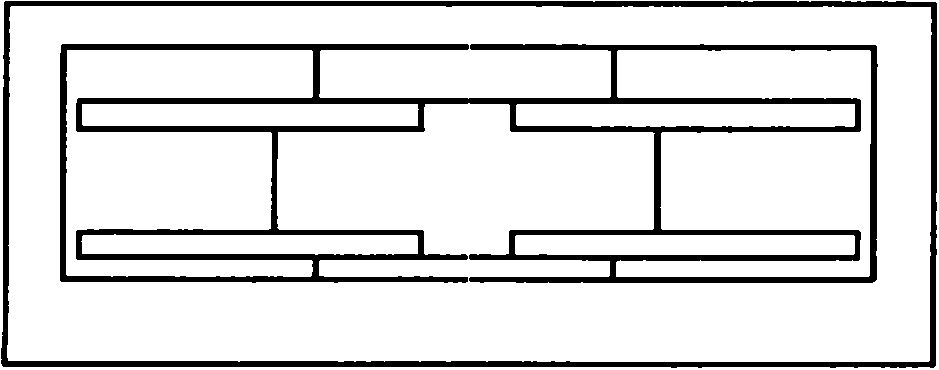

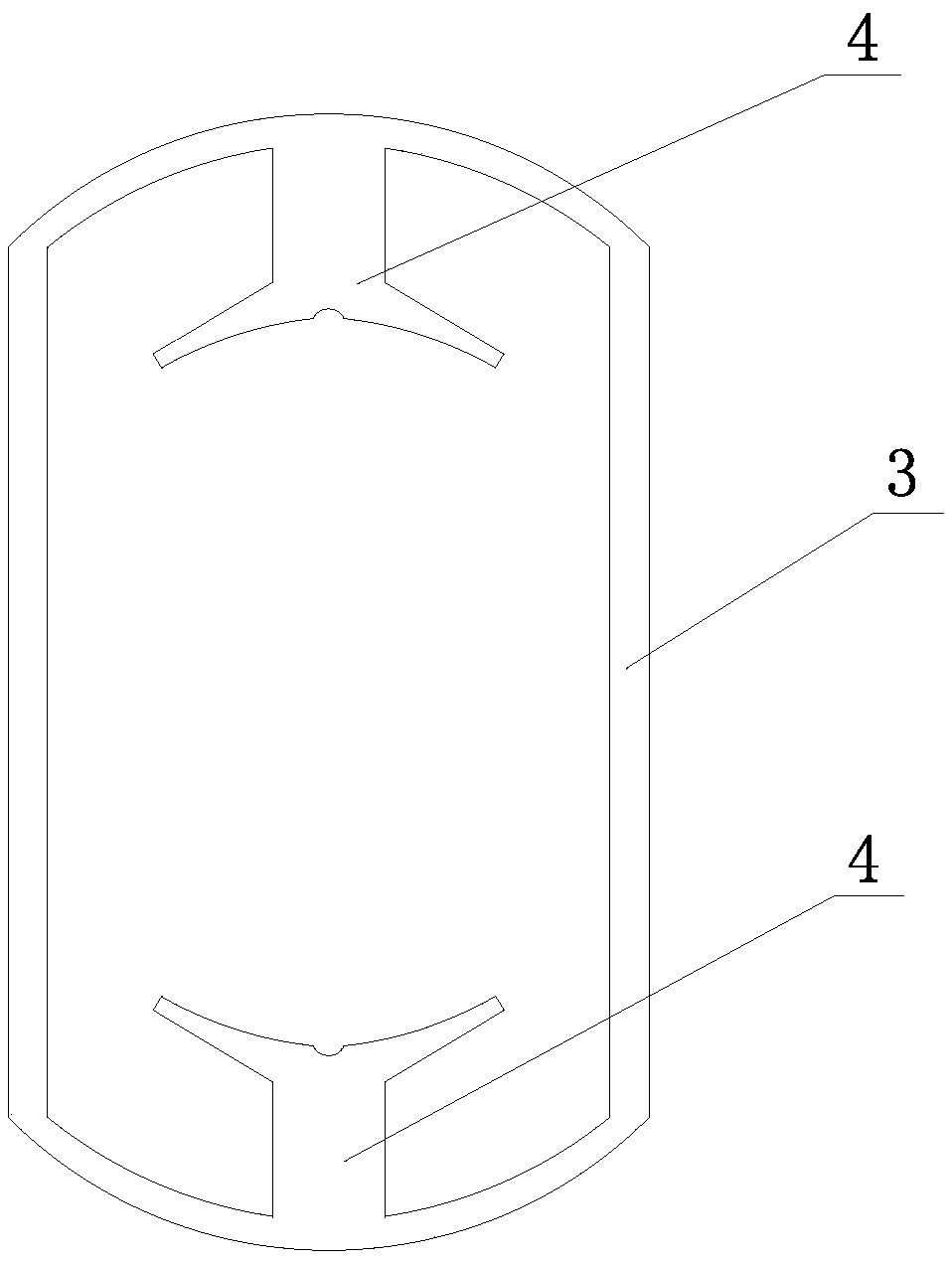

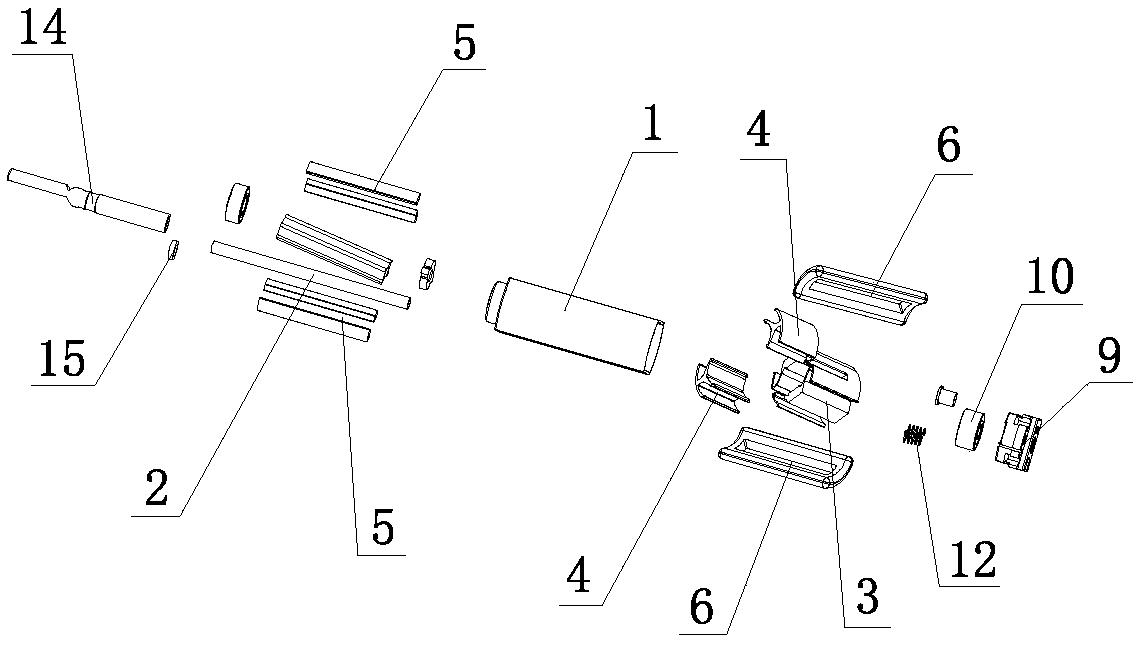

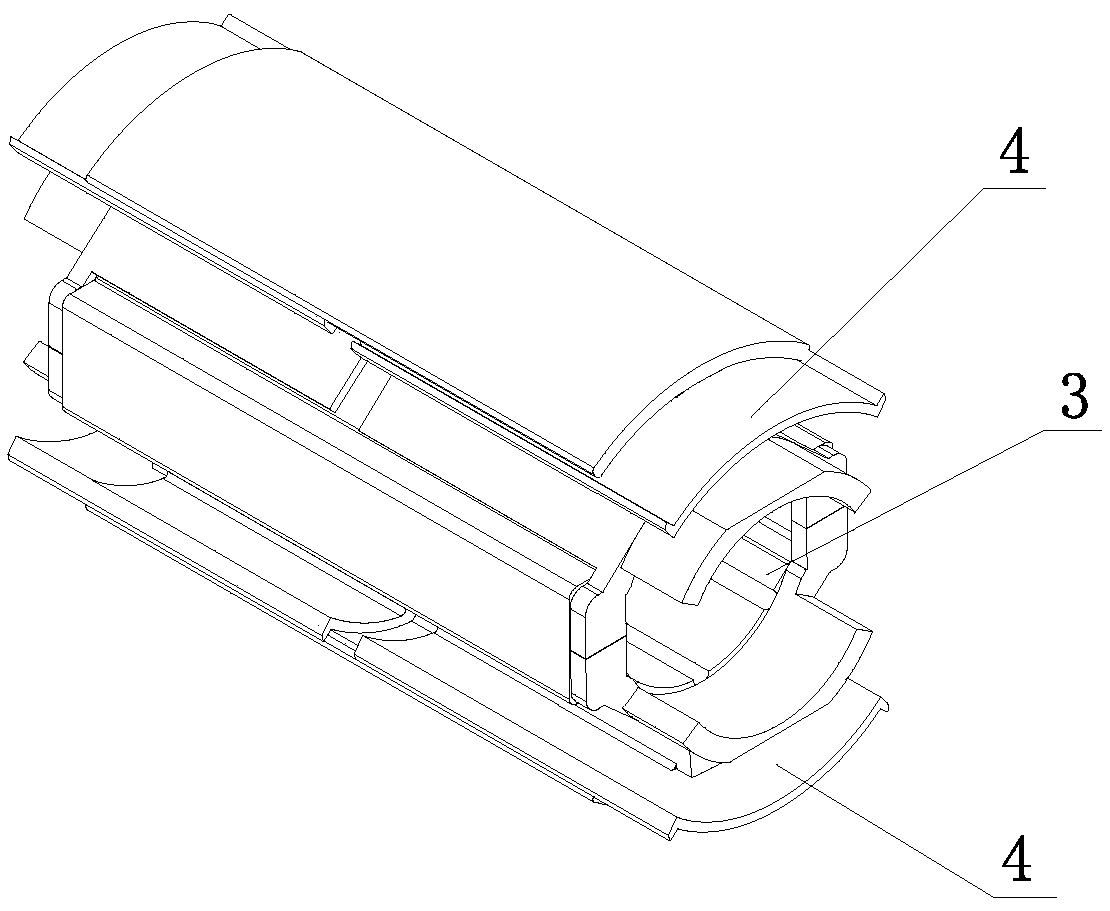

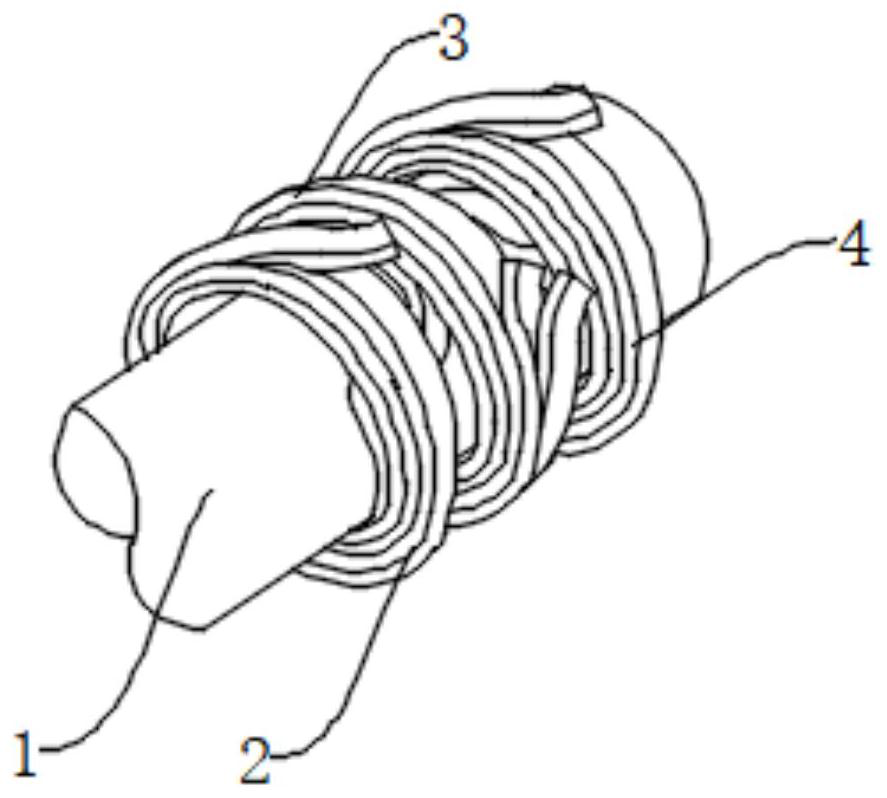

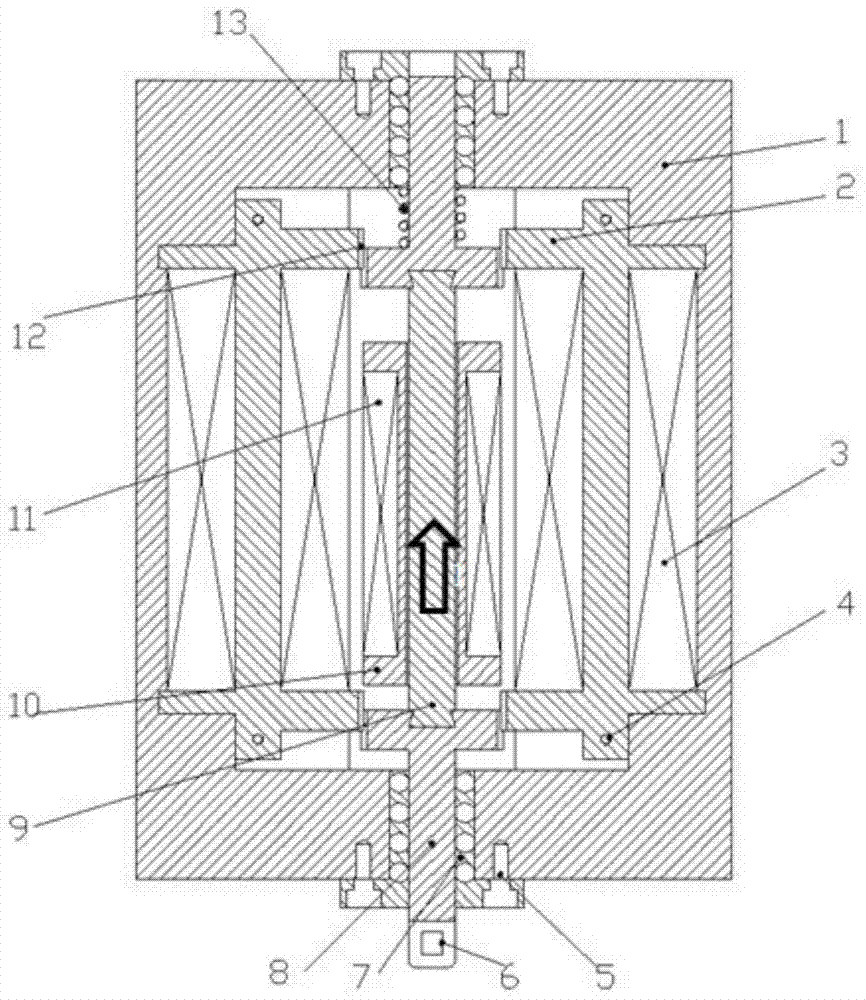

Endoscopic esophageal variceal ligation apparatus

The invention discloses an endoscopic esophageal variceal ligation apparatus which comprises a ligation outer tube and an endoscope connecting base. The ligation outer tube is in a cone shape of which the front part is thin and the rear part is thick; a ligation inner tube is arranged in the ligation outer tube; the front end of the ligation inner tube is in sealing connection with the front end of the ligation outer tube; the rear end of the ligation inner tube is connected with a negative pressure suction tube; a plurality of positioning holes are distributed at an equal interval front and back on the side wall of the ligation outer tube; a positioning pin is arranged in each positioning hole; a pulling ring is arranged at the inner end of each positioning pin; the pulling rings of a plurality of positioning pins are fixedly connected with a stay wire; the ligation outer tube is sleeved with rubber rings of which the number is equal to that of the positioning pins; each rubber ring is respectively limited by one positioning pin to be prevented from sliding forwards by the self. The endoscopic esophageal variceal ligation apparatus has a simple, small and compact structure, can be used for continuously carrying out ligation and is high in efficiency; the endoscopic esophageal variceal ligation apparatus is convenient and rapid to operate and works stably and ligation success efficiency is improved; moreover, the esophageal wall cannot be contused, so that pain of a patient is reduced and the infection risk is reduced.

Owner:王维国

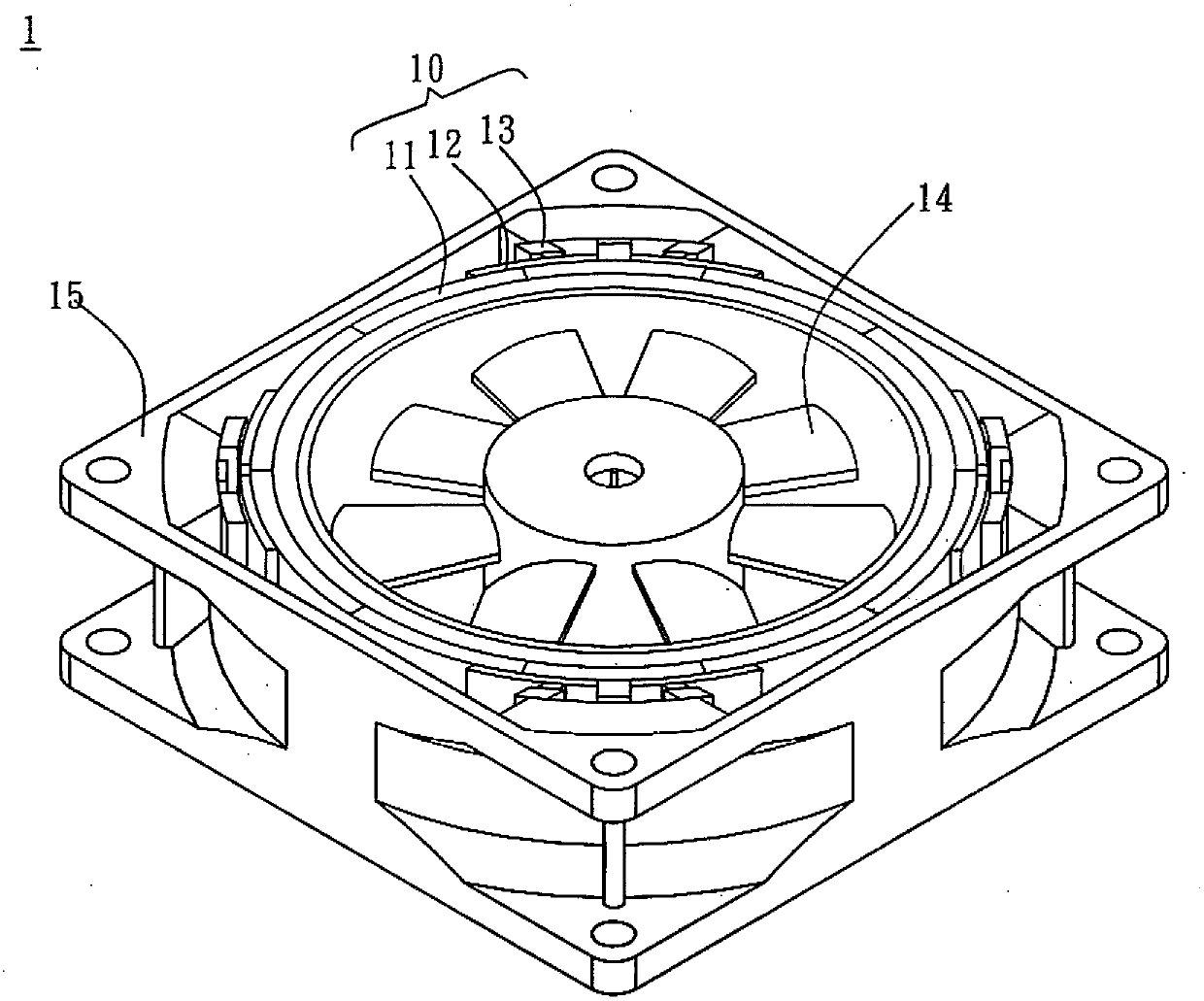

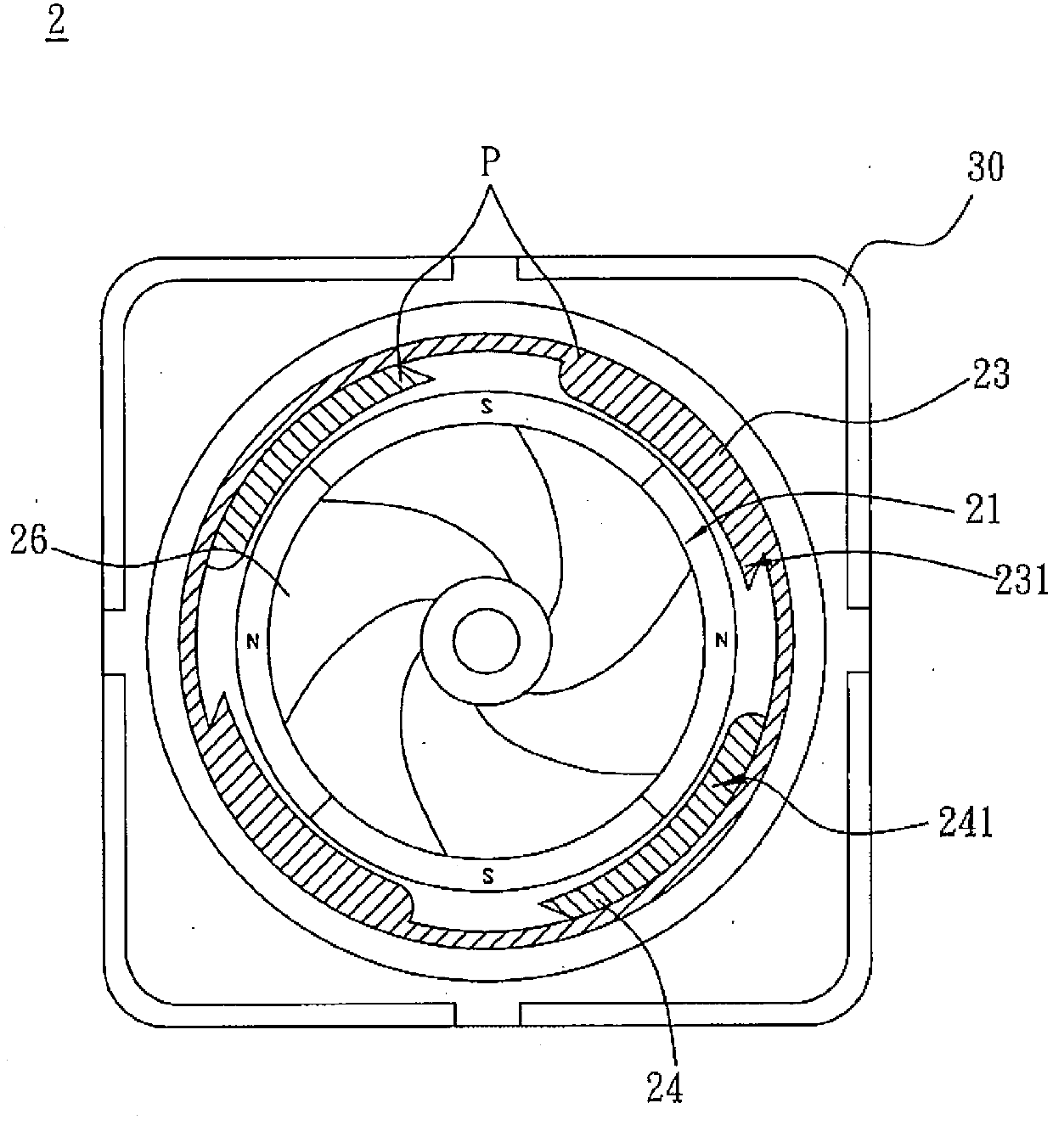

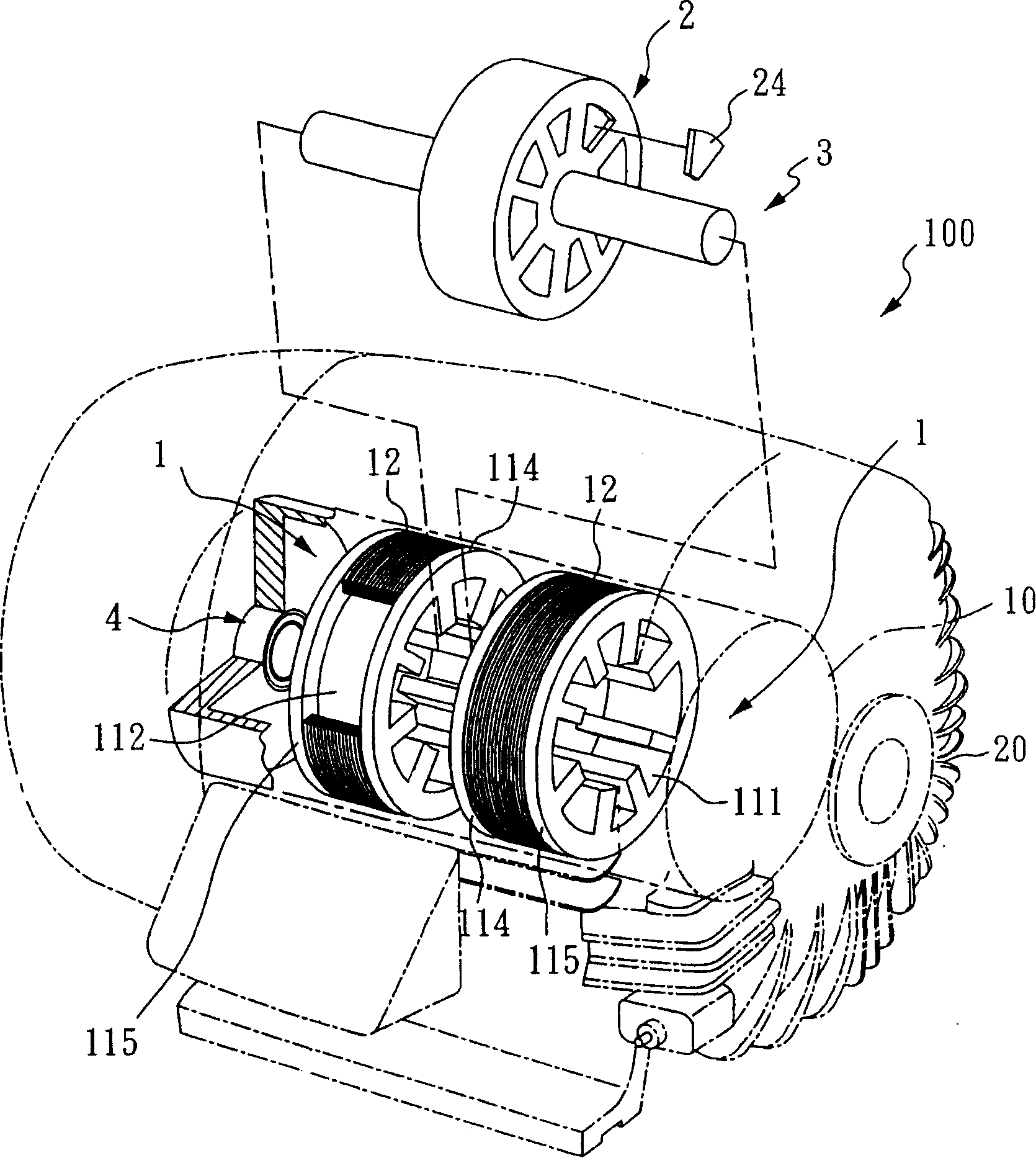

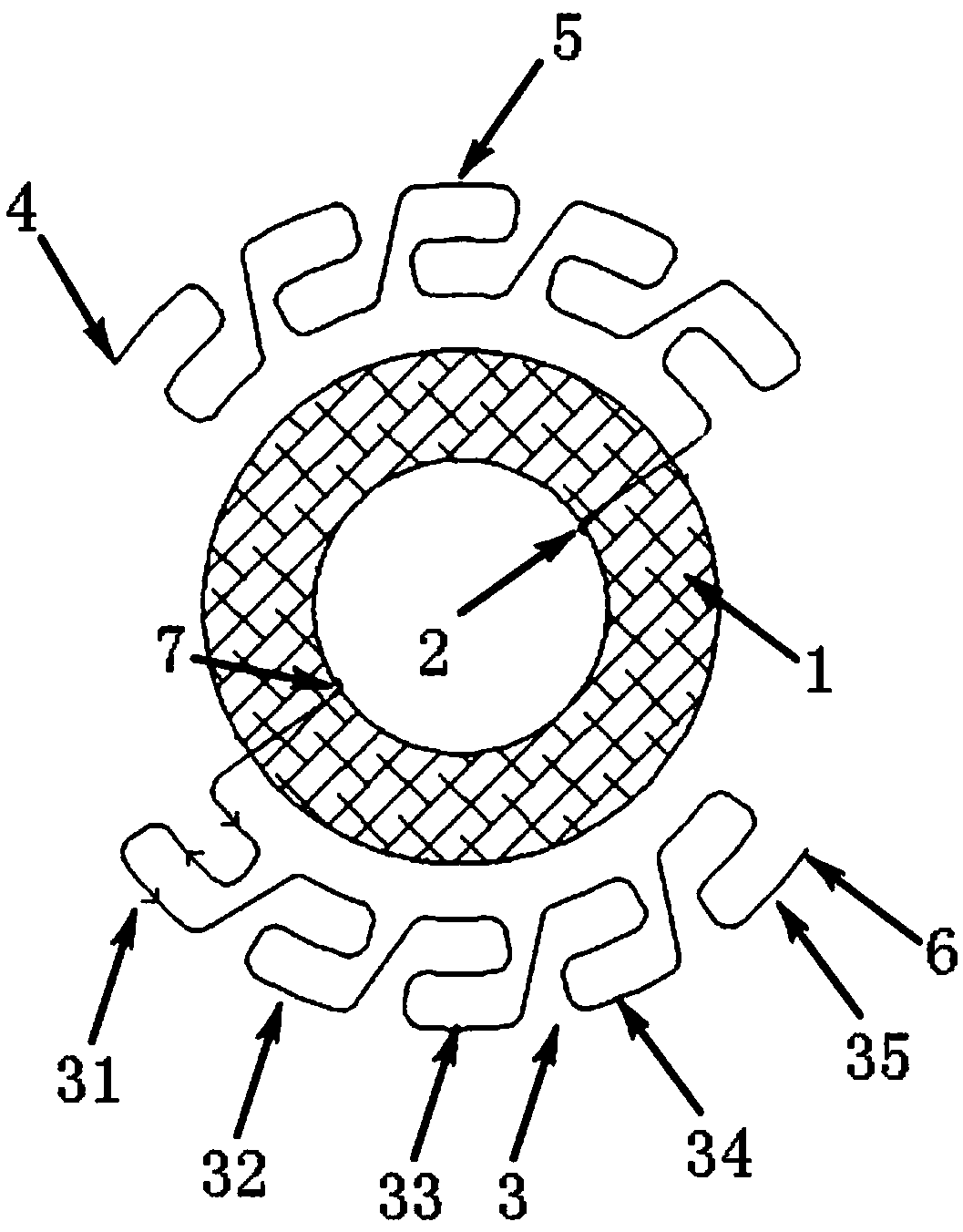

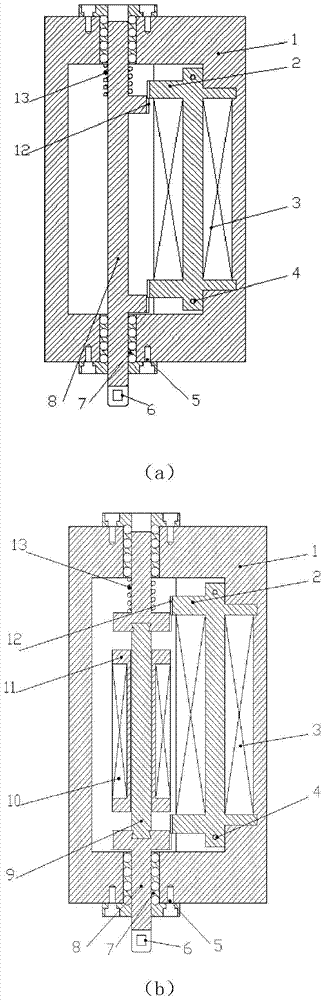

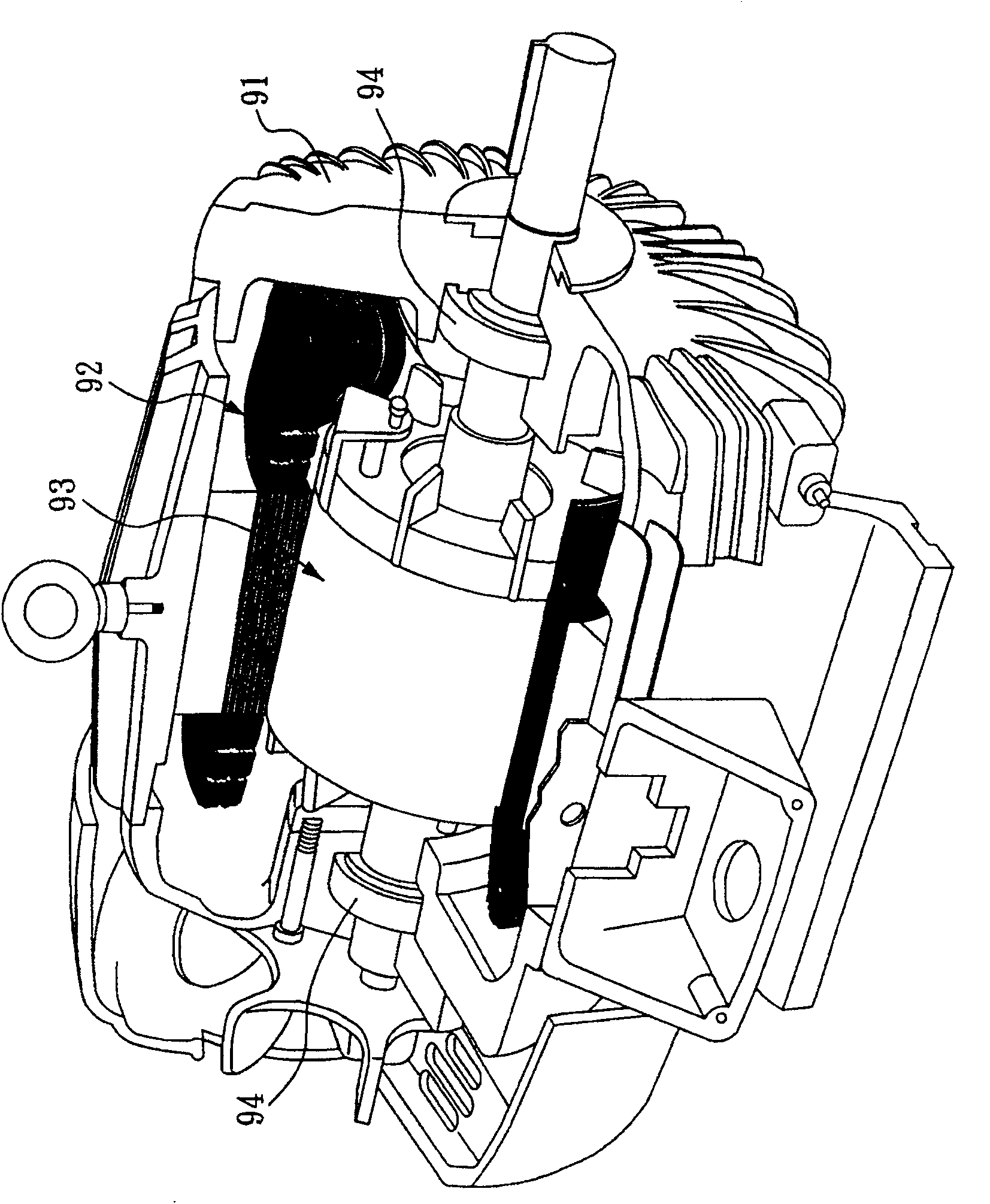

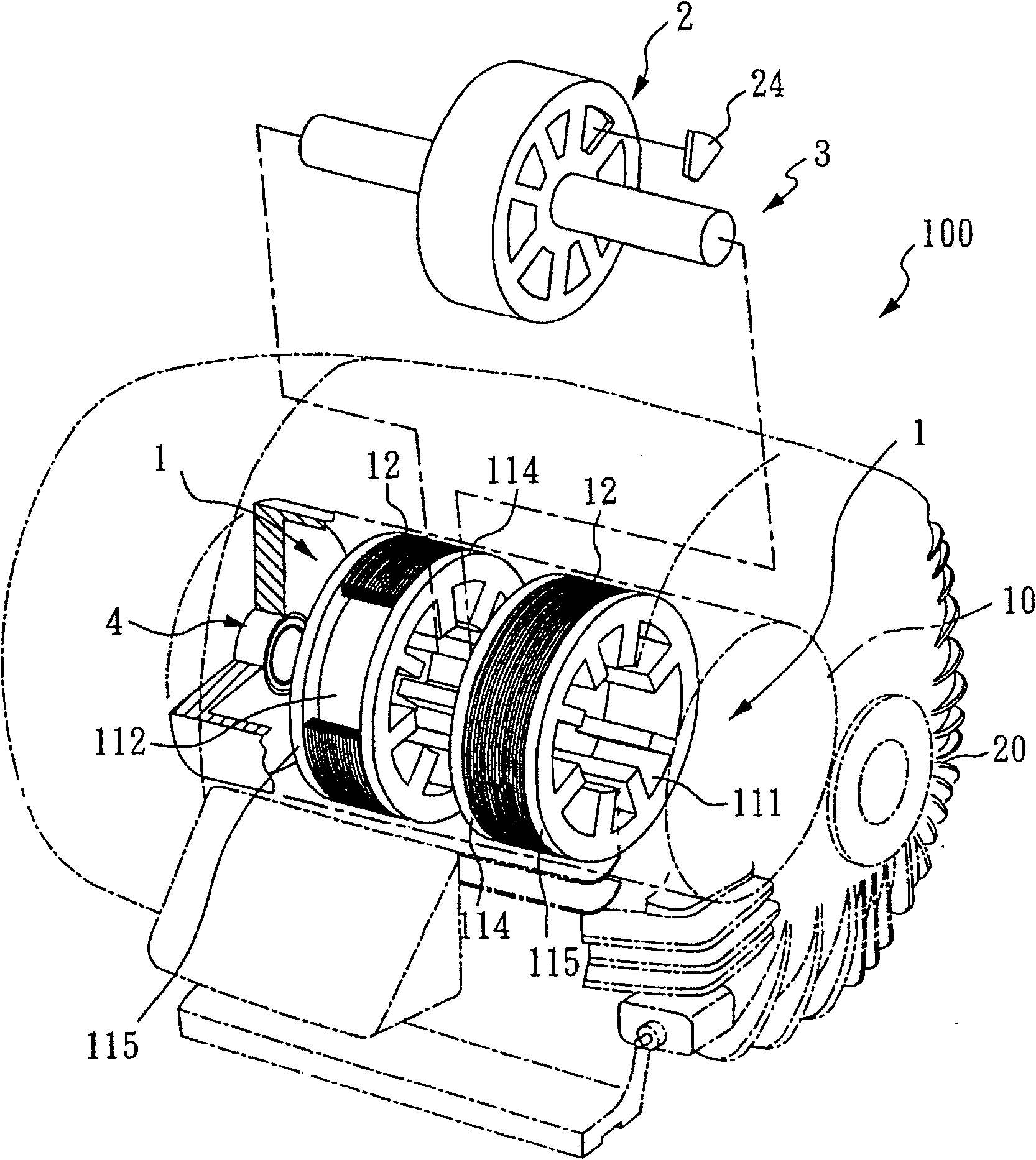

Fan and motor

InactiveCN103107648AReduce manufacturing costIncrease the setting areaMechanical energy handlingPump installationsRotor magnetsMagnetic poles

The invention discloses a motor which comprises a rotor magnet ring, a stator iron core, a first silicon steel sheet, and a second silicon steel sheet. The stator iron core is arranged outside the rotor magnet ring. The first silicon steel sheet is ring-shaped, arranged on an upper side of the stator iron core and provided with at least one first magnetic pole. The second silicon steel sheet is ring-shaped, arranged on a lower side of the stator iron core and provided with at least one second magnetic pole. The first magnetic pole and the second magnetic pole are arranged in the projection direction in a staggered mode. The invention further discloses a fan with the motor.

Owner:DELTA ELECTRONICS INC

Motor

ActiveCN101192763AWinding method is simpleSave winding timeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

The invention relates to a motor, in particular to a two-stator convolved in a radial winding way. The two-stator is staggered from a special angle of the motor and forms a specific structure through coaxial arrangement with rotors, so that stator loops can be convolved with relatively a small amount of materials and a simple winding way, and the purpose of saving winding time and material is achieved.

Owner:TECO ELECTRIC AND MACHINERY

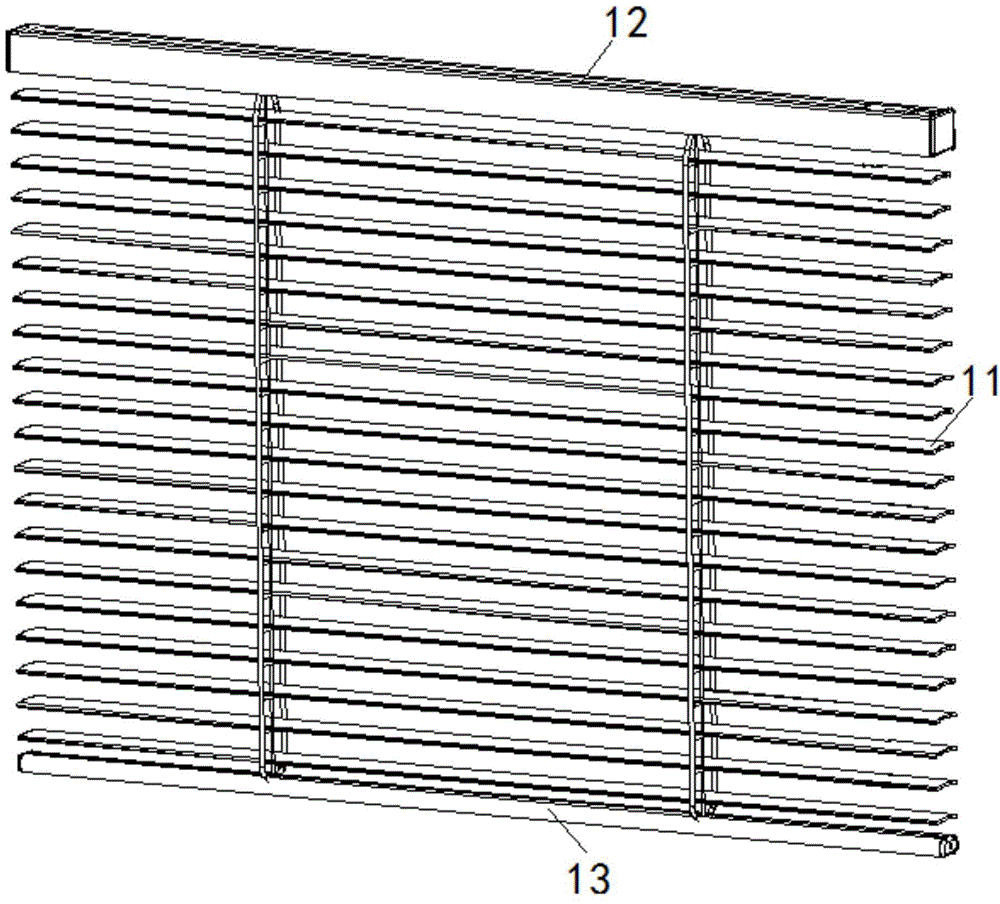

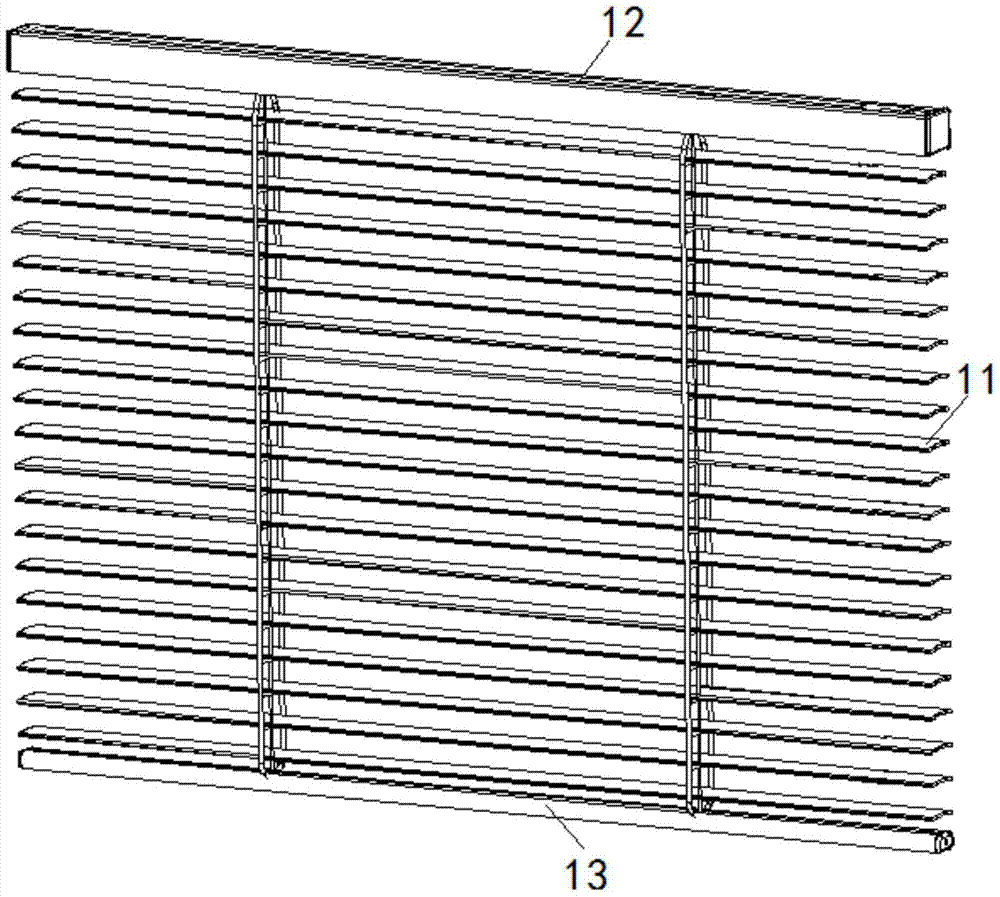

Rope-free curtain

ActiveCN104832076AWinding method is simplePull effortLight protection screensEngineeringMoving parts

The invention provides a rope-free curtain used for simplifying the winding mode of a digging rope. According to the technical scheme, the rope-free curtain comprises a moving part, an extensible part, a pulling rope fixing base and a pulling rope. One end of the extensible part is used for being fixedly connected with an external environment, the other end of the extensible part is connected with the moving part, and the moving part moves left and right along with the extensible part. The pulling rope fixing base is used for being fixedly connected with the external environment. The moving part is provided with at least one first transverse pillar which is transversely arranged, the pulling rope fixing base is provided with at least one second transverse pillar which is transversely arranged, and the pulling rope which penetrates through a curtain body bypasses the first transverse pillar and the second transverse pillar and then is fixed on the moving part or the pulling rope fixing base.

Owner:GUANGZHOU GARDEN RUBBER & PLASTIC

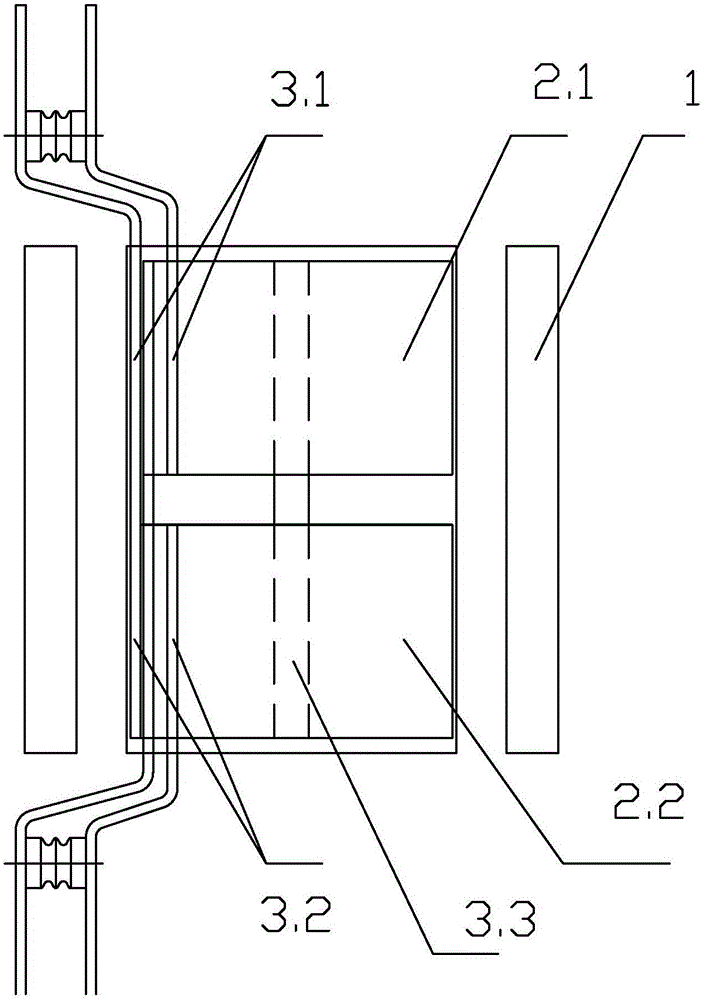

Double-splitting photovoltaic variable structure

ActiveCN105070491ANot easy to fall offReduce winding difficultyTransformers/inductances coils/windings/connectionsCoils manufactureLow voltageCopper

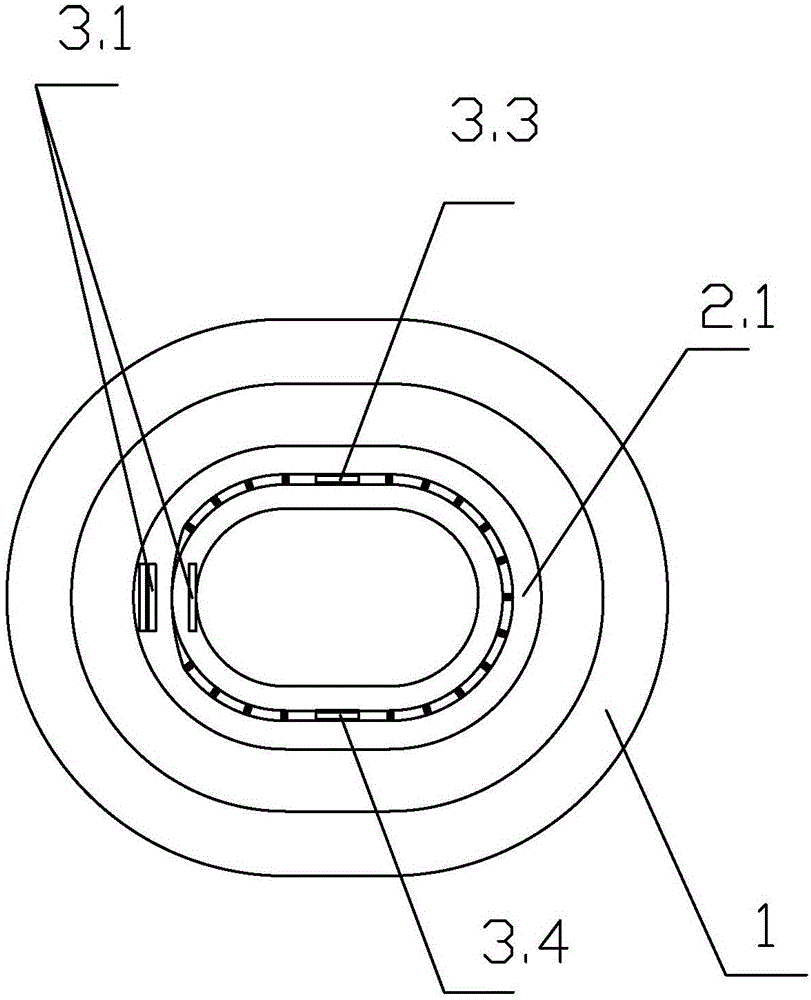

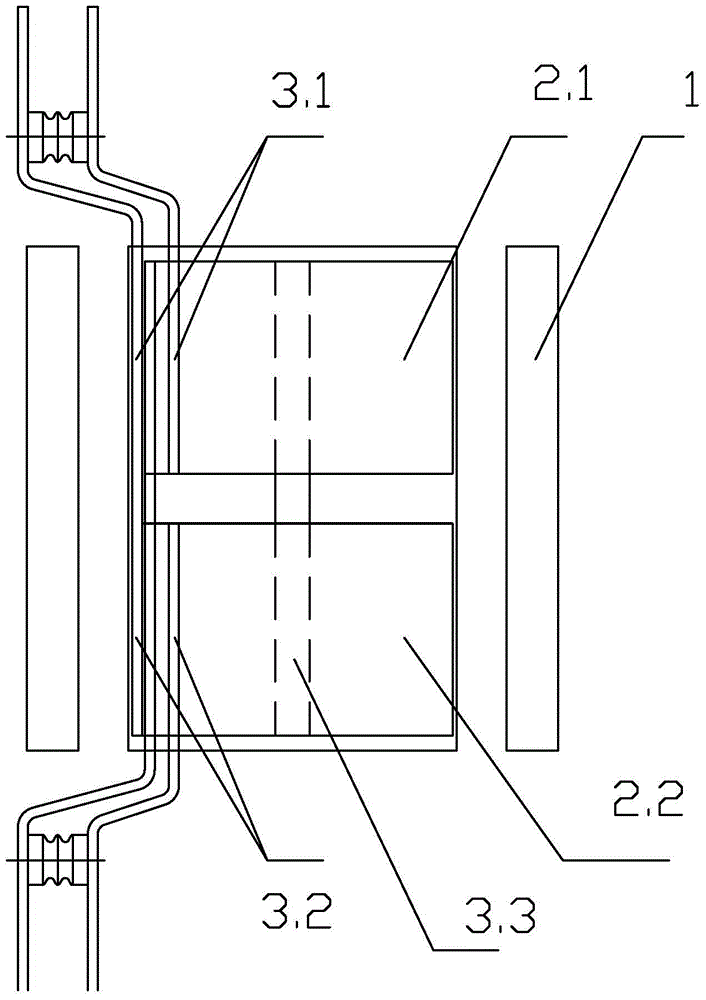

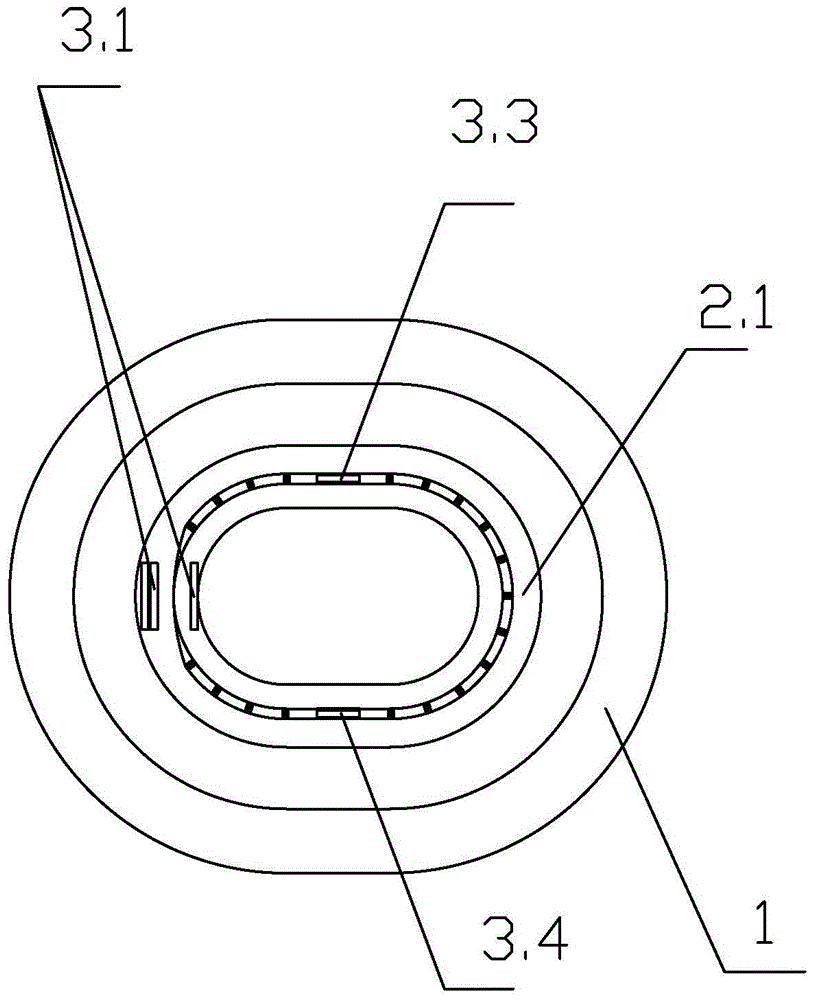

A double-splitting photovoltaic variable structure comprises a barrel-shaped high-voltage coil (1) and a first low-voltage coil (2.1) and a second low-voltage coil (2.2) which are located in the high-voltage coil (1), the first low-voltage coil (2.1) and the second low-voltage coil (2.2) are axially arranged, a gap is formed between the first low-voltage coil (2.1) and the second low-voltage coil (2.2) in the axial direction, the first low-voltage coil (2.1) is provided with a first conductive copper bar (3.1), and the second low-voltage coil (2.2) is provided with a second conductive copper bar (3.2); the double-splitting photovoltaic variable structure further comprises a first transposition copper bar (3.3) and a second transposition copper bar (3.4) which are internally embedded in the low-voltage coils, and the two ends of the first transposition copper bar (3.3) and the two ends of the second transposition copper bar (3.4) are welded to the first low-voltage coil (2.1) and the second low-voltage coil (2.2) respectively.

Owner:宁波奥克斯智能科技股份有限公司

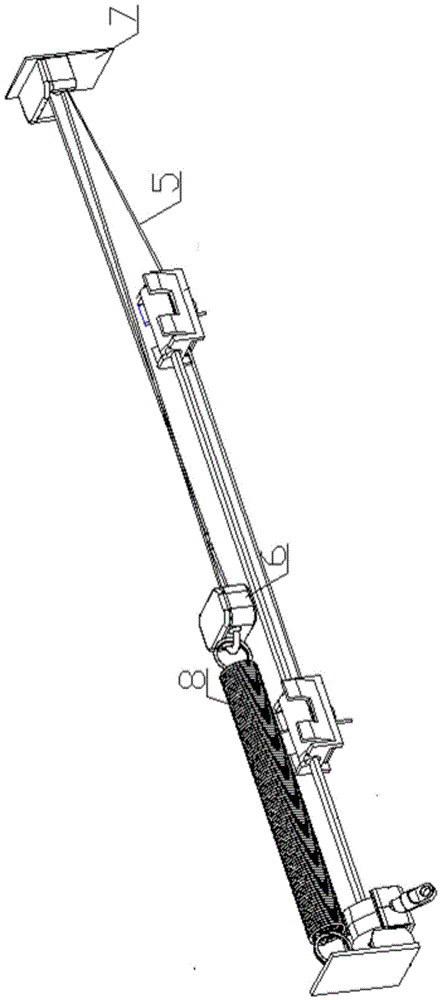

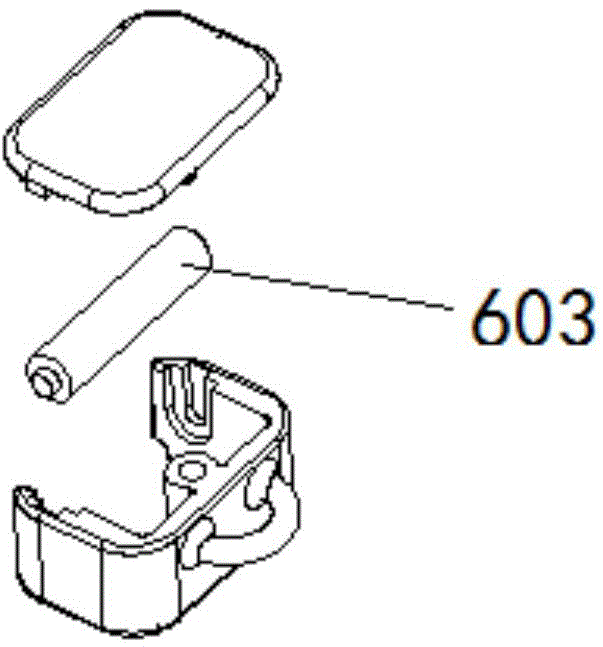

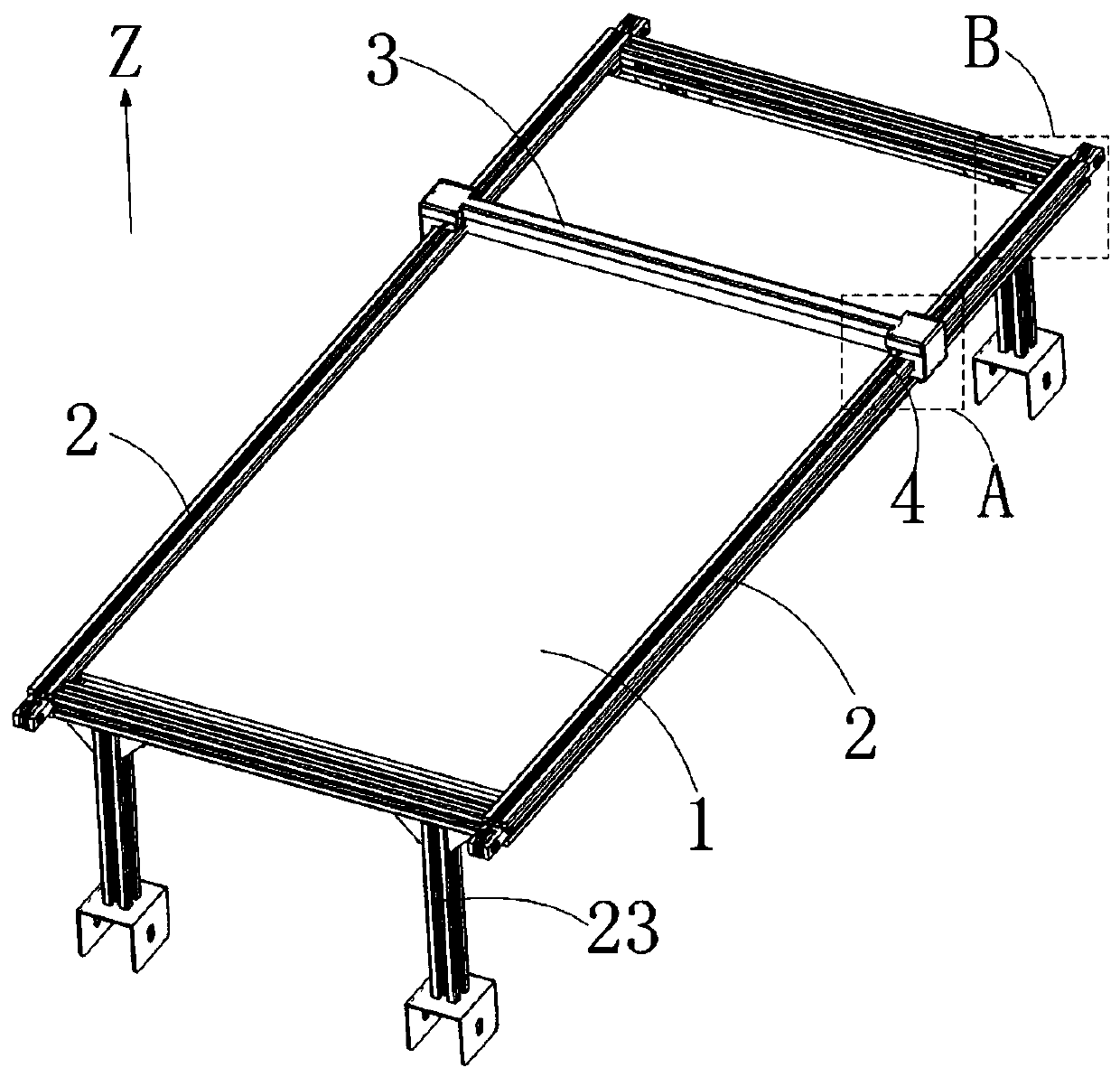

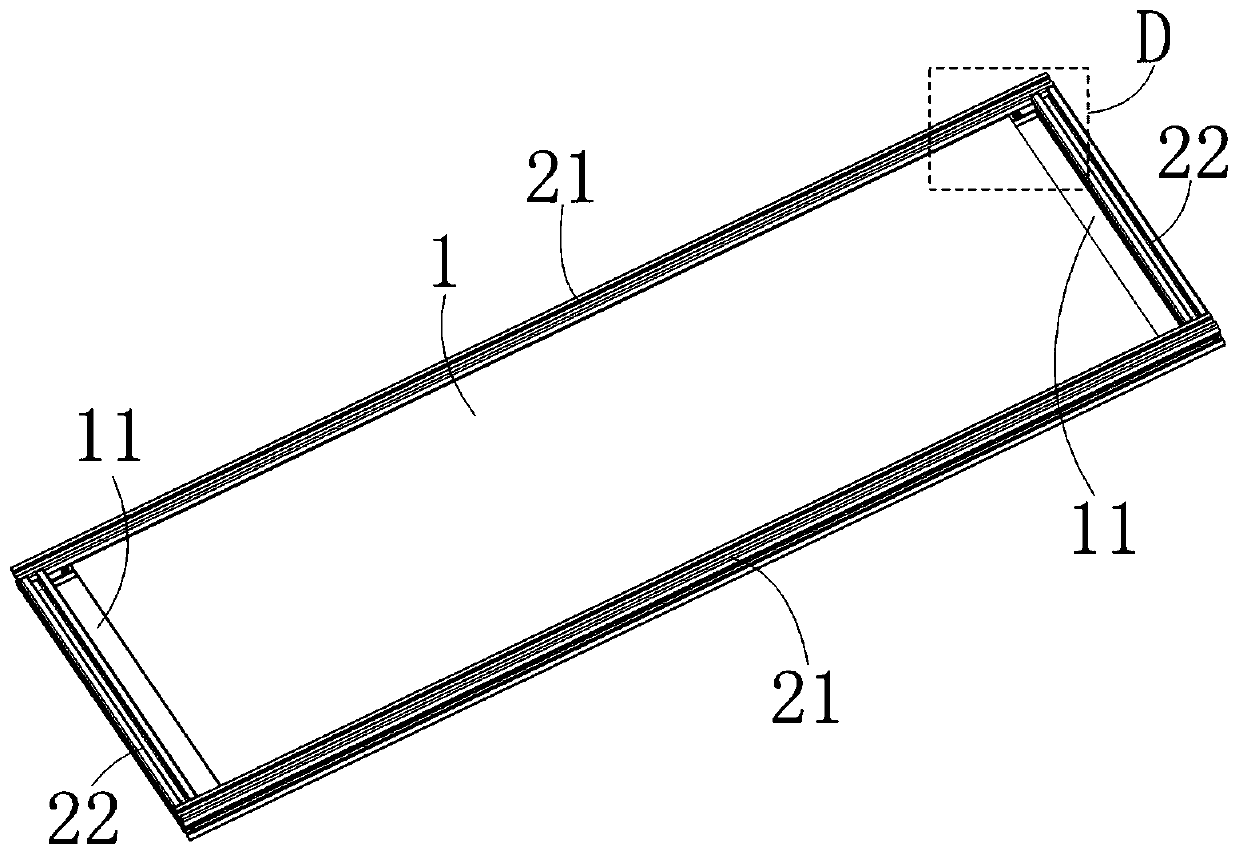

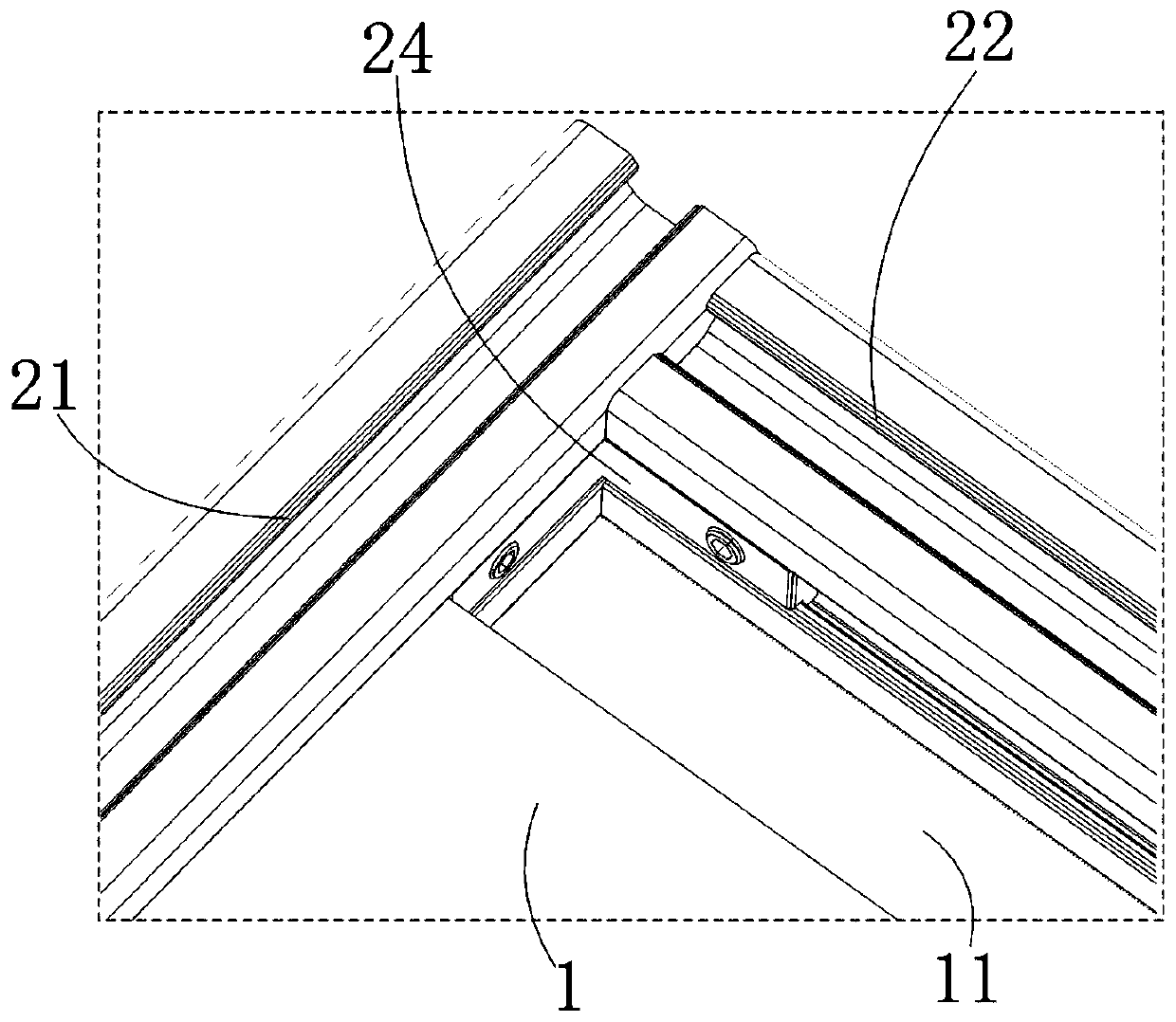

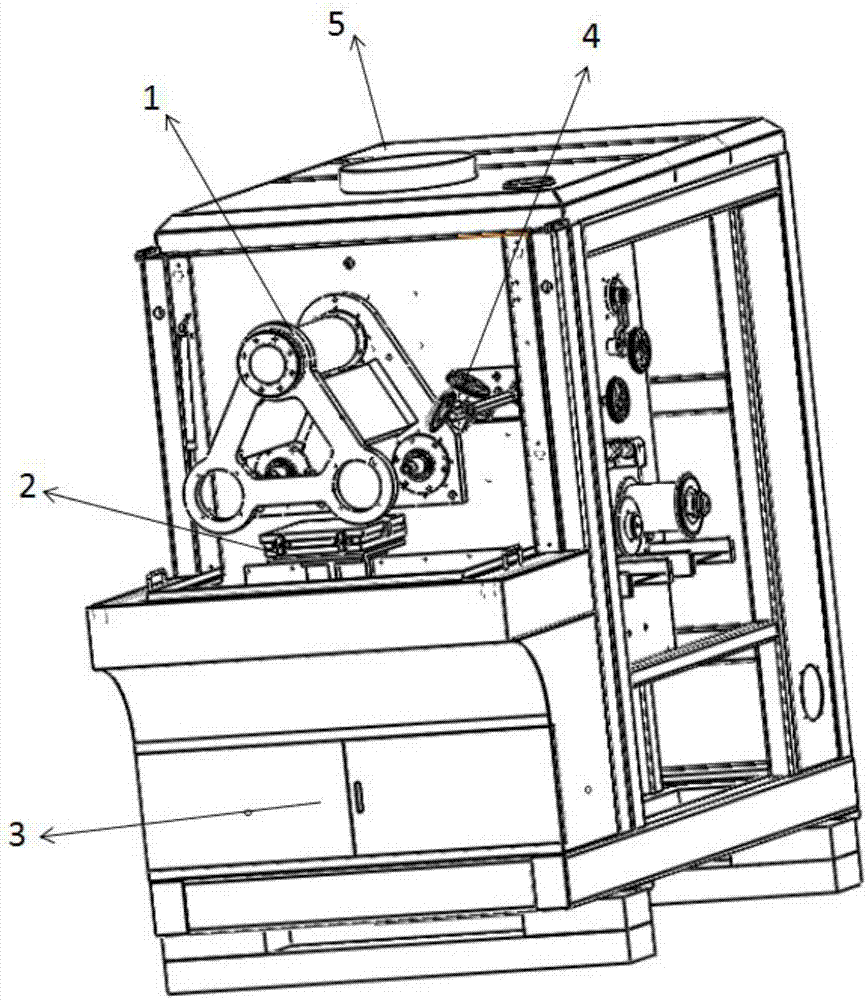

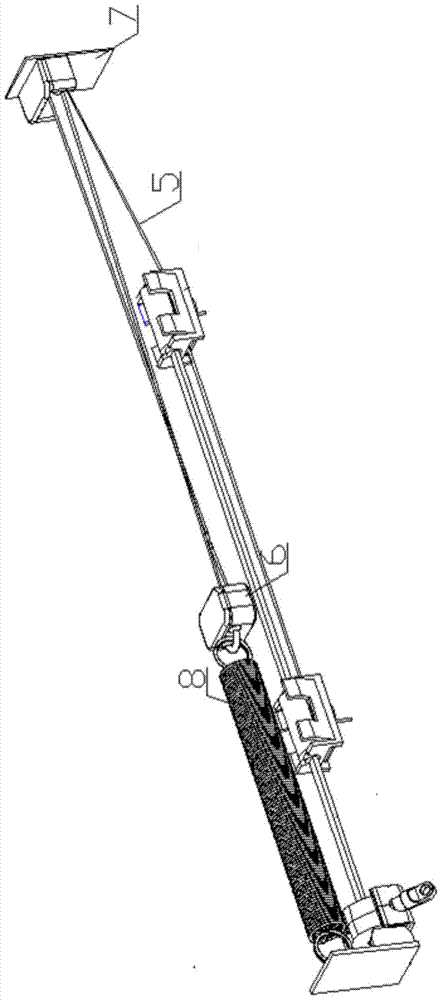

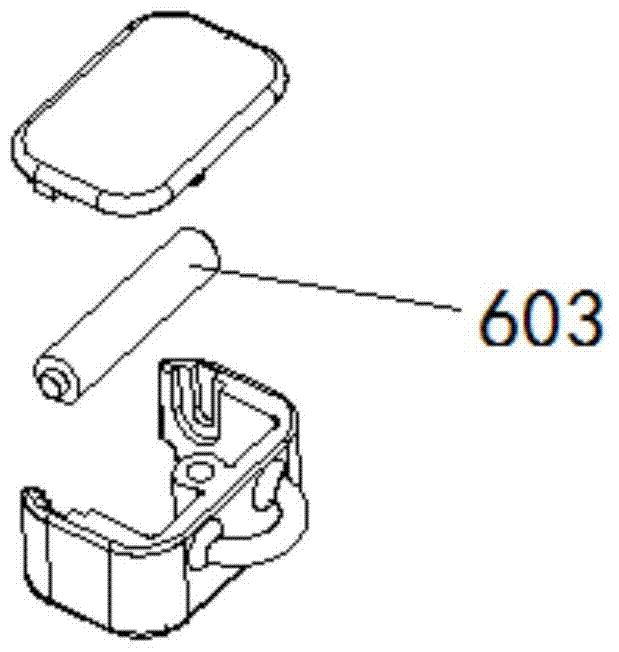

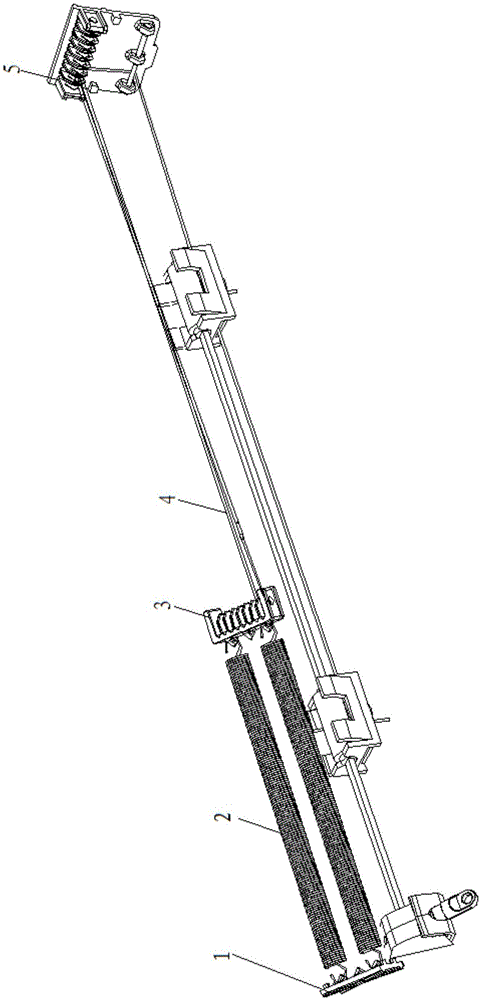

Photovoltaic panel self-cleaning device and photovoltaic panel cleaning robot

PendingCN110548705AEasy to installCompact structurePhotovoltaicsCleaning using toolsEngineeringElectrical and Electronics engineering

The invention relates to the technical field of photovoltaic panel cleaning equipment, in particular to a photovoltaic panel self-cleaning device and a photovoltaic panel cleaning robot. The photovoltaic panel self-cleaning device comprises a photovoltaic panel, a frame, a cleaning assembly and a pull rope. At least two edges of the photovoltaic panel and the frame are clamped, the cleaning assembly is crossed over the photovoltaic panel, the two ends of the cleaning assembly are in sliding connection with the frame, and the pull rope is fixedly connected with the two ends of the cleaning assembly. The photovoltaic panel cleaning robot comprises the photovoltaic panel self-cleaning device. The photovoltaic panel self-cleaning device is directly installed on the photovoltaic panel cleaningrobot and moves along with the robot, dust on the photovoltaic panel of the cleaning robot can be cleaned at any time, the two edges of the photovoltaic panel and the frame are clamped, the frame andthe robot are fixedly connected, the installing structure is simplified, and it is ensured that the photovoltaic panel is stably installed.

Owner:BOSON ROBOTICS LTD

Transformer foil type coil winding method

InactiveCN103354172ARealize the winding processWinding method is simpleCoils manufactureCopper foilWinding machine

The invention relates to the technical field of a transformer coil winding method, and specifically relates to a transformer foil type coil winding method. The winding method comprises the following steps of: (1) selecting a proper winding former according to the inner diameter of a coil, and suspending and clamping the winding former on a spindle of a winding machine; (2) taking out a copper busbar going out of the coil, flatly shearing the end part of a copper foil synchronously, pulling out the copper foil, inserting the copper foil into a welder crack of the winding machine, and welding a prepared internally led-out uranium busbar on the copper foil; and (3) pulling back the copper foil, fixing the internally led-out copper busbar of the coil in a winding former groove, and then winding the coil. According to the invention, the existing winding machine is used for directly winding the coil without new devices and tools, the short-circuit resistance is improved, and the stability of the winding to impact over-voltage is improved.

Owner:JIANGSU HENGTE GRP VALTTE ELECTRIC

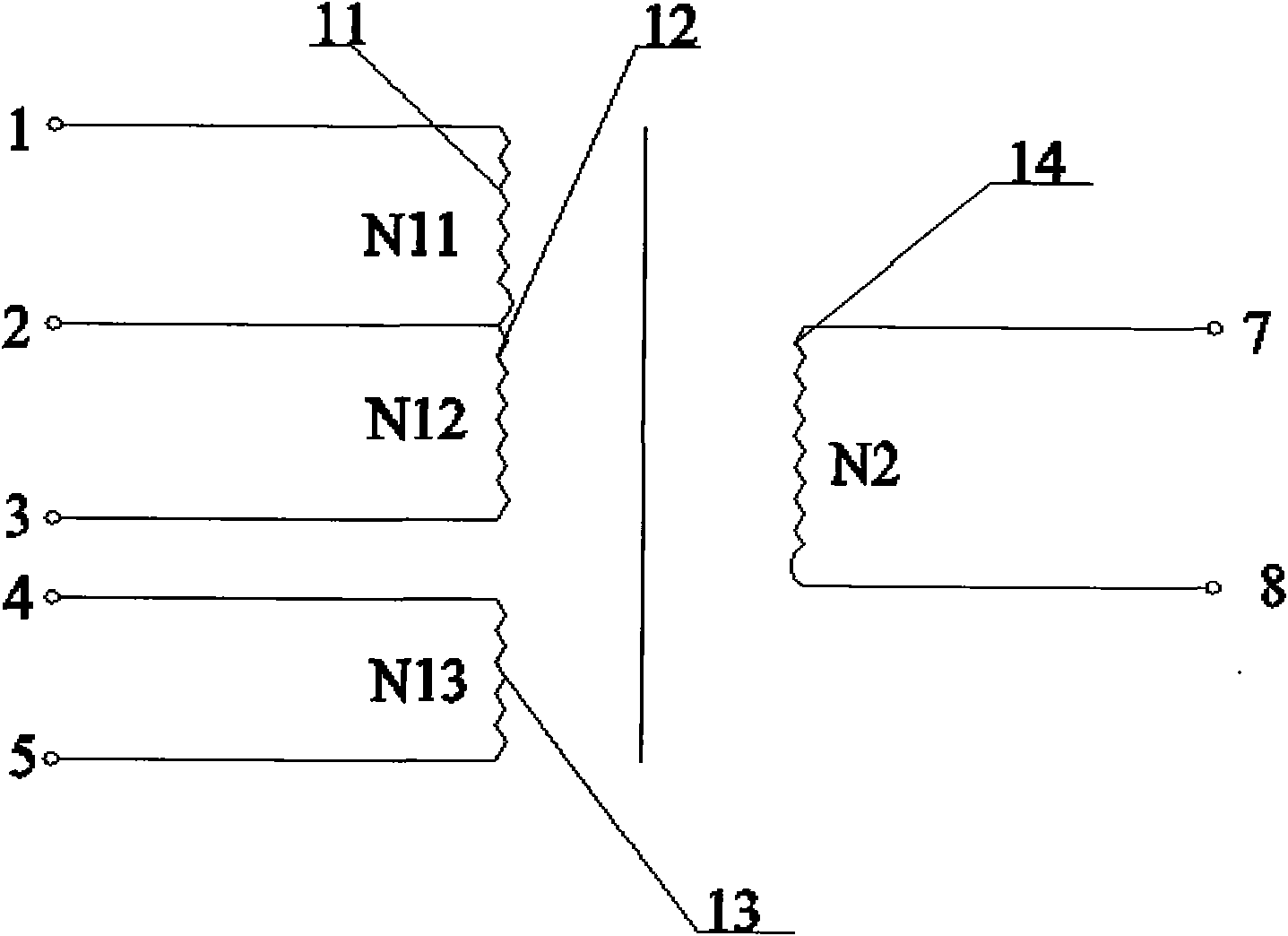

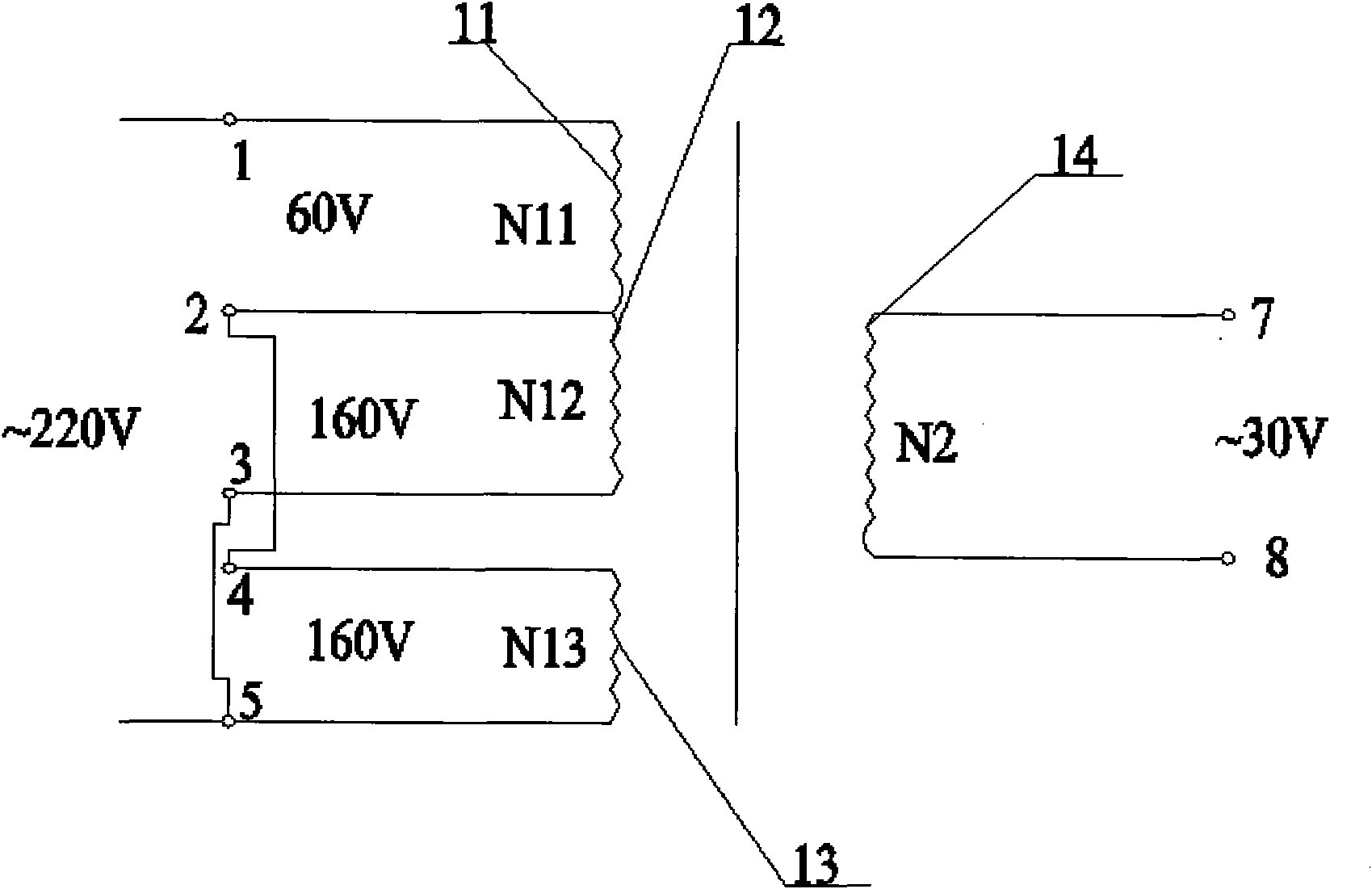

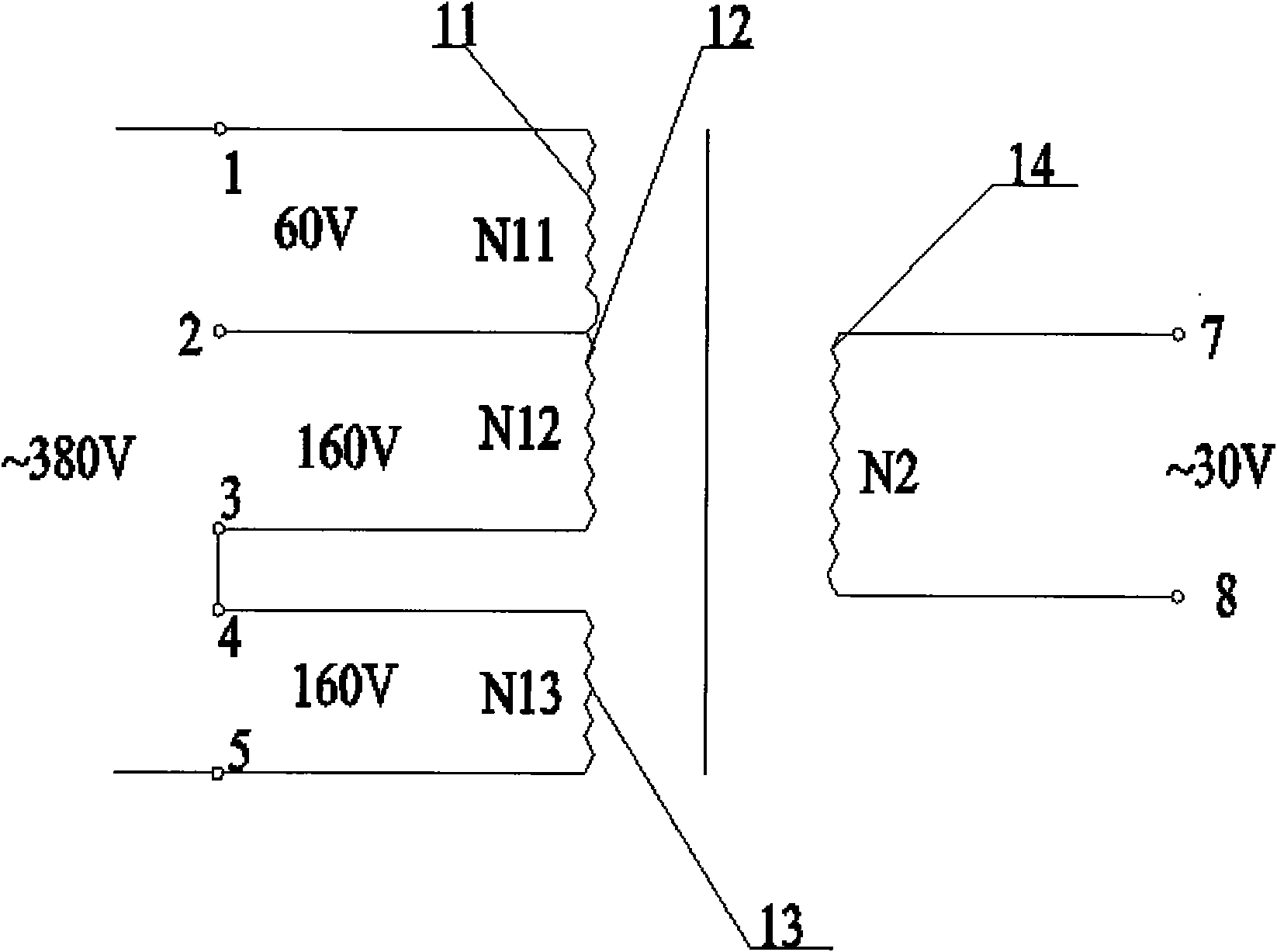

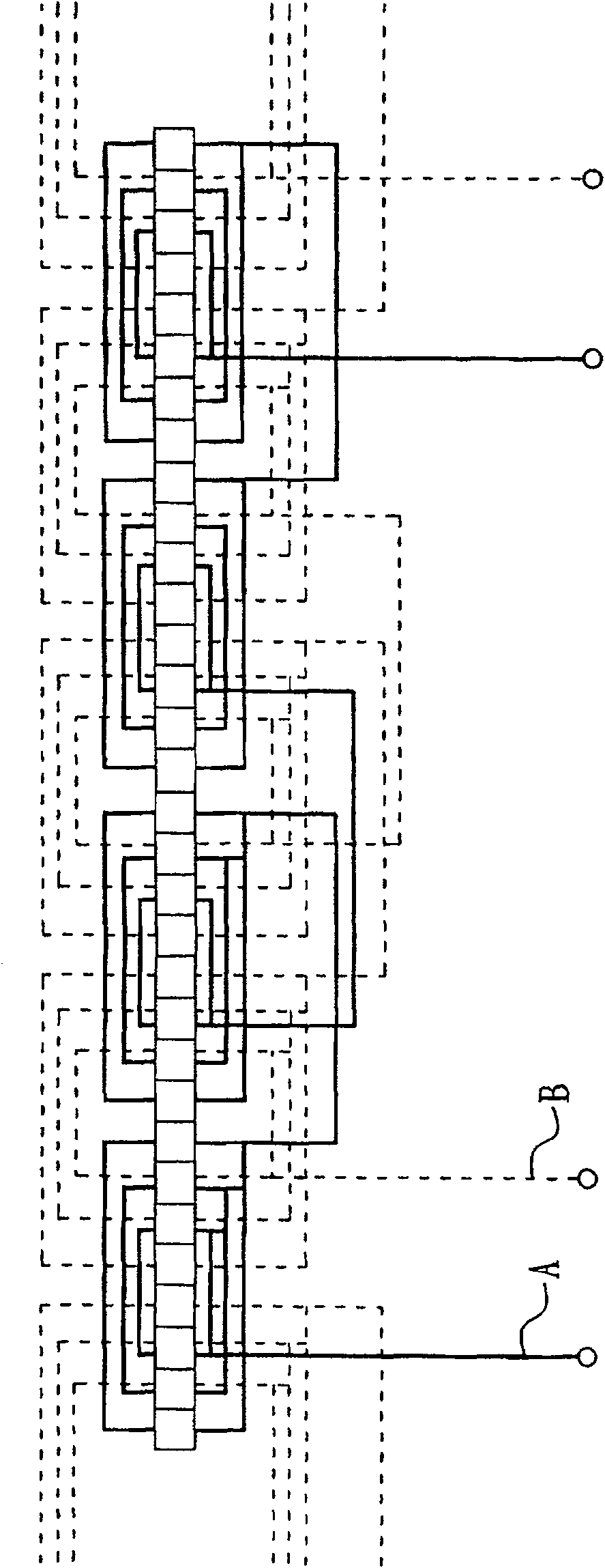

Primary coil winding structure of power supply transformer

InactiveCN101923947AEasy to connect and operateWinding method is simpleTransformers/inductances coils/windings/connectionsConductor CoilSecondary side

The invention relates to a primary coil winding structure of a power supply transformer. In the structure, when an input voltage on a primary side is transformed between 220V and 380V, an output voltage on a secondary side is unchanged. A primary coil of the transformer comprises a first winding wire, a second winding wire and a third winding wire, wherein the turn number of the first winding wire is N11, and the first winding wire has a first connecting end and a second connecting end; the turn number of the second winding wire is N12, and the second winding wire has the second connecting end and a third connecting end; the turn number of the third winding wire is N13, and the third winding wire has a fourth connecting end and a fifth connecting end; the turn number N13 of the third winding wire is equal to the turn number N12 of the second winding wire; the ratio of the turn number N11 of the first winding wire to the turn number N12 of the second winding wire is 3: 8; when the input voltage on the primary side of the transformer is 220V, the third and second winding wires are connected in parallel; and when the input voltage on the primary side of the transformer is 380V, the third and second winding wires are connected in series. The winding method of the invention has the advantages of simplicity, winding cost reduction, convenient connection operation, safety and reliability.

Owner:WUXI JUKE ELECTRIC

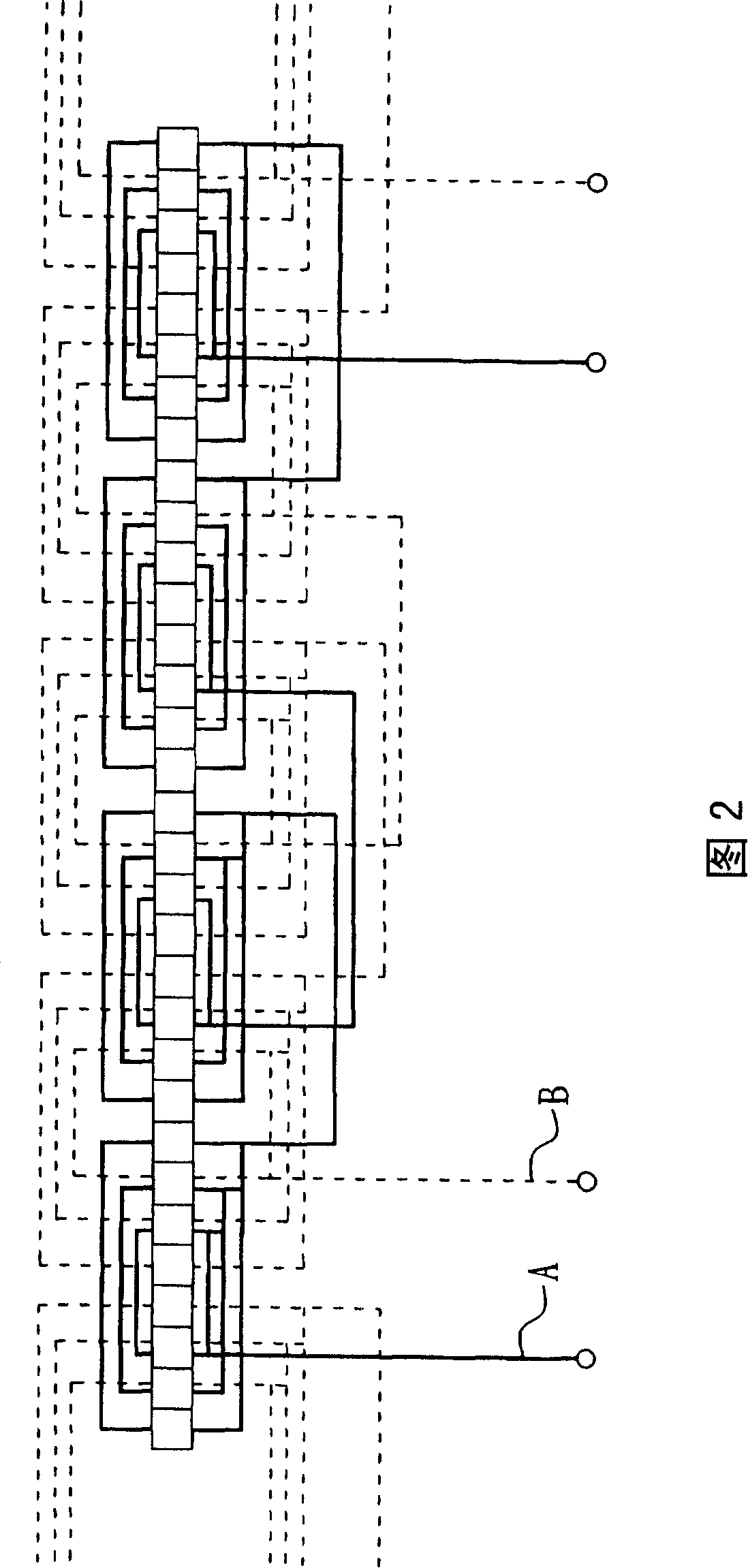

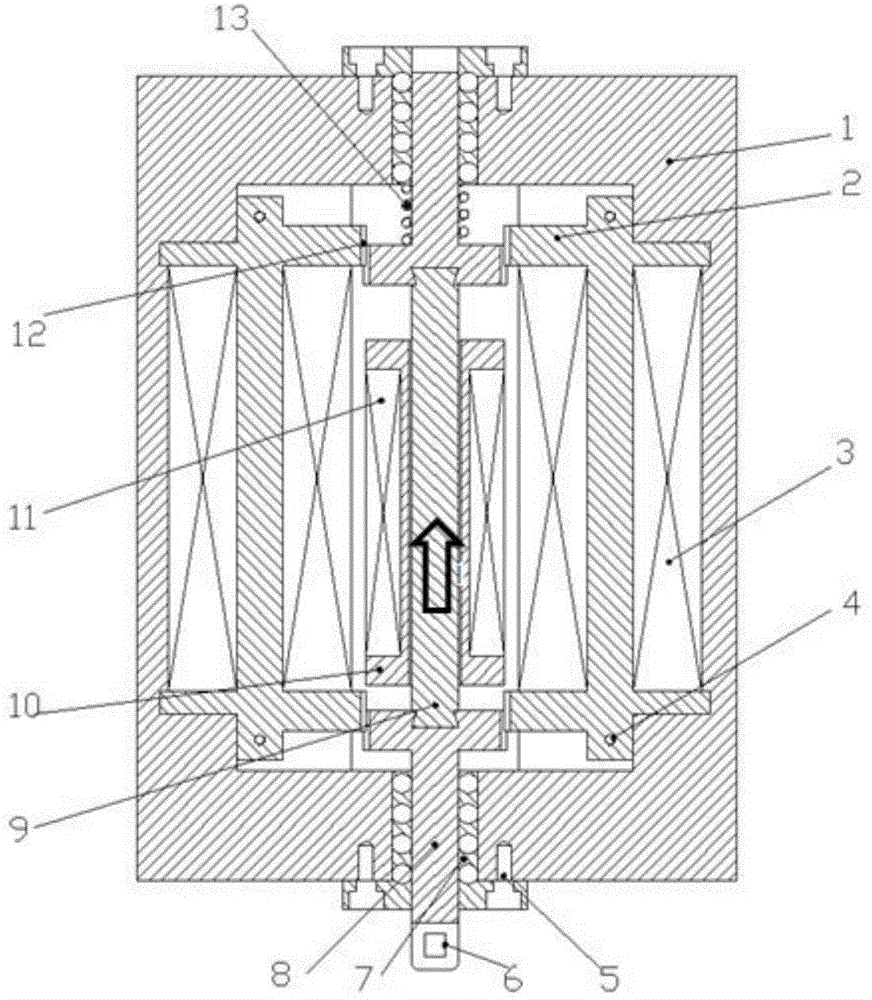

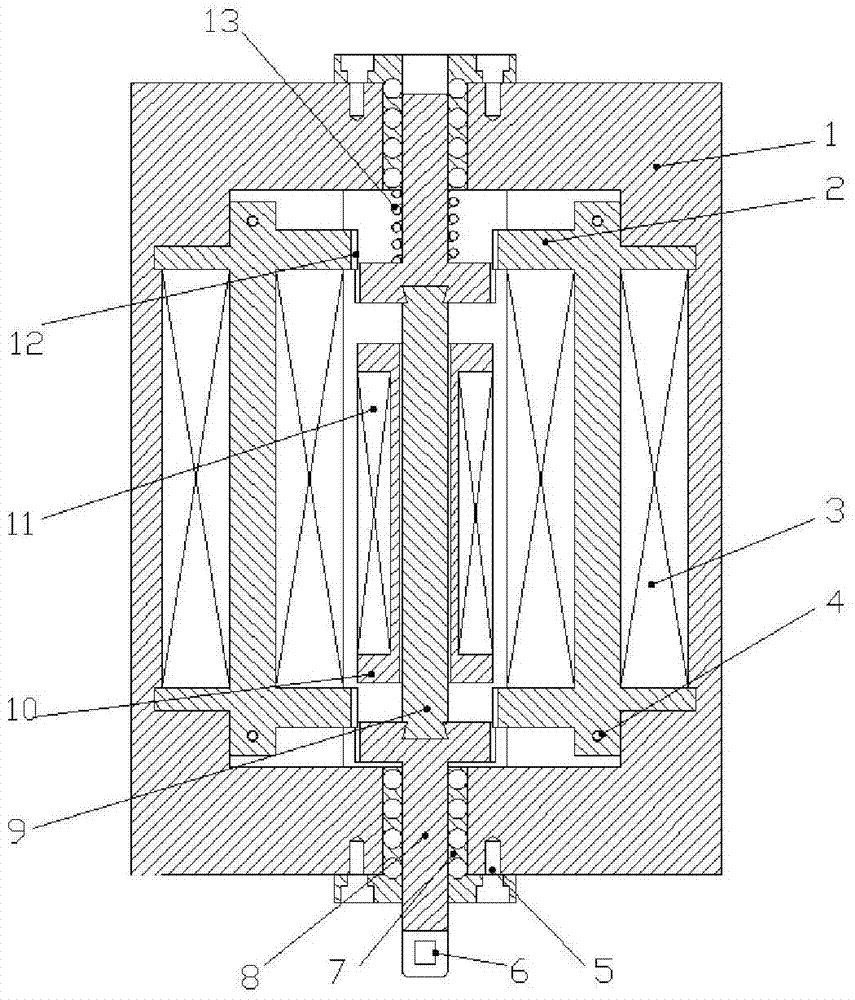

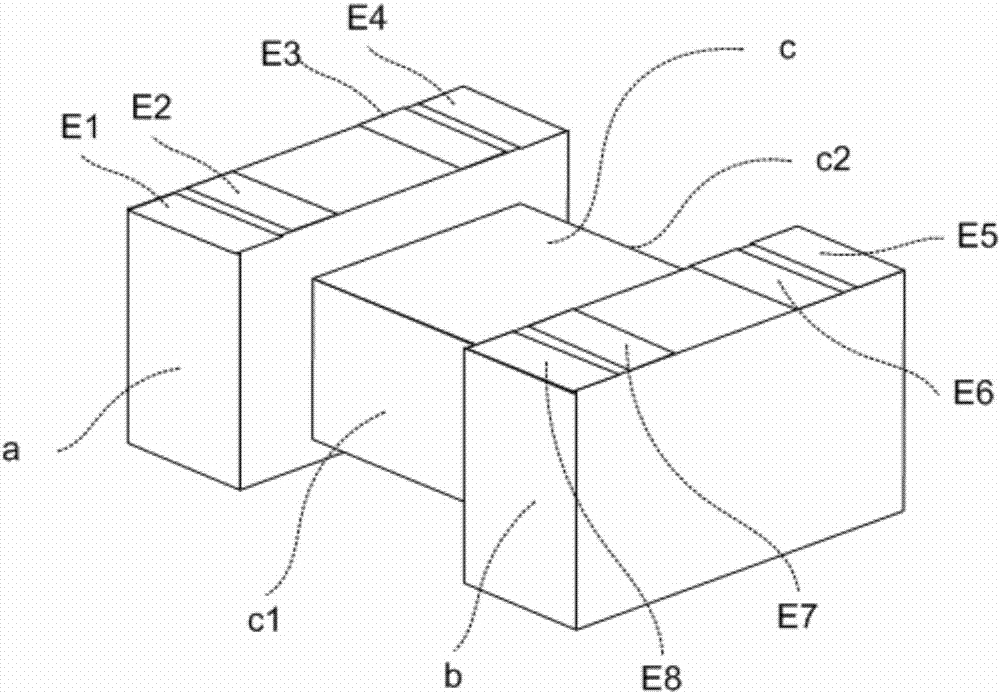

Precision controllable linear driver and its combination

ActiveCN104793564AMove preciselyActive Control PreciseMechanical oscillations controlNumerical controlEngineeringElectrical and Electronics engineering

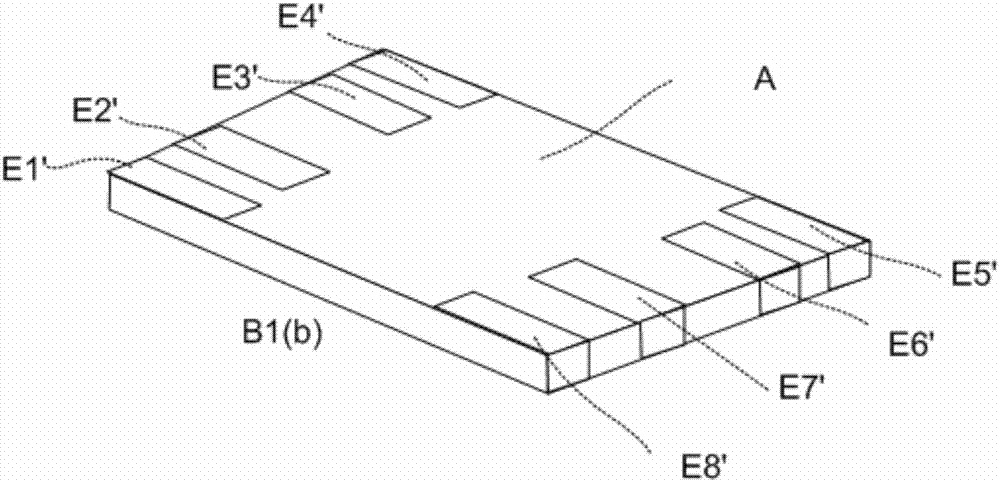

The invention provides a precision controllable linear driver comprising a base, a mover part and at least one drive member. The base is provided with a first cavity allowing relative movement of the mover part and a second cavity used for holding the drive members. The mover part comprises two outer end parts and a middle part; the outer end parts are detachably and rigidly connected with or integrated to the middle part; the mover part is made of permeability magnetic material; magnetic circuit structures in mutual action are formed between the drive members and the mover part. The invention further provides a combined precision controllable linear driver based on the precision controllable linear driver. The precision controllable linear driver and its combination are simple in structure and light in weight and meet the need of the modern industry for precision control drive equipment.

Owner:SHANGHAI JIAO TONG UNIV

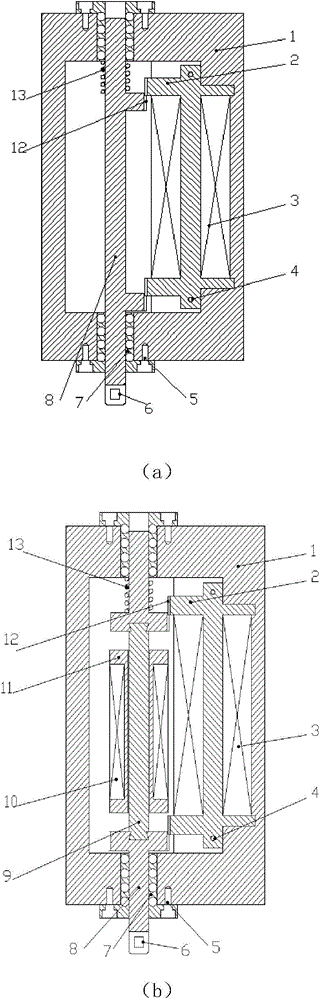

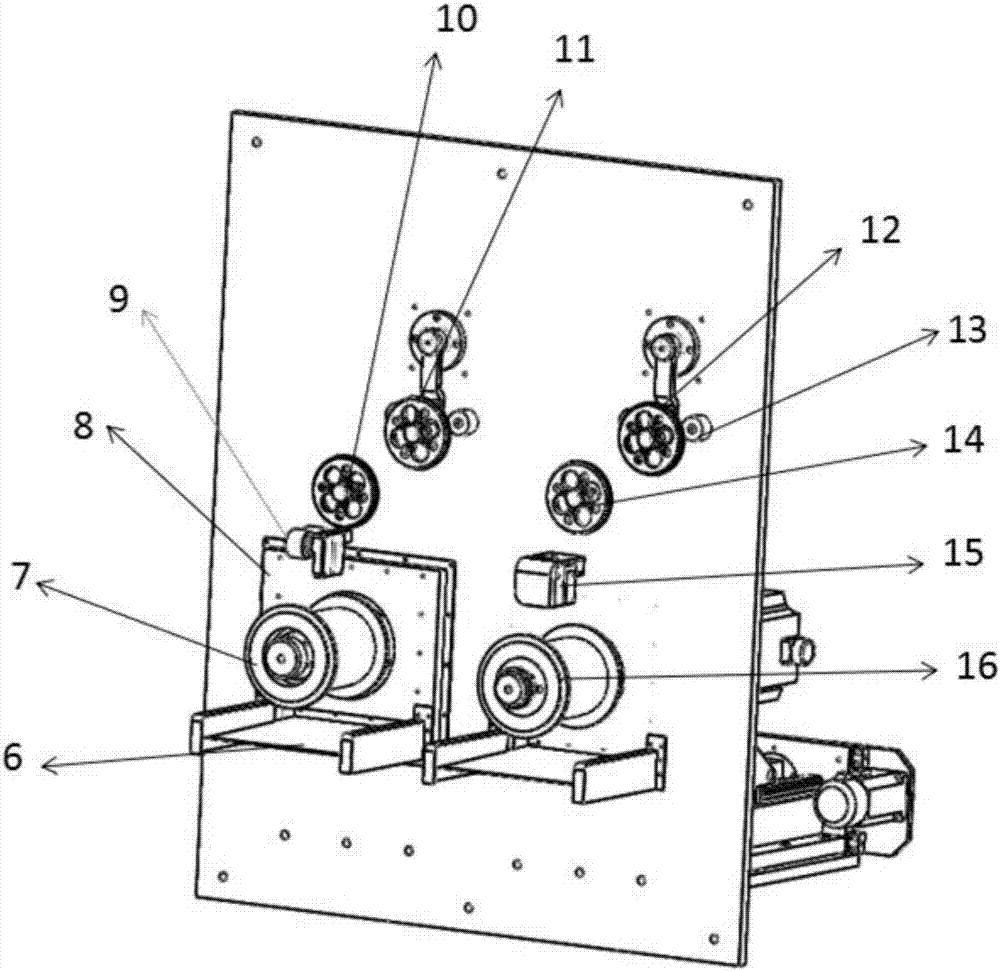

Six-guide-wheel multi-line cutter

InactiveCN107225702AWinding method is simpleShorten the timeWorking accessoriesGrinding machinesWork cycleEngineering

The invention discloses a six-guide-wheel multi-line cutter. The six-guide-wheel multi-line cutter comprises a rack, a work line roller, a worktable, a worktable driving device, a reverse wheel, a first line roller, a first auxiliary wheel, a first adjusting wheel, a first tensioning wheel, a second line roller, a second tensioning wheel, a second adjusting wheel and a second auxiliary wheel. The work line roller comprises three triangularly-arranged work main shafts. The reverse wheel is arranged on one side of the work line roller. The first line roller, the first auxiliary wheel, the first adjusting wheel, the first tensioning wheel, the second line roller, the second tensioning wheel, the second adjusting wheel and the second auxiliary wheel are arranged on the other side of the rack. The first line roller, the first auxiliary wheel, the first adjusting wheel and the first tensioning wheel are arranged in sequence from bottom to top. The second tensioning wheel, the second adjusting wheel, the second auxiliary wheel and the second line roller are arranged on one sides of the first line roller, the first auxiliary wheel, the first adjusting wheel and the first tensioning wheel in sequence from top to bottom. A steel wire is wound through the six guide wheels, the winding mode is simple, under the premise of completing functions, each work cycle time is reduced greatly, and the time cost of the equipment is also reduced to a certain extent.

Owner:玉田县昌通电子有限公司

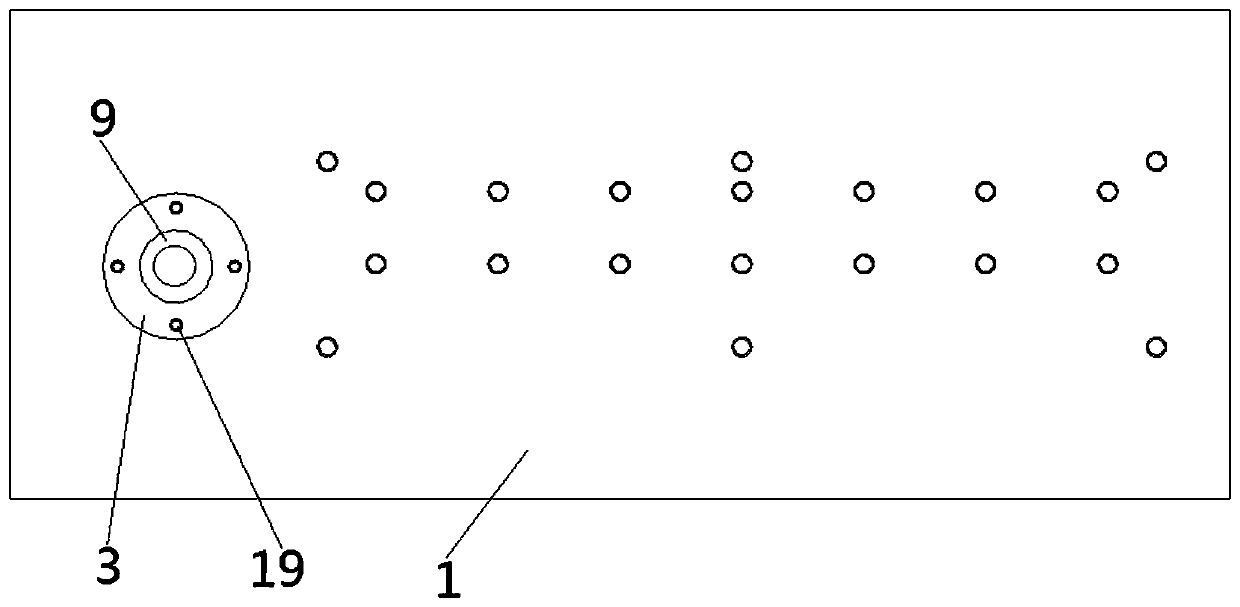

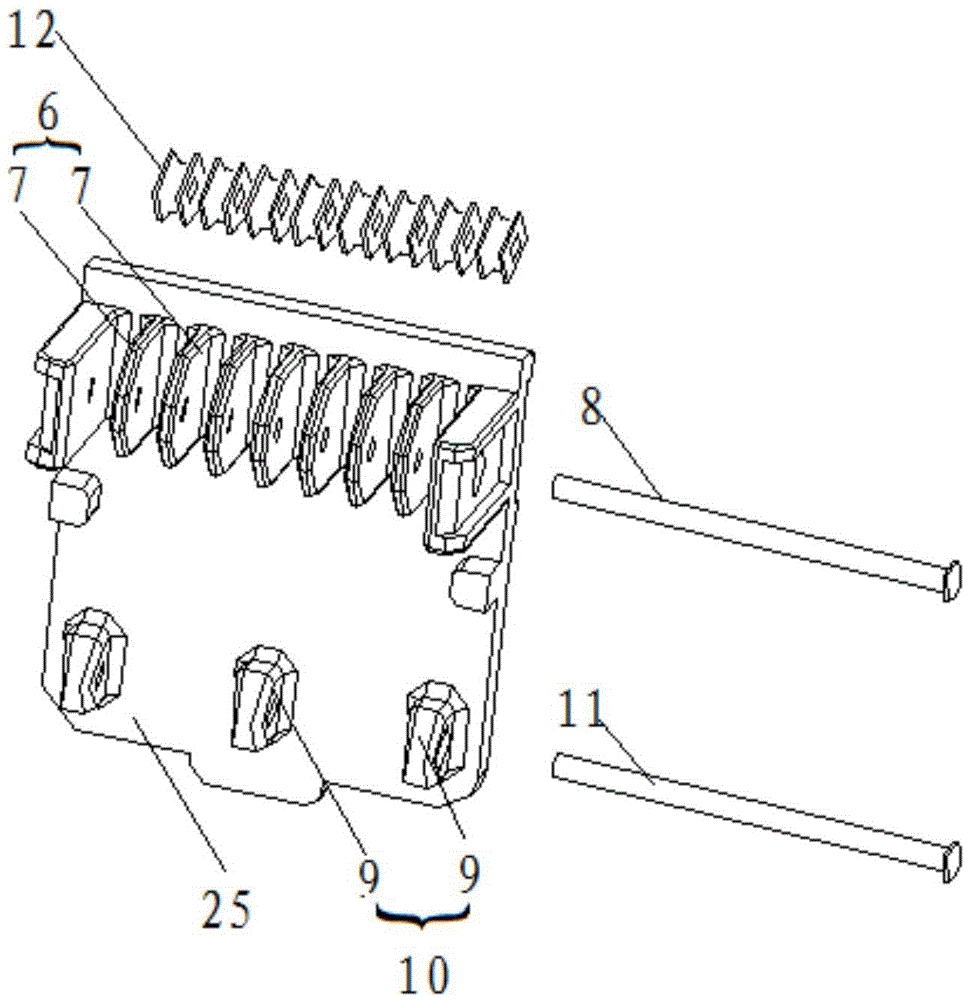

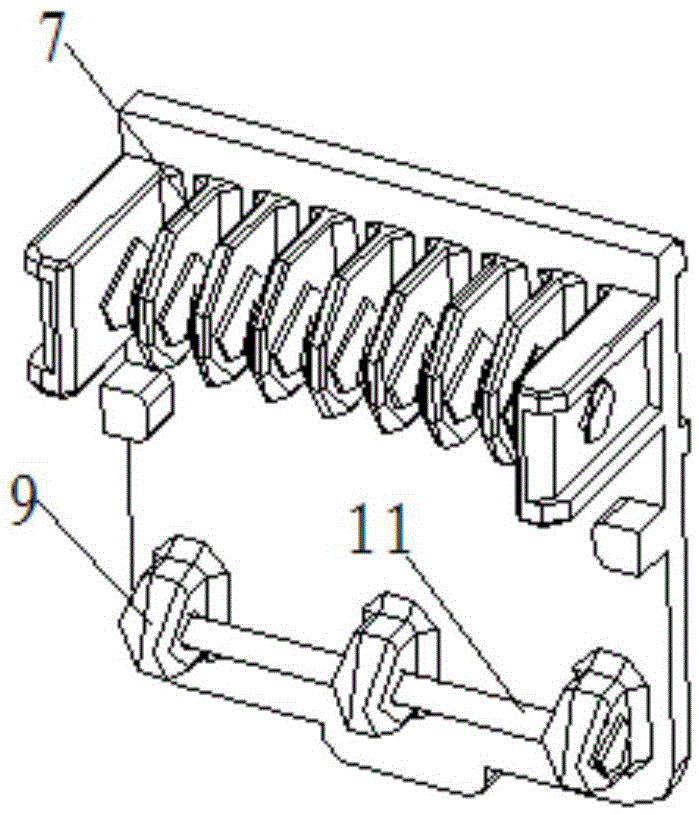

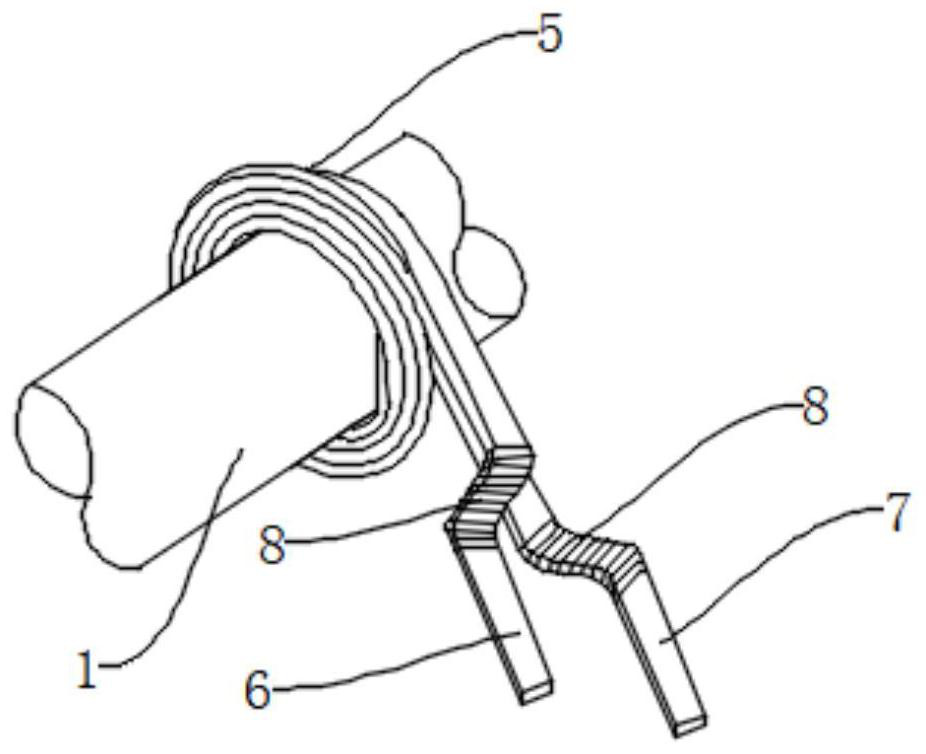

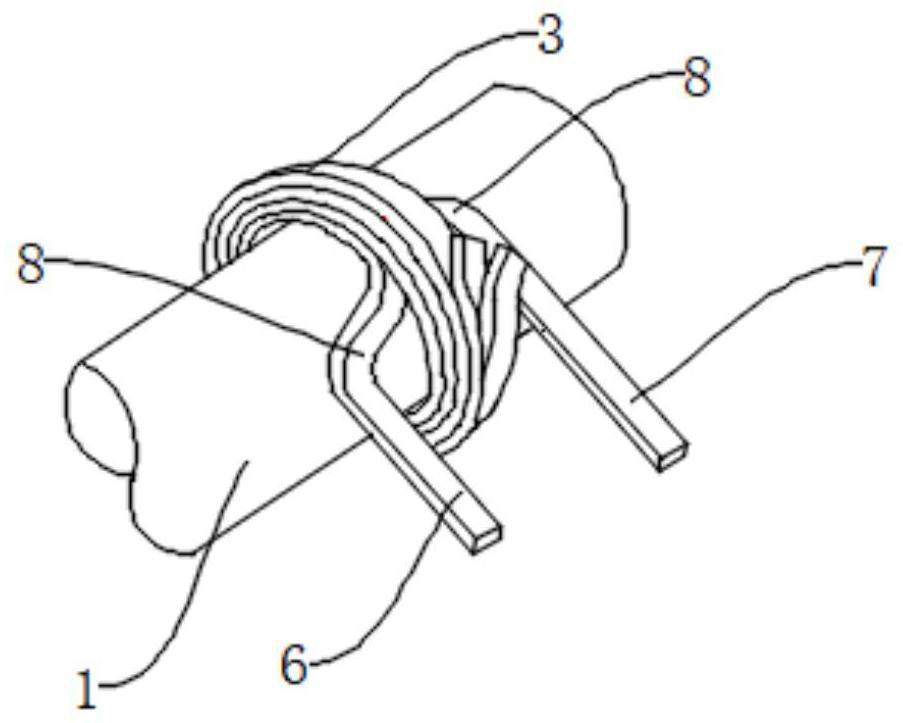

Transformer flat wire vertical winding coil manufacturing tool and coil manufacturing method

PendingCN110729122ATurn-by-turn windingImprove winding efficiencyCoils manufactureManufacturing cost reductionTransformer

The invention provides a transformer flat wire vertical winding coil manufacturing tool applied to the technical field of transformers and further relates to a transformer flat wire vertical winding coil manufacturing method. The tool is characterized in that a mounting groove hole (2) is formed on a tool bottom plate (1) of the transformer flat wire vertical winding coil manufacturing tool, a threaded sleeve (3) is mounted in the mounting groove hole (2), a threaded hole (4) is arranged in the threaded sleeve (3), a middle rod (6) is movably mounted on a stud (5), a threaded part (7) is arranged at a lower end of the middle rod (6), the middle rod (6) is movably screwed with the threaded hole (4) in the threaded sleeve (3) through the threaded part (7), and a starting pressing part (8) isfurther arranged on the tool bottom plate (1). According to the transformer flat wire vertically-wound coil manufacturing tool and the coil manufacturing method, winding manufacturing of the flat wire vertically-wound coil can be conveniently and rapidly achieved, when different types of flat wires are replaced or different types of coils are manufactured, only a small number of parts of the toolneed to be replaced, the manufacturing cost is reduced, and the machining time is saved.

Owner:GLORYMV ELECTRONICS

a cordless curtain

The invention provides a cordless curtain, which is used for simplifying the winding method of a stay cord. The specific technical solution of a cordless curtain in the embodiment of the present invention is: a moving part, a telescopic part, a traction rope fixing seat, and a traction rope; one end of the telescopic part is used for fixed connection with the external environment, and the other end is connected with the The parts are connected, and the moving part moves left and right with the telescopic part; the traction rope fixing seat is used for fixed connection with the external environment; the moving part is provided with at least one horizontally arranged first horizontal column, At least one second horizontal column is arranged on the traction rope fixing seat, and the traction rope passing through the curtain body is fixed on the moving part or The traction rope is fixed on the seat.

Owner:GUANGZHOU GARDEN RUBBER & PLASTIC

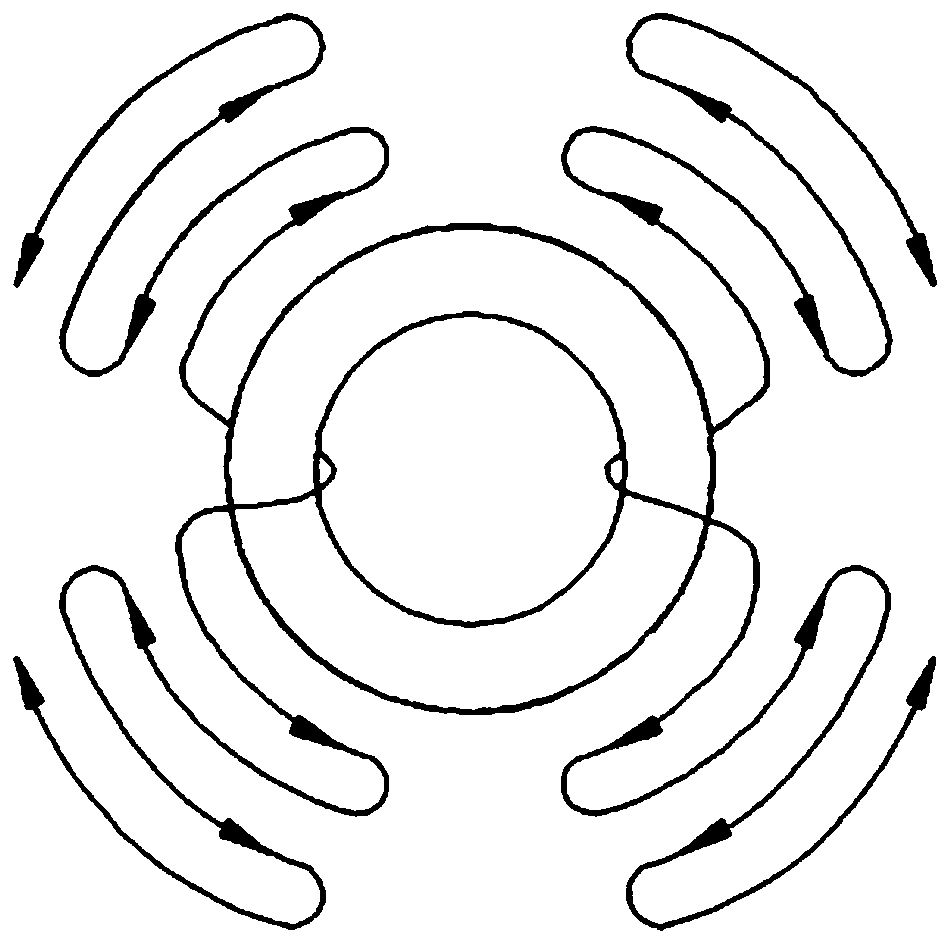

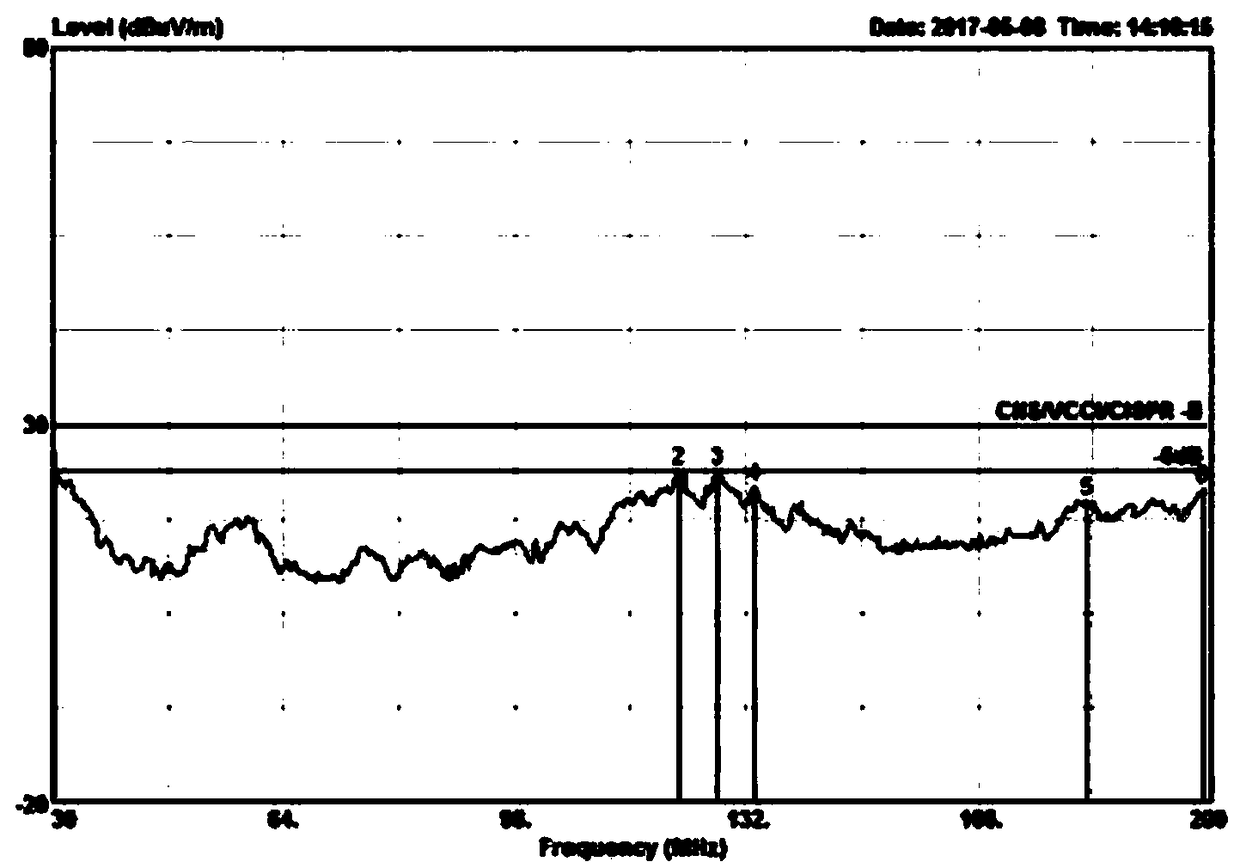

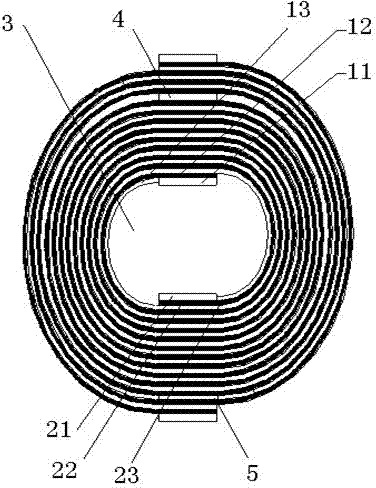

New winding method of emi common mode inductor and its winding method

ActiveCN107195428BChange distributionReduce distributed capacitanceTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringInductor

The embodiments of the present invention disclose an EMI common-mode inductor of a new winding method and a winding method for the EMI common-mode inductor, relating to the technical field of common-mode inductors. The EMI common-mode inductor of the new winding method comprises a toroidal magnetic core, and wound at symmetric positions on two sides of the toroidal magnetic core, two windings and four lead ends. Each winding is a multi-segment winding, and multiple layers are wound around each segment of a winding. Two lead ends of each winding are disposed at two ends of the winding respectively, and one of the lead ends is positioned at the innermost layer of the winding and the other lead end is positioned at the outermost layer of the winding. The embodiments of the present invention can ensure EMI effect, realize automatic winding, effectively improve production efficiency, greatly save labor, lower reject ratio, reduce product cost, and achieve win-win between a client and a supplier.

Owner:SHANDONG ZHONGRUI ELECTRONICS

Rope-free curtain

InactiveCN105545196ASimple structureWinding method is simpleLight protection screensEngineeringMechanical engineering

Owner:GUANGZHOU GARDEN RUBBER & PLASTIC

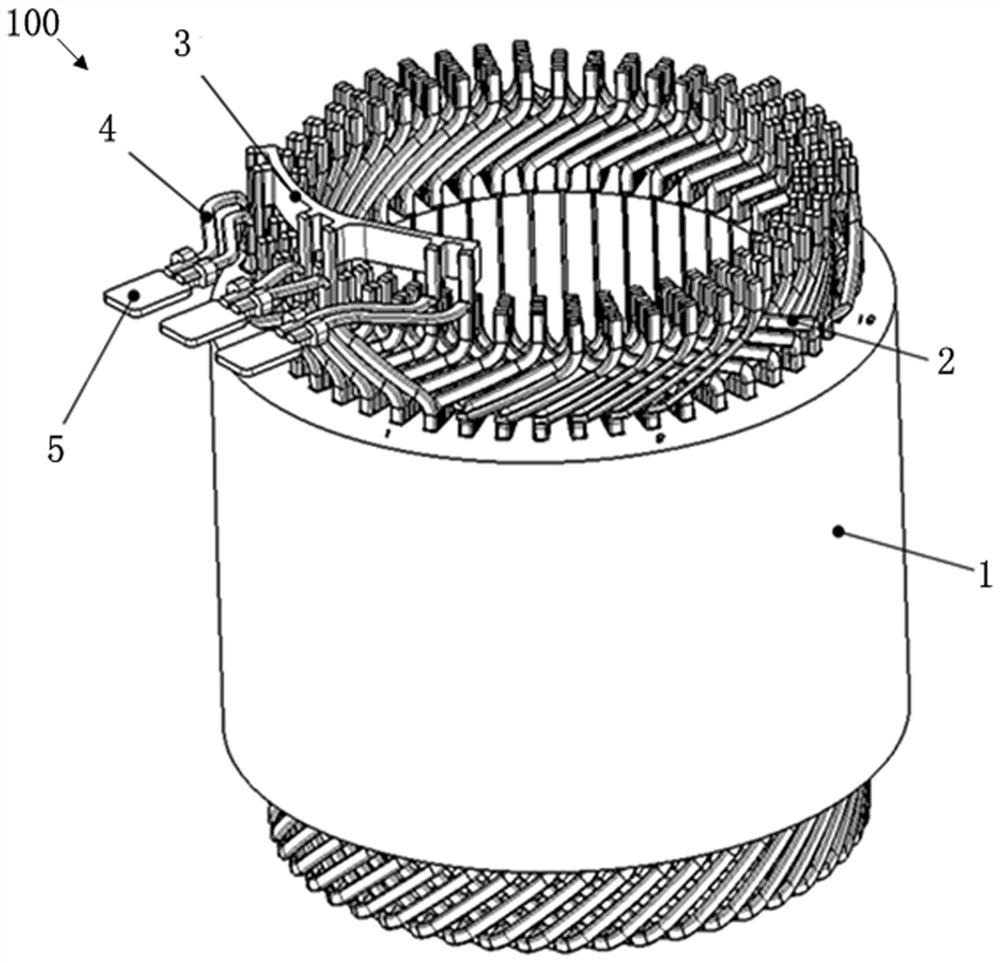

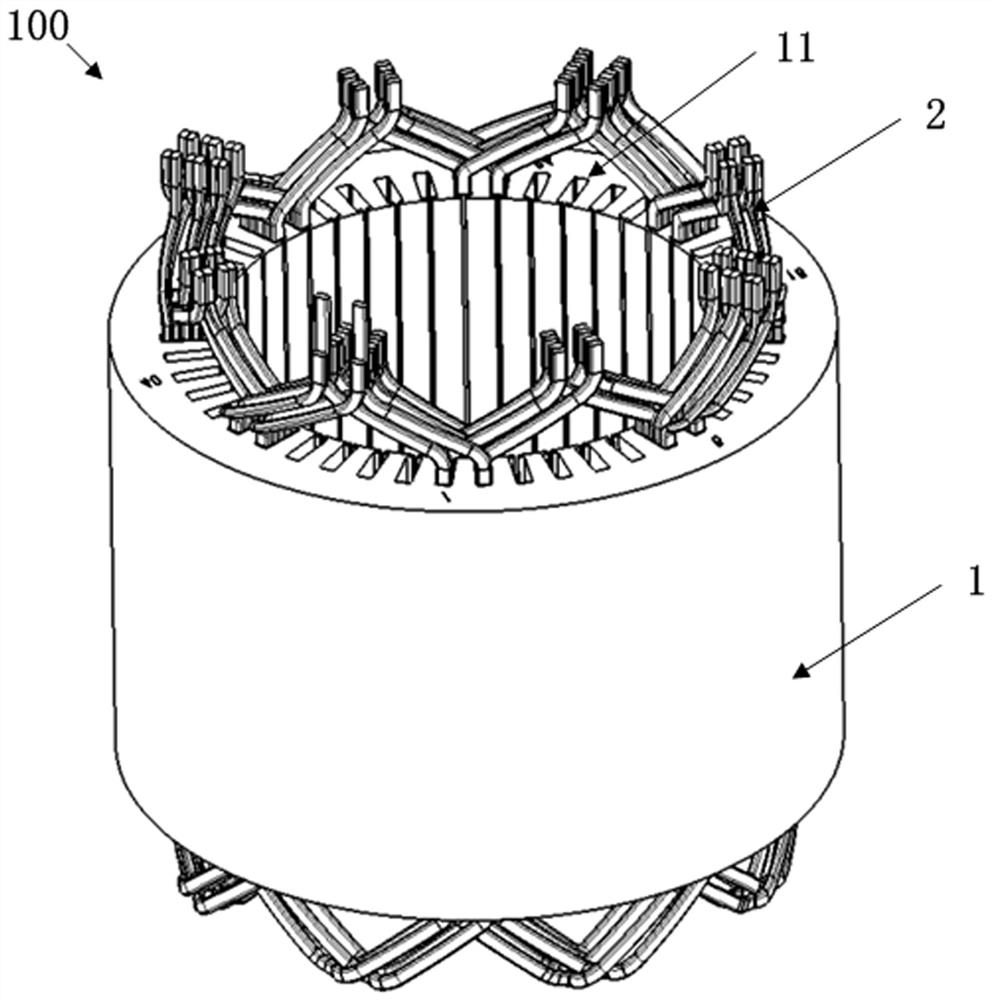

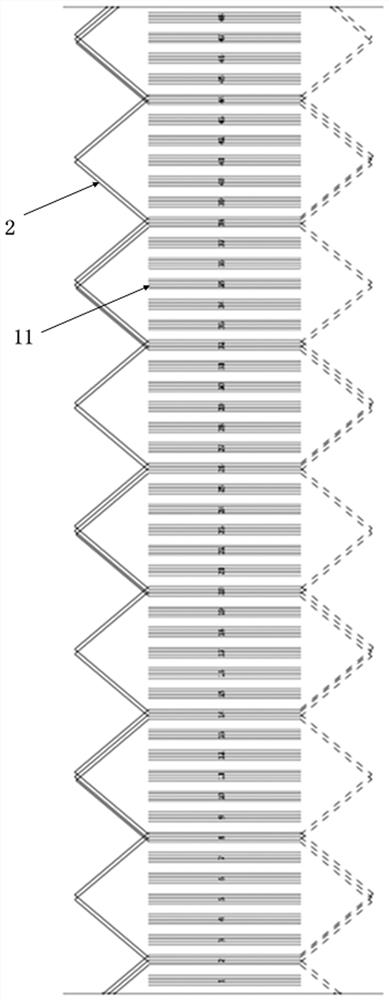

Motor stator, manufacturing method of motor stator and hairpin motor

PendingCN113629906AIncrease powerIncrease torqueMagnetic circuit stationary partsEmbedding prefabricated windingsElectrical conductorElectric machine

The invention discloses a motor stator, a manufacturing method of the motor stator and a hairpin motor. Independent loops forming the first-phase winding, the second-phase winding and the third-phase winding in the motor stator are respectively and sequentially arranged in three adjacent continuous winding grooves in a staggered manner, each independent loop is formed by alternately connecting winding coils with the span of (1+3m) winding grooves, and m is a positive integer; a repeated winding unit is contained in three adjacent winding grooves forming an independent loop and having the span of (1+3m) winding grooves, and the repeated winding unit is formed in the three adjacent winding grooves through two-time lap winding, one-time wave winding and two-time lap winding. The number of conductors in each winding groove is set to be odd number layers, the winding mode is simple, the adjustability of the number of turns of the winding is improved, the power and torque during motor design are balanced, the collector ring is simplified, and the wire outlet height is reduced.

Owner:上海伊控动力系统有限公司

Radial double split foil winding and winding method thereof

ActiveCN102360797BReduce Flux LeakageEvenly distributedTransformers/inductances coils/windings/connectionsCoils manufactureCapacitanceMetallurgy

The invention discloses a radial double split foil winding and a winding method thereof. A first wire outlet copper bar and a second wire outlet copper bar of the winding are positioned on the inner side of the winding; a first-layer copper foil is welded on the first wire outlet copper bar, a first-layer insulation material is coated on the inner side of the first-layer copper foil; a second-layer copper foil is welded on the second wire outlet copper bar; a second-layer insulation material is coated on the inner side of the second-layer copper foil; and the first-layer copper foil and the second copper foil are arranged at an interval. During winding, the first wire outlet copper bar and the first-layer copper foil are wound on a winding former simultaneously; when a semicycle of the inner diameter of the winding is formed, the second-layer copper foil is placed on the inner side of the first-layer insulation material and is wound simultaneously; and the winding method is simple andconvenient and contributes to realizing mechanization of the winding process of the winding. The obtained winding is low in brow leakage, small in axial force and strong in short circuit bearing capacity during short circuit; and turn-to-turn capacitance of the winding along the winding is distributed uniformly, and impulse overvoltage stability of the winding is enhanced.

Owner:JIANG SU ZHONGRONG TECH

Transformer and DC/DC converter

InactiveCN103971903AWinding method is simpleSolution volumeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerSurface mounting

The embodiment of the invention discloses a transformer and a DC / DC converter and relates to the technology of transformers. According to the transformer and the DC / DC converter, the size of a magnetic material is reduced, the limitation on the increase of power is eliminated, and the coupling performance and noise output performance are improved. The transformer comprises a magnetic core and a framework, wherein the magnetic core is a surface mount device, the framework comprises a cylinder, neither end of the cylinder is provided with a bottom, the outer wall of each end of the cylinder is provided with two fan-shaped surfaces which are in axial symmetry, the distance between the two fan-shaped surfaces on the outer wall of one end is equal to the distance between the two fan-shaped surfaces on the outer wall of the other end, the fan-shaped surfaces are perpendicular to the surface of the cylinder, and a winding is arranged on the surface of the cylinder and is led out through notches between the fan-shaped surfaces. The transformer is mainly used for the DC / DC converter.

Owner:航天科工惯性技术有限公司

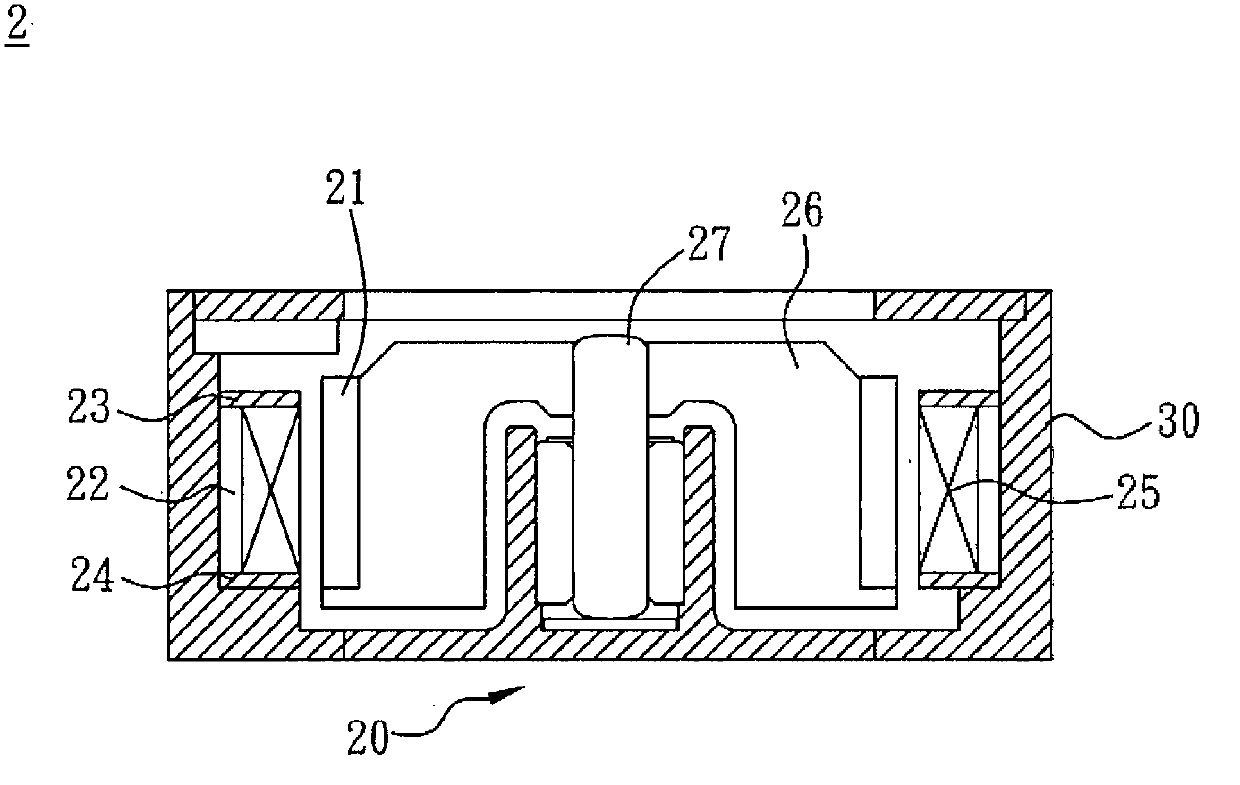

Motor device and electric toothbrush

PendingCN110932426AIncrease spatial structureWinding method is simpleWindings insulation shape/form/constructionMagnetic circuit stationary partsPhysicsWire frame

The invention relates to the technical field of motors, in particular to a motor device and an electric toothbrush. The motor device comprises a shell; a motor shaft, an insulation wire frame and at least one pair of stator iron cores are arranged in the shell, a magnetic steel structure is arranged in each stator iron core, the insulation wire frame comprises a first framework and a second framework, and a first connecting frame body is arranged between the first framework and the second framework and is connected through the first connecting frame body; the first framework is provided with an open groove, the stator iron core comprises a first arc-shaped punching sheet and a second arc-shaped punching sheet, and a second connecting frame body is arranged between the first arc-shaped punching sheet and the second arc-shaped punching sheet and connected with the first arc-shaped punching sheet and the second arc-shaped punching sheet through the second connecting frame body. Accordingto the invention, the stator iron core slides into the insulating wire frame; the coil winding, the stator core and the insulation coil holder are assembled in a split independent structure, so that the space structure in the insulation coil holder is expanded, the winding mode of the coil is simplified, the electromagnetic assembly with higher output power can be accommodated in the insulation coil holder, the motor can transmit higher torque, and the motor performance is improved.

Owner:东莞市米贝科技有限公司

Manufacturing method and structure of three-cake entangled reverse unit and transformer

ActiveCN112951585AAvoid truncated welding operationsImprove affordabilityCoils manufactureTransformerMechanical engineering

The invention provides a manufacturing method of a three-cake entangled reverse unit, and belongs to the technical field of transformers. During winding, 2k wires jointly wind two continuous wire cakes and an entangled wire cake located between the two continuous wire cakes, the 2k wires are wound in parallel to a specified number of turns to obtain a temporary wire cake, the 2k wires are averagely divided into two groups, namely a first group wire and a second group of wires, the first group of wires and the second group of wires are transposed in the left direction and the right direction and temporarily fixed, temporary wire cakes are scattered, wire cakes are turned between the first group of wires and the second group of wires to obtain entangled wire cakes to be fixed, and temporary fixing of the first group of wires and the second group of wires is relieved; the first continuous wire cake and the second continuous wire cake are obtained by winding the two sides of the entangled wire cake to the specified number of turns respectively, the turn number adjusting range is large, large impulse voltage can be borne, the phenomenon of breakdown short circuit is avoided, the coil structure is optimized, and the use safety is improved.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

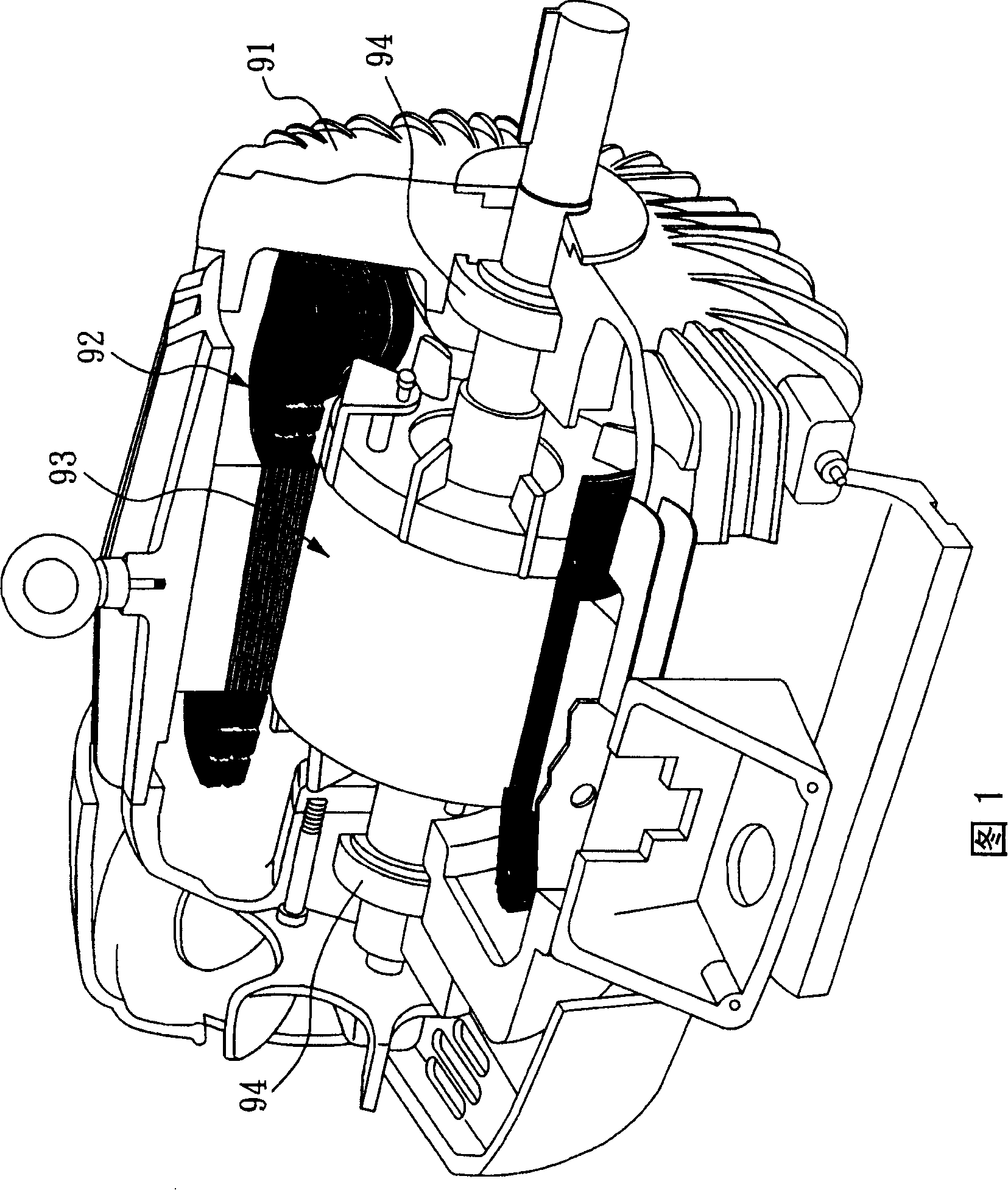

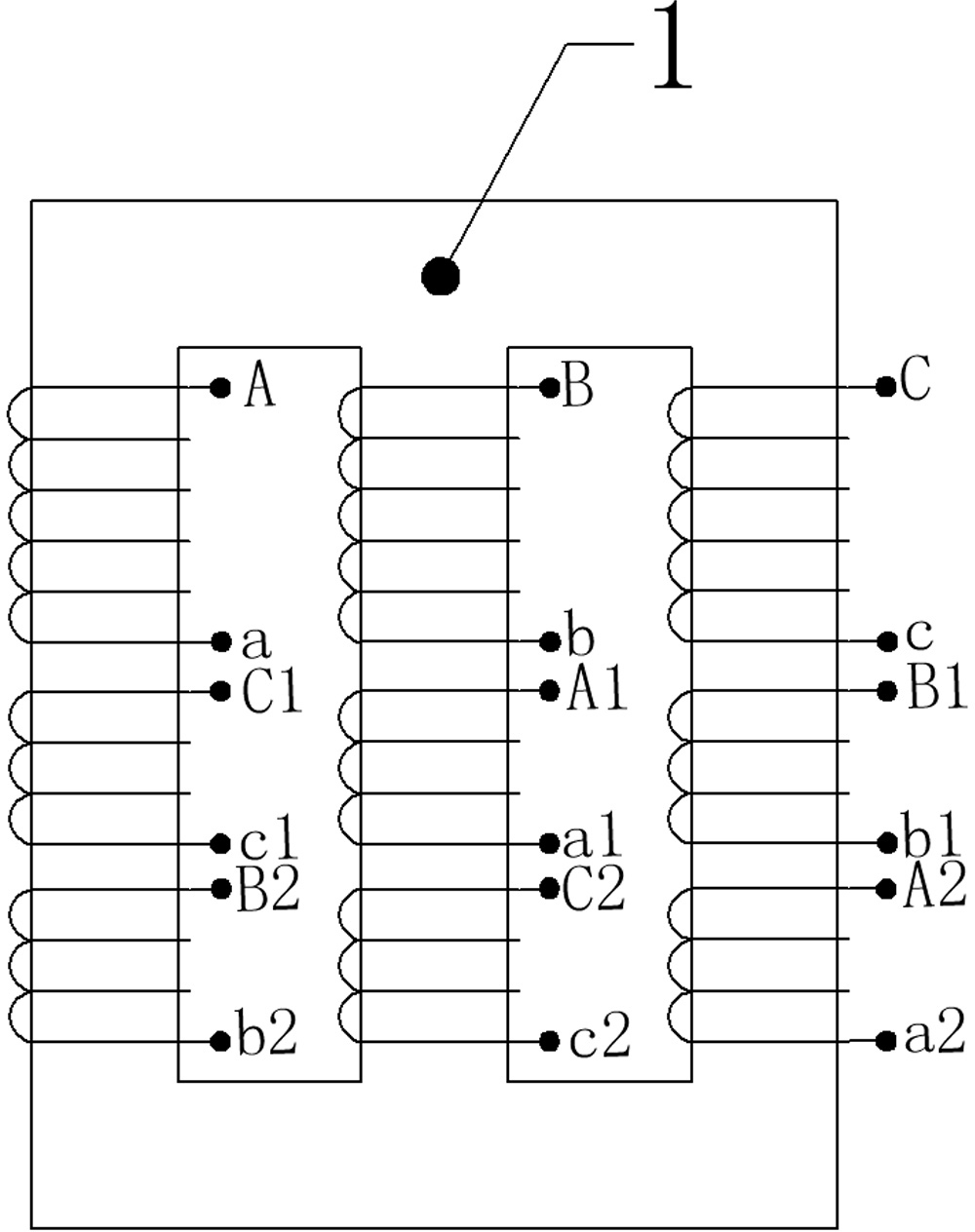

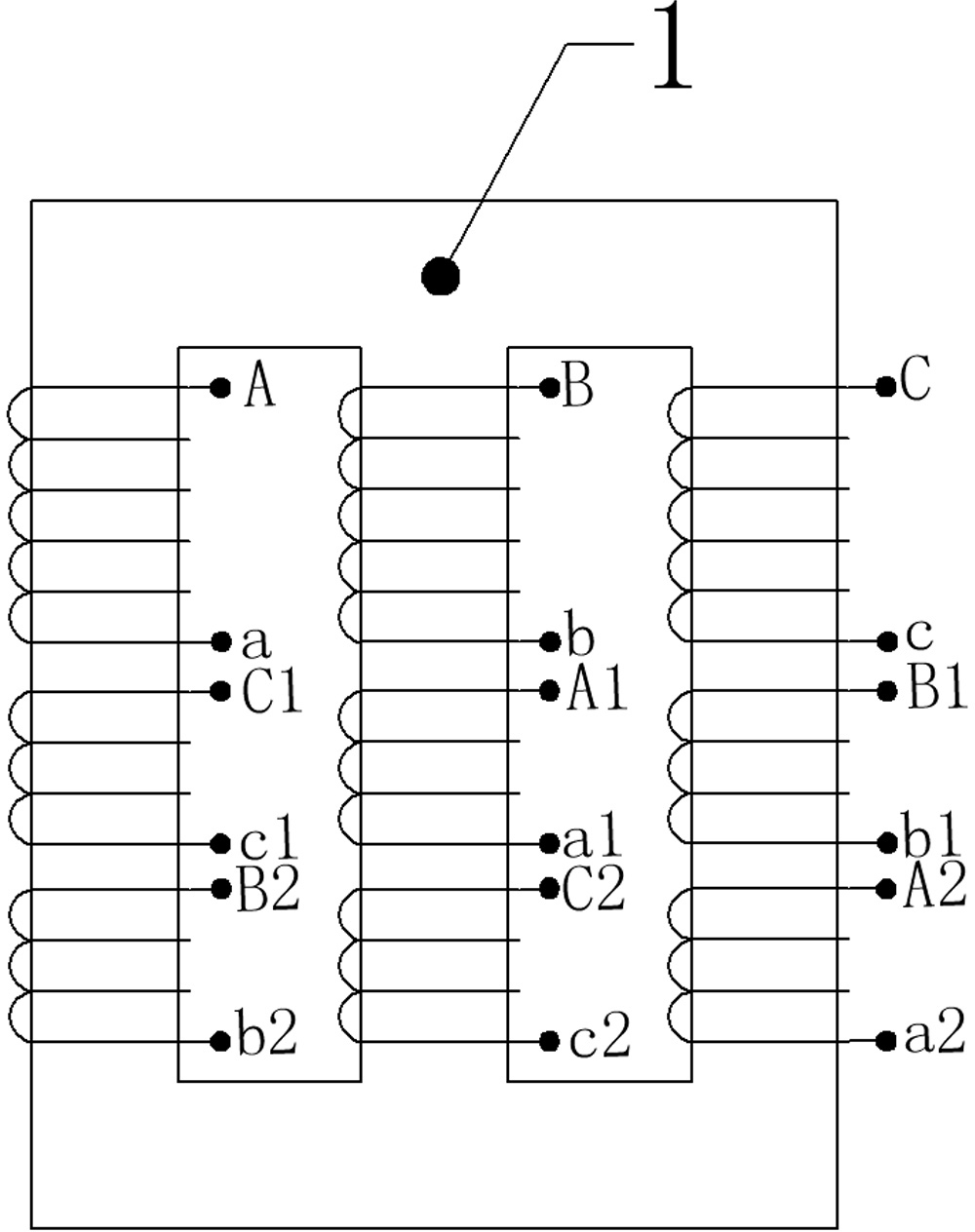

Modular filter

InactiveCN101986498AAvoid harmWinding method is simpleHarmonic reduction arrangementAc network to reduce harmonics/ripplesHarmonicPartial current

The invention discloses a modular filter consisting of a winding iron core and a three-phase winding ABC, wherein the winding iron core is formed by overlapping a plurality of steel discs. The modular filter is characterized in that the winding iron core is provided with three wrapping posts; the first winding of a three-phase line is respectively wound on the three wrapping posts in sequence; the second winding of the three-phase line is wound as follows: phase A is wound below phase B wound below phase C, phase C is wound below phase A; the third winding of the three-phase line is wound as follows: phase A is wound below phase C wound below phase B, phase B is wound below phase A; and in the winding method, current flowing past phase A and opposing windings wound on the iron cores of phase B and phase C are utilized to offset partial current of phase B and phase C, thereby preventing the generation of harmonics.

Owner:ZHOUSHAN DAHAO ENERGY SAVING +2

Precise controllable linear drive device and its combination

ActiveCN104793564BMove preciselyActive Control PreciseMechanical oscillations controlNumerical controlLinear driveMagnetic circuit

The invention provides a precision controllable linear driver comprising a base, a mover part and at least one drive member. The base is provided with a first cavity allowing relative movement of the mover part and a second cavity used for holding the drive members. The mover part comprises two outer end parts and a middle part; the outer end parts are detachably and rigidly connected with or integrated to the middle part; the mover part is made of permeability magnetic material; magnetic circuit structures in mutual action are formed between the drive members and the mover part. The invention further provides a combined precision controllable linear driver based on the precision controllable linear driver. The precision controllable linear driver and its combination are simple in structure and light in weight and meet the need of the modern industry for precision control drive equipment.

Owner:SHANGHAI JIAOTONG UNIV

Pulse transformer and manufacturing method thereof

ActiveCN105489344BEasy to manufactureAvoid crossingTransformers/inductances coils/windings/connectionsMagnetic-bias transformersEngineeringConductor Coil

A pulse transformer comprises a first core body, wherein the first core body is provided with a plurality of electrodes, multiple winding wires wind around the first core body and are connected with corresponding electrodes to form multiple windings, the multiple windings are in corresponding wiring connection with PCB (printed circuit board) welding plates, and accordingly, the characteristics of a transformer product are obtained due to combination with the PCB welding plates; one part of the multiple windings are connected with the corresponding PCB welding plates to form primary windings, and the other part of the multiple windings are connected with the corresponding PCB welding plates to form secondary windings. The invention further discloses a corresponding manufacturing method of the pulse transformer. The pulse transformer is simple to manufacture and has remarkable advantages of avoidance of lead crossing and prevention of poor voltage resistance.

Owner:SHENZHEN SUNLORD ELECTRONICS

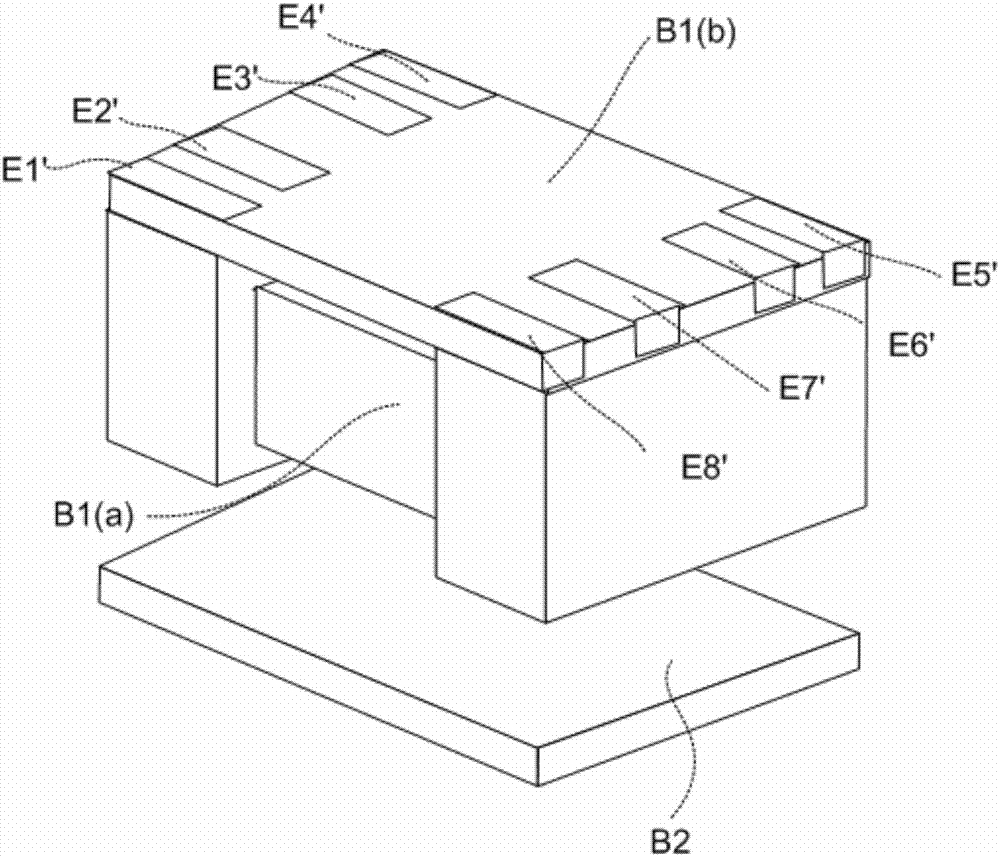

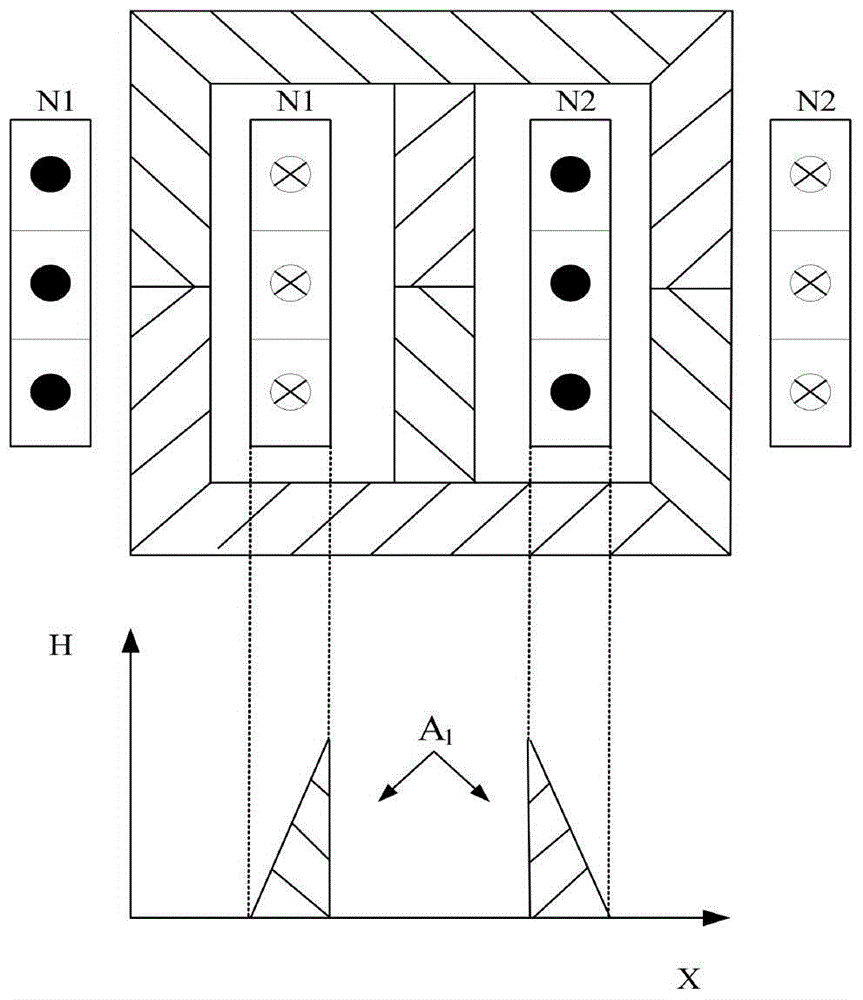

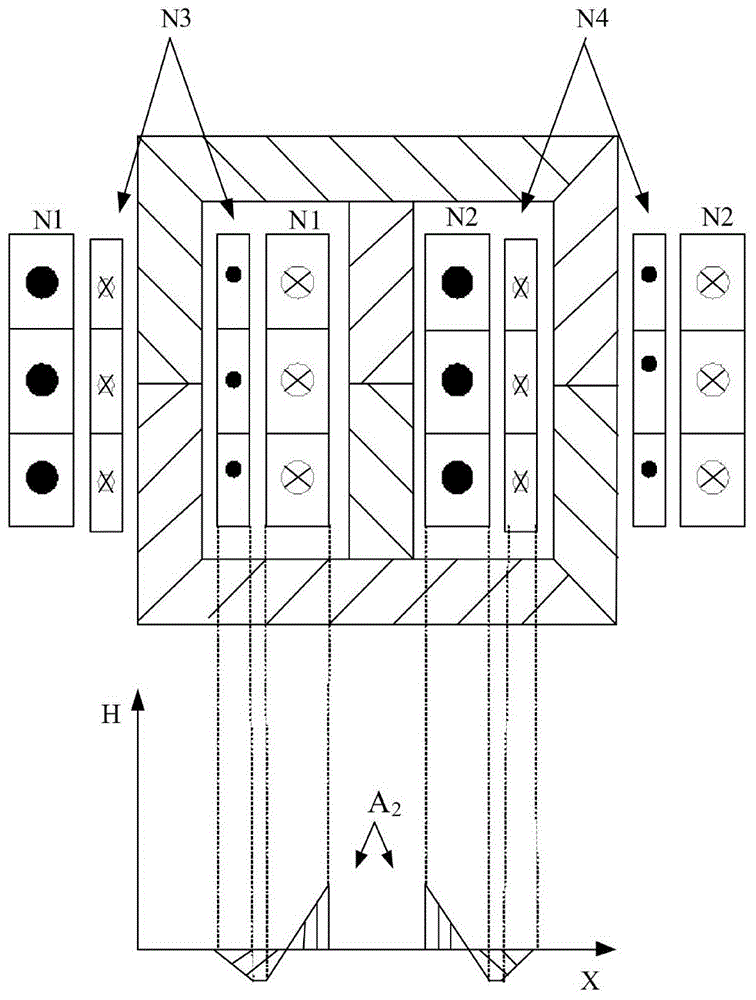

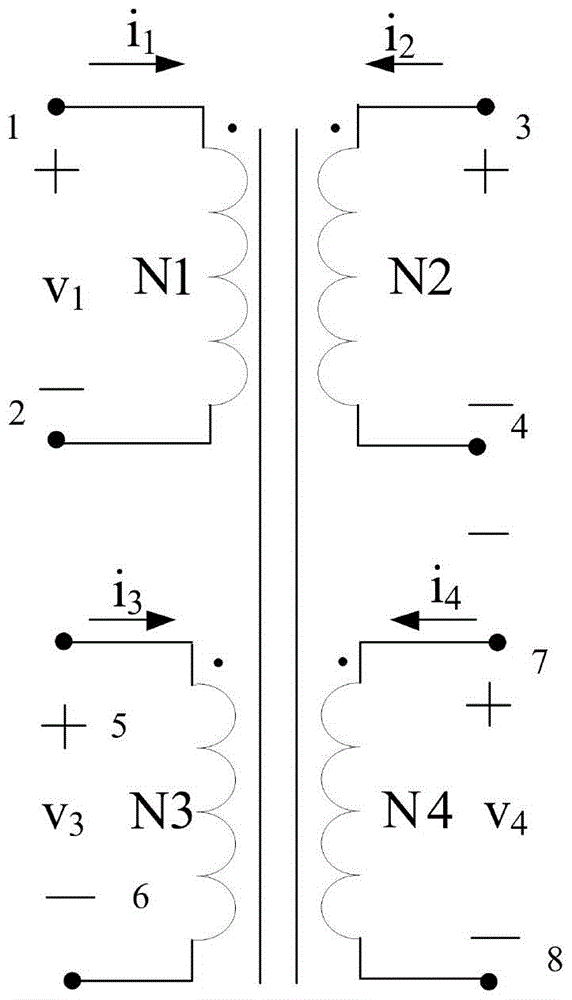

a pulse transformer

ActiveCN104851575BWinding method is simpleDecrease rising edgeTransformers/inductances coils/windings/connectionsMagnetic-bias transformersVoltage pulseEngineering

The invention provides a pulse transformer, which comprises an E-type magnetic core formed by a core body and a central column, a primary winding N1, a secondary winding N2, a first auxiliary winding N3 and a second auxiliary winding N4, wherein the primary winding N1 and the secondary winding N2 are wound on two magnetic yokes of the core body respectively, the first auxiliary winding N3 and the second auxiliary winding N4 are wound on the two magnetic yokes respectively, the first auxiliary winding N3 is wound in the direction opposite to that of the primary winding N1, and the second auxiliary winding N4 is wound in the direction opposite to that of the secondary winding N2. Through the first auxiliary winding N3 and the second auxiliary winding N4 which are wound on the two magnetic yokes respectively and wound in the directions opposite to that of the primary winding N1 and that of the secondary winding N2 respectively, a rising edge of the output voltage pulse waveform is obviously reduced, and the sterilization efficiency of a pulsed electric field food sterilization device applying the pulse transformer is improved. Meanwhile, the auxiliary windings are simple in winding mode, the size of the pulse transformer is obviously reduced, and the manufacturing cost is reduced.

Owner:HRG INT INST FOR RES & INNOVATION

Dry yarn winding forming method for pressure container

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

A double-split photovoltaic variable structure

ActiveCN105070491BReduce fill rateNot easy to fall offTransformers/inductances coils/windings/connectionsCoils manufactureLow voltageCopper

A double-splitting photovoltaic variable structure comprises a barrel-shaped high-voltage coil (1) and a first low-voltage coil (2.1) and a second low-voltage coil (2.2) which are located in the high-voltage coil (1), the first low-voltage coil (2.1) and the second low-voltage coil (2.2) are axially arranged, a gap is formed between the first low-voltage coil (2.1) and the second low-voltage coil (2.2) in the axial direction, the first low-voltage coil (2.1) is provided with a first conductive copper bar (3.1), and the second low-voltage coil (2.2) is provided with a second conductive copper bar (3.2); the double-splitting photovoltaic variable structure further comprises a first transposition copper bar (3.3) and a second transposition copper bar (3.4) which are internally embedded in the low-voltage coils, and the two ends of the first transposition copper bar (3.3) and the two ends of the second transposition copper bar (3.4) are welded to the first low-voltage coil (2.1) and the second low-voltage coil (2.2) respectively.

Owner:NINGBO AUX HIGH TECH

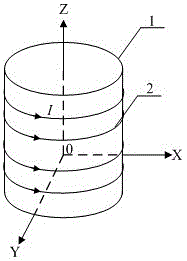

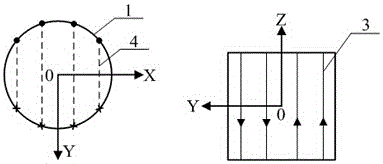

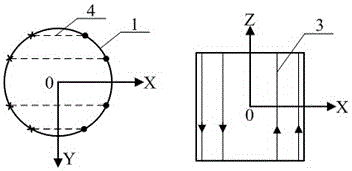

A three-axis magnetic field coil suitable for atomic spin gyroscopes

ActiveCN104299747BCounteracts magnetic field disturbancesNumber of turns controllableMagnetic/electric field screeningTurn-sensitive devicesPower flowGyroscope

The invention discloses a three-axis magnetic field coil suitable for an atomic spin gyroscope. According to the three-axis magnetic field coil, the problems that the traditional coil is poor in magnetic consistency and uniformity, single in direction and the like are solved. The three-axis magnetic field coil comprises a magnetic shielding tube, a cylindrical or rectangular hollow framework mounted in the magnetic shielding tube as well as a coil body winding the side face of the hollow framework; the coil body comprises a transverse coil and a longitudinal coil; the transverse coil is parallel to the bottom surface of the hollow framework, is circular-arc-shaped or a rectangular, and can generate a uniform magnetic filed in the Z-axis direction; the longitudinal coil is perpendicular to the bottom surface of the framework and is linear; uniform magnetic fields in the X-axis direction and the Y-axis direction can be generated by changing the direction of coil current. According to the three-axis magnetic field coil disclosed by the invention, the uniform magnetic fields which are independent to one another in the X-axis, Y-axis and Z-axis directions can be generated; the magnetic field in the Z-axis direction is a constant magnetic field B required by the working of the atomic spin gyroscope; the magnetic fields in the X-axis direction and the Y-axis direction can be used for offsetting magnetic field disturbance generated by the outside; the three-axis magnetic field coil is very suitable for the atomic spin gyroscope.

Owner:CHENGDUSCEON ELECTRONICS

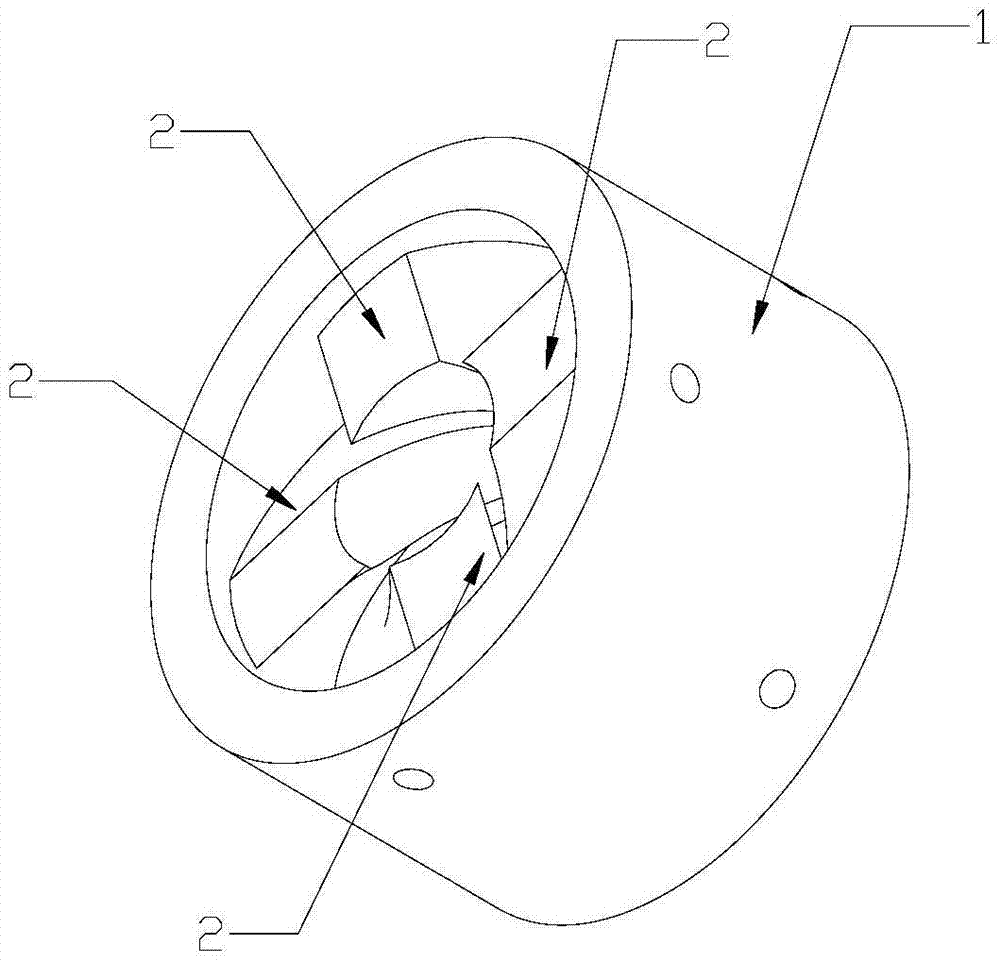

A magnetizing fixture for multi-pole magnetization on the outer surface of a ring magnet

The invention discloses a magnetizing fixture for multi-pole magnetization of the outer circumference surface of an annular magnet. The magnetizing fixture comprises a tubular substrate with an upper open end and a lower open end and 2n magnetizing coils, wherein n is an integer more than or equal to 1; each magnetizing coil includes a spiral magnetizing pole head and a multi-turn lead winding on the spiral magnetizing pole head; the spiral magnetizing pole head takes the shape of a spiral which is formed by stretching along a cylindrical spiral from a horizontal reference plane; the spiral magnetizing pole head is provided with a left curved surface, a right curved surface, an upper end face, a lower end face, an internal cylindrical surface and an external cylindrical surface; one lead is formed into the multi-turn lead by uniformly winding on a closed ring surface formed by the left curved surface, the right curved surface, the upper end face and the lower end face of the spiral magnetizing pole head. The magnetizing fixture adopts the winding manner of winding the single lead, thus being simple in winding mode, uniform in winding displacement, high in magnetizing field energy and magnetizing consistency; and furthermore, due to the single lead, the potential safety hazard of electric leakage caused by damage is inexistent, and thereby the magnetizing fixture is high in safety.

Owner:NINGBO YUNSHENG BONDED MAGNET CO LTD +1

Motor

ActiveCN100570989CWinding method is simpleSave winding timeMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

The invention relates to a motor, in particular to a two-stator convolved in a radial winding way. The two-stator is staggered from a special angle of the motor and forms a specific structure through coaxial arrangement with rotors, so that stator loops can be convolved with relatively a small amount of materials and a simple winding way, and the purpose of saving winding time and material is achieved.

Owner:TECO ELECTRIC AND MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com