A magnetizing fixture for multi-pole magnetization on the outer surface of a ring magnet

A multi-pole magnetization and magnetic fixture technology, which is applied to magnetic objects, electrical components, circuits, etc., can solve the problems of low magnetizing field energy, broken wires and leakage, poor magnetization consistency, etc., and achieves good cooling effect and magnetization. High consistency and uniform wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

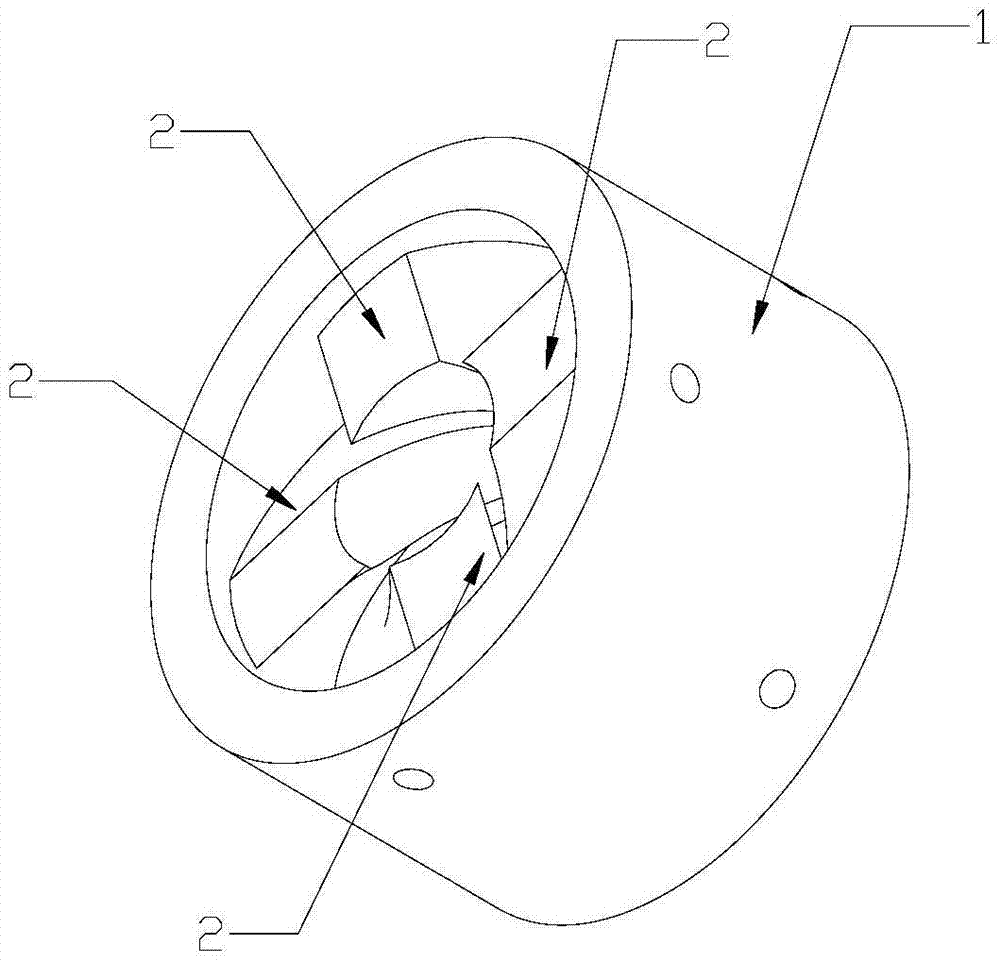

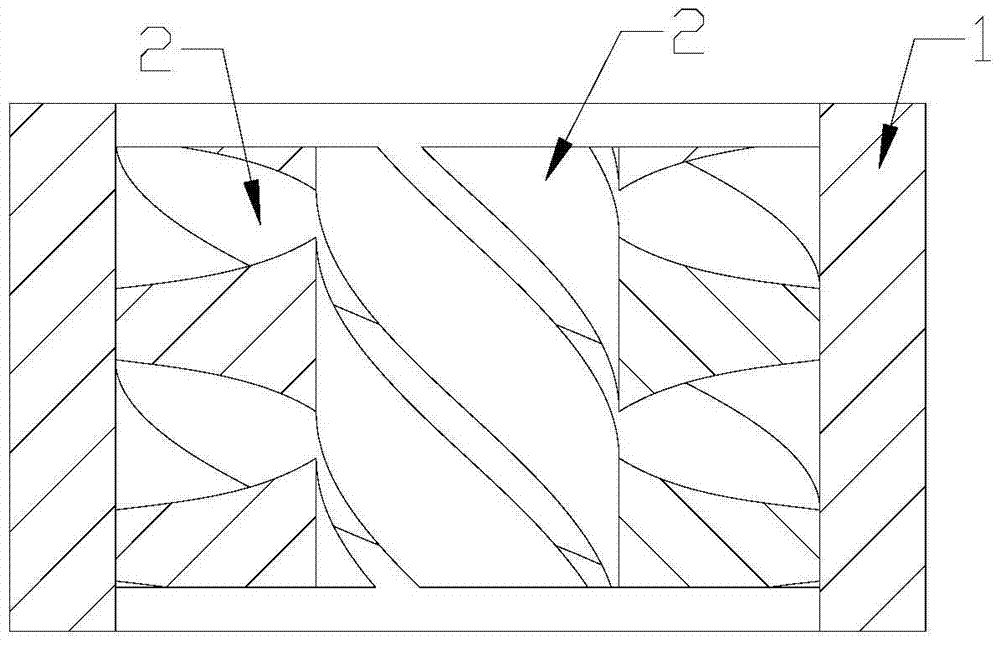

[0029] Embodiment one: if figure 1 , figure 2 , Figure 4 , Figure 5(a) ~ Figure 5(e) As shown, a magnetizing fixture for multi-pole magnetization of the outer circular surface of a ring magnet, including a circular tube-shaped substrate 1 with openings at both upper and lower ends and 2n magnetization coils, where n is an integer greater than or equal to 1;

[0030] The magnetizing coil includes a helical magnetizing pole head 2 and a multi-turn wire 3 wound on the helical magnetizing pole head 2; the shape of the helical magnetizing pole head 2 is a helical shape formed by stretching a horizontal reference plane 4 along a cylindrical helical line , the horizontal datum plane 4 is an axisymmetric closed figure composed of two parallel line segments and two concentric arcs connected; the two parallel line segments are denoted as A and B respectively, and the two concentric arcs are respectively denoted as C and D, record the distance between line segment A and line segmen...

Embodiment 2

[0033] Embodiment two: if figure 1 , figure 2 , Figure 4 , Figure 5(a) ~ Figure 5(e) As shown, a magnetizing fixture for multi-pole magnetization of the outer circular surface of a ring magnet, including a circular tube-shaped substrate 1 with openings at both upper and lower ends and 2n magnetization coils, where n is an integer greater than or equal to 1;

[0034] The magnetizing coil includes a helical magnetizing pole head 2 and a multi-turn wire 3 wound on the helical magnetizing pole head 2; the shape of the helical magnetizing pole head 2 is a spiral shape formed by stretching a horizontal reference plane 4 along a cylindrical helix , the horizontal datum plane 4 is an axisymmetric closed figure composed of two parallel line segments and two concentric arcs connected; the two parallel line segments are denoted as A and B respectively, and the two concentric arcs are respectively denoted as C and D, record the distance between line segment A and line segment B as d...

Embodiment 3

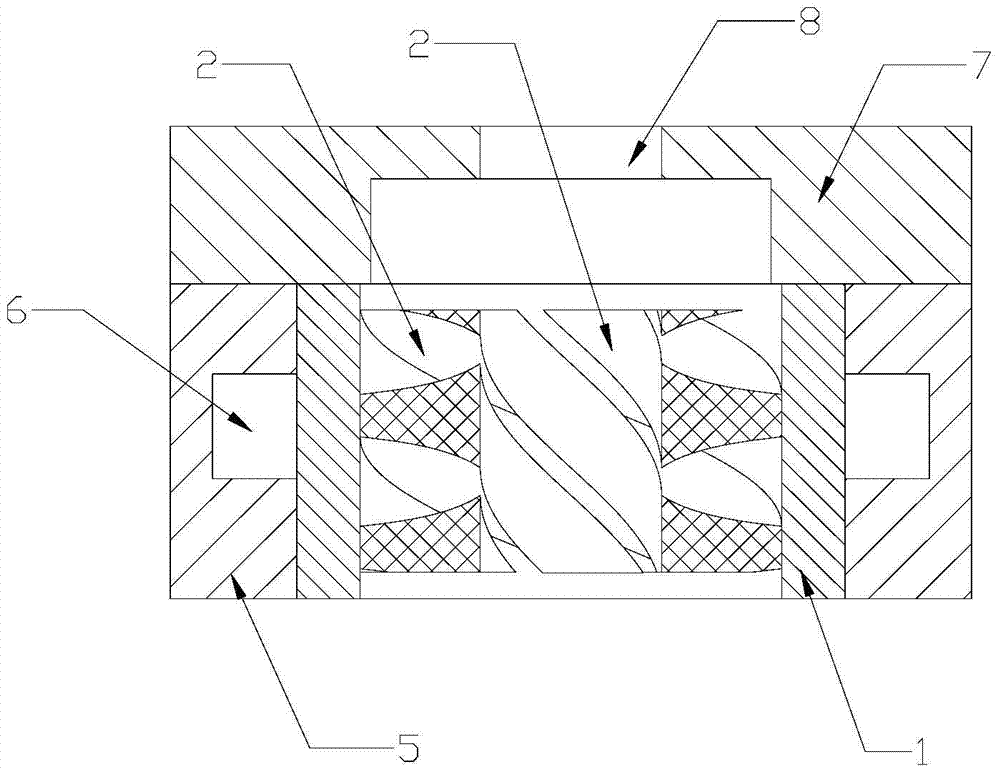

[0037] Embodiment three: as image 3 , Figure 4 , Figure 5(a) ~ Figure 5(e) As shown, a magnetizing fixture for multi-pole magnetization of the outer circular surface of a ring magnet, including a circular tube-shaped substrate 1 with openings at both upper and lower ends and 2n magnetization coils, where n is an integer greater than or equal to 1;

[0038] The magnetizing coil includes a helical magnetizing pole head 2 and a multi-turn wire 3 wound on the helical magnetizing pole head 2; the shape of the helical magnetizing pole head 2 is a helical shape formed by stretching a horizontal reference plane 4 along a cylindrical helical line , the horizontal datum plane 4 is an axisymmetric closed figure composed of two parallel line segments and two concentric arcs connected; the two parallel line segments are denoted as A and B respectively, and the two concentric arcs are respectively denoted as C and D, record the distance between line segment A and line segment B as d, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com