Patents

Literature

55results about How to "Reduce fill rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

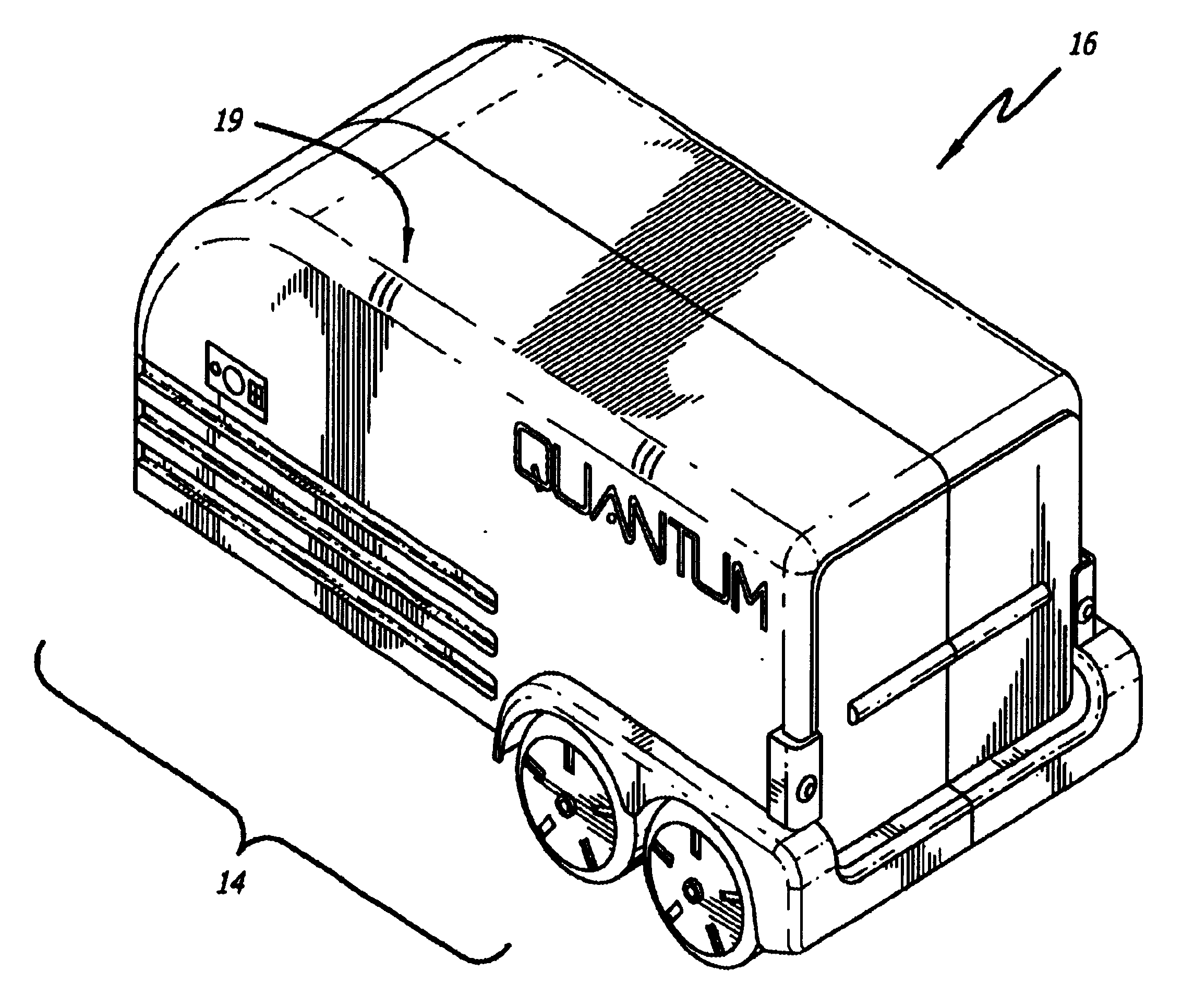

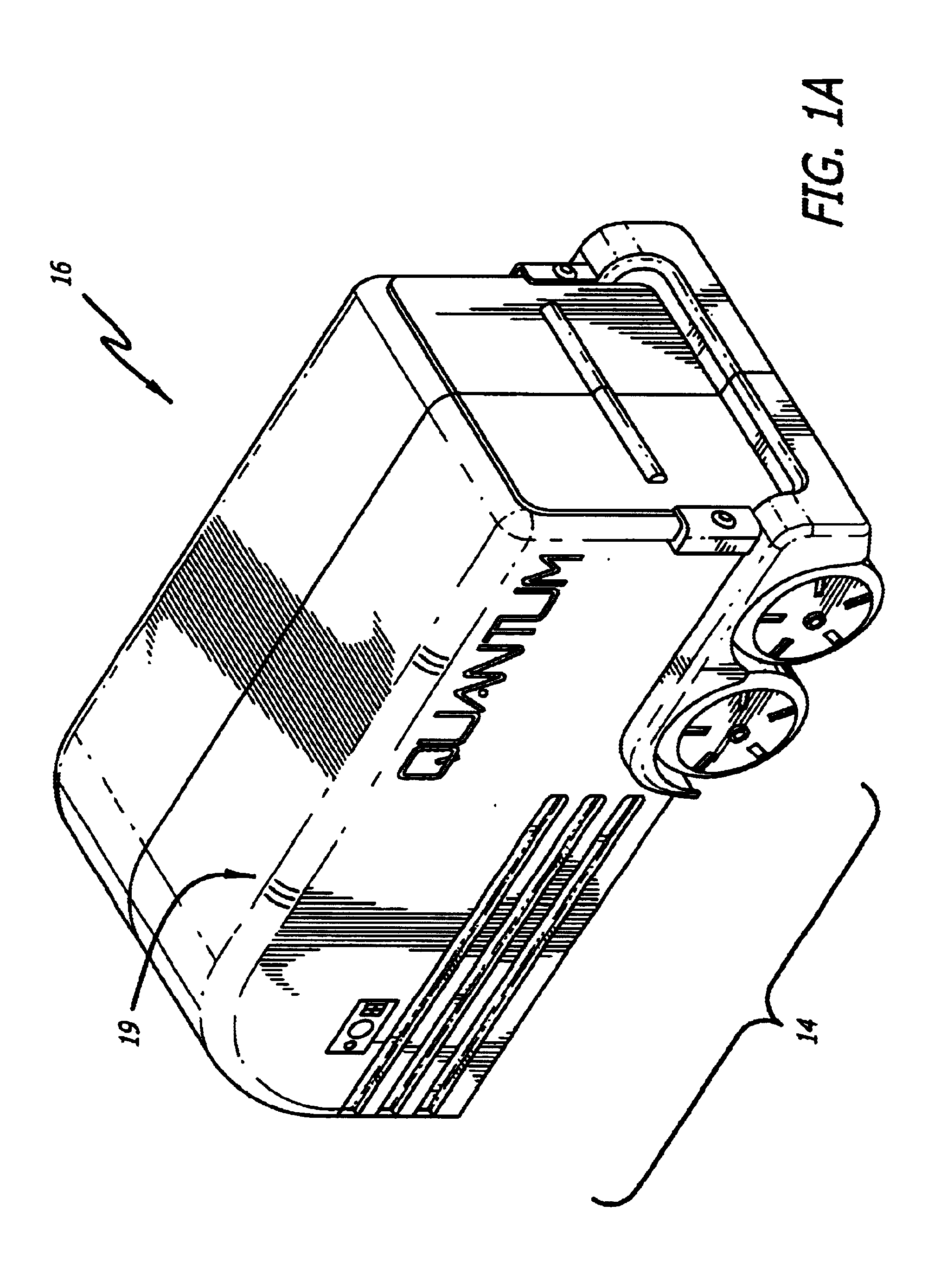

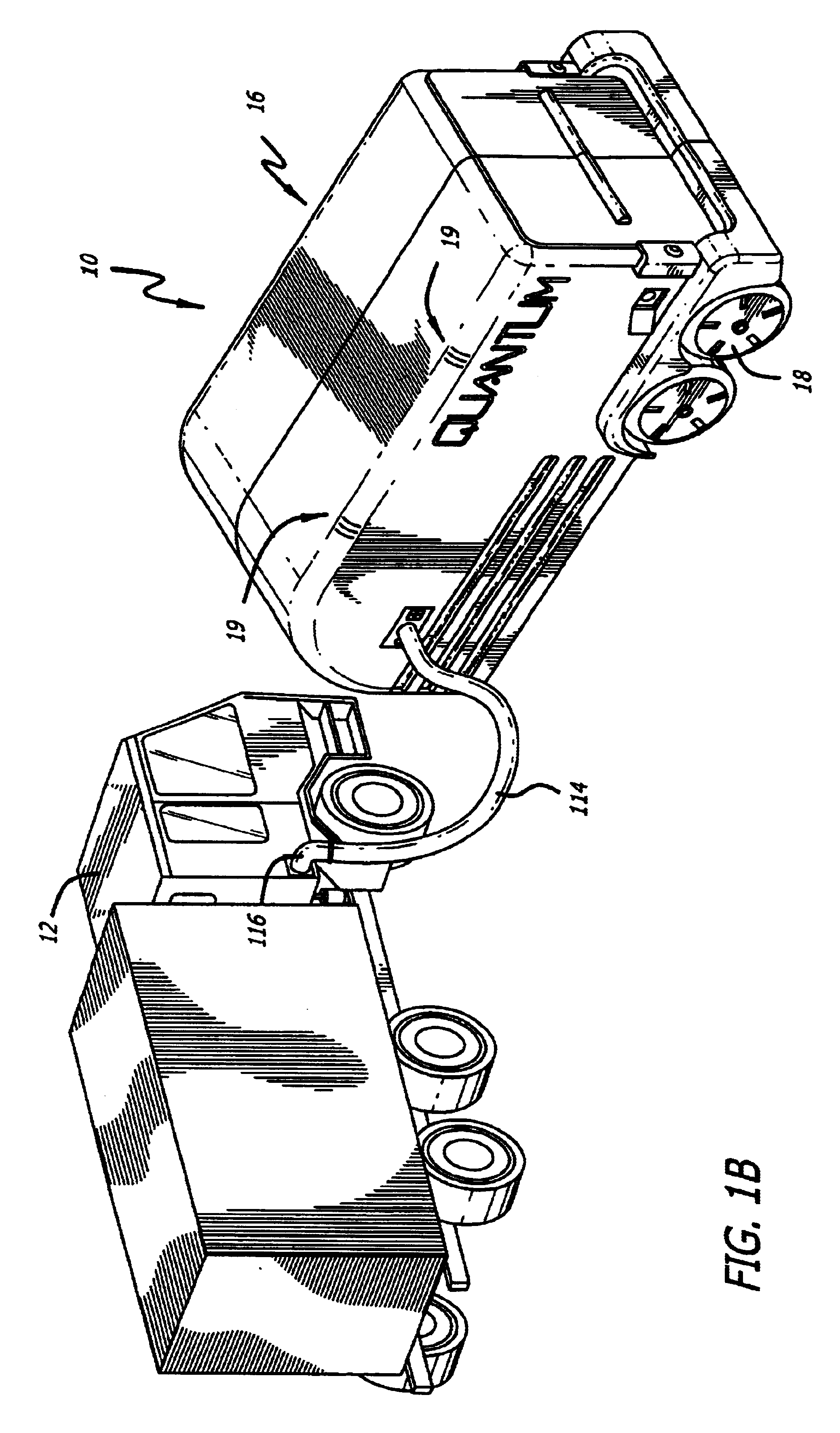

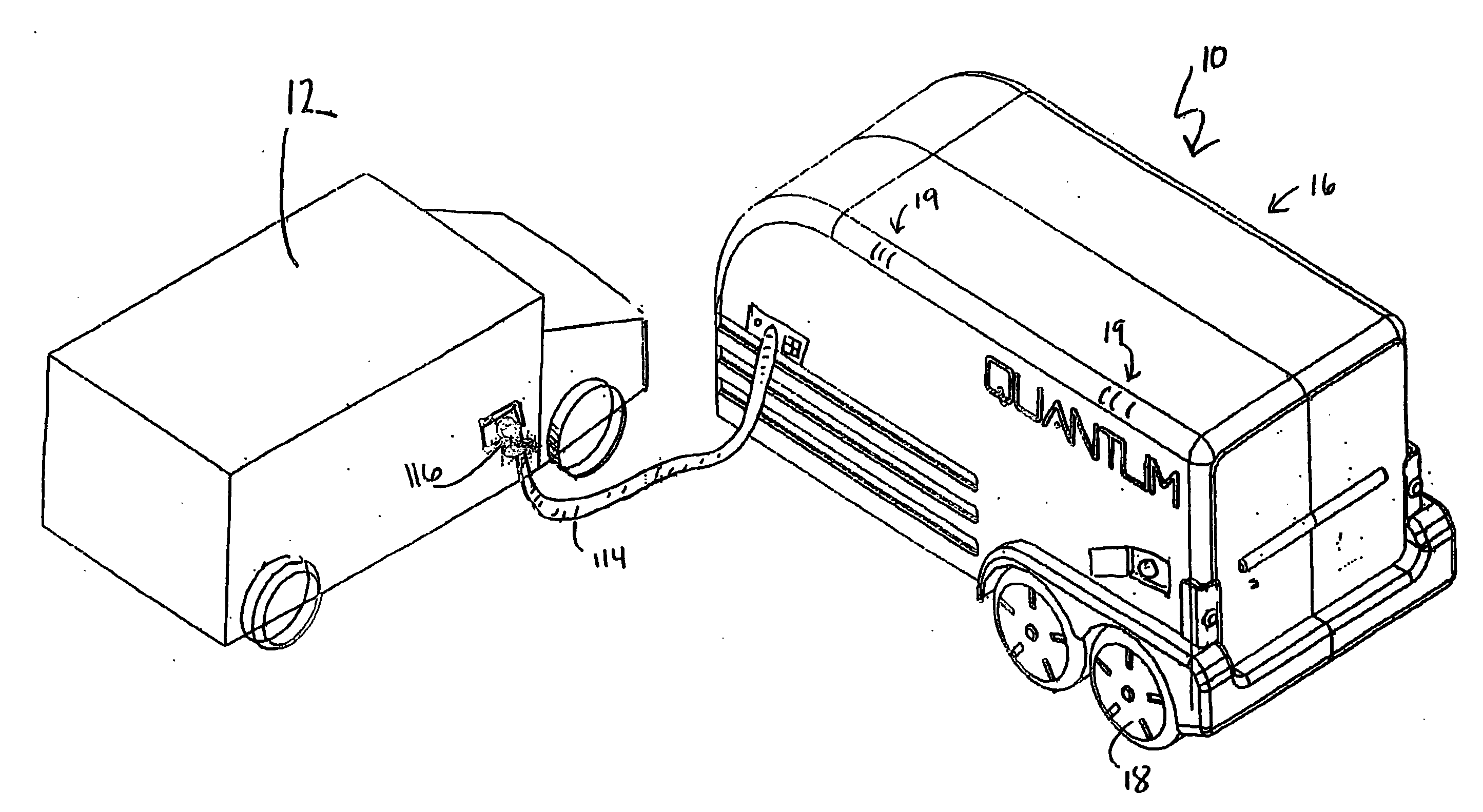

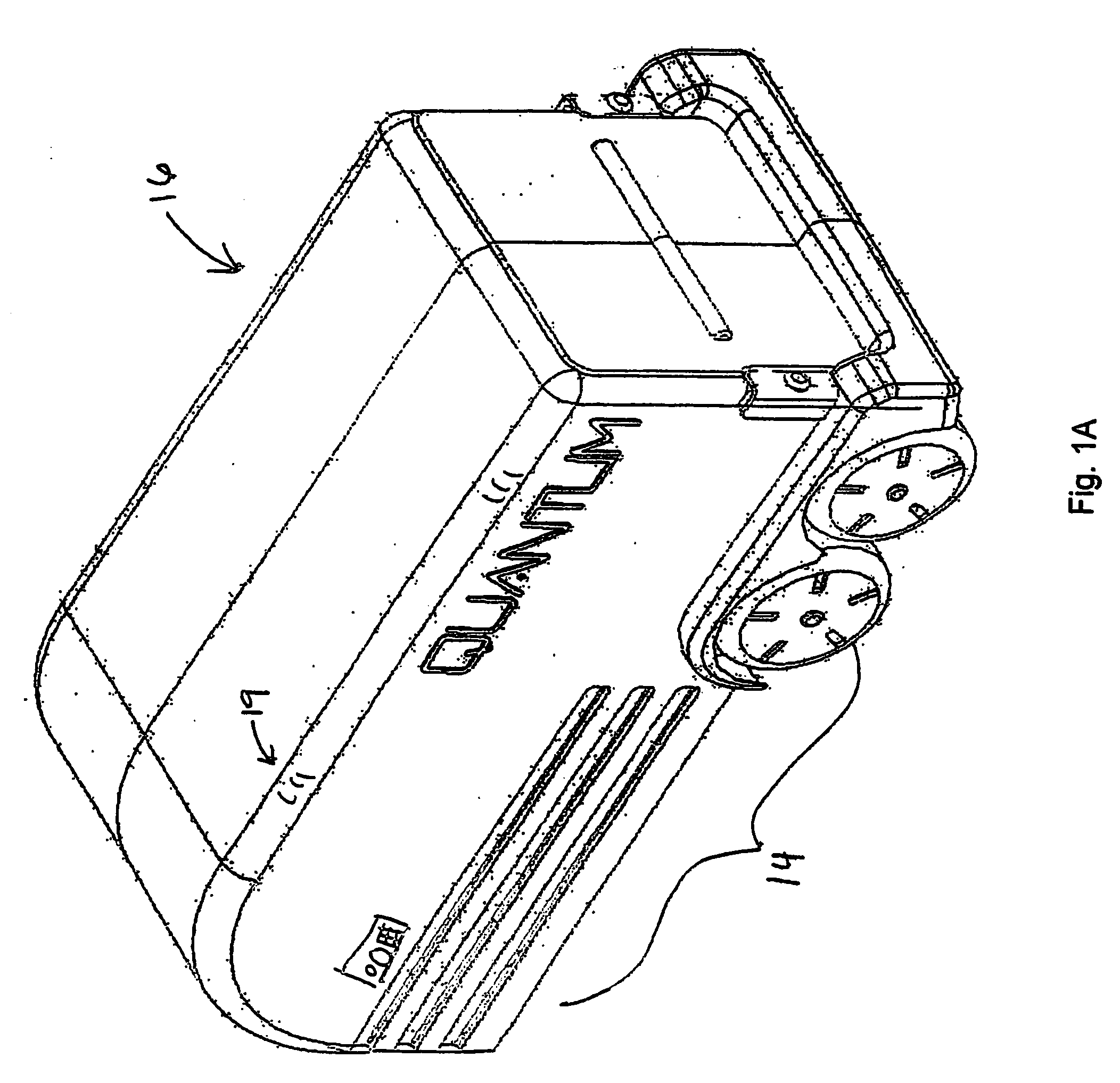

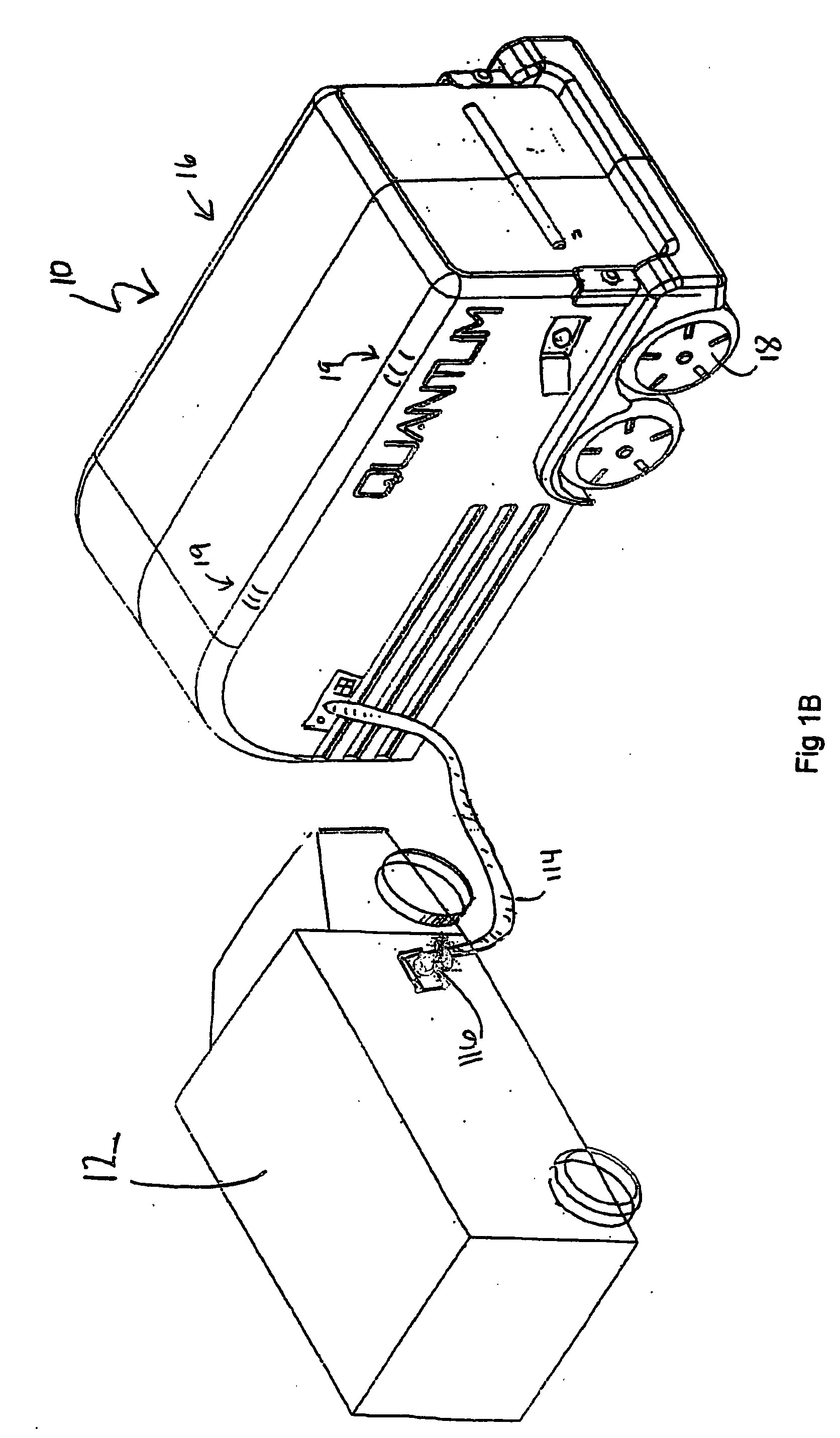

Transportable hydrogen refueling station

InactiveUS6755225B1Easy to monitorReduce riskTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within the refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

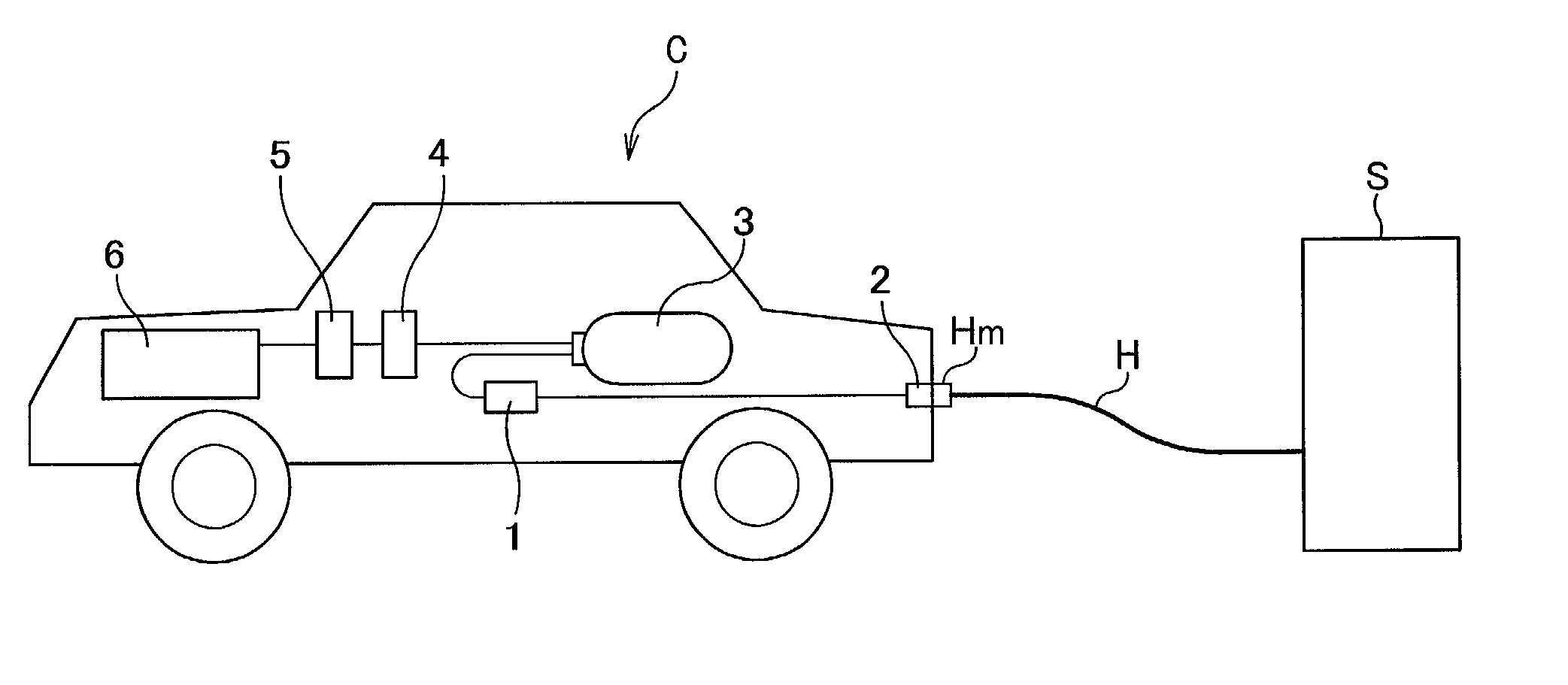

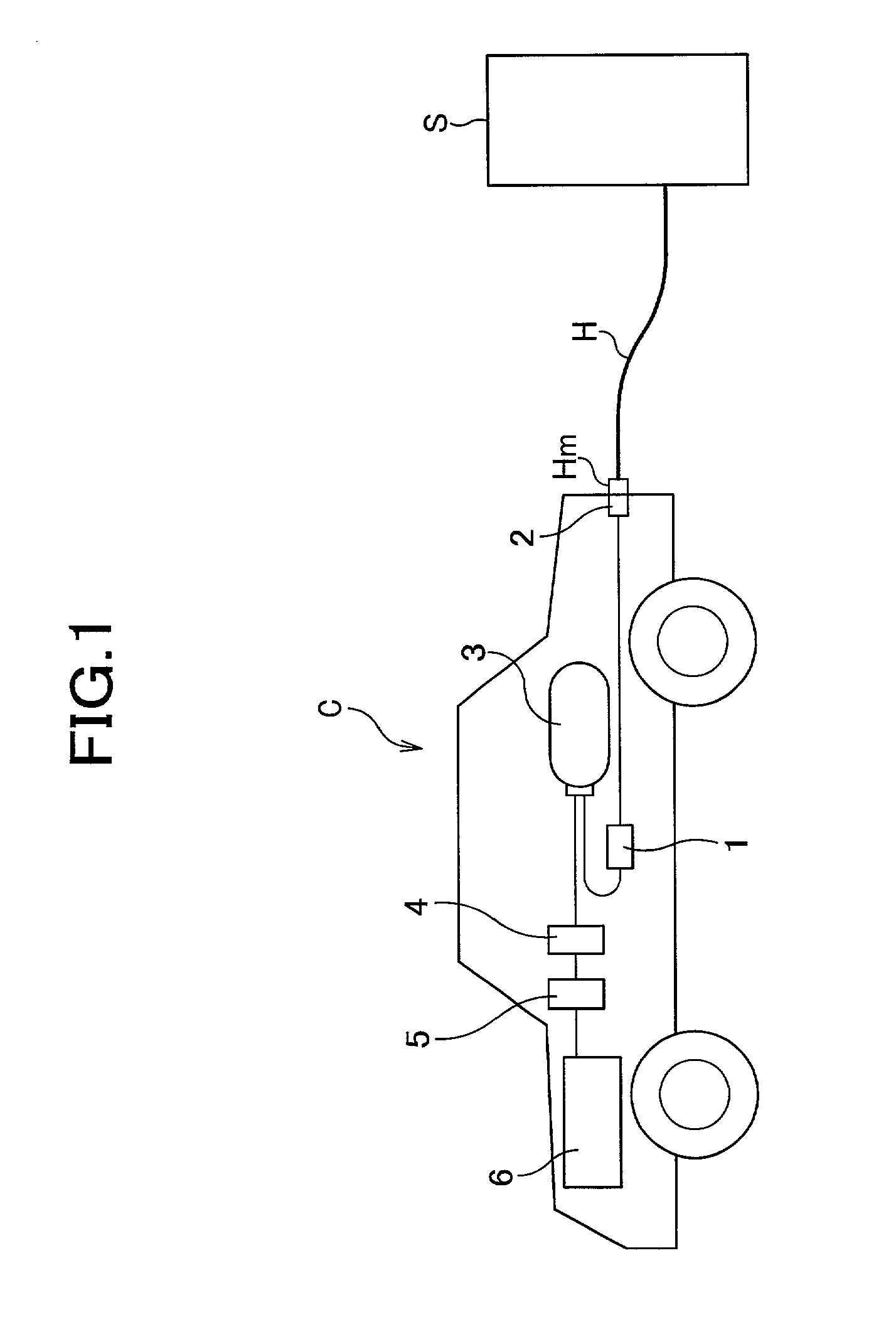

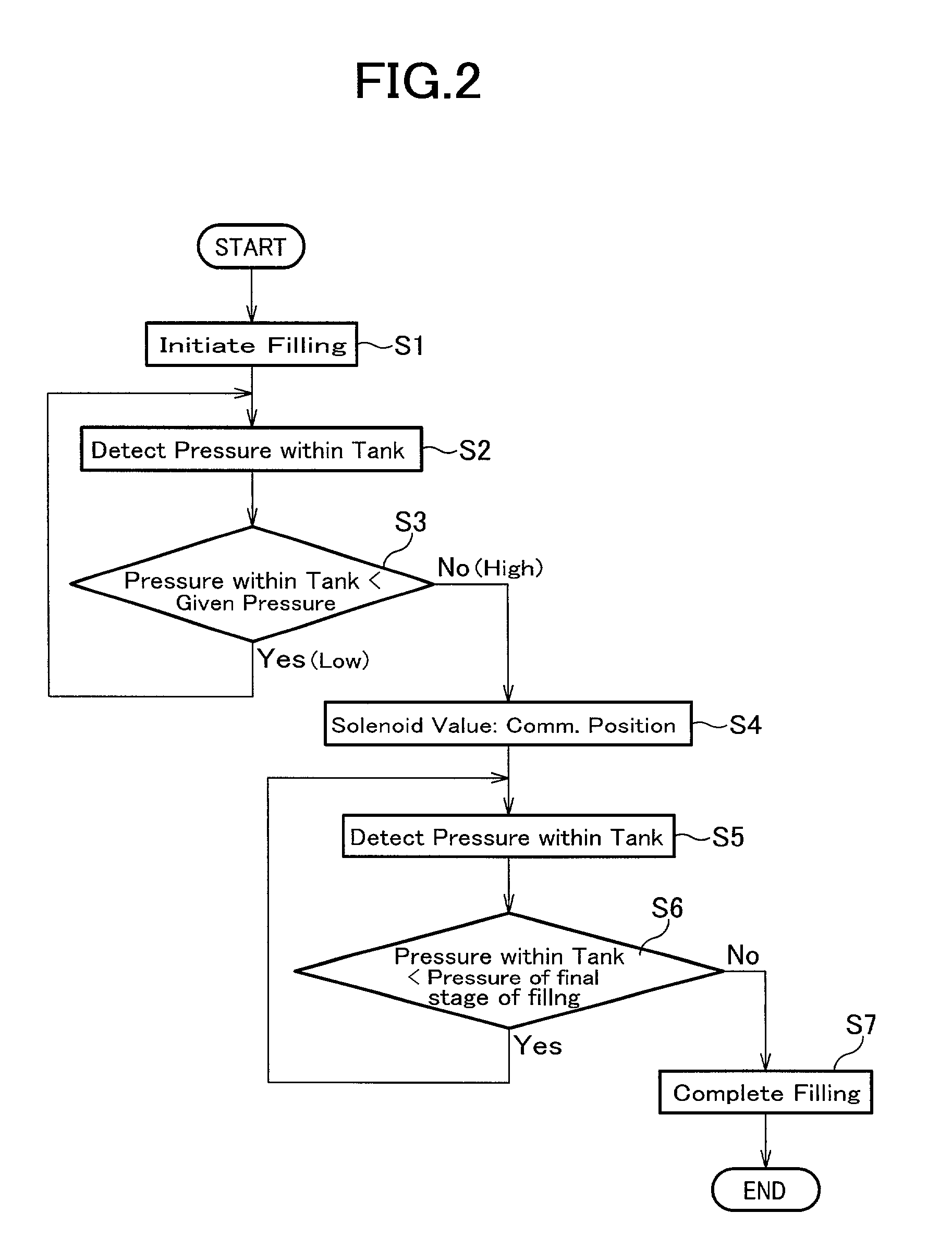

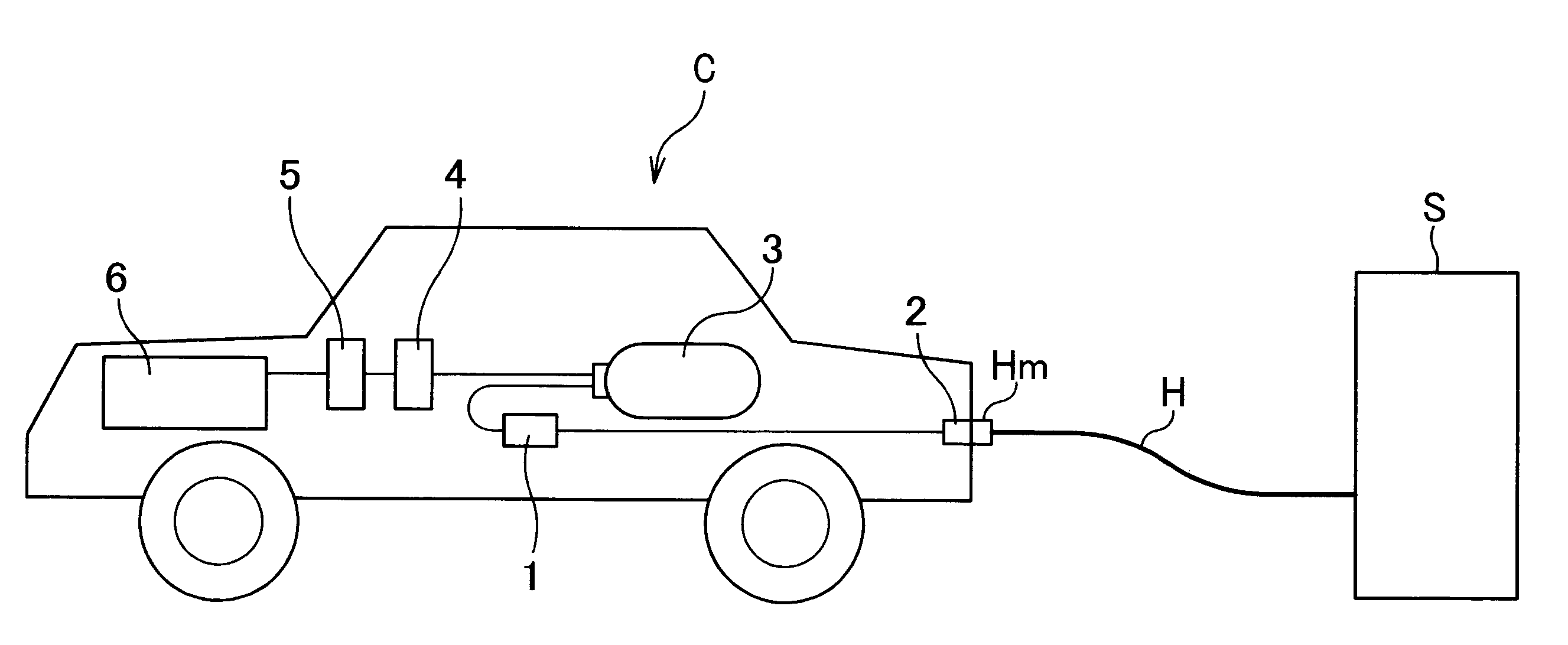

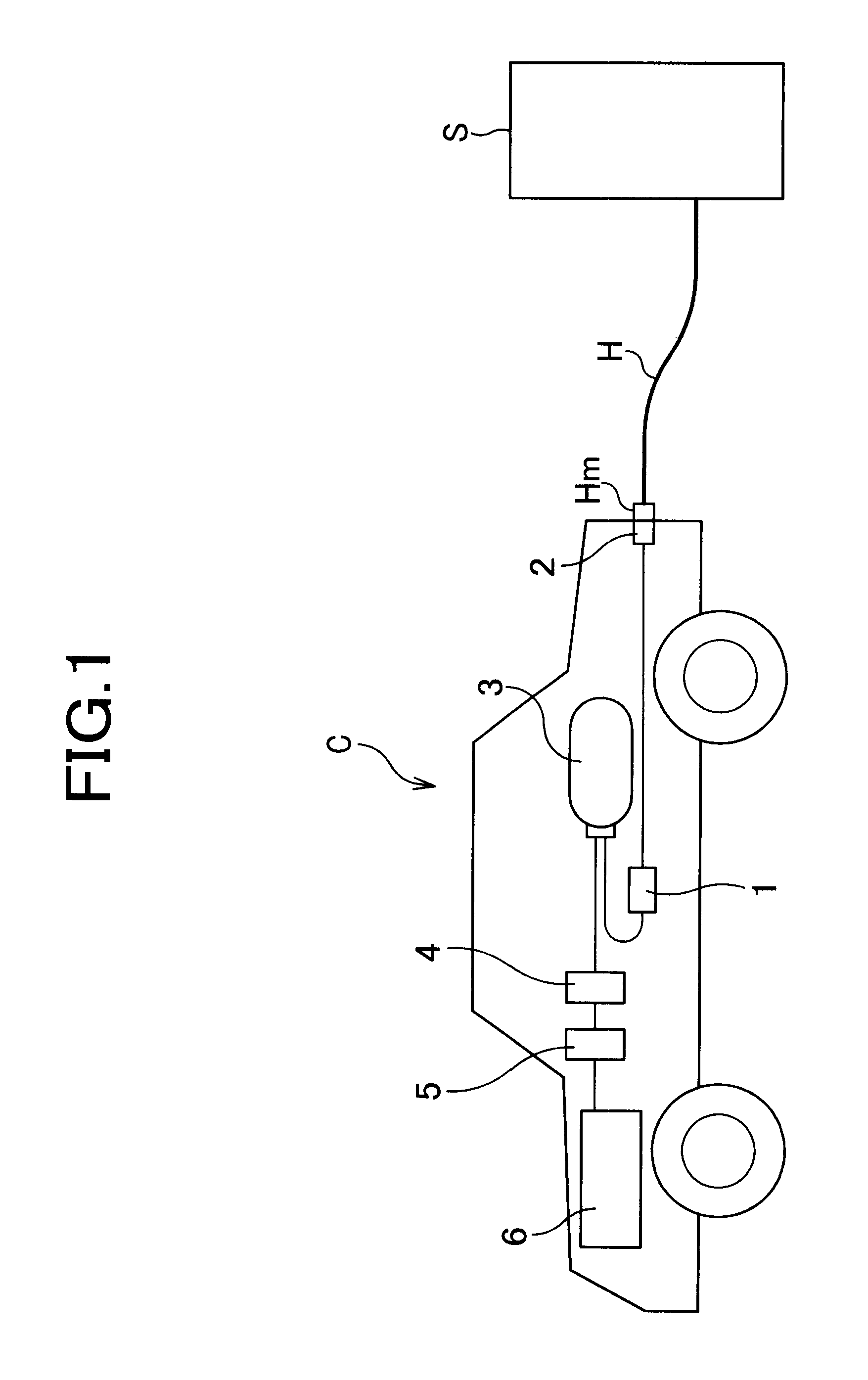

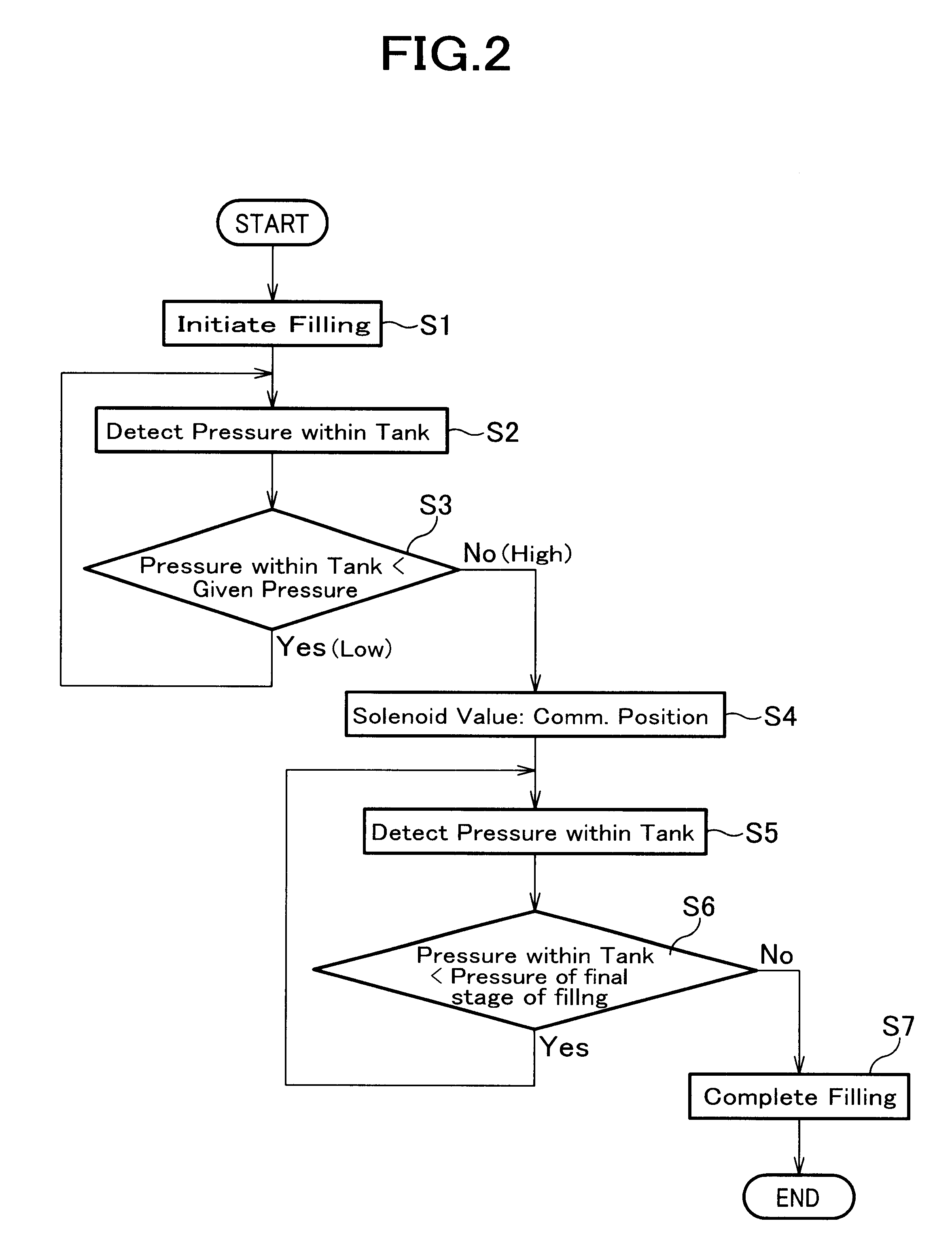

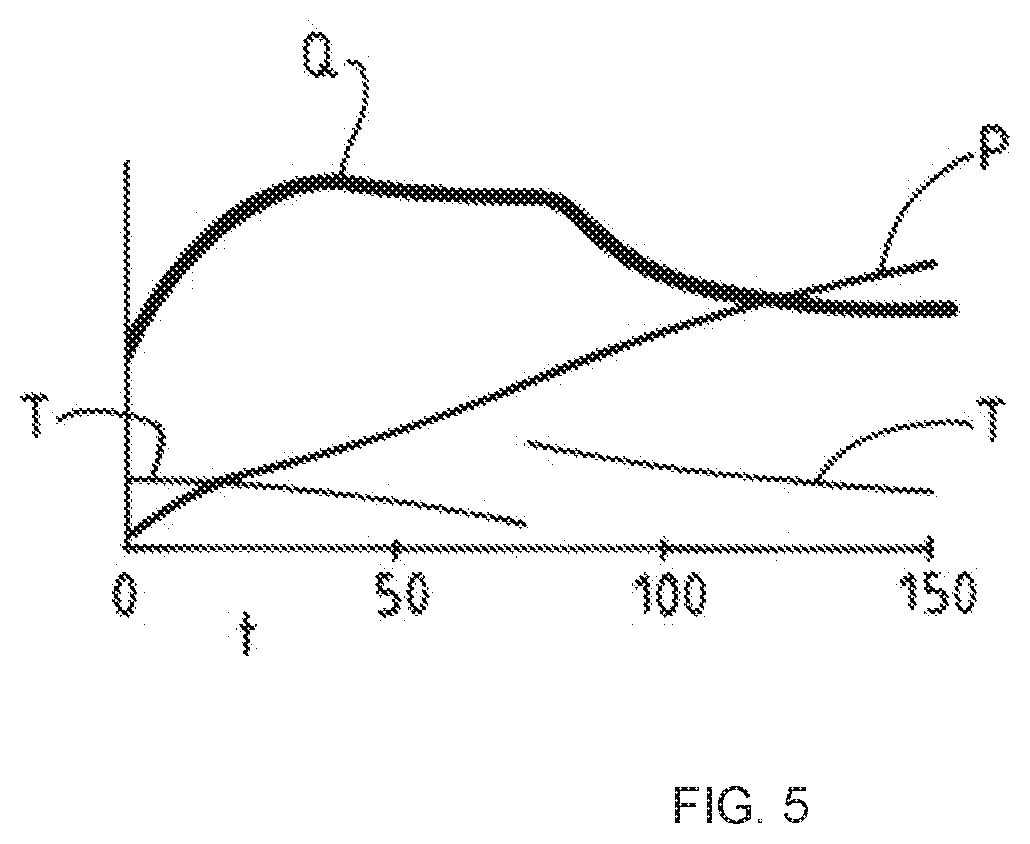

Apparatus and process for rapidly filling with hydrogen

InactiveUS20020014277A1Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

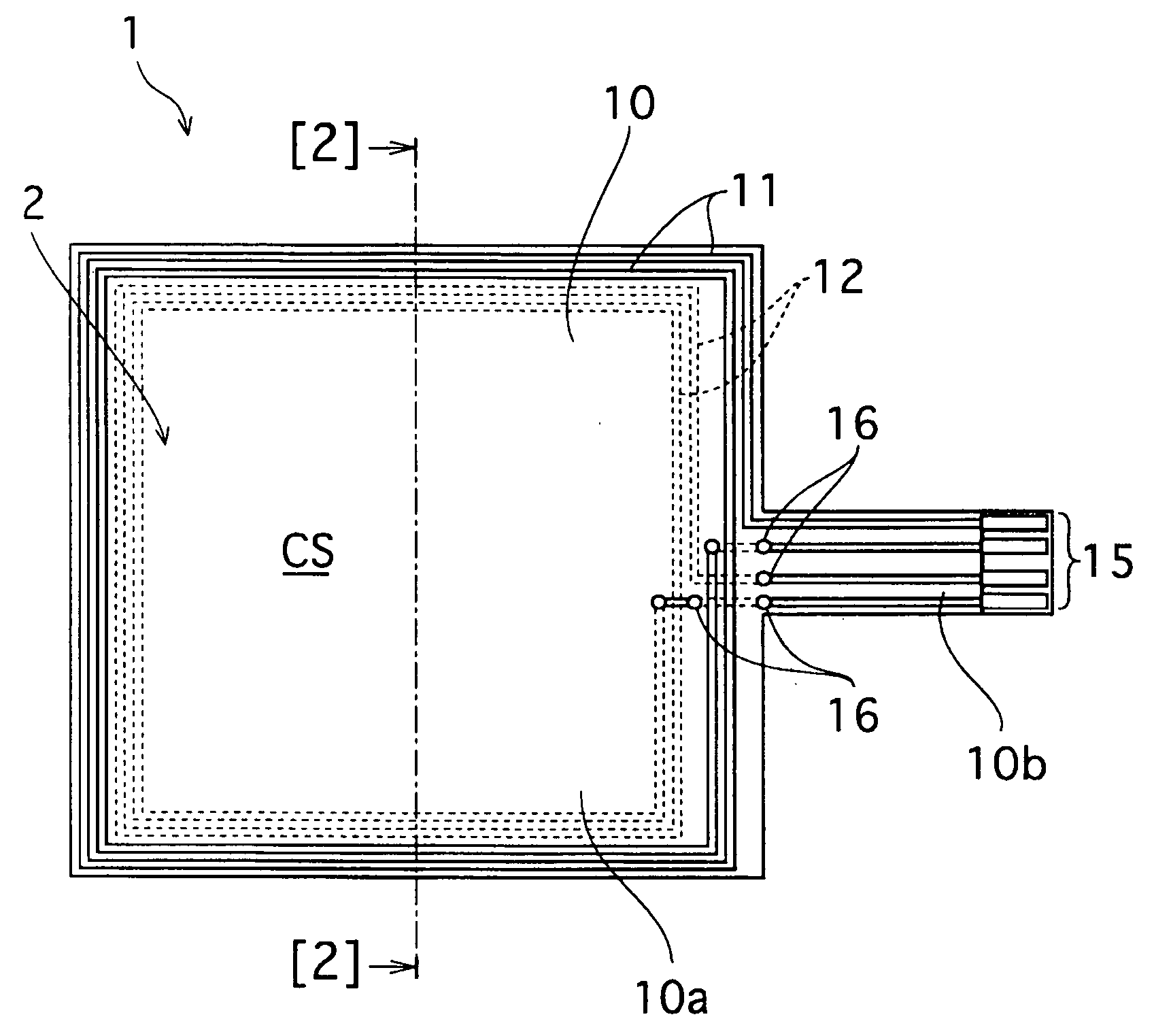

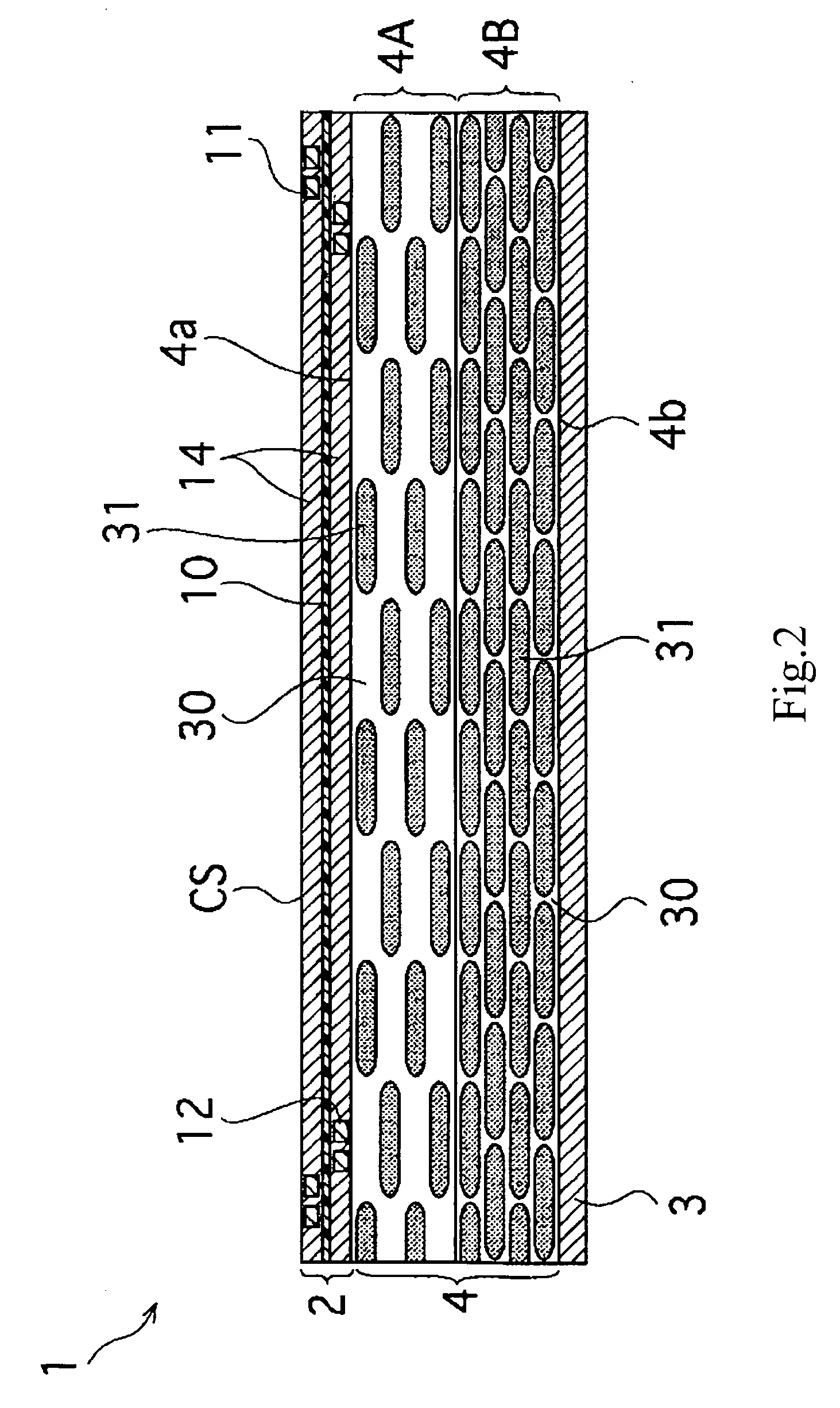

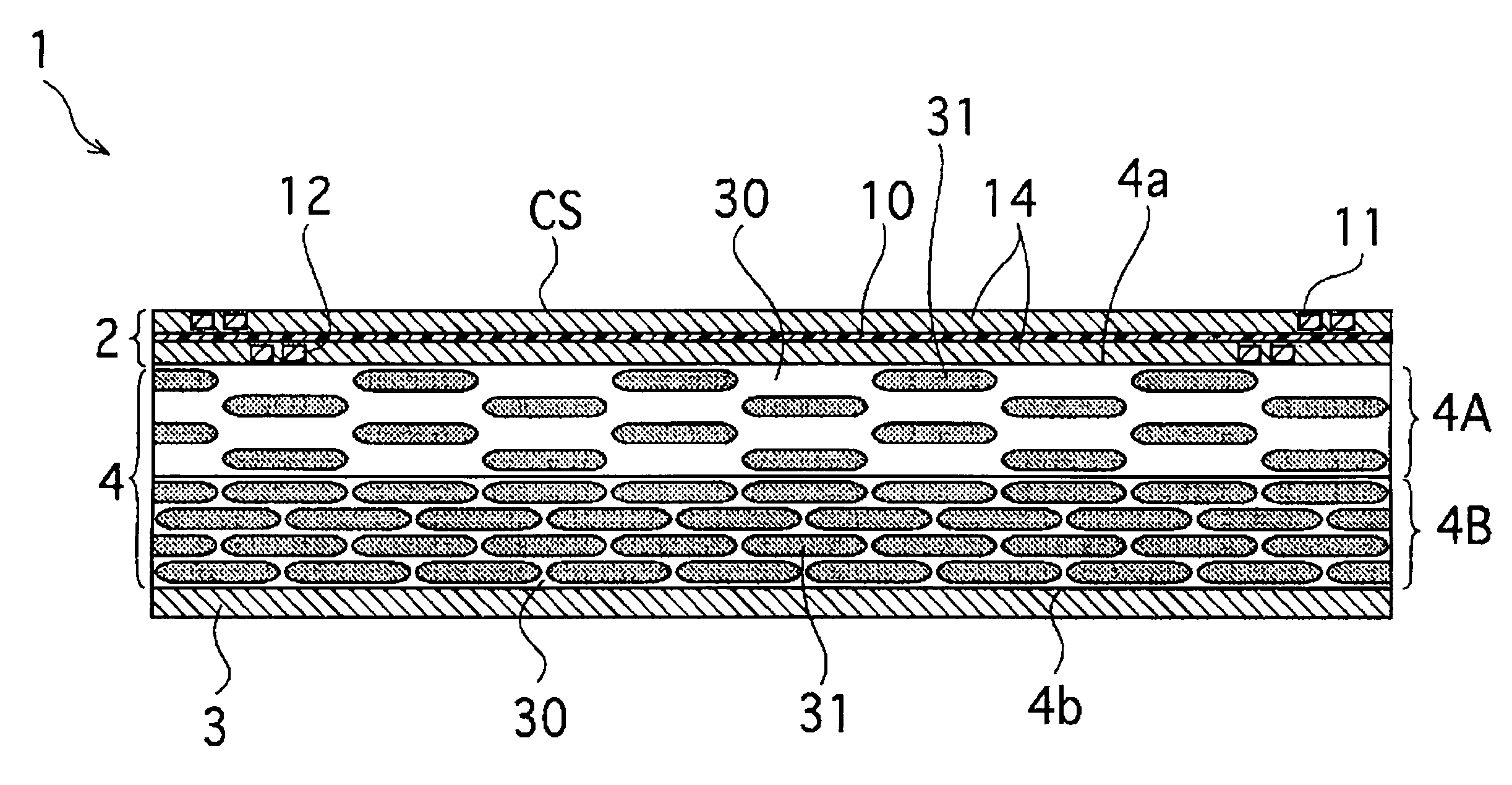

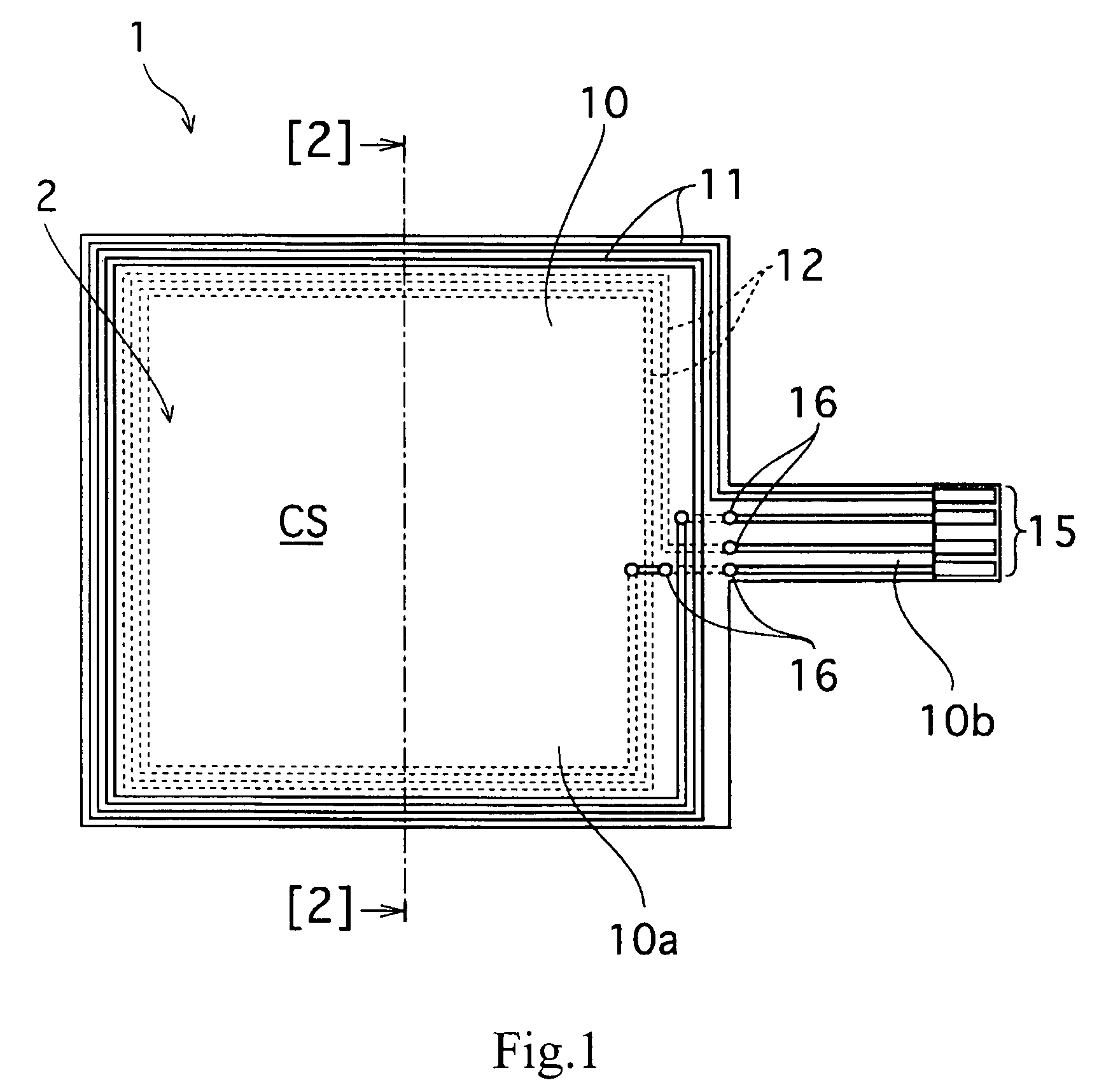

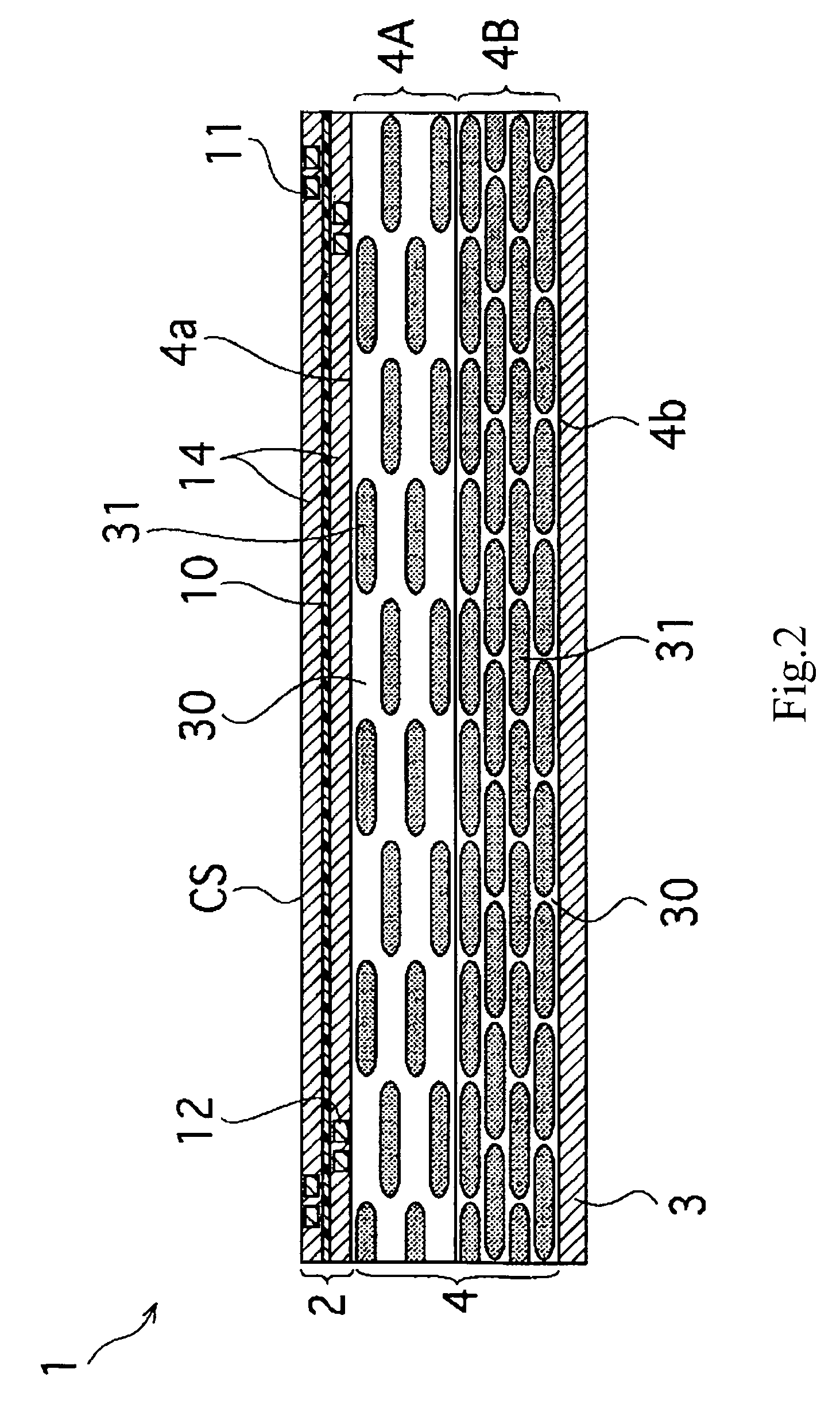

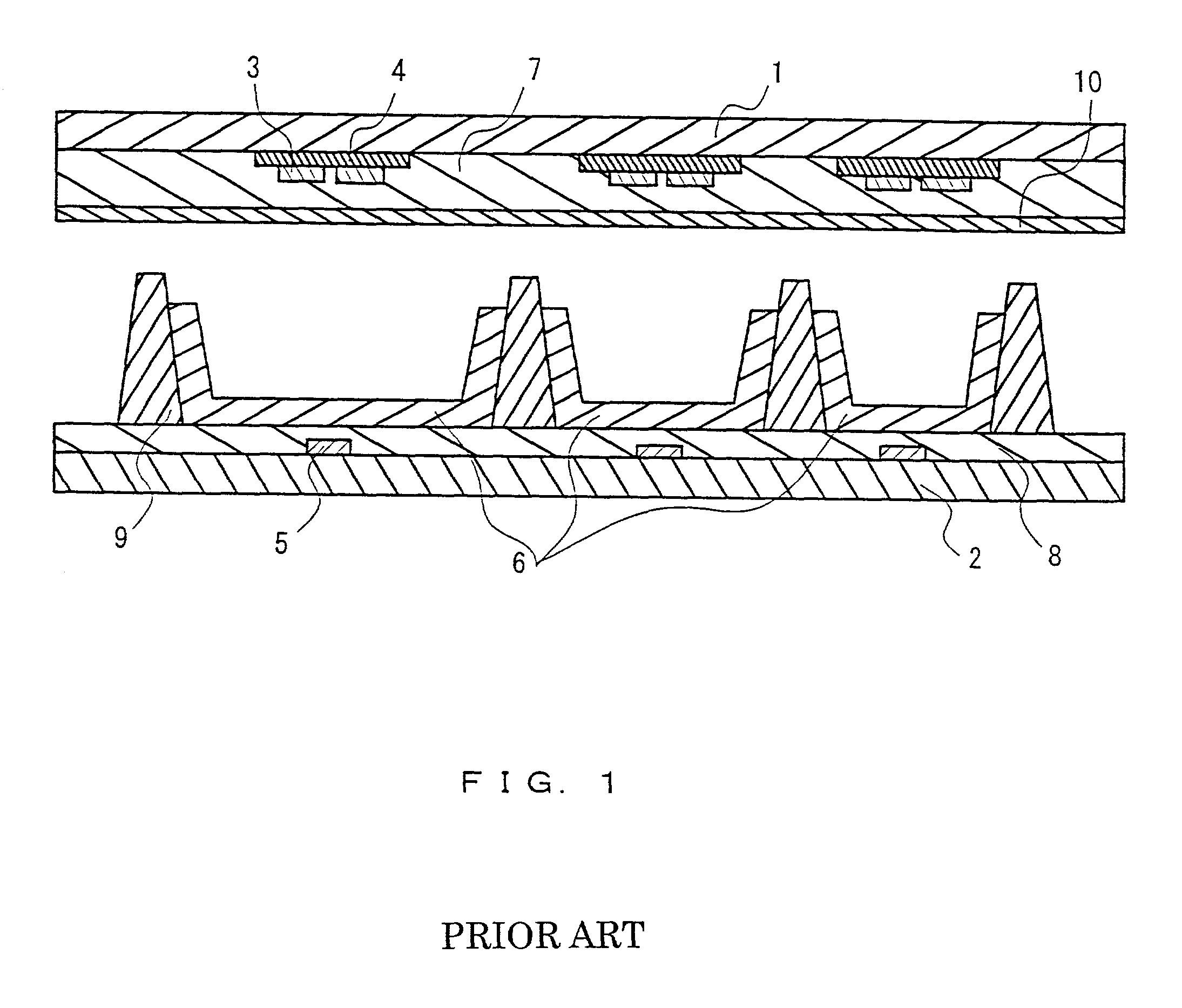

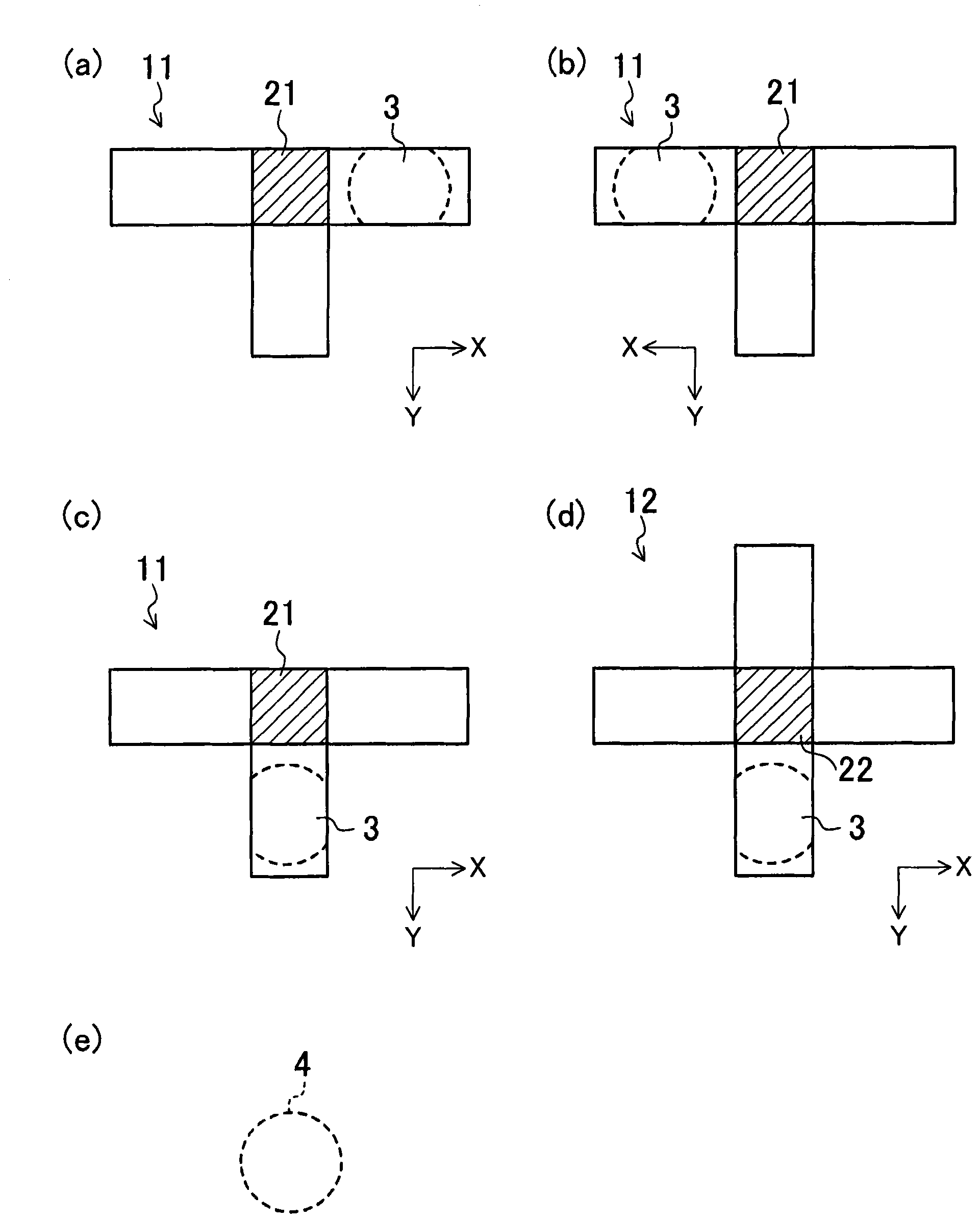

Magnetic core member, antenna module, and mobile communication terminal having the same

InactiveUS20070001921A1Enhancement of communication distanceCurrent be suppressLoop antennas with ferromagnetic coreAntenna supports/mountingsLayered structureMagnetic core

A magnetic core member, an antenna module, and a portable communication terminal having this, which have a configuration capable of satisfying enhancement of communication characteristics of antenna coils as well as their sufficient electromagnetic shielding function from a shield plate. A magnetic core member (4) is disposed between an antenna substrate having antenna coils (11), (12) formed therein and a conductive shield plate (3), and is formed by filling an insulating material (30) with a magnetic powder (31). The magnetic core member (4) has a two-layered structure including a first layer (4A) and a second layer (4B), thereby making a filling rate of the magnetic powder (31) in the first layer (4A) be lower than that of the magnetic powder (31) in the second layer (4B) so that a first surface (4a) on a side opposed to the antenna substrate (2) and a second surface (4b) on a side opposed to the shield plate (3) have magnetic properties different from each other.

Owner:SONY CORP

Apparatus and process for rapidly filling with hydrogen

InactiveUS6598624B2Increase heatIncrease rangeLiquid fillingGas handling applicationsFilling rateDelayed time

An apparatus for rapidly filling a hydrogen tank with a hydrogen gas comprises a hydrogen source; a hydrogen tank; a passage which connects the hydrogen source and said hydrogen tank; and a mechanism for varying the hydrogen-filling rate. The mechanism for varying the hydrogen-filling rate changes the hydrogen-filling rate depending upon the pressure within said hydrogen tank. The apparatus can suppress heat generation at the initial filling stage where the temperature is easily increased. Also, even if it takes longer time for increasing the pressure within the hydrogen tank at the initial filling state, the delayed time can be caught up and, the apparatus and the process of the present invention can totally attain a rapidly filling with hydrogen.

Owner:HONDA MOTOR CO LTD

Transportable hydrogen refueling station

InactiveUS20060180240A1Reduce riskEasy to monitorTank vehiclesGas handling applicationsHigh pressureGaseous hydrogen

A portable hydrogen refueling stations which can dispense gaseous hydrogen from one or more internal high pressure tanks. The refueling station can be refilled with a lower pressure hydrogen gas feed and then compressed for storage within a refueling station.

Owner:QUANTUM FUEL SYST TECH WORLDWIDE INC

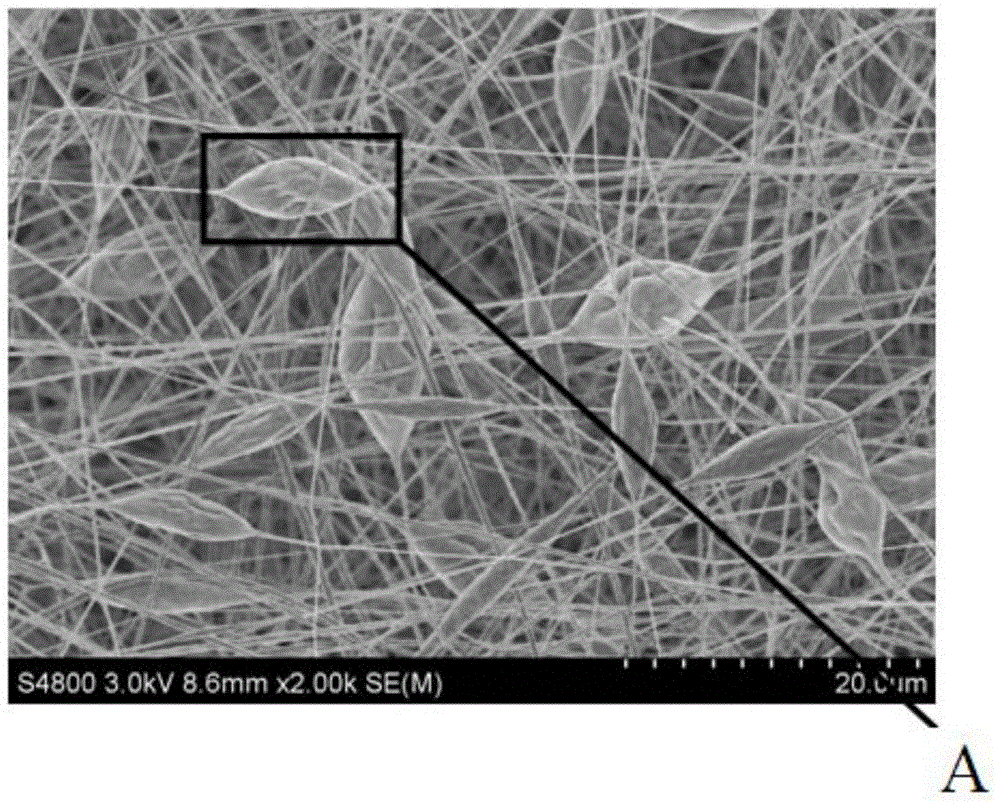

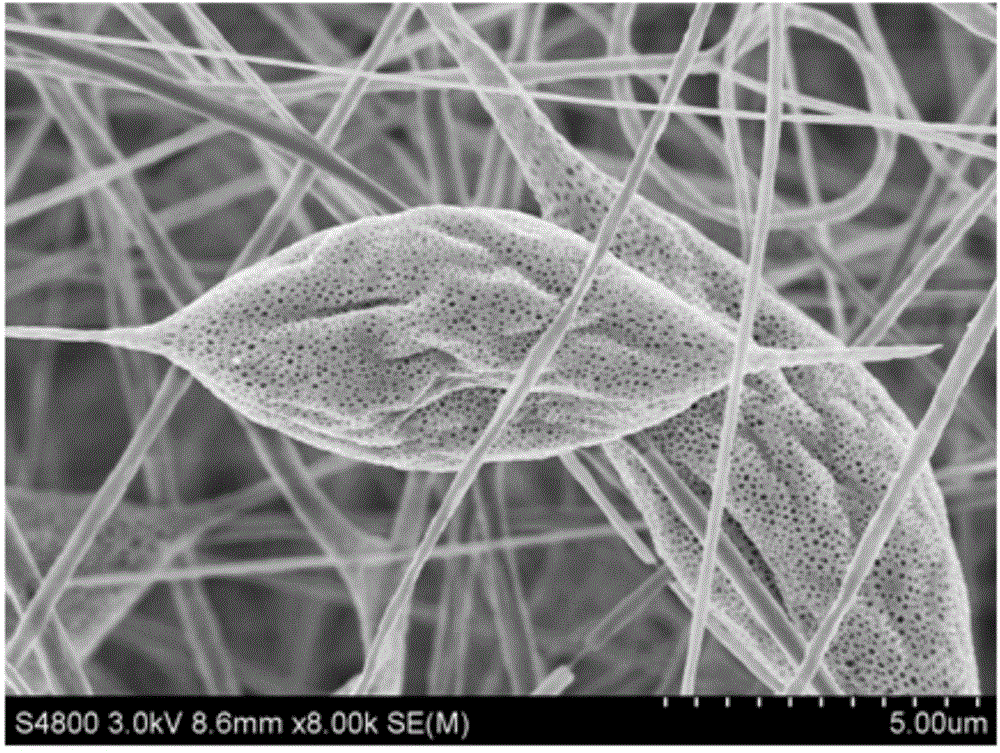

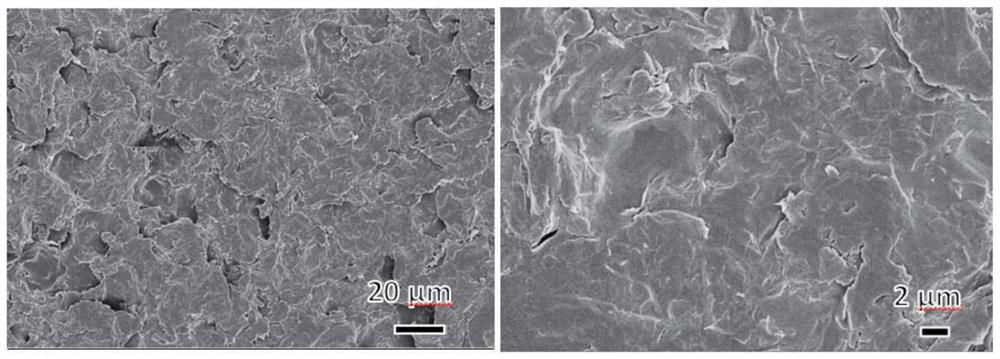

Bead-like porous PLA (Poly Lactic Acid) nano fiber as well as preparation method and application thereof

ActiveCN103952783AReduce fill rateImprove air filtration efficiencySemi-permeable membranesDispersed particle separationFiberAir filtration

The invention discloses a bead-like porous PLA (Poly Lactic Acid) nano fiber which is characterized in that pearls in the bead-like porous PLA nano fiber accounts for 8.0-22% of the area of the bead-like porous PLA nano fiber and the geometrical dimensions of stringed beads are as follows: the pearls have the mean area of 10-80mu m <2> and the length-width ratio of 2-4; the average diameter of fibers for connecting the beads is 100-800nm; the surface pore coverage rate of the beads is 3-30%. Due to the bead-shaped porous structure and the nano porous fibers for connecting the beads, the bead-like porous PLA nano fiber has high specific surface area, and high surface energy is provided for absorbing micro particles; meanwhile, the bead-like porous PLA nano fiber is beneficial to gas circulation, the air filtration resistance is reduced, especially the air filtratione efficiency for micro particles with the mass median diameter of 75nm is 99.9-99.999%, and the average filtration resistance is 120-360 Pa. The invention also provides a preparation method of the bead-like porous PLA nano fiber and application of the bead-like porous PLA nano fiber serving as an air filtration film.

Owner:江苏正大易方科技有限公司

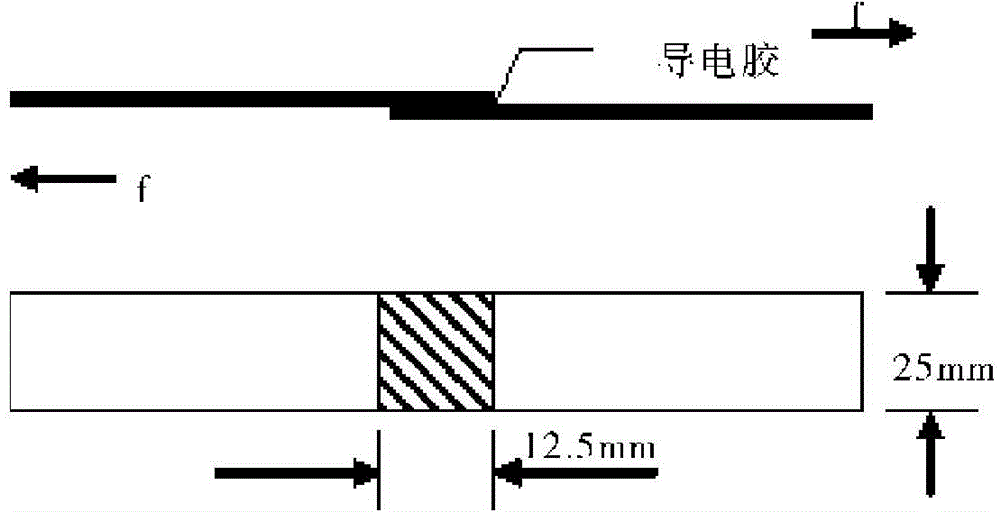

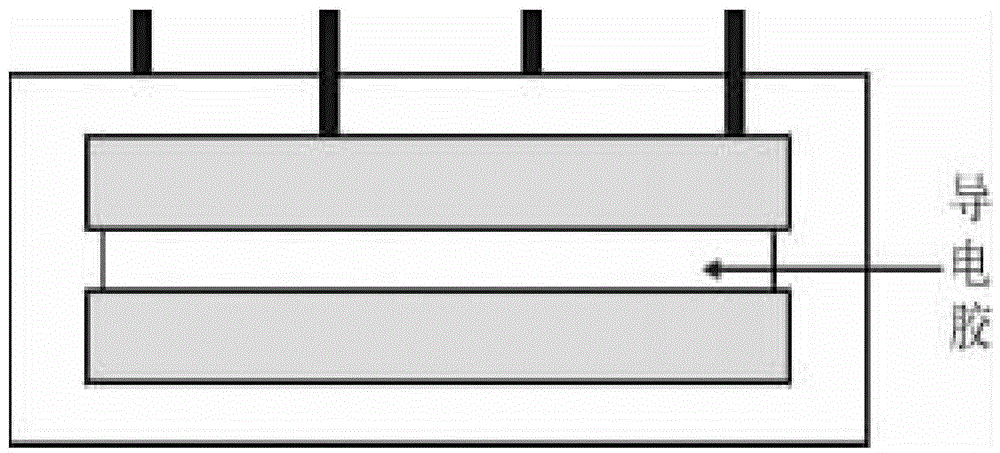

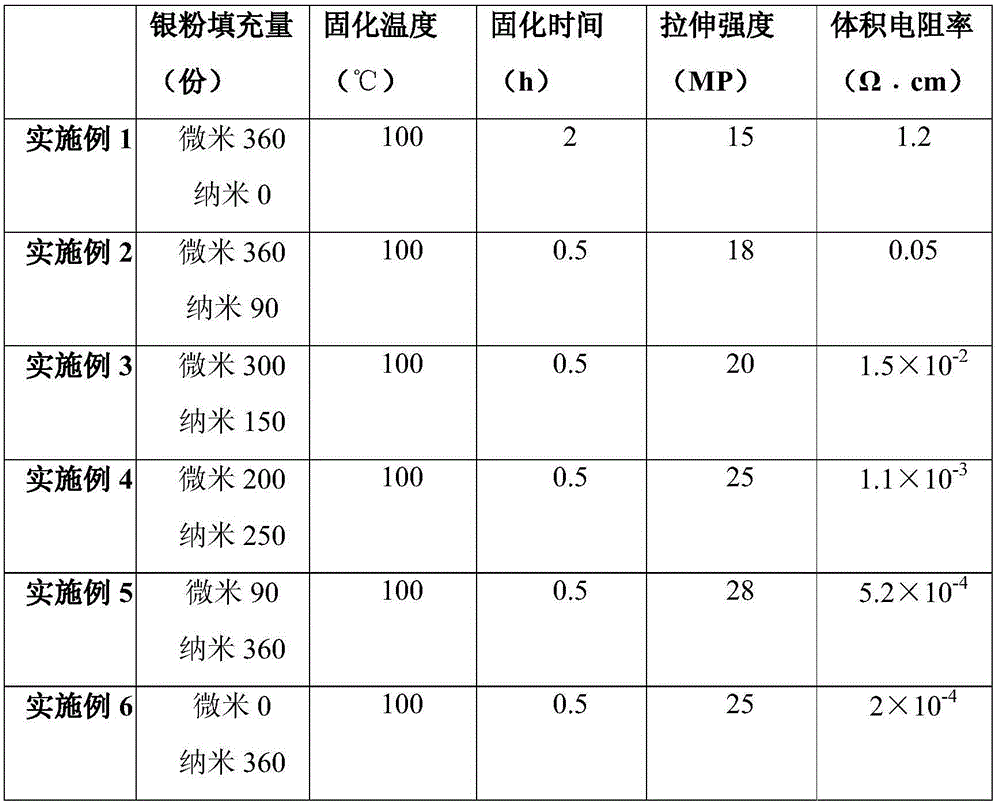

Medium temperature curing high-performance conductive silver adhesive, preparation method thereof and application

ActiveCN104449455AImprove conductivityImprove thermal conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesive

The invention belongs to the technical field of nano-materials, and discloses a medium temperature curing high-performance conductive silver adhesive, a preparation method thereof and an application. The method includes the steps: adding 0-360 parts of micron silver powder and 0-360 parts of linear nano-silver into 100 parts of epoxy resin, and sufficiently and uniformly stirring the silver powder, the linear nano-silver and the epoxy resin to obtain silver powder dispersion liquid; sequentially adding 10-50 parts of epoxy resin latent curing agents, 1-5 parts of epoxy resin accelerants, 5-20 parts of epoxy resin active diluents and 0.5-2 parts of epoxy resin storage stabilizers into the silver powder dispersion liquid at the low temperature of 5-20 DEG C, and pumping bubbles by a vacuum pump under the action of stirring after uniform stirring to obtain the medium temperature curing high-performance conductive silver adhesive.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

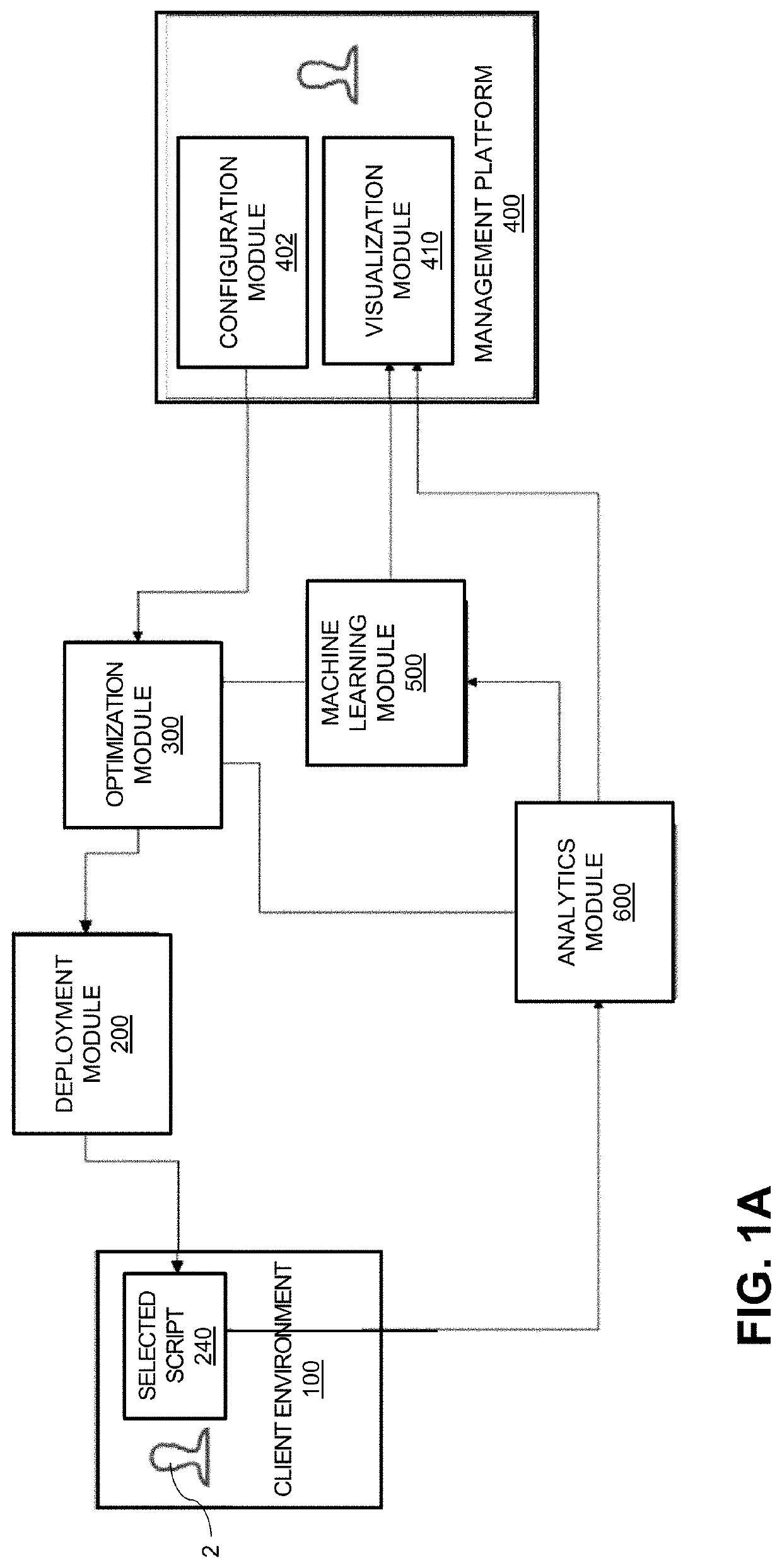

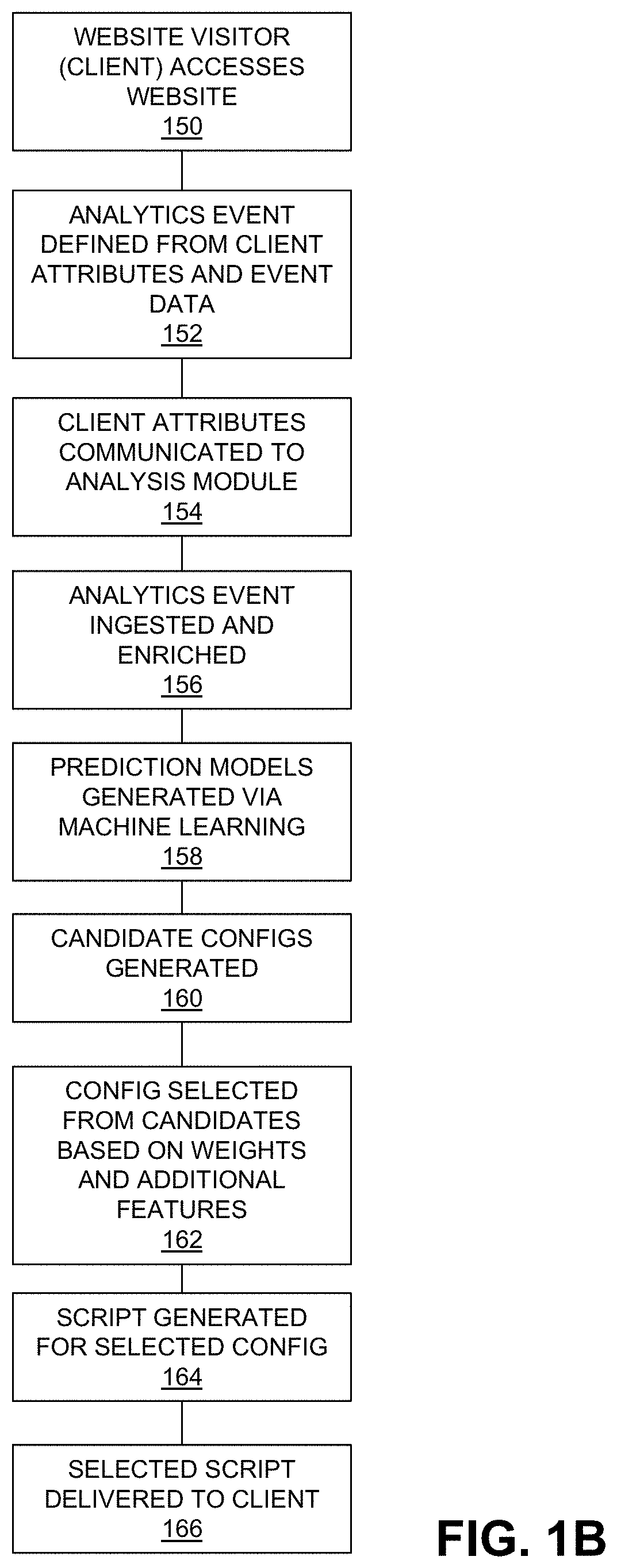

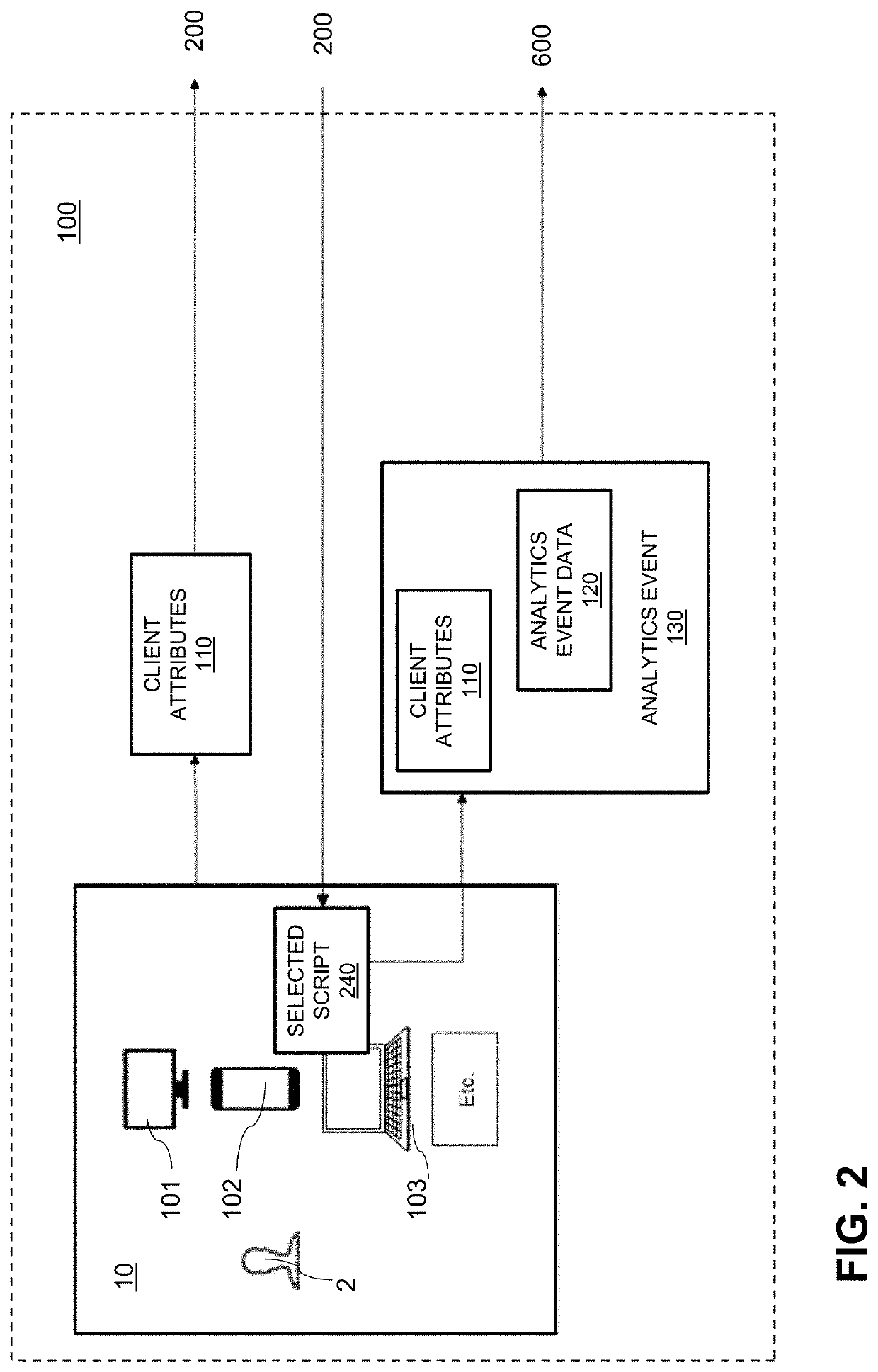

Digital advertising platform with demand path optimization

ActiveUS20200019983A1Optimization pathImprove efficiencyMathematical modelsAdvertisementsWeb siteDigital advertising

A digital advertising system includes at least one processor configured to execute a plurality of functional modules including an analytics module to receive and analyze client attributes associated with a website visitor and a requested website to define an analytics event. The analytics module ingests and enriches data within the analytics event and provides it to a machine learning module that generates prediction models for potential bids. A management platform receives the bidding prediction and generates candidate configs. An optimization module receives the candidate configs and applies weights and additional features to select a config and generate an optimized script for the selected config. A deployment module receives the optimized script and delivers the script to the website visitor.

Owner:PUBWISE LLLP

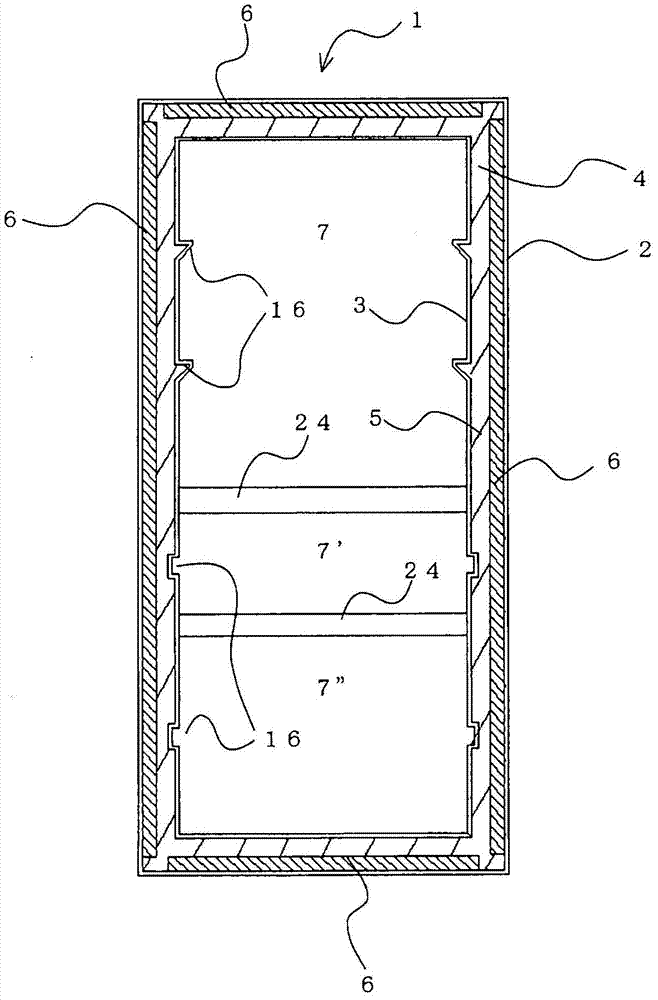

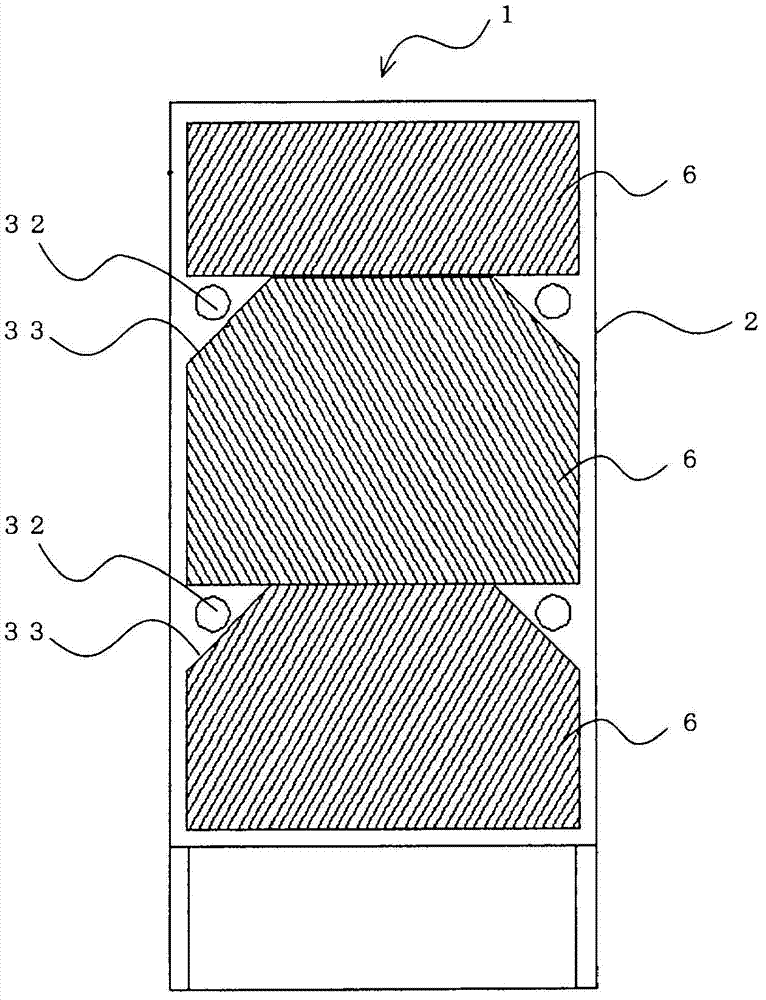

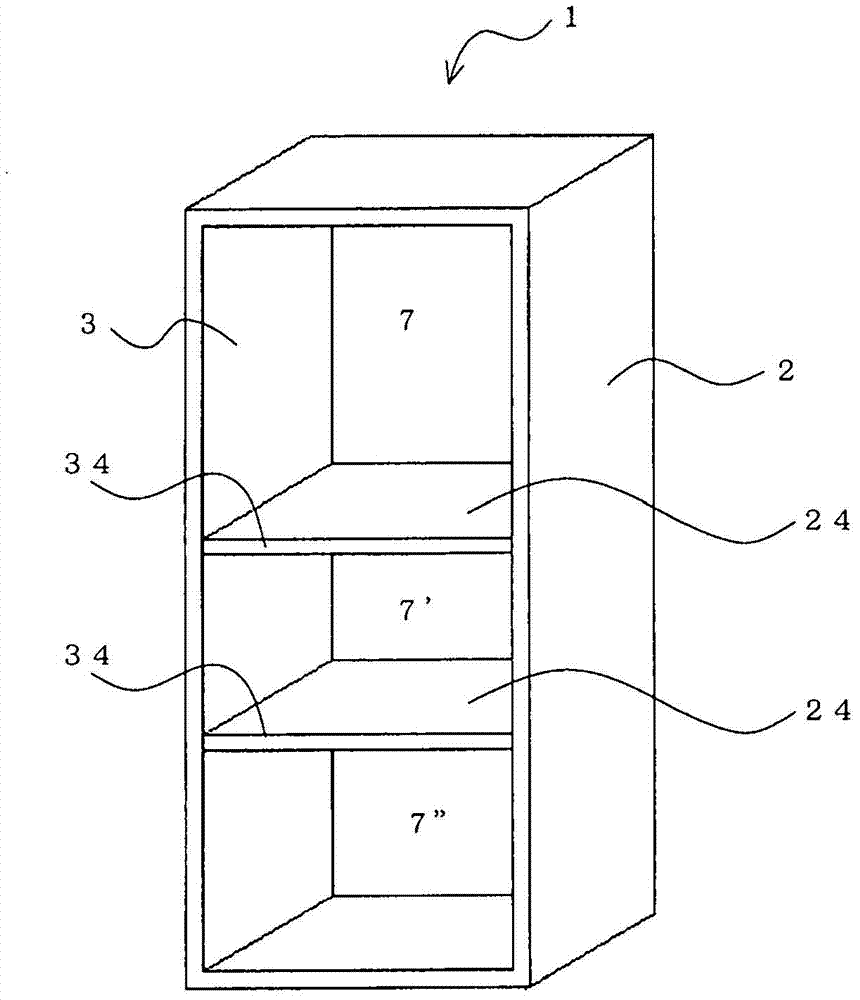

Heat insulating box, and refrigerator and hot-water storage device each comprising heat insulating box

InactiveCN103363764AAdequate insulationReduce wall thicknessThermal insulationInsulation for cooling apparatusWater storageFill factor

A heat insulating box (1) is provided with: an outer box (2); an inner box (3); and a vacuum heat insulating material (6) and hard urethane foam (5), which are filled into the space (4) formed between the outer box (2) and the inner box (3). The filling factor of the vacuum heat insulating material (6) in the space (4) is 40% to 80%, the ratio of the area of the vacuum heat insulating material (6) to the area of the surface of the outer box is 60% or more, and the bending elastic modulus of the hard urethane foam (5) is 15.0 MPa or higher.

Owner:MITSUBISHI ELECTRIC CORP

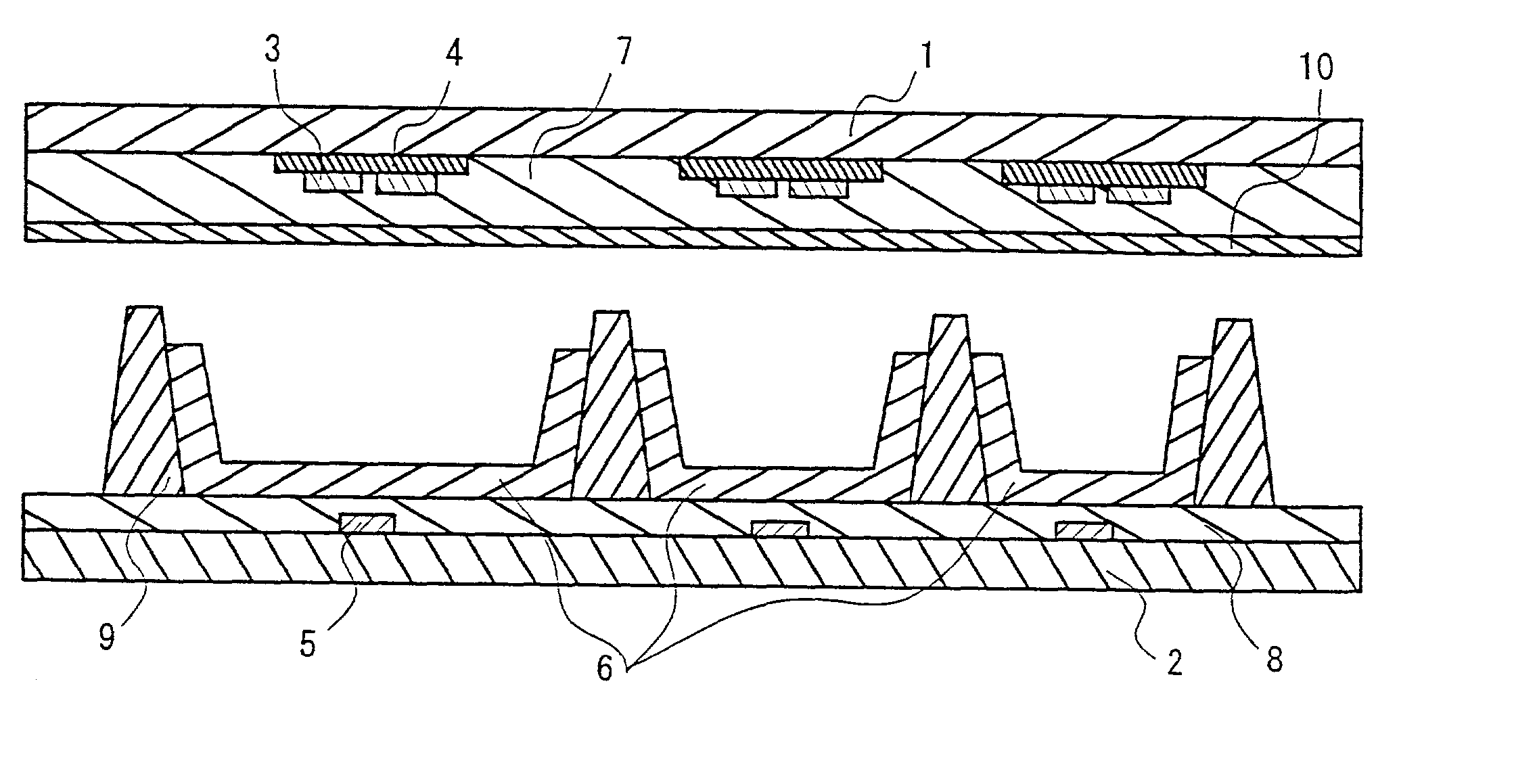

Magnetic core member, antenna module, and mobile communication terminal having the same

InactiveUS7405709B2Sufficient electromagnetic functionReduce coil lossLoop antennas with ferromagnetic coreAntenna supports/mountingsComputer moduleEngineering

A magnetic core member, an antenna module, and a portable communication terminal having this, which have a configuration capable of satisfying enhancement of communication characteristics of antenna coils as well as their sufficient electromagnetic shielding function from a shield plate. A magnetic core member (4) is disposed between an antenna substrate having antenna coils (11), (12) formed therein and a conductive shield plate (3), and is formed by filling an insulating material (30) with a magnetic powder (31). The magnetic core member (4) has a two-layered structure including a first layer (4A) and a second layer (4B), thereby making a filling rate of the magnetic powder (31) in the first layer (4A) be lower than that of the magnetic powder (31) in the second layer (4B) so that a first surface (4a) on a side opposed to the antenna substrate (2) and a second surface (4b) on a side opposed to the shield plate (3) have magnetic properties different from each other.

Owner:SONY CORP

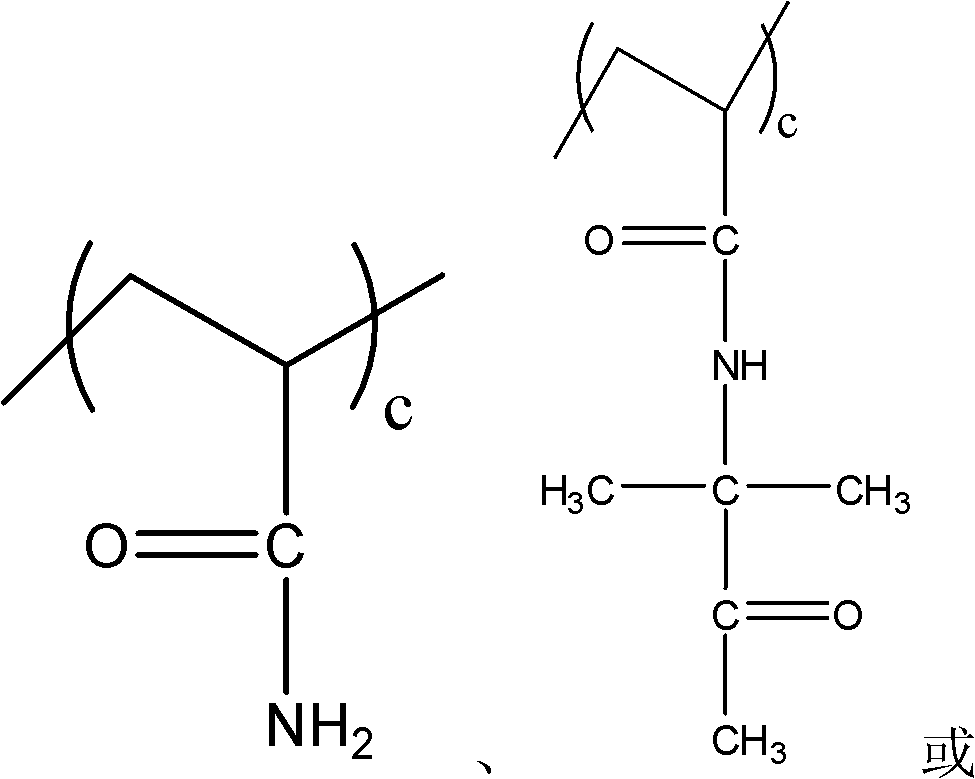

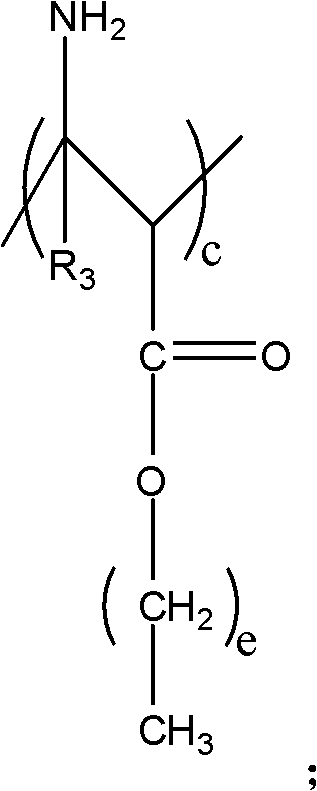

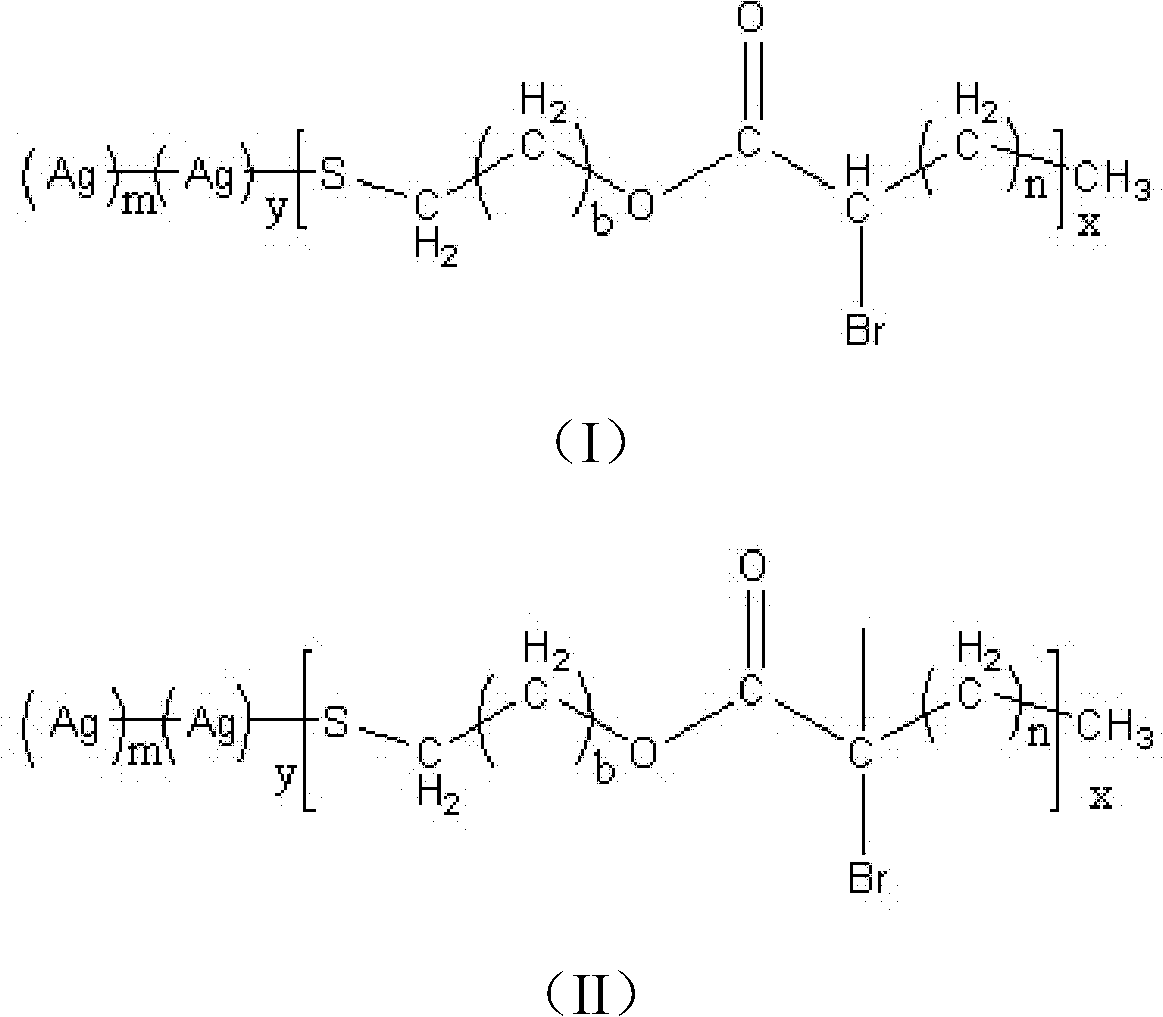

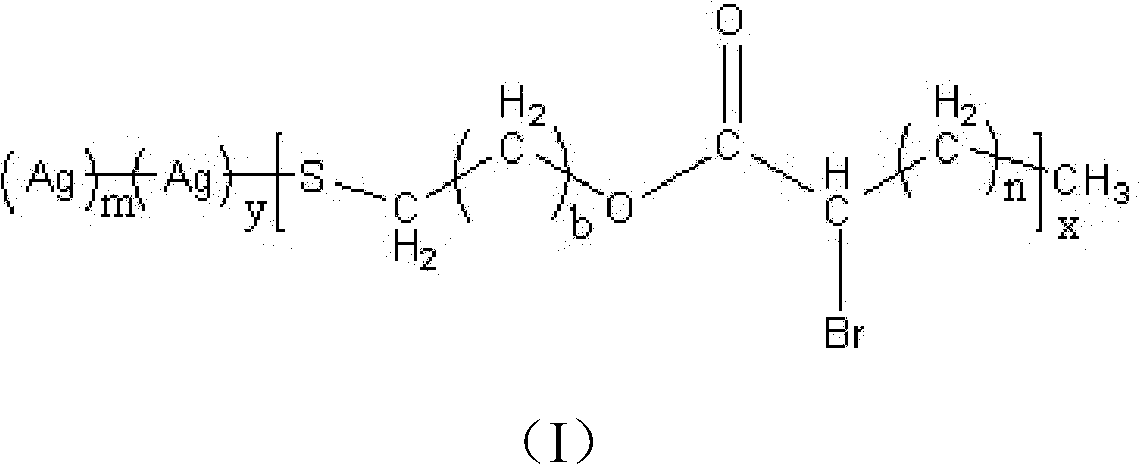

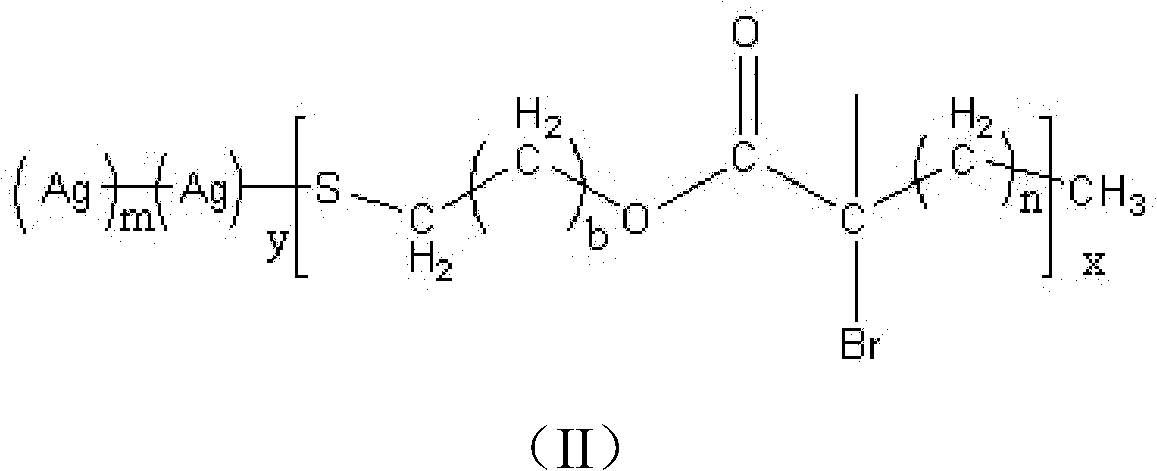

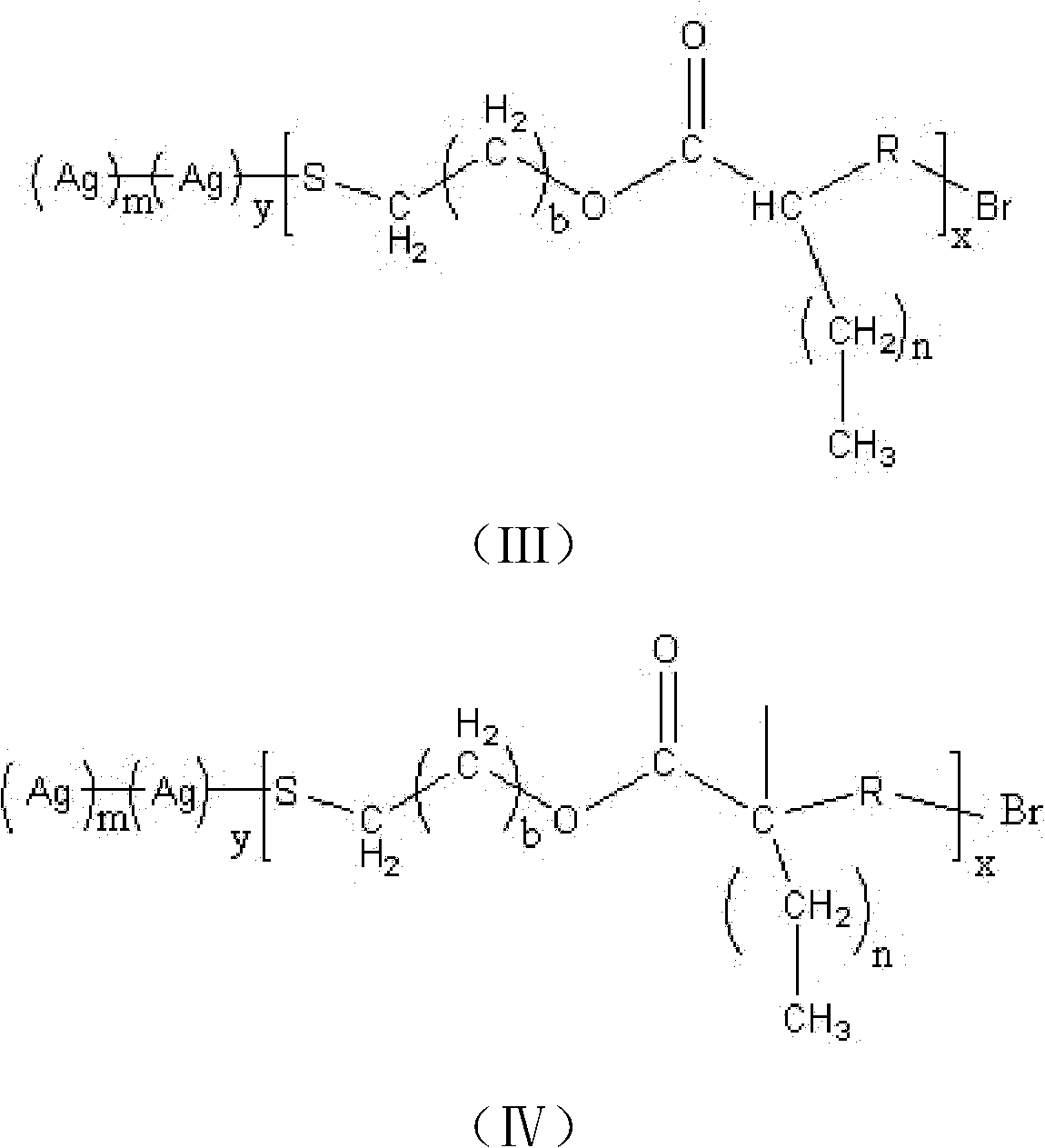

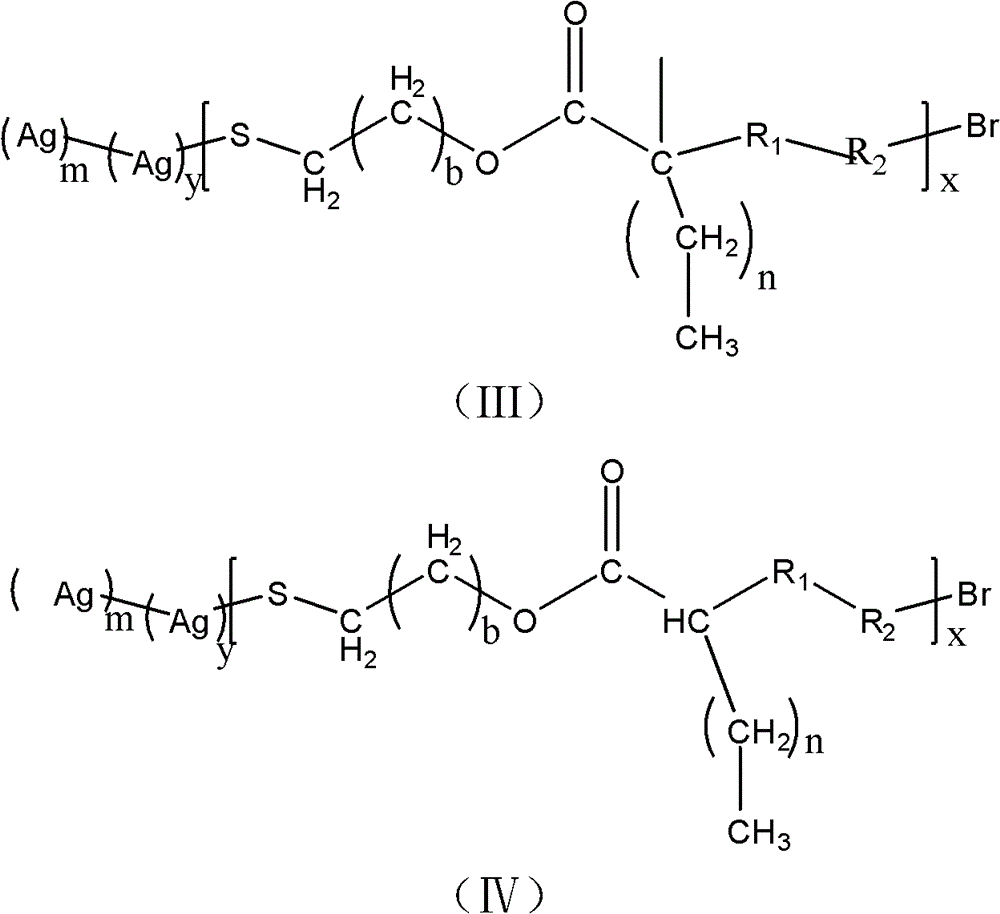

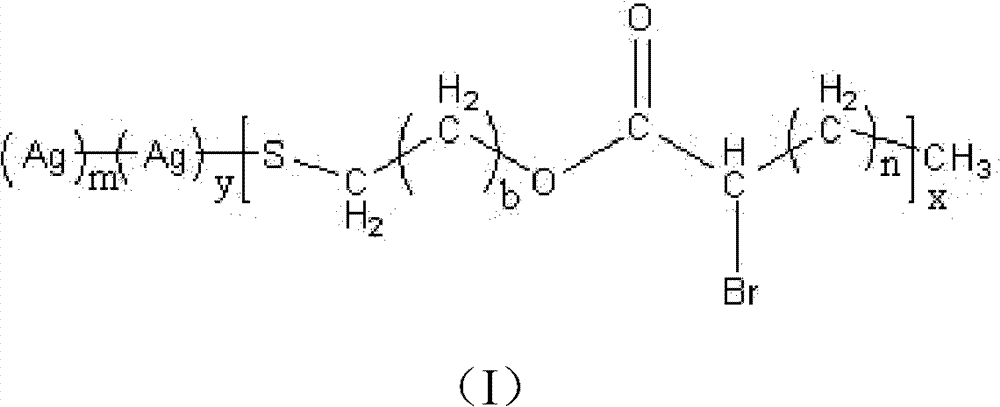

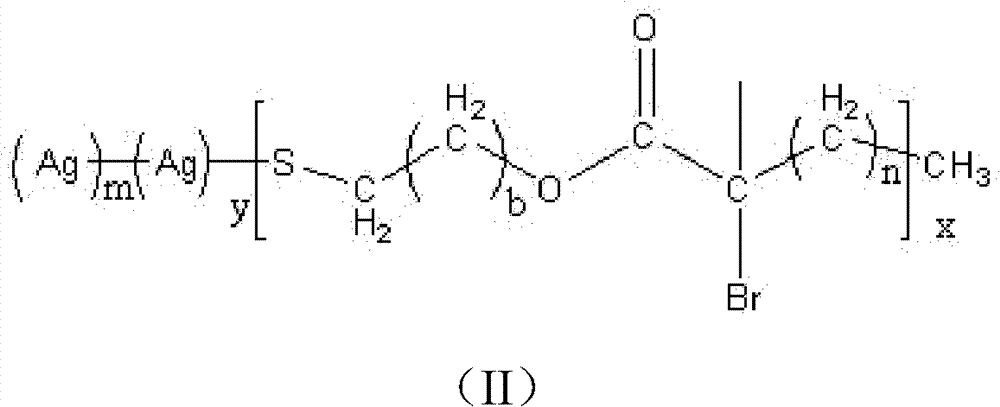

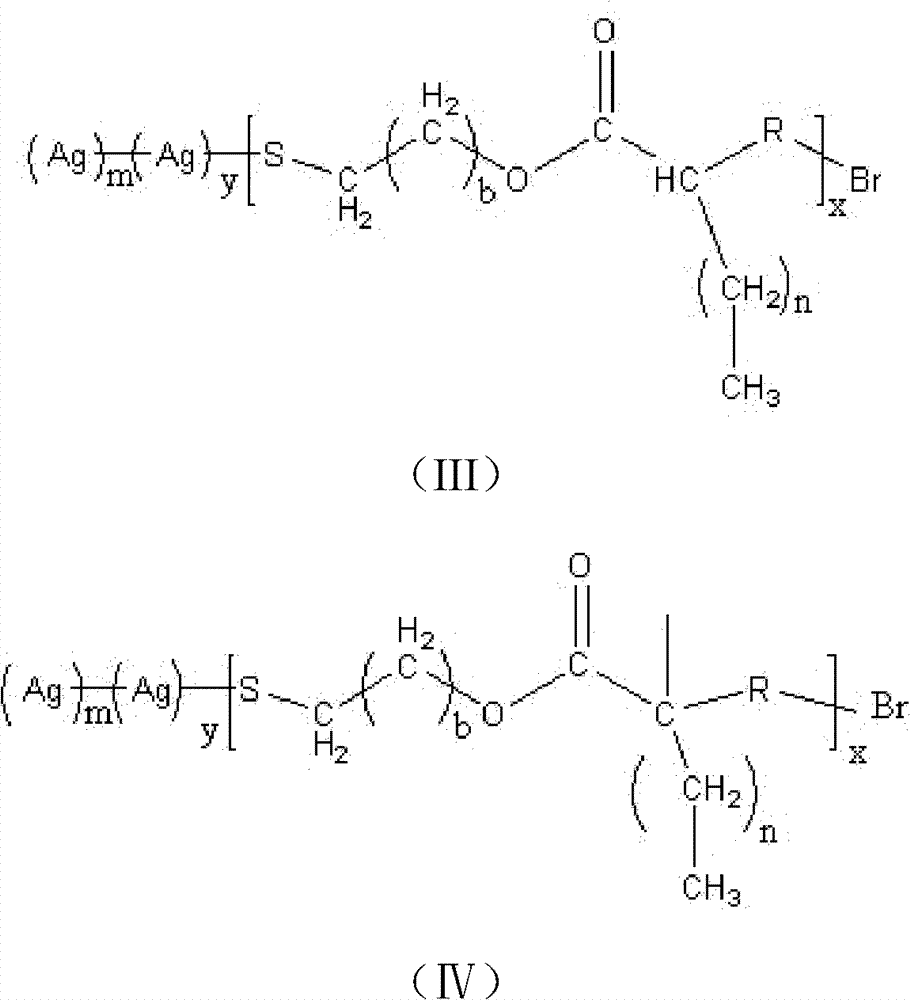

High-dispersing nanometer silver and high-performance conductive adhesive

InactiveCN102199407AIncrease surface activation energyHigh grafting rateNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyAdhesive

The invention discloses high-dispersing nanometer silver and a high-performance conductive adhesive. A preparation method for the high-performance conductive adhesive comprises the following steps of: mixing an epoxy resin curing agent and an accelerating agent uniformly; mixing the high-dispersing nanometer silver and epoxy resin uniformly; and dripping a mixture of the epoxy resin curing agent and the accelerating agent into a mixed component of the high-dispersing nanometer silver and the epoxy resin, which are being mixed, at the temperature of between 10 and 25 DEG C, and mixing for 3 to 10 hours to obtain the high-performance conductive adhesive. The nanometer silver can be fixed in the epoxy resin and has the excellent dispersibility in the epoxy resin, and the conductive adhesive prepared from the nanometer silver can fix a conductive network in the conductive adhesive, improve electric conductivity and solve the problem of silver migration in the using process of conductive silver. In addition, in epoxy resin of the high-performance conductive adhesive, four epoxy resin combinations with different functions are adopted, so the defects of insufficient bonding strength and shear strength in the current conductive adhesive are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

High-dispersion silver powder and solar battery electrode conductive silver paste

InactiveCN102139368ALow percolation valueReduce fill rateSemiconductor devicesSilver pasteElectrical battery

The invention discloses high-dispersion silver powder and solar battery electrode conductive silver paste, wherein the conductive silver paste is prepared from the following components in mass percentage: 53-61.8% of high-dispersion silver powder in claim 1, 21.5-31% of glass cement and 15-17.6% of organic carrier. The high-dispersion silver powder provided by the invention has very good dispersity and by means of the conductive silver paste prepared by the high-dispersion silver powder, the usage amount of the silver powder is reduced and the conductive efficiency is improved in the mean time; in addition, the conductive silver paste provided by the invention is clean and environmental-friendly and is suitable for popularization and application. By means of the high-dispersion silver powder and the solar battery electrode conductive silver paste which are provided by the invention, the defects of poor dispersity of the conventional silver powder and large usage amount of the silver powder of the conventional conductive silver paste are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

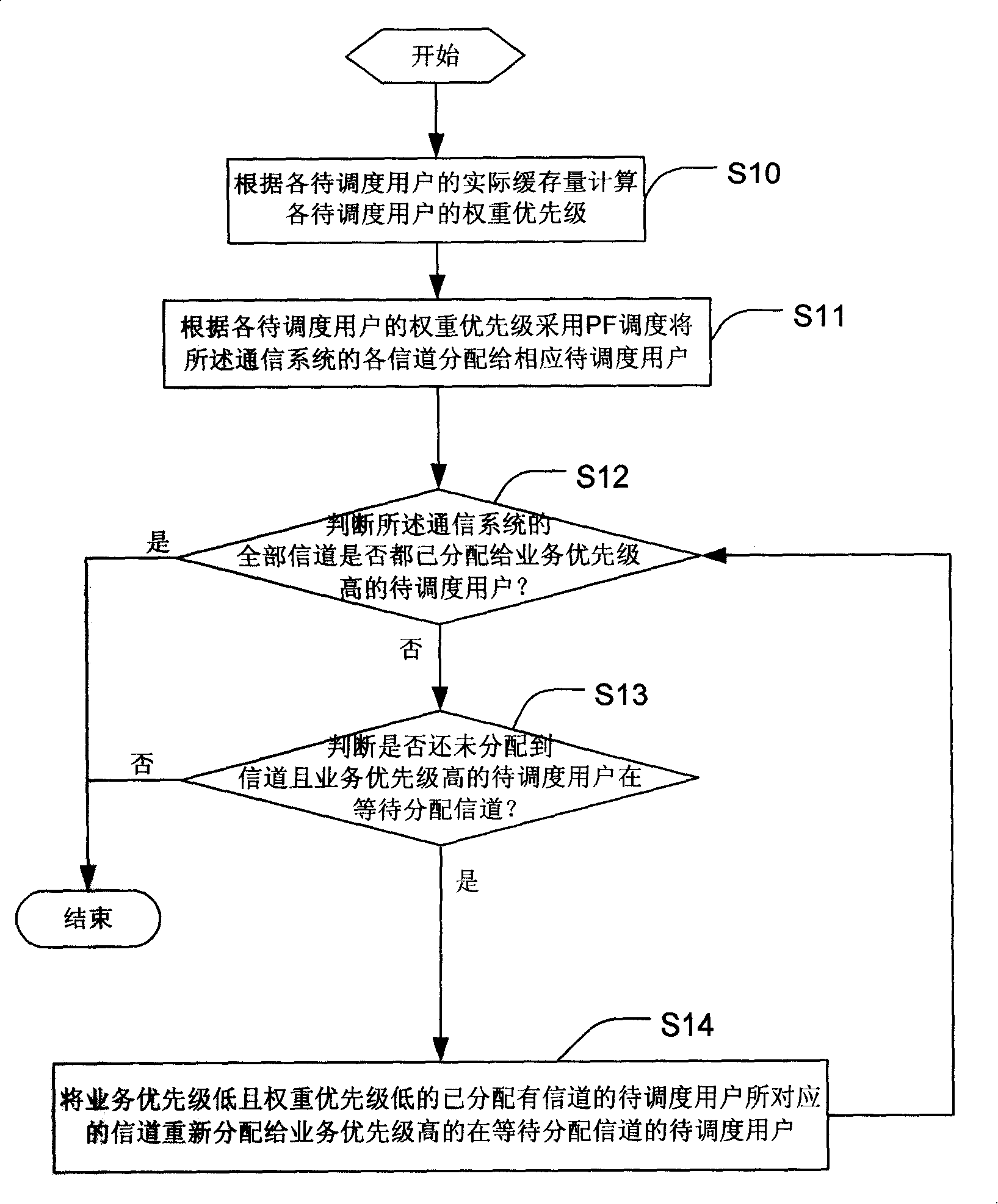

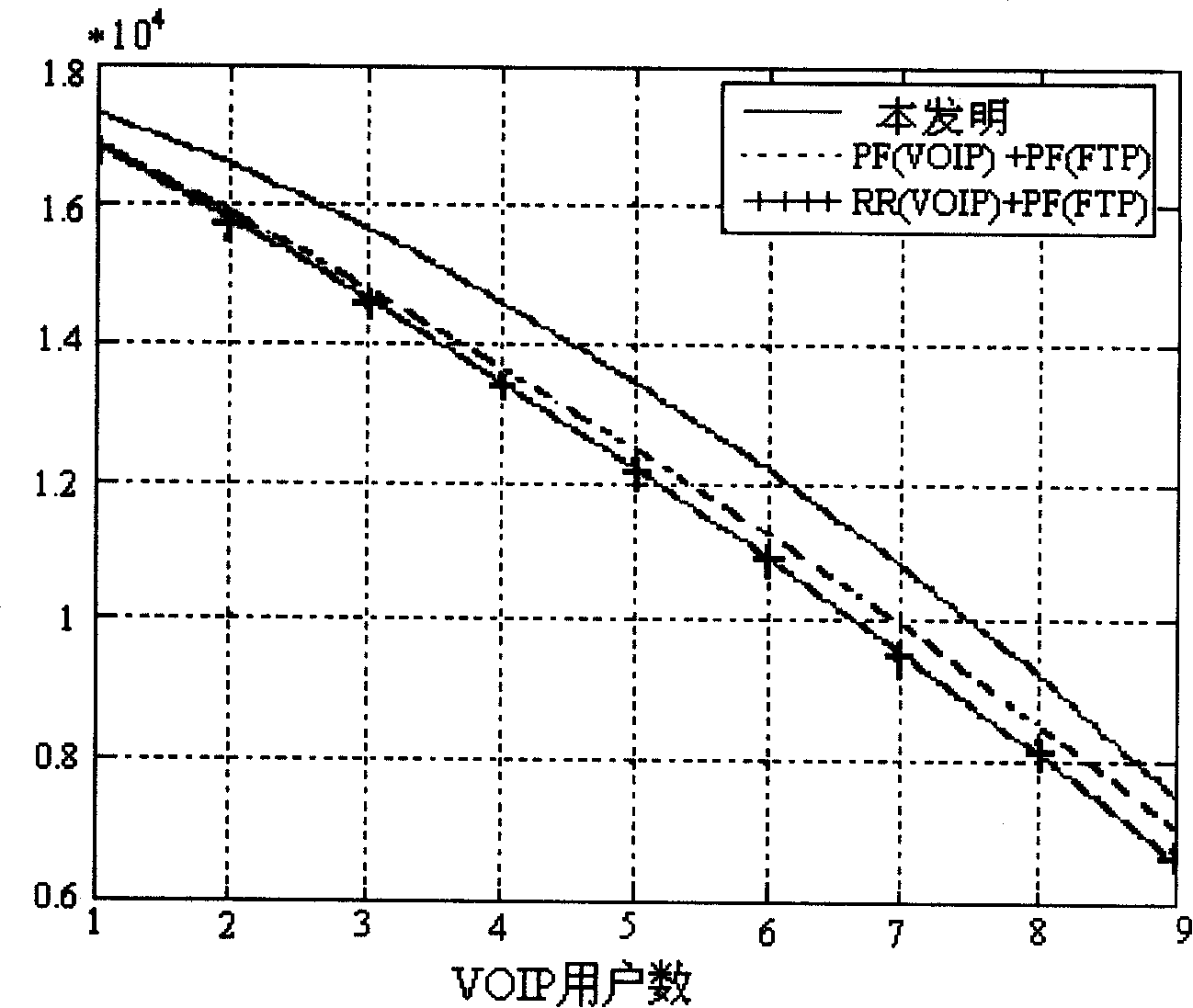

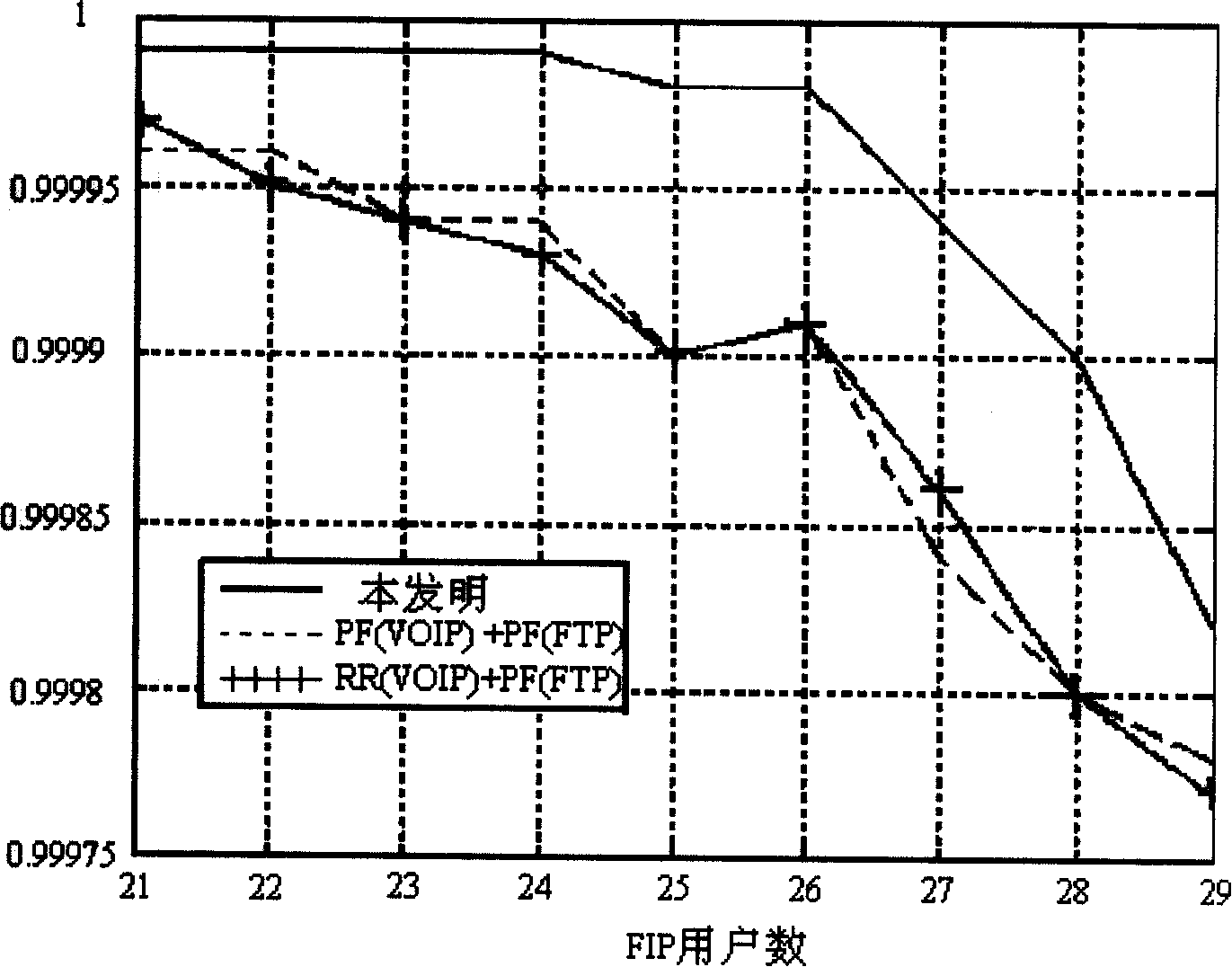

Method for multi-business scheduling based on communication system real buffer memory

InactiveCN101227226AEnhanced Diversity EffectReduce fill rateSpatial transmit diversityRadio/inductive link selection arrangementsMulti professionalCommunications system

The invention relates to a method for modulating in multi-professional work, which is based on the actual cache amount of a communication system and comprises: firstly calculating the weight priority of each user who will be modulated only according to the actual cache amount not to differentiate the weight priority of each user who will be modulated, distributing sub-channels of the communication system to each user who will be modulated according to the weight priority, then judging if all communication channels of the communication system are distributed to users who will be modulated with high professional work priority according to the professional work priority of each user which will be modulated or not, if all communication channels of the communication system are not distributed to users which will be modulated with high professional work priority, further judging if the users with high professional work priority are waiting for distributing communication channels or not, if all communication channels of the communication system are distributed to users which will be modulated with high professional work priority, redistributing the communication channels which are corresponded to the users which will be modulated and are distributed with the communication channels with low professional work priority and low weight priority to the users which will be modulated with high professional work priority and are waiting for distributing communication channels, thereby the diversity efficiency of the users can be intensified, the filling probability can be reduced, the increase of system throughput can be realized and multi-professional works treating principles can be satisfied.

Owner:SHANGHAI RES CENT FOR WIRELESS COMM

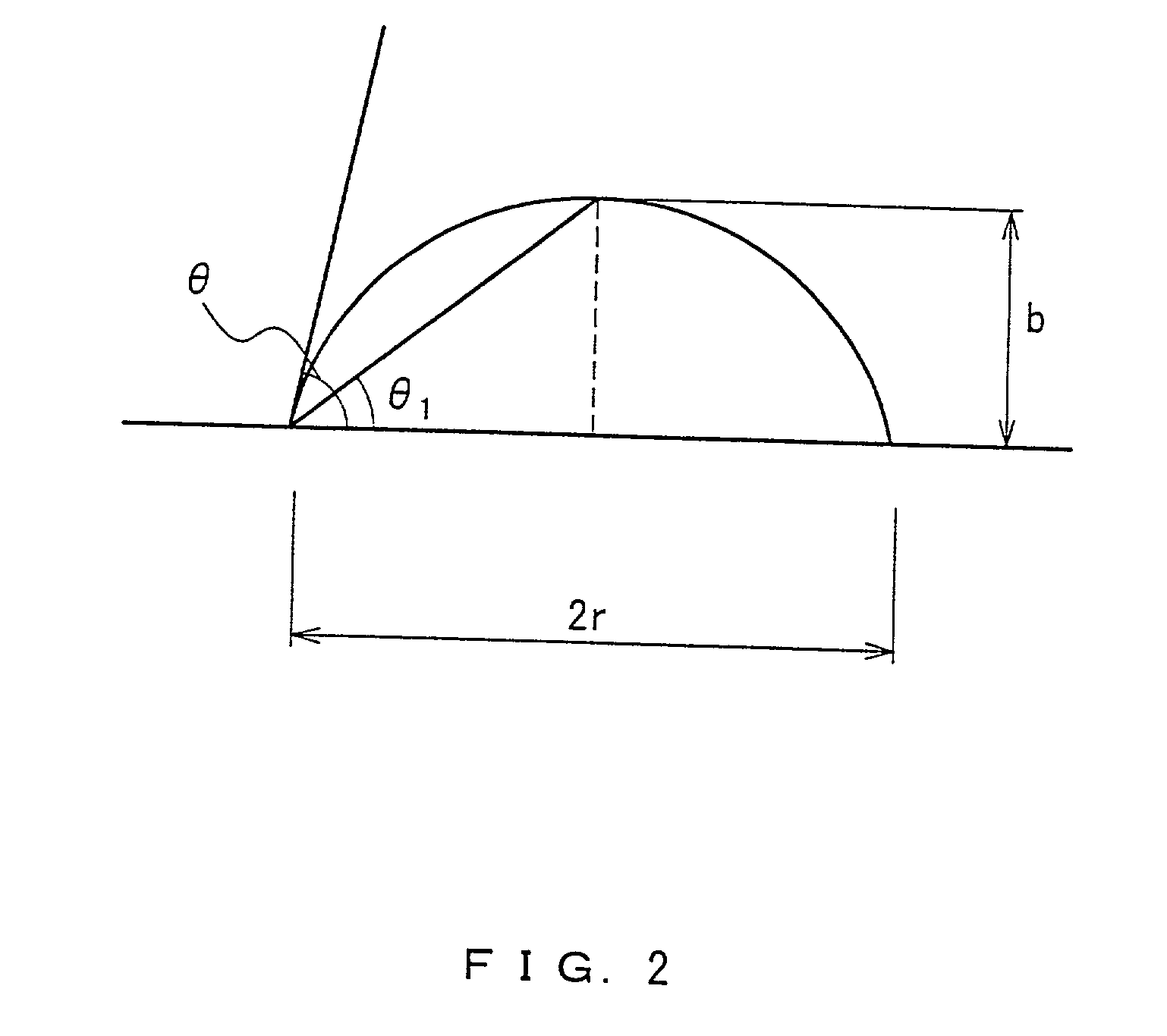

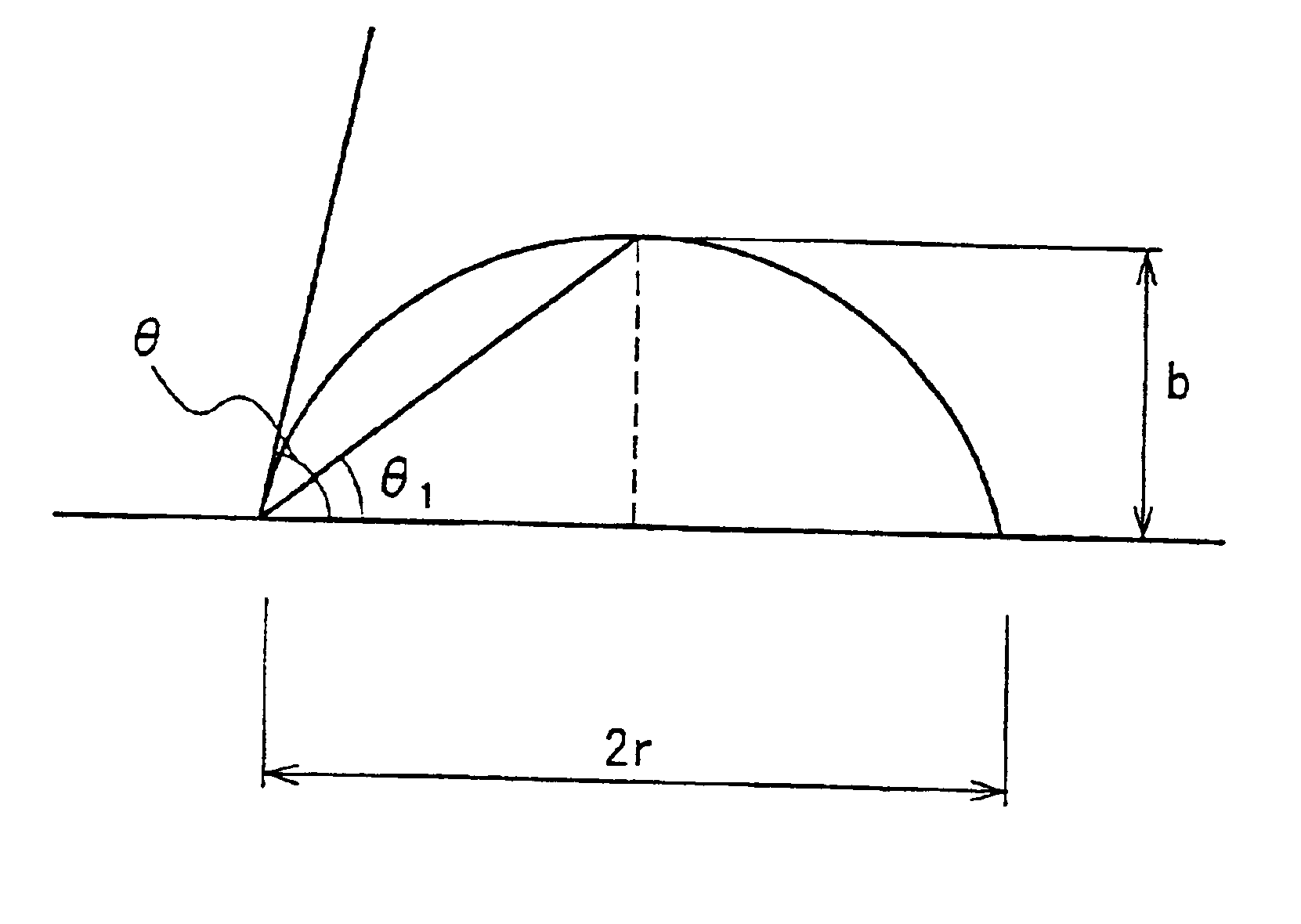

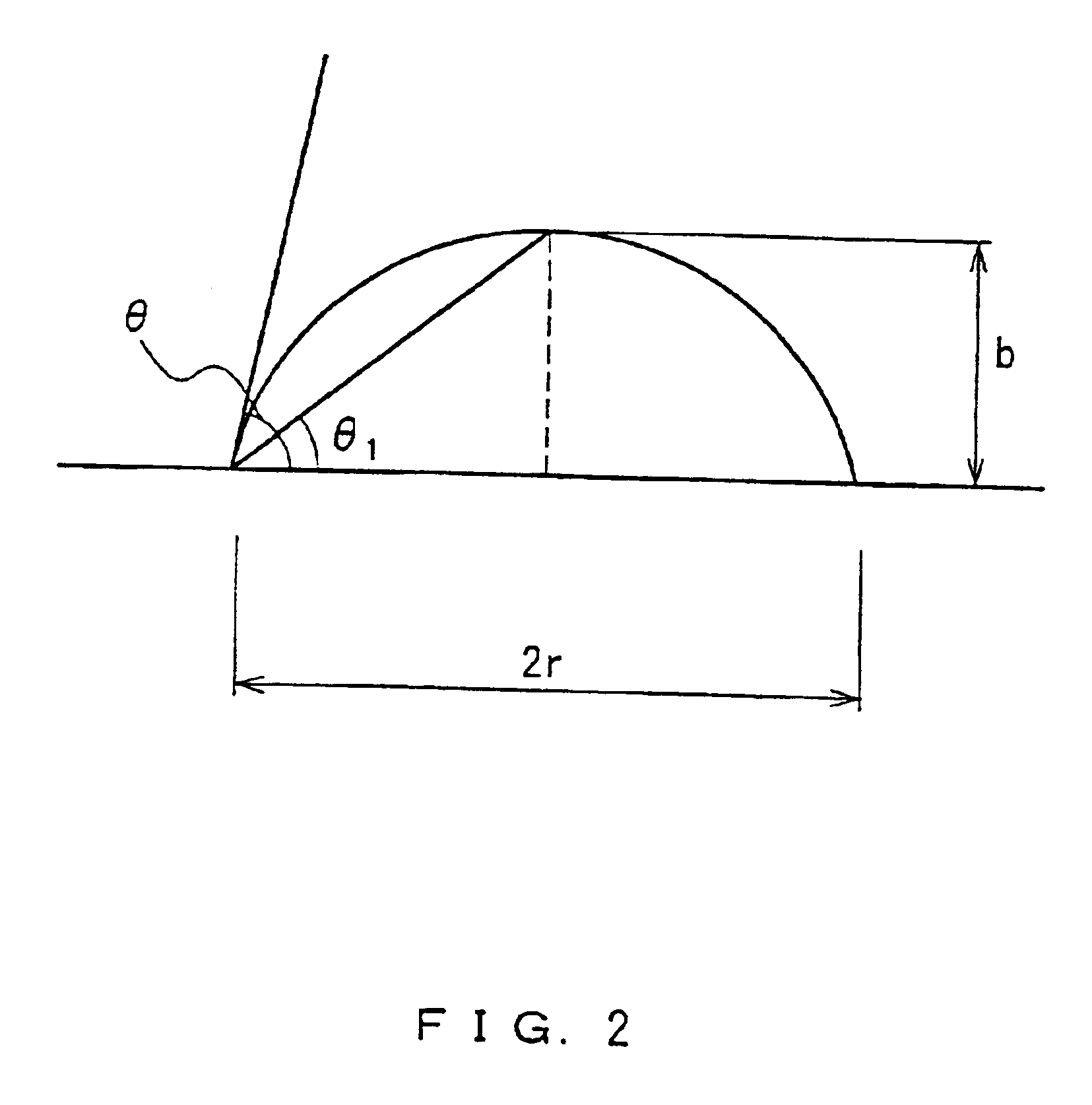

Paint for forming insulating film, and plasma display panel using the paint and method of manufacturing the same

InactiveUS20020063527A1Improve wettabilityLow costSynthetic resin layered productsAlternating current plasma display panelsOrganic solventInorganic materials

The present invention provides a paint for forming an insulating film, which has a good wettability to a surface to be coated with the paint and has no voids or pin-holes after being fired; a plasma display panel including a dielectric layer formed using the paint; and a method of manufacturing the plasma display panel. The paint contains inorganic fine particles, a binder resin, and an organic solvent that has a good wettability to glass such as a glass substrate, ceramic as an Ag electrode, and a metal compound such as an ITO film and forms a contact angle of less than 5° with these inorganic materials. Accordingly, the paint has a good wettability to a glass substrate, an Ag electrode, and an ITO film and the resultant insulating film thus has no voids or pin-holes.

Owner:PANASONIC CORP

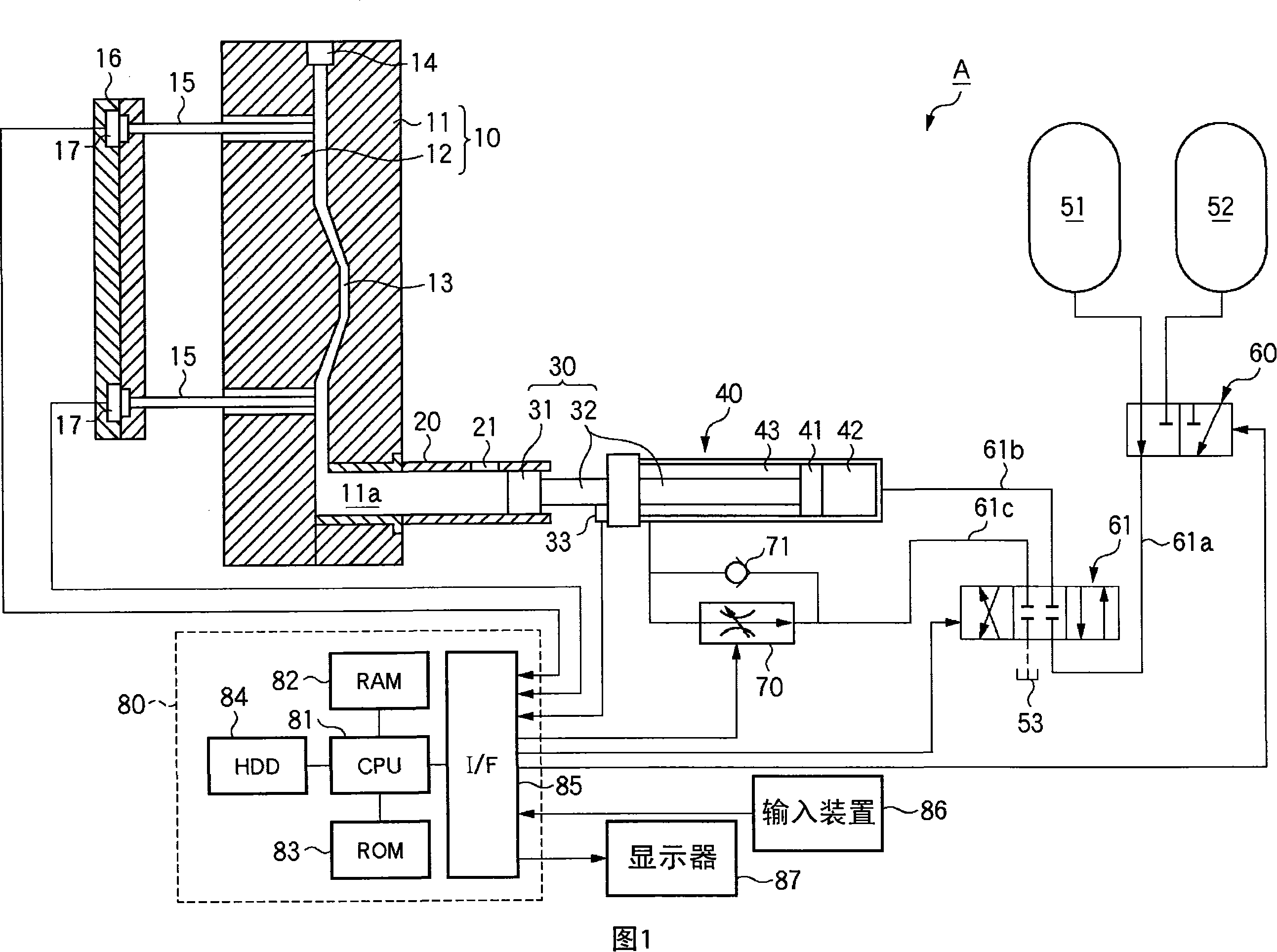

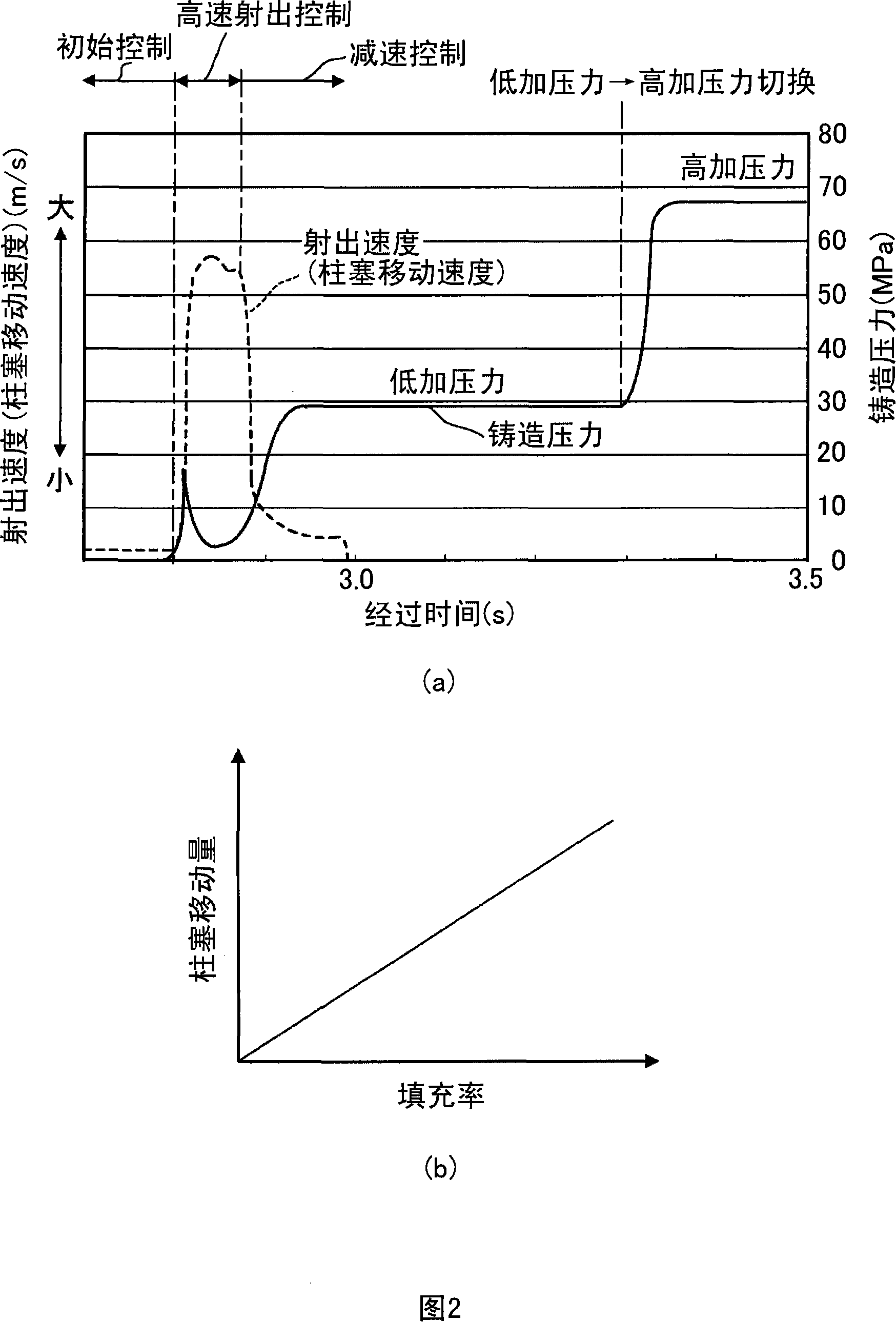

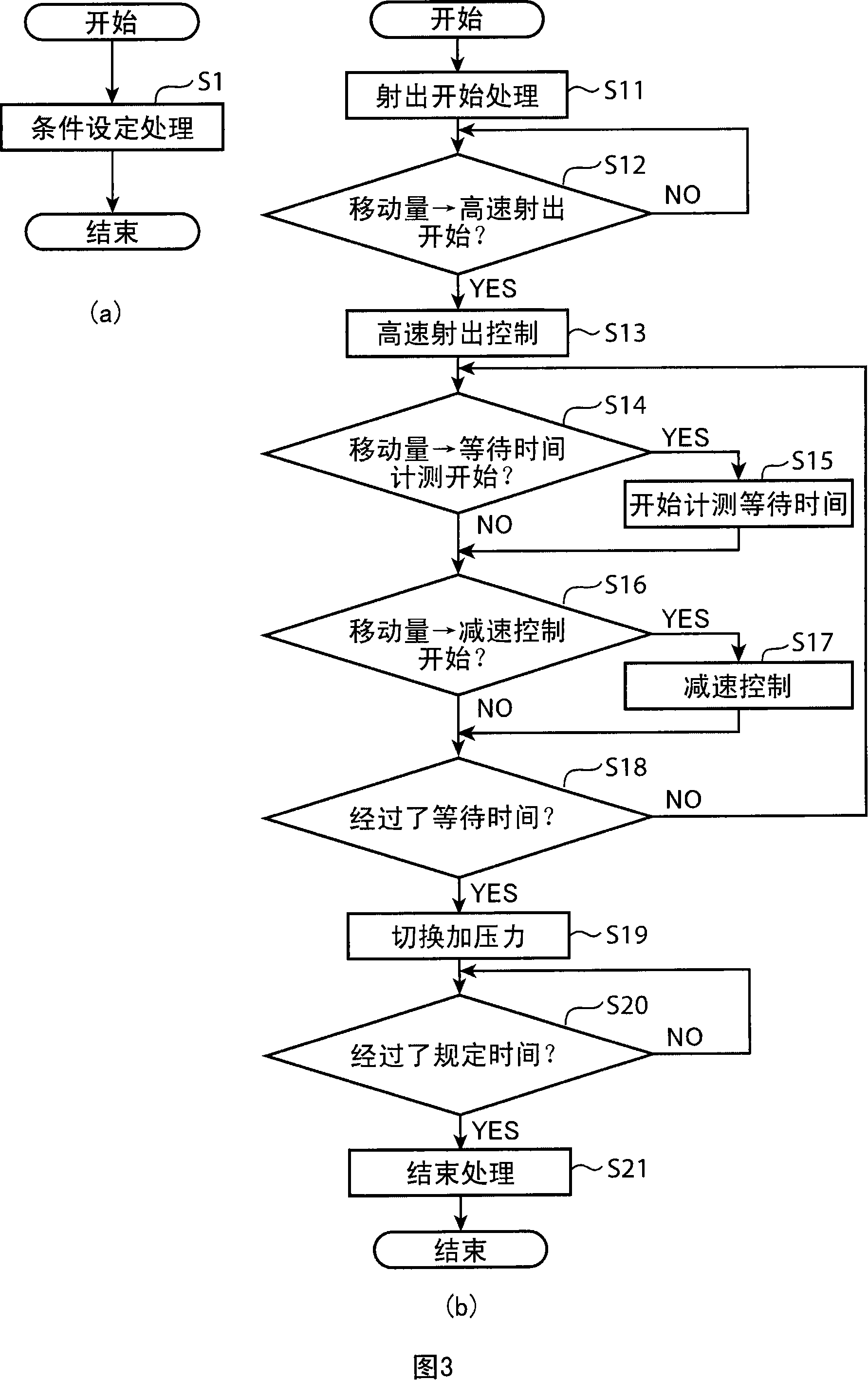

Press die casting device and press die casting method

The present invention relates to a pressure casting device, by means of ejaculating solution with high speed, to ensure the filling ratio of the molten to reach the prescribed filling ratio selected from the range of 90 percent to 98 percent relative to the filling ratio of the mould cavity, then to implement deceleration control of a plunger piston and increase the pressure of the melted step by step.

Owner:MAZDA MOTOR CORP

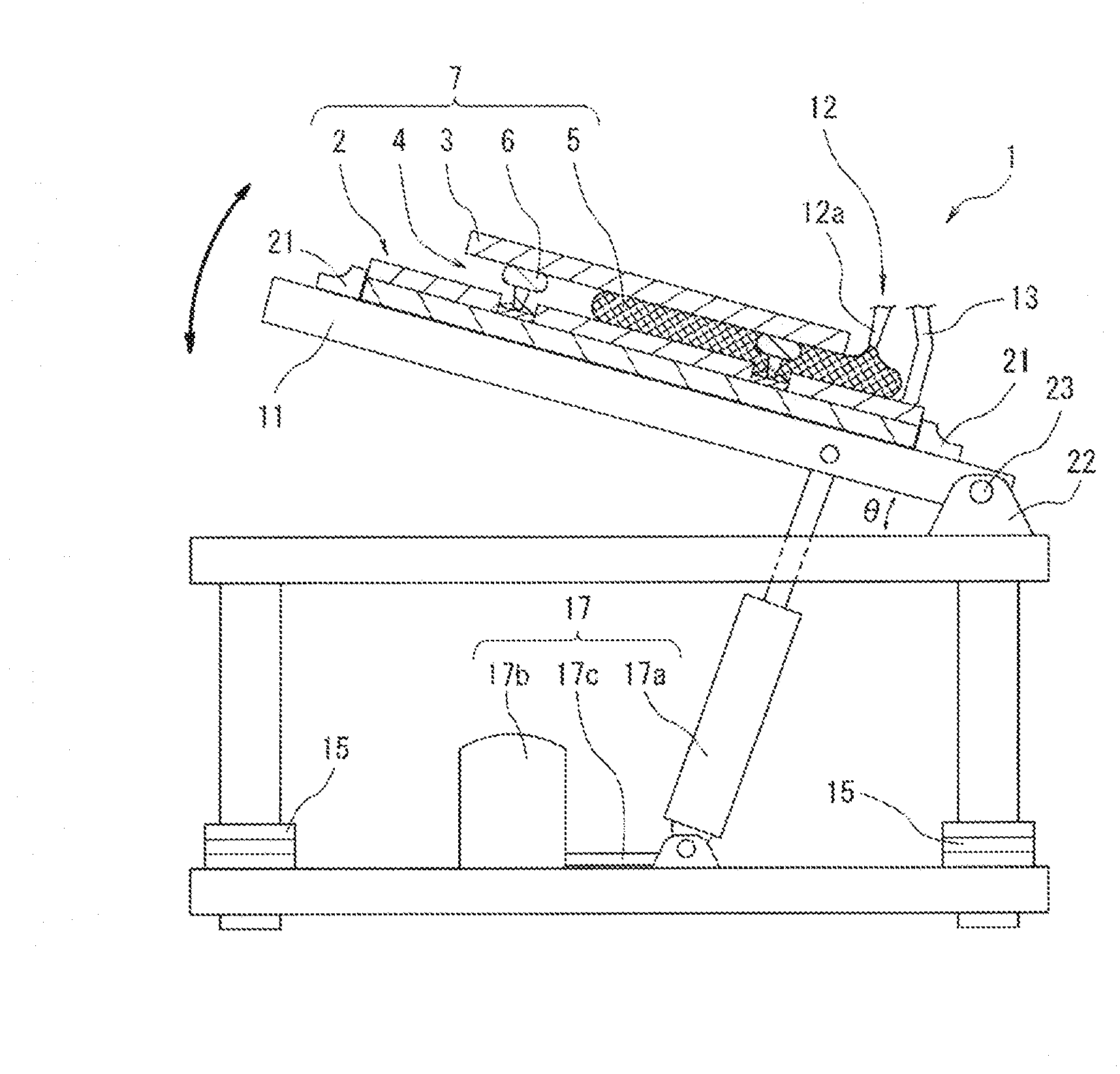

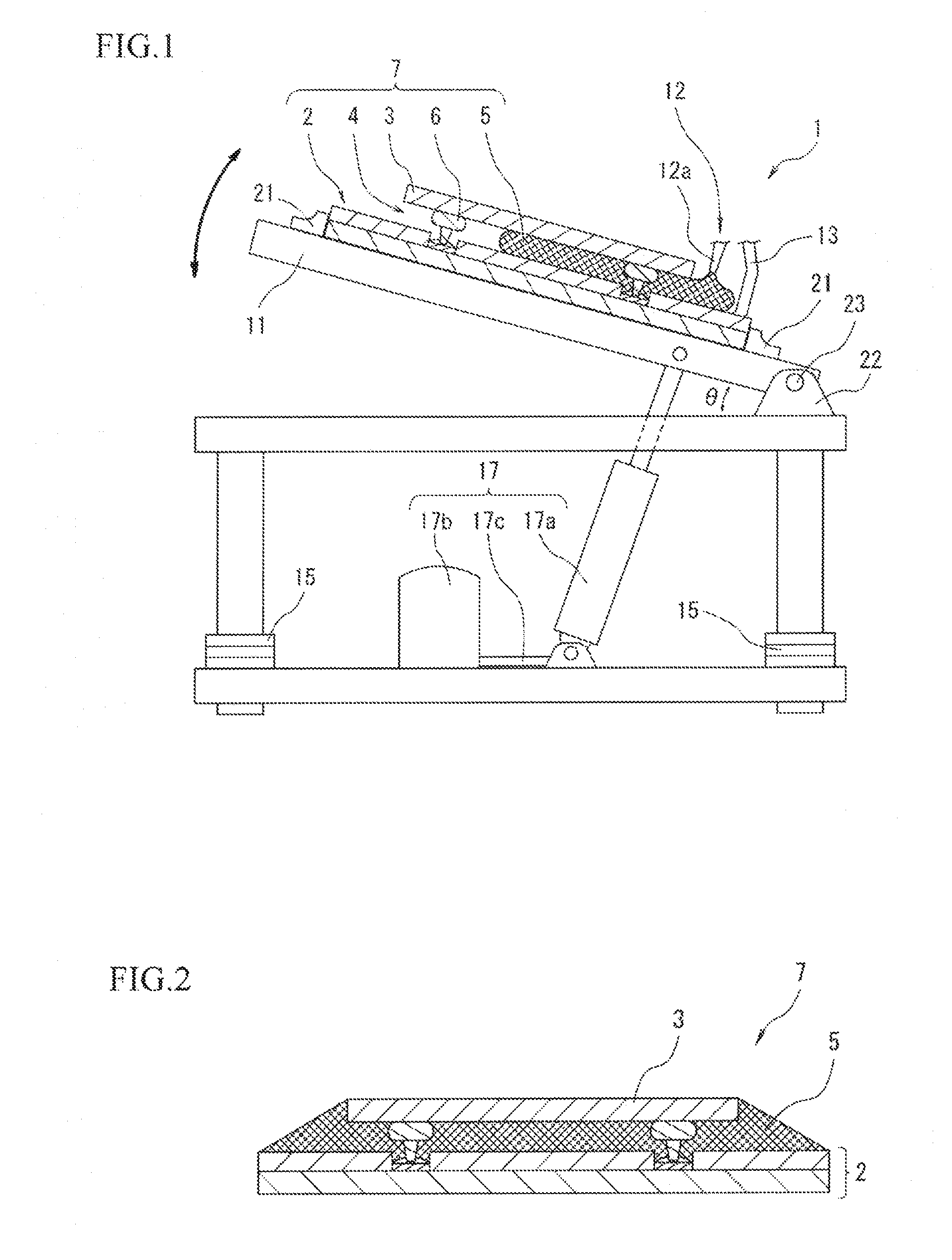

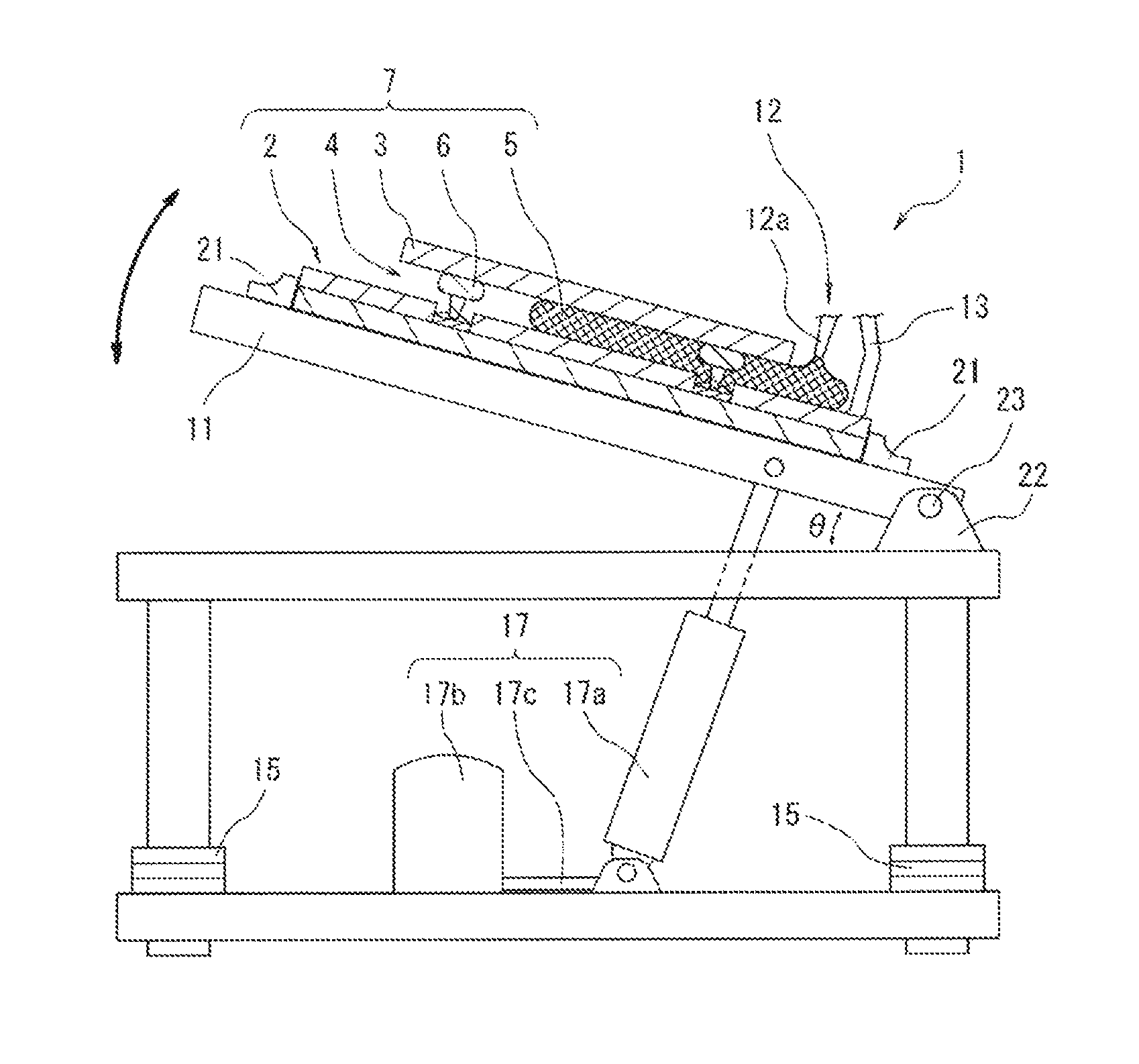

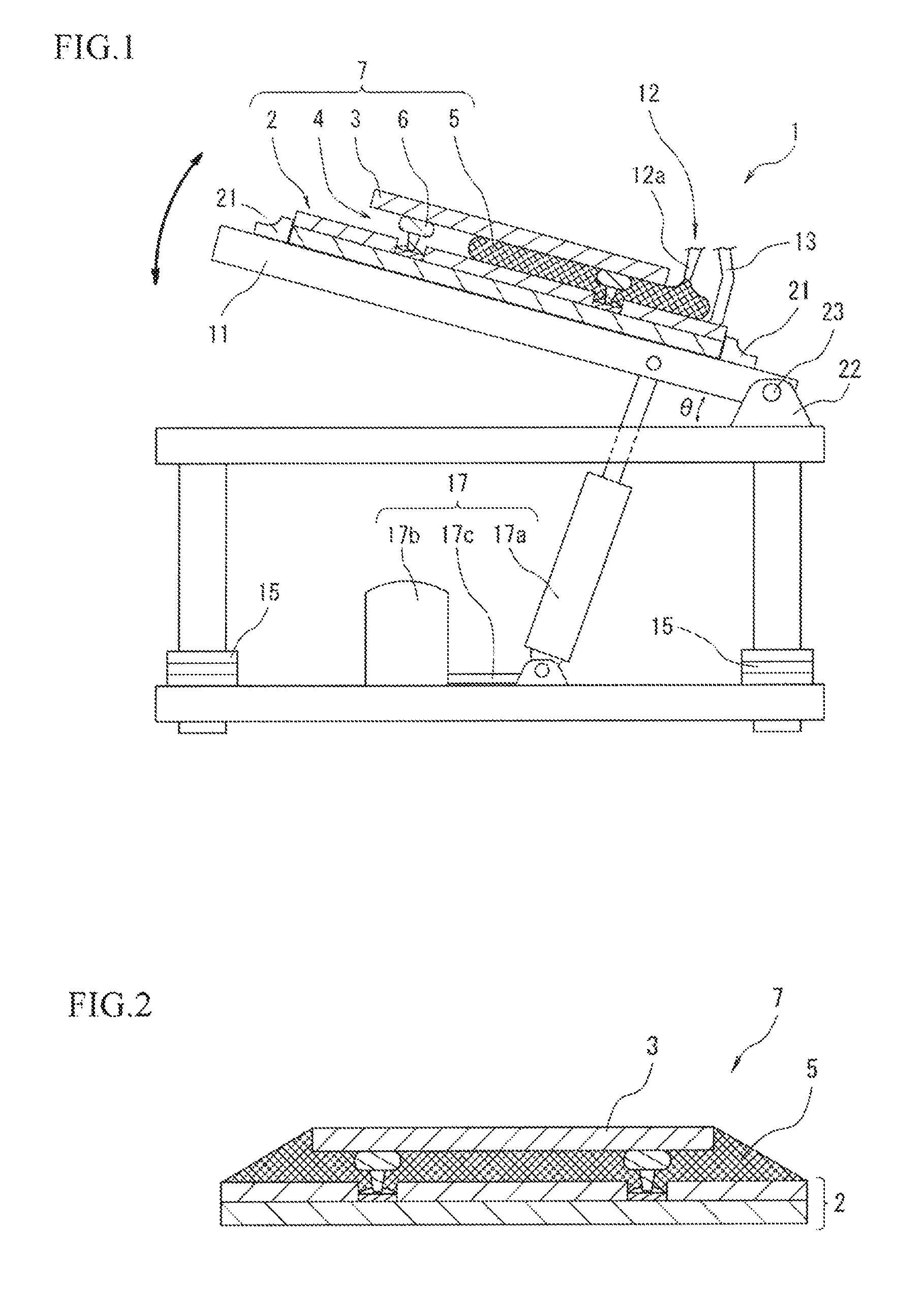

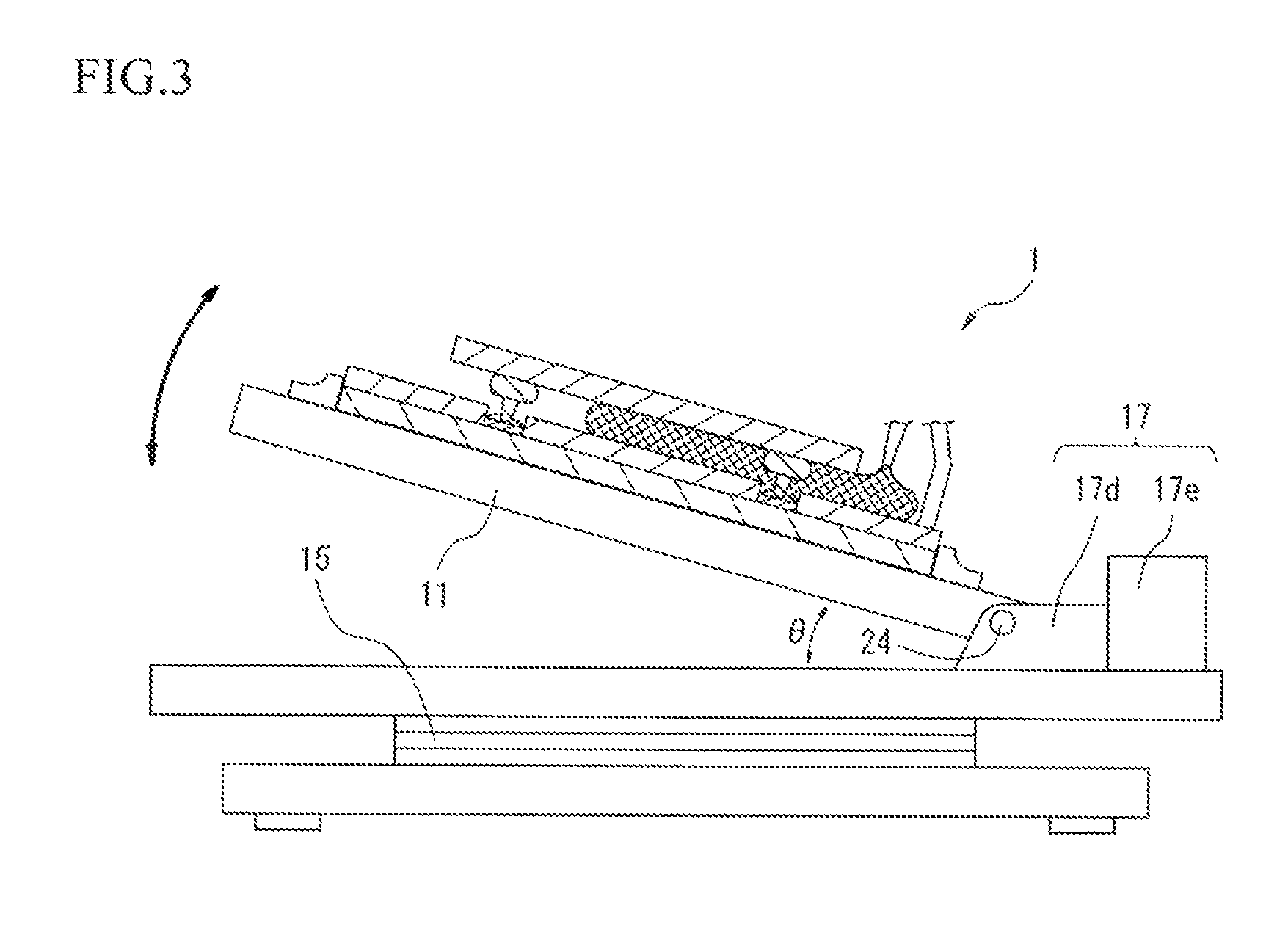

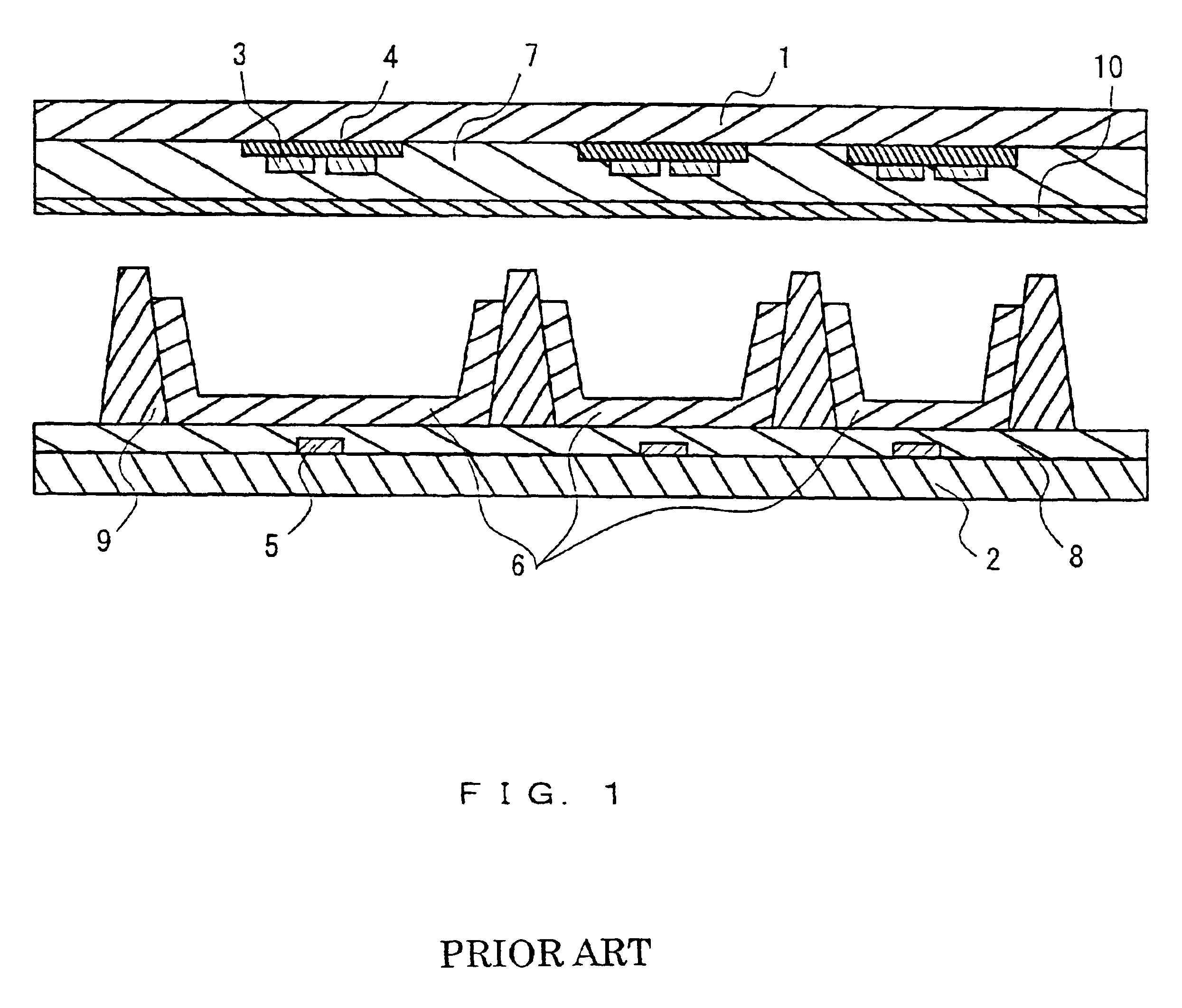

Resin filling apparatus, filling method, and method of manufacturing an electronic device

InactiveUS20080216917A1Reduce entrainmentSimple processWave amplification devicesFinal product manufactureEngineeringElectronic component

A resin filling apparatus, a filling method, and a method of manufacturing an electronic device fill a cavity between a substrate and an electronic component mounted on the substrate with resin. The resin filling apparatus includes a stage for supporting the substrate in an inclined state, and an application head for filling the cavity with resin from a lower side of the inclined substrate.

Owner:FUJITSU LTD

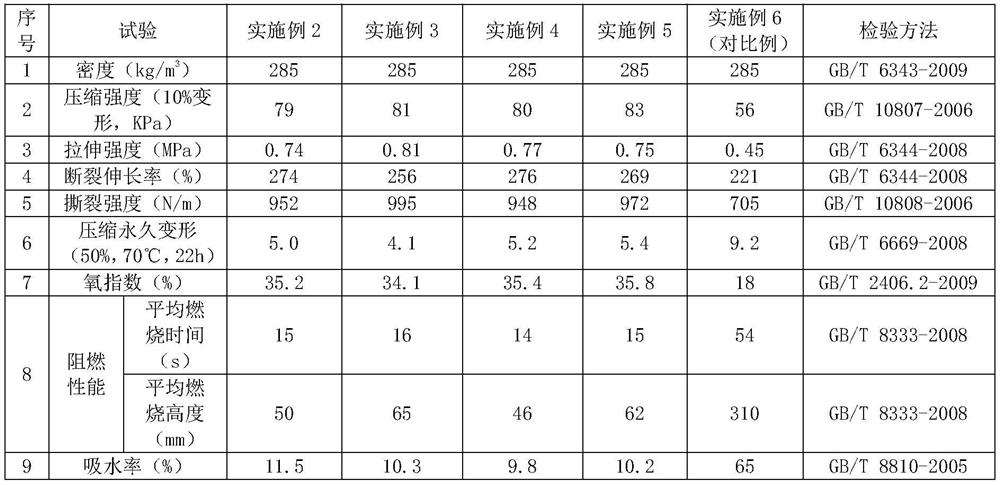

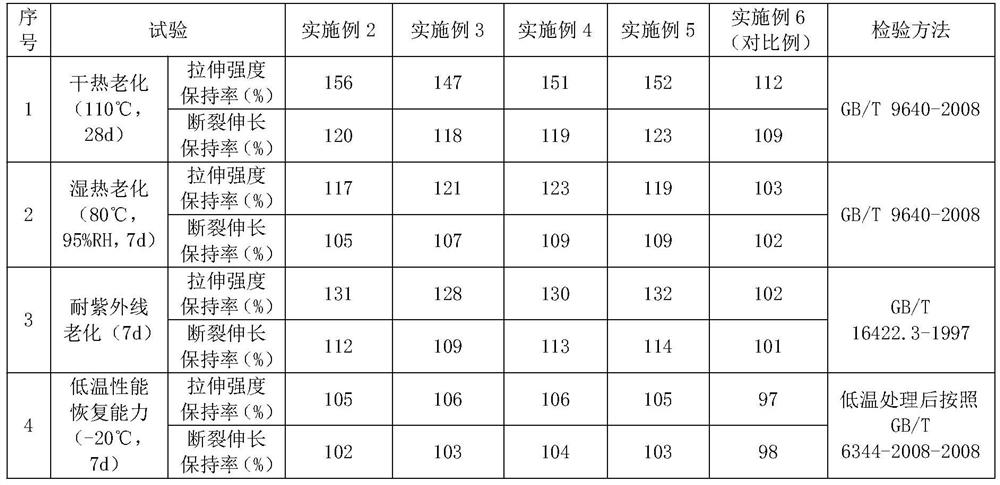

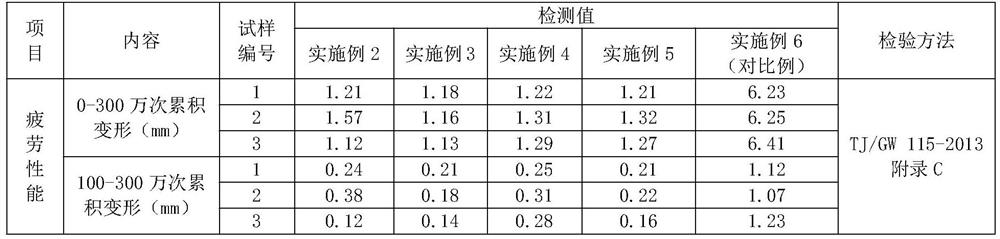

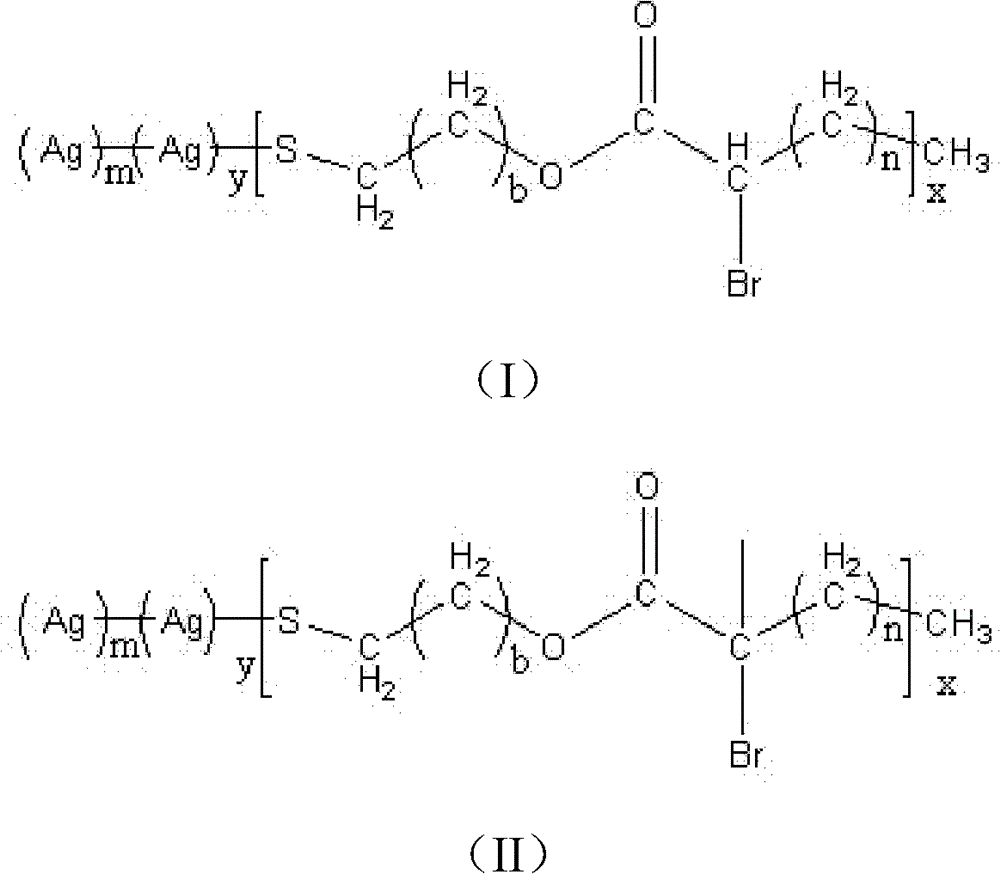

Polyurethane flexible foam material for railway curing ballast bed and preparation method thereof

The invention relates to a polyurethane flexible foam material for a railway curing ballast bed, and belongs to the technical field of curing ballast bed materials. The polyurethane flexible foam material comprises the following components in parts by mass: 100 parts of a material A and 86-91 parts of a material B, wherein the material A is prepared from the following materials in parts by mass: 100 parts of polyether polyol, 30-40 parts of bio-based polyol, 20-30 parts of a flame retardant, 4-8 parts of a small molecule chain extender, 1.75-2.75 parts of a foaming agent and 0.6-1.2 parts of a catalyst; the material B is prepared from the following materials in parts by mass: 57 to 63 parts of isocyanate and 37 to 43 parts of polyether polyol.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

High-dispersing nanometer silver and high-performance conductive adhesive

InactiveCN102199407BIncrease surface activation energyHigh grafting rateNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyAdhesive

The invention discloses high-dispersing nanometer silver and a high-performance conductive adhesive. A preparation method for the high-performance conductive adhesive comprises the following steps of: mixing an epoxy resin curing agent and an accelerating agent uniformly; mixing the high-dispersing nanometer silver and epoxy resin uniformly; and dripping a mixture of the epoxy resin curing agent and the accelerating agent into a mixed component of the high-dispersing nanometer silver and the epoxy resin, which are being mixed, at the temperature of between 10 and 25 DEG C, and mixing for 3 to10 hours to obtain the high-performance conductive adhesive. The nanometer silver can be fixed in the epoxy resin and has the excellent dispersibility in the epoxy resin, and the conductive adhesive prepared from the nanometer silver can fix a conductive network in the conductive adhesive, improve electric conductivity and solve the problem of silver migration in the using process of conductive silver. In addition, in epoxy resin of the high-performance conductive adhesive, four epoxy resin combinations with different functions are adopted, so the defects of insufficient bonding strength and shear strength in the current conductive adhesive are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

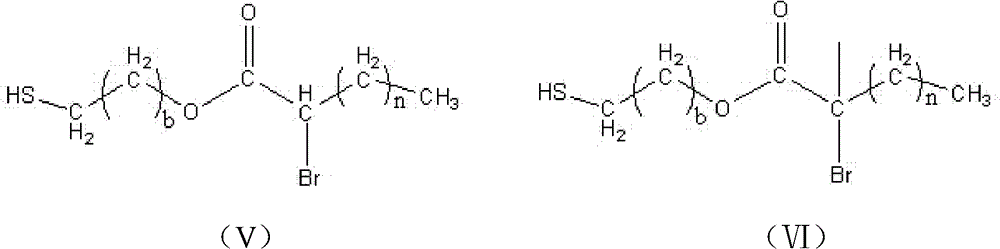

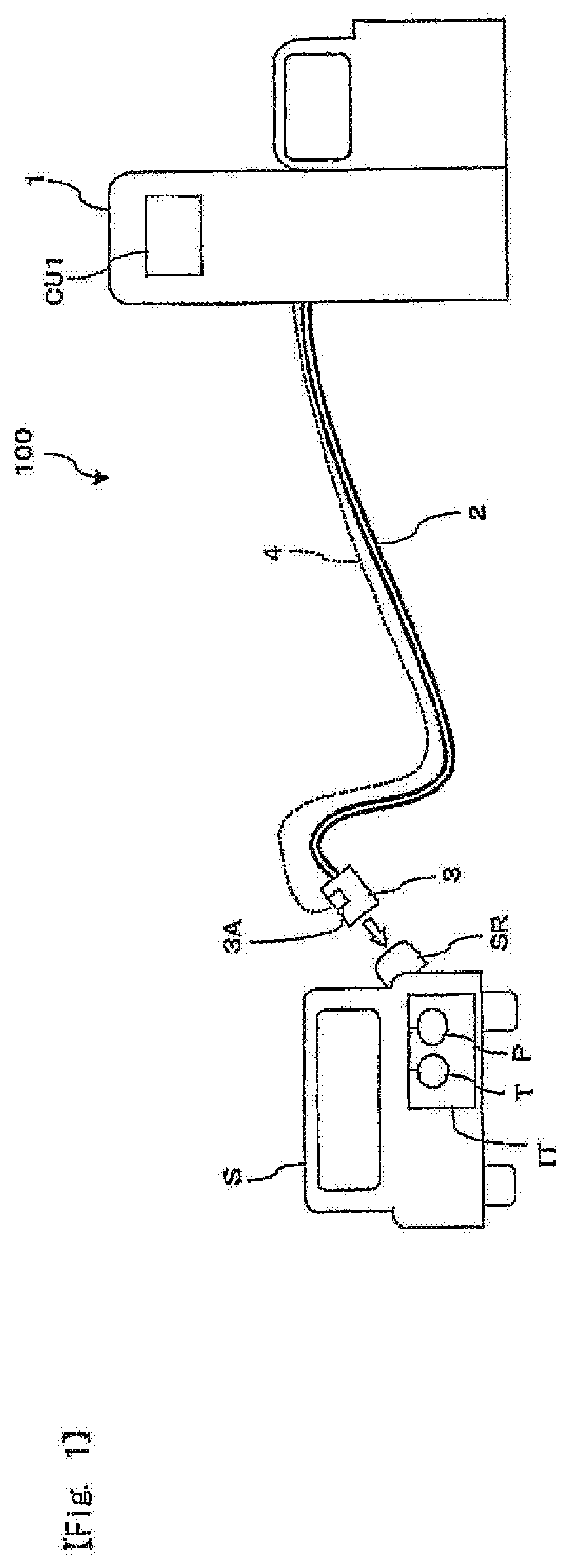

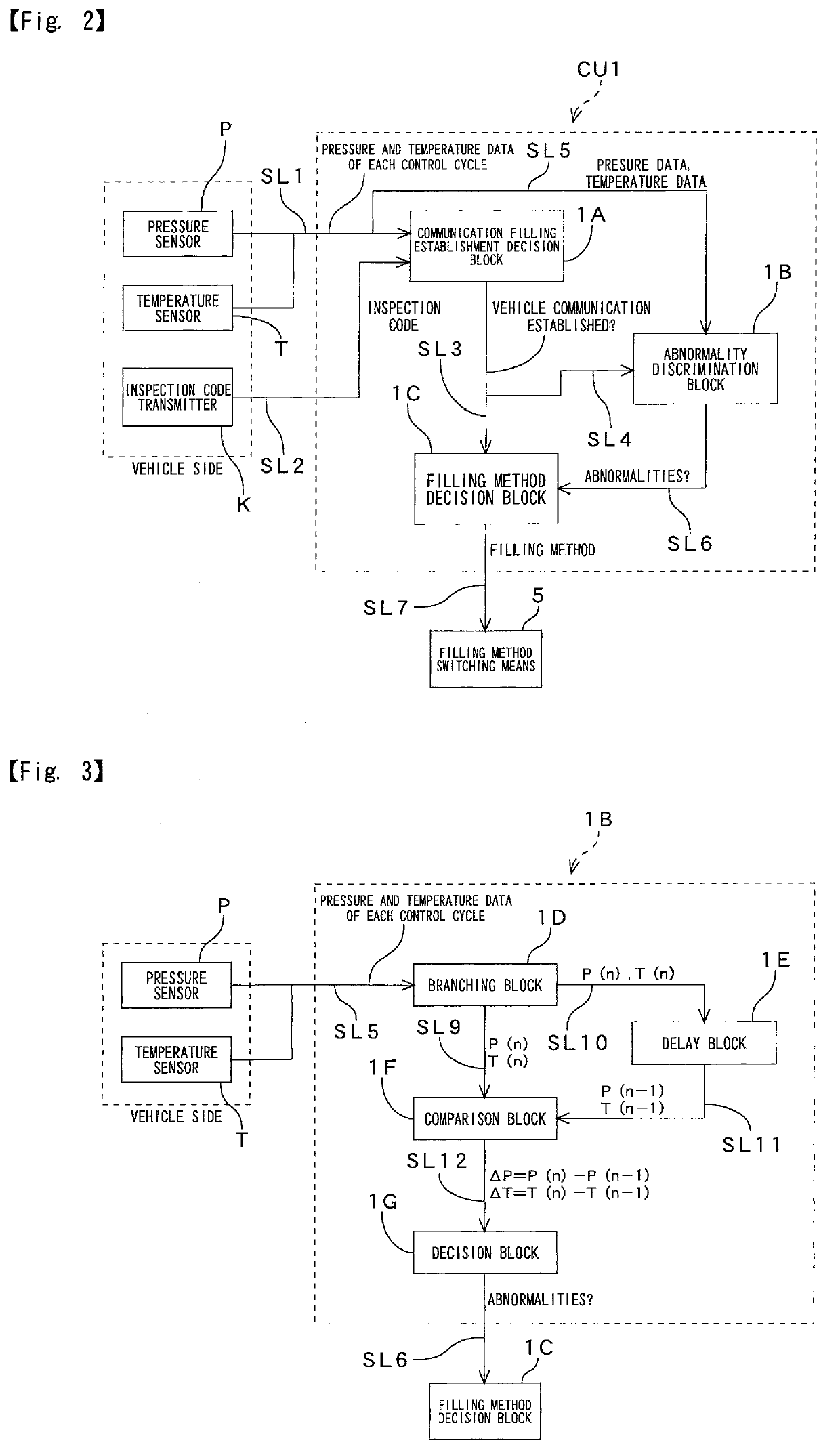

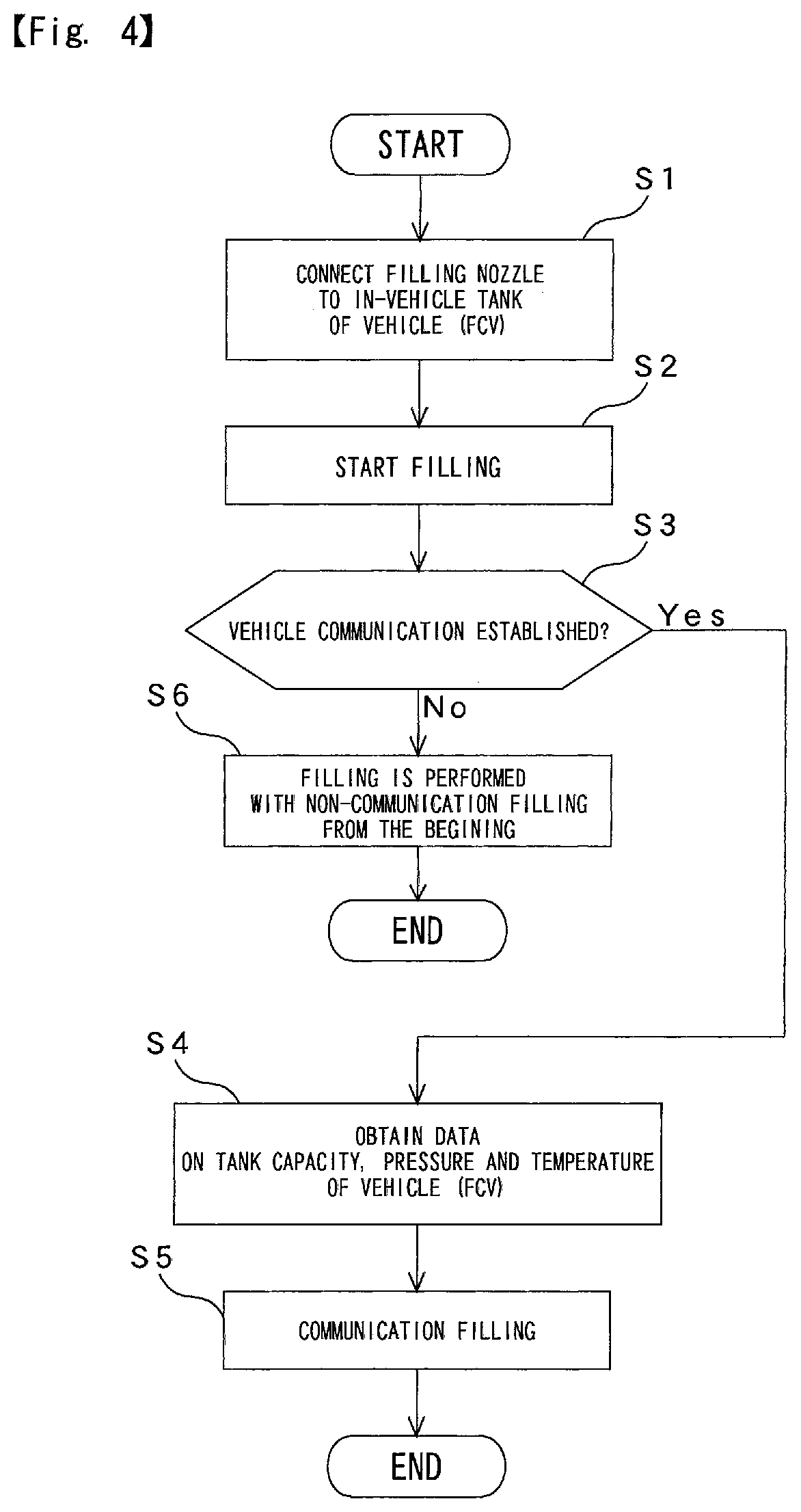

Hydrogen filling system and hydrogen filling method

ActiveUS20200223684A1Reduce fill rateLow filling rateGas handling applicationsGas handling/storage effectsIn vehicleControl cell

To provide a hydrogen filling system and a hydrogen filling method capable of preventing hydrogen from being filled at high filling rate in the same manner as the communication filling despite a condition that pressure, temperature and so on in the in-vehicle tank are not precisely grasped. The hydrogen filling system (100) of the present invention includes a control unit (CU1, CU2, CU3) for controlling hydrogen filling, wherein the control unit has a function of judging whether or not there is an abnormality in pressure or temperature data in an in-vehicle tank (IT) at communication filling and a function of stopping the communication filling and converting to non-communication filling when there is an abnormality in the pressure or the temperature data.

Owner:TOKYO TATSUNO CO LTD

High-dispersion silver powder and solar battery electrode conductive silver paste

InactiveCN102139368BLow percolation valueReduce fill rateSemiconductor devicesSilver pasteElectrical battery

The invention discloses high-dispersion silver powder and solar battery electrode conductive silver paste, wherein the conductive silver paste is prepared from the following components in mass percentage: 53-61.8% of high-dispersion silver powder in claim 1, 21.5-31% of glass cement and 15-17.6% of organic carrier. The high-dispersion silver powder provided by the invention has very good dispersity and by means of the conductive silver paste prepared by the high-dispersion silver powder, the usage amount of the silver powder is reduced and the conductive efficiency is improved in the mean time; in addition, the conductive silver paste provided by the invention is clean and environmental-friendly and is suitable for popularization and application. By means of the high-dispersion silver powder and the solar battery electrode conductive silver paste which are provided by the invention, the defects of poor dispersity of the conventional silver powder and large usage amount of the silver powder of the conventional conductive silver paste are overcome.

Owner:中科广化(重庆)新材料研究院有限公司 +3

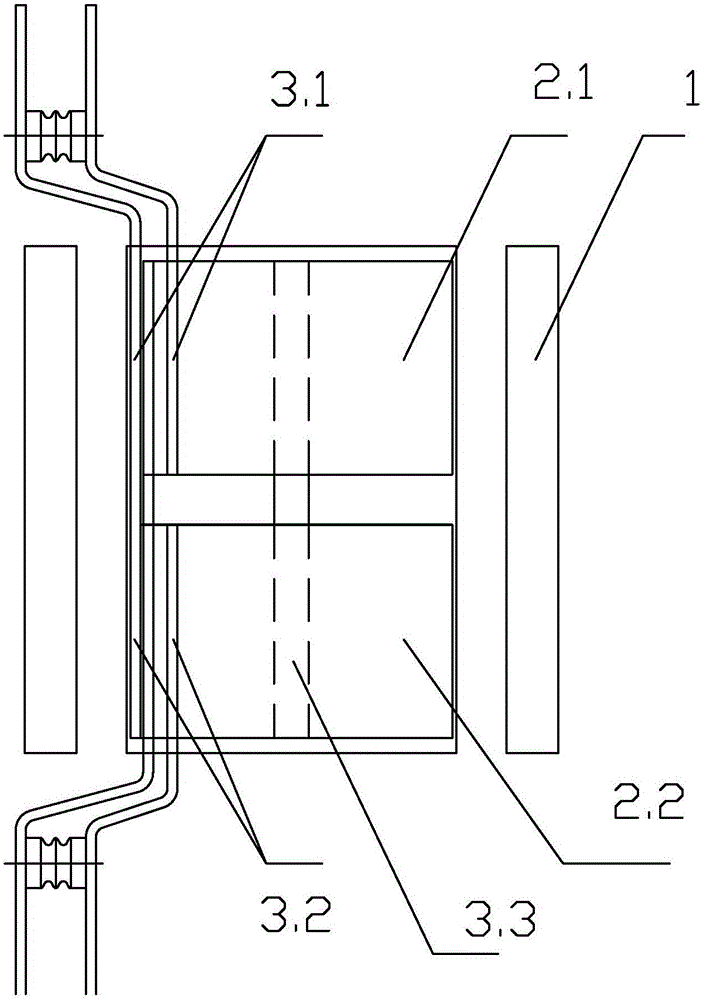

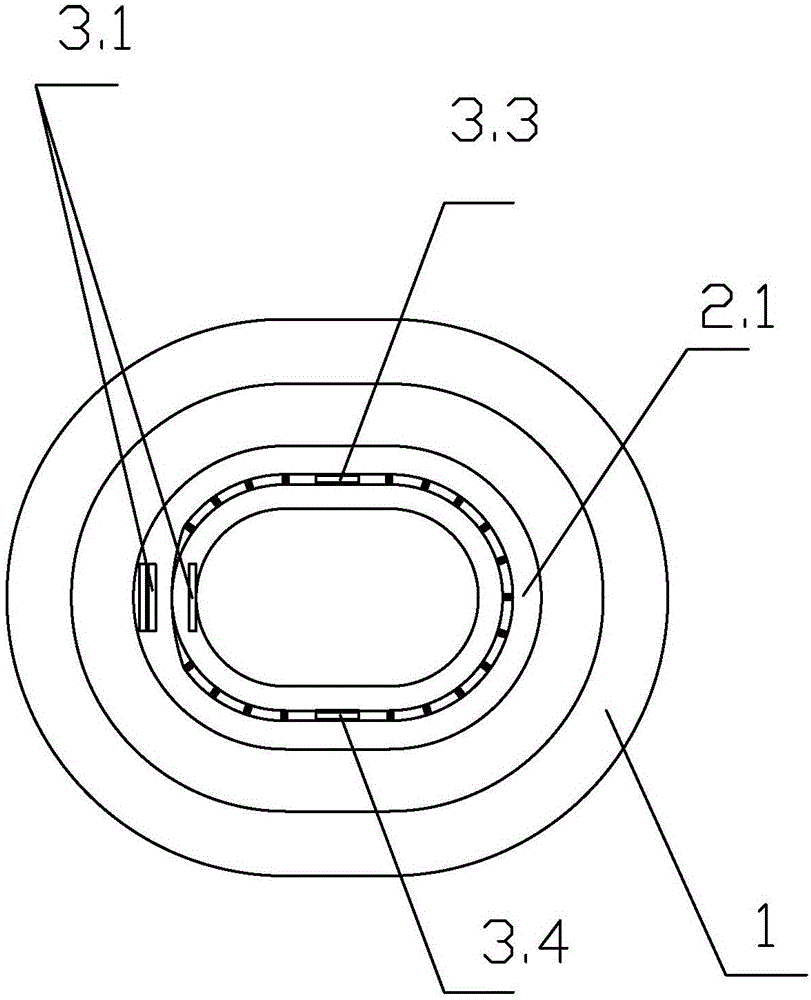

Double-splitting photovoltaic variable structure

ActiveCN105070491ANot easy to fall offReduce winding difficultyTransformers/inductances coils/windings/connectionsCoils manufactureLow voltageCopper

A double-splitting photovoltaic variable structure comprises a barrel-shaped high-voltage coil (1) and a first low-voltage coil (2.1) and a second low-voltage coil (2.2) which are located in the high-voltage coil (1), the first low-voltage coil (2.1) and the second low-voltage coil (2.2) are axially arranged, a gap is formed between the first low-voltage coil (2.1) and the second low-voltage coil (2.2) in the axial direction, the first low-voltage coil (2.1) is provided with a first conductive copper bar (3.1), and the second low-voltage coil (2.2) is provided with a second conductive copper bar (3.2); the double-splitting photovoltaic variable structure further comprises a first transposition copper bar (3.3) and a second transposition copper bar (3.4) which are internally embedded in the low-voltage coils, and the two ends of the first transposition copper bar (3.3) and the two ends of the second transposition copper bar (3.4) are welded to the first low-voltage coil (2.1) and the second low-voltage coil (2.2) respectively.

Owner:宁波奥克斯智能科技股份有限公司

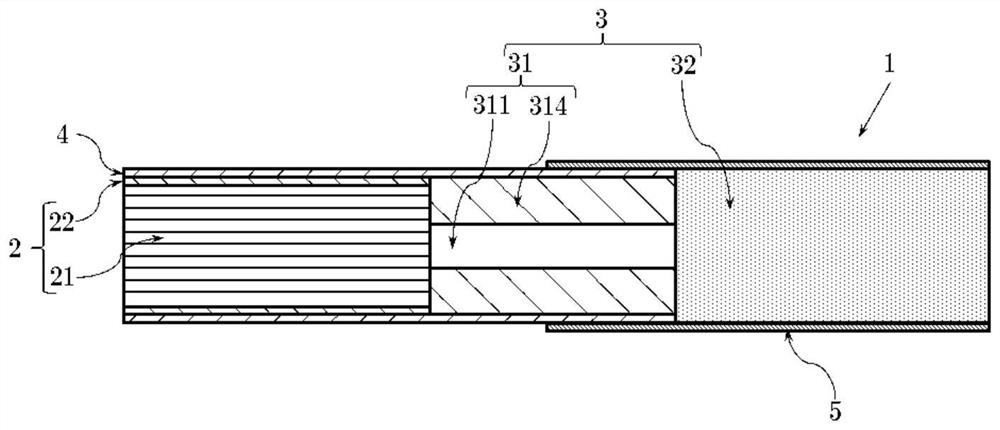

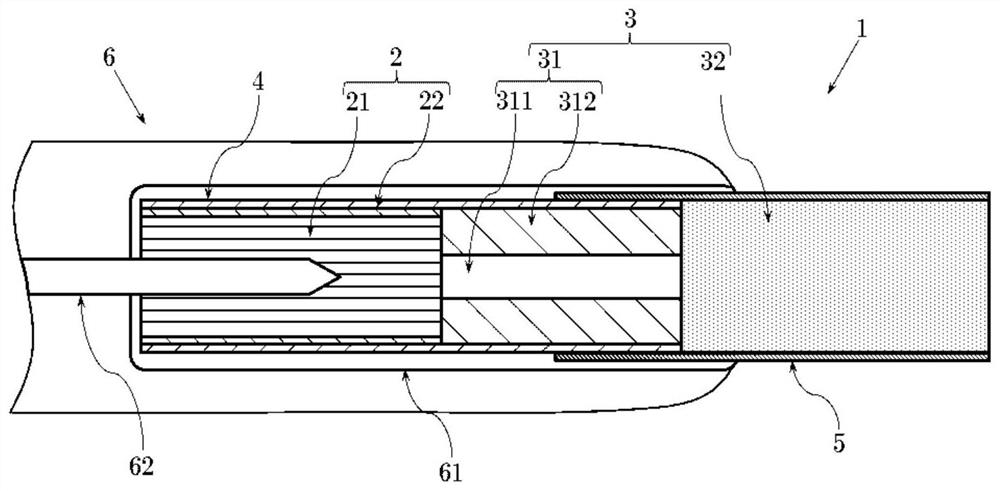

Heated aroma-producing body, aroma cartridge, and manufacturing method and manufacturing device for heated aroma-producing body

PendingCN112384088AEasy to insertImprove fill rateTobacco preparationTobacco treatmentAromaEngineering

Provided are a heated aroma-producing body and an aroma cartridge that is provided therewith, as well as a manufacturing method and a manufacturing device for the heated aroma-producing body, which can solve the problems of a heated aroma-producing substrate burning during a draw and the heated aroma-producing substrate falling during installation / removal of an aroma cartridge, in addition to increasing the filling rate of the heated aroma-producing substrate and ensuring a suitable number of instances of smoking, while also forming a vapor flow path that allows pleasant smoking of an aroma cartridge that is provided with a heated aroma-producing body in which a heated aroma-producing substrate including an aerosol former is rolled up in a packaging material. Provided are a heated aroma-producing body and an aroma cartridge that is provided therewith, as well as a manufacturing method and manufacturing device for this heated aroma-producing body, said heated aroma-producing body beingcharacterized by comprising: a vapor flow path of gaps that are formed by noodle-shaped heated aroma-producing substrates being gathered into a primary aggregate; a vapor flow path of gaps that are formed by noodle-shaped heated aroma-producing substrates and this primary aggregate being gathered into a secondary aggregate; and a vapor flow path of gaps that are formed by contact of a heated aroma-producing body packaging material and heated aroma-producing substrates, wherein these vapor flow paths penetrate in the lengthwise direction of the heated aroma-producing body.

Owner:MIRE TECH CO LTD

Resin filling apparatus, filling method, and method of manufacturing an electronic device

InactiveUS7955065B2Reduce entrainmentSimple processWave amplification devicesFinal product manufactureEngineeringElectronic component

Owner:FUJITSU LTD

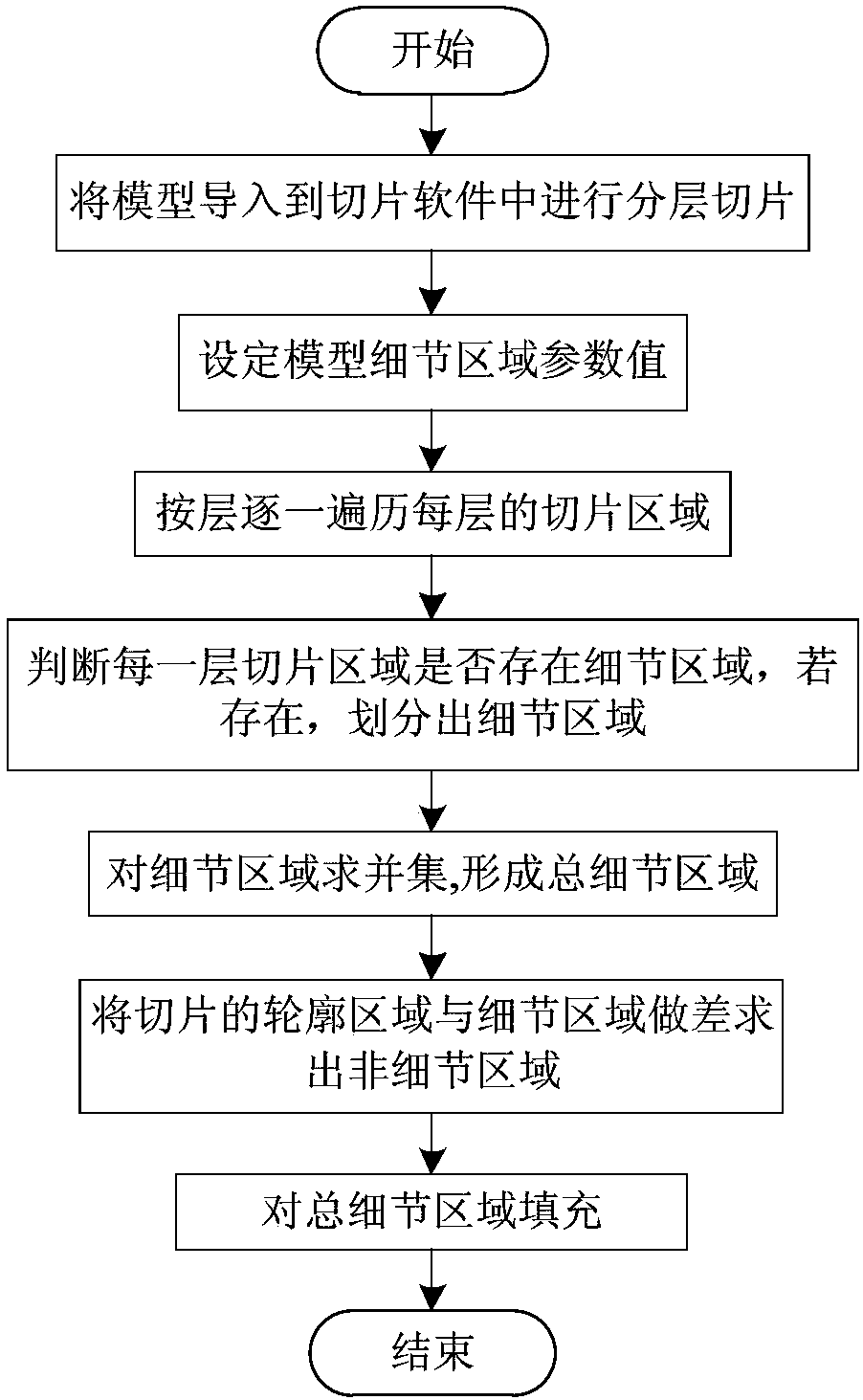

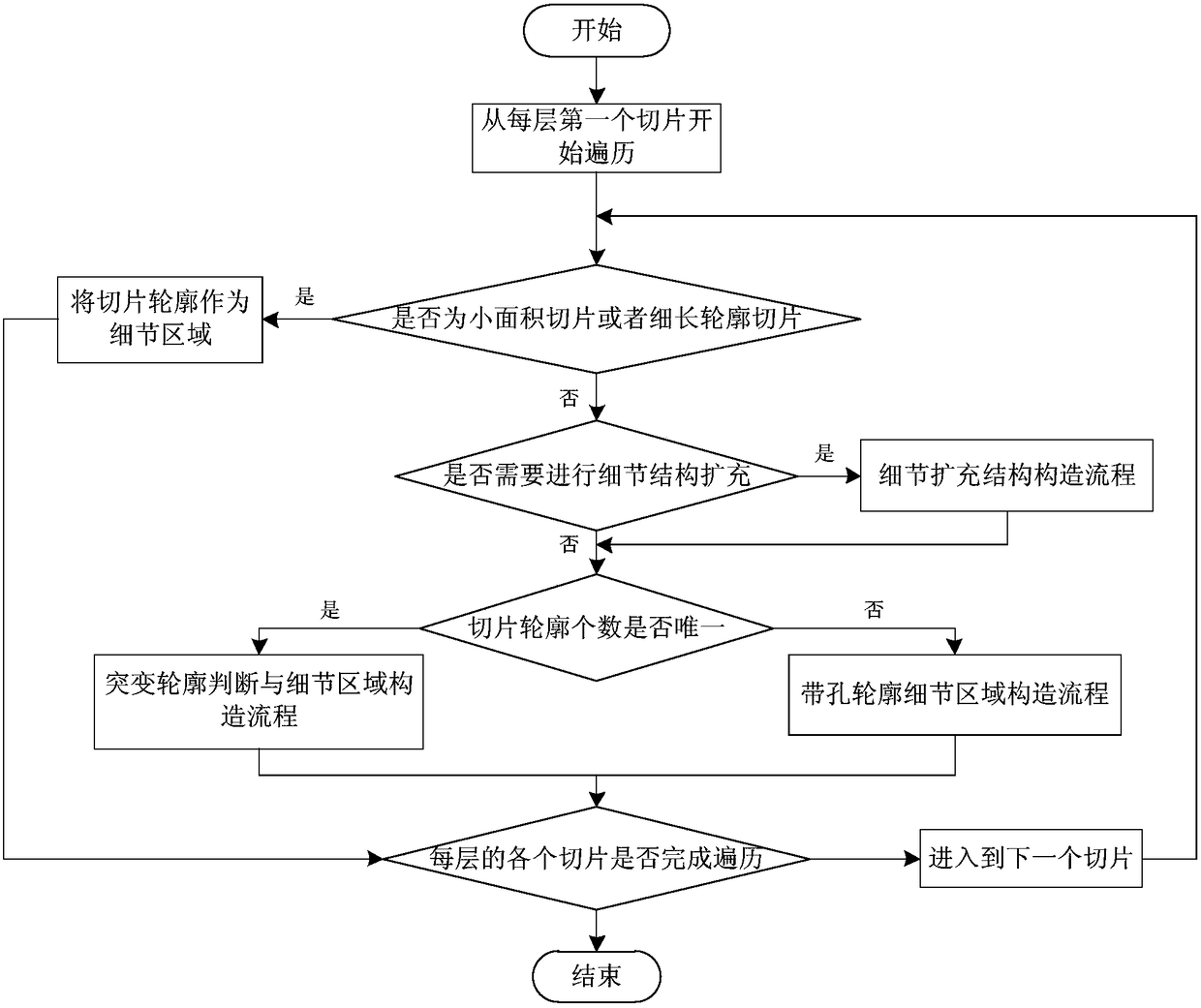

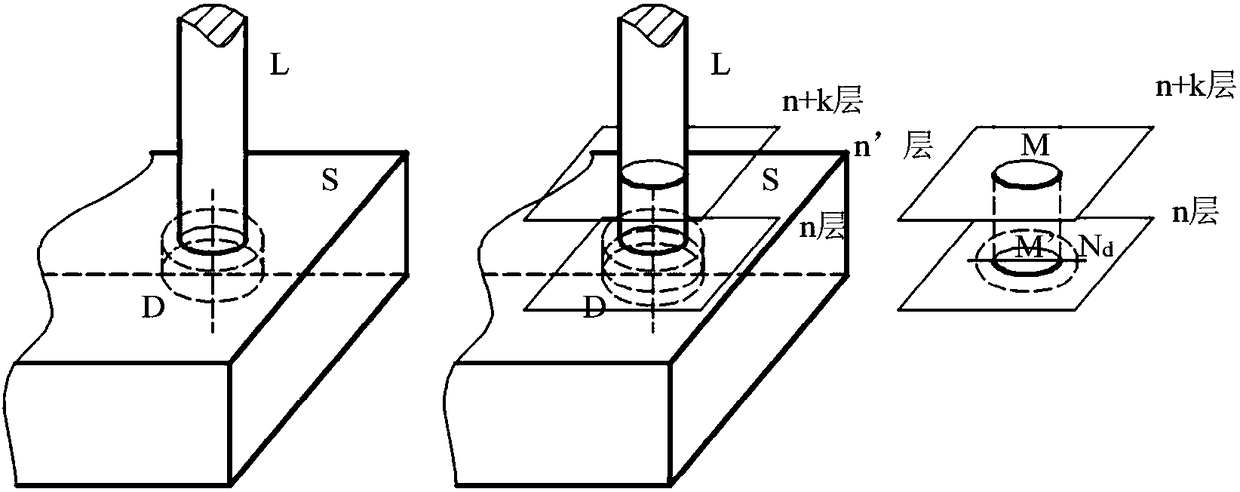

A 3D printing model detail region filling method based on shape features

The invention provides a 3D printing model detail area partition filling method based on shape features. The method comprises the steps as follows: first, layering and slicing a model, and setting model detail area parameters; then, traversing the slice areas layer by layer and judging whether there is a detail area in each slice layer, and if there is a detail area in a slice layer, marking out the detail area according to the contour features of the slice area; and finally, getting the detail area and the non-detail area of each layer through Boolean operation, and filling the detail area of each layer at high filling rate. A printing model obtained using the 3D printing model detail area partition filling method based on shape features put forward by the invention is of high strength in detail positions, and has the advantages of high printing efficiency and printing supply saving.

Owner:SOUTHEAST UNIV

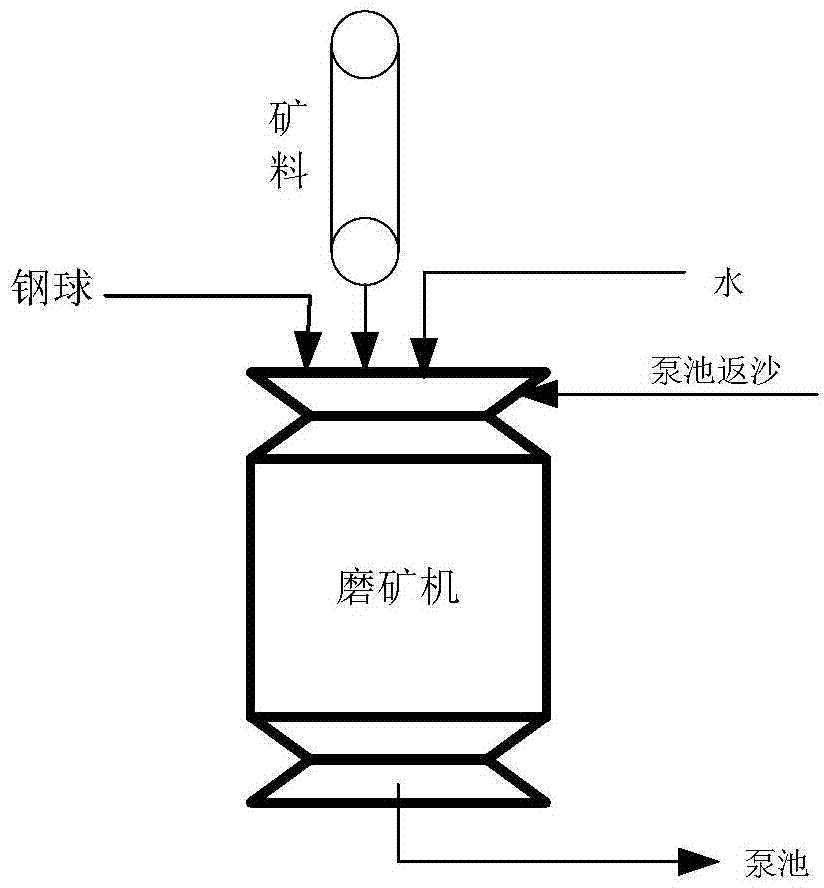

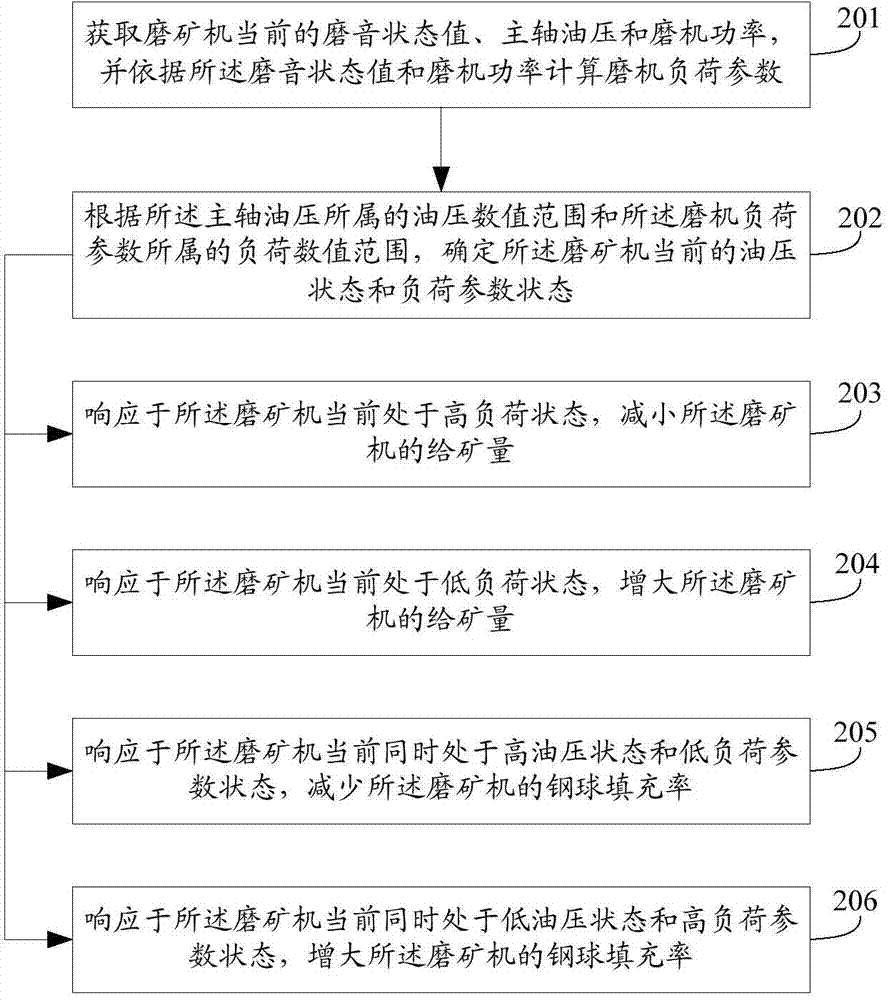

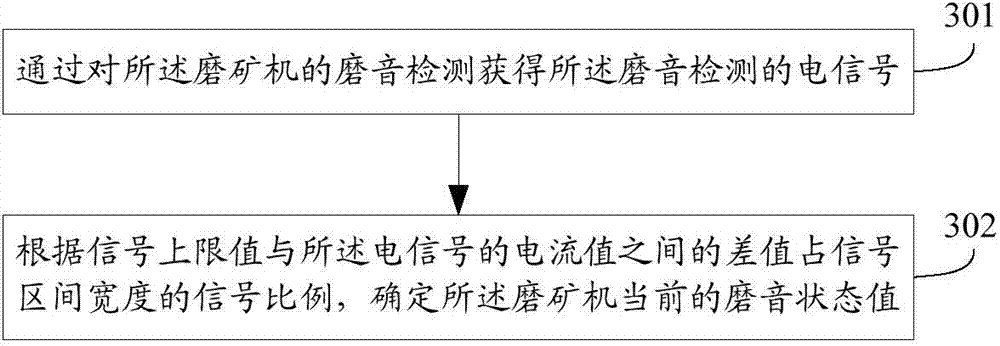

Method and device for adjusting steel ball filling rate in control of ore grinding machine

The application discloses a method and device for adjusting the steel ball filling rate in control of an ore grinding machine. The method comprises the following steps: obtaining a current grinding sound status value, a current main shaft oil pressure and a current grinding machine power of the ore grinding machine, calculating a load parameter of the grinding machine according to the grinding sound status value and the grinding machine power; determining a current oil pressure status and a current load parameter status of the ore grinding machine according to an oil pressure value range to which the main shaft oil pressure belongs and a load value range to which the grinding machine load parameter belongs; when the ore grinding machine is in a high-load status currently, reducing the ore feeding quantity; when the ore grinding machine is in a low-load status currently, increasing the ore feeding quantity; when the ore grinding machine is simultaneously in high-oil pressure status and a low-load parameter status currently, reducing the steel ball filling rate; when the ore grinding machine is simultaneously in low-oil pressure status and a high-load parameter status currently, increasing the steel ball filling rate. According to the technical scheme of the application, the steel ball filling rate can be increased when steel balls of the ore grinding machine are less, and can be reduced when the steel balls of the ore grinding machine are more, so that the production efficiency of the ore grinding machine is increased.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

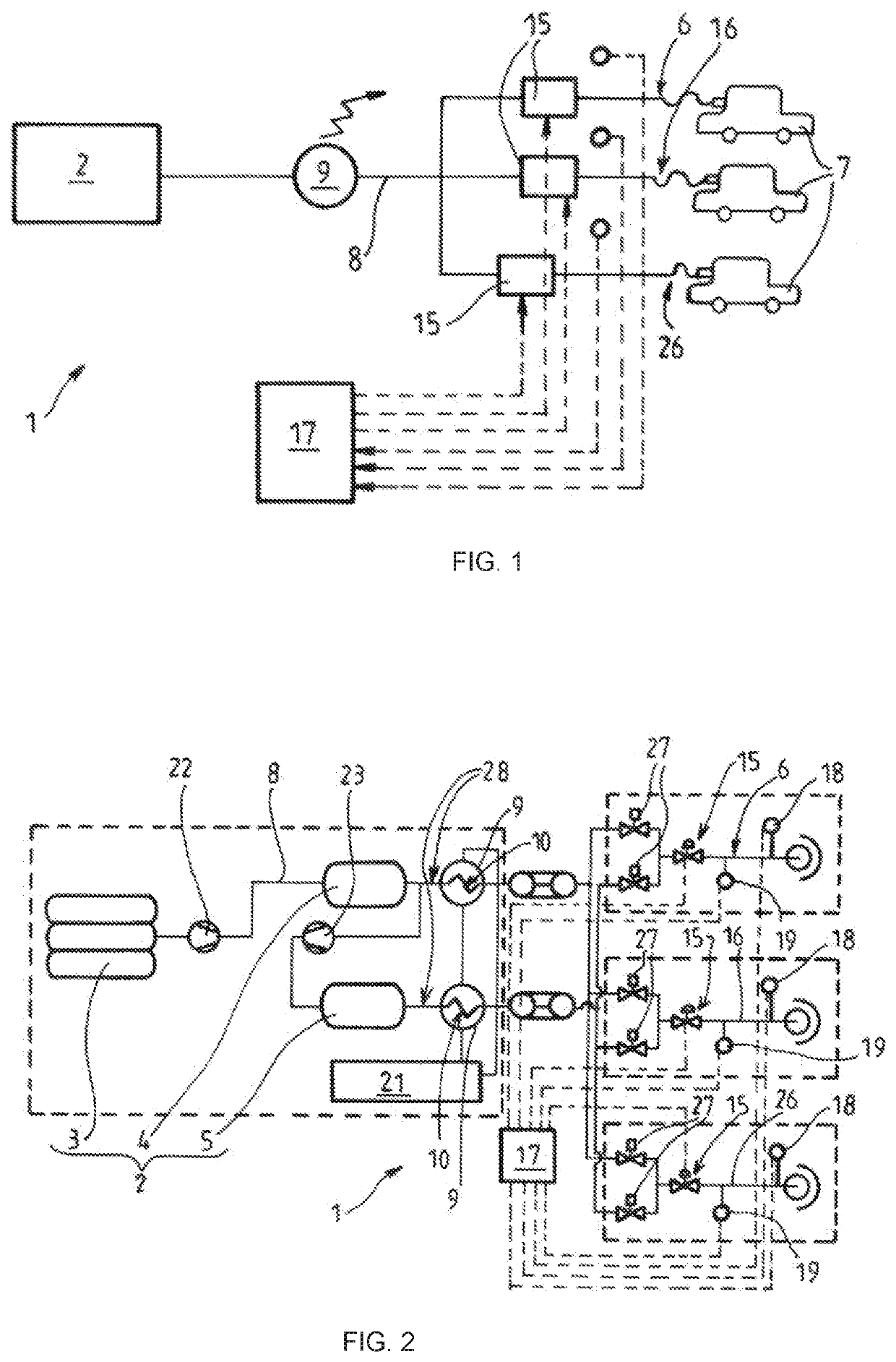

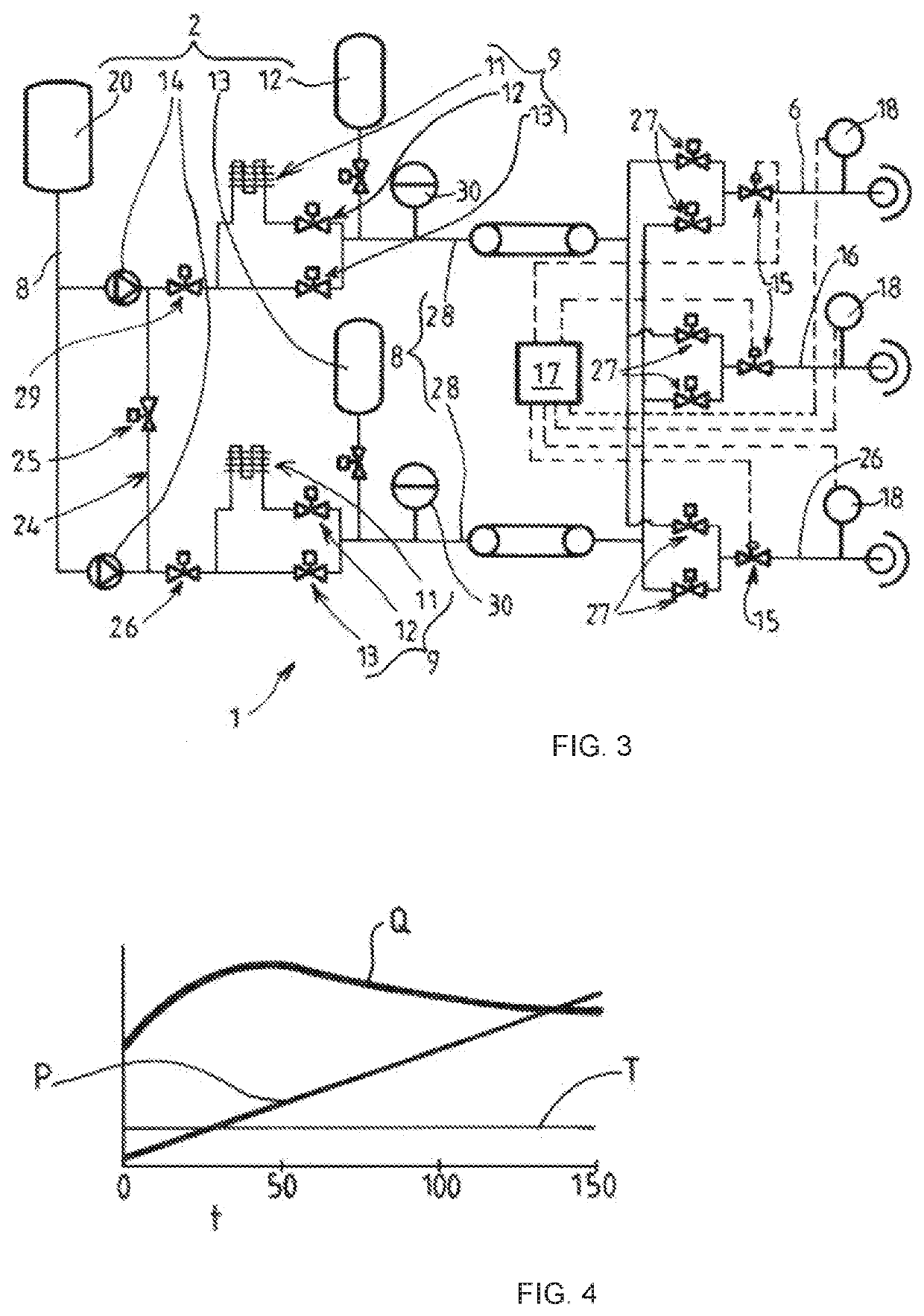

Device and method for filling tanks

ActiveUS20210003253A1Improve fill rateReduce fill rateGas handling applicationsGas handling/storage effectsEngineeringMechanical engineering

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

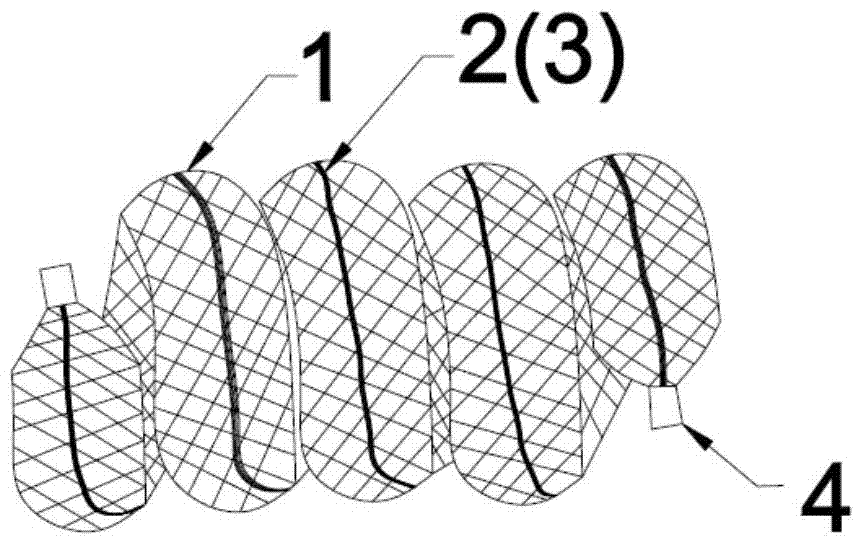

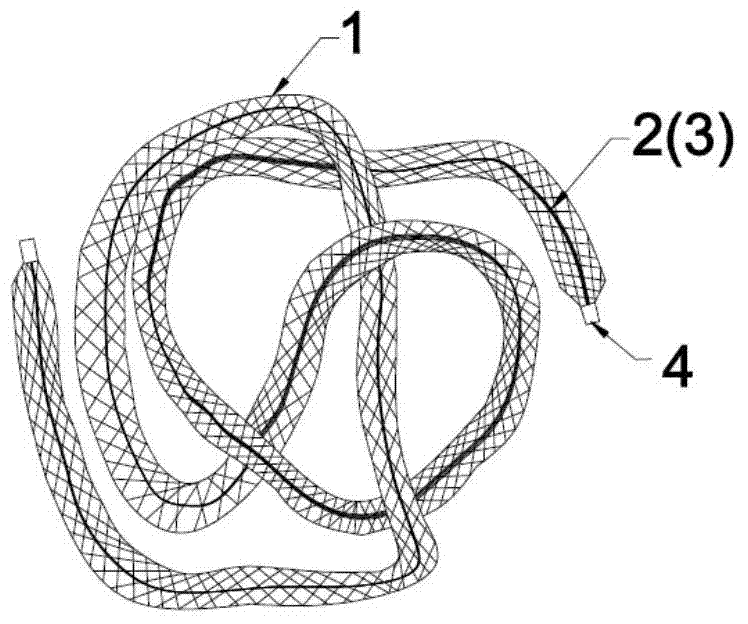

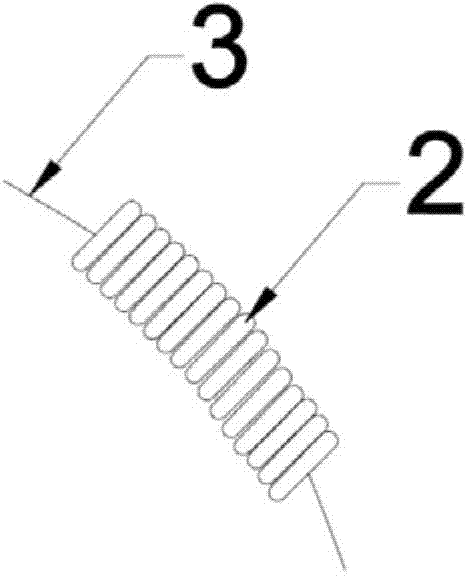

Mesh spring ring and manufacturing method thereof

The invention provides a mesh spring ring. The mesh spring ring comprises a metal mesh sleeve and a spring. The spring is sleeved with the metal mesh sleeve, and the inner diameter of the metal mesh sleeve is larger than the outer diameter of the spring. The metal mesh sleeve is a memory alloy mesh. A metal core is arranged in the spring in a penetrating mode. The metal core and the metal mesh sleeve are fixed to the two ends of the spring. The mesh spring ring is used for replacing an existing spring ring structure, the embolism effect is enhanced to a large degree through an expanded mesh shape, the filling rate is low, meanwhile, the weight of fillers is lowered, arterial aneurysm is prevented from oppressing surrounding nervous tissue, the mesh hole structure has the good flexibility and elasticity, and can be attached to the wall of the arterial aneurysm well after being released in a tumor cavity, and the mesh hole structure is stably placed in the arterial aneurysm and cannot fall off. Meanwhile, certain mechanical strength can be achieved in the conveying process through the spring in the spring ring in the metal mesh sleeve, the spring ring has good mechanical conduction, and the shape and position of the mesh spring ring can be displayed under X rays.

Owner:APT MEDICAL HUNAN INC

Paint for forming insulating film, and plasma display panel using the paint and method of manufacturing the same

InactiveUS6808435B2Improve wettabilityDecrease in flowabilitySynthetic resin layered productsAlternating current plasma display panelsOrganic solventInorganic materials

The present invention provides a paint for forming an insulating film, which has a good wettability to a surface to be coated with the paint and has no voids or pin-holes after being fired; a plasma display panel including a dielectric layer formed using the paint; and a method of manufacturing the plasma display panel. The paint contains inorganic fine particles, a binder resin, and an organic solvent that has a good wettability to glass such as a glass substrate, ceramic as an Ag electrode, and a metal compound such as an ITO film and forms a contact angle of less than 5° with these inorganic materials. Accordingly, the paint has a good wettability to a glass substrate, an Ag electrode, and an ITO film and the resultant insulating film thus has no voids or pin-holes.

Owner:PANASONIC CORP

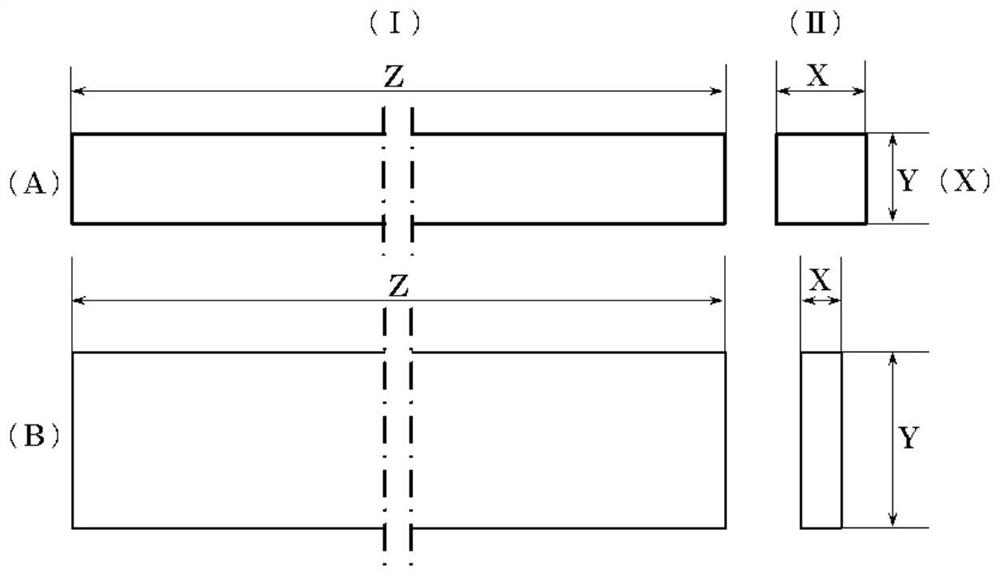

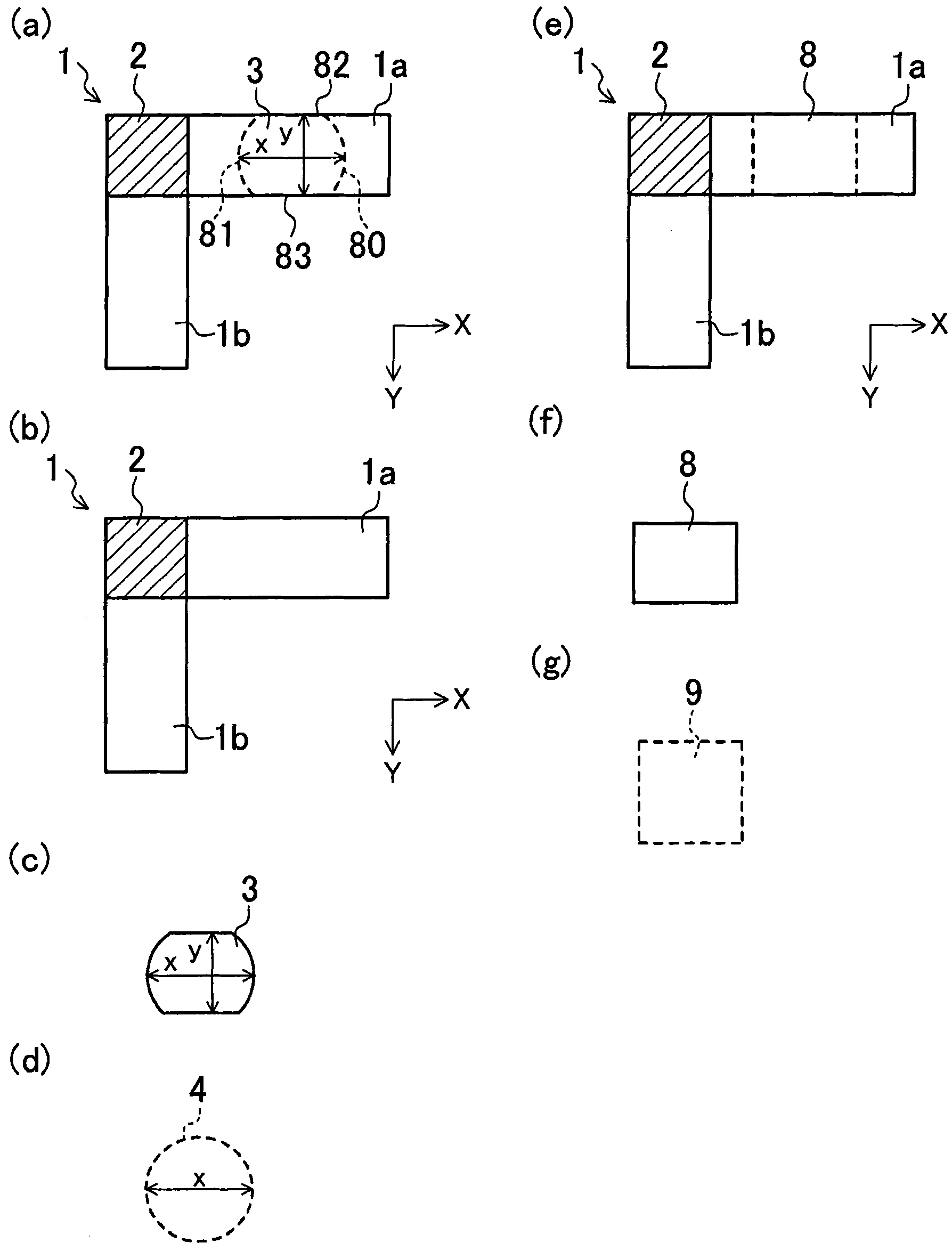

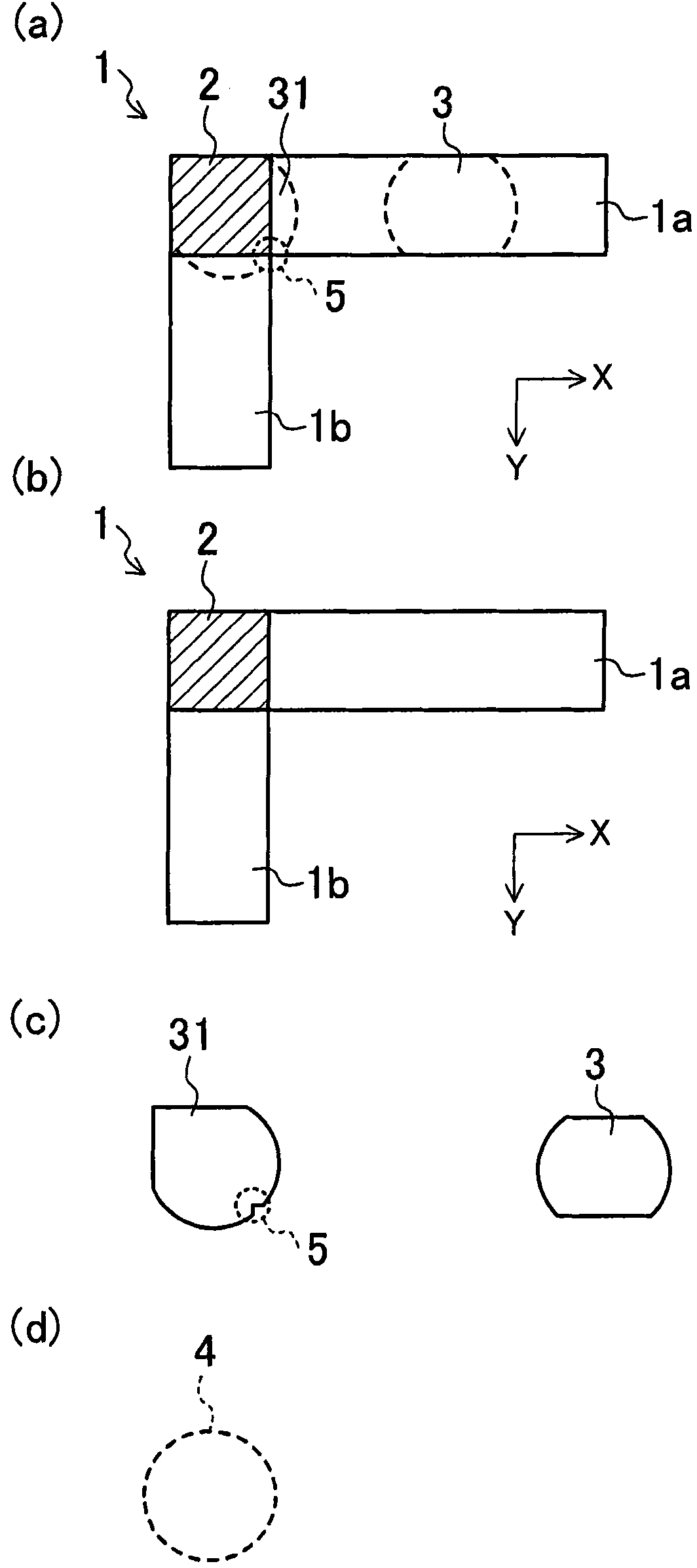

Semiconductor device, basic cell and semiconductor integrated circuit device

ActiveCN101960583AReduce fill rateSuppresses decline in manufacturing yieldSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

A semiconductor device provided with an interconnect (1) comprising a bent part (2), a first interconnect region (1a) extending from the bent part (2) to the X-direction, and a second interconnect region (1b) extending from the bent part (2) to the Y-direction. A via (3) is formed under the interconnect (1). The via (3) is formed at the first interconnect region (1a) so as to not overlap with the region of the bent part (2). The length (x) of the via (3) in the X-direction is longer than the length (y) in the Y-direction, and the two ends of the same in the Y-direction overlap with the two ends of the first interconnect region (1a) in the Y-direction.

Owner:SOCIONEXT INC

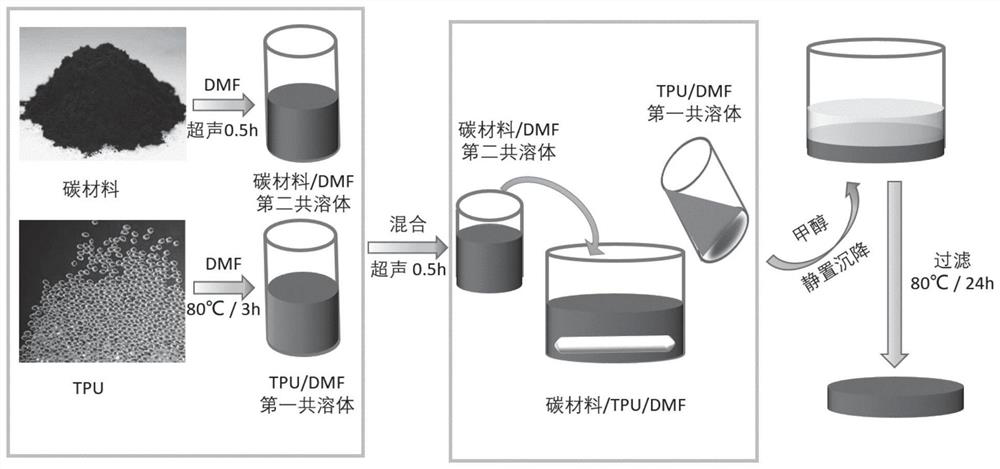

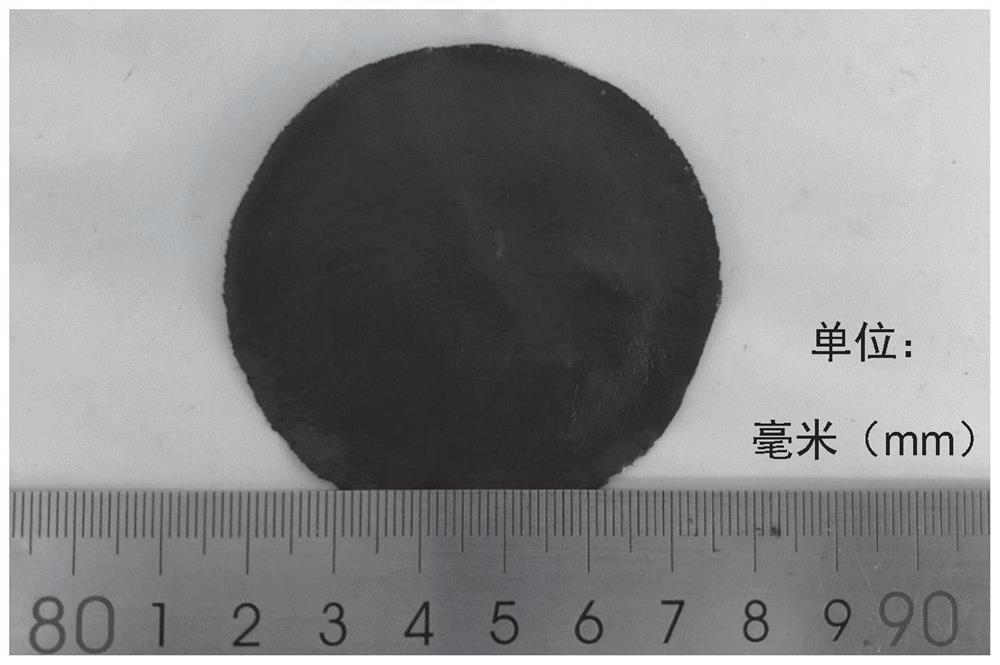

Carbon-based flexible conductive film, preparation method and application

The invention relates to a carbon flexible conductive film and a preparation method thereof. The carbon flexible conductive film comprises TPU and a carbon material. The carbon flexible conductive film is characterized in that the mass ratio of the carbon material to TPU is 1: 250 to 1: 50, the carbon material comprises a first component and a second component, the first component comprises graphene and / or reduced graphene oxide, the second component comprises one or more of graphite, conductive carbon black and carbon nanotubes, the ID / IG value of the Raman spectrum peak of the first component is A, the ID / IG value of the Raman spectrum peak of the second component is B, and the absolute value of the difference between A and B is less than or equal to 0.4. The carbon-based flexible conductive film provided by the invention uses less carbon material, the dispersion process is relatively simple, the conductivity can be as low as 10<-4> ohm.m, and the final product meets the anti-staticperformance requirement and the conductive performance requirement in GBT 15662-1995 that the volume resistivity is lower than 10<6>ohm.m, and can be applied to flexible electronic devices.

Owner:XIAMEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com