Hydrogen filling system and hydrogen filling method

a hydrogen filling system and hydrogen filling technology, applied in the direction of electrochemical generators, liquid transfer devices, container discharging methods, etc., can solve the problems of high hydrogen filling rate and inconvenient hydrogen filling, and no technology for dealing with the above inconvenience has been proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

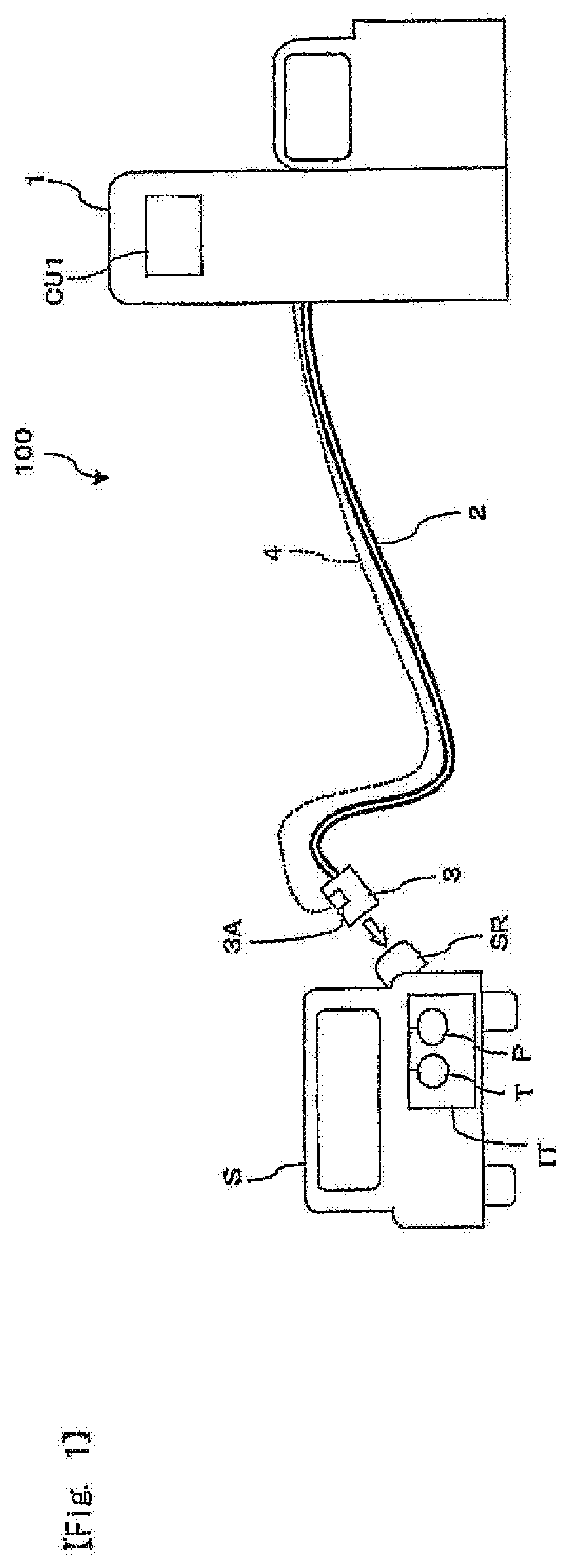

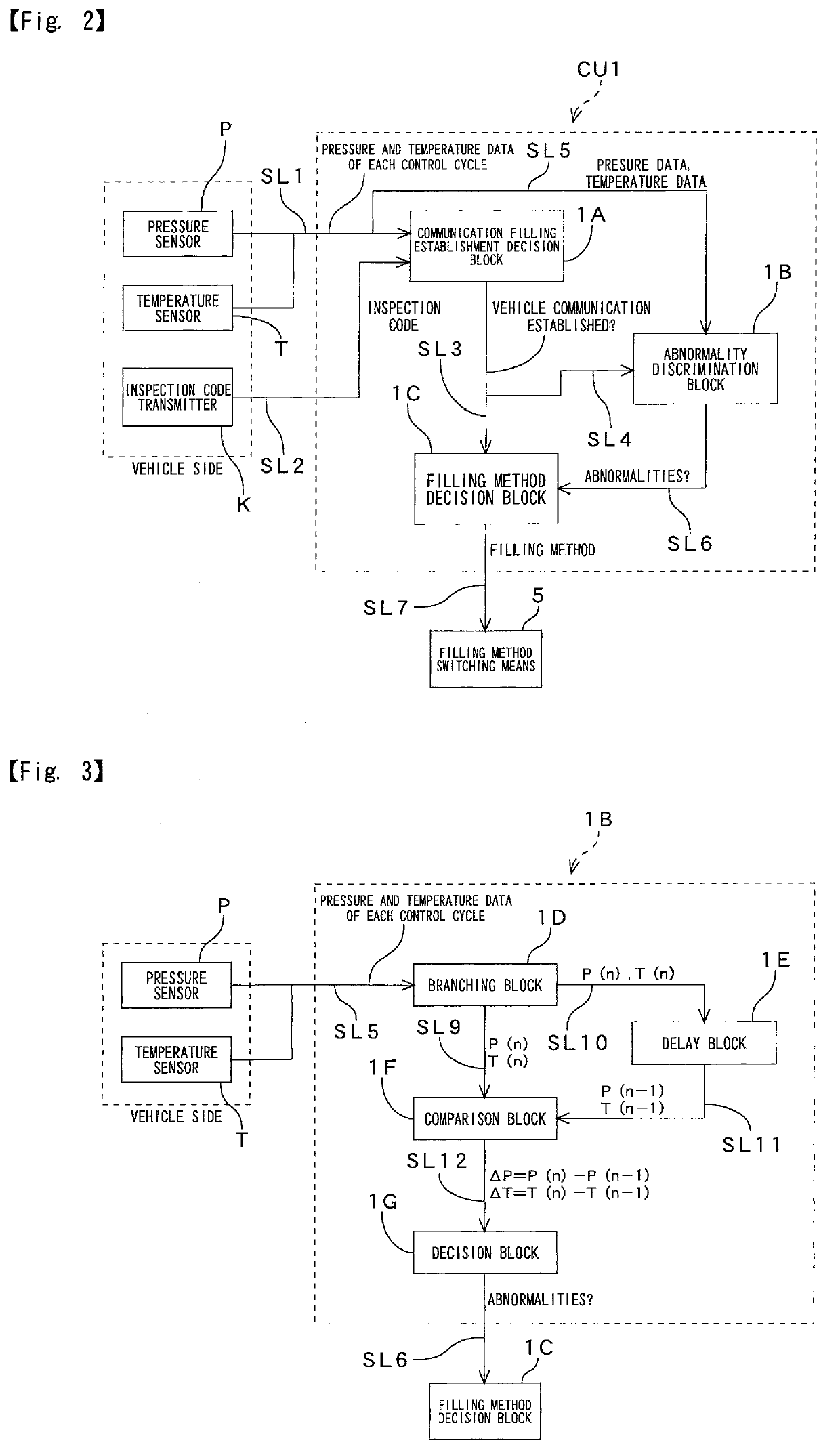

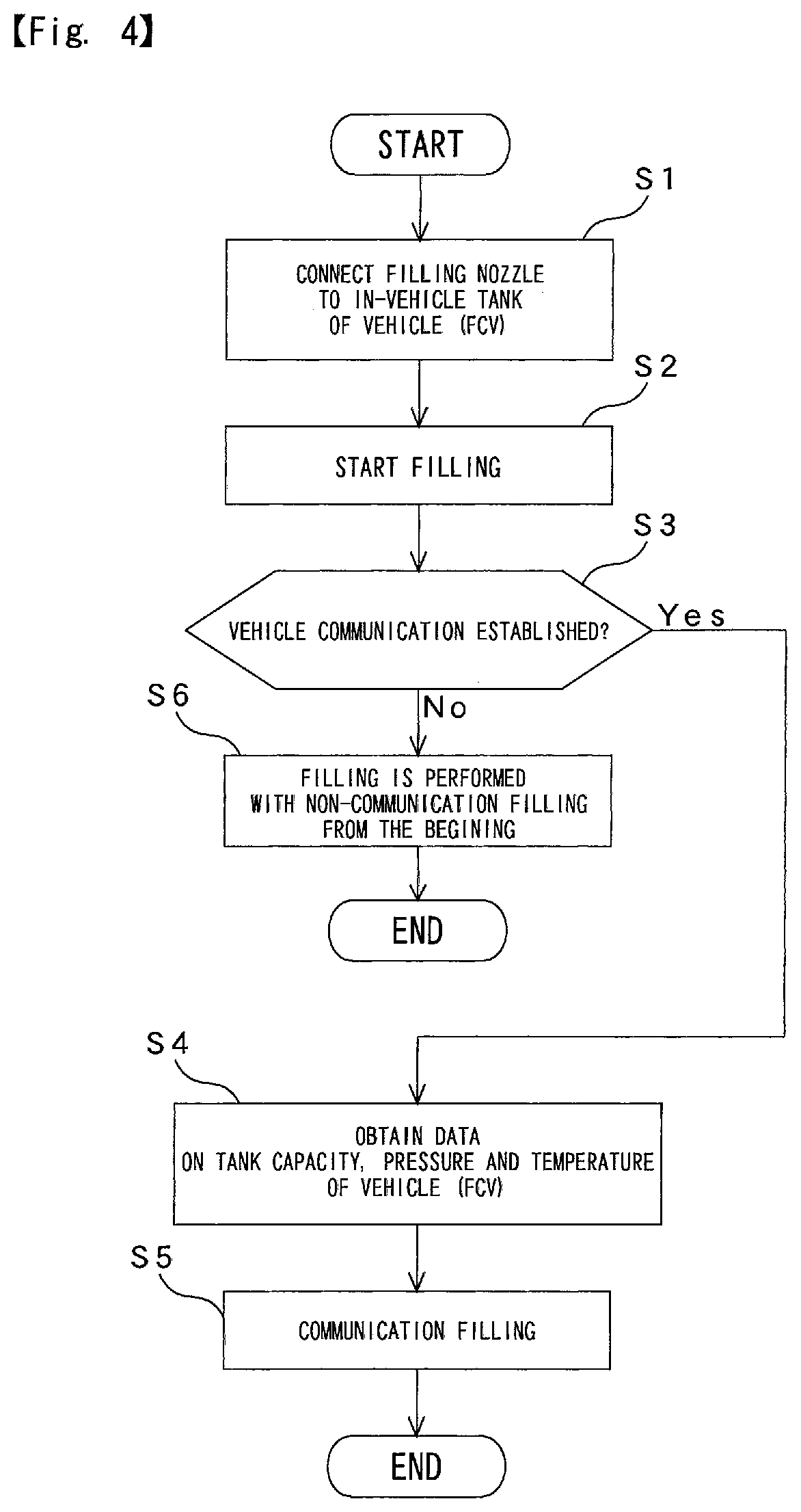

[0023]Next, embodiments of the present invention will be explained with reference to the drawings. At first, the present invention will be explained with reference to FIGS. 1 to 5. In FIG. 1, a hydrogen filling system of the present invention whose overall construction is indicated with numeral 100 includes a hydrogen filling device 1 and a control unit CU1 for controlling hydrogen filling, and the control unit CU1 is installed in the hydrogen filling device 1. To the hydrogen filling device 1 is connected a filling hose 2, and to an end of the filling hose 2 is attached a filling nozzle 3. The filling nozzle 3 is connectable and disconnectable to a receptacle SR on an in-vehicle tank IT (fuel tank) of a vehicle S to which hydrogen is filled (for instance, a fuel cell vehicle FCV). In addition, the hydrogen filling device 1 includes a signal transmitting system 4 for transmitting information on the in-vehicle tank of the S such as pressure and temperature data. The signal transmitti...

second embodiment

[0048]Next, with reference to FIG. 6, the present invention will be explained. In the hydrogen filling system 100-1 shown in FIG. 6, the control unit CU2 is mounted, not to each hydrogen filling device 1, but to a rear equipment 10. Here, the “rear equipment” includes so-called “POS” also in this specification. And, the rear equipment is mounted in an office for instance in a gas station. In FIG. 6, the rear equipment 10 is installed in an office of a gas station with plurality of hydrogen filling devices (dispensers) 1, and the control unit CU2 is mounted in the rear equipment 10. The control unit CU2 of the rear equipment 10 is connected to a plurality (three in FIG. 6) of hydrogen filling devices 1, 1-1, 1-2 through signal transmitting systems 11, 11-1, 11-2 capable of bidirectional communication such as optical communication path, and each hydrogen filling devices 1, 1-1, 1-2 is connectable to each in-vehicle tank IT, IT-1, IT-2 of each vehicle S, S-1, S-2 through a filling hose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com