Carbon-based flexible conductive film, preparation method and application

A flexible conductive, carbon-based technology, applied in the field of conductive materials, can solve the problems of high surface resistance, difficulty in meeting the requirements of antistatic performance and conductive performance, and achieve the effect of excellent conductive performance, low filling rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

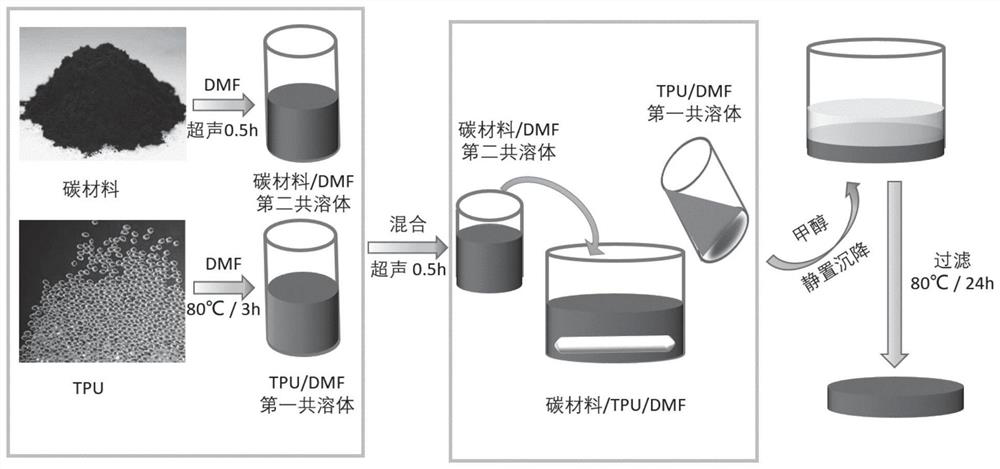

[0043] The present invention provides the preparation method of above-mentioned carbon-based flexible conductive film, such as figure 1 , is a flow chart of the preparation process of the carbon-based flexible conductive film of the present invention.

[0044] include:

[0045] Step S1: Dissolving the TPU masterbatch into a solvent, the solvent is DMF (dimethylformamide) or DMAC (dimethylacetamide), heating and stirring at 70-90°C to obtain the first co-solution;

[0046] Step S2: Disperse the carbon material into a solvent, the solvent is DMF or DMAC, the concentration of the carbon material is 1-3 mg / mL, and the temperature is controlled for ultrasonic dispersion to obtain the second co-solution, solvent selection and the solvent used in the preparation of the first co-solution Consistent; the mass ratio of carbon material and TPU masterbatch is 1:250~1:50, the carbon material includes the first component and the second component, the first component includes graphene and / or ...

Embodiment 1

[0053] The present embodiment carbon-based flexible conductive film comprises TPU and carbon material, and the mass ratio of carbon material and TPU is 1: 50, and carbon material is graphene (I D / I G =0.10) and graphite (I D / I G =0.18), the mass ratio of graphene and graphite is 1:1.

[0054] The preparation method of the carbon-based flexible conductive film in this embodiment is as follows:

[0055] Preparation of the first co-solution: Dissolve the TPU masterbatch with DMF, the ratio of TPU masterbatch and DMF is 1-3g / mL, place it in a magnetic stirrer and heat and stir at 70-90°C for 3h.

[0056] Preparation of the second co-solution: Utilize DMF to disperse graphene (I D / I G =0.10) and graphite (I D / I G =0.18), the concentration is 1-3mg / mL, the mass ratio of graphene and graphite is 1:1, ultrasonic dispersion is 30min and the temperature is controlled at 30°C.

[0057] Slowly pour the second co-solution into the first co-solution, ultrasonically disperse for ...

Embodiment 2

[0059] The present embodiment carbon-based flexible conductive film comprises TPU and carbon material, and the mass ratio of carbon material and TPU is 1: 50, and carbon material is graphene (I D / I G =0.11) and carbon nanotubes (I D / I G =0.23), the mass ratio of graphene and carbon nanotubes is 1:1.

[0060] The preparation method of the carbon-based flexible conductive film in this embodiment is as follows:

[0061] Preparation of the first co-solution: Dissolve the TPU masterbatch with DMF, the ratio of TPU masterbatch and DMF is 1-3g / mL, place it in a magnetic stirrer and heat and stir at 70-90°C for 3h.

[0062] Preparation of the second co-solution: Utilize DMF to disperse graphene (I D / I G =0.11) and carbon nanotubes (I D / I G =0.23), the concentration is 1-3mg / mL, the mass ratio of graphene and carbon nanotubes is 1:1, ultrasonic dispersion is 30min and the temperature is controlled at 30°C.

[0063] Slowly pour the second co-solution into the first co-soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com