Medium temperature curing high-performance conductive silver adhesive, preparation method thereof and application

A conductive silver glue, curing type technology, applied in the direction of conductive adhesives, adhesives, epoxy resin glue, etc., can solve the problems of increased cost, high curing temperature, environmental protection, etc., to improve electrical conductivity and thermal conductivity, good Mechanical properties, effect of reducing filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

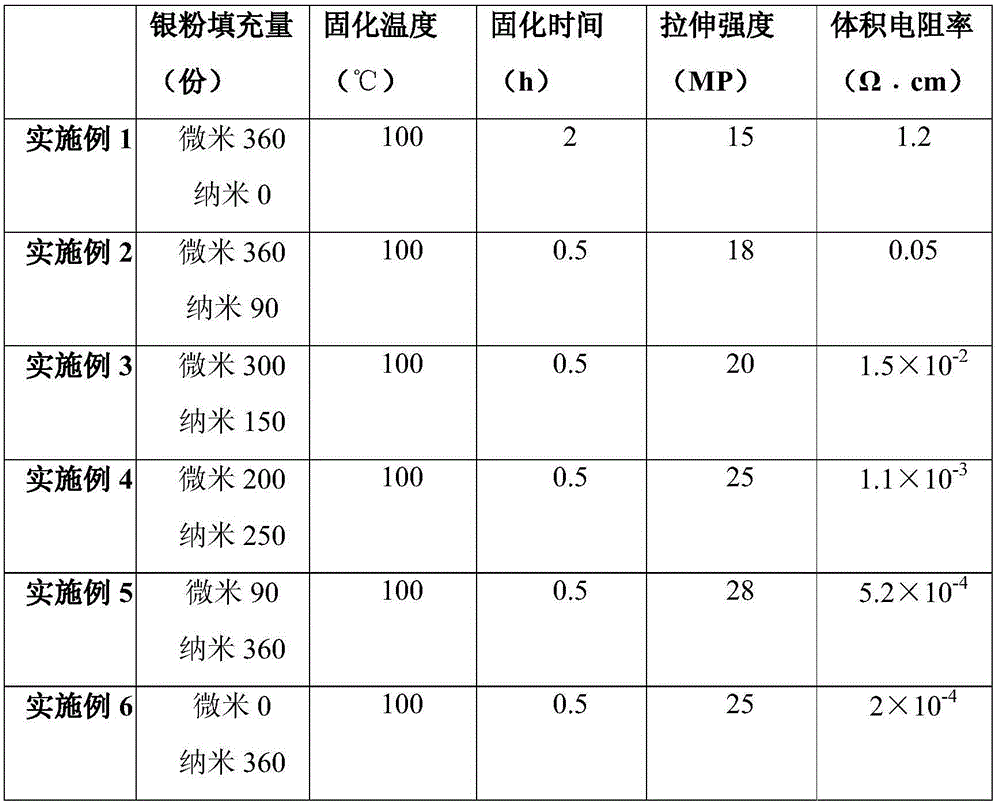

Embodiment 1

[0036]First, micron silver powder with a particle size of 1-8 μm and linear nano-silver with a length of 20-1000 μm and a diameter of 20-100 nm (refer to patent 201210437235.8 for the preparation method of the above-mentioned linear nano-silver, that is: use soluble silver salt, polyol , inorganic salt and linear silver guide agent to prepare linear nano-silver, add thiol substance that is easy to precipitate from ethylene glycol in the later stage of the nano-silver reaction system, because the thiol group has a strong chemical chelation force with the silver surface, it can be used on silver Alkyl chains are grafted on the surface, so that the silver powder is easier to precipitate) into the low-halogen bisphenol F epoxy resin 7001lv, fully stirred until uniform, to obtain a silver powder dispersion, and then dispersed to the above silver powder at a low temperature of 10°C Add epoxy resin latent curing agent dicyandiamide derivatives, epoxy resin accelerator tertiary amine s...

Embodiment 2

[0038] First, micron silver powder with a particle size of 1-8 μm and linear nano-silver with a length of 20-1000 μm and a diameter of 20-100 nm (refer to patent 201210437235.8 for the preparation method of the above-mentioned linear nano-silver, that is: use soluble silver salt, polyol , inorganic salt and linear silver guide agent to prepare linear nano-silver, add thiol substance that is easy to precipitate from ethylene glycol in the later stage of the nano-silver reaction system, because the thiol group has a strong chemical chelation force with the silver surface, it can be used on silver Alkyl chains are grafted on the surface, so that the silver powder is easier to precipitate) added to the bisphenol A epoxy resin, fully stirred until uniform, to obtain a silver powder dispersion, and then added to the above silver powder dispersion at a low temperature of 10°C Epoxy resin latent curing agent organic acid hydrazide derivatives, epoxy resin accelerator modified imidazole...

Embodiment 3

[0040] First, micron silver powder with a particle size of 1-8 μm and linear nano-silver with a length of 20-1000 μm and a diameter of 20-100 nm (refer to patent 201210437235.8 for the preparation method of the above-mentioned linear nano-silver, that is: use soluble silver salt, polyol , inorganic salt and linear silver guide agent to prepare linear nano-silver, add thiol substance that is easy to precipitate from ethylene glycol in the later stage of the nano-silver reaction system, because the thiol group has a strong chemical chelation force with the silver surface, it can be used on silver Alkyl chains are grafted on the surface, so that the silver powder is easier to precipitate) into the bisphenol S epoxy resin, fully stirred until uniform to obtain a silver powder dispersion, and then added to the above silver powder dispersion at a low temperature of 10°C Epoxy resin latent curing agent boron trifluoride-amine complex, epoxy resin accelerator triphenylphosphine derivat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com