Heated aroma-producing body, aroma cartridge, and manufacturing method and manufacturing device for heated aroma-producing body

A manufacturing method and generating body technology, applied in the manufacture of cigarettes, cigars, tobacco, etc., can solve the problems of burning of substrates, reducing the filling rate of aerosol-forming substrates, and the inability to enjoy the pleasure of smoking comfortably, and achieve improved The effect of fill rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in more detail through an embodiment below, but the present invention is not limited to this embodiment, and can be implemented after various changes within the scope not departing from the gist of the present invention, only limited in the claims Documented technical ideas.

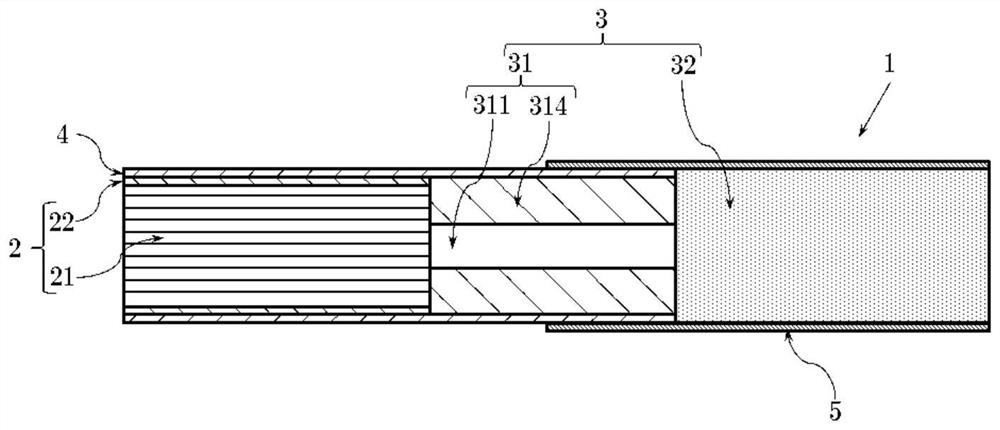

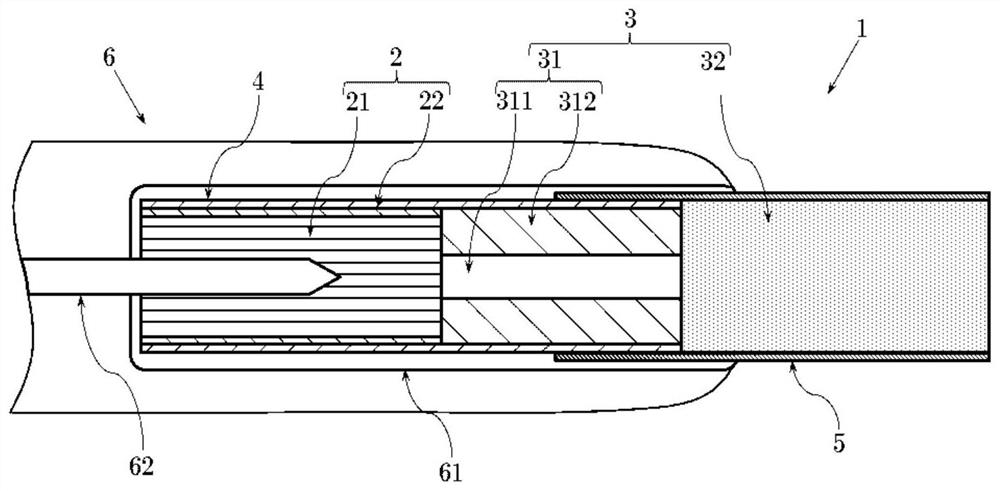

[0072]Fig. 1 is a schematic cross-sectional view of an aromatic cartridge 1 (aroma cartridge equipped with a heated aroma generating body 2 (with irregular gas channels)) cut along the central axis along the length direction according to an embodiment of the present invention. The aroma cartridge 1 is connected to the heated aroma generating body 2 and the mouthpiece 3 (composed of a support member 31 and a filter tip 32 ) in the length direction. In addition, the heated aroma generating substrate 21 is bundled by the heated aroma generating body packaging member 22 to form an approximately cylindrical heated aroma generating body 2 , and the supporting memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com