Patents

Literature

88results about How to "Reduce winding difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

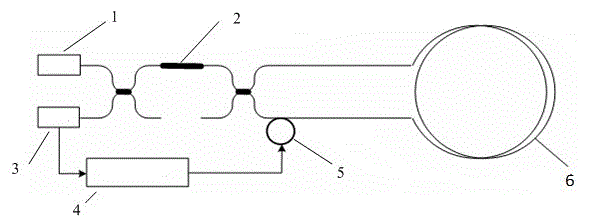

Tri-axial digital closed ring optical fiber peg-top time-sharing modulation method

InactiveCN101126644AAvoid crosstalkReduce winding difficultySpeed measurement using gyroscopic effectsSagnac effect gyrometersTime-sharingPhase modulation

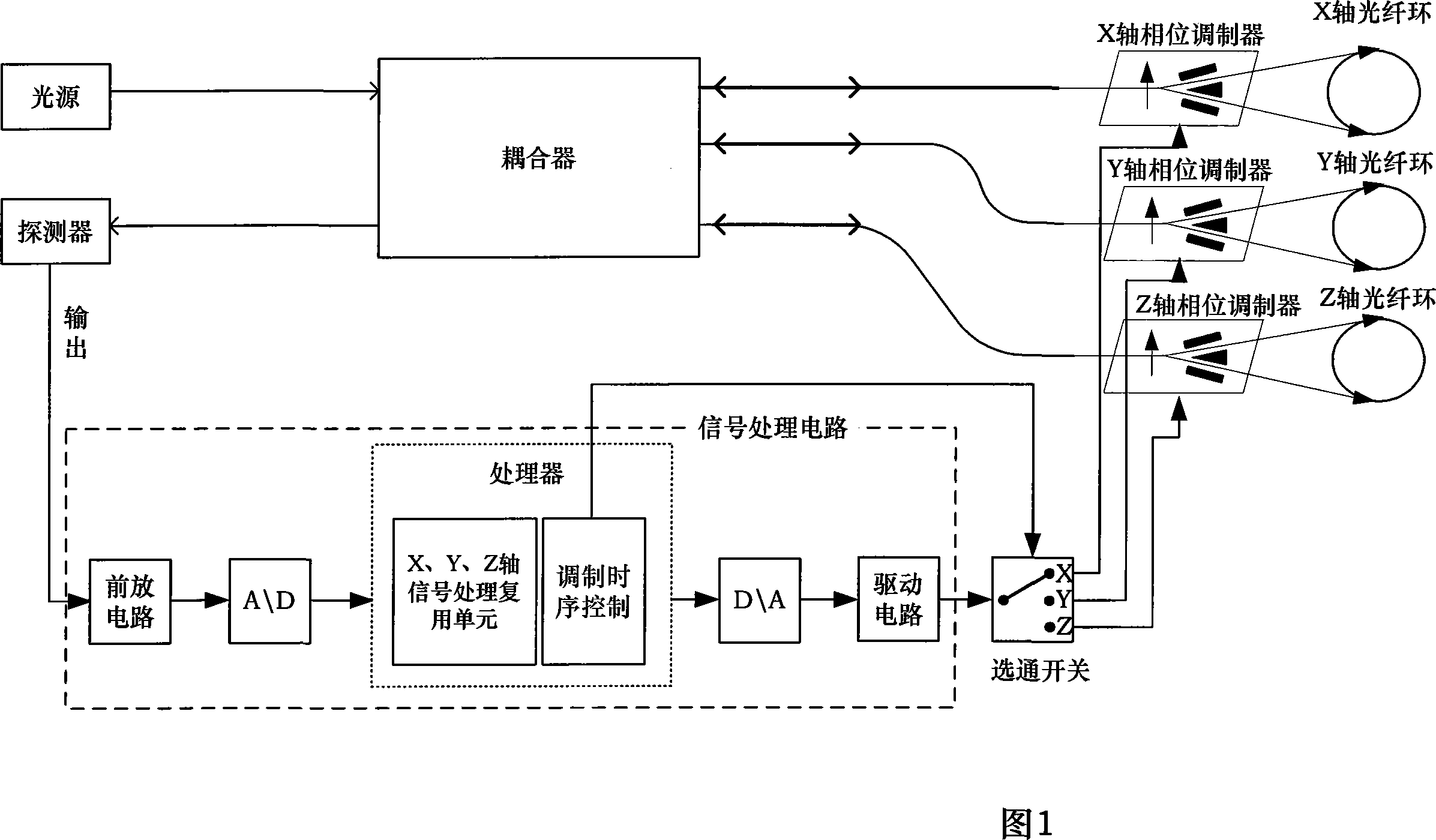

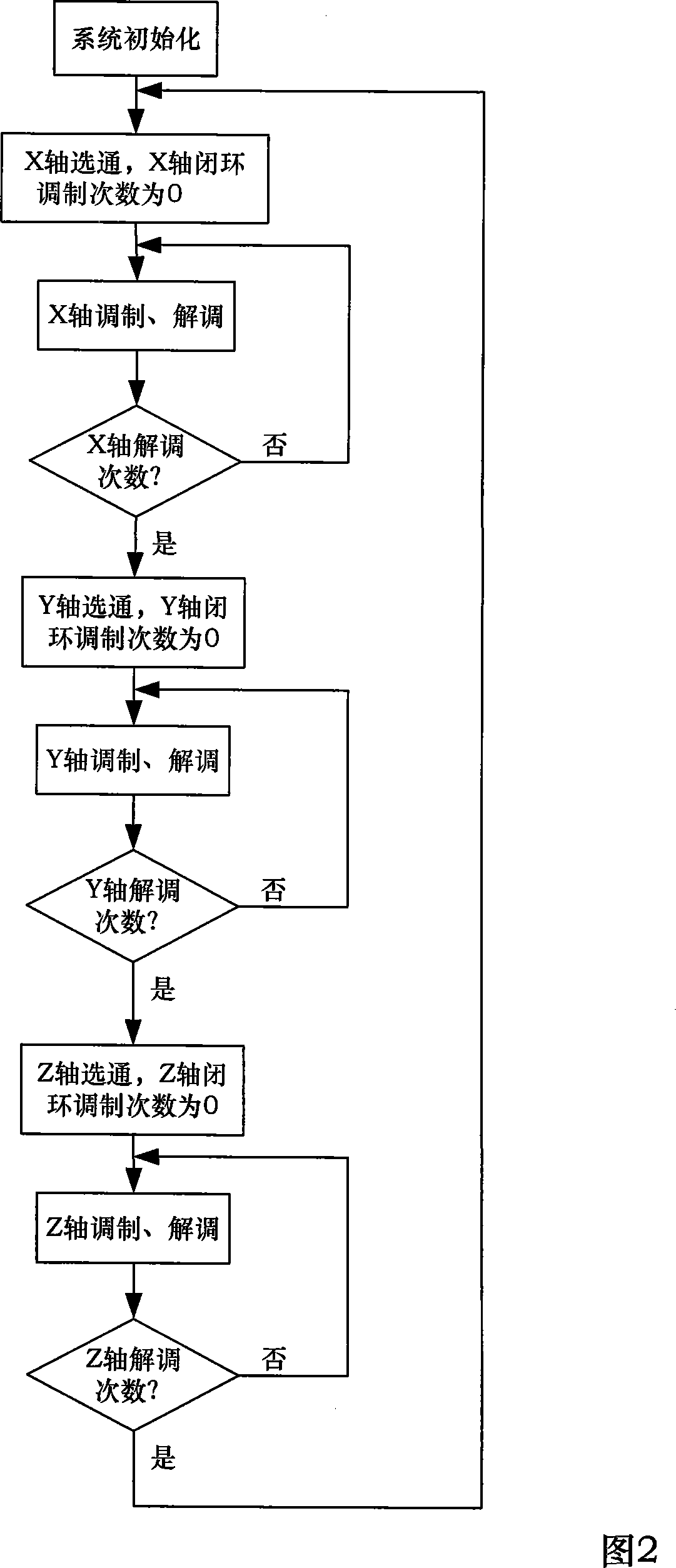

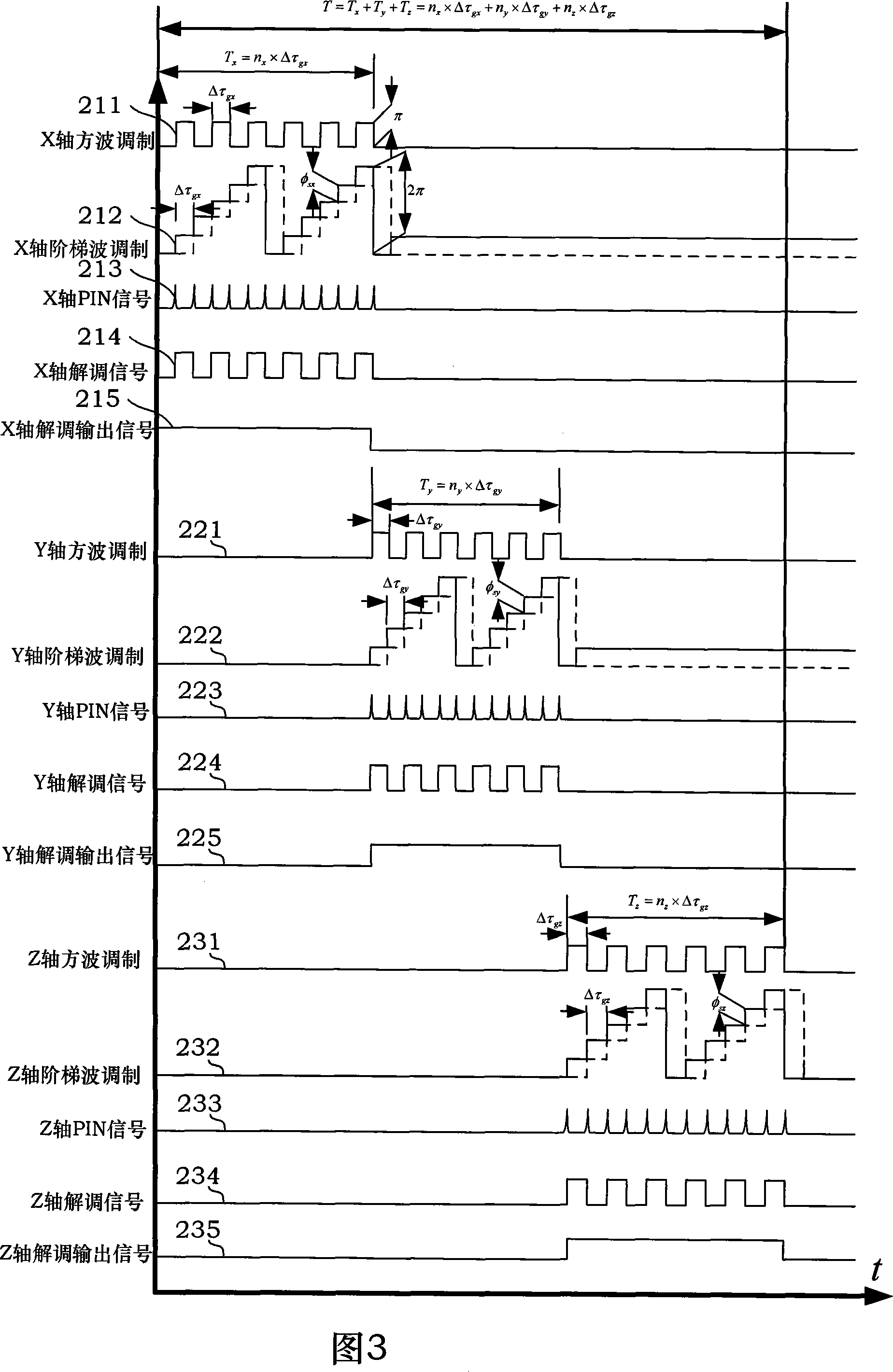

The utility model discloses a timesharing modulation method for the three-axis digital closed loop optical fiber gyroscopes; wherein, a time sequence modulation control is arranged in a selected processor through Verilog programming language, and fitted with a gating switch to realize the purpose that three phase modulators and fiber-optic rings are alternately controlled by one signal processing circuit. The utility model adopts the technical proposal that: in the modulation time Tx of the X-axis, the X-axis is modulated by the gating switch, while the Y-axis and Z-axis are not modulated; in the modulation time Ty of the Y-axis, the Y-axis is modulated by the gating switch, while the X-axis and Z-axis are not modulated; in the modulation time Tz of the Z-axis, the Z-axis is modulated by the gating switch, while the X-axis and Y-axis are not modulated. The utility model has the advantages of utilizing one shared signal processing circuit for the three-axis digital closed loop optical fiber gyroscopes, effectively reducing the volume and weight of the three-axis optical fiber gyroscopes, lowering the power consumption of the gyroscopes and dissipating heat efficiently.

Owner:BEIHANG UNIV

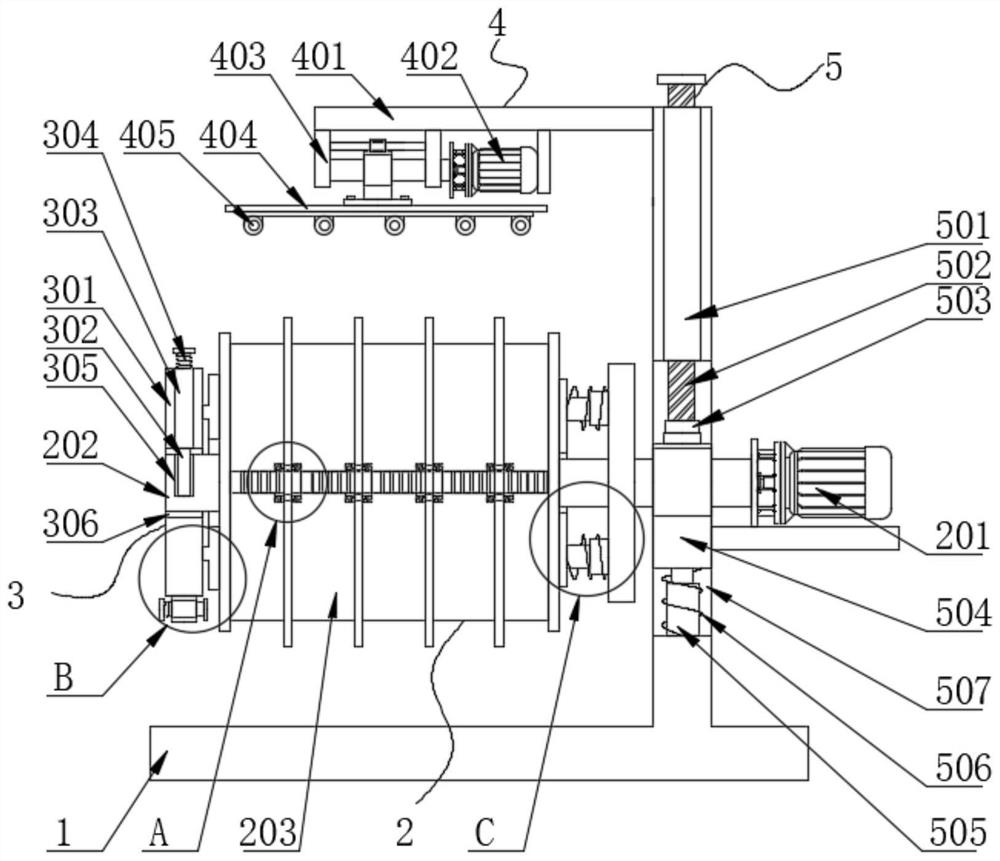

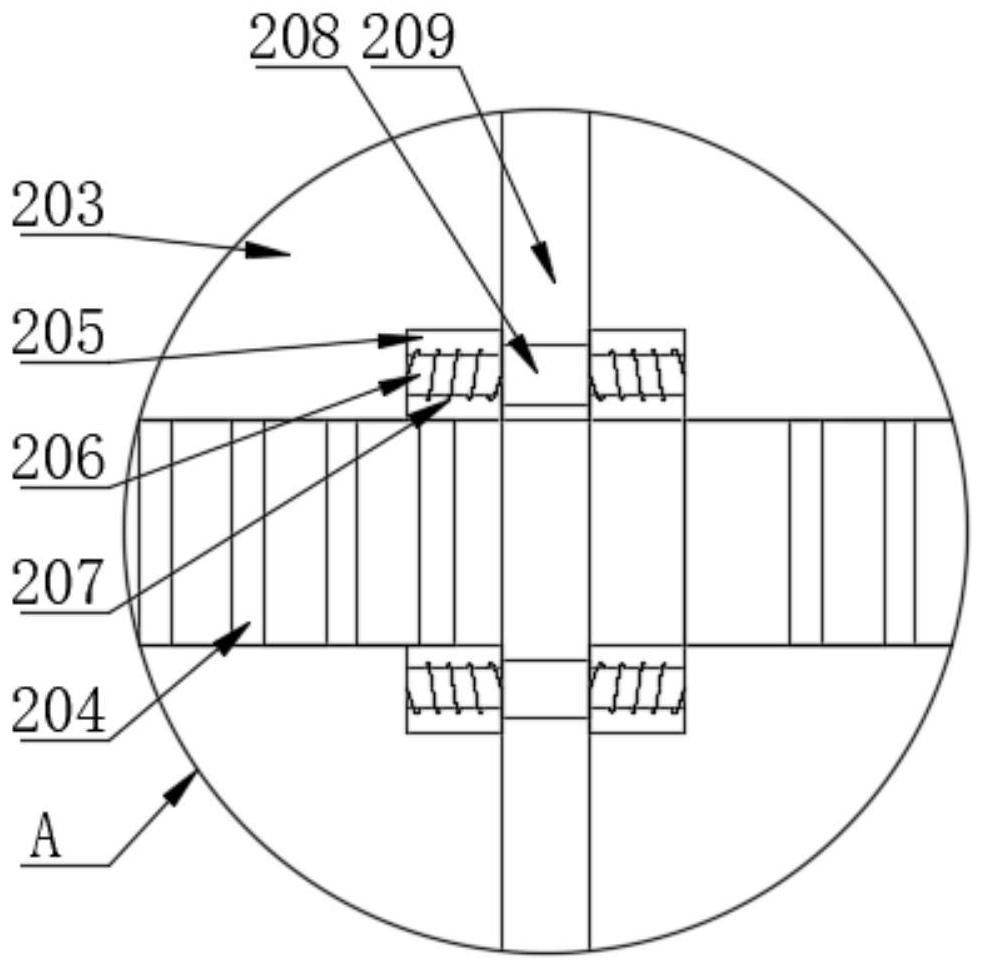

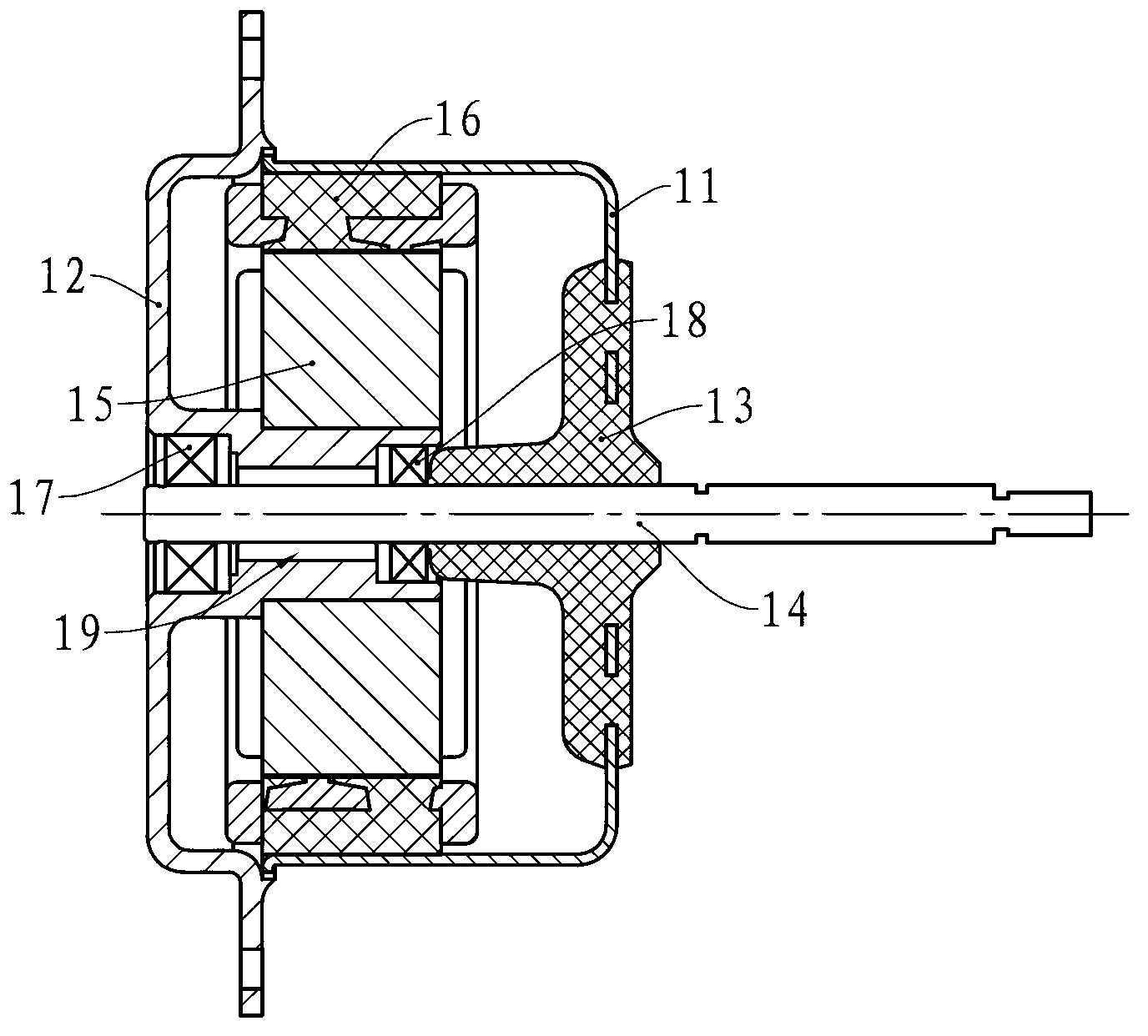

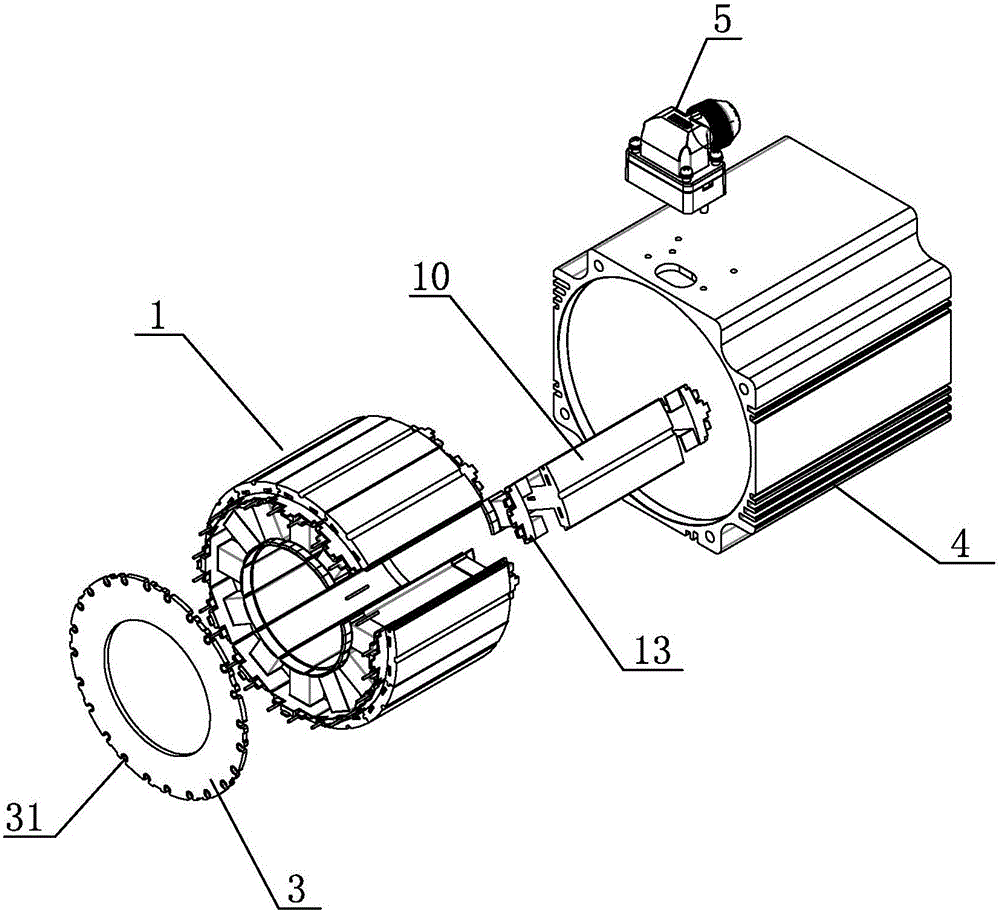

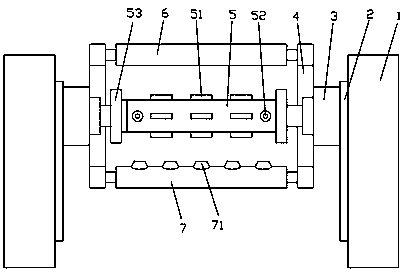

Low-frequency and large-displacement angular vibration table

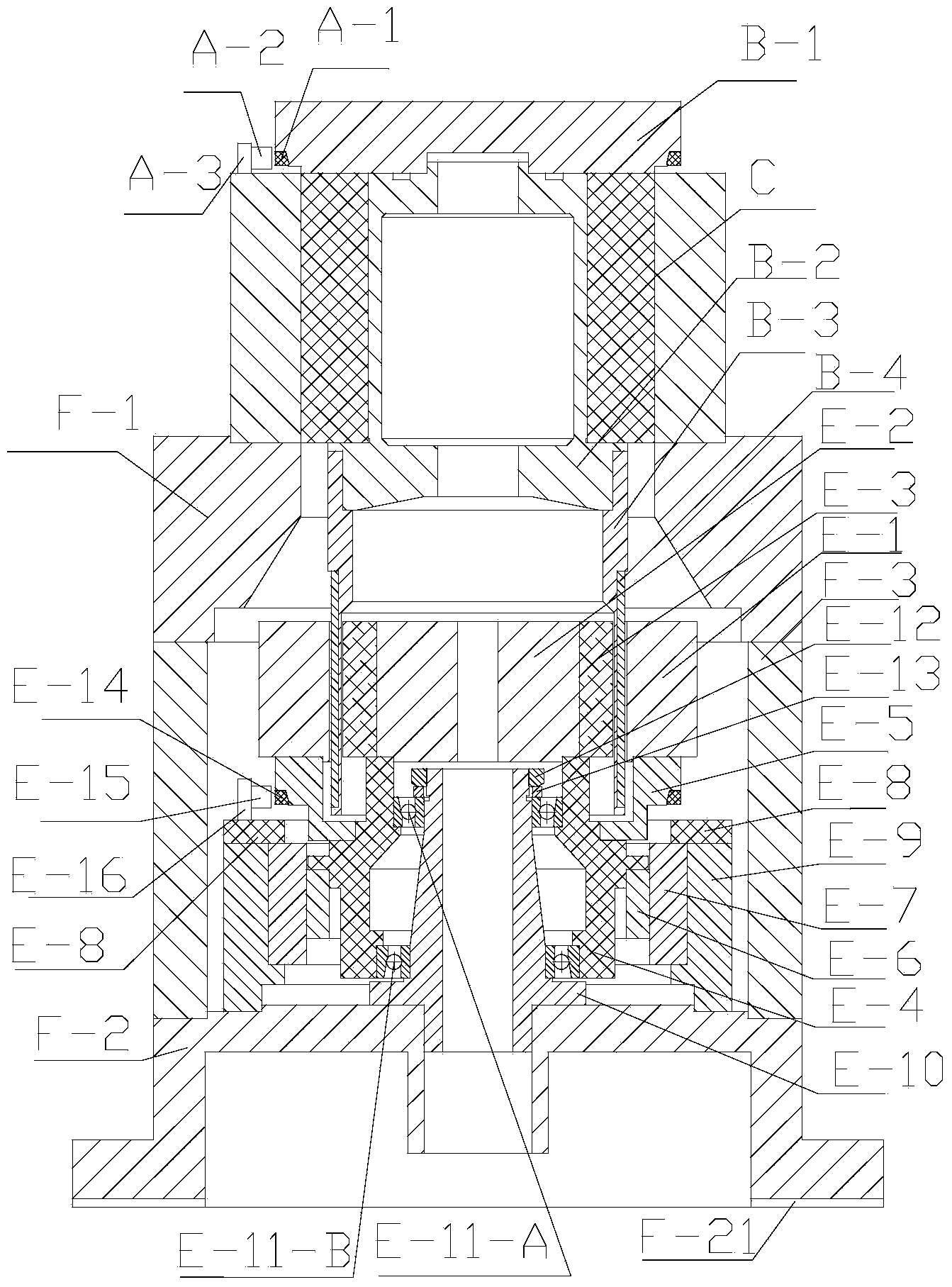

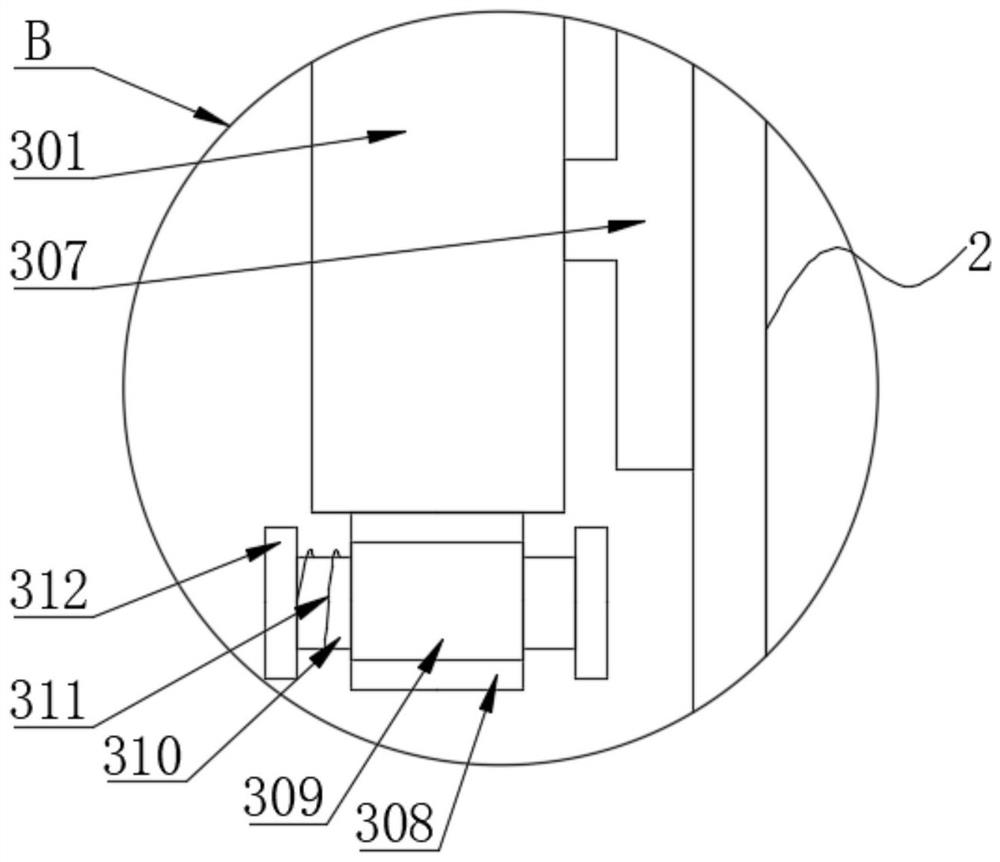

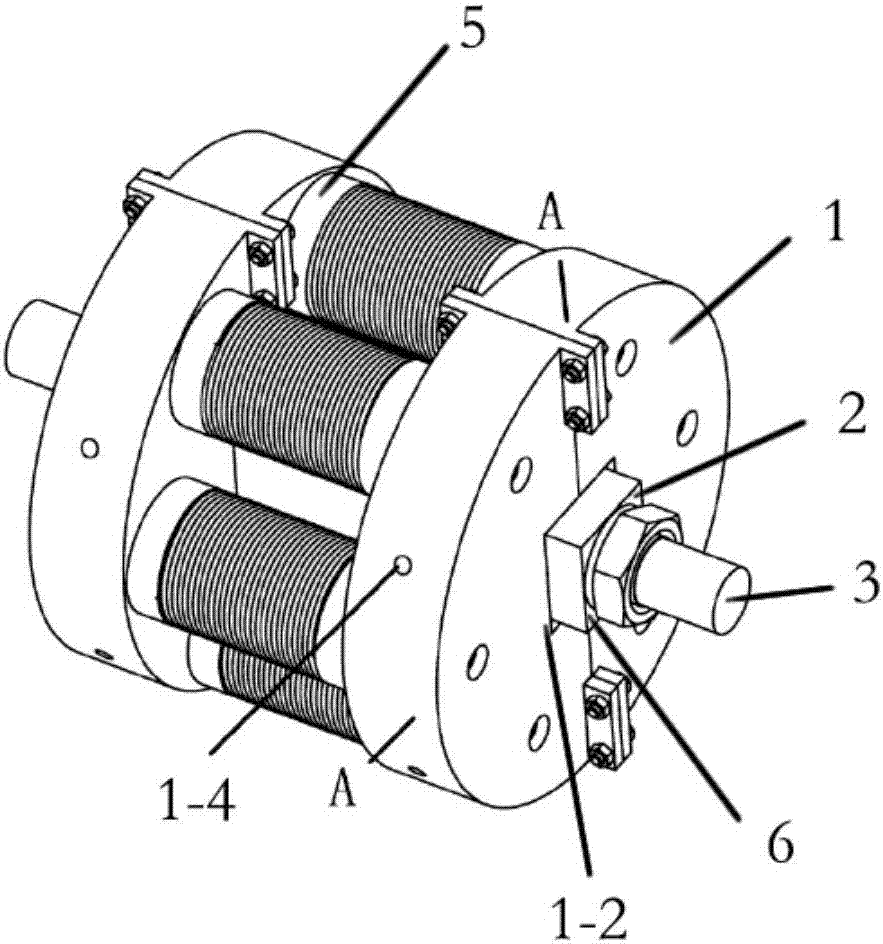

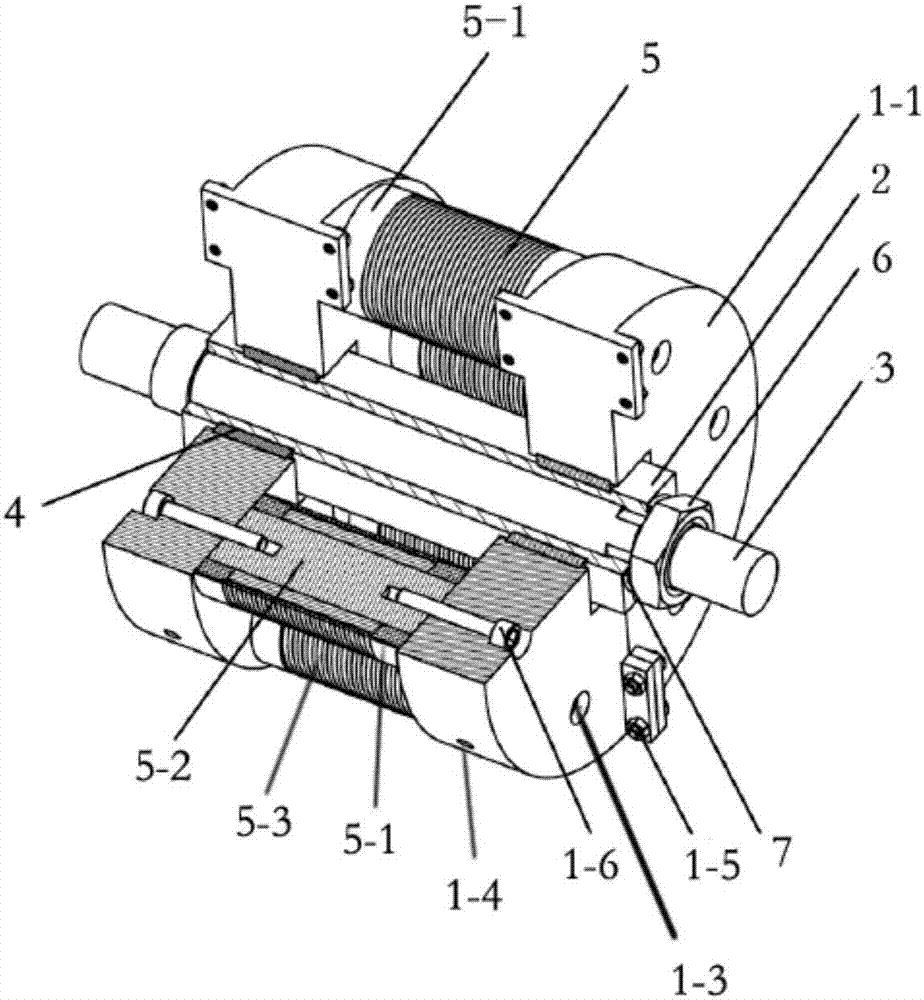

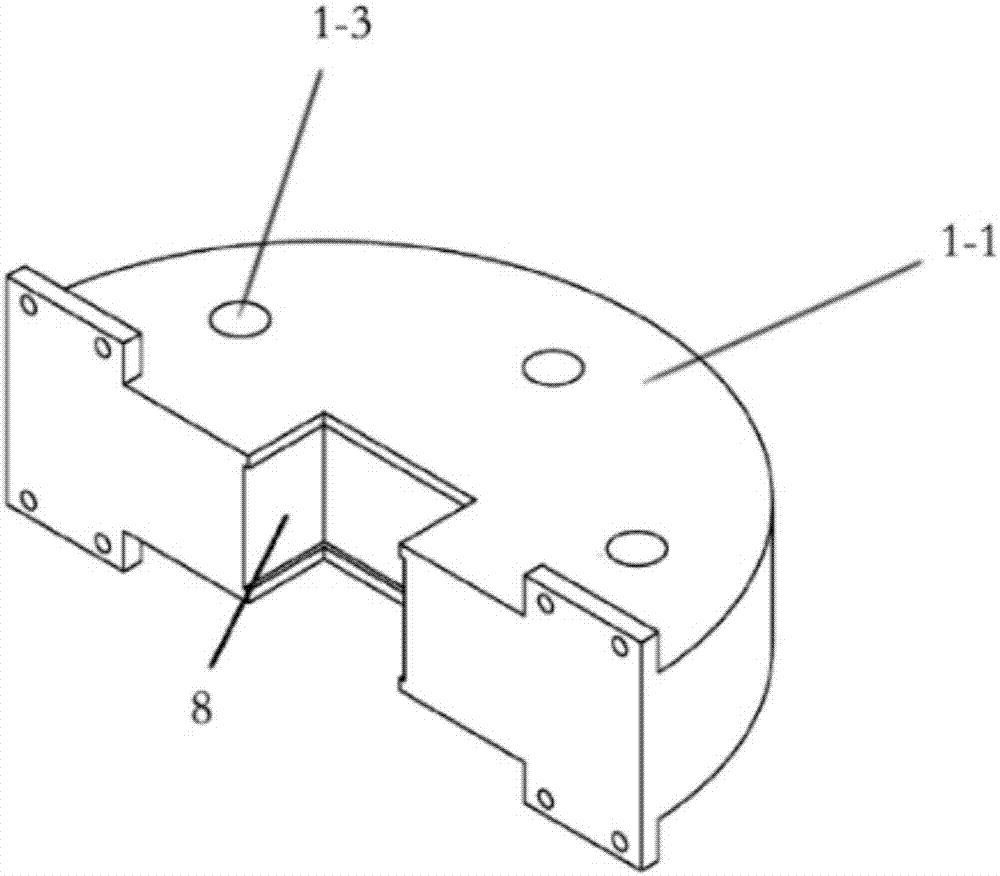

A low-frequency and large-displacement angular vibration table comprises a case, a work tabletop, a main shaft driving the work tabletop to rotate, a moving coil assembly, a magnetic circuit assembly, a motor driving the magnetic circuit assembly to rotate, a closed-loop control assembly of the motor, an electric viscoelastic feedback control assembly, an air bearing and an angular displacement sensor. The main shaft is fixedly connected with the moving coil assembly, and the magnetic circuit assembly is fixedly connected with a rotor of the motor through a connector. The moving coil assembly comprises a moving coil base body and coils, wherein the moving coil base body is fixedly connected with the main shaft. The magnetic circuit assembly comprises a magnetism guide ring, a central magnetic pole and magnetic steel, wherein the magnetism guide ring, the central magnetic pole, the magnetic steel and an air gap form a closed magnetic loop. The central magnetic pole is located in the magnetism guide ring, the magnetism guide ring is coaxial with the central magnetic pole, and the magnetic steel is located between the magnetism guide ring and the central magnetic pole and attracted to the central magnetic pole. The moving coil assembly is located between the magnetic steel and the magnetism guide ring and is coaxial with the magnetism guide ring. The low-frequency and large-displacement angular vibration table has the advantages that the distortion factor of output wave forms is small, and the output angular displacement is large.

Owner:ZHEJIANG UNIV

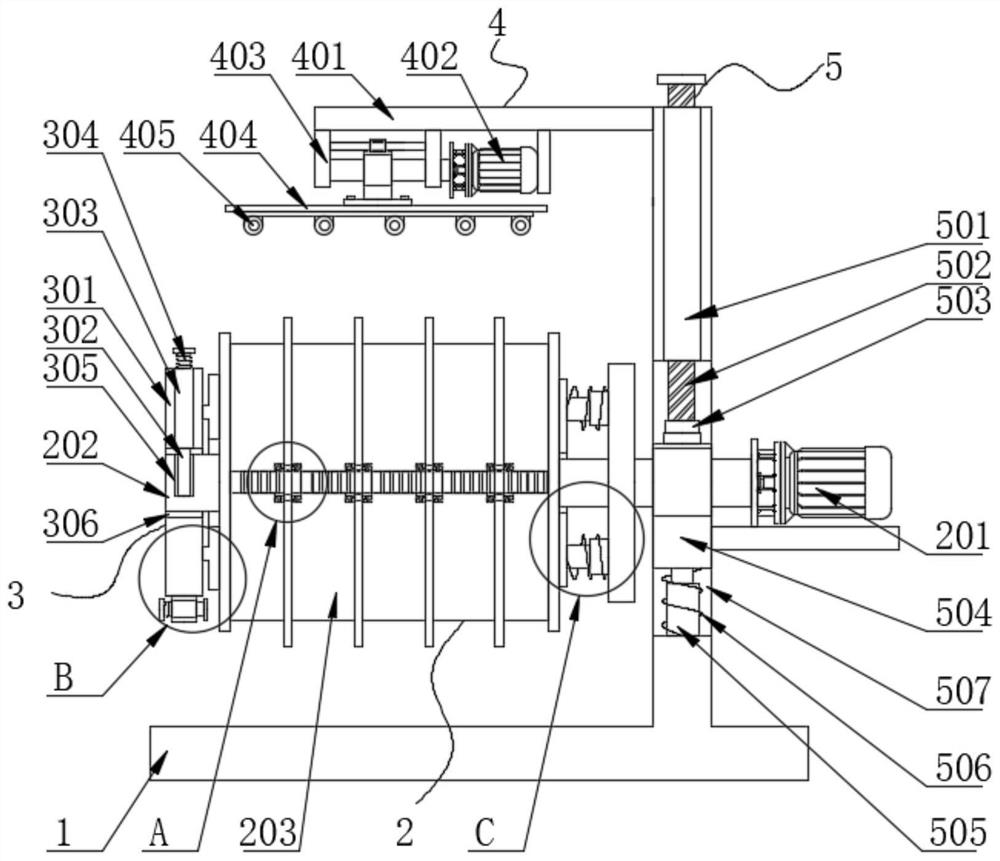

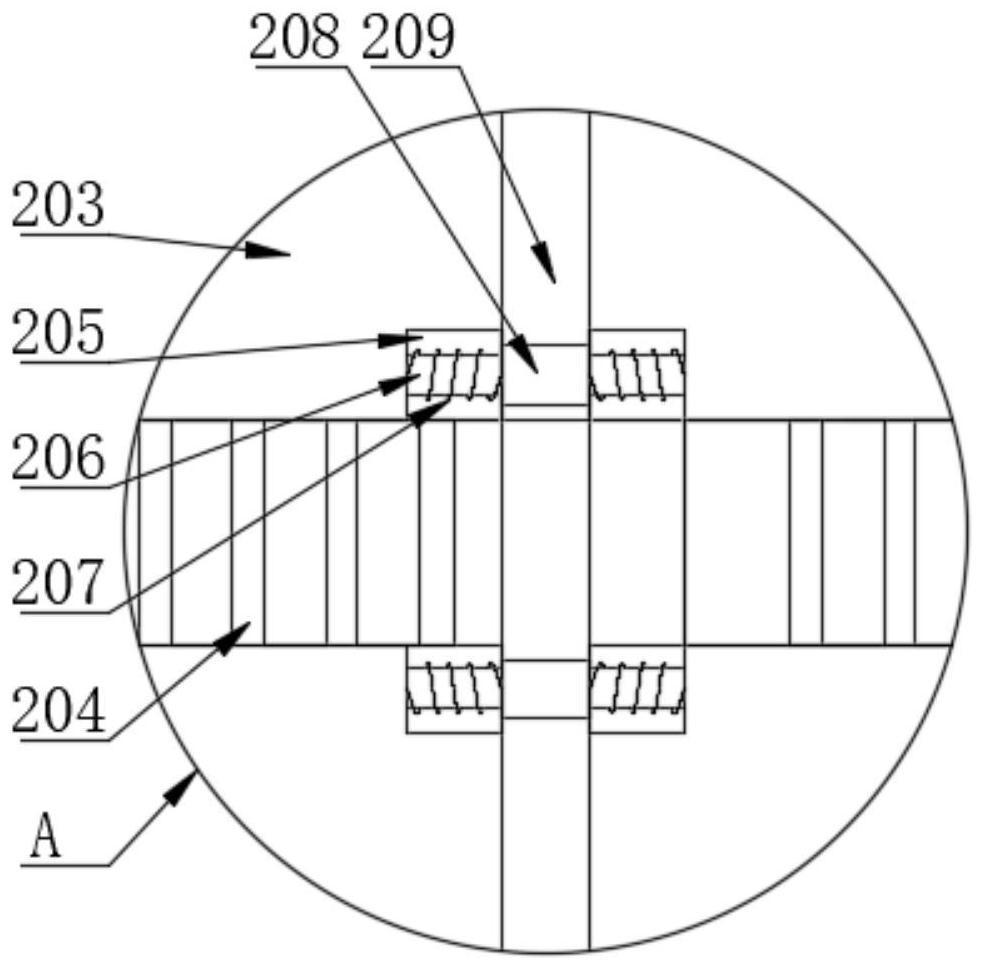

Take-up structure with anti-winding effect for textile operation

The invention discloses a take-up structure with an anti-winding effect for textile operation, and belongs to the technical field of textile assistive devices. The take-up structure comprises a rack,one side of the rack is movably connected with a winding mechanism, one side of the winding mechanism is provided with a clamping mechanism, and the top of the winding mechanism is movably connected with the rack through a lifting mechanism; and the top of one side of the rack is fixedly connected with a wire arranging mechanism, the winding mechanism comprises a first motor, and an output shaft of the first motor is fixedly connected with a first rotating shaft. According to the take-up structure, by the arrangement of the winding mechanism and the wire arranging mechanism, wire harnesses canbe effectively prevented from being wound with one another during winding, the multiple wire harnesses can be taken up at the same time, the separation effect during simultaneous winding of the multiple wire harnesses can be guaranteed through a baffle connected to the outer wall of a winding drum, and burrs of the wire harnesses during pulling can be avoided through a smooth guide sleeve; and the winding efficiency is remarkably improved while winding of thread bodies is avoided, and the requirement for adapting to the textile operation is met.

Owner:青岛富思特纺织股份有限公司

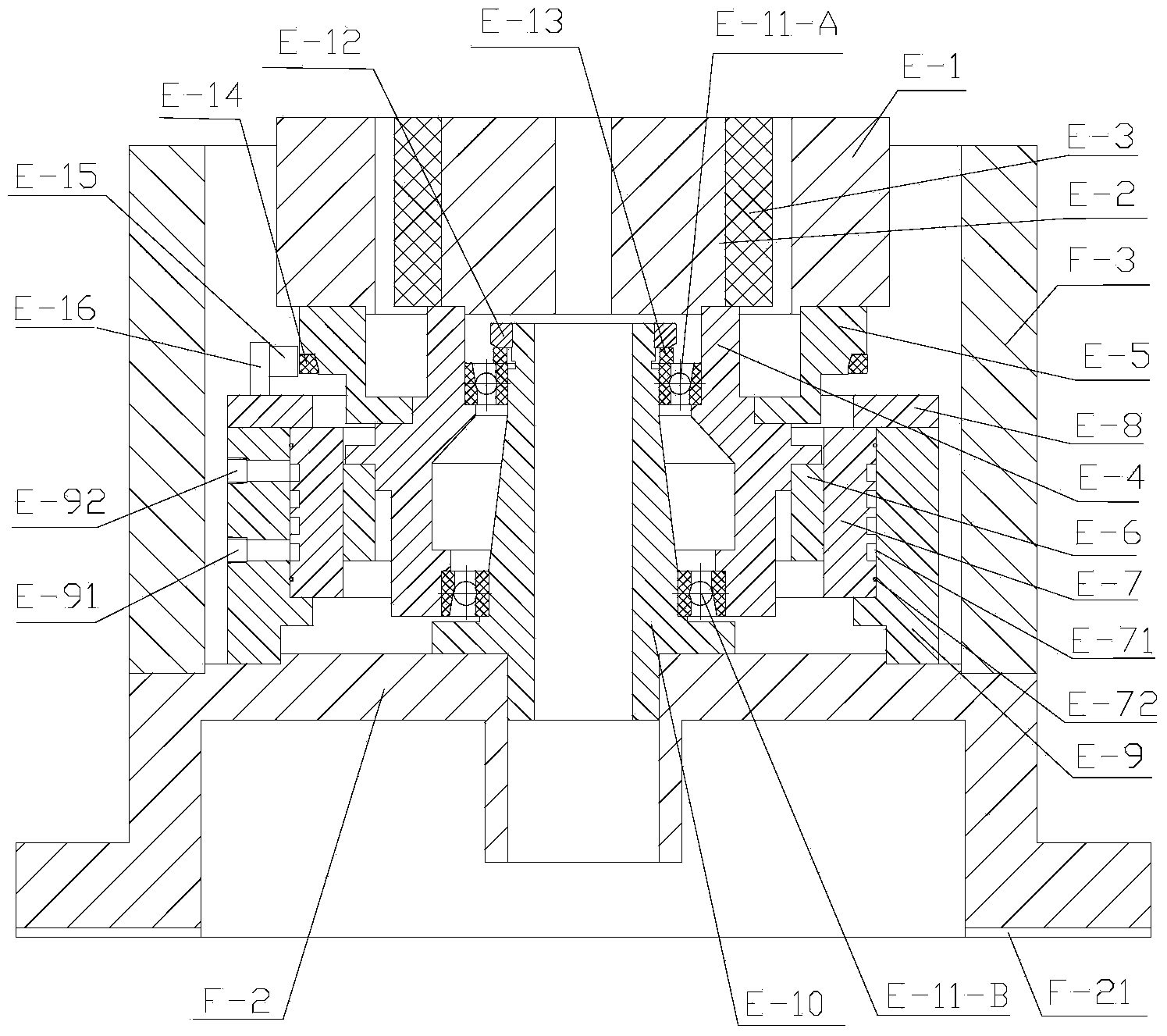

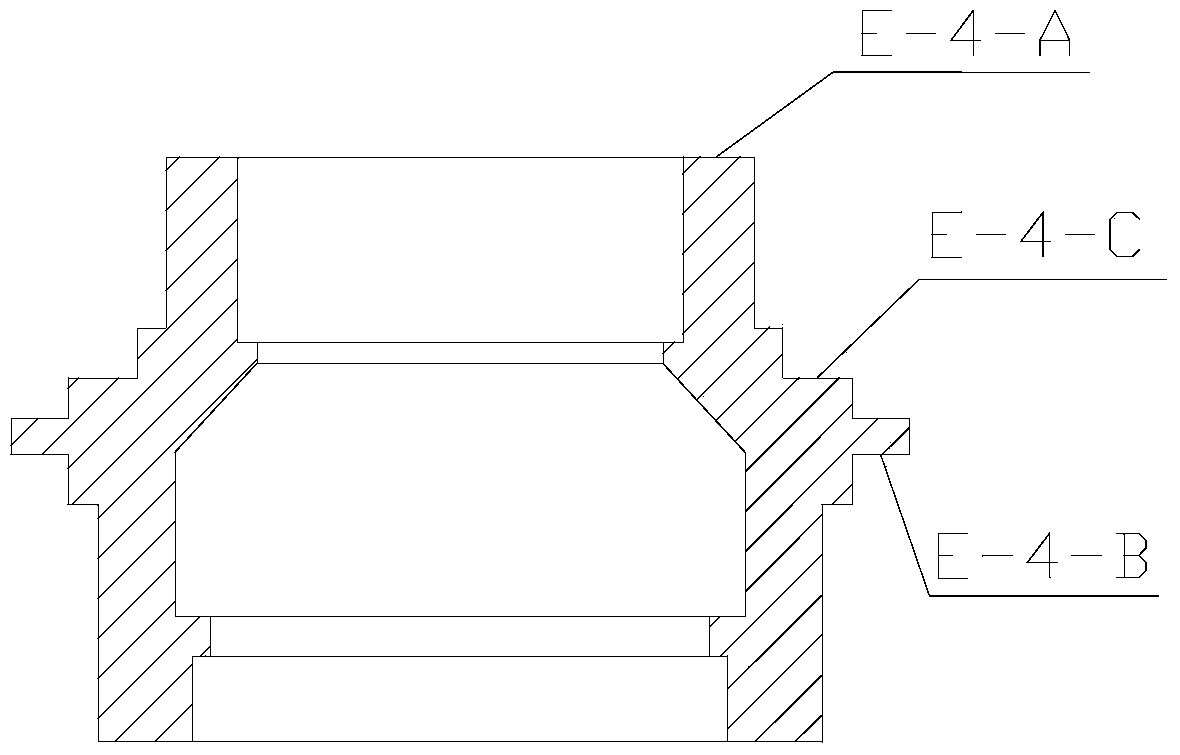

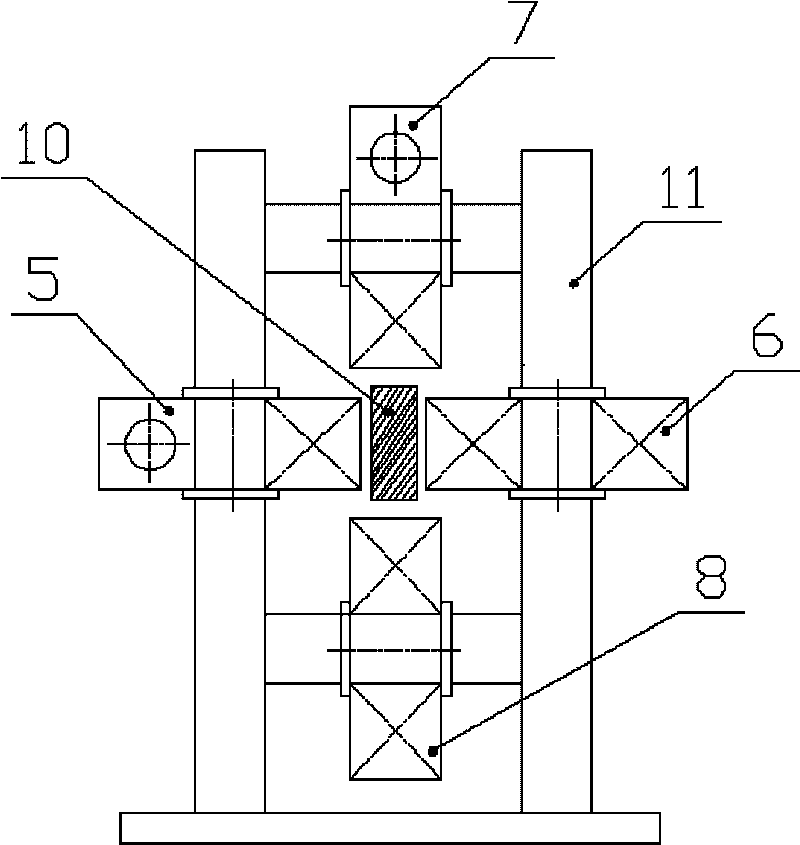

Magnetorheological elastomer thrust bearing base dynamic vibration absorber and use method

InactiveCN107191529ALongitudinal vibration controlReduce transmission rateSpringsNon-rotating vibration suppressionThrust bearingPropeller

The invention relates to the technical field of marine power, in particular to a magnetorheological elastomer thrust bearing base dynamic vibration absorber and a use method. The dynamic vibration absorber is arranged on a thrust bearing base and comprises magnet yoke sets, a magnetism isolating support shaft, a magnetic conductive shaft sleeve, magnetorheological elastomers and an electromagnetic assembly. The outer layer of the magnetism isolating support shaft is sleeved with the magnetic conductive shaft sleeve. The two ends of the magnetic conductive shaft sleeve are provided with the parallelly arranged magnet yoke sets correspondingly. The joints of the magnetic conductive shaft sleeve and the magnet yoke sets are provided with the magnetorheological elastomers. At least one electromagnetic assembly is arranged around the part, between the two magnet yoke sets, of the magnetic conductive shaft sleeve. According to the magnetorheological elastomer thrust bearing base dynamic vibration absorber and the use method, longitudinal vibration of the thrust bearing base is controlled effectively, then the transmitting ratio of pulsating force of a propeller through the bearing base to a boat body is lowered, and the purpose of reducing of radiation noise is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Sensing head of all-fiber current transformer

InactiveCN103149405ASolve problemsReduce adverse effectsCurrent/voltage measurementVoltage/current isolationLinear birefringenceEngineering

The invention discloses a sensing head of an all-fiber current transformer. Grooves are respectively formed in an upper cover of the sensing head and a lower cover of the sensing head; a sensing optical fiber, an all-fiber one-fourth wave plate and an optical fiber end surface reflecting mirror form an optical fiber sensing part of the all-fiber current transformer by a welding mode; the optical fiber sensing part is uniformly wound on a sensing framework in a spiral manner; the sensing framework wound with the optical fiber sensing part is placed in the groove of the lower cover of the sensing head and integrally packages the upper cover of the sensing head with the lower cover of the sensing head; a lead head which is internally provided with a lead hole is processed in the upper cover of the sensing head; and a polarization-preserving optical fiber is used as a lead-out end of the sensing head of the all-fiber current transformer, is partially connected with the optical fiber sensing part and is led out of the lead hole. According to the sensing head disclosed by the invention, various negative influences such as linear birefringence, Verdet constant temperature effect and one-fourth wave plate phase delay temperature effect of the optical fiber sensing part can be effectively eliminated.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Double-speed winding switch reluctance motor

ActiveCN103166337AWide speed rangeReduce the number of turnsMagnetic circuit stationary partsWindings conductor shape/form/constructionLow speedEngineering

Owner:SOUTHEAST UNIV

Permanent magnet motor stator and multi-parallel-soft-winding transposition coil inserting method

ActiveCN106849554AReduce imbalanceReduce circulationWindings insulation materialWindings insulation shape/form/constructionElectric machineMotor vibration

The invention provides a permanent magnet motor stator and a multi-parallel-soft-winding transposition coil inserting method of the permanent magnet motor. The method comprises the steps of winding stator coils which are in parallel winding with multiple leads in multiple groups, and reducing the winding difficulty of the coil. When the coil is inserted, all the coils are inserted into a groove layer-to-layer, and layers are formed in the groove; to prevent insulation among the coil turn from being damaged, a layer of thin film insulation material is padded on each group of coil, and insulating performance of the insulation is strengthened. Multiple coils which are in series connection with each branch circuit of a stator winding are located in different layers in the groove, that is, the branch circuit of which the multiple coils is located in different magnetism positions in the groove is formed, the influence of an skin effect caused by an alternating magnetic field can be lowered to the greatest extent, imbalance of currents among strands is lowered, motor vibration is reduced, and motor temperature raising is lowered.

Owner:HEBEI NEWSTAR ELECTRIC MOTOR CO LTD

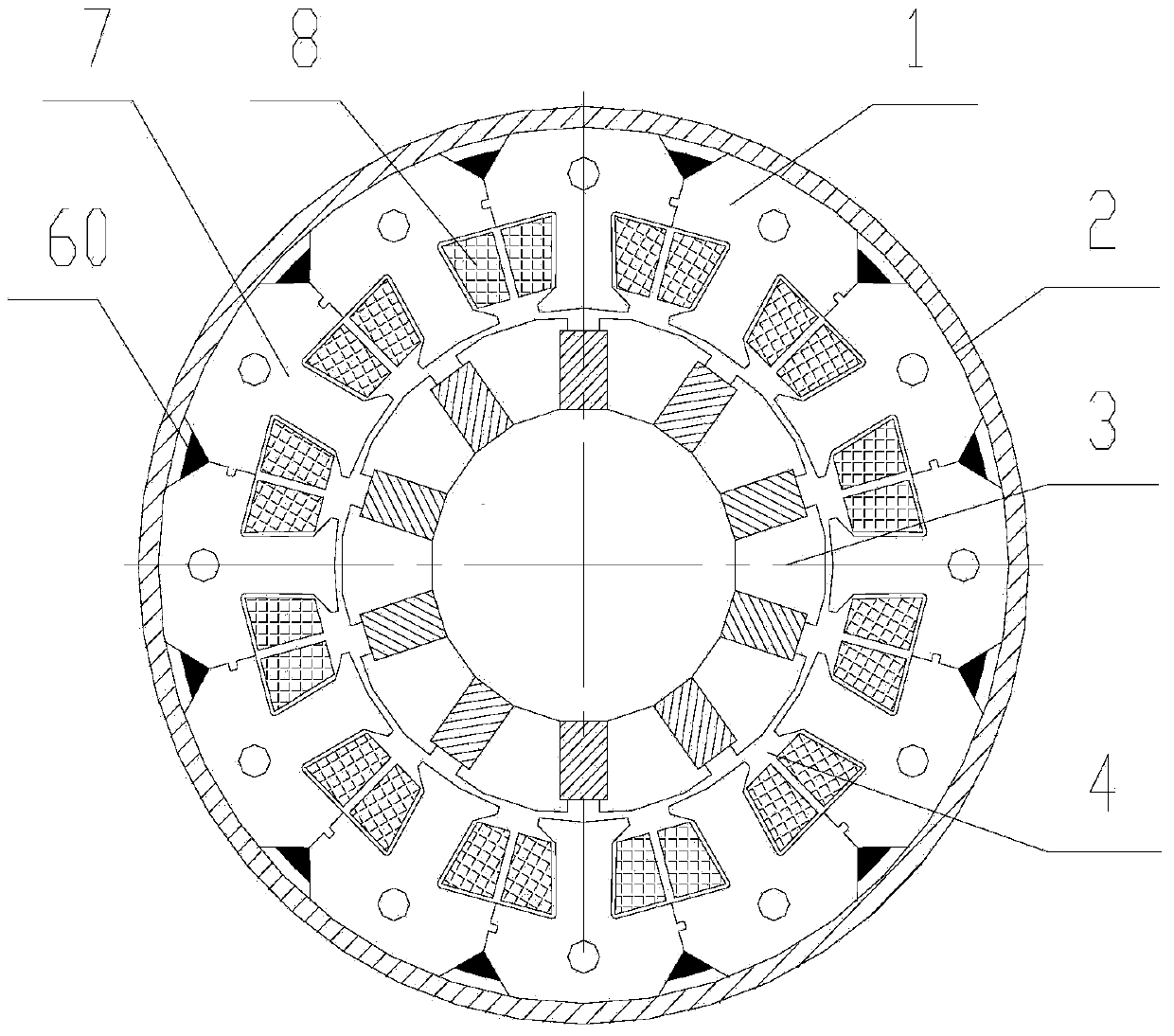

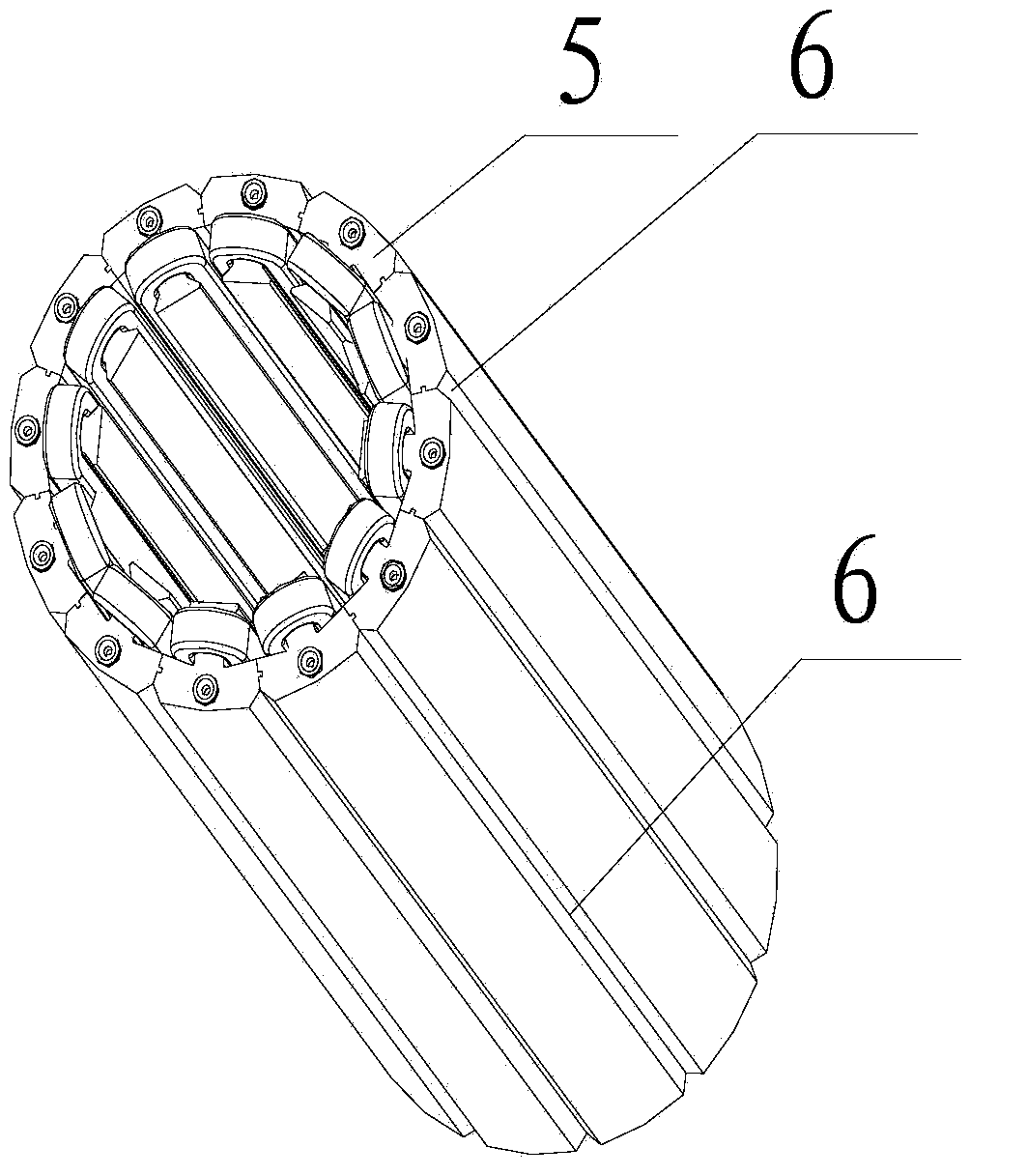

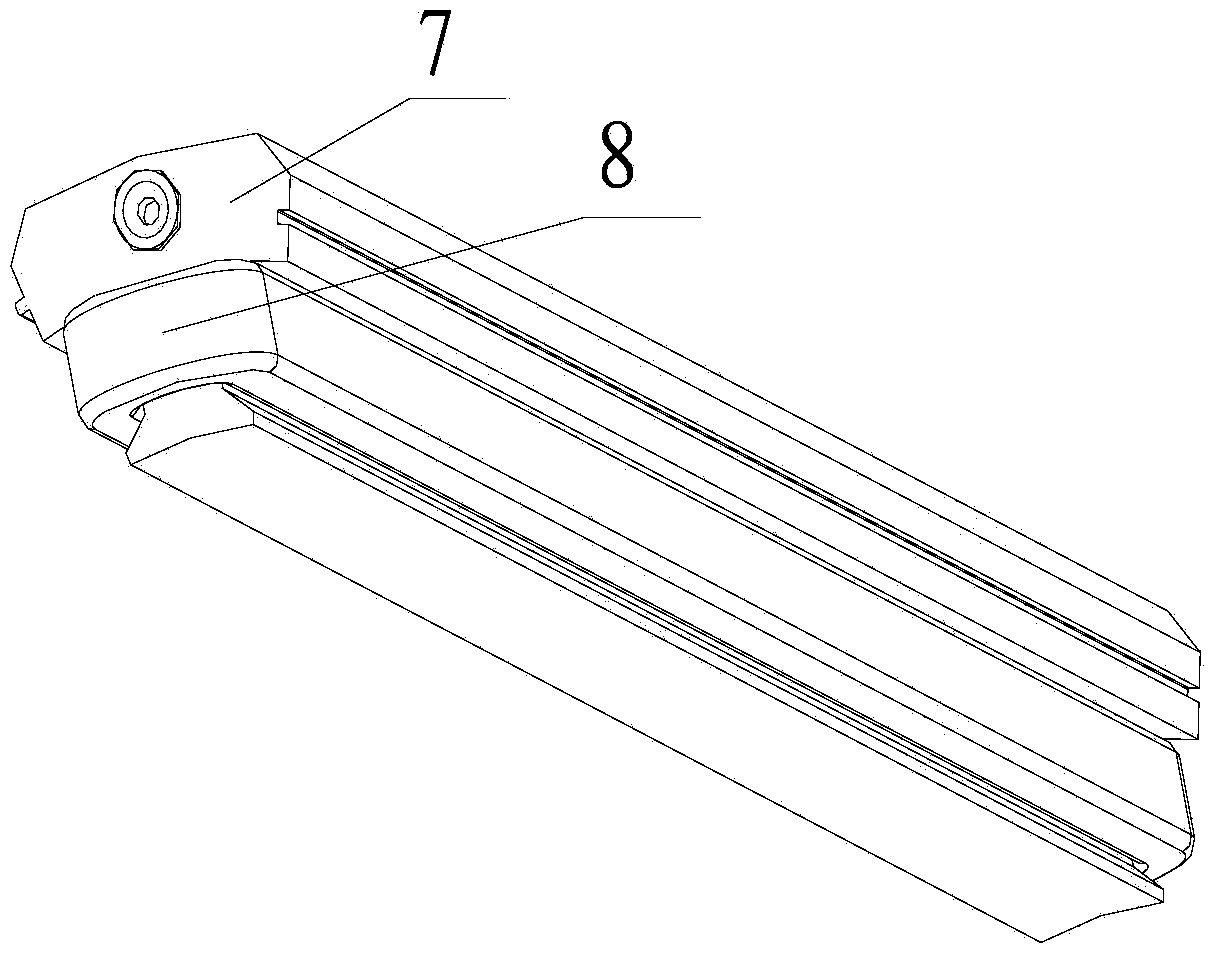

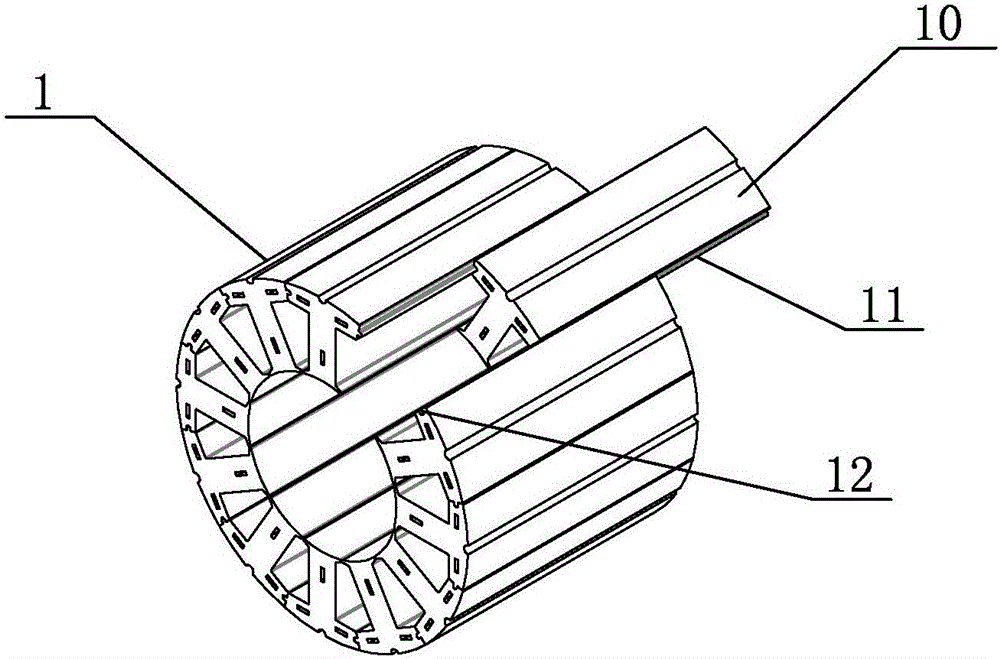

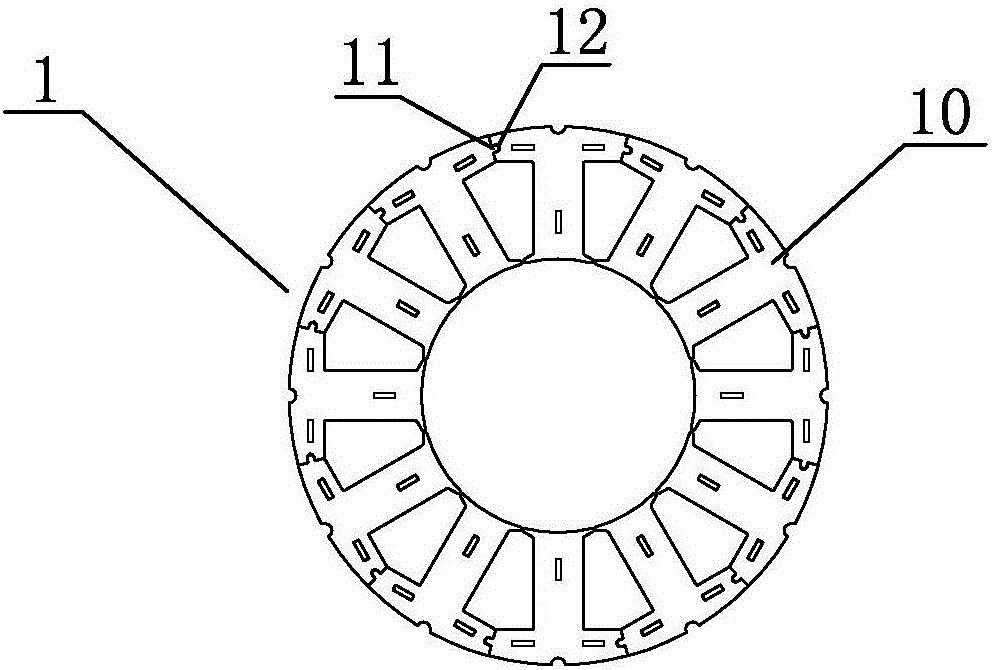

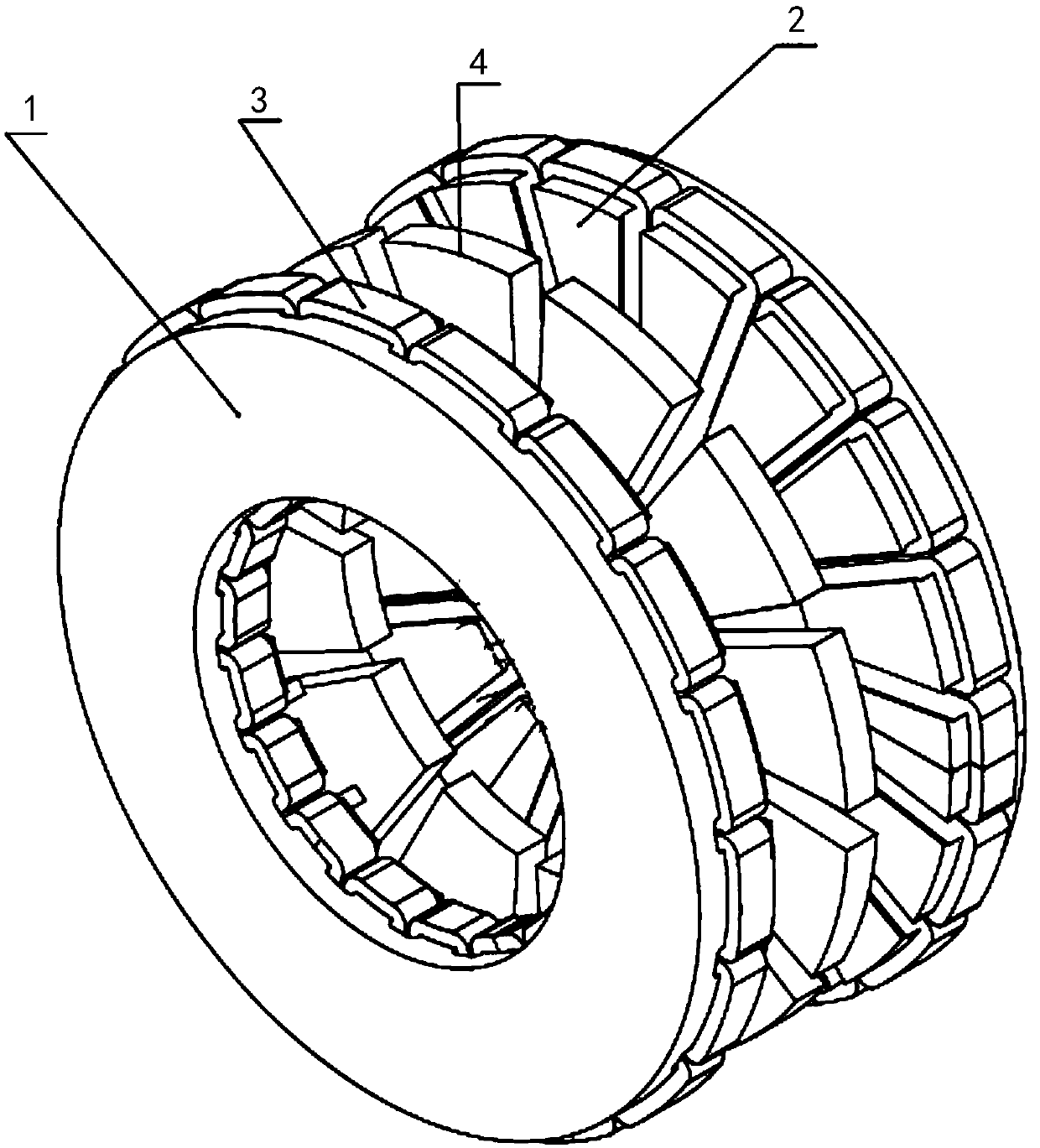

Oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and manufacture method

InactiveCN103633755AImprove the winding methodIncrease the winding spaceMagnetic circuit stationary partsManufacturing stator/rotor bodiesCopper wirePermanent magnet motor

The invention provides an oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor and a manufacture method. The oil-submerged pump direct-drive ultra-slender concentrated winding permanent magnet motor comprises a motor unit, wherein the motor unit comprises a stator core of a split type structure, the stator core is assembled into an annular shape by multiple core blocks with windings, each core block with one winding comprises a slender core block and a winding copper wire, each slender core block is formed by overlaying T-shaped punched pieces and is provided with a stator tooth, and the winding copper wires are wound on the stator teeth. The manufacture method of the permanent magnet motor comprises the steps of overlaying the T-shaped punched pieces to form the slender core blocks, and winding the winding copper wires on the stator teeth to form the core blocks with the windings; connecting the multiple core blocks with the windings in sequence along the peripheral direction and assembling to form the annular stator core; arranging the annular stator core into an enclosure by press-fitting. The winding process of the core blocks with the windings is easy to realize, and the manufacturing is simple.

Owner:PETROCHINA CO LTD

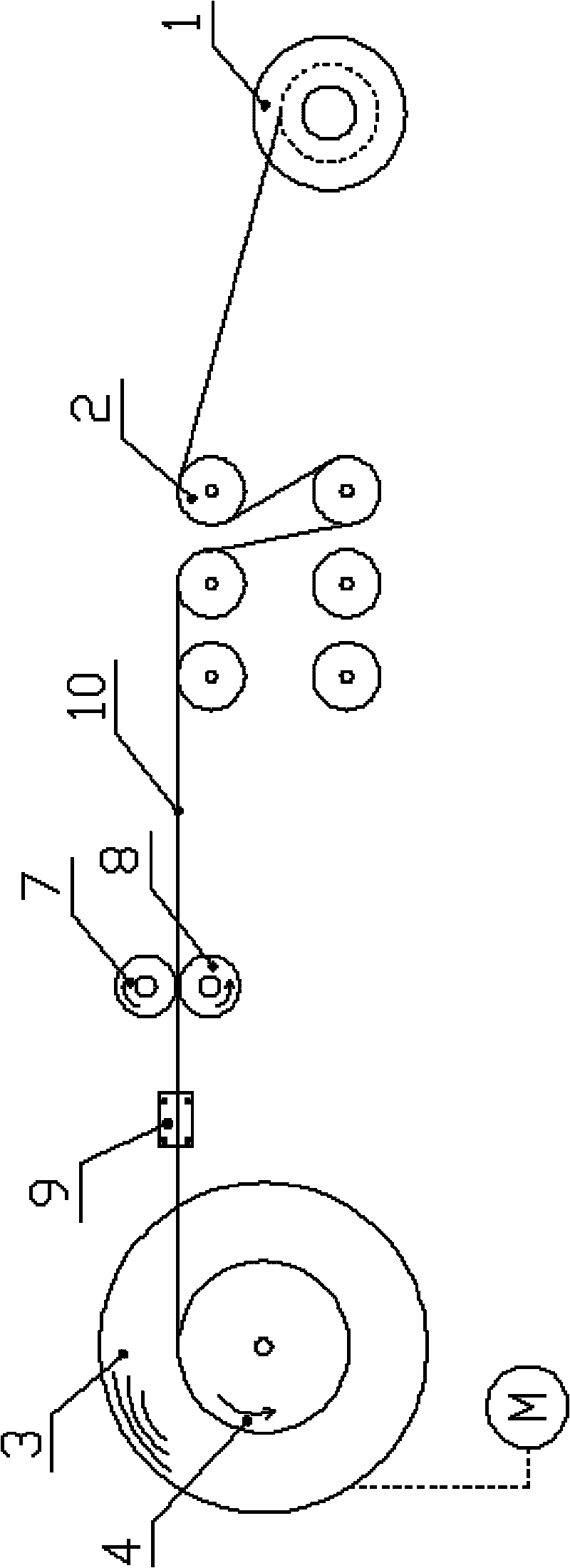

Device for winding coil by rectangular conducting wire

InactiveCN101702373AAxially arranged tightly and neatlyReduce labor intensityCoils manufactureWinding machineEngineering

The invention discloses a device for winding a coil by a rectangular conducting wire, which can enhance the winding quality of the rectangular conducting wire. The device for winding the coil by the rectangular conducting wire comprises a wire coil disk, a wire pressing device and a horizontal type wire winding machine which are sequentially arranged, wherein a coil framework is arranged on the horizontal type wire winding machine, and a positioning device which can penetrate and sleeve the rectangular conducting wire and enable the narrow side of the section of the rectangular conducting wire to be in a horizontal state is arranged between the wire pressing device and the horizontal type wire winding machine. The device has simple structure, very low cost and very convenient turning, lightens the labor strength of operators, reduces the number of the operators, lowers the winding difficulty, also shortens the winding time, ensures the tight and tidy axial arrangement and the tight radial winding of the coil after the winding is completed, ensures the winding quality and is especially suitable for popularization and use on a winding device which needs to wind the narrow side of the section of a conducting wire onto a coil framework; in addition, the rectangular conducting wire only needs to penetrate through the positioning device.

Owner:攀枝花钢城集团瑞泰电器有限公司

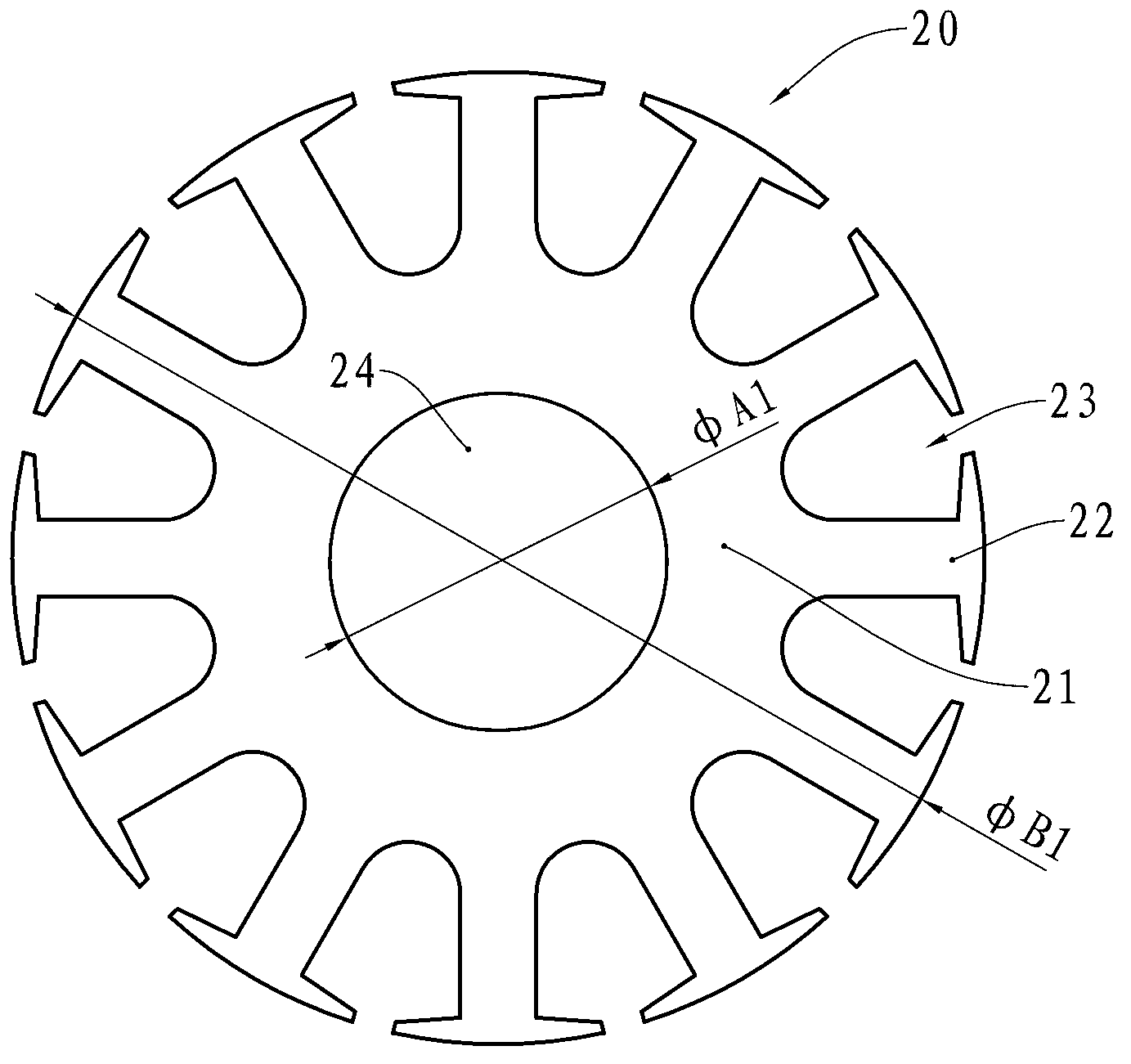

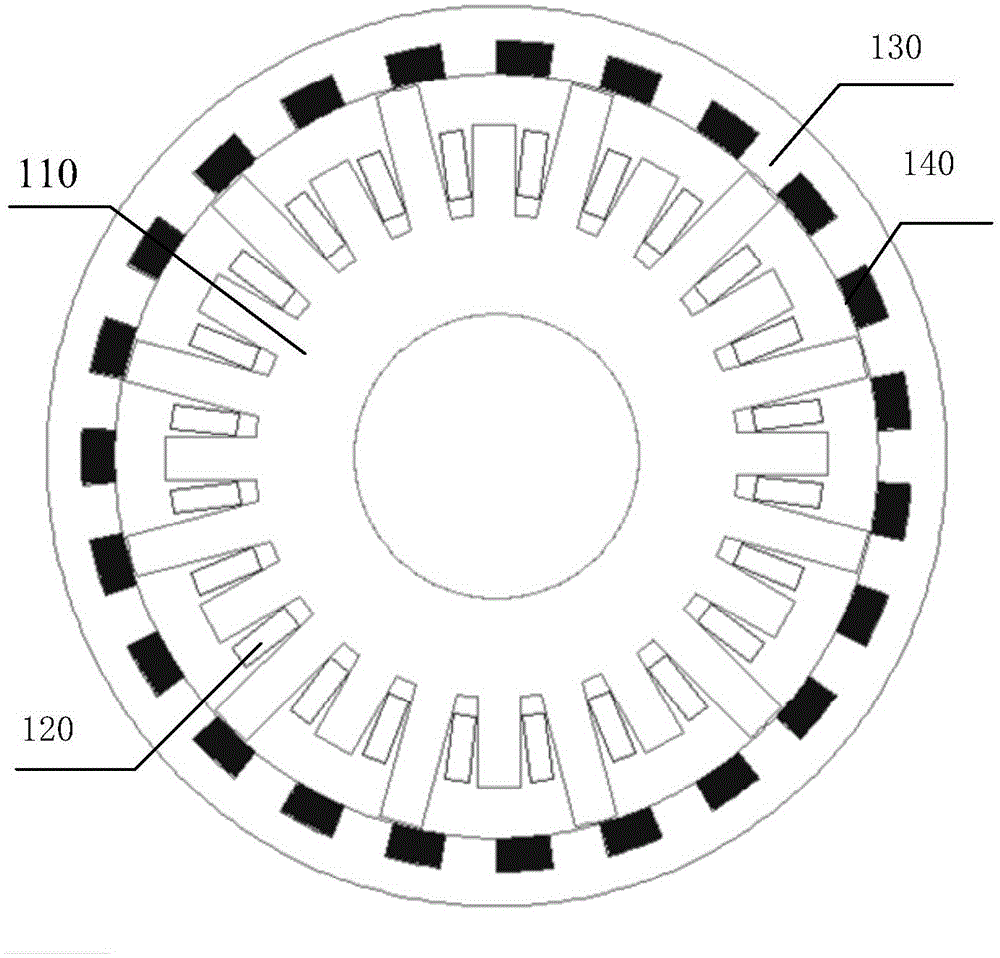

Stator stamping and motor

InactiveCN103078423AReduced insulation requirementsReduce manufacturing costMagnetic circuit stationary partsWindings conductor shape/form/constructionEngineeringOuter coil

The invention provides a stator stamping and a motor. The stator stamping is provided with an annular yoke and a plurality of teeth, the teeth are outwardly extended from the yoke along the radial direction of the stator stamping, a notch is formed between each two neighboring teeth, moreover, the middle of the stator stamping is provided with an inner round hole, wherein the notches are shallow notches and deep notches, which are arranged alternately, and the opening height of the deep notch is greater than the total height of the shallow notch. The motor is provided with a stator and a rotor, the stator is provided with a stator core made of the laminated stator stampings and coils wound on the stator core, the coils are a plurality of inner coils and a plurality of outer coils, each inner coil is wound between two deep notches, and each outer coil is wound between two shallow notches. The invention can decrease the difficulty of the coil-winding process; moreover, the coils are not overlapped spatially, so that the requirement on the insulation of the coils is decreased, and thereby the production cost of the motor is reduced; moreover, when the motor operates, the magnetic density is more uniform, and operation is more stable.

Owner:GREE ELECTRIC APPLIANCES INC +4

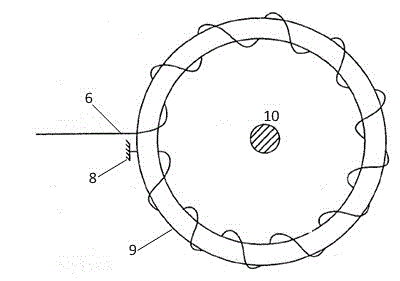

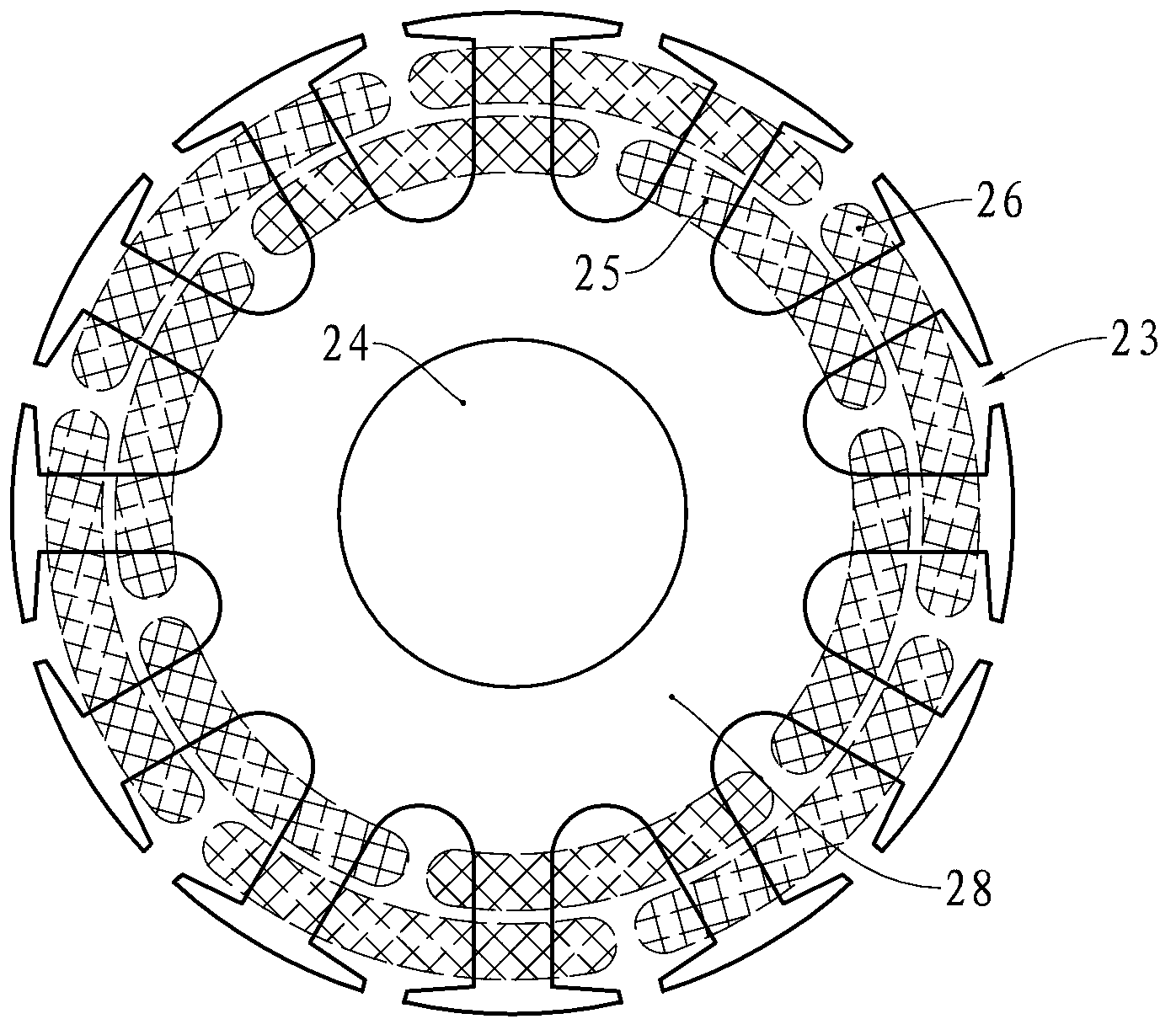

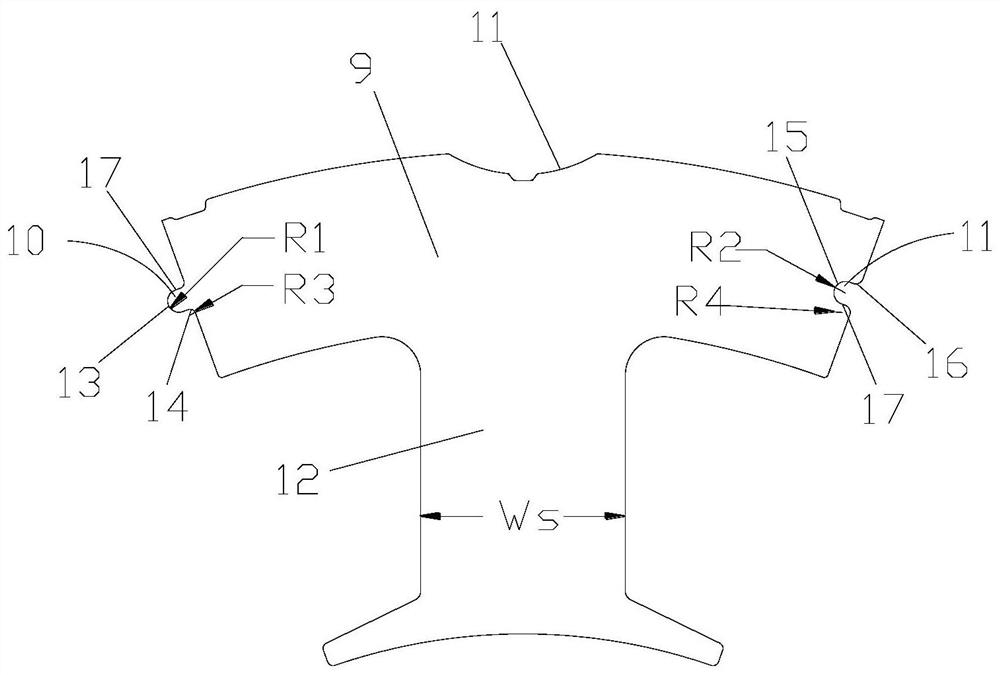

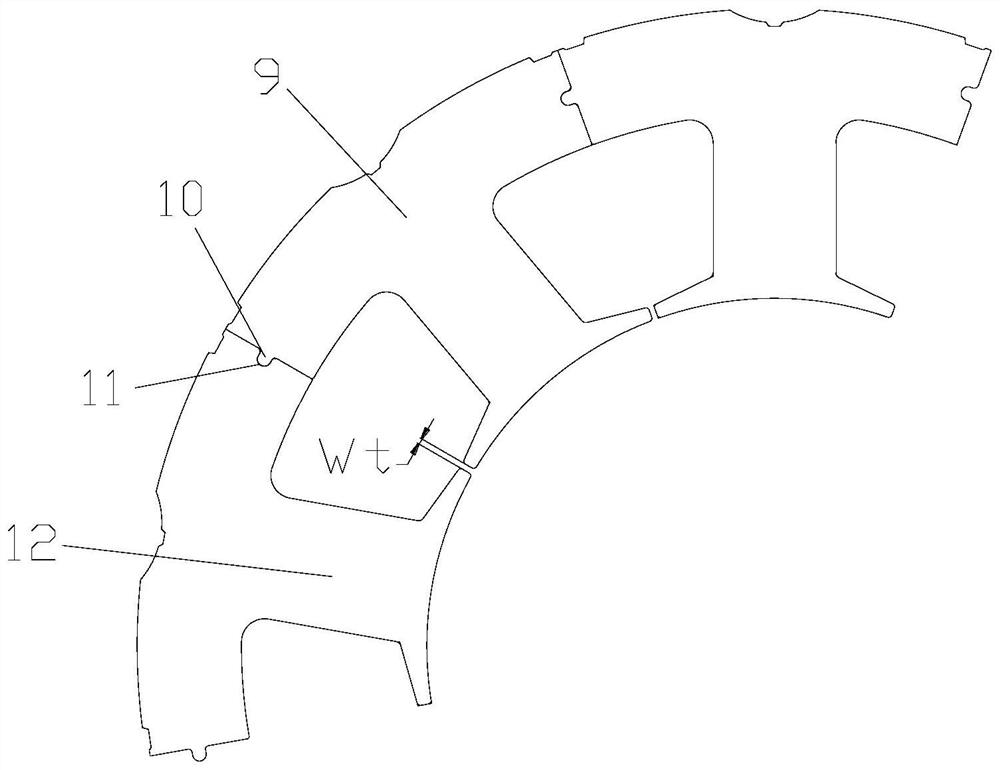

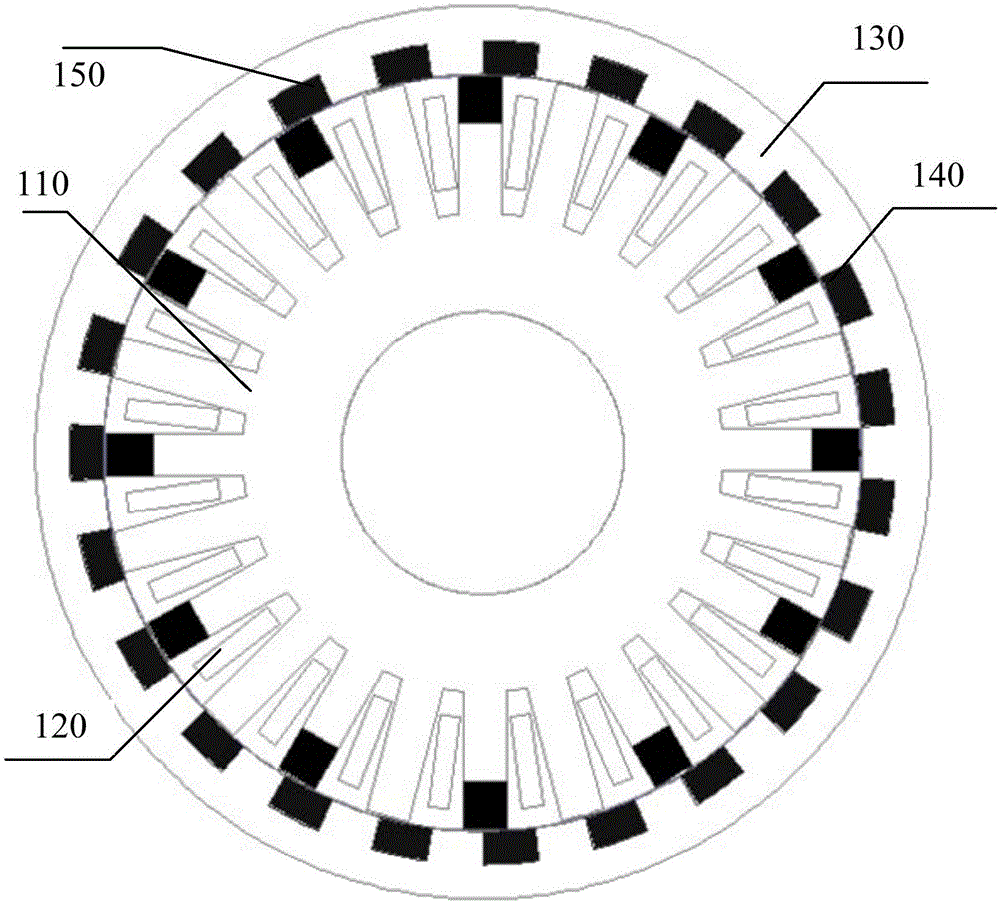

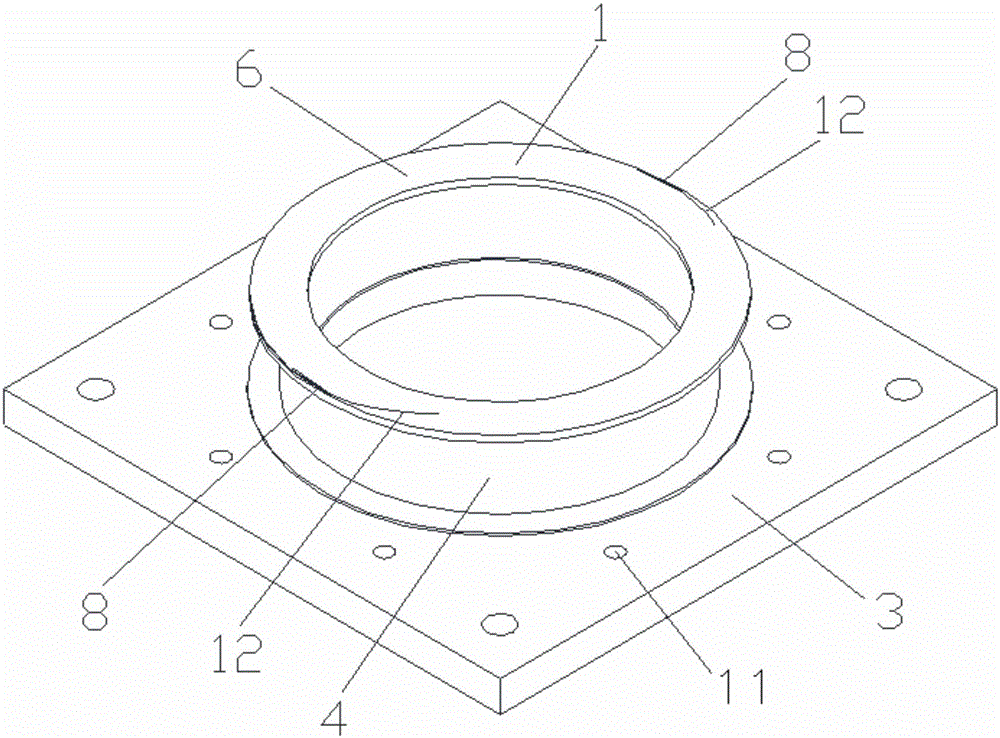

Stator and permanent magnet motor

PendingCN112701813AReduce winding difficultyImprove winding efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineClassical mechanics

The invention provides a stator and a permanent magnet motor. The stator comprises a plurality of iron core blocks (9) which are sequentially arranged in the circumferential direction, each iron core block (9) comprises a protrusion (10) and a groove (11), the protrusions (10) are located on the first side surfaces of the iron core blocks (9) in the circumferential direction, the grooves (11) are located on the second side surfaces of the iron core blocks (9) in the circumferential direction, and the protrusions (10) are matched with the grooves. And the bulge (10) of each iron core block (9) is embedded into the groove (11) of the adjacent iron core block (9). According to the stator provided by the invention, the coil winding difficulty of the stator can be reduced, and the stator coil winding efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Wide-speed variable-speed motor with excitation direct-control alternating current-direct current shaft self decoupling

ActiveCN106712332AImprove power density and efficiencySimple winding structureMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsDirect control

The invention discloses a wide-speed variable-speed motor with excitation direct-control alternating current-direct current shaft self decoupling. The variable-speed motor is composed of a stator, a rotor, and a permanent magnet. The stator consists of a stator iron core and armature windings; the stator iron core is designed to have an opening groove structure; and the armature windings are arranged in the opening grooves of the stator iron core. The armature windings provide power through an inverter and generate alternating currents with direct-current biases; the armature windings are arranged in a distributed centralized winding manner and each winding winds around stator teeth. The rotor includes a rotor iron core. According to the motor disclosed by the invention, the winding structure is simplified; the direct-current winding and the alternating-current winding of the existing hybrid excitation motor are combined into one set of windings, so that the winding difficulty can be reduced, the space, occupied by the windings, inside the stator can be saved. And reliability and control flexibility of the motor can be improved. Moreover, speed regulation of a motor in a wide rotating speed range can be realized.

Owner:THE HONG KONG POLYTECHNIC UNIV

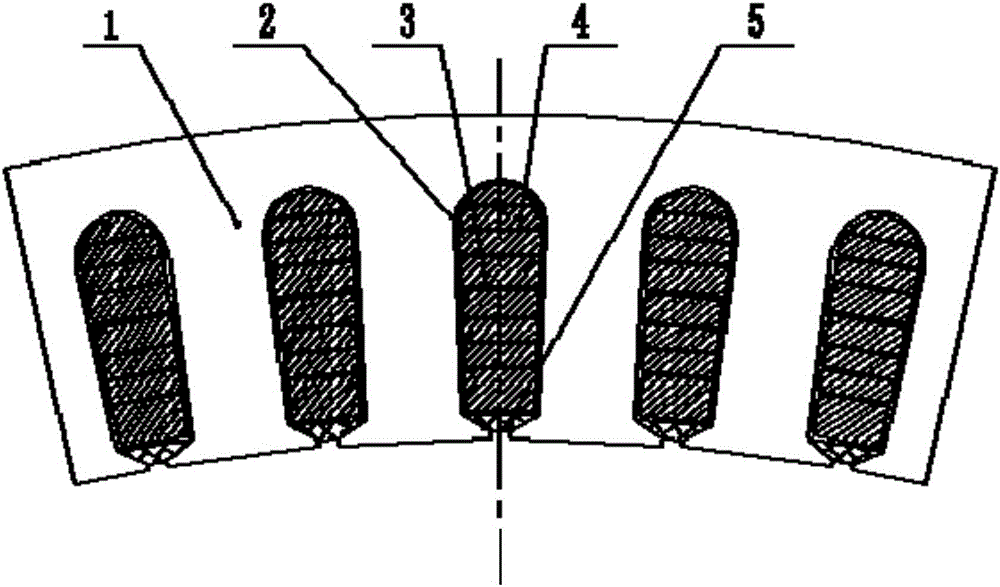

Energy emission end of multi protruded type magnetic coupling mechanism applied to wireless power supply of electromobile

InactiveCN106059102AEnhanced couplingImprove the coupling effectTransformersCircuit arrangementsCouplingMagnetic poles

The invention relates to an energy emission end of a multi protruded type magnetic coupling mechanism applied to wireless power supply of electromobile, belongs to the technical field of wireless energy transmission, and aims at solving the problems that there is no gap among magnetic cores of a present wireless power supply device of the electromobile, structure adjustment is inconvenient, and the using amount of magnetic cores is large. N magnetic poles are arranged successively along the length direction, and the distance between adjacent magnetic poles is q; each magnetic pole comprises at least one protruded magnetic core, two adjacent magnetic poles include at least three protruded magnetic cores, all protruded magnetic cores in one magnetic pole are arranged successively along the length direction, and the distance between adjacent protruded magnetic cores is d; each protruded magnetic core is composed of a long-strip-shaped bottom magnetic core part and a long-strip-shaped vertical magnetic core part, and the protruded magnetic core includes homocentric squares in the downward view; and a power supply cable is wound around all the long-strip-shaped vertical magnetic core part of each magnetic pole sequentially. The energy emission end is applied to wireless power supply of the electromobile.

Owner:HARBIN INST OF TECH

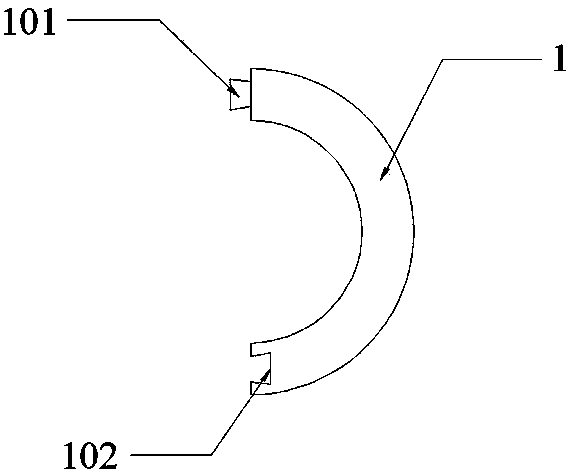

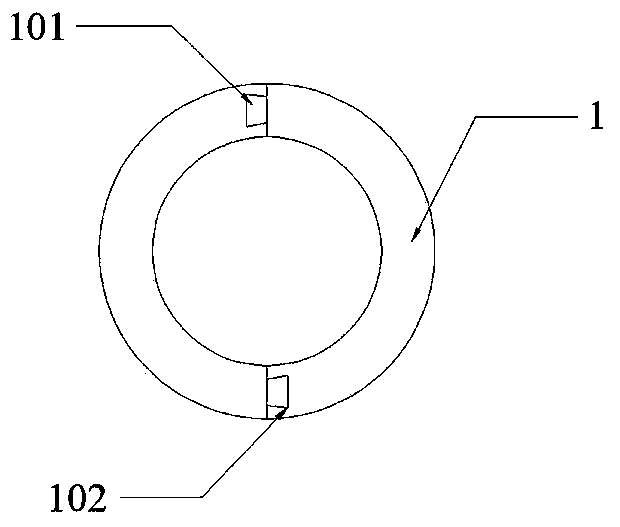

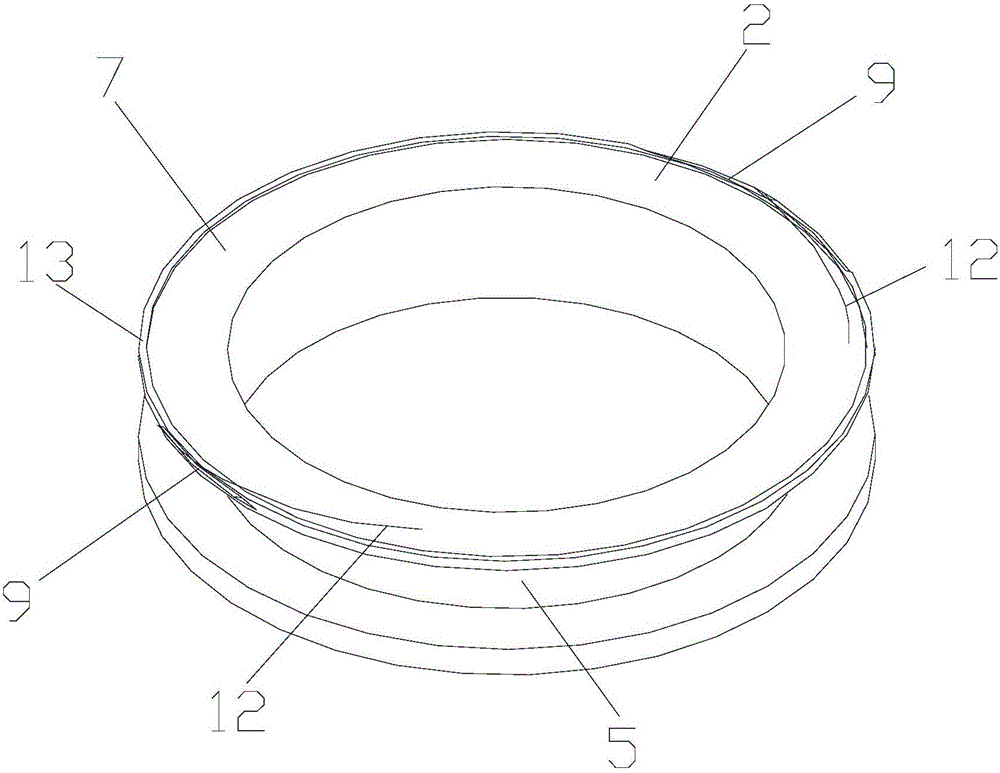

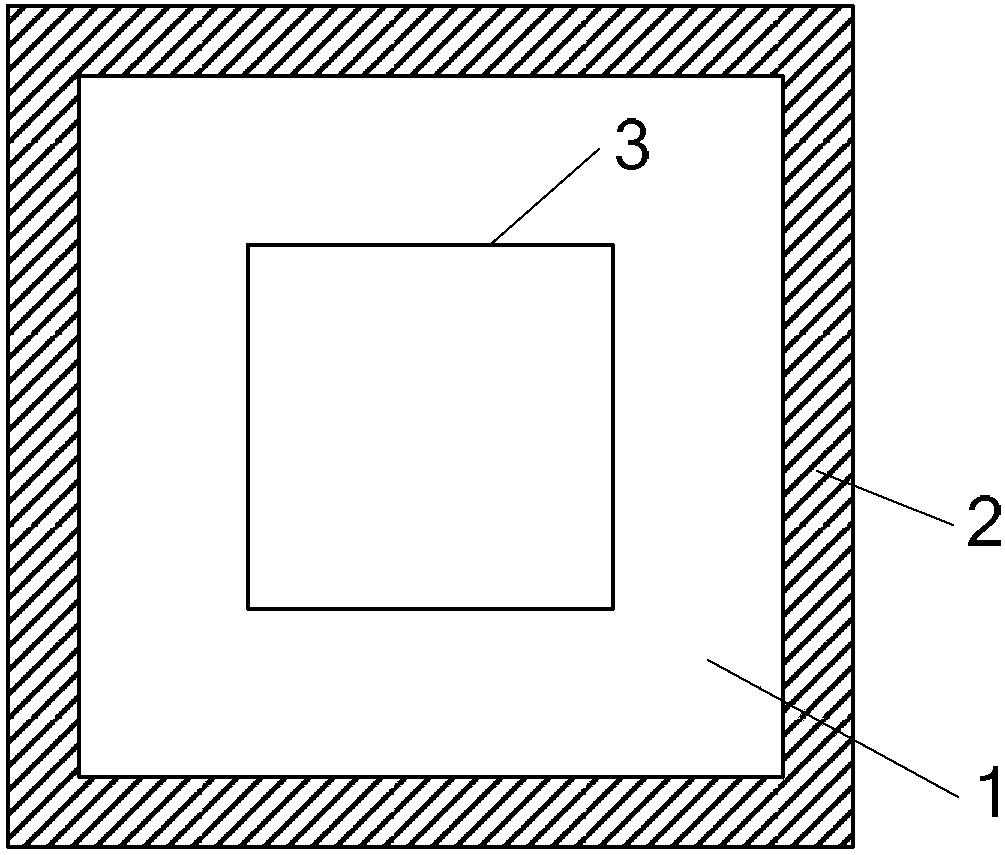

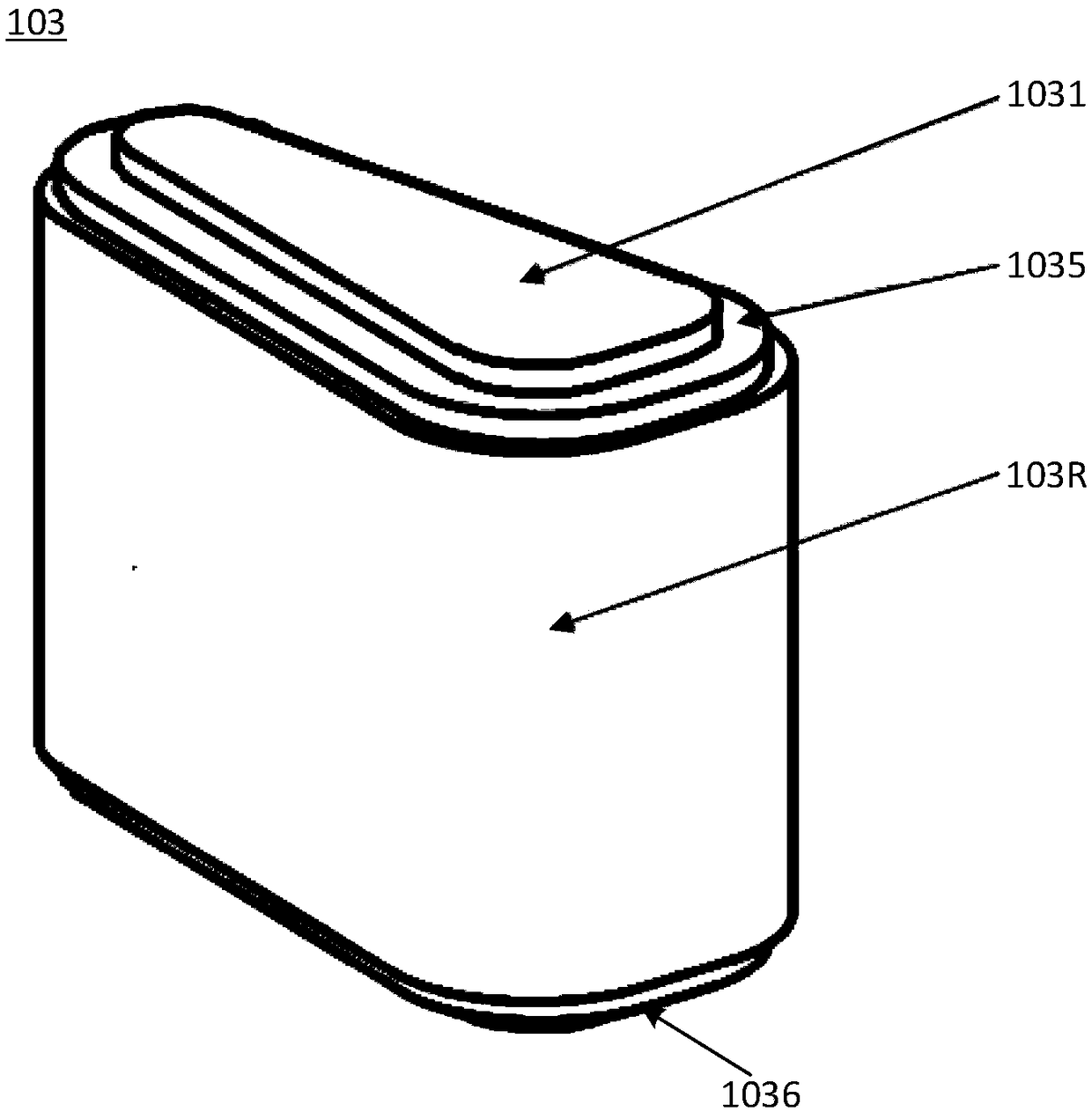

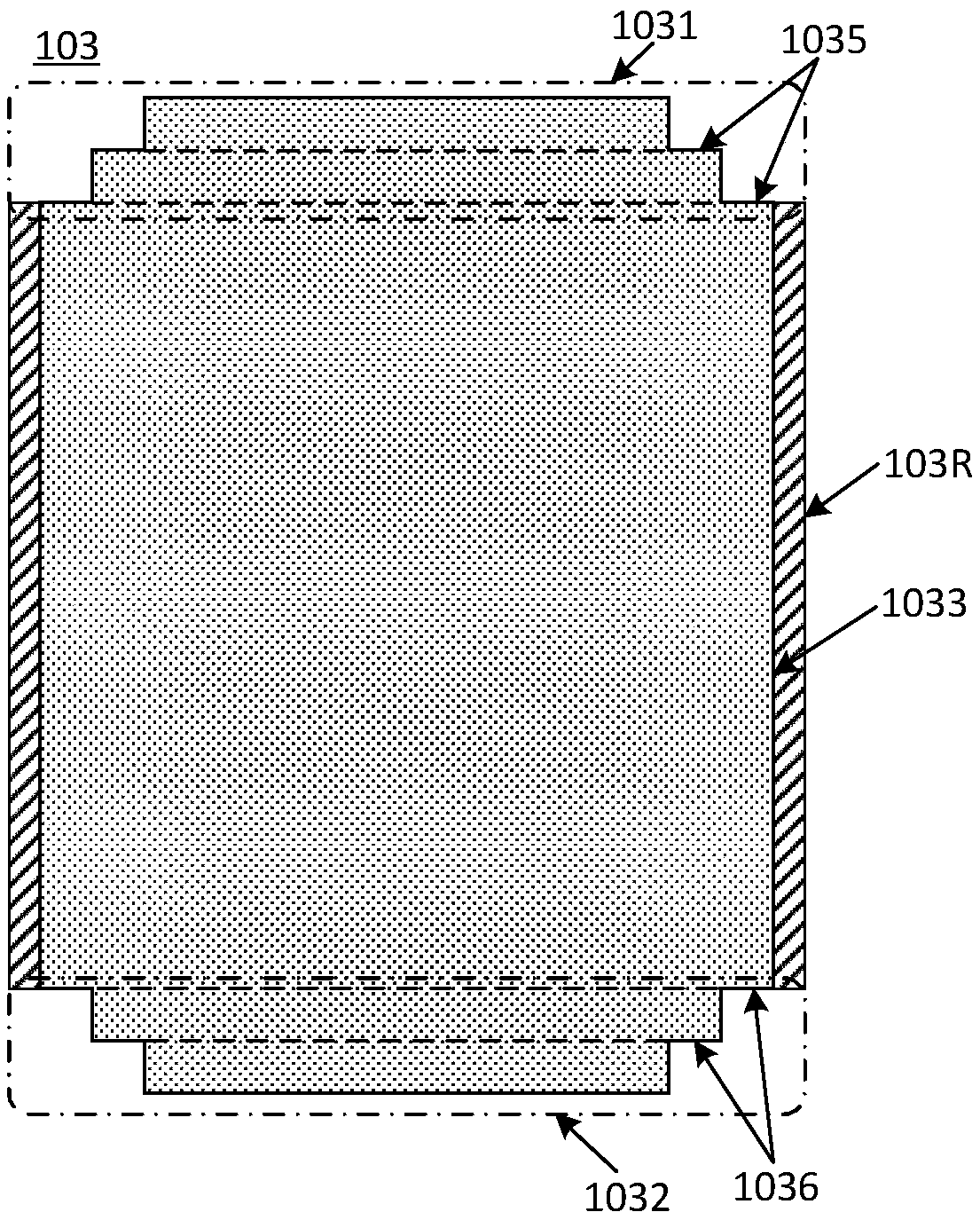

Magnet ring component

InactiveCN103474194AReduce winding difficultyImprove winding efficiencyMagnetsTransformers/inductances magnetic coresEngineeringConductor Coil

The invention discloses a magnet ring component comprising two semicircular connectors. The magnet ring component is characterized in that one end of each connector is provided with a projecting fastener part, the other end of each connector is provided with a concave groove part fitting the fastener part, the axial section of each fastener part, on the connector, is trapezoid shaped, a topline of each trapezoid is connected with the corresponding connector, the axial section of each groove part, on the connector, is also trapezoid shaped, and a topline of each trapezoid contacts with the edge of the corresponding connector. The magnet ring component has the advantages that the magnet ring is split during winding into two independent semicircular connectors respectively used for winding; after winding, the connectors are combined into the complete magnet ring by means of axial sliding; winding is easier and more efficient.

Owner:KUNSHAN YOUXIANG ELECTRONICS SCI & TECH

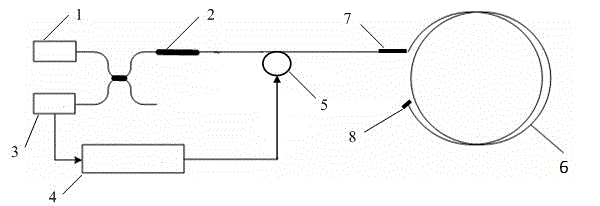

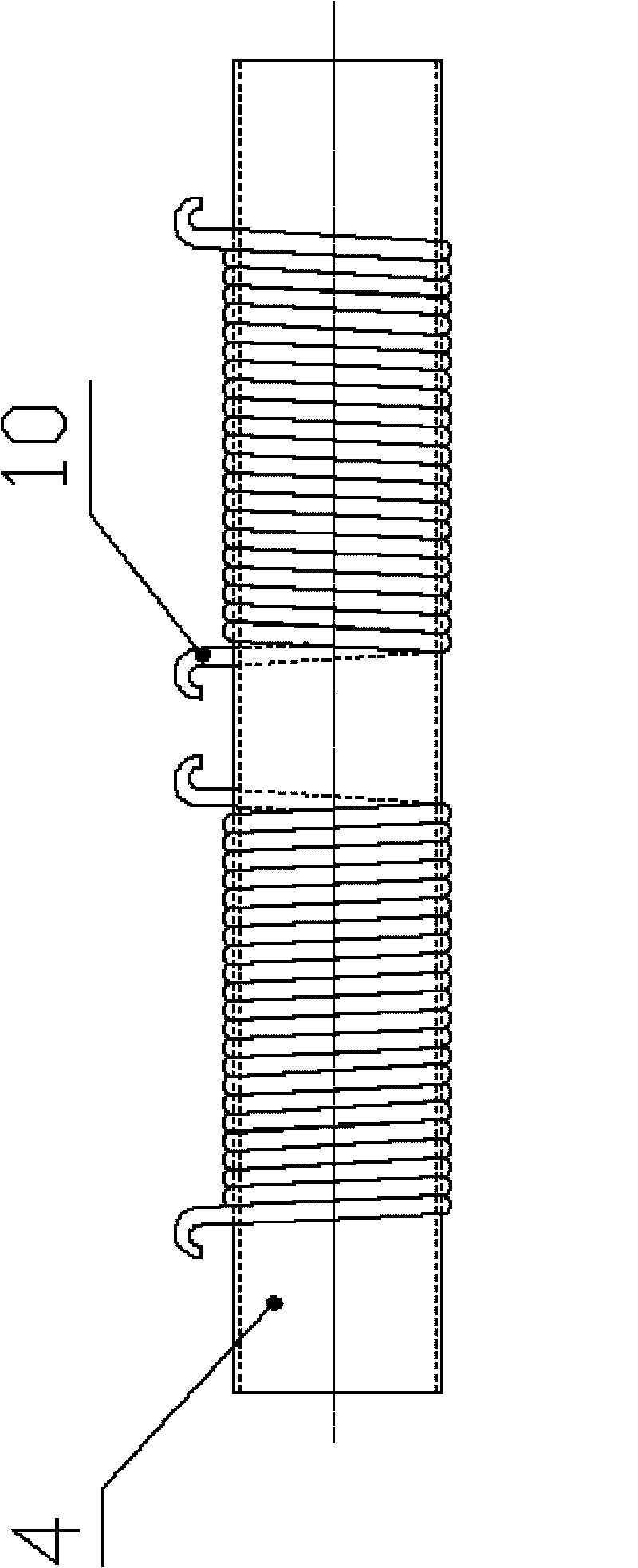

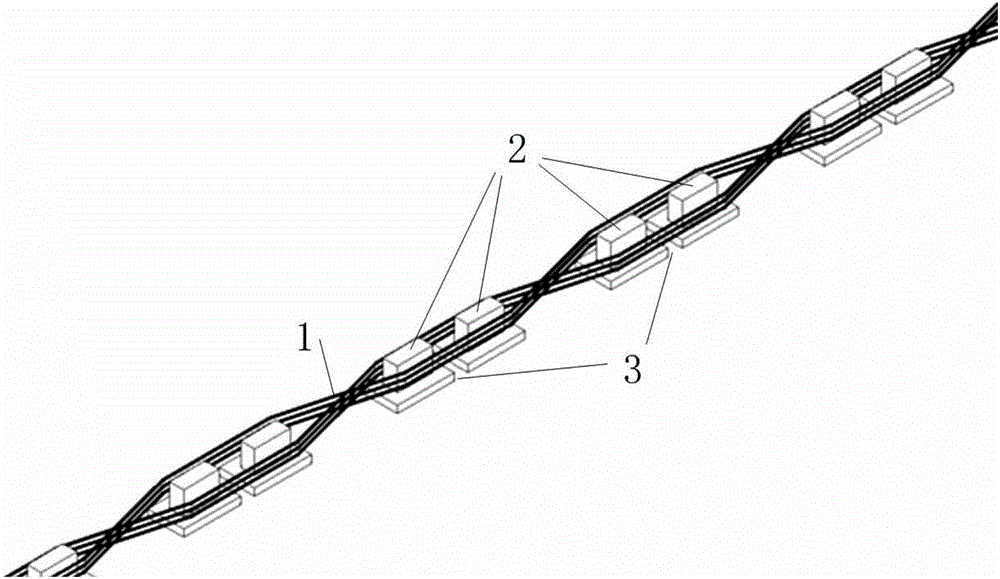

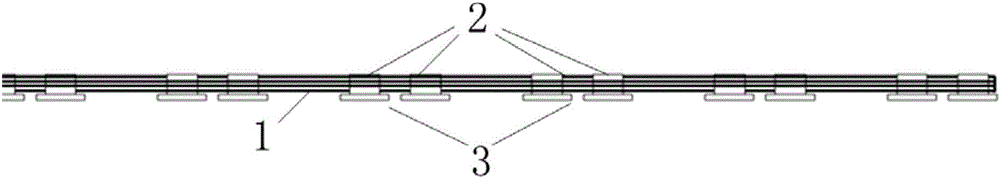

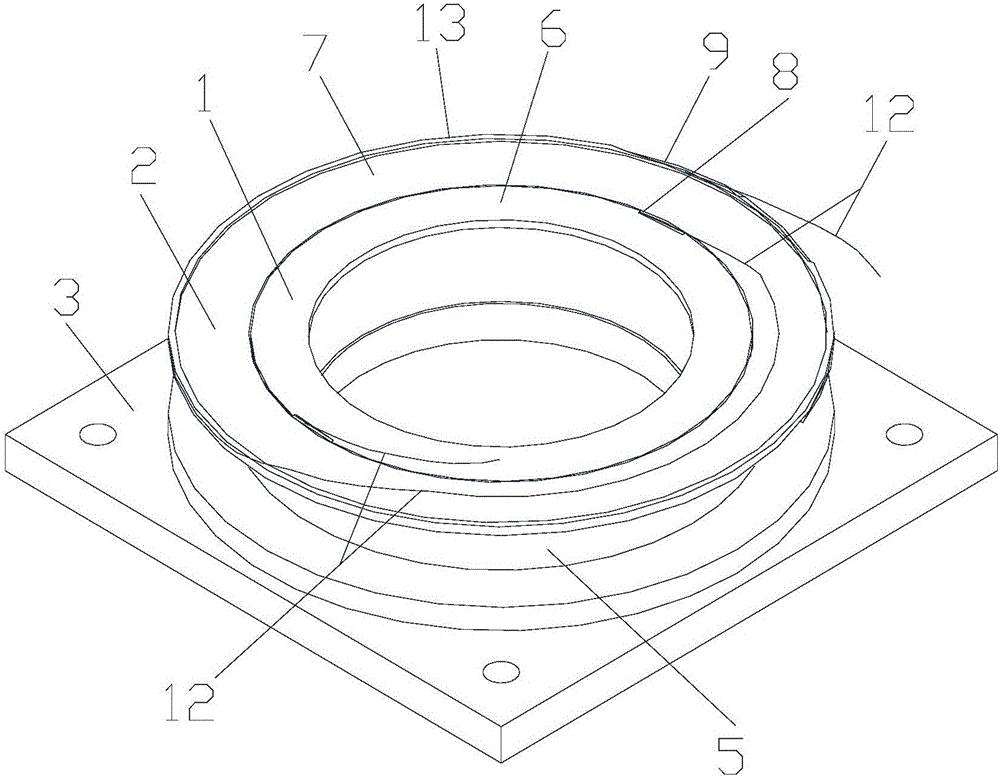

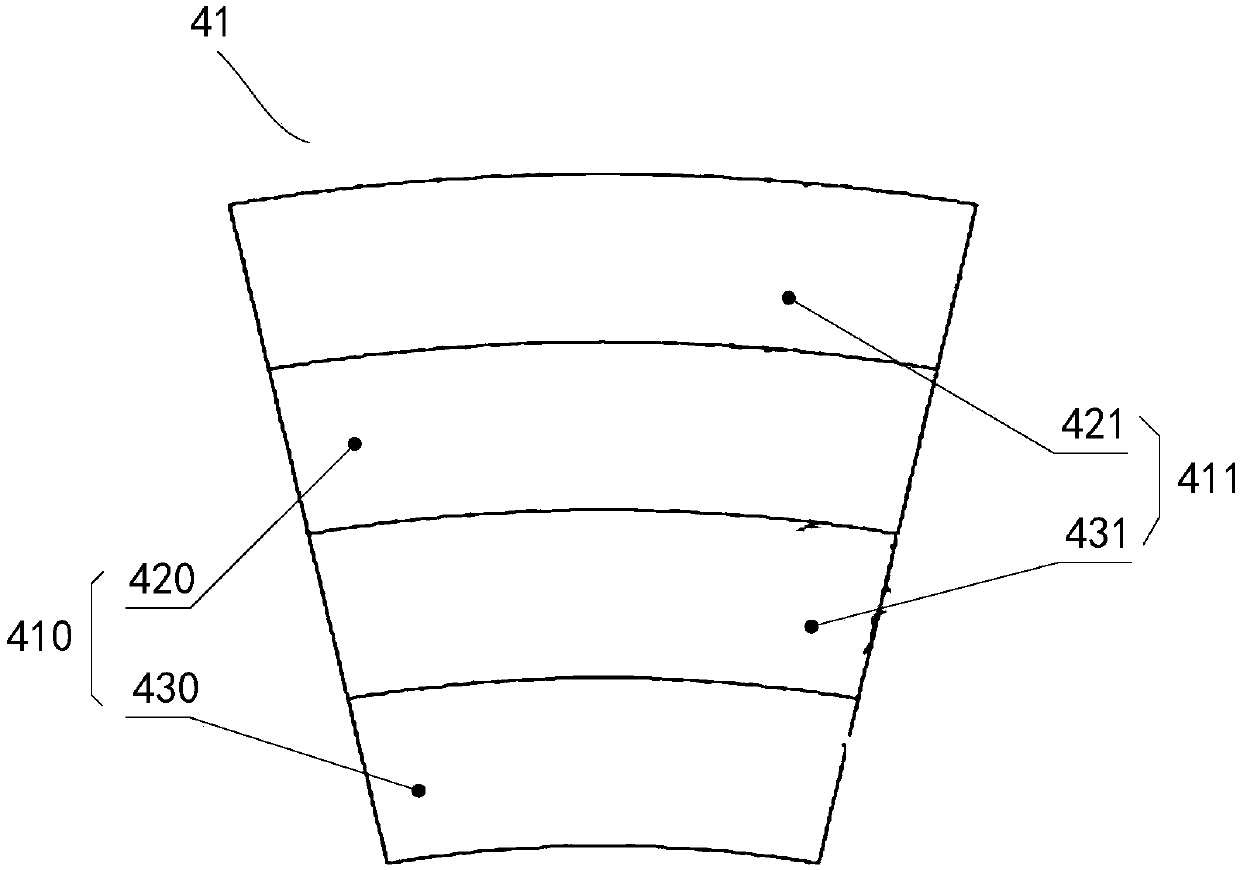

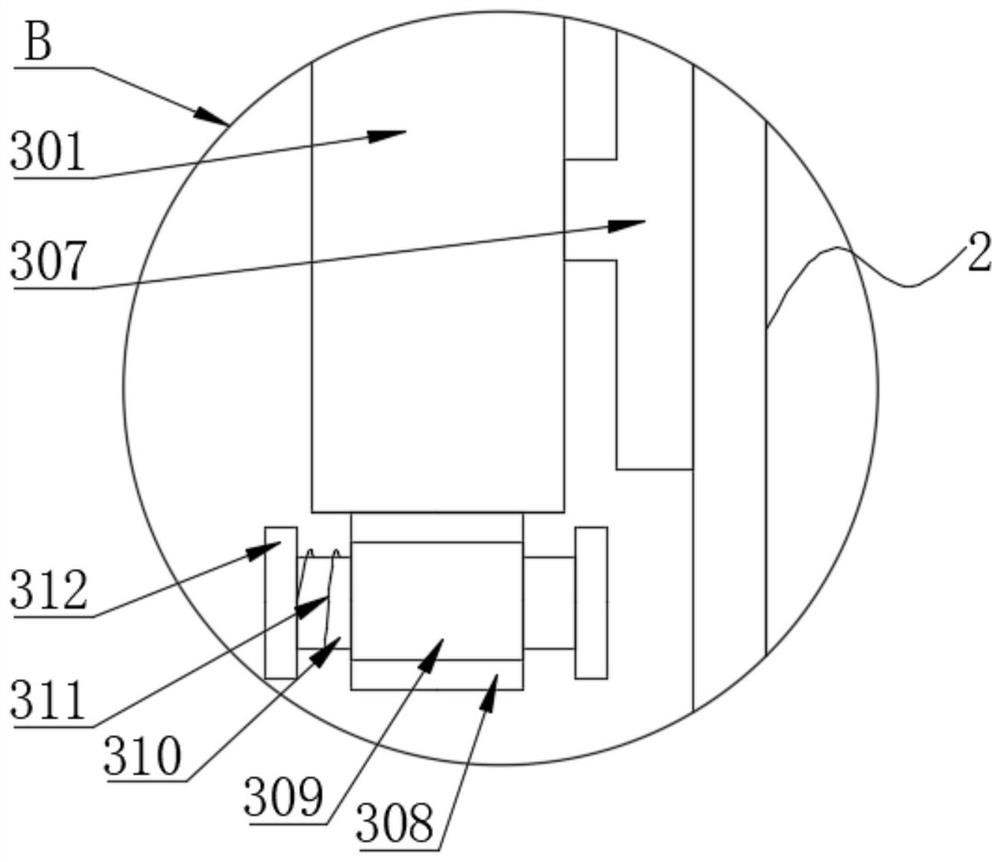

Combined type fiber loop framework for fiber-optic gyroscope

InactiveCN105910597AImprove pass rateReduce winding difficultySagnac effect gyrometersGyroscopeEngineering

The invention provides a combined type fiber loop framework for a fiber-optic gyroscope. The combined type fiber loop framework is provided with an internal fiber loop framework body, an external fiber loop framework body and a mounting plate. The internal fiber loop framework body and the external fiber framework body are both of I-shaped loop structures, and the lower end face of the internal fiber loop framework body is fixed to the mounting plate. An optical fiber winding loop face I and an optical fiber winding loop face II are both provided with optical fibers wound in a quadrupolar symmetry mode, and gluing discs at the two optical fiber outlet ends of the optical fiber on each of the optical fiber winding loop face I and the optical fiber winding loop face II are mounted on the optical fiber winding loop face I and the optical fiber winding loop face. The internal fiber loop framework body is embedded into a center hole of the external fiber loop framework body, and the lower end of the external fiber loop framework body is fixed to the mounting plate. The high-precision fiber loop winding length is distributed to the internal fiber loop framework body and the external fiber loop framework body, the number of winding turns is reduced, the winding difficulty for staff is lowered, and the yield is increased; meanwhile, quadrupolar symmetry optical fiber winding is adopted, so that the influence of the temperature gradient effect on the performance of the fiber-optic gyroscope is effectively reduced, the vibration performance of the fiber-optic gyroscope is improved, the structure is simple, and operation is easy.

Owner:SHAANXI BAOCHENG AVIATION INSTR

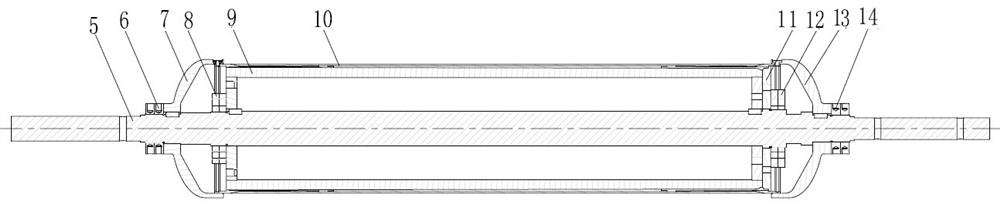

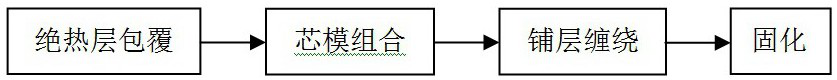

Large-opening composite shell, forming method and forming tool

PendingCN112644039AEasy to assemble and disassembleGuaranteed lightweight and high-strength performanceRocket engine plantsInsulation layerForming processes

The invention relates to a large-opening composite material shell, a forming method and a forming tool. The large-opening composite material shell comprises a front joint, a fiber reinforced plastic shell and a rear joint, the appearances of the connecting parts of the front joint and the fiber reinforced plastic shell and the connecting parts of the rear joint and the fiber reinforced plastic shell are of inverted cone structures, and the inverted cone angle ranges from 0.3-1 degree; a forming process is divided into the procedures of heat insulation layer coating, core mold combination, laying and winding and curing; the forming tool comprises a main shaft, a front connector positioning disc, a winding integral metal core die and a rear connector positioning disc. The structure is simplified, longitudinal reinforcing fibers adopt unidirectional fiber cloth layers and circumferential reinforcing fibers adopt a circumferential winding forming method, so that the winding difficulty is reduced, and the production efficiency is improved; the light weight and high pressure performance of the large-opening composite material shell are ensured, good manufacturability is achieved, and the requirement for efficient batch production is met.

Owner:内蒙动力机械研究所 +1

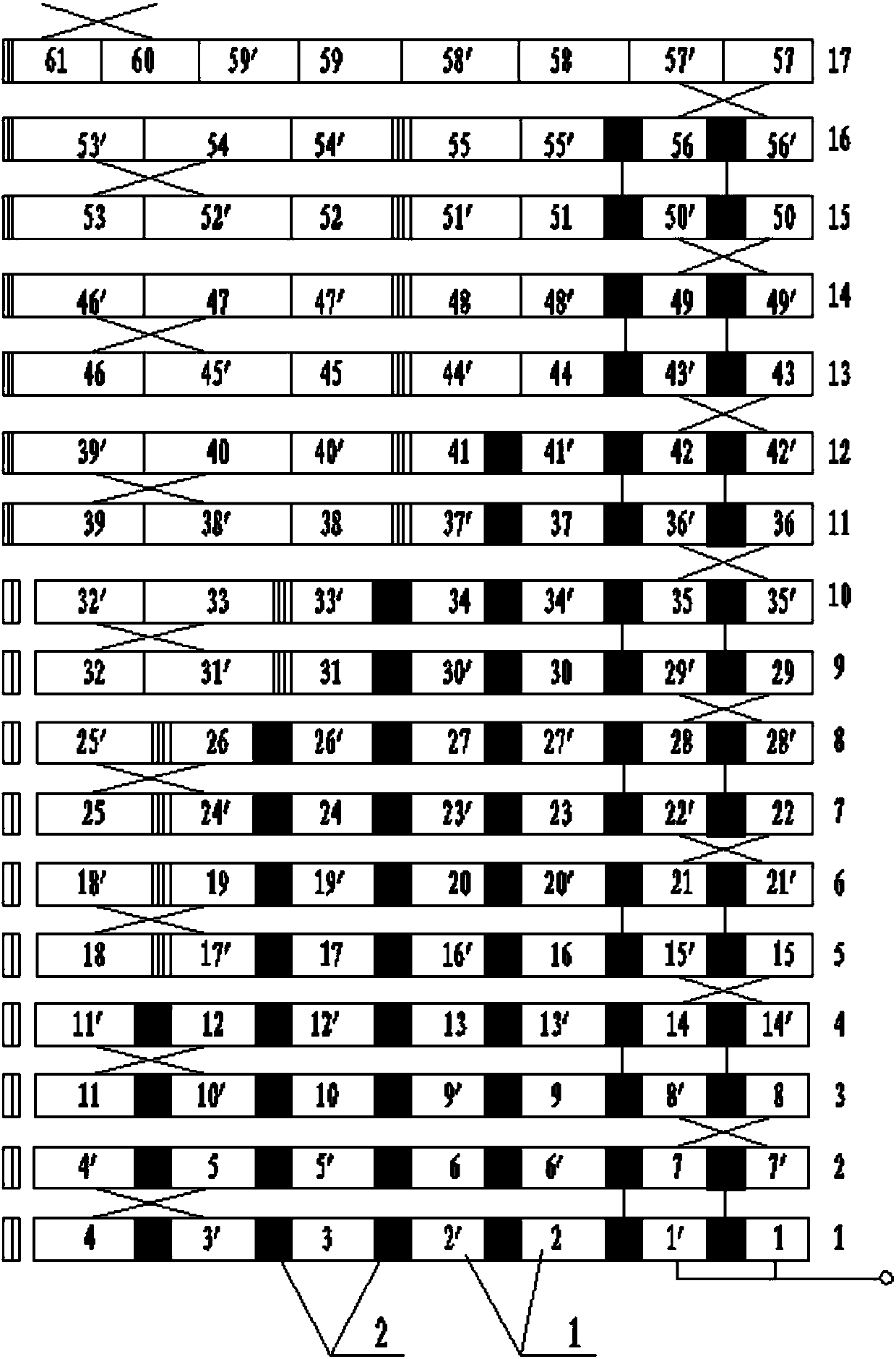

Inner screen continuous type coil adopting fractional turn integer winding method and winding method thereof

PendingCN107785165AImprove fill rateLow costInductances/transformers/magnets manufactureCapacitanceFilling rate

The invention relates to an inner screen continuous type coil adopting a fractional turn integer winding method and a winding method thereof. The coil comprises operating wires and a shielding wire. The operating wires are two wires wound in parallel, the shielding wire is arranged between the interturn and wire space of the operating wires; at the wire segment changing position of the operating wires, one of the two operating wires wound in parallel winds one more circle and then moves upward to the next segment, and the other of the two operating wires wound in parallel directly moves upwardto the next segment, and accordingly an integer plus half turn structure is formed. The coil adopts two wires for winding, the number of turns of each segment is no longer limited to an integer turn,but to an integer plus half turn; filling rate of the coil is effectively improved, coil costs are reduced, longitudinal capacitance of the coil is effectively increased, turn insulation thickness ofthe shielding wire can be correspondingly smaller, and anti-short circuit capacity of the coil is enhanced while the filling rate is improved.

Owner:TBEA SHENYANG TRANSFORMER GRP CO LTD

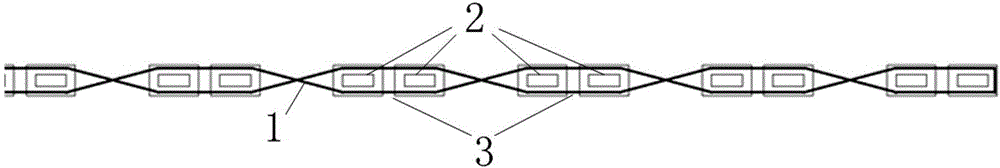

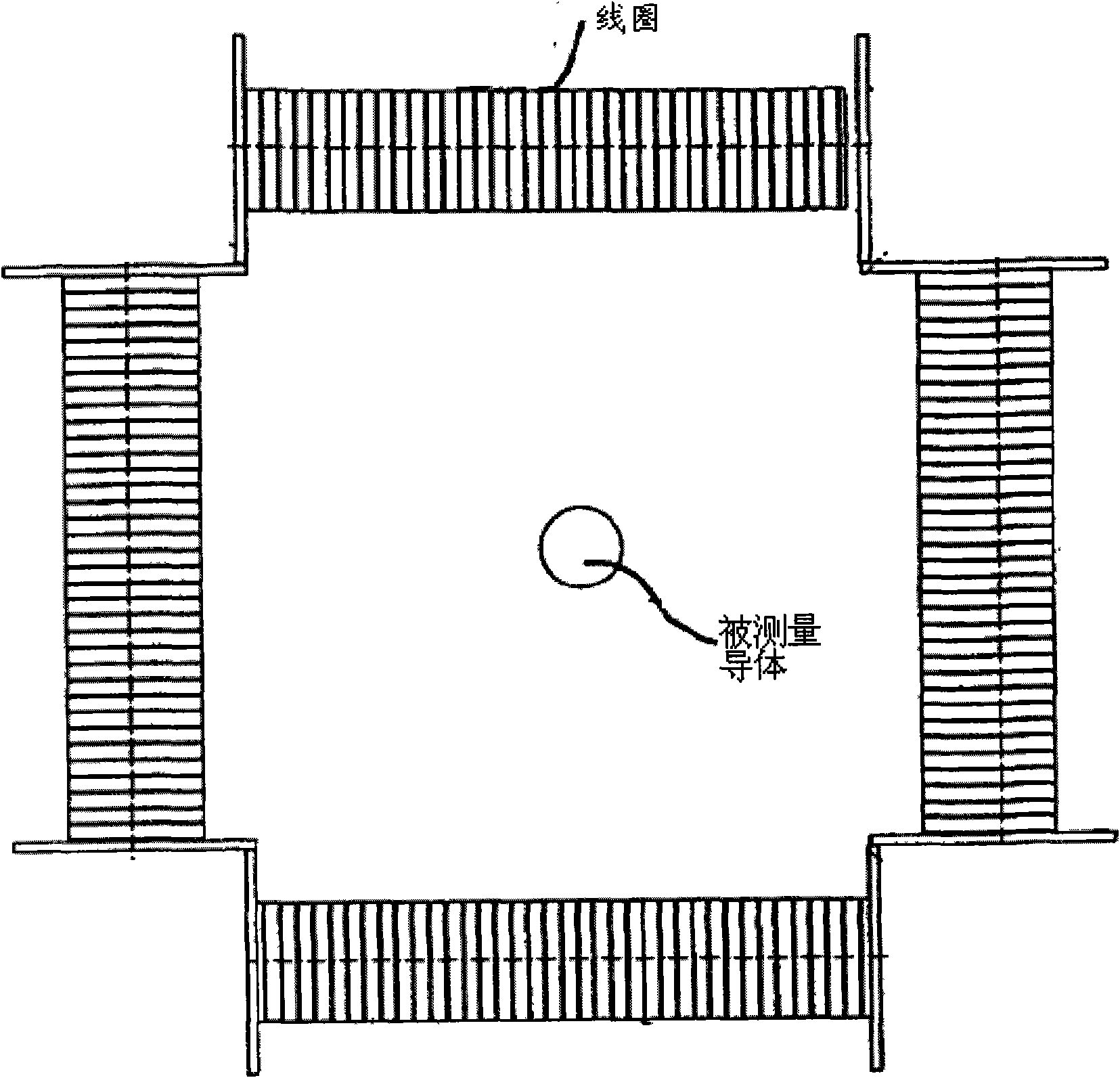

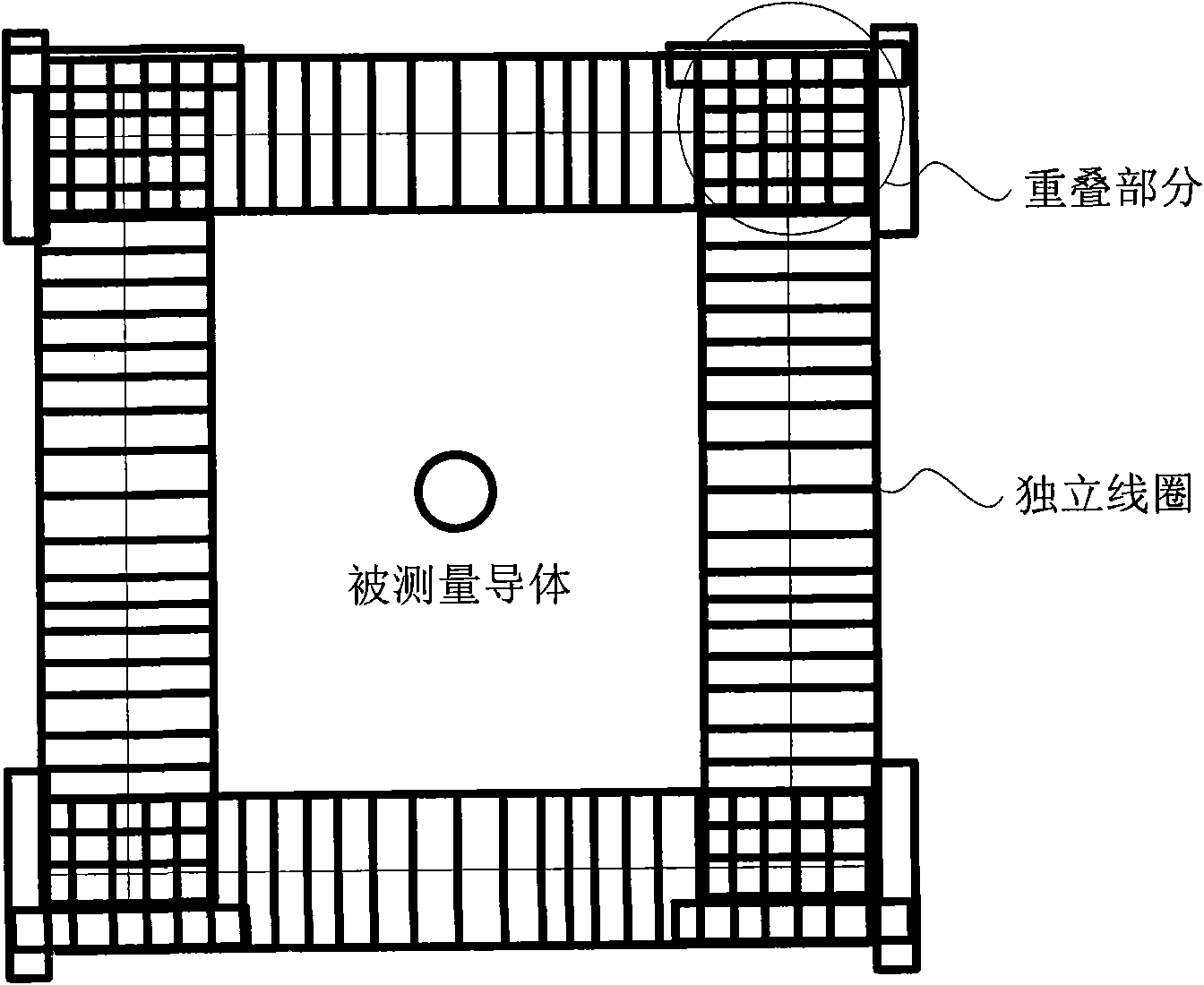

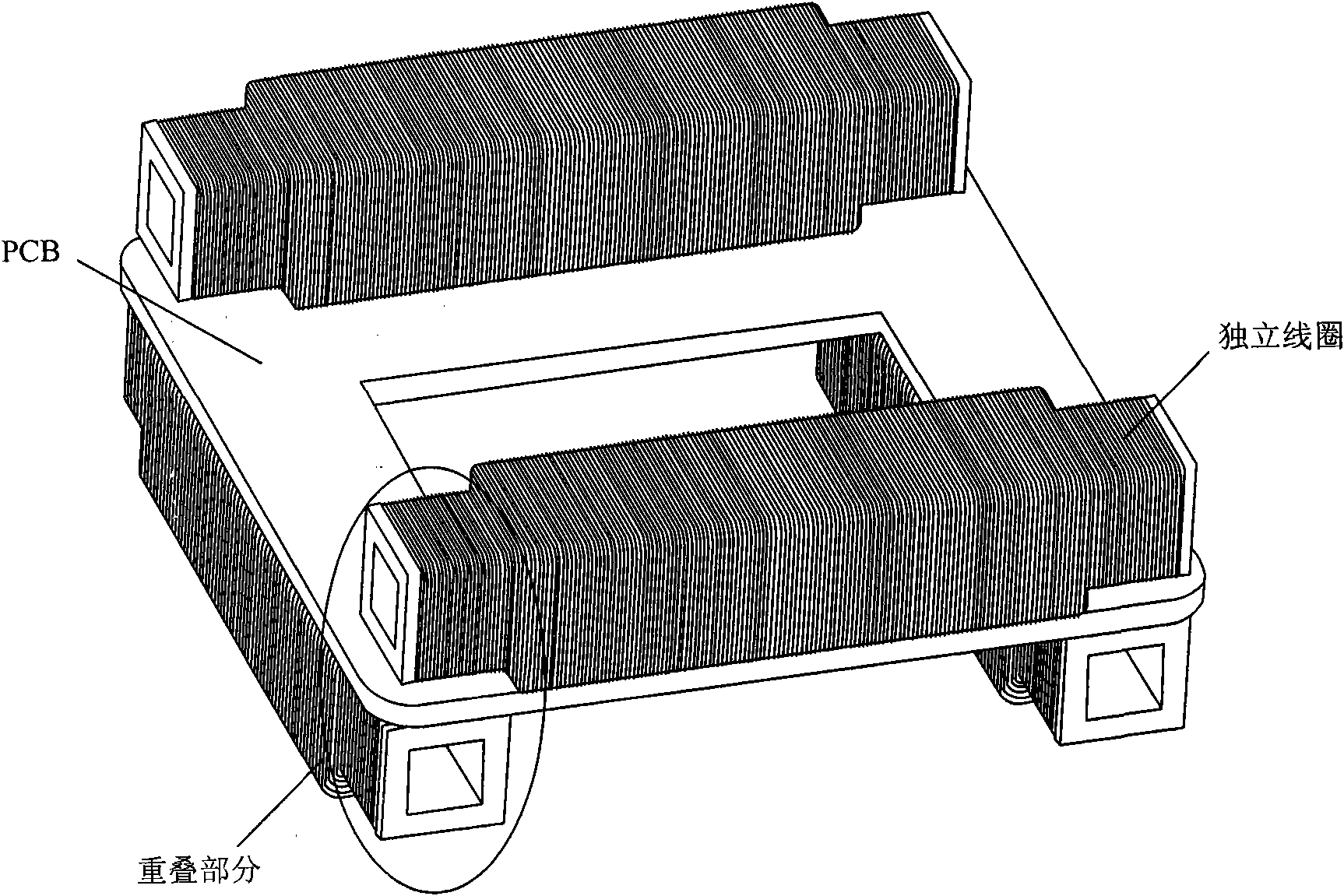

Mutual inductor in current transformer

InactiveCN102005291AGuaranteed continuityGuarantee winding uniformityTransformersTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

The invention provides a mutual inductor in a current transformer, which is a polygon coil formed by end-to-end connection of at least three independent coils, wherein two ends of two adjacent independent coils are mutually overlapped, and the winding density of the overlapped part of each independent coil with other independent coils is less than that of the non-overlapped part. The invention can reduce the influence from external interference and the sensibility to the position of a measured conductor, improves the measurement precision of the current transformer, lowers the winding difficulty, and has more remarkable advantages especially when the volume of the current transformer is smaller.

Owner:SIEMENS AG

Non-alveolar splicing stator of servo motor and assembly process of non-alveolar splicing stator

InactiveCN105743236AIncrease usageReduce manufacturing costMagnetic circuit stationary partsManufacturing stator/rotor bodiesPrinted circuit boardMotor torque

The invention discloses a non-alveolar splicing stator of a servo motor. The non-alveolar splicing stator comprises a stator main body, coils and a printed circuit board (PCB), wherein the stator main body is formed by splicing a plurality of T-shaped stator groups, and the coils are respectively wound around the stator groups. The invention also discloses an assembly process of the non-alveolar splicing stator. The stator main body is formed by splicing the plurality of stator groups, the stator is not needed to be provided with alveolars, no distance is generated between pole numbers, the material utilization rate is effectively improved, the production cost is reduced, the motor torque is also increased, and the motor efficiency is improved; during assembly, wires can be directly wound around the stator groups in an external winding way, and the winding efficiency is improved; and during the assembly process, three processes of wire insertion, wire binding and shaping are omitted, the damage to an enameled wire is reduced, and the production efficiency is improved.

Owner:FOSHAN DEYI IND TECH CO LTD

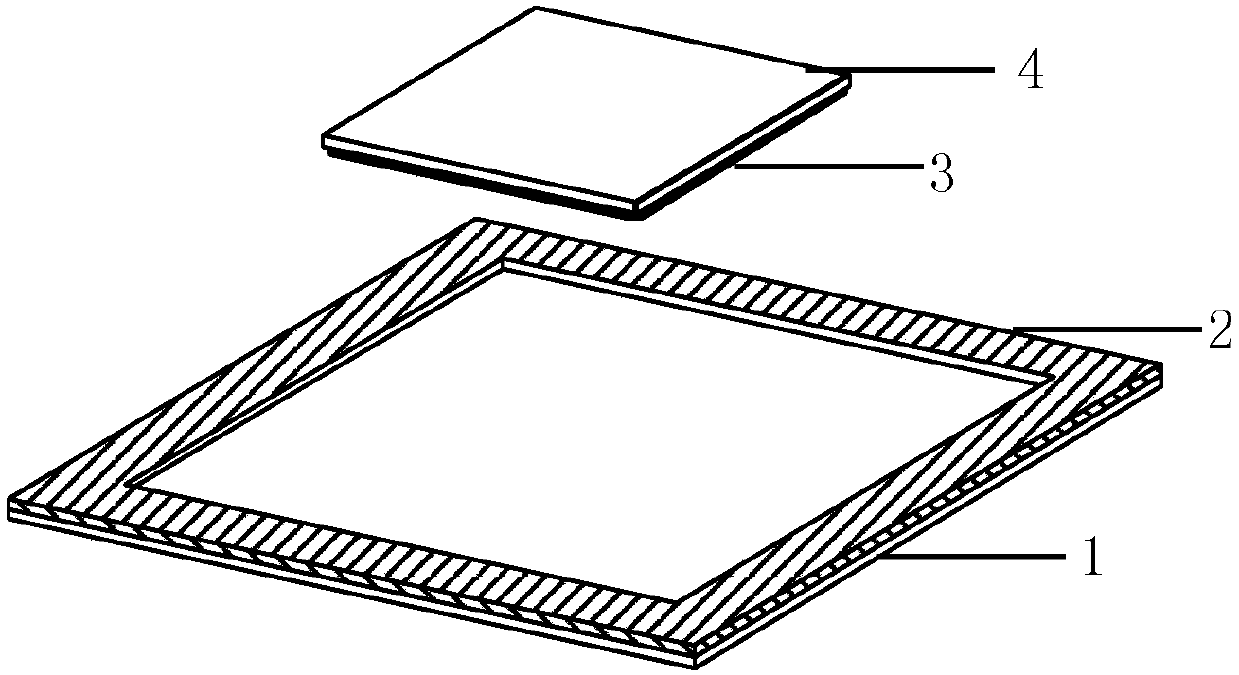

Magnetic coupling mechanism applied to wireless charging system of electric vehicle

InactiveCN107627887ASimple structureThin structureBatteries circuit arrangementsElectric powerCouplingEngineering

The invention relates to a magnetic coupling mechanism applied to a wireless charging system of an electric vehicle, and belongs to the technical field of wireless electric energy transmission. The problem of low transmission efficiency of system energy due to the inaccurate parking position when the electric vehicle is charged in a static state is solved. The mechanism comprises a transmission terminal and a receiving terminal, the transmission terminal is located below the receiving terminal, and the transmission terminal and the receiving terminal are oppositely arranged and conduct magnetic coupling; the transmission terminal comprises a rectangle transmission magnetic core and a transmission coil which are composed of m*m transmission flat plates; the transmission coil evenly winds the transmission flat plates on four frames of the rectangle transmission magnetic core; m is an integer which is larger than 1; the receiving terminal comprises a rectangle receiving magnetic core anda receiving coil which are composed of n*n receiving flat plates; the receiving coil evenly winds the receiving flat plates on four frames of the rectangle receiving magnetic core; n is an integer which is larger than 1. The magnetic coupling mechanism is mainly applied to wireless electric energy transmission.

Owner:HARBIN INST OF TECH +1

Automatic winding device

The invention discloses an automatic winding device. The automatic winding device comprises two control cases, lifting tracks mounted on the inner sides of the two control cases, a rotatable adjustingmiddle shaft mounted between the two lifting tracks, a winding frame mounted on the adjusting middle shaft, a rotatable winding roller mounted on the winding frame, a thickness measuring roller and an electrostatic eliminator, wherein the thickness measuring roller and the electrostatic eliminator are mounted on the positions, on the two sides of the winding roller, of the winding frame; and theelectrostatic eliminator is provided with a plurality of ionizing air guns, the roller surface of the winding roller is provided with a plurality of pneumatic bulges, and air nozzles are formed in thetwo sides of the winding roller. The automatic winding device is simple in structure and reasonable in design, a plastic film is wound conveniently, and after the plastic film is wound, the winding roller is taken out conveniently.

Owner:高新芳

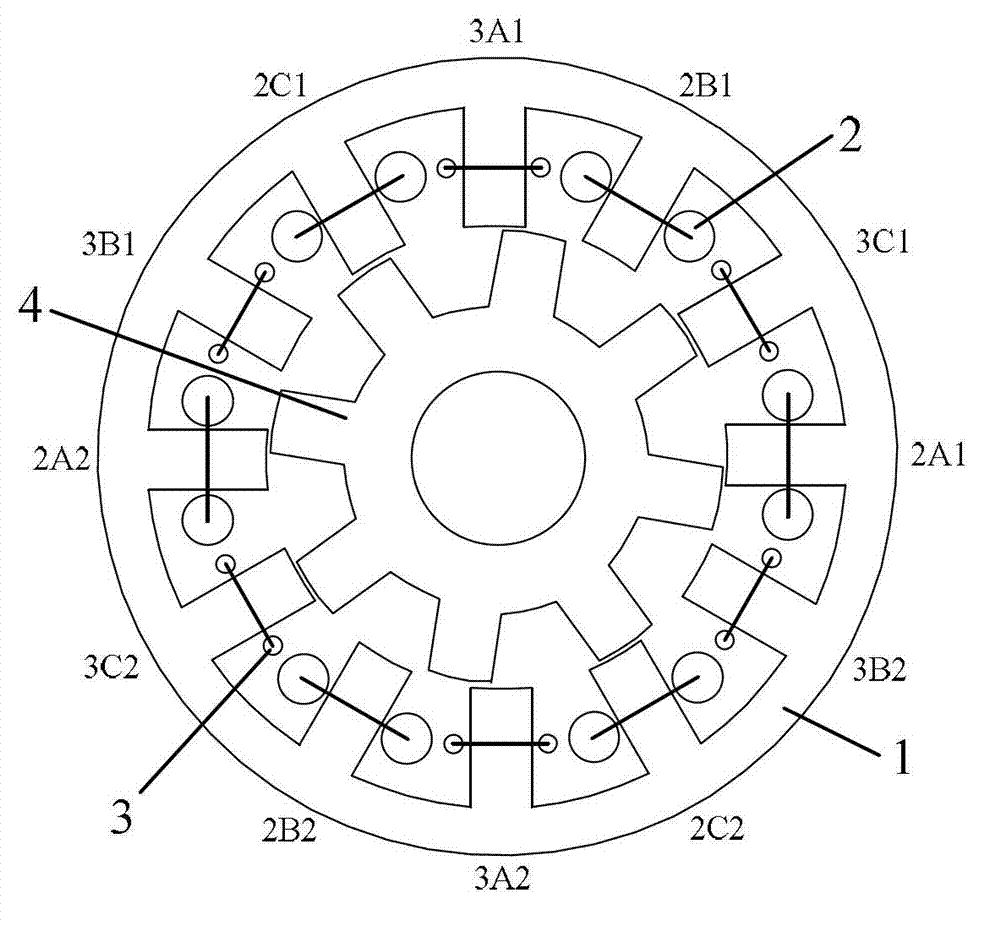

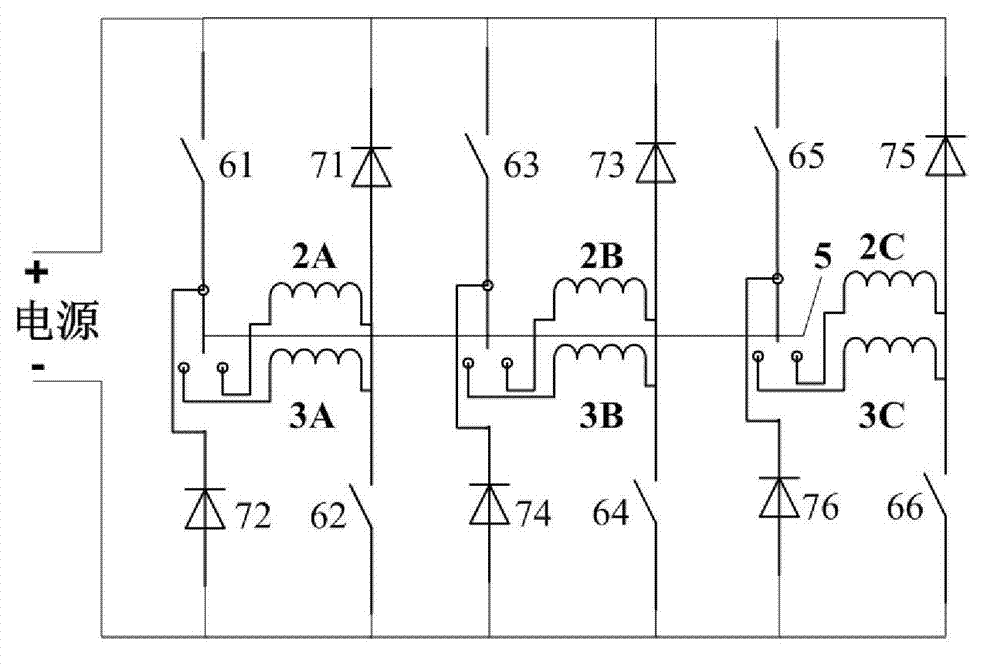

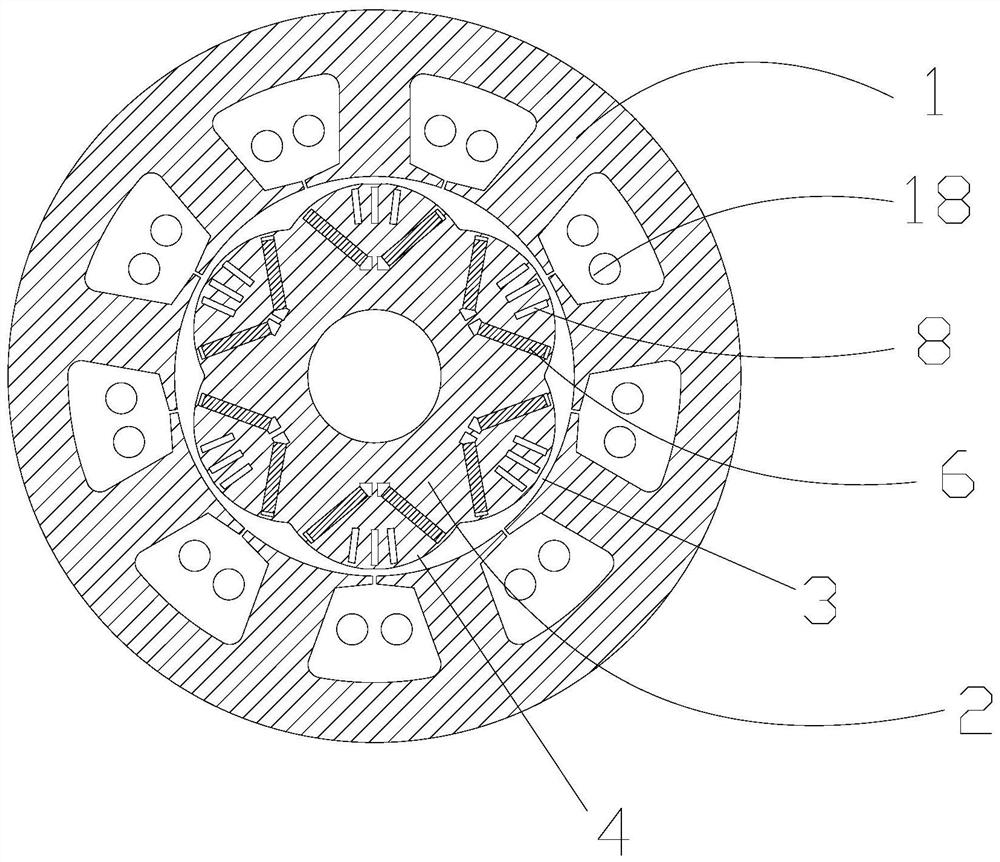

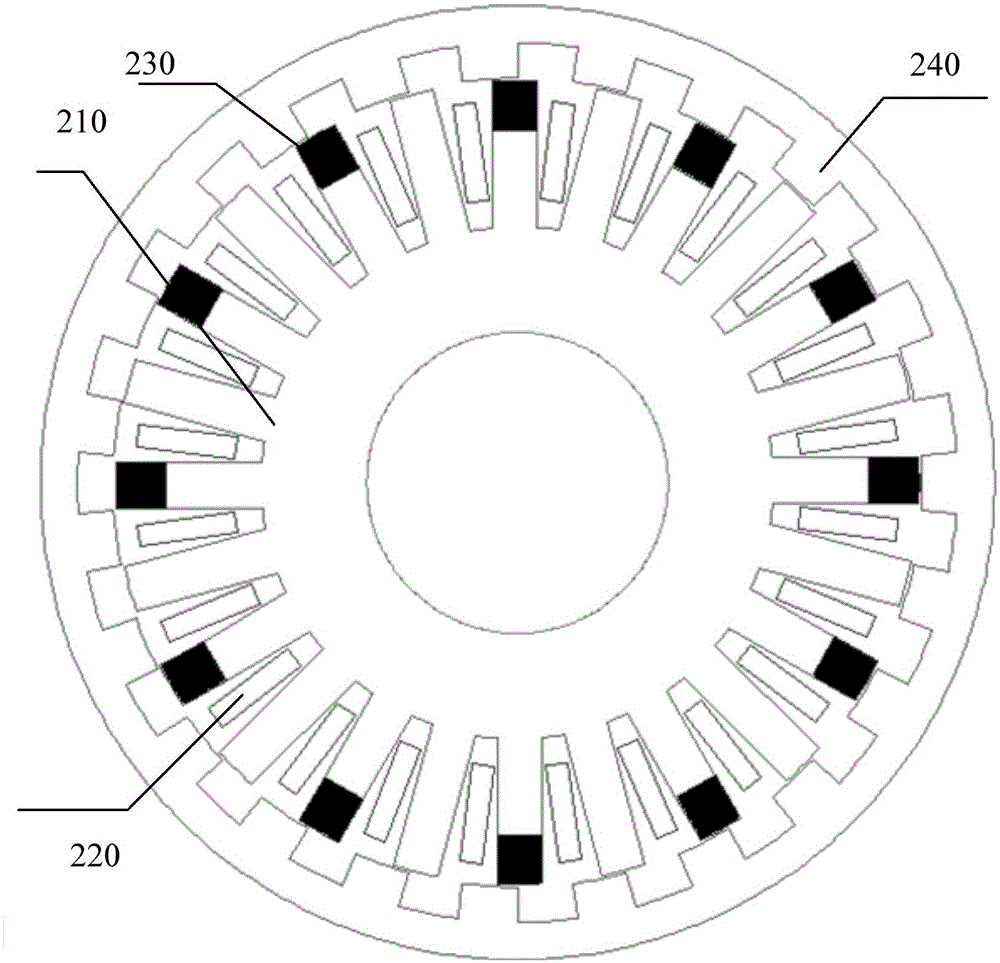

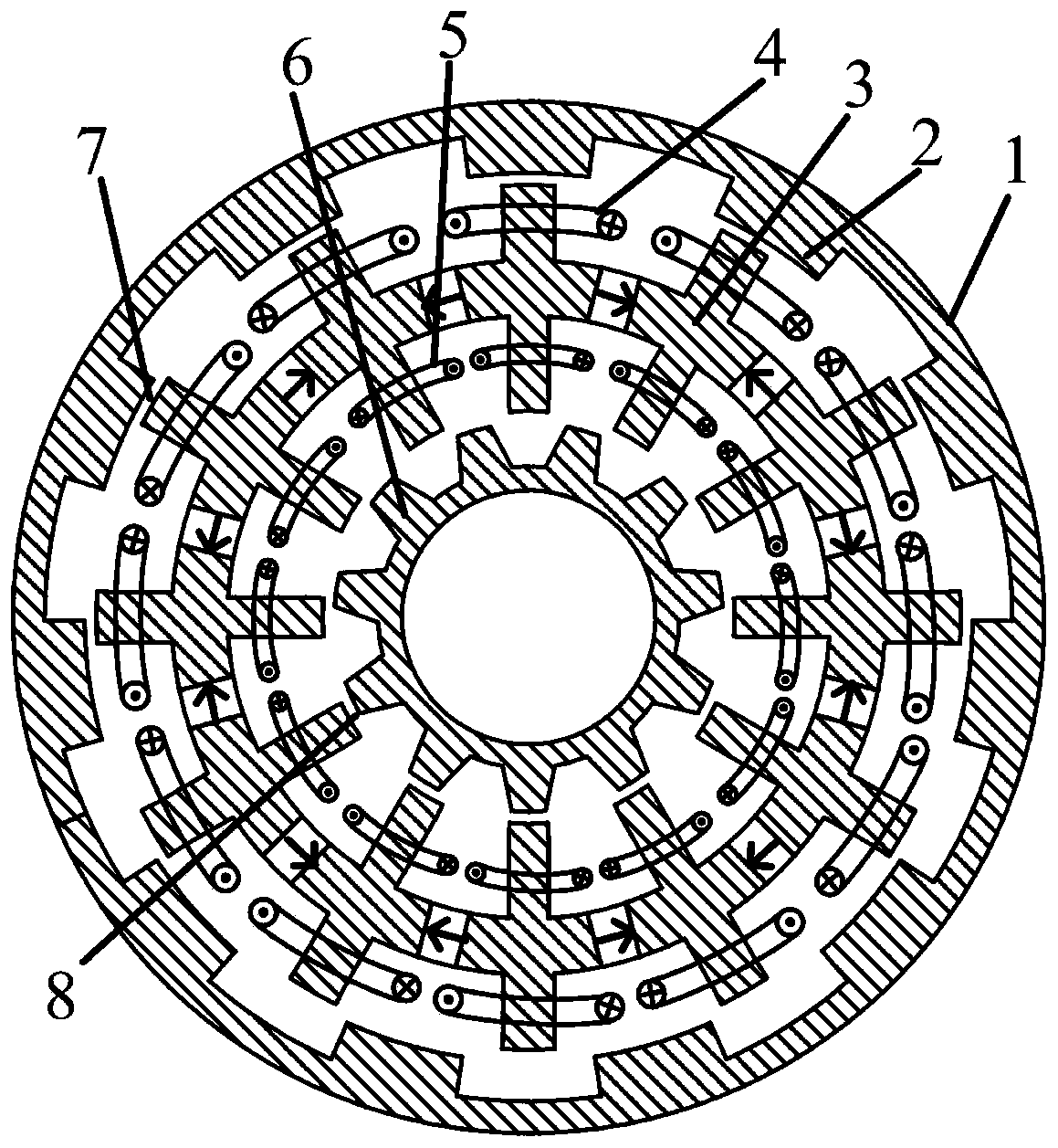

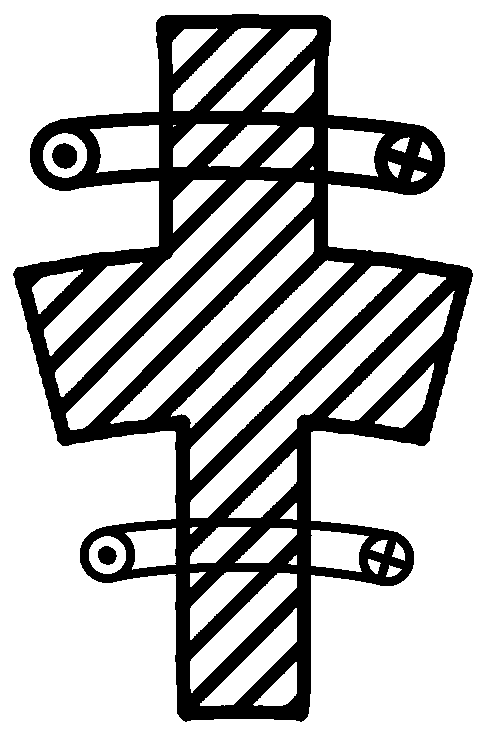

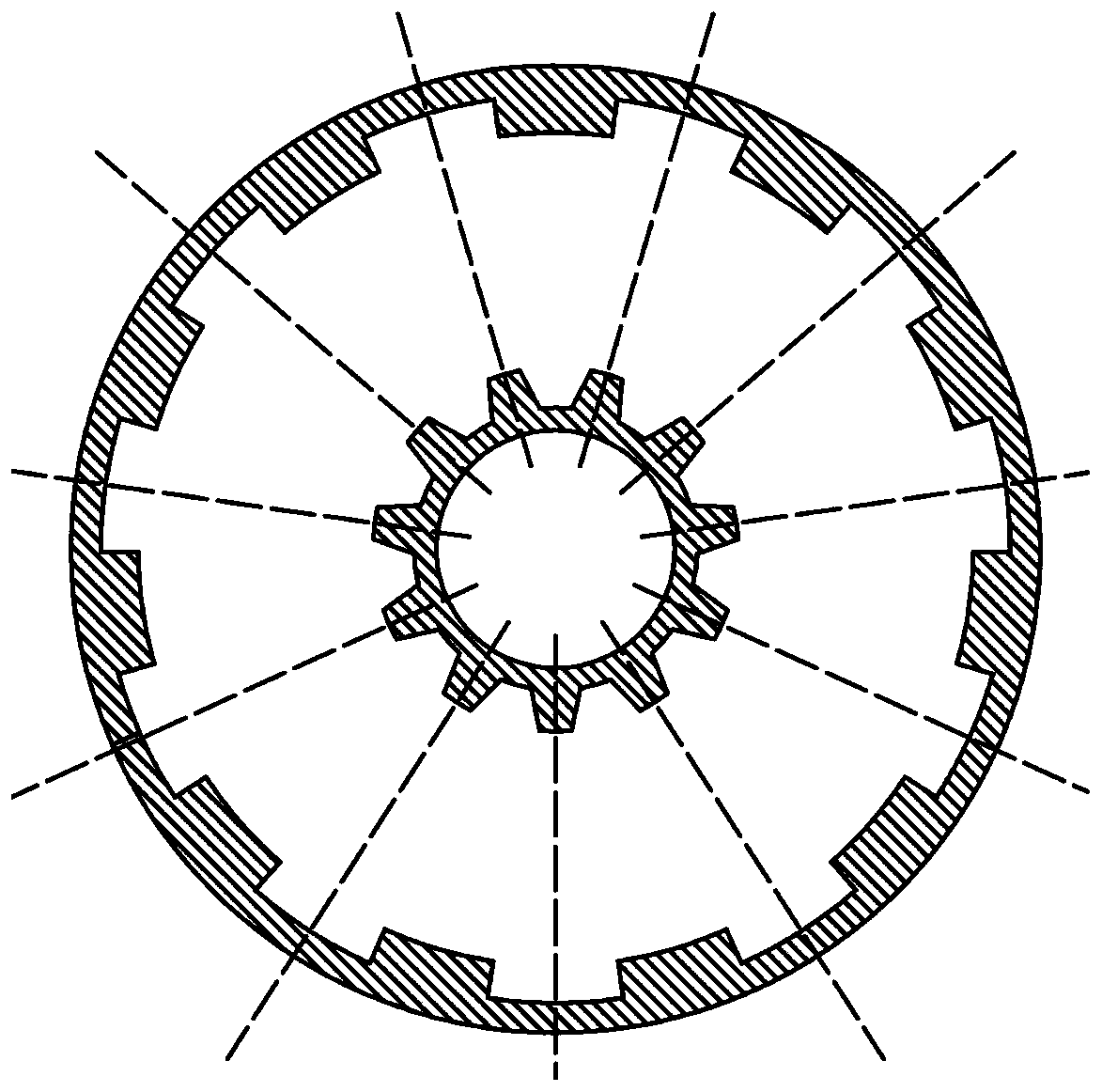

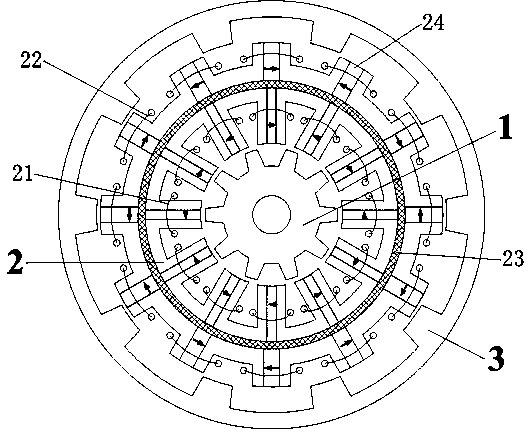

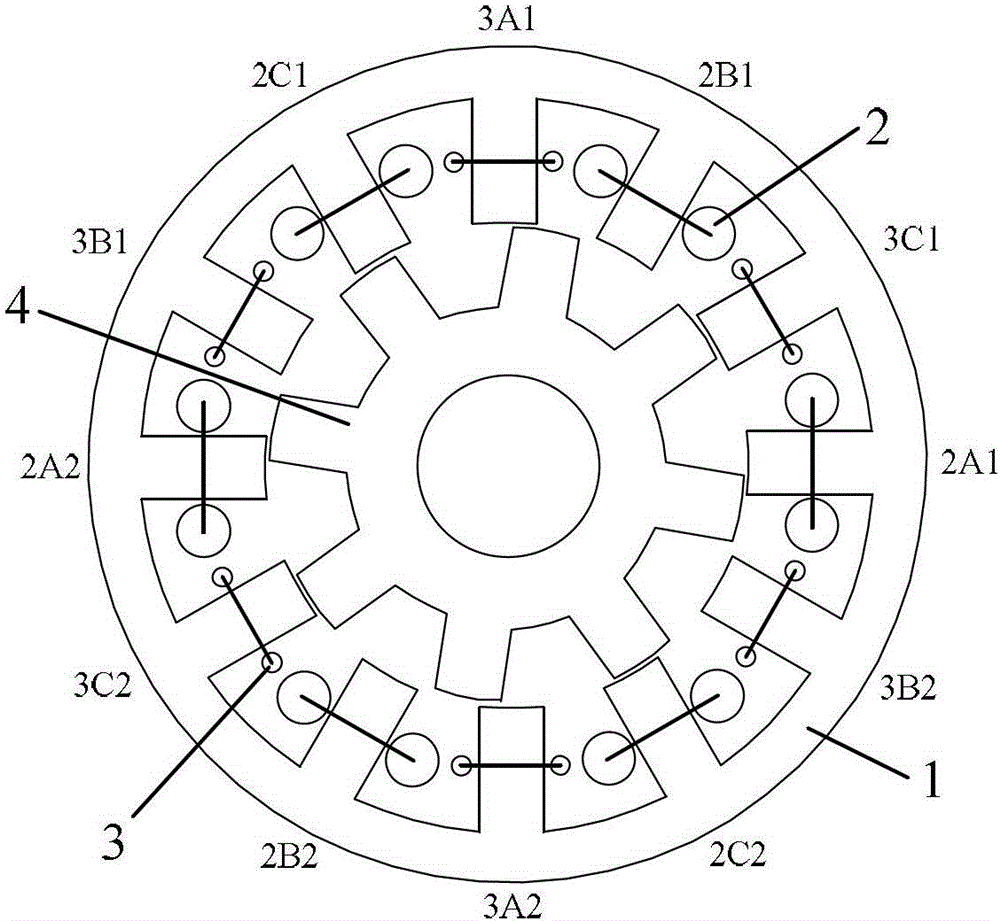

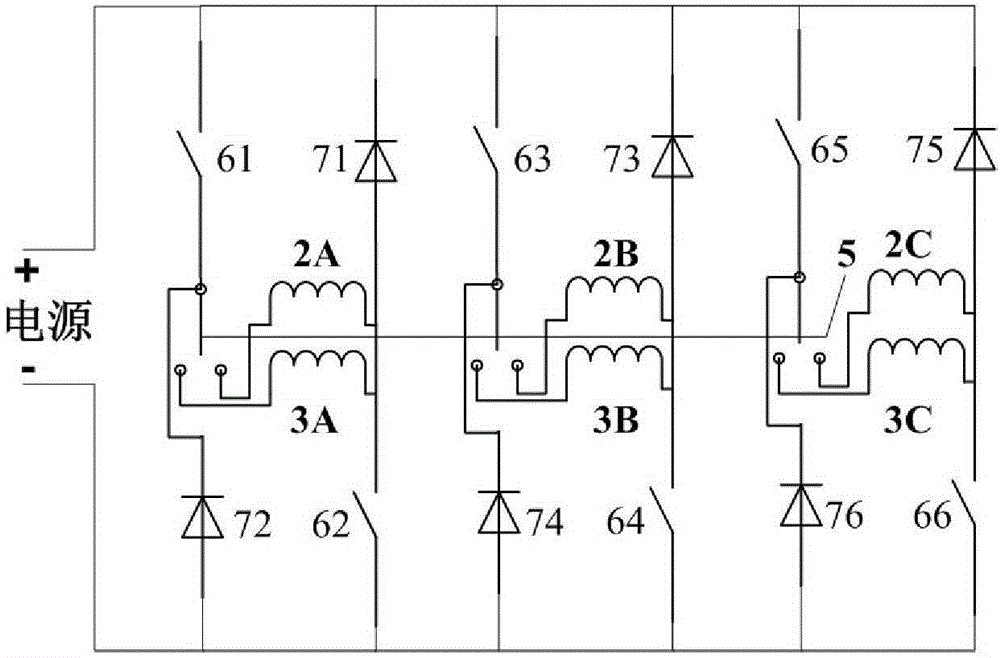

Stator modular double-rotor doubly salient permanent magnet motor

InactiveCN111181339AAvoid Flux Leakage ProblemsIncrease utilization and motor torque densityDynamo-electric machinesMagnetoDoubly salient

The invention discloses a stator modular double-rotor doubly salient permanent magnet motor, which comprises an inner salient pole rotor, an outer salient pole rotor and a stator located between the inner salient pole rotor and the outer salient pole rotor, wherein independent air gaps are formed between the inner salient pole rotor and the stator and between the outer salient pole rotor and the stator respectively; the stator comprises a plurality of stator modules, each stator module comprises a stator yoke part, outer stator teeth and inner stator teeth, the outer stator teeth and the innerstator teeth are connected with the outer side and the inner side of the middle position of the stator yoke part respectively, and the stator yoke parts of the stator modules are connected through permanent magnets to form a complete stator; armature windings are wound on the outer stator teeth and the inner stator teeth of each stator module; and positive and negative alternating counter electromotive forces are induced in armature windings of the inner and outer stators of the motor along with synchronous rotation of the inner and outer rotors and change of relative positions of the stators. The problem of serious stator side flux leakage of the traditional single-rotor doubly salient permanent magnet motor is solved, and the permanent magnet utilization rate and the motor torque density are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

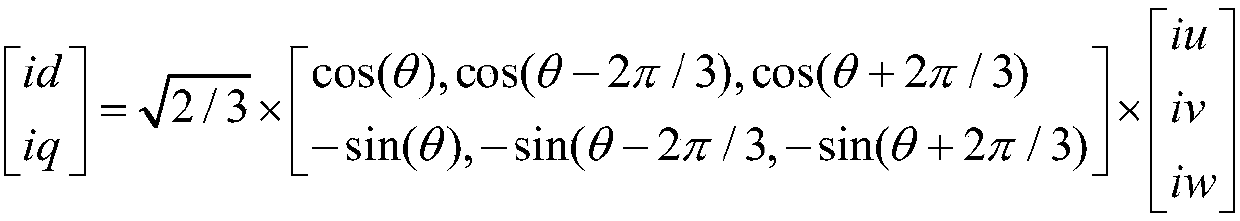

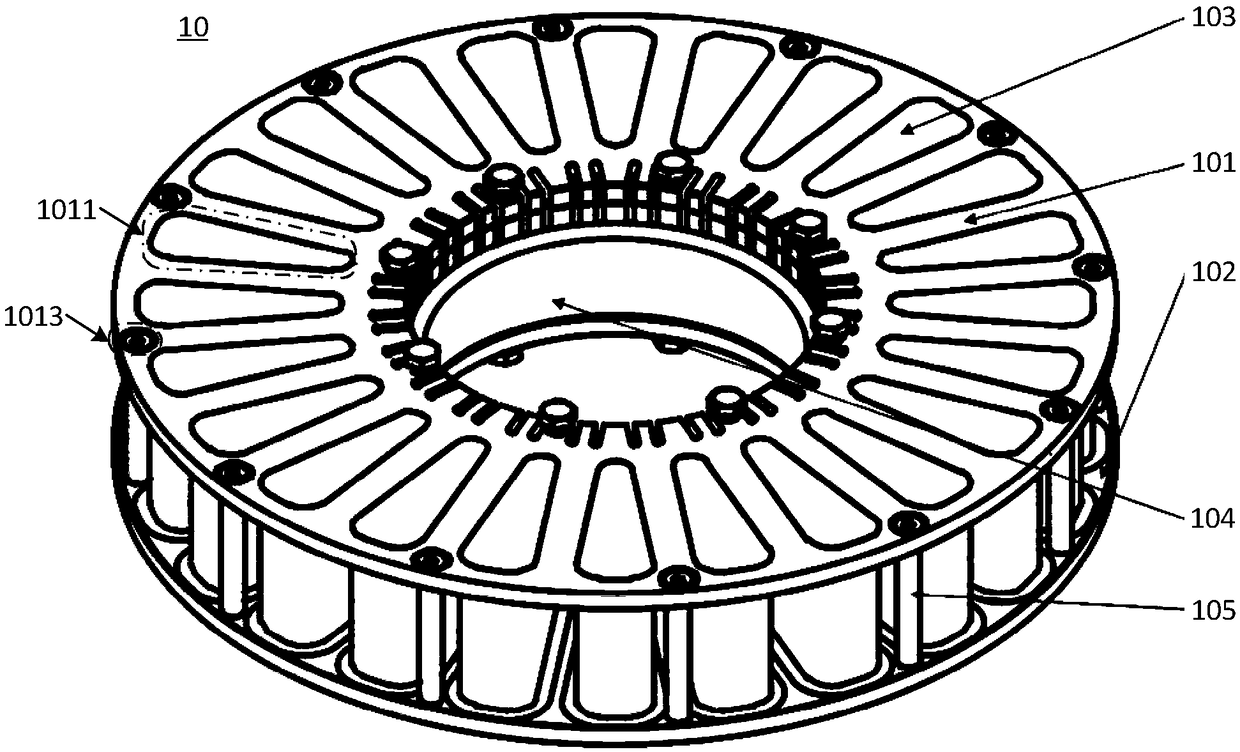

Disc-type motor and control method thereof

PendingCN109617278AMeet magnetic performanceReduce winding difficultyMagnetic circuit rotating partsCurrent controllersPulse currentMagnetic field

The invention provides a disc-type motor. The disc-type motor comprises a first stator core, a second stator core and a rotor, wherein the first stator core and the second stator core are arranged axially, the rotor is arranged between the first stator core and the second stator core and comprises a disc-type support member and a plurality of magnetic steel, the plurality of magnetic steel encircles the disc-type support member and is circumferentially arranged, each magnetic steel comprises a magnetic steel body and an embedment hole, the magnetic steel body is fabricated from non-memory character magnetic steel, the embedment hole is formed in the magnetic steel body and penetrates through a width direction of the magnetic steel body, and magnetic supplement steel made of memory characteristic magnetic steel is arranged in the embedment hole. By inputting a pulse current to the magnetic supplement steel, a variable magnetic field can be generated, a constant magnetic field is generated with the magnetic steel body for synthesis, and the magnetic field performance of the disc-type motor under different rotational speed requirements is met. The invention also provides a control method of the disc-type motor.

Owner:SHANGHAI PANGOOD POWER TECH CO LTD

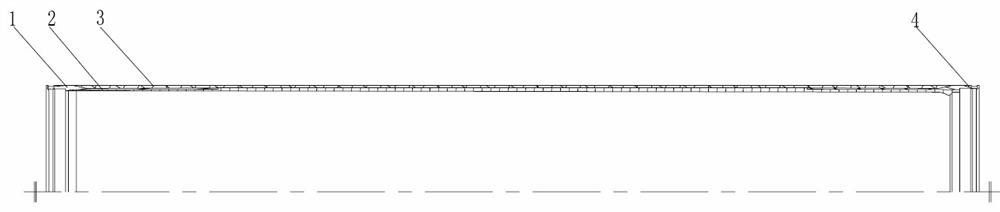

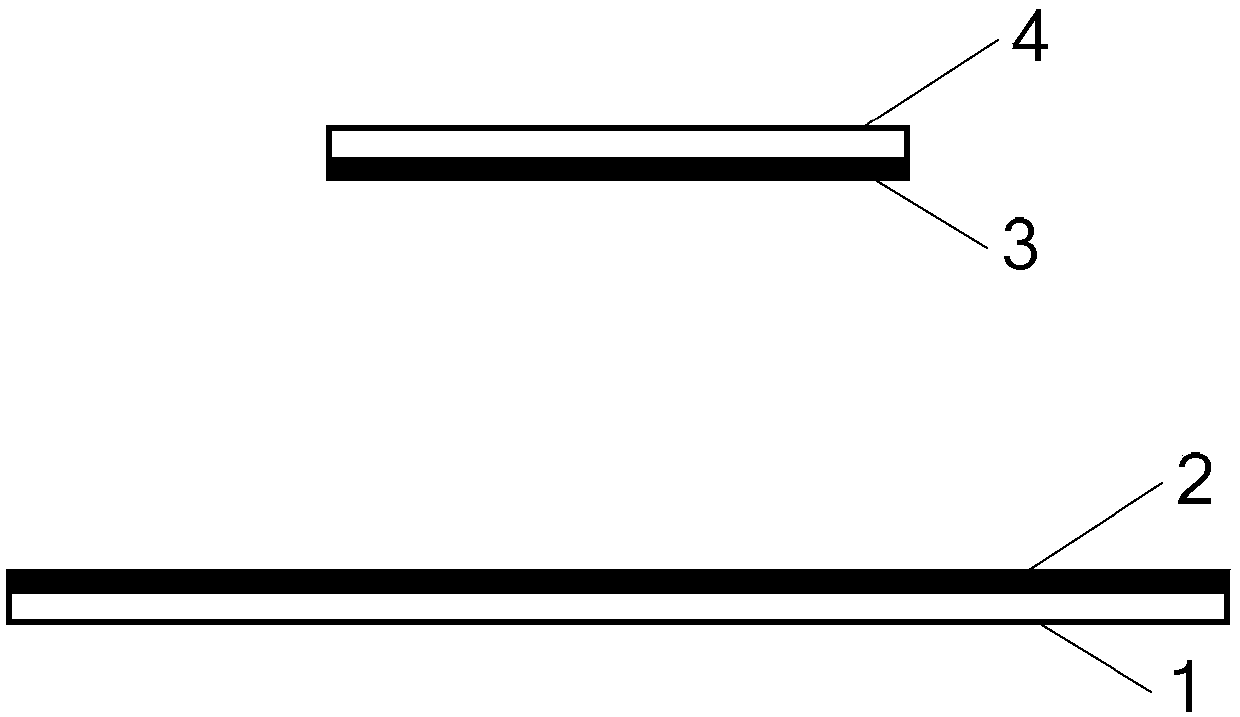

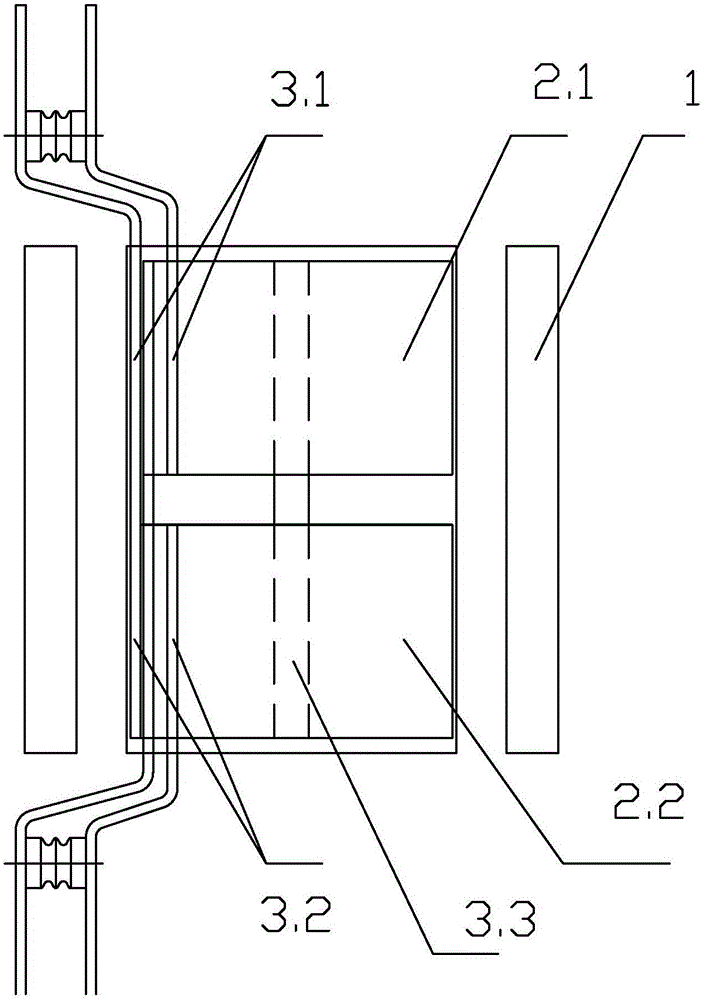

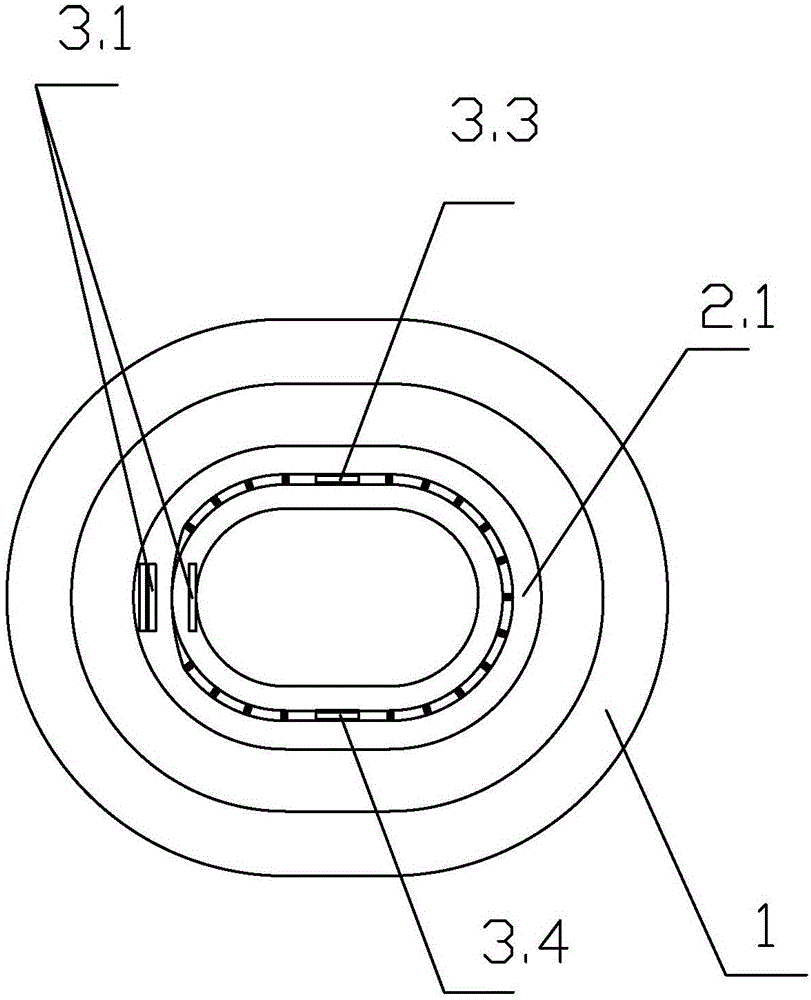

Double-splitting photovoltaic variable structure

ActiveCN105070491ANot easy to fall offReduce winding difficultyTransformers/inductances coils/windings/connectionsCoils manufactureLow voltageCopper

A double-splitting photovoltaic variable structure comprises a barrel-shaped high-voltage coil (1) and a first low-voltage coil (2.1) and a second low-voltage coil (2.2) which are located in the high-voltage coil (1), the first low-voltage coil (2.1) and the second low-voltage coil (2.2) are axially arranged, a gap is formed between the first low-voltage coil (2.1) and the second low-voltage coil (2.2) in the axial direction, the first low-voltage coil (2.1) is provided with a first conductive copper bar (3.1), and the second low-voltage coil (2.2) is provided with a second conductive copper bar (3.2); the double-splitting photovoltaic variable structure further comprises a first transposition copper bar (3.3) and a second transposition copper bar (3.4) which are internally embedded in the low-voltage coils, and the two ends of the first transposition copper bar (3.3) and the two ends of the second transposition copper bar (3.4) are welded to the first low-voltage coil (2.1) and the second low-voltage coil (2.2) respectively.

Owner:宁波奥克斯智能科技股份有限公司

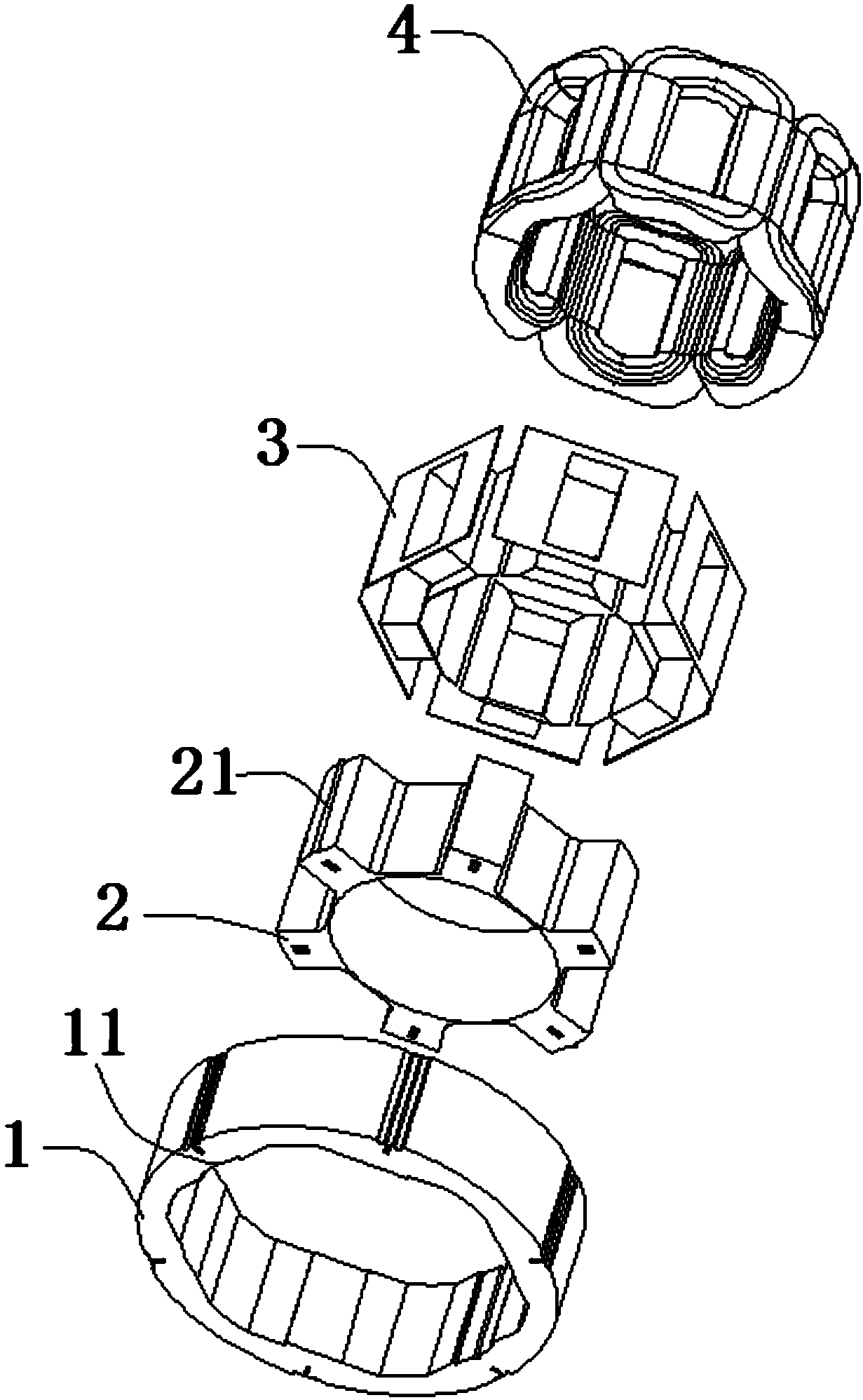

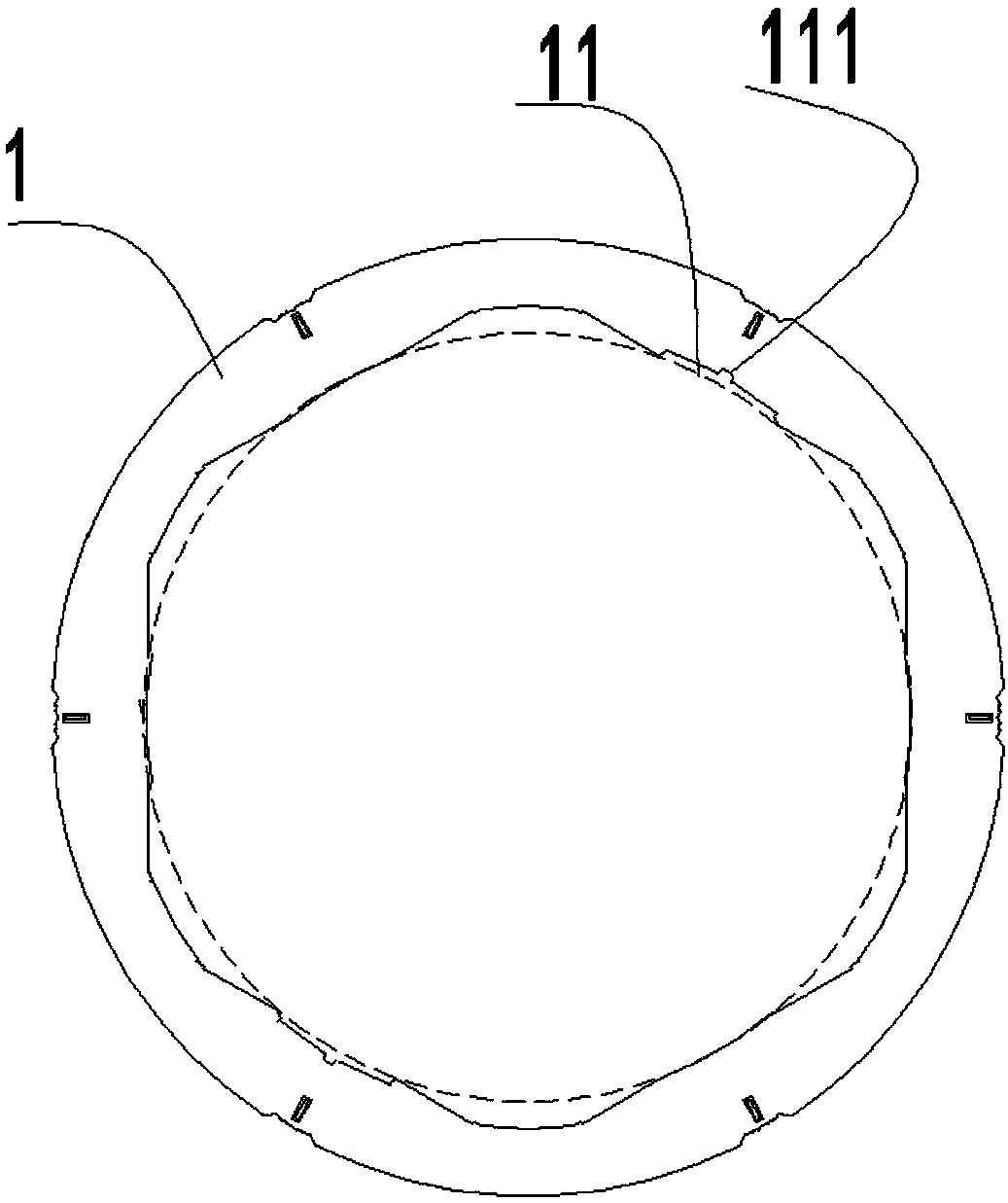

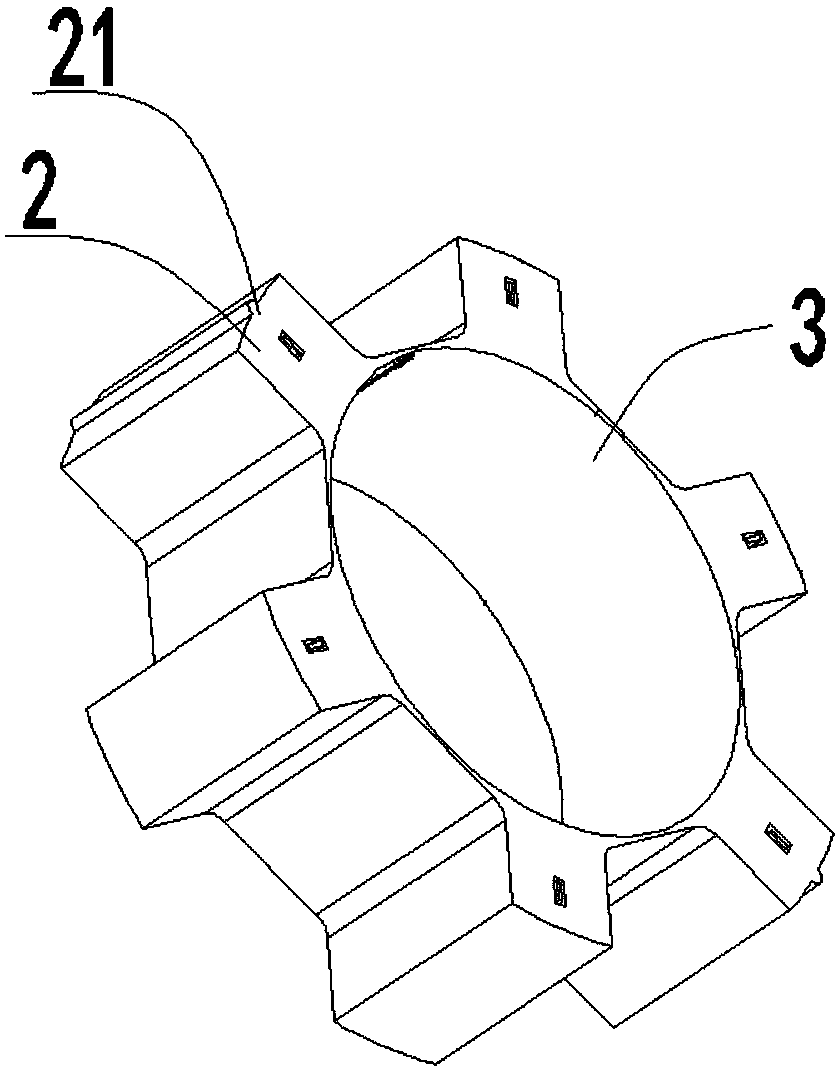

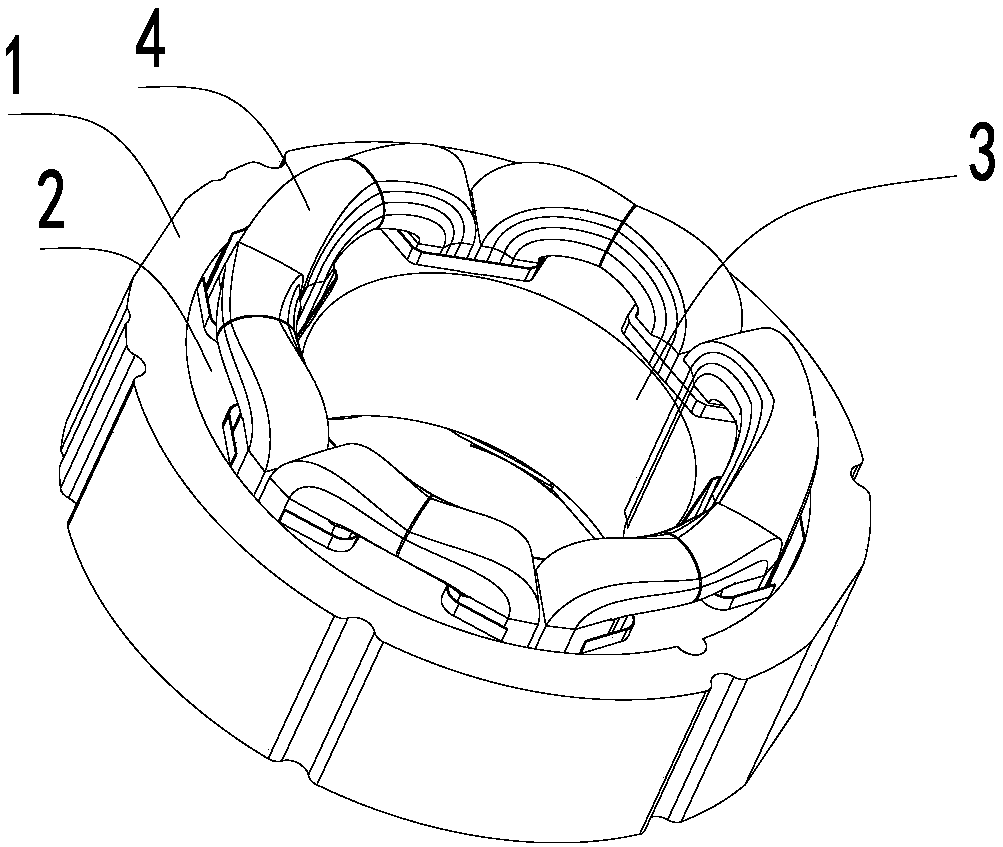

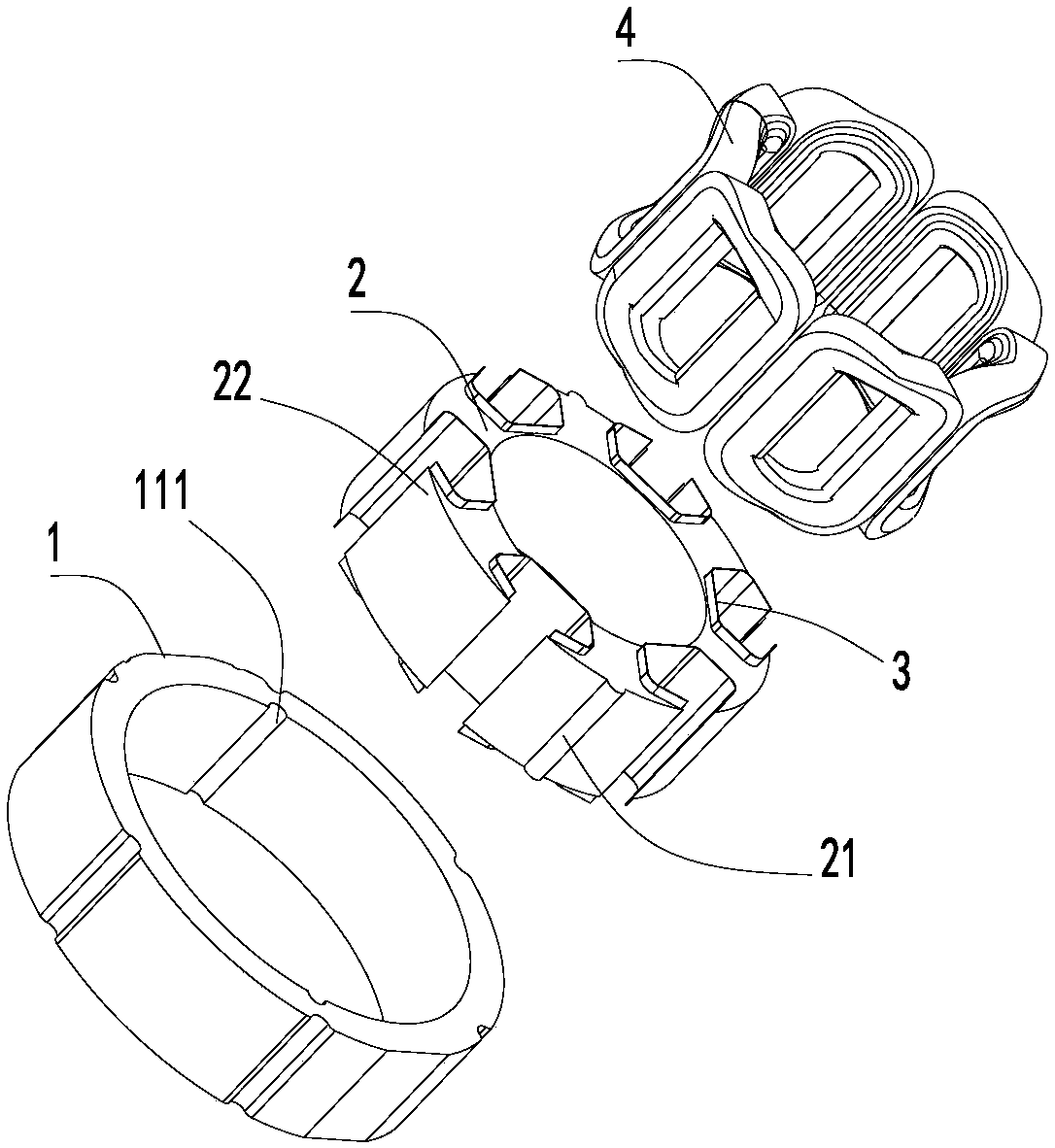

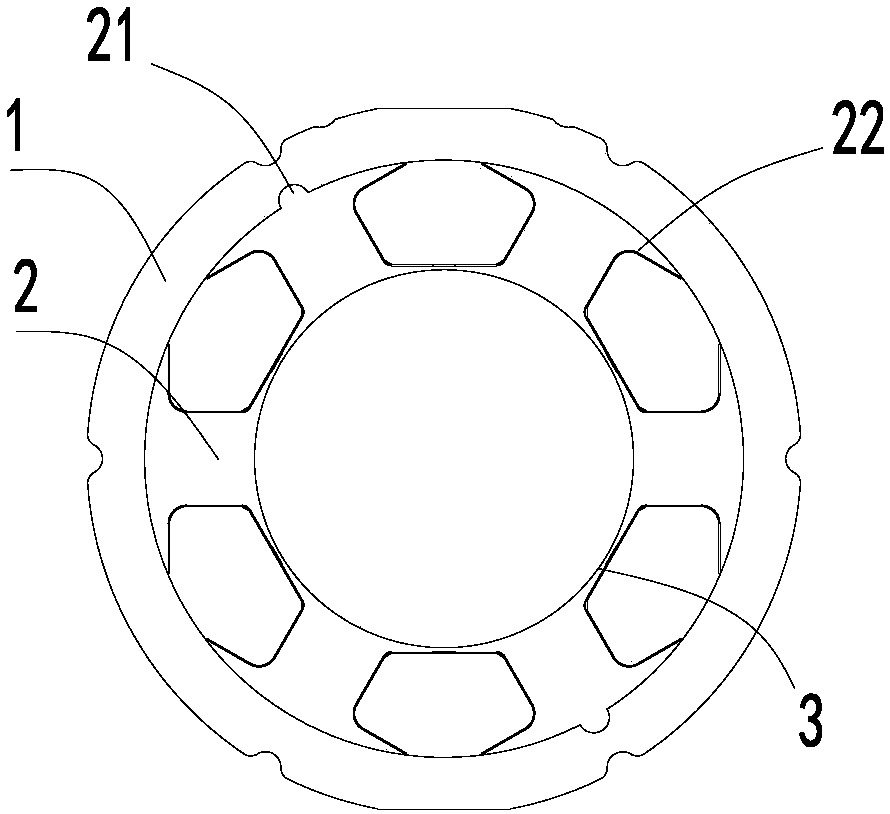

Stator component, motor and compressor

InactiveCN108429365AReduce winding difficultyEasy to set upMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineEngineering

The invention relates to the field of motors and discloses a stator component, a motor and a compressor. The stator component comprises a stator yoke part (1), a connecting ring (3) and a plurality ofstator tooth parts (2), wherein the plurality of the stator tooth parts (2) are detachably sleeved with a support sleeve (5); a coil (4) which surrounds the stator tooth parts (2) is arranged on thesupport sleeve (5); the stator tooth parts (2) and the connecting ring (3) are capable of moving relative to the stator yoke part (1) in an axial direction; the radial outer ends of the stator tooth parts (2) and the stator yoke part (1) are connected in a mutually detachable manner. By adopting the technical scheme of the invention, the stator tooth parts and the stator yoke part are arranged ina mutually detachable manner, and the coils can be relatively easily arranged on the stator tooth parts before the stator tooth parts are mounted at the stator yoke part, so that the coil winding difficulties can be reduced, the problem of too large magnetic pressure reduction caused by too large intervals of tooth parts can be solved, and the problem of too large winding and torque pulsation canbe solved.

Owner:ANHUI MEIZHI COMPRESSOR

Stator assembly, motor and compressor

InactiveCN108521179AReduce winding difficultyEasy to set upMagnetic circuit stationary partsWindings conductor shape/form/constructionLarge toothElectric machine

The invention belongs to the motor field and discloses a stator assembly, a motor and a compressor. The stator assembly comprises a stator yoke portion (1), a connecting ring (3) and a plurality of stator tooth portions (2); the stator tooth portions (2) are provided with a coil (4) surrounding the stator tooth portion portions (2); the radial outer ends of the stator tooth portions (2) are provided with stopping portions (22); the stator tooth portions ( 2) and the connecting ring (3) can axially move relative to the stator yoke portion (1); and the stator tooth portions (2) are detachably connected with the stator yoke portion (1). With the above technical schemes of the invention adopted, the stator tooth portions and the stator yoke portion can be detachable from each other; the coil can be disposed on the stator tooth portions more easily before the stator tooth portions are mounted on the stator yoke portion; the winding difficulty of the coil can be reduced; excessive magnetic pressure drop caused by excessively large tooth intervals can be avoided; and winding problems and the problem of excessive torque ripples can be solved.

Owner:ANHUI MEIZHI COMPRESSOR

Motor stator and axial magnetic field motor

PendingCN109450127AReduce the difficulty of windingImprove winding efficiencyMagnetic circuit stationary partsWinding machineStator

The present invention discloses a motor stator and an axial magnetic field motor. The motor stator comprises a first ring bracket, a second ring bracket and a plurality of soft magnetic composite SMCcores. The first ring bracket and the second ring bracket are oppositely arranged in a parallel manner, and the plurality of SMC cores are fixed between the first ring bracket and the second ring bracket. According to the technical scheme of the present invention, a winding machine can be separately used by a plurality of SMC cores to wind the wires, the difficulty of winding is reduced, and the winding efficiency is improved; at the same time, the plurality of SMC cores are fixed through the oppositely arranged first ring bracket and second ring bracket, so that the rigidity of the cores canbe ensured to enhance the overall rigidity of the motor stator and reduce the probability of deformation of the cores; and in addition, the SMC cores do not require a stator yoke, so that the axial length of the motor can be shortened while reducing the overall weight of the motor.

Owner:清华大学苏州汽车研究院(吴江)

Combined-type flux switching permanent magnet motor

ActiveCN102832771BImprove reliabilityAvoid serious temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet motorPhysics

The invention discloses a combined-type flux switching permanent magnet motor which comprises an inner rotor, a stator and an outer rotor,wherein the stator surrounds the inner rotor; the outer rotor surrounds the stator; air clearances are arranged between the two rotors and the stator; salient pole gears without windings are arranged at one sides, which are towards the stator, of the inner rotor and the outer rotor; salient pole gears are arranged on the inner side and outer side of the stator; an inner side winding and an outer side winding which are sleeved on the salient pole gears are respectively arranged on the inner side and the outer side of the stator; an insulation magnetic ring is embedded on the yoke part of the stator; the salient pole gears at the inner side and outer side of the stator are internally provided with excitation devices; the magnetizing directions of the excitation devices are the circumferential tangency direction of the stator, and are at the same side of the stator; and the magnetizing directions of the excitation devices in the two adjacent salient pole gears are opposite.

Owner:SUZHOU KAIBO YIKONG DRIVE TECH CO LTD

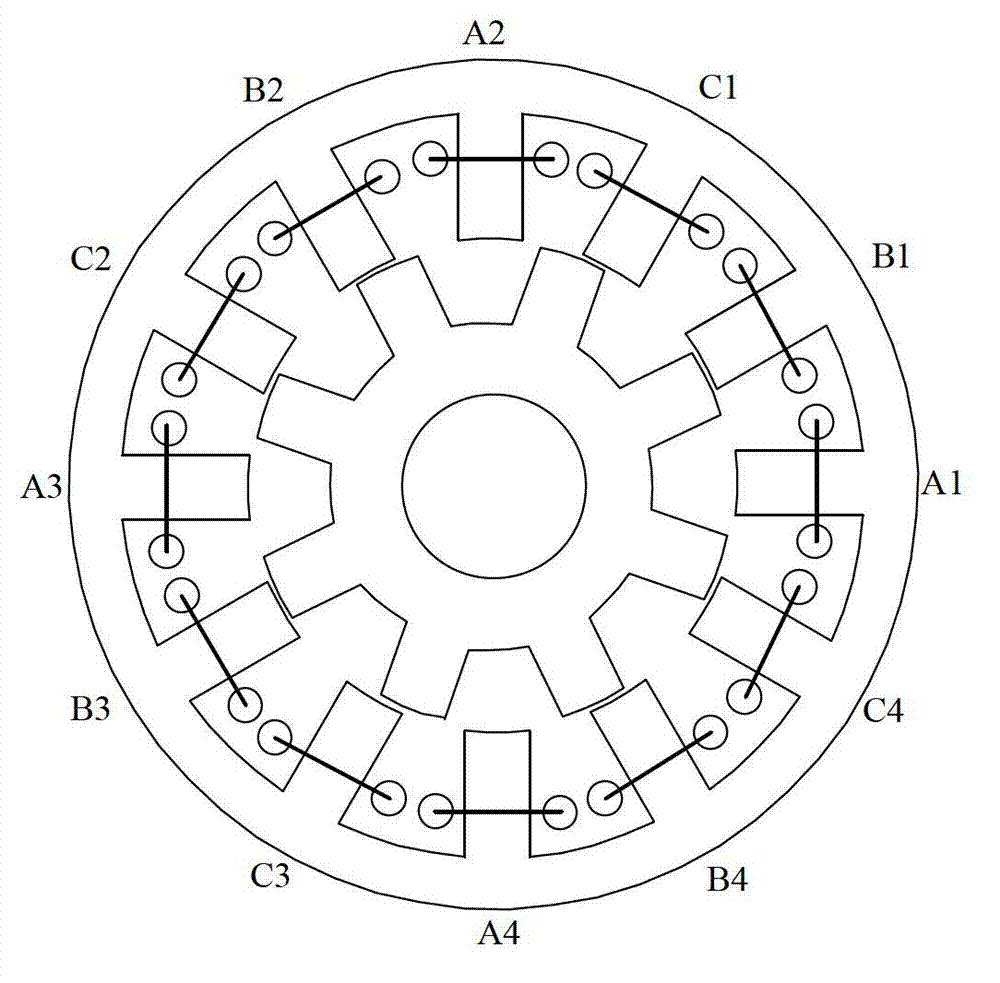

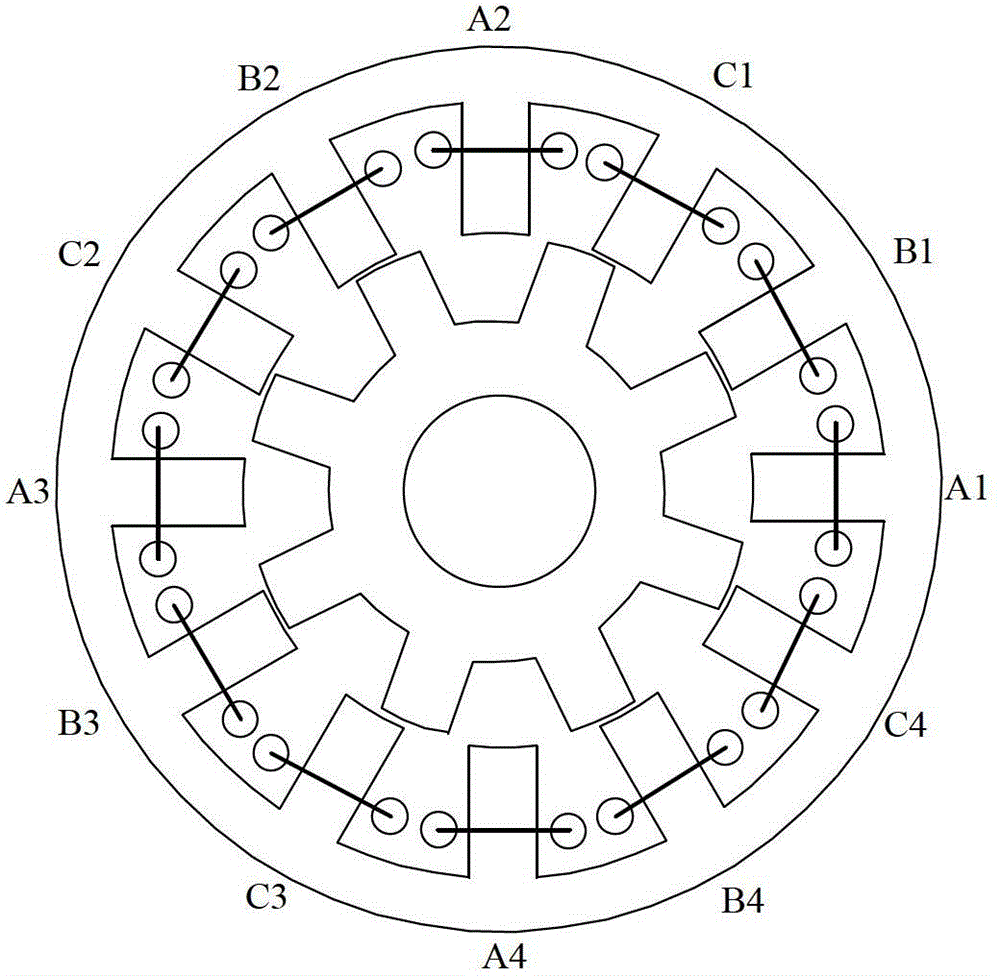

Double-speed winding switch reluctance motor

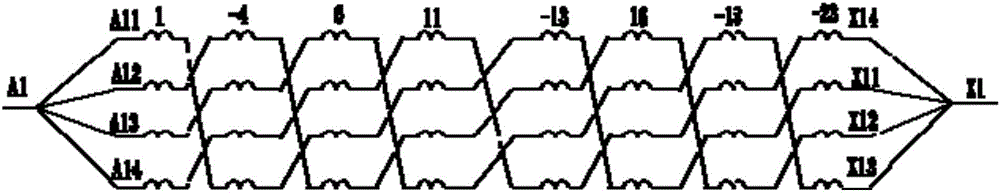

ActiveCN103166337BWide speed rangeReduce the number of turnsMagnetic circuit stationary partsWindings conductor shape/form/constructionLow speedConductor Coil

The invention discloses a double-speed winding switch reluctance motor. Stator teeth in even number are arranged on a stator, and concentrated windings are arranged on the stator teeth. The concentrated windings comprise low-speed concentrated windings and high-speed concentrated windings, and the number of turns of the low-speed concentrated windings is more than that of the high-speed concentrated windings. The wire diameter of each low-speed concentrated winding is smaller than that of one high-speed concentrated winding, and in two adjacent stator teeth, one stator tooth is coiled with a low-speed concentrated winding, and the other stator tooth is coiled with a high-speed concentrated winding. A low-speed concentrated winding is arranged on the opposite side of another low-speed concentrated winding in the radial direction of the stator, and moreover the two low-speed concentrated windings are connected in series or in parallel to form a one-phase low-speed winding. The opposite side of each high-speed concentrated winding is provided with another high-speed concentrated winding in the radial direction of the stator, and the two high-speed concentrated windings are connected in series or in parallel to form a one-phase high-speed winding. The double-speed winding switch reluctance motor can output large torque in low-speed operation, and has a wide speed regulation range in high-speed operation.

Owner:SOUTHEAST UNIV

A take-up structure for textile operation with anti-winding effect

The invention discloses a take-up structure for textile operation with an anti-winding effect, which belongs to the technical field of textile auxiliary appliances, and comprises a frame, one side of the frame is movably connected with a winding mechanism, and one side of the winding mechanism is provided with There is a clamping mechanism, the top of the winding mechanism is movably connected with the frame through a lifting mechanism, and the top of one side of the frame is fixedly connected with a wire management mechanism, the winding mechanism includes a first motor, and the output shaft of the first motor The first rotating shaft is fixedly connected. In the present invention, by providing a winding mechanism and a wire management mechanism, it is possible to effectively prevent the wire bundles from being entangled with each other during winding, and it is possible to simultaneously take up multiple wire bundles, and the baffle connected to the outer wall of the reel can ensure that multiple wire bundles are wound at the same time The separation effect when pulling, and the smooth guide sleeve can avoid the burr of the wire harness when pulling, which can significantly improve the winding efficiency while avoiding the winding of the wire body, and meet the needs of adapting to the textile operation.

Owner:青岛富思特纺织股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com