Patents

Literature

62 results about "Linear birefringence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

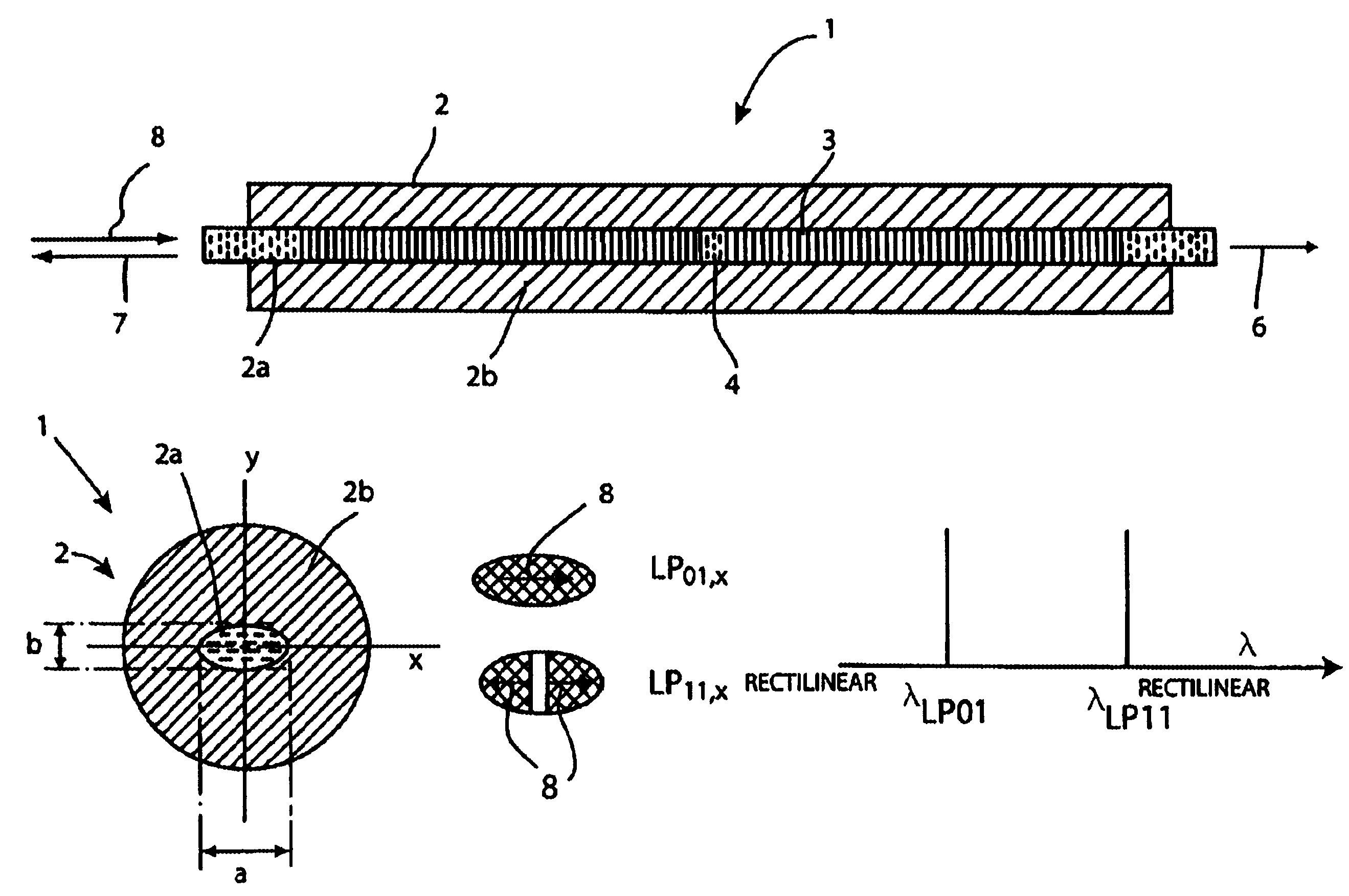

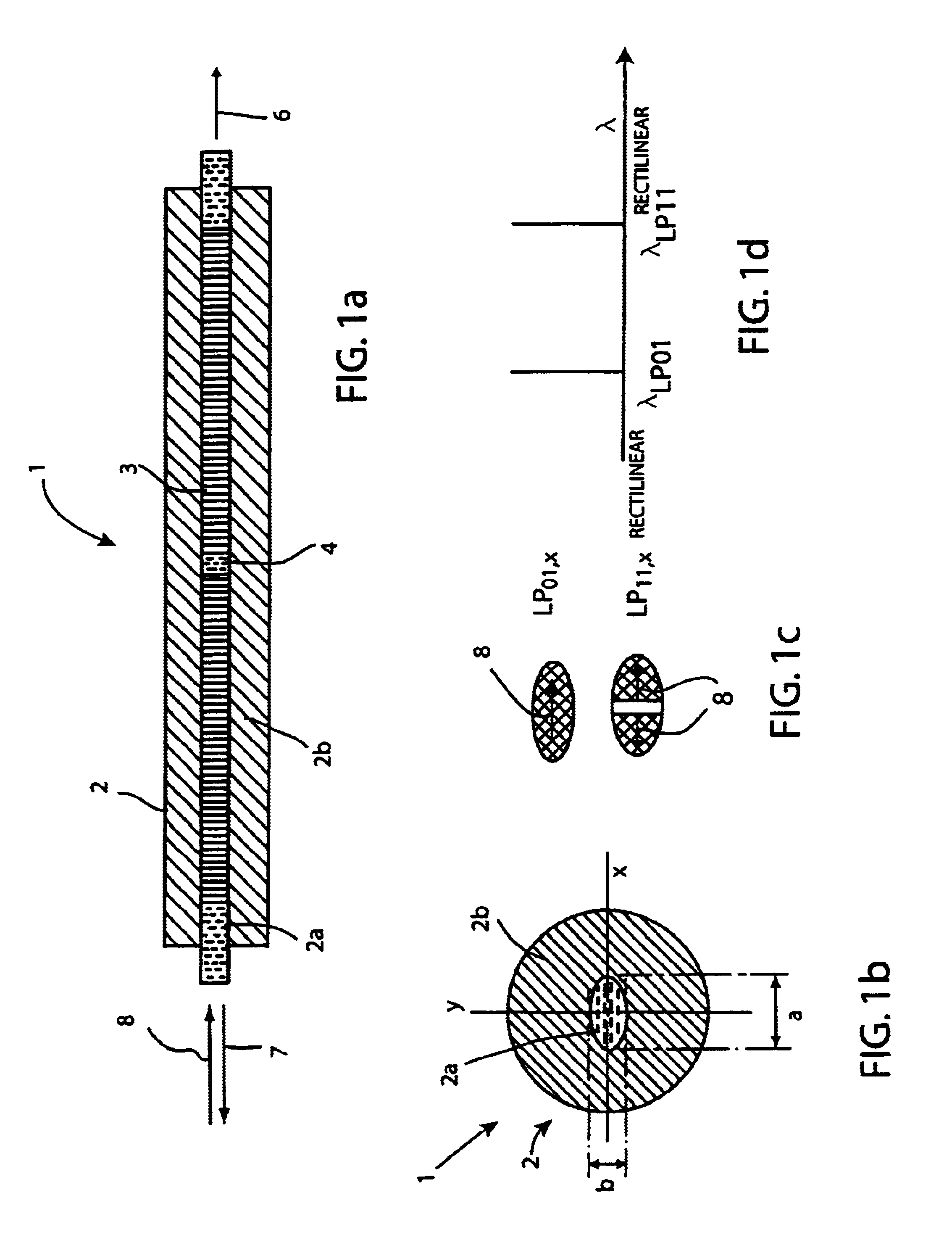

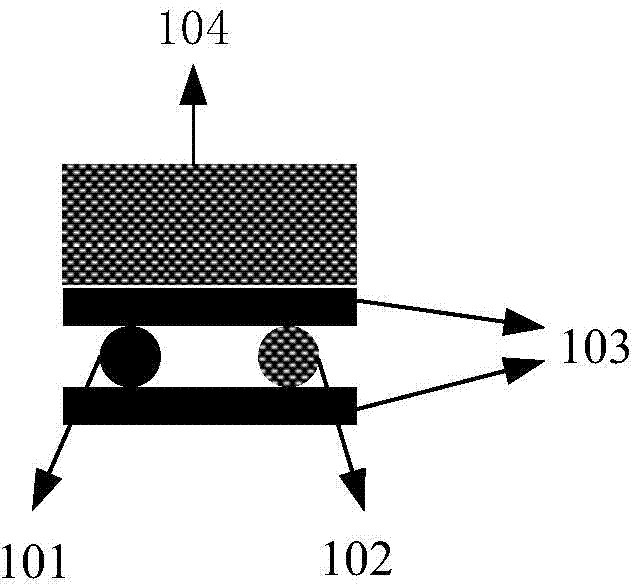

Anisotropic distributed feedback fiber laser sensor

The invention relates to a DFB fiber laser sensor (1). A measurement quantity makes it possible to induce a linear birefringence between mode pairs of the laser-amplifying fiber (2) and to measure an associated beat frequency (Δν1, Δν2, Δν3). According to the invention, the laser-amplifying fiber (2) has a nonrotationally symmetrical structure, so that it is possible to detect isotropic pressures p, acoustic waves or chemical substances that can be added radially to the laser-amplifying fiber (2). In a second aspect of the invention, an emission wavelength range and parameters (a, b, ΔN) of the laser-amplifying fiber (2) and also a grating period L of the fiber Bragg grating resonator (3) are coordinated with one another such that at least two different spatial modes (LP01, LP11even, LP11odd, LP21even) are propagatable and it is possible to measure beat frequencies (Δν1, Δν2, Δν3) between oscillatory longitudinal laser modes assigned to them. Exemplary embodiments relate to: rotationally asymmetrical fiber types, a choice of special spatial modes (LP11odd, LP21even) and / or multiple fiber Bragg gratings (3) for reducing the beat frequencies (Δν1, Δν2, Δν3) below 100 GHz; and elimination of temperature influences e.g. by the detection of a plurality of beat frequencies (Δνa, Δνb, Δνc, Δνd) between different pairs of spatial modes (LP01, LP11even, LP11odd, LP21even) and / or polarization modes (X, Y).

Owner:GE OIL & GAS UK LTD

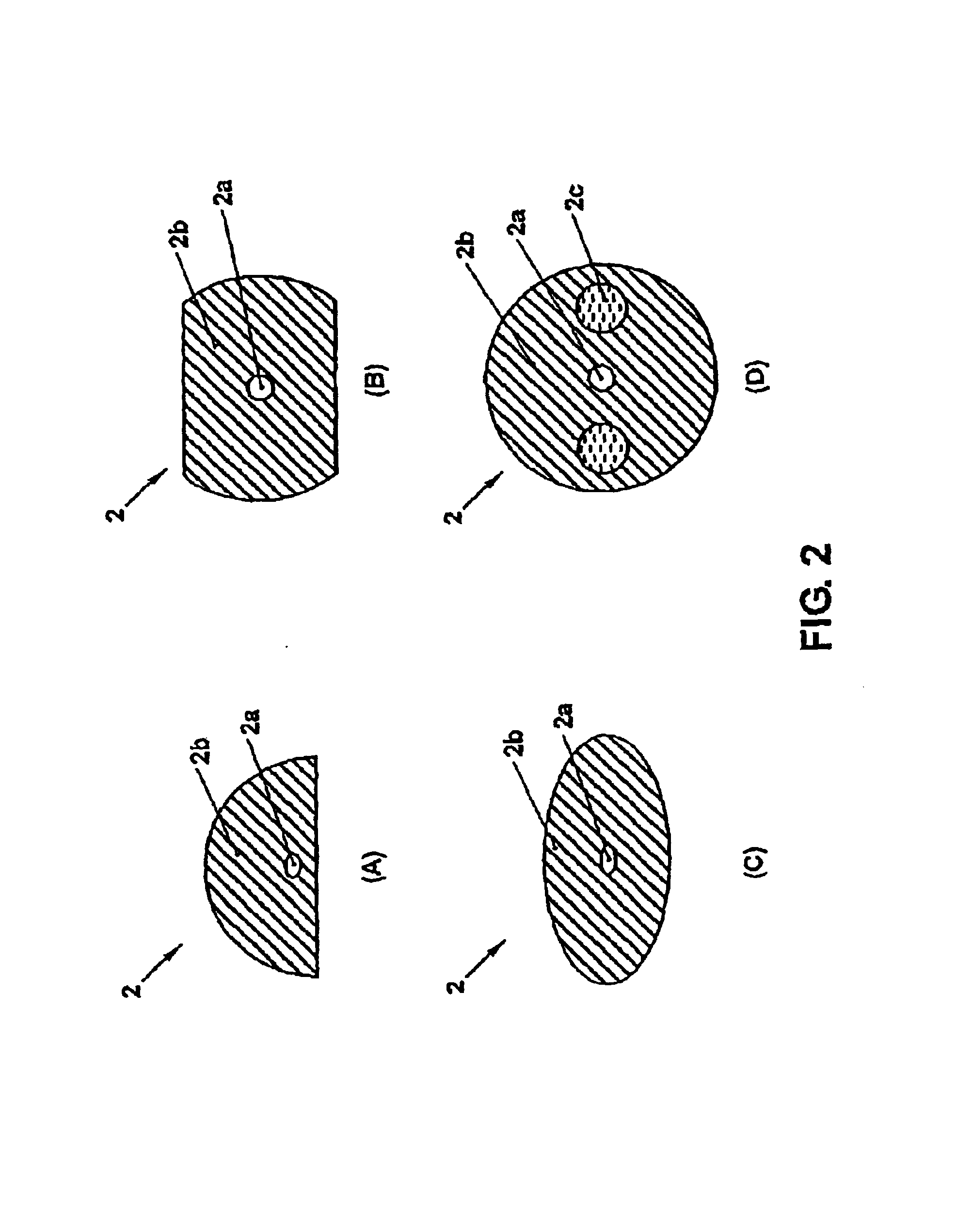

Fiber-based optical low coherence tomography

InactiveUS7177491B2Increase contrastEasy to measureInterferometersScattering properties measurementsSample rotationLinear birefringence

Generally, and in one form of the present invention, is a polarization-maintaining fiber-based polarization sensitive optical low coherence reflectometer for depth resolved birefringence measurement. With the present invention, linear birefringence of a sample may be measured from data recorded in a single A-Scan. In addition, the present invention provides for the simultaneous measurement of retardation and orientation of birefringent axes, wherein measured retardation is insensitive to sample rotation in the plane perpendicular to ranging.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

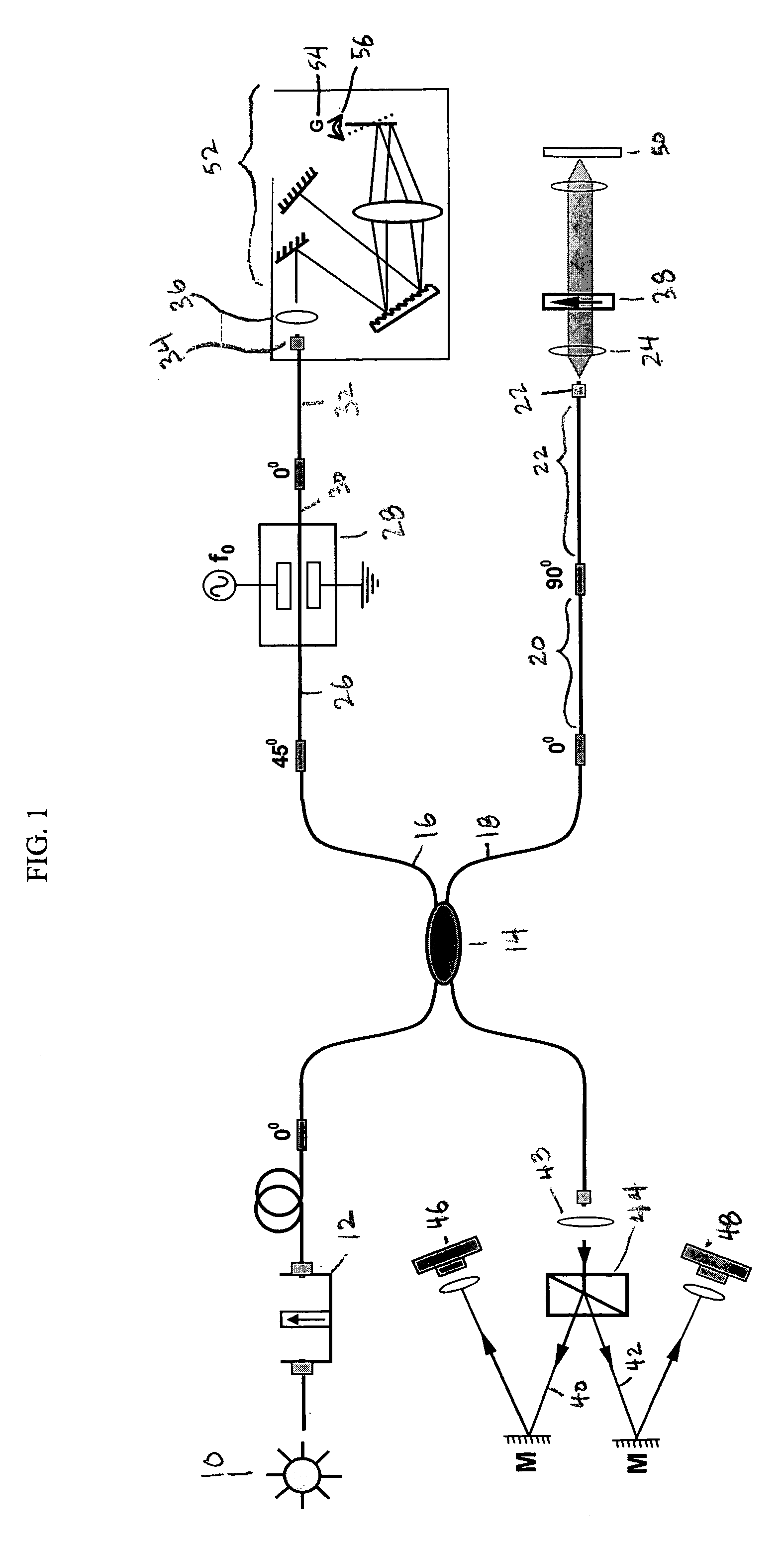

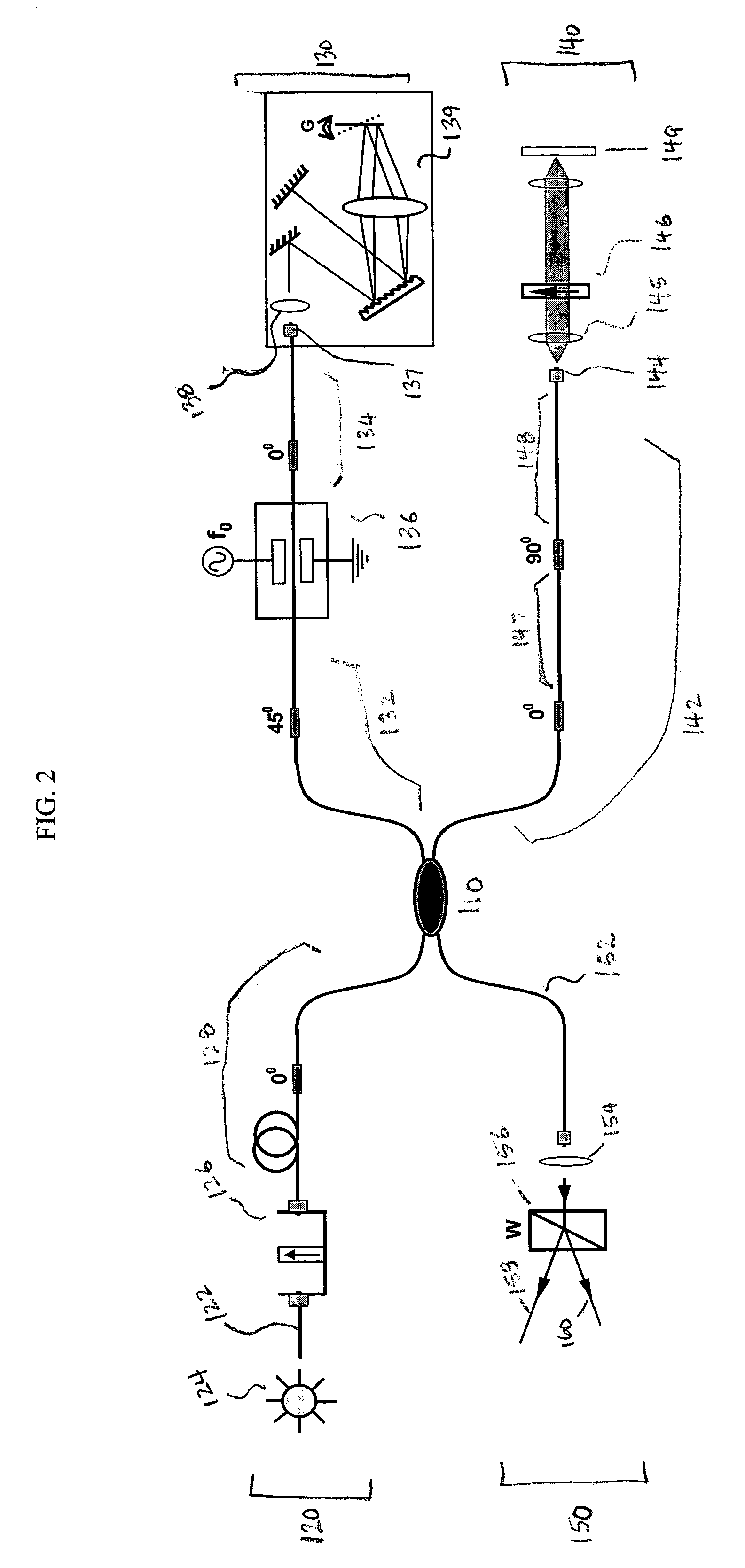

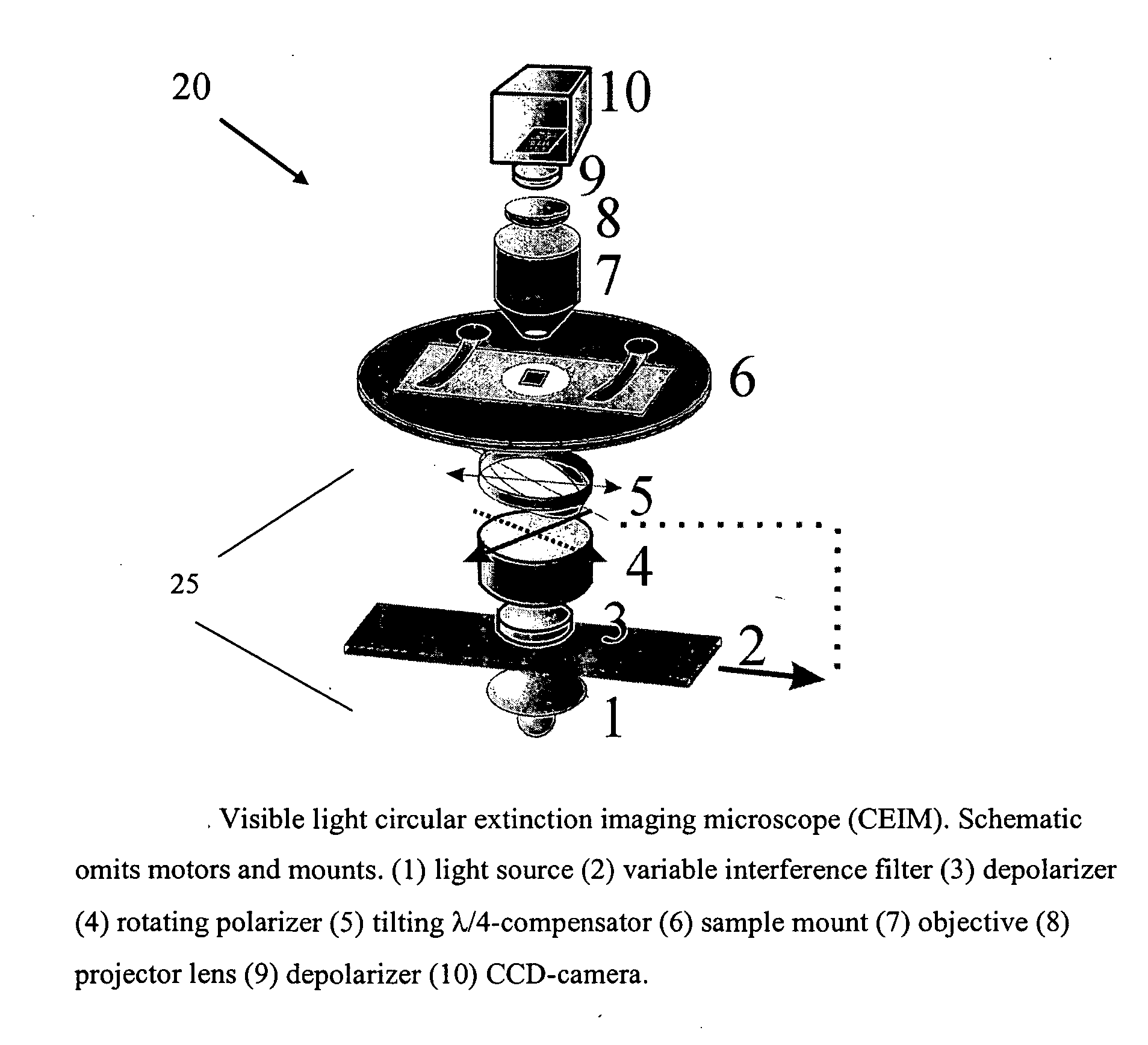

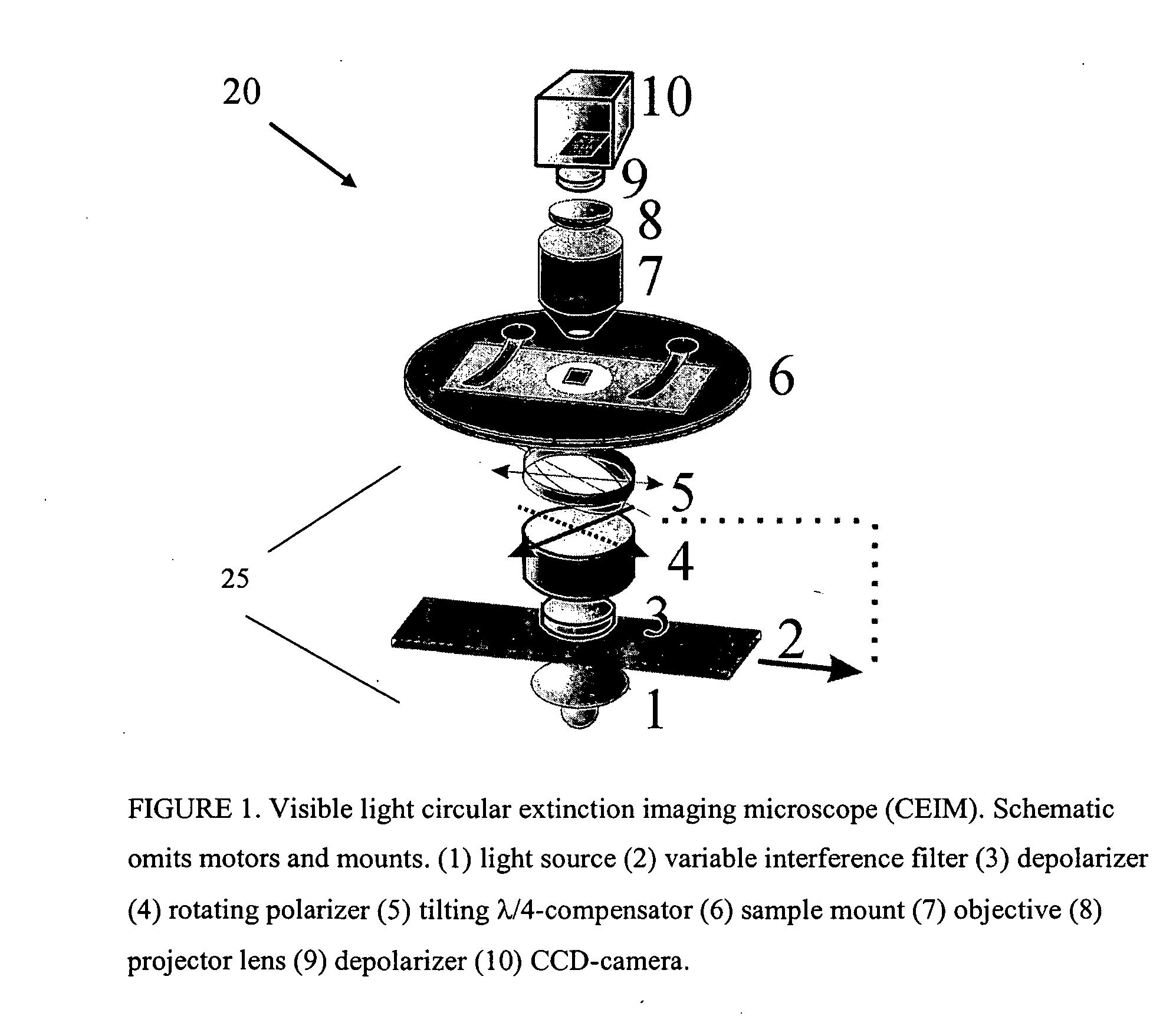

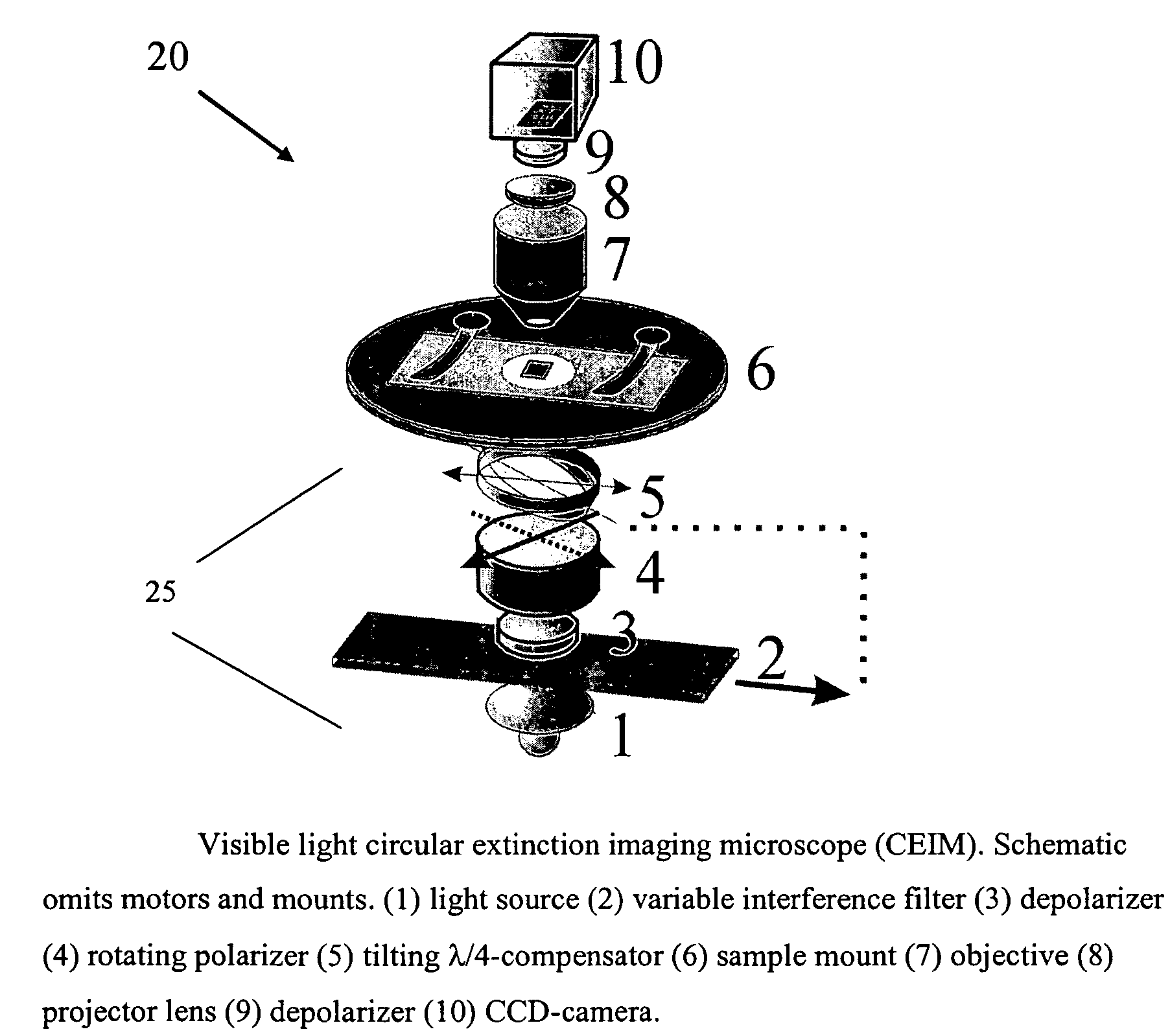

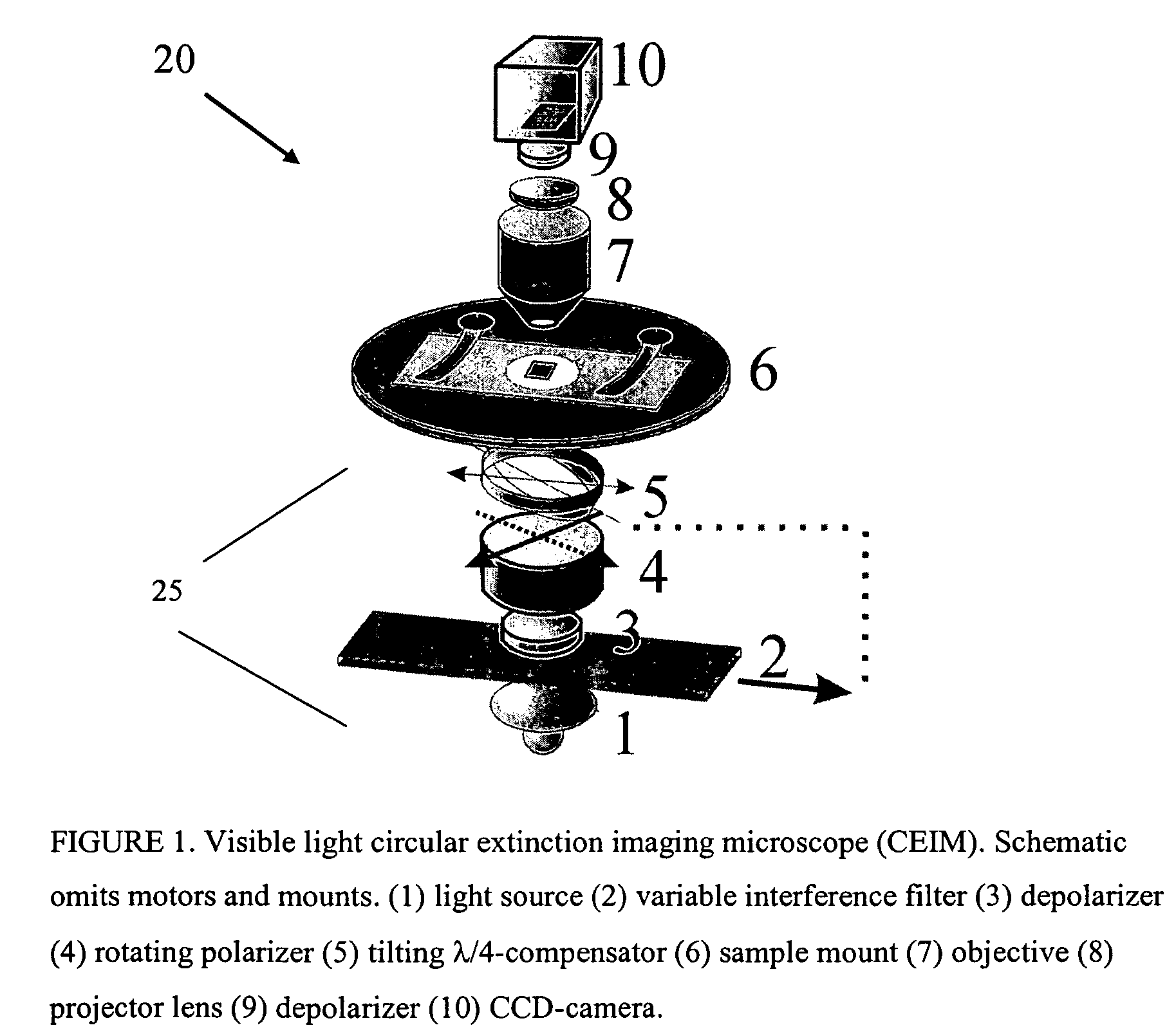

Circular extinction contrast imaging microscope

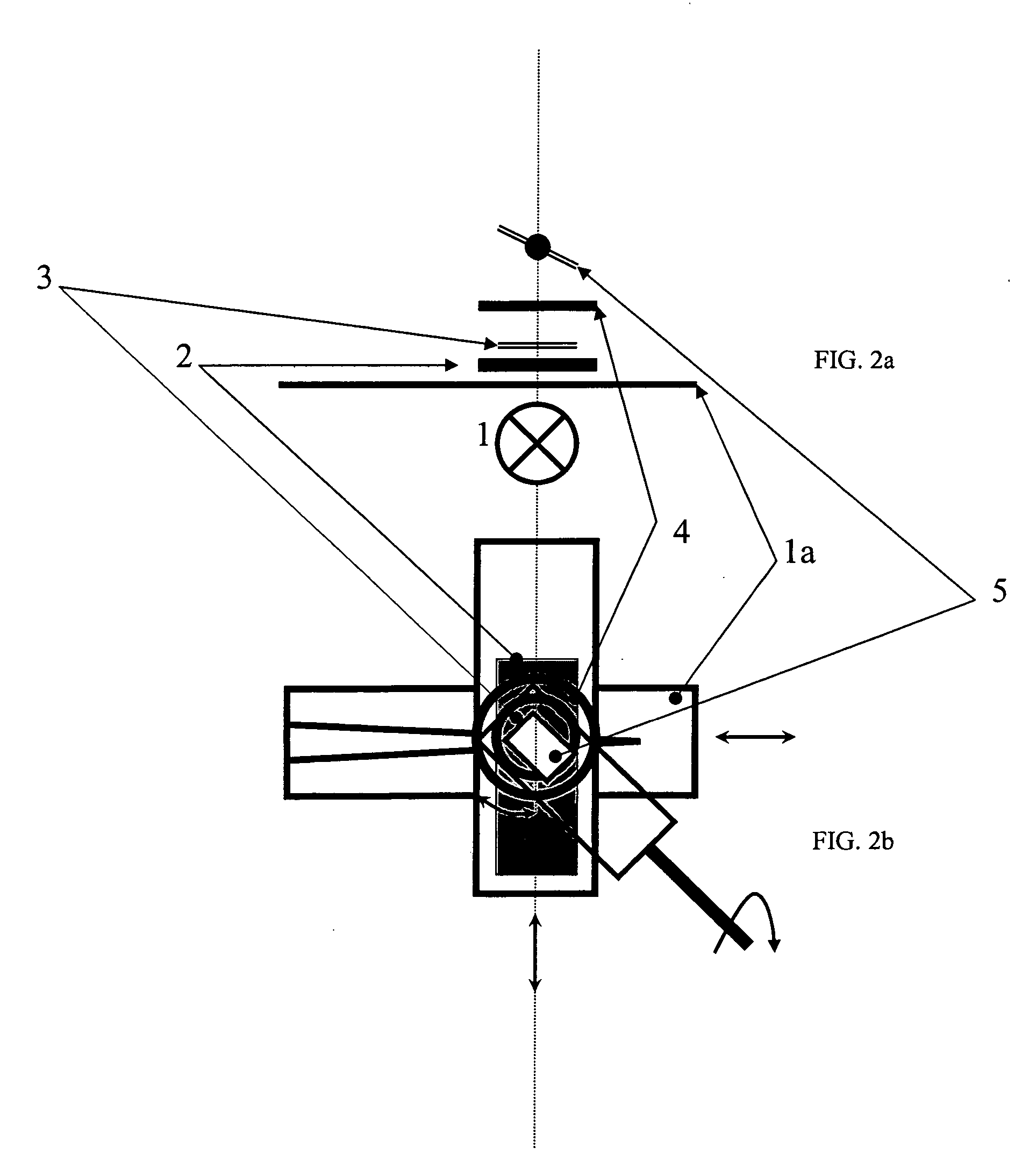

InactiveUS20050134687A1Increased signal noiseImprove signal-to-noise ratioTelevision system detailsColor television detailsExtinctionDifferential transmission

Systems and methods for producing circular extinction (CE) contrast images of anisotropic samples. Microscope systems for determining circular extinction (CE), the differential transmission of left and right circularly polarized light resulting from circular dichroism (CD) of an anisotropic sample, include mechanically driven optical components and an image detector such as a monochromatic CCD camera to detect light intensities. In one aspect, optical components include a tunable filter, a rotatable linear polarizer and a variable retarder. The tunable filter is adjustable to provide light at a specific desired wavelength. The linear polarizer is adjustable to provide linearly polarized light with a specific wave vector, and the variable retarder is adjustable to produce near perfect circular polarized light at every selected wavelength. For example, in one aspect, the variable retarder includes a linear birefringent plate tiltable around one of its eigenmodes perpendicular to the wave vector of polarized light. The plate may be controllably tilted so that it functions as a perfect λ / 4 plate at each wavelength.

Owner:UNIV OF WASHINGTON

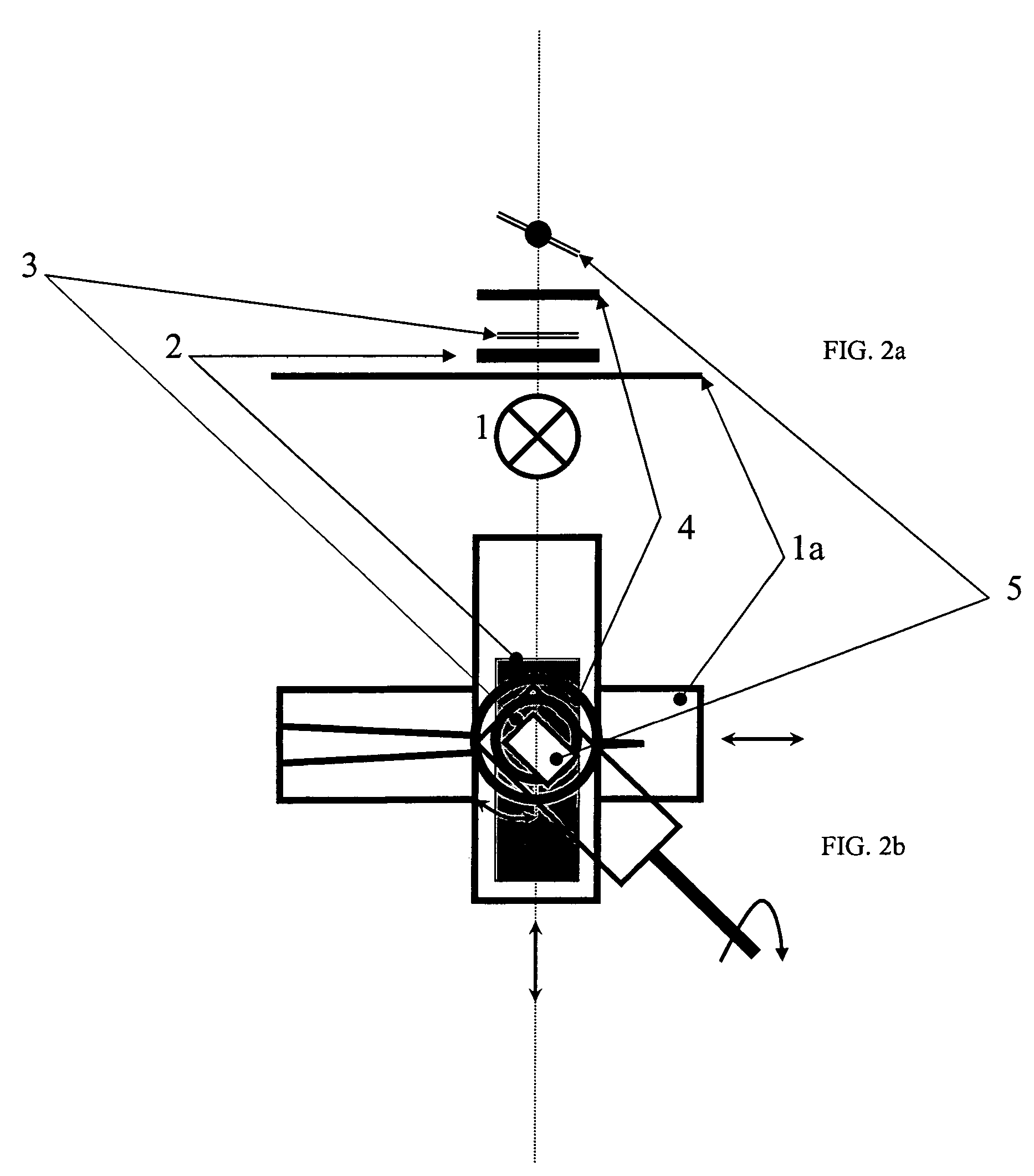

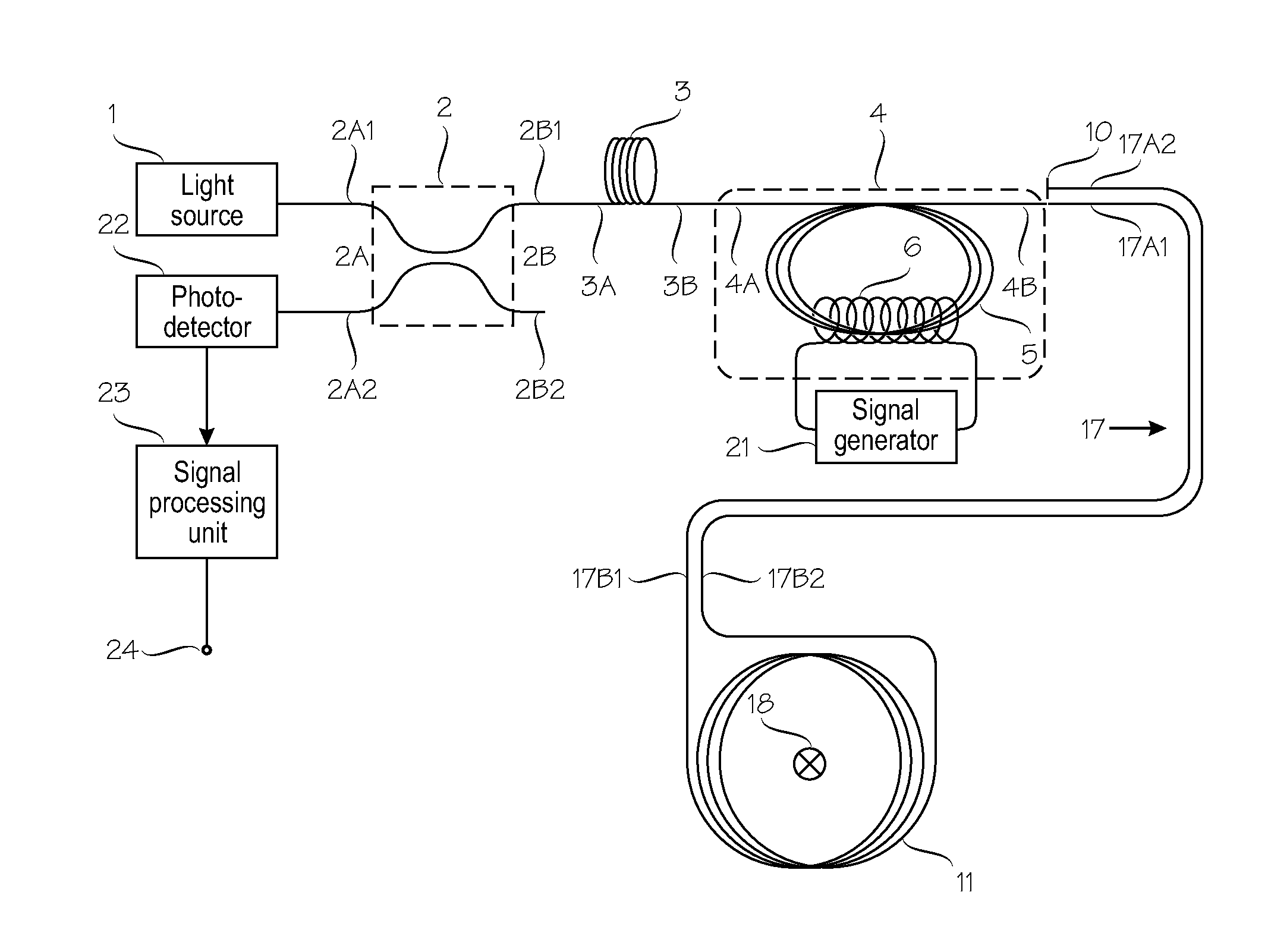

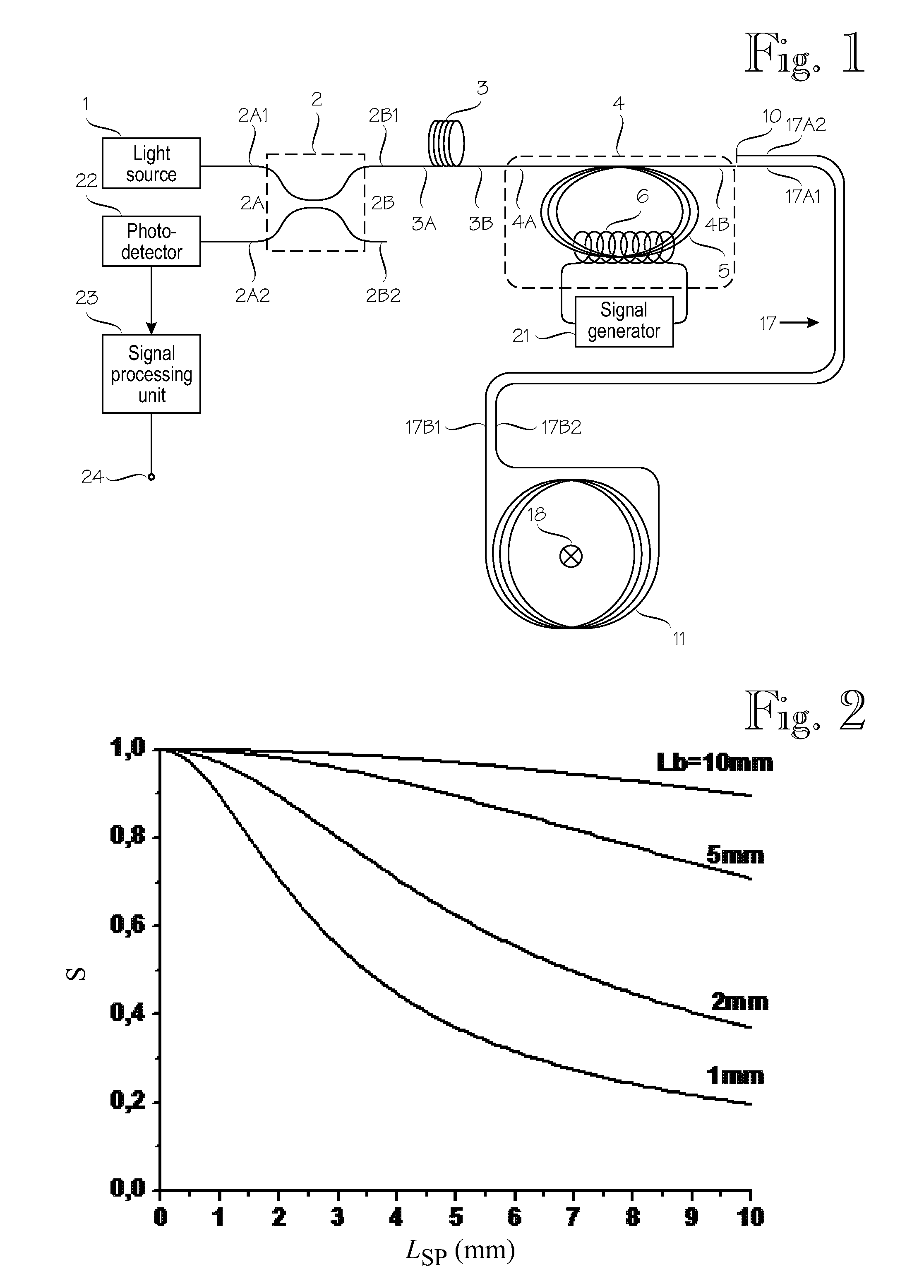

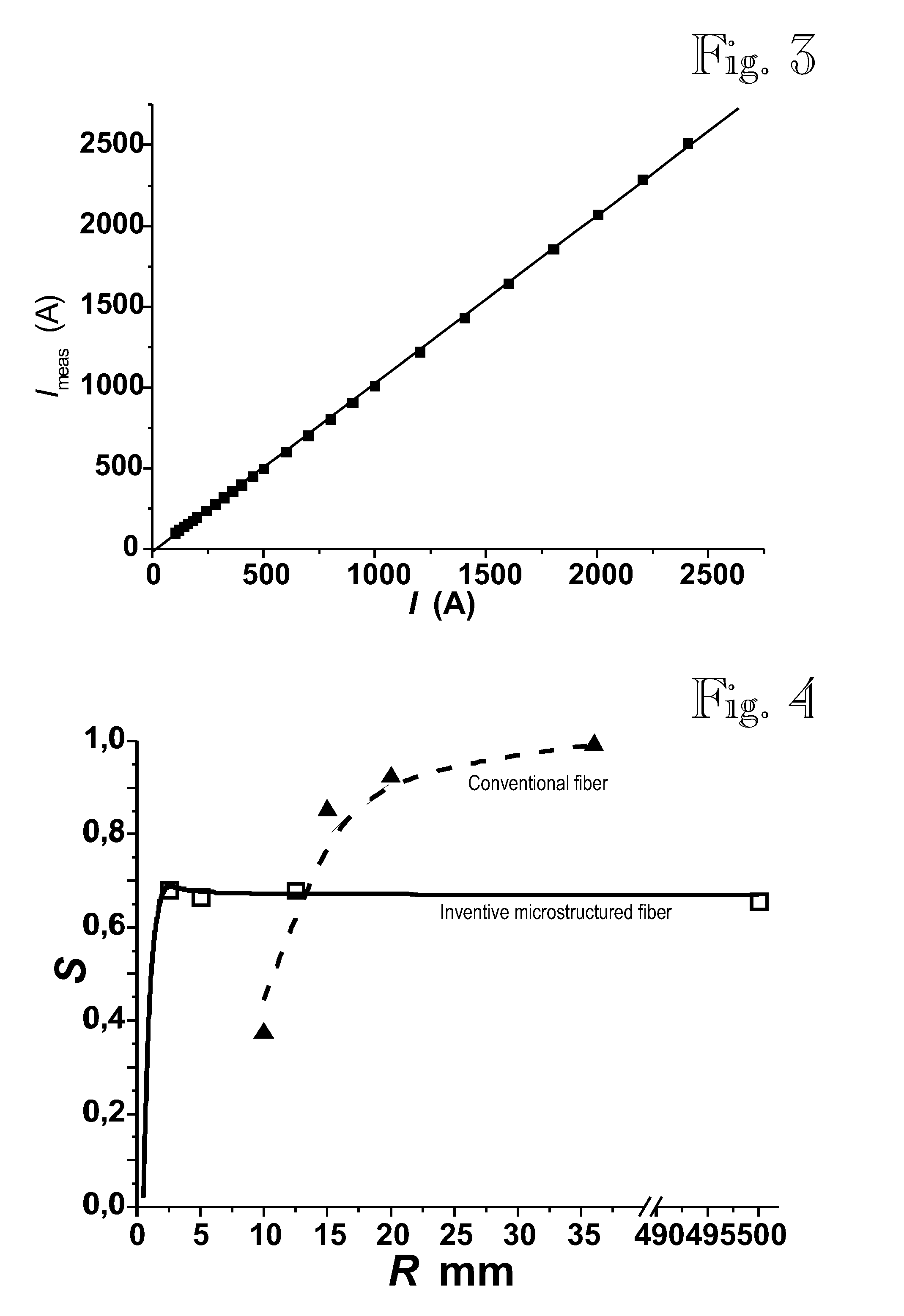

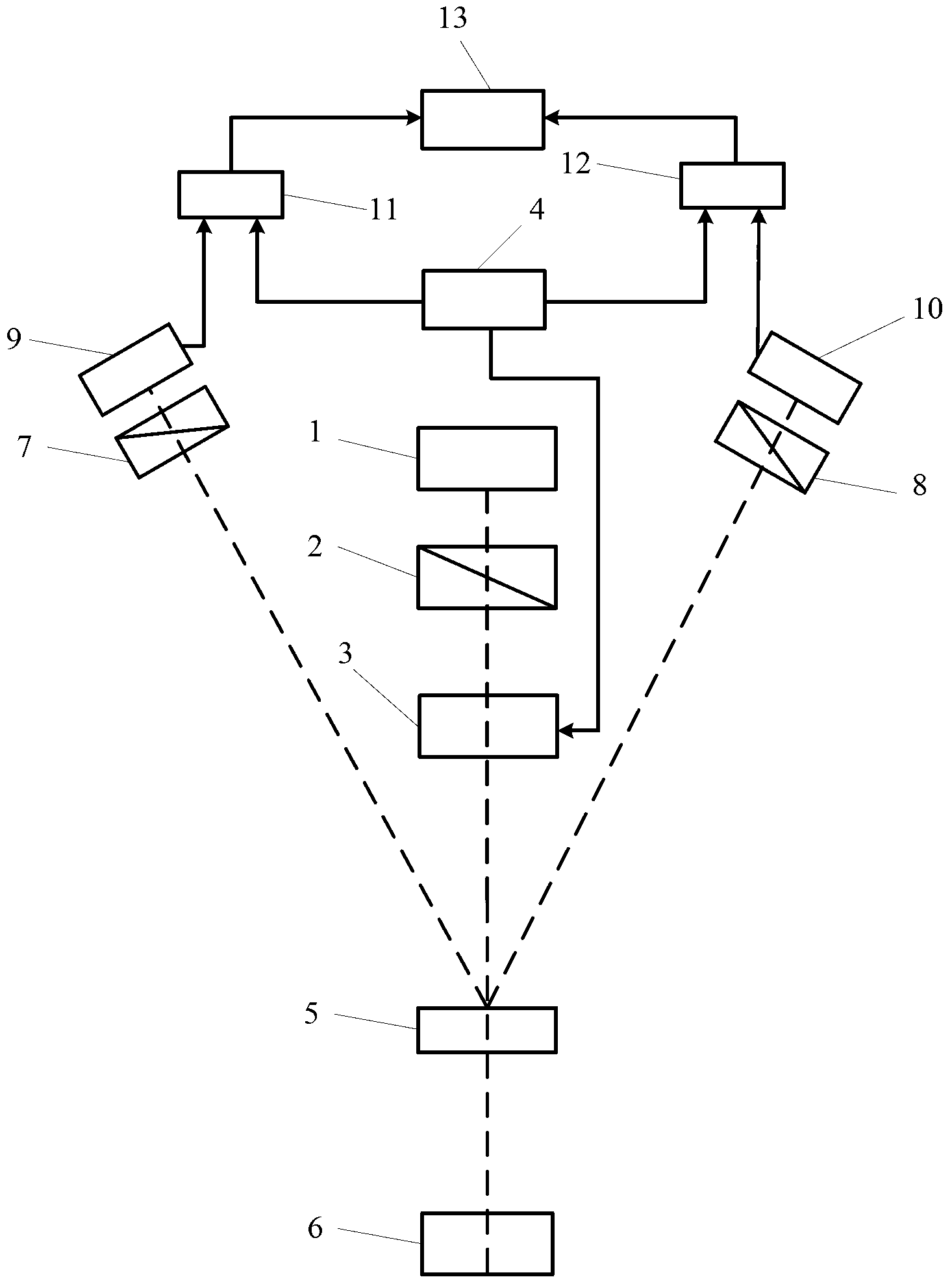

Fiber optic current sensor

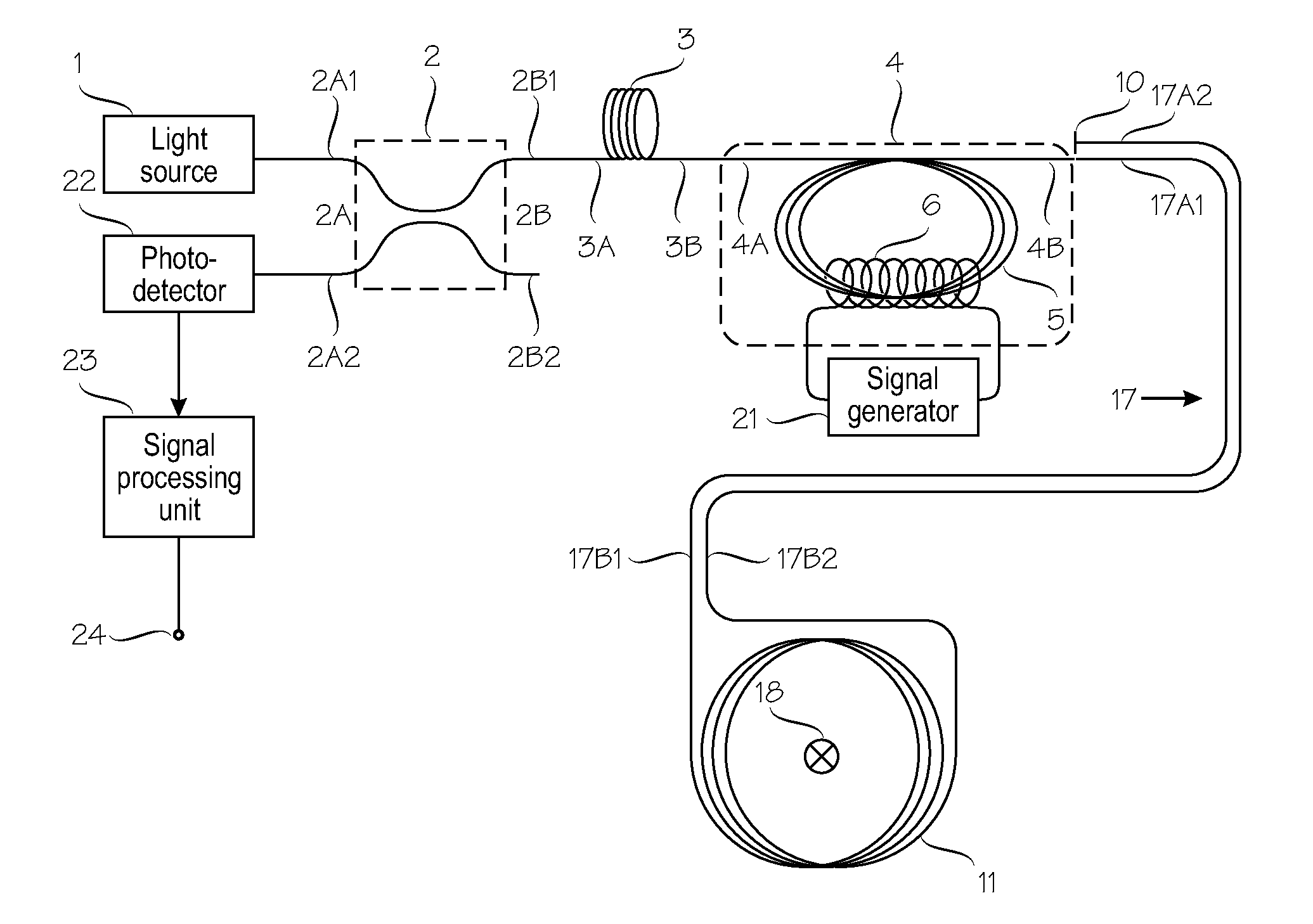

ActiveUS20120286767A1Increased sensitivity and precisionReduce sensitivityElectrical testingMagnetic field measurement using magneto-optic devicesPhotodetectorCurrent sensor

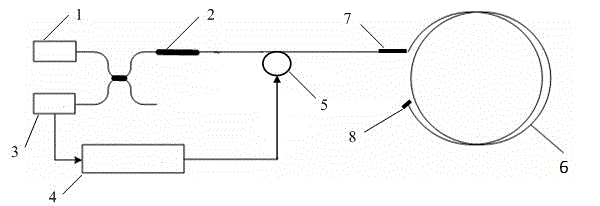

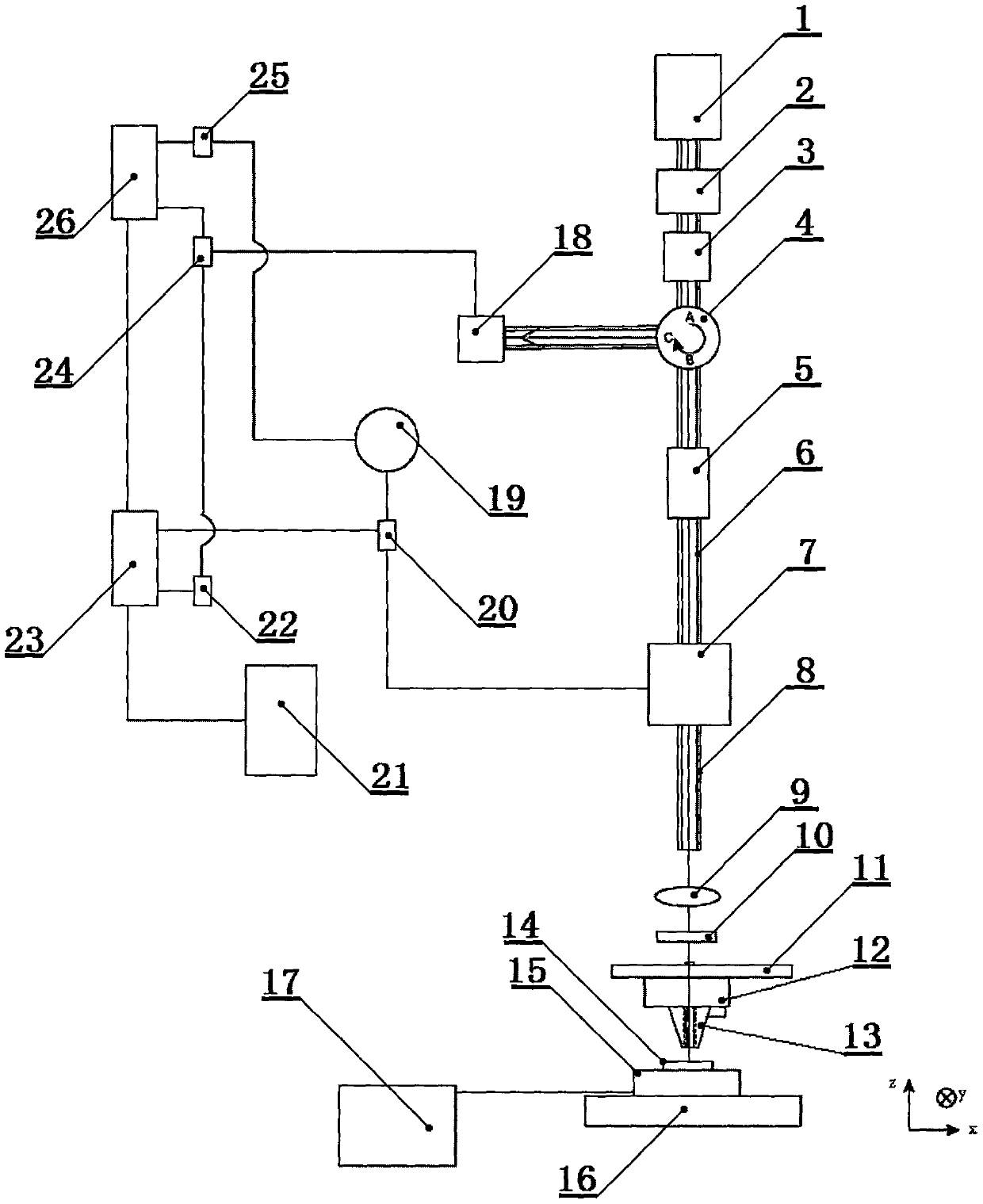

A Fiber-optic current sensor for sensing electric current carried in an electric conductor (18). Its optical section comprises: a light source (1); a directional coupler (2) with two ports (2A, 2B) of two arms each; a radiation polarizer (3); a polarization modulator (4); a fiber line (17) coupled to a current-sensing fiber loop (11); a mirror (10); and a photodetector (22). The first port of the coupler (2) is coupled to the light source (1) and to the photodetector (22). Its second port is coupled via the radiation polarizer (3) to the polarization modulator (4). The polarization modulator comprises a magneto-sensitive element (5), around which a solenoid (6) is wound. The fiber loop (11) comprises a magneto-sensitive optical fiber with embedded linear birefringence. An electronic section comprises a signal generator (21) which drives the solenoid (6); and a signal processing unit which receives the optical signal from the photodetector (22).

Owner:CLOSED PROFOTECH CJSC PROFOTECH

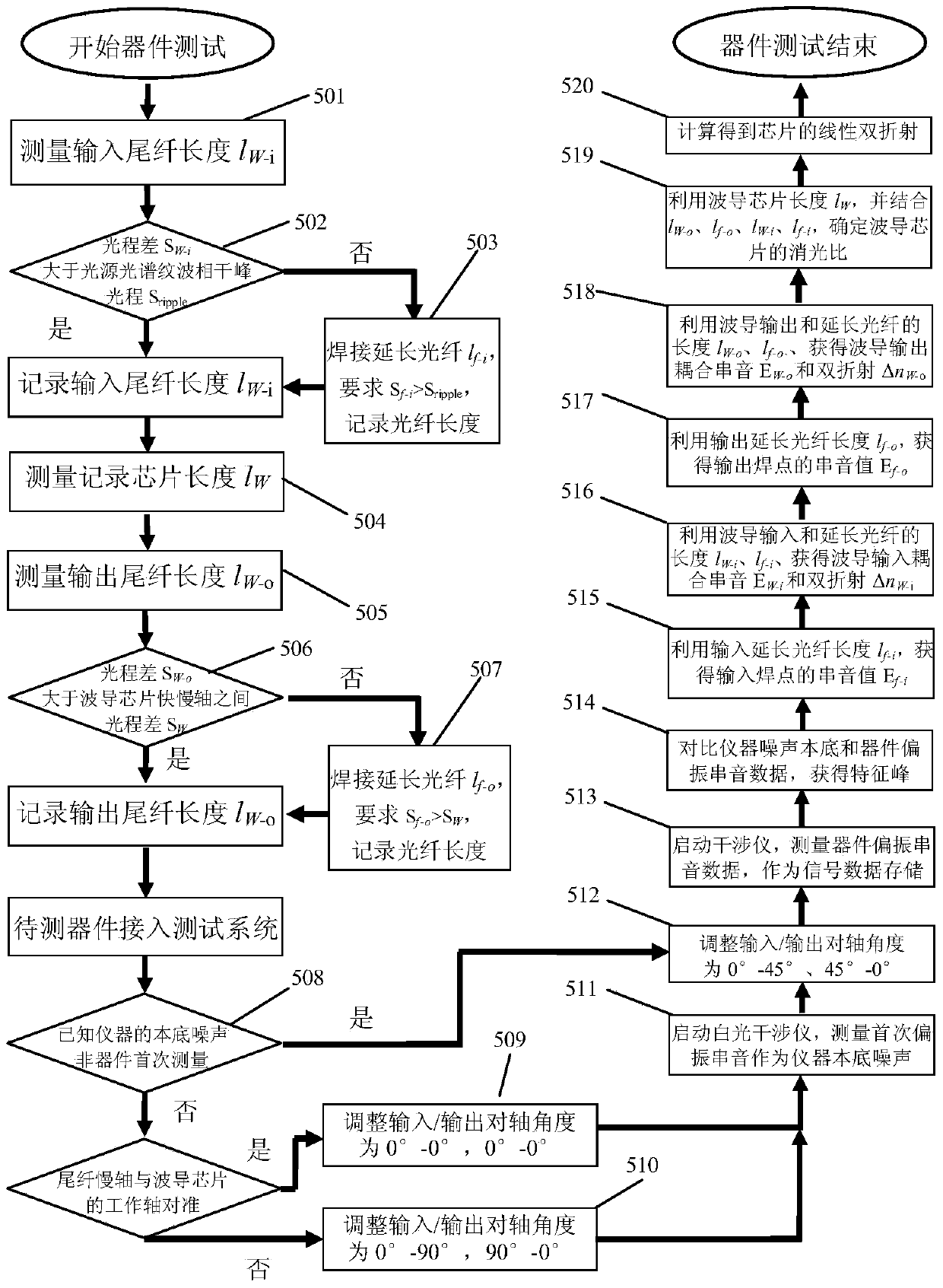

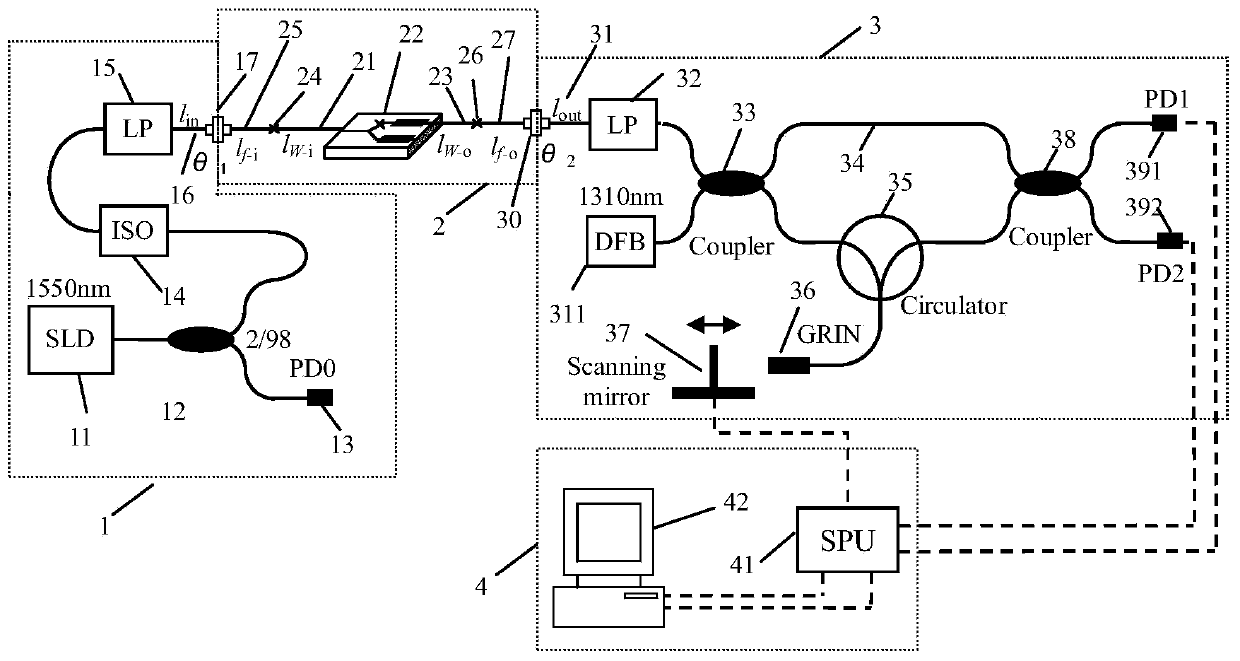

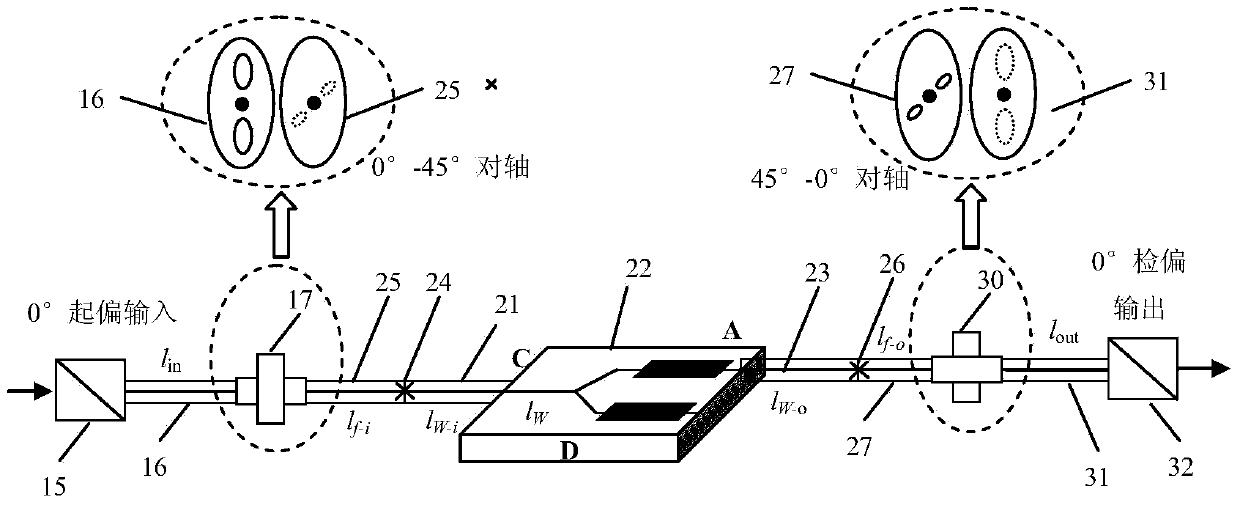

Method for measuring optical performance of multi-functional lithium niobate integrator

ActiveCN103743551AExtended Optical DefectEasy to distinguishTesting optical propertiesFiberIntegrator

The invention belongs to the techical field of measurement of optical devices, in particular to a method for measuring optical performance of multi-functional lithium niobate integrator. The method includes the steps of: measuring a waveguide device inputting the length of a tail polarization-maintaining fiber; measuring the length waveguide chips; measuring the waveguide device outputting the length of a tail polarization-maintaining fiber; aiming at conveying axises of input / output a tail fiber slow axis and the waveguide chip; gaining the result of measuring a first distributed polarization crosstalk; changing the light injecting condition of the waveguide device; gaining the result of measuring a second distributed polarization crosstalk; through analyzing and calculating the data, gaining the optic parametric of the waveguide device. The method can not only exactly gain the extinction ratio of the waveguide chips and the linear birefringence, but also gain a coupling crosstalk and the linear birefringence of the chip waveguide fiber input / output end, an input / output extend fiber solder joint, and an optical defect inside of the waveguide chip and the connecting tail fiber, thereby decreasing the difficulty of reading and analyzing the signal, and simplifying the process of analyzing and managing the data.

Owner:HARBIN ENG UNIV

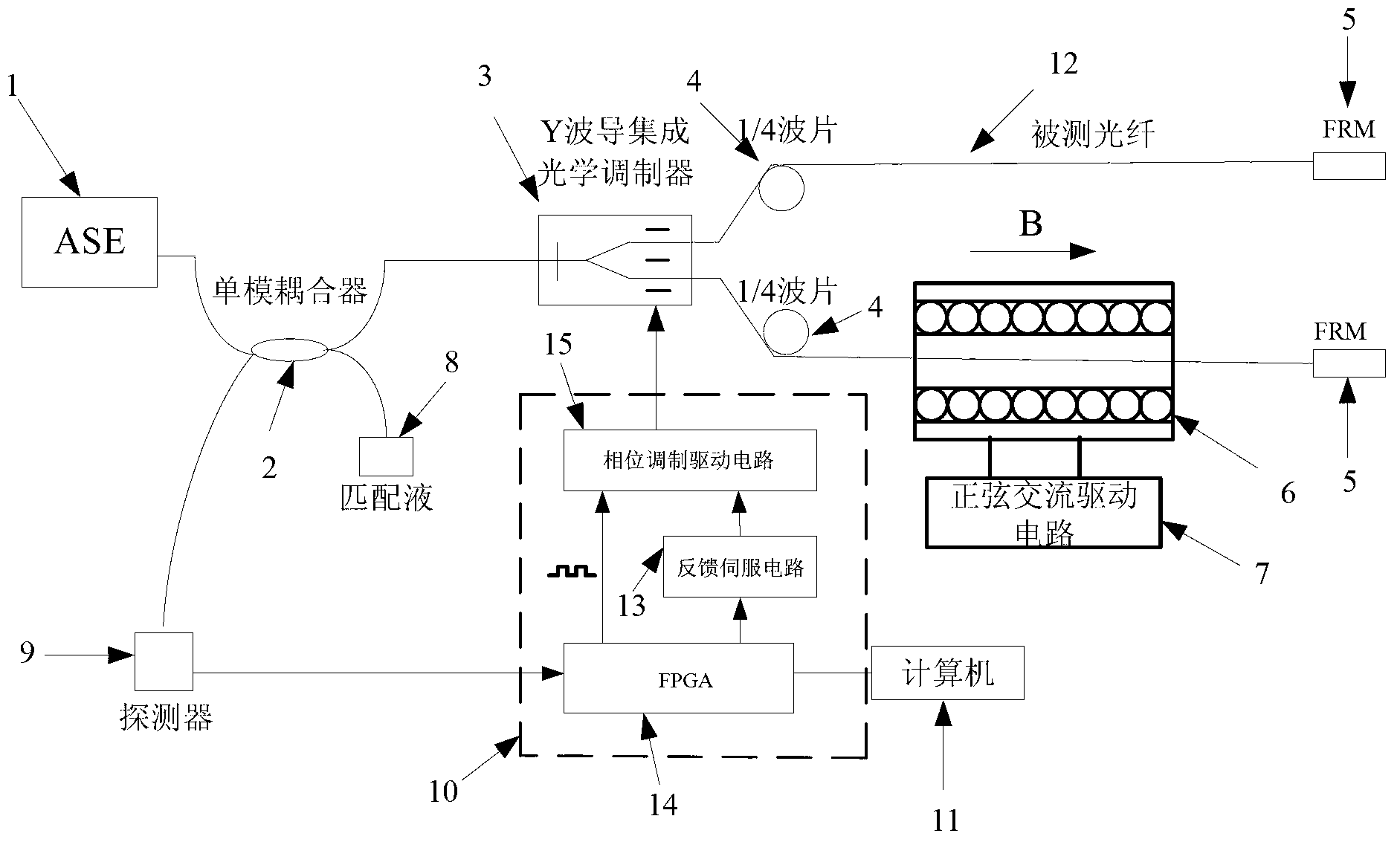

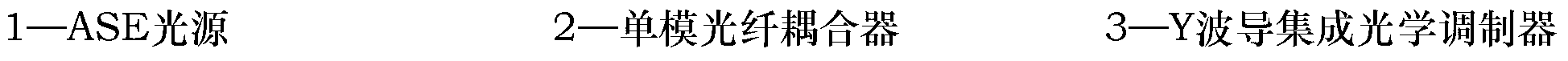

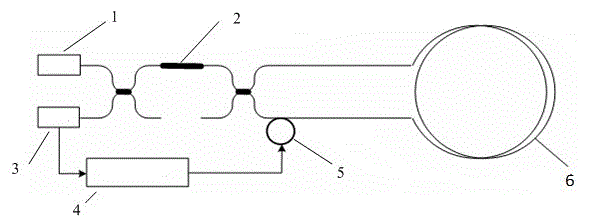

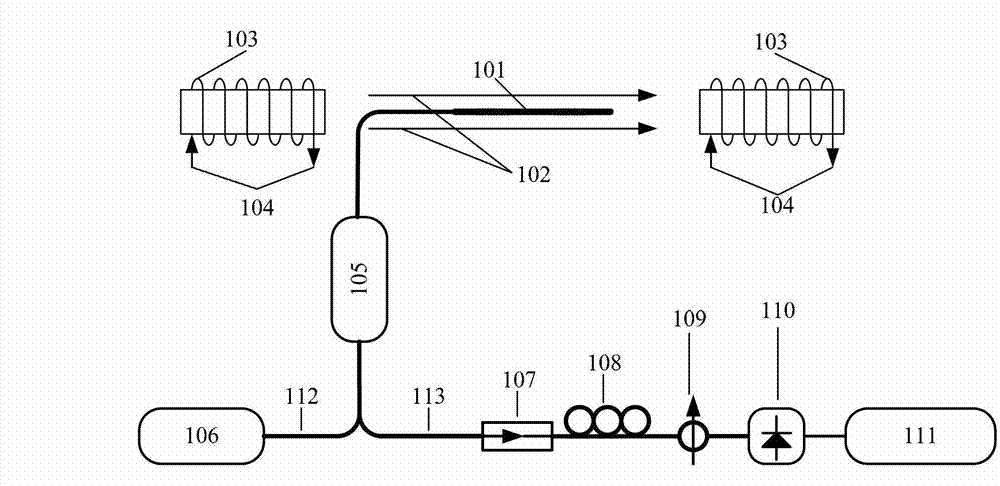

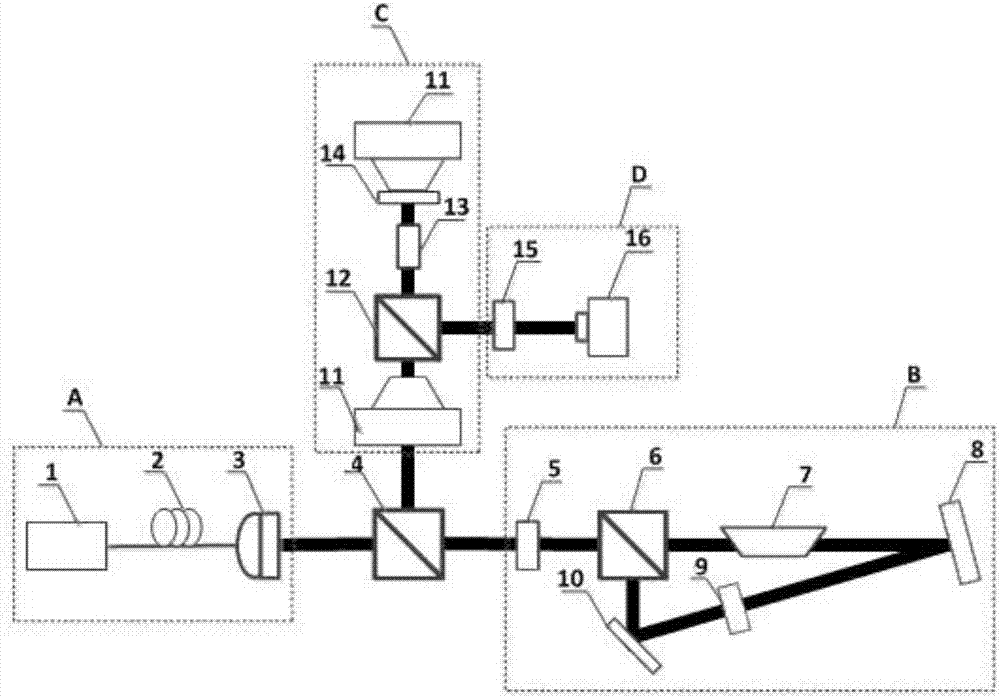

Interferometry-based optical fiber Verdet constant measuring system

InactiveCN103292976AEasy to buildEliminate measurement effectsOptical apparatus testingInformation processingAlternating current

The invention discloses an interferometry-based optical fiber Verdet constant measuring system. The system comprises an ASE (amplified spontaneous emission) light source, a single-mode optical fiber coupler, a Y-waveguide integrated optical modulator, 1 / 4 wave plates, Faraday rotator mirrors, a solenoid, a sine alternating-current driving circuit, matching fluid, a probe, an information processing module, a computer and measured optical fibers. The ASE light source, the single-mode optical fiber coupler, the Y-waveguide integrated optical modulator, the measured optical fibers and the Faraday rotator mirrors are connected through optical fibers in sequence. Each 1 / 4 wave plate is arranged between the Y-waveguide integrated optical modulator and the corresponding measured optical fiber. A signal processing portion comprises a feedback servo circuit, an FPGA (field programmable gate array) module and a phase modulation driving circuit. The system is of an all-optical-fiber structure and simple and convenient to set up; by the aid of the Faraday rotator mirrors, influences of linear birefringence of the optical fibers on measurement can be eliminated, and measurement accuracy is improved; and Verdet constants of various optical fibers can be measured by the system.

Owner:BEIHANG UNIV

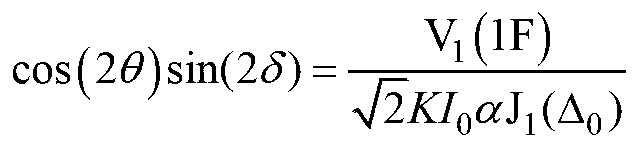

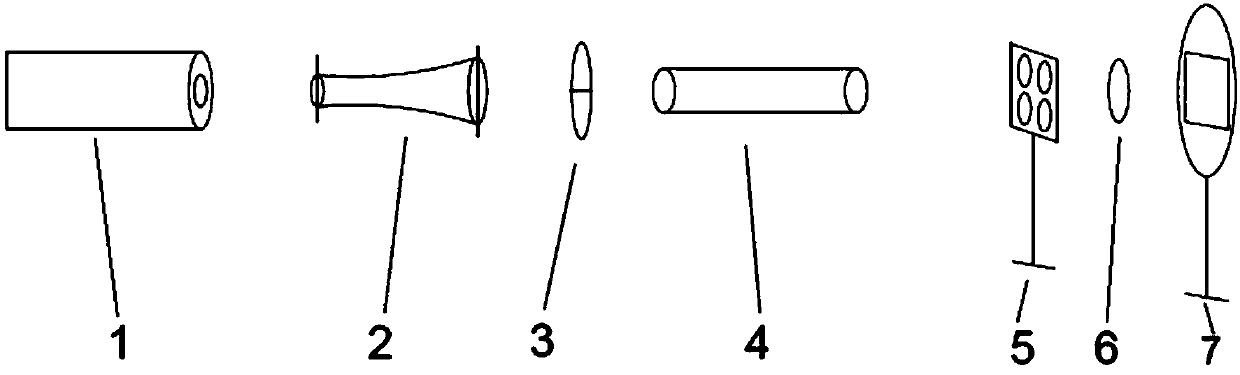

Device for measuring micro-linear birefringence through photoelastic modulation and electro-optical modulation cascading

InactiveCN105136681ANo mechanical adjustmentImprove stabilityMaterial analysis by optical meansMeasurement deviceFundamental frequency

The invention relates to the technical field of linear birefringence measurement, in particular to a device for measuring micro-linear birefringence through photoelastic modulation and electro-optical modulation cascading. The device is high in speed, precision and sensitivity, convenient to operate, controllable, high in stability and low in cost. Detection laser light is collimated, then passes through a polarizer, a photoelastic modulator, a sample to be measured and an electro-optical modulator in sequence, and finally is output and irradiated on a photoelectric detector after polarization detection is conducted, signal detection is conducted, a direct-current item is obtained through lowpass filtering, photoelastic modulation fundamental-frequency item data are obtained through FPGA digital phase locking, direct-current item data are transmitted to a computer together with the fundamental-frequency item data, and finally linear birefringence data processing, storage and display are achieved through the computer. The device is mainly applied to photoelastic polarization modulation, the amplitude and direction of linear birefringence can be obtained at the same time, mechanical adjustment is not needed, working is stable, industrialized integration is facilitated, and a new theory and a new method are provided for linear birefringence measurement and relevant application fields.

Owner:ZHONGBEI UNIV

Circular extinction contrast imaging microscope

InactiveUS7292389B2Enhanced signalTelevision system detailsColor television detailsExtinctionDifferential transmission

Systems and methods for producing circular extinction (CE) contrast images of anisotropic samples. Microscope systems for determining circular extinction (CE), the differential transmission of left and right circularly polarized light resulting from circular dichroism (CD) of an anisotropic sample, include mechanically driven optical components and an image detector such as a monochromatic CCD camera to detect light intensities. In one aspect, optical components include a tunable filter, a rotatable linear polarizer and a variable retarder. The tunable filter is adjustable to provide light at a specific desired wavelength. The linear polarizer is adjustable to provide linearly polarized light with a specific wave vector, and the variable retarder is adjustable to produce near perfect circular polarized light at every selected wavelength. For example, in one aspect, the variable retarder includes a linear birefringent plate tiltable around one of its eigenmodes perpendicular to the wave vector of polarized light. The plate may be controllably tilted so that it functions as a perfect λ / 4 plate at each wavelength.

Owner:UNIV OF WASHINGTON

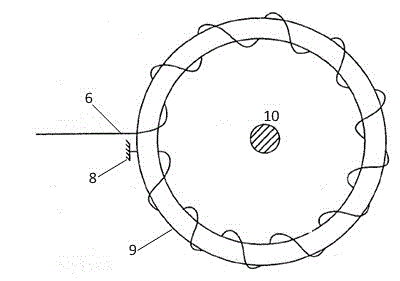

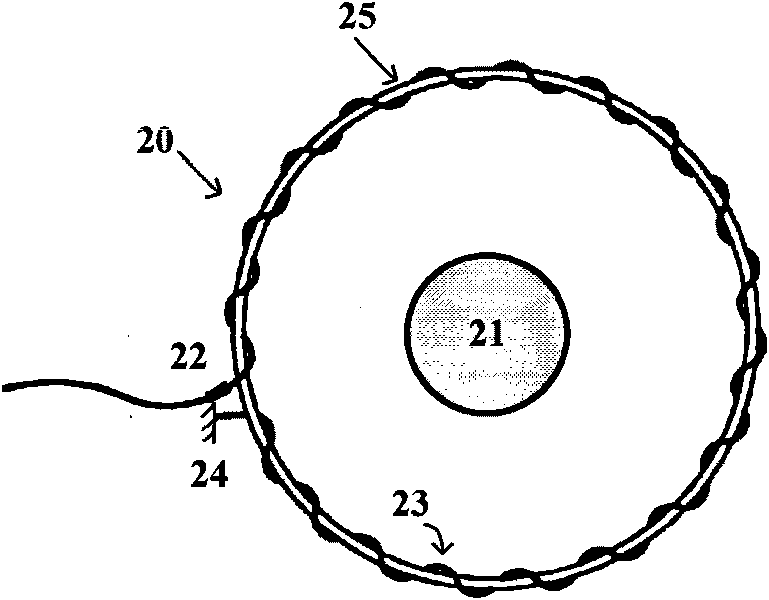

Sensing head of all-fiber current transformer

InactiveCN103149405ASolve problemsReduce adverse effectsCurrent/voltage measurementVoltage/current isolationLinear birefringenceEngineering

The invention discloses a sensing head of an all-fiber current transformer. Grooves are respectively formed in an upper cover of the sensing head and a lower cover of the sensing head; a sensing optical fiber, an all-fiber one-fourth wave plate and an optical fiber end surface reflecting mirror form an optical fiber sensing part of the all-fiber current transformer by a welding mode; the optical fiber sensing part is uniformly wound on a sensing framework in a spiral manner; the sensing framework wound with the optical fiber sensing part is placed in the groove of the lower cover of the sensing head and integrally packages the upper cover of the sensing head with the lower cover of the sensing head; a lead head which is internally provided with a lead hole is processed in the upper cover of the sensing head; and a polarization-preserving optical fiber is used as a lead-out end of the sensing head of the all-fiber current transformer, is partially connected with the optical fiber sensing part and is led out of the lead hole. According to the sensing head disclosed by the invention, various negative influences such as linear birefringence, Verdet constant temperature effect and one-fourth wave plate phase delay temperature effect of the optical fiber sensing part can be effectively eliminated.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

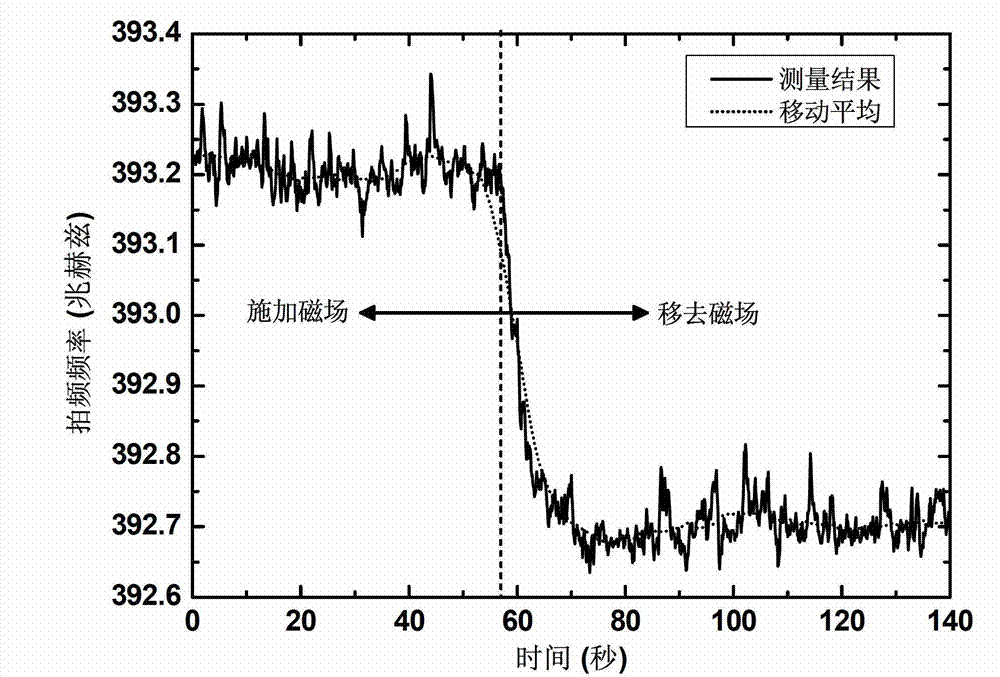

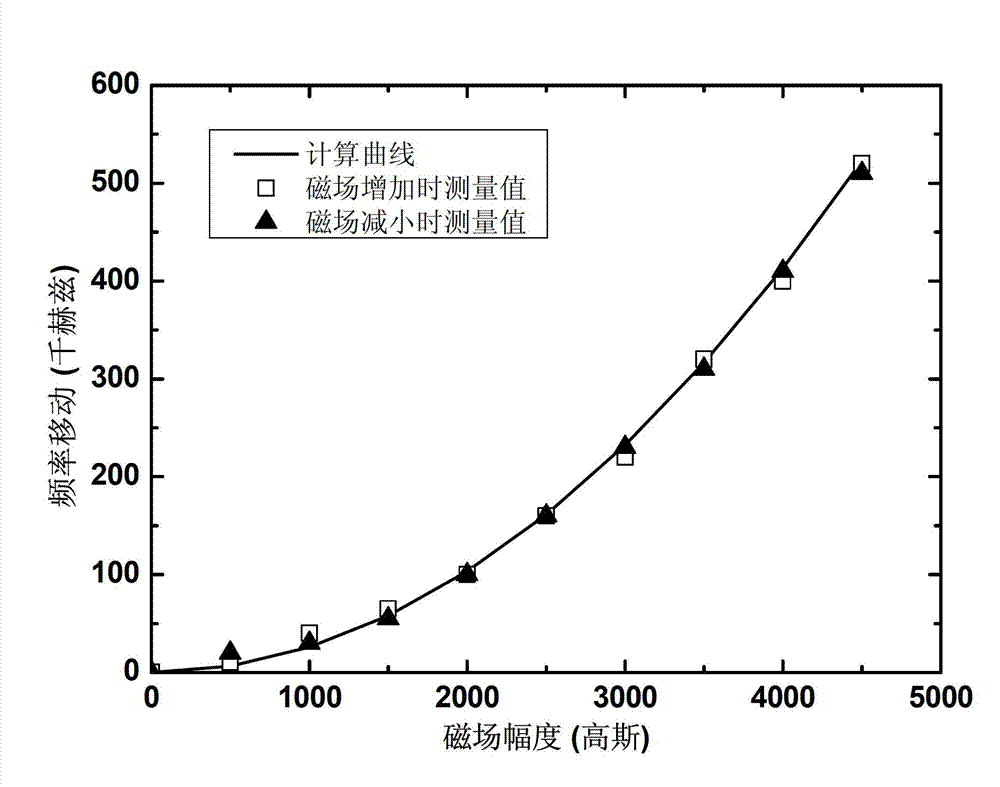

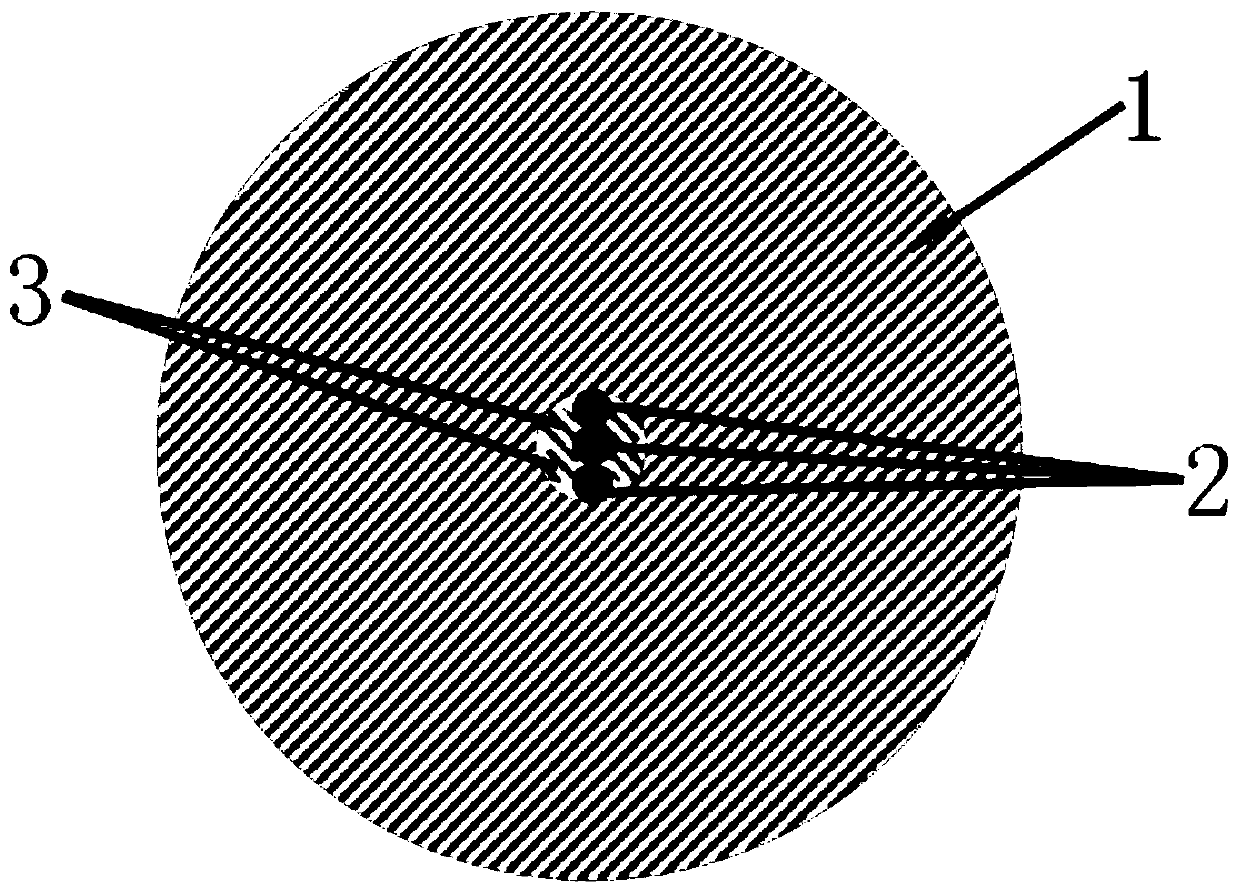

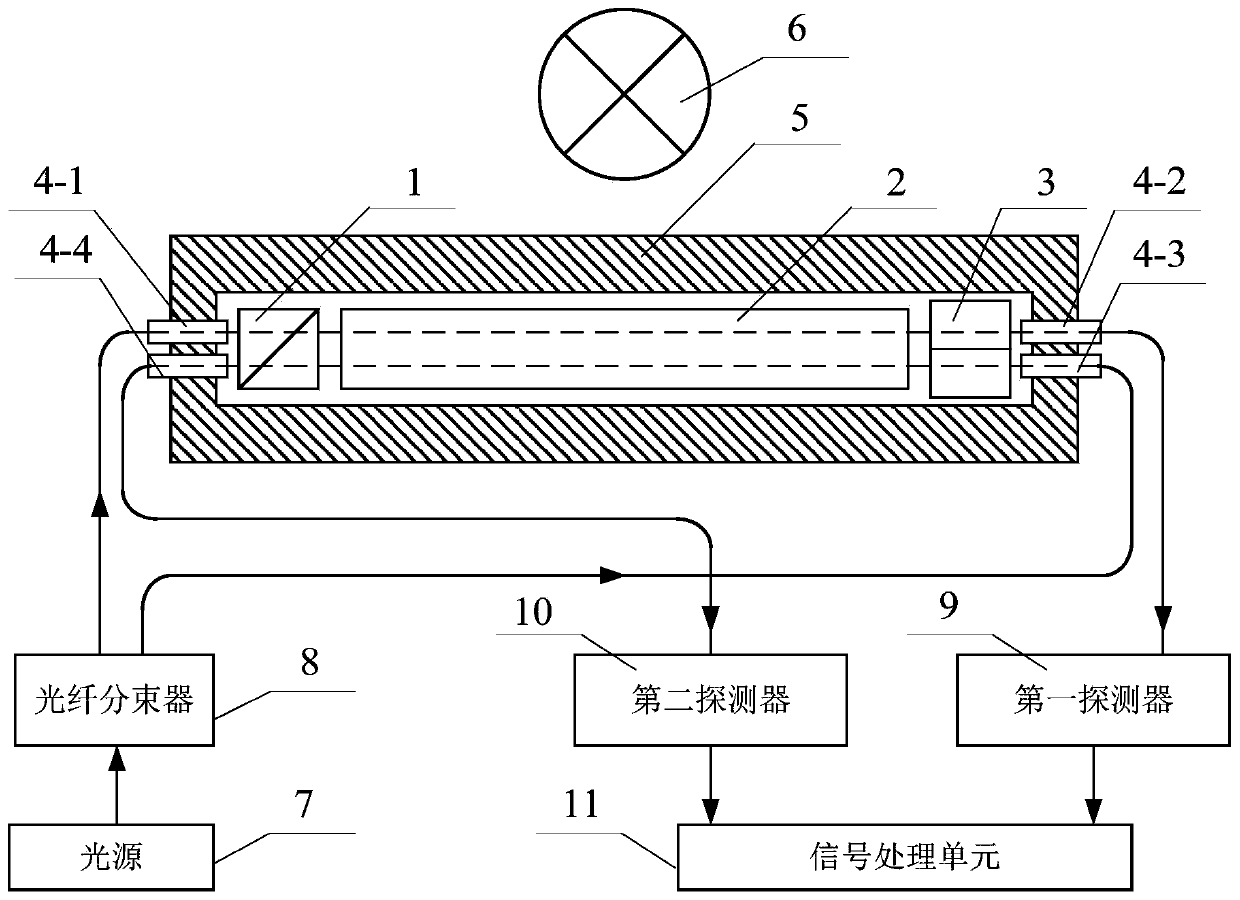

Magnetic field sensor and measurement method based on fiber Bragg grating laser

InactiveCN103048631AOvercoming shortcomings of wavelength detectionSuitable for applications requiring point measurementMagnetic field measurement using magneto-optic devicesFiberGrating

The invention discloses a magnetic field sensor and a measurement method based on a fiber Bragg grating laser. The magnetic field sensor comprises the fiber Bragg grating laser, a polarizer and a photoelectric detector, which are sequentially connected, wherein linear birefringence which is generated in the laser cavity of the fiber Bragg grating laser is combined with circular birefringence caused by a magnetic field to be measured to form elliptical birefringence; the fiber Bragg grating laser works in a single-longitudinal-mode double-cross-polarization state to generate two laser outputs which belong to a longitudinal mode, have frequency difference and are crossed in a polarization state; the two laser outputs pass through the polarizer, and are input into the photoelectric detector and then mixed to generate a beat frequency signal; and by detecting the frequency change of the beat frequency signal, the change of the elliptical birefringence is calculated, and then the magnetic field intensity of the magnetic field to be measured is computed. The invention has the characteristics of small size and flexibility, and is particularly applicable to an application occasion where the point measurement is required. The problems that the conventional magnetic field sensor is large in size and difficult to apply to the application occasion where the point measurement is required are solved.

Owner:JINAN UNIVERSITY

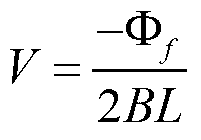

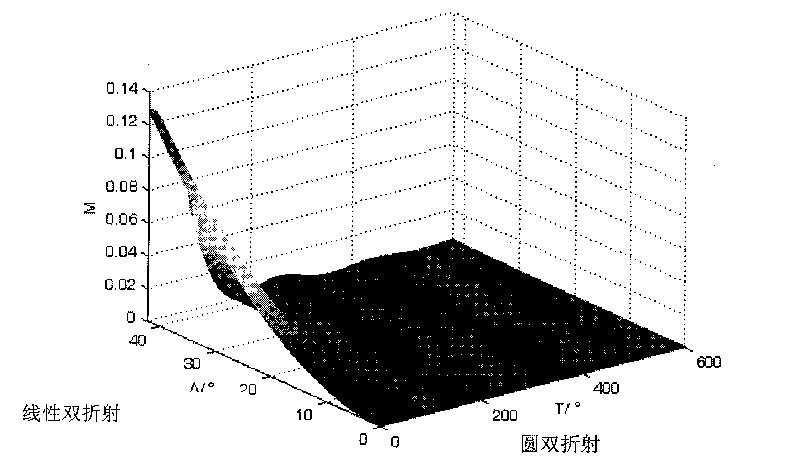

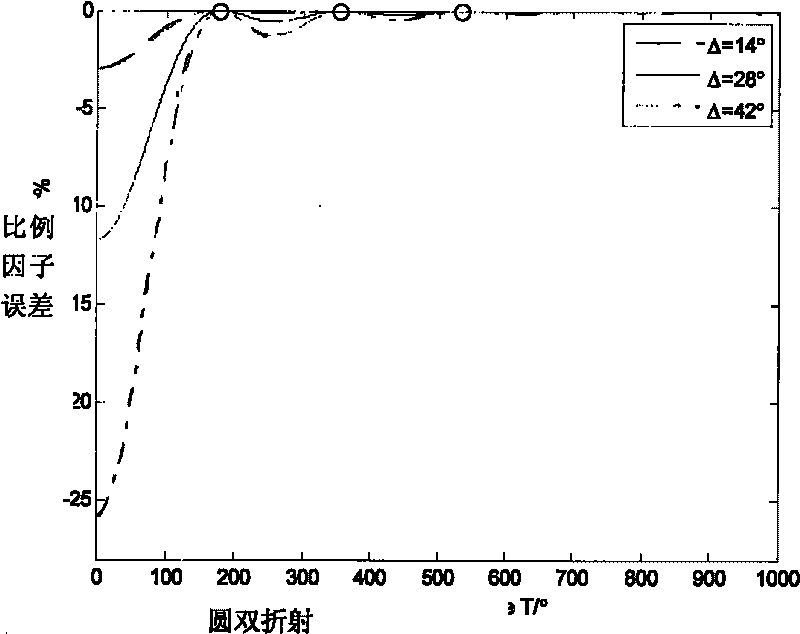

Method of restraining the influence of linear birefringence on full optical fiber current transformer

ActiveCN101701974AHigh precisionImprove stabilityVoltage/current isolationElectrical conductorLinear birefringence

The invention discloses a method of restraining the influence of linear birefringence on a full optical fiber current transformer, which is as follows: spirally winding a sensing optical fiber on a circular hoop on the periphery of a current-carrying conductor to form an optical fiber solenoid; selecting an appropriate helical angle and radius to accurately control the round birefringence of a sensing ring; introducing the persistent existence round birefringence meeting T=178 degrees in a form 1; and restraining an error introduced by the linear birefringence; wherein M is a dying oscillation function of the round birefringence T; T is the round birefringence existing in the sensing optical fiber; and Delta is the linear birefringence existing in the sensing optical fiber. The method cansimply and accurately control the round birefringence of the optical fiber sensing ring so as to restrain the error caused by the linear birefringence, thus being capable of effectively increasing the precision and stability of the optical fiber current transformer.

Owner:STATE GRID CORP OF CHINA +2

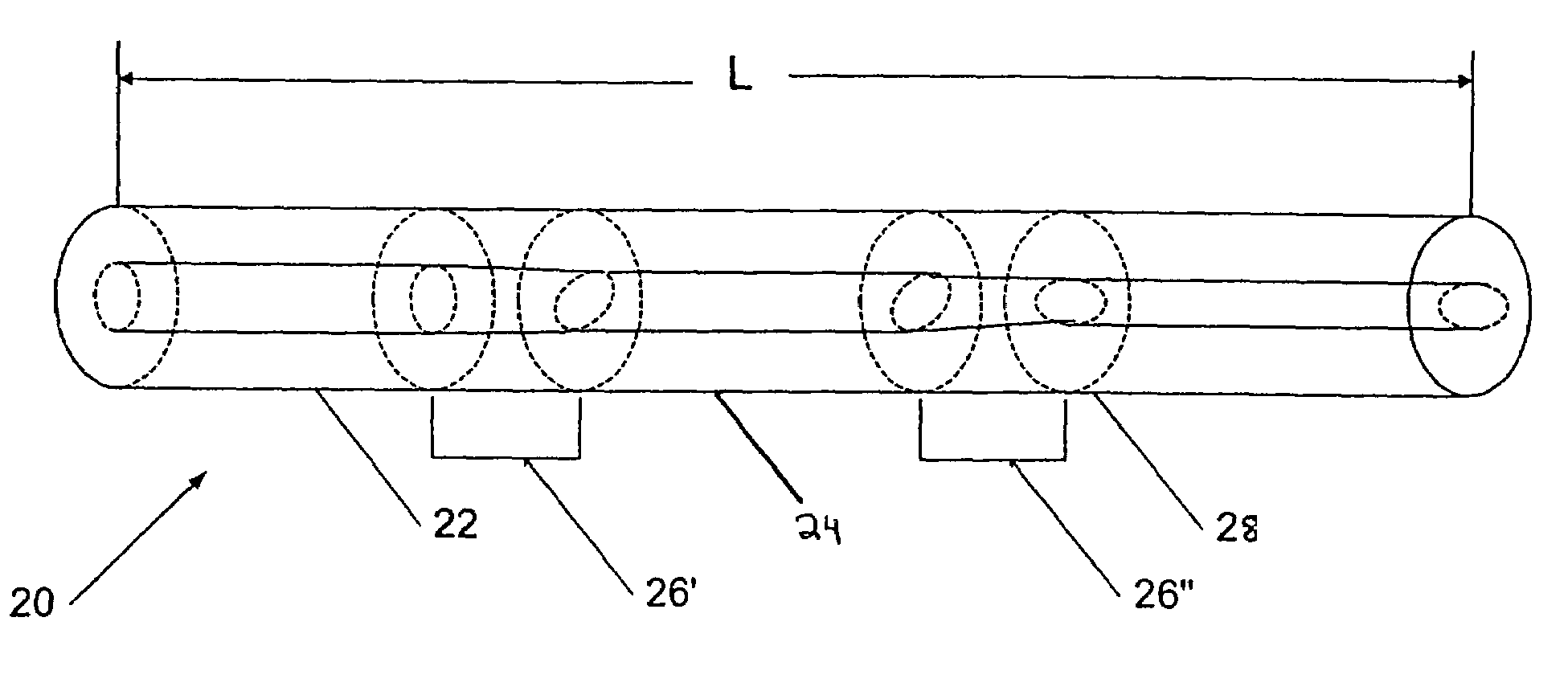

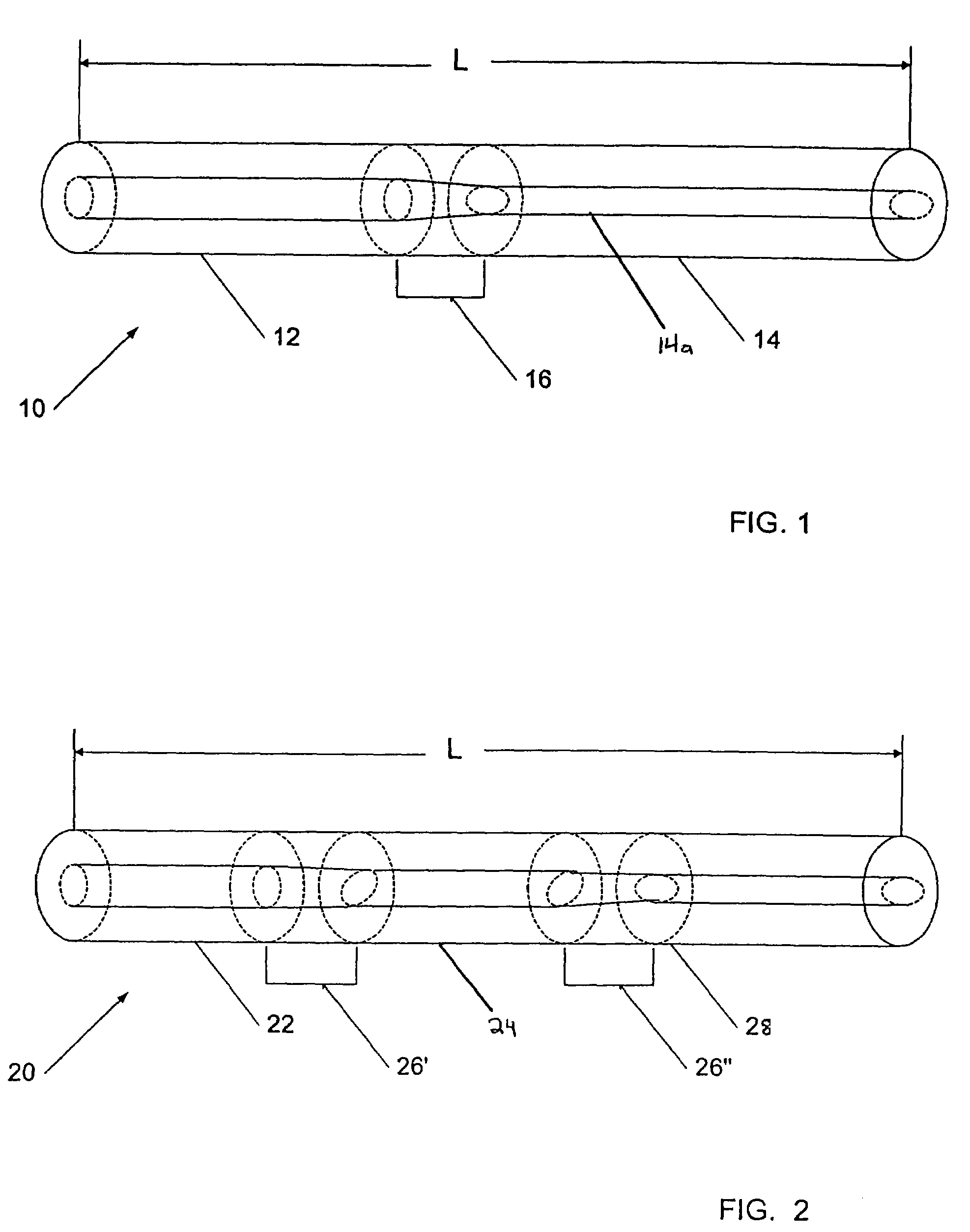

Reduction of linear birefringence in circular-cored single-mode fiber

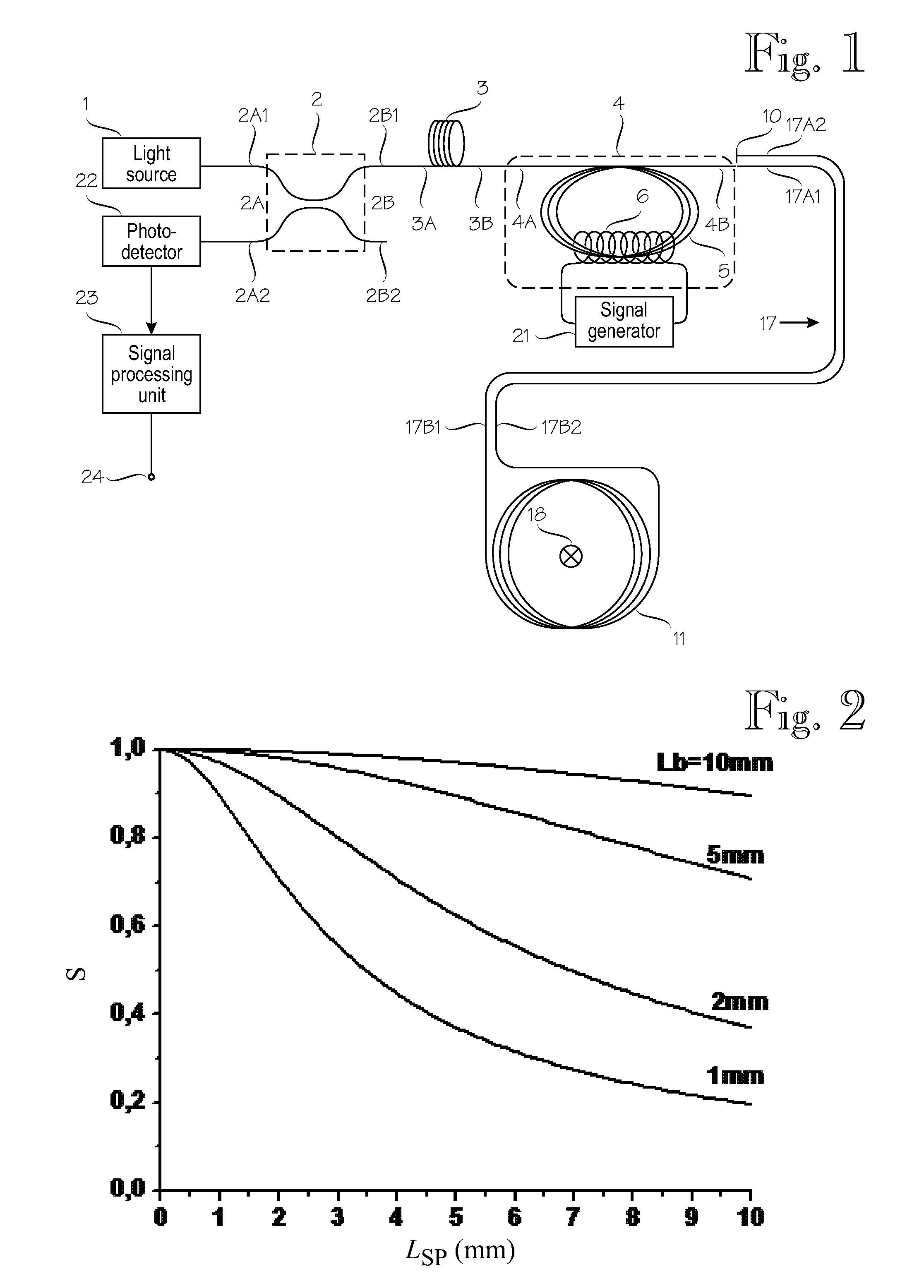

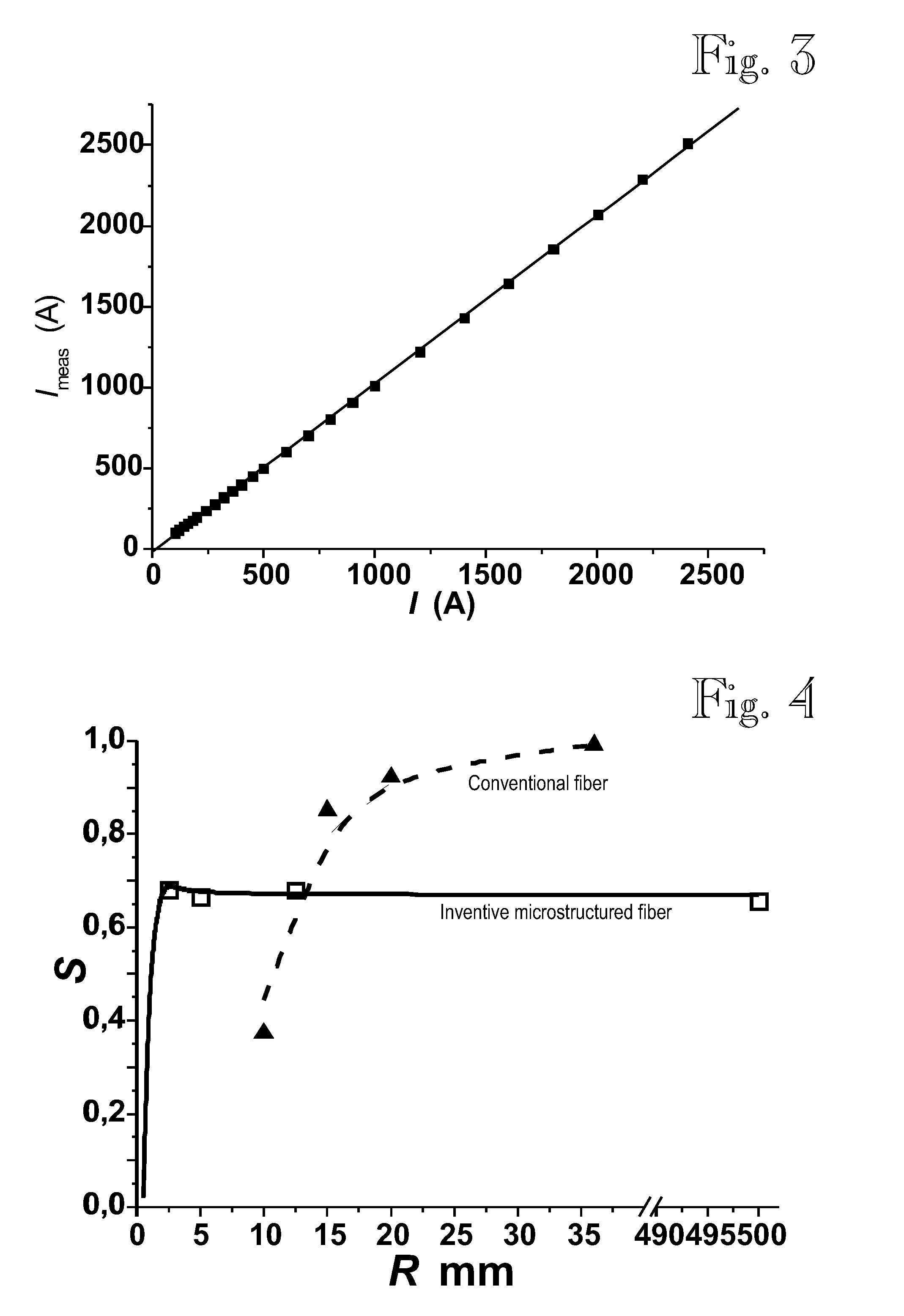

InactiveUS7120323B2Reducing effect of linear birefringenceReduced linear birefringenceCladded optical fibreCoupling light guidesLinear birefringenceEngineering

A method is described for reducing the effect of linear birefringence in an optical fiber, in particular a circular-cored single-mode fiber. The invention may also be directed to an optical fiber having a reduced linear birefringence. A length of the optical fiber may be subdivided into a plurality of sections and a twist having a predetermined sense of rotation and a twist angle may be introduced between the sections. Fibers of this type may find applications, for example, in fiber-optic current and magnetic field sensors.

Owner:KVH IND INC

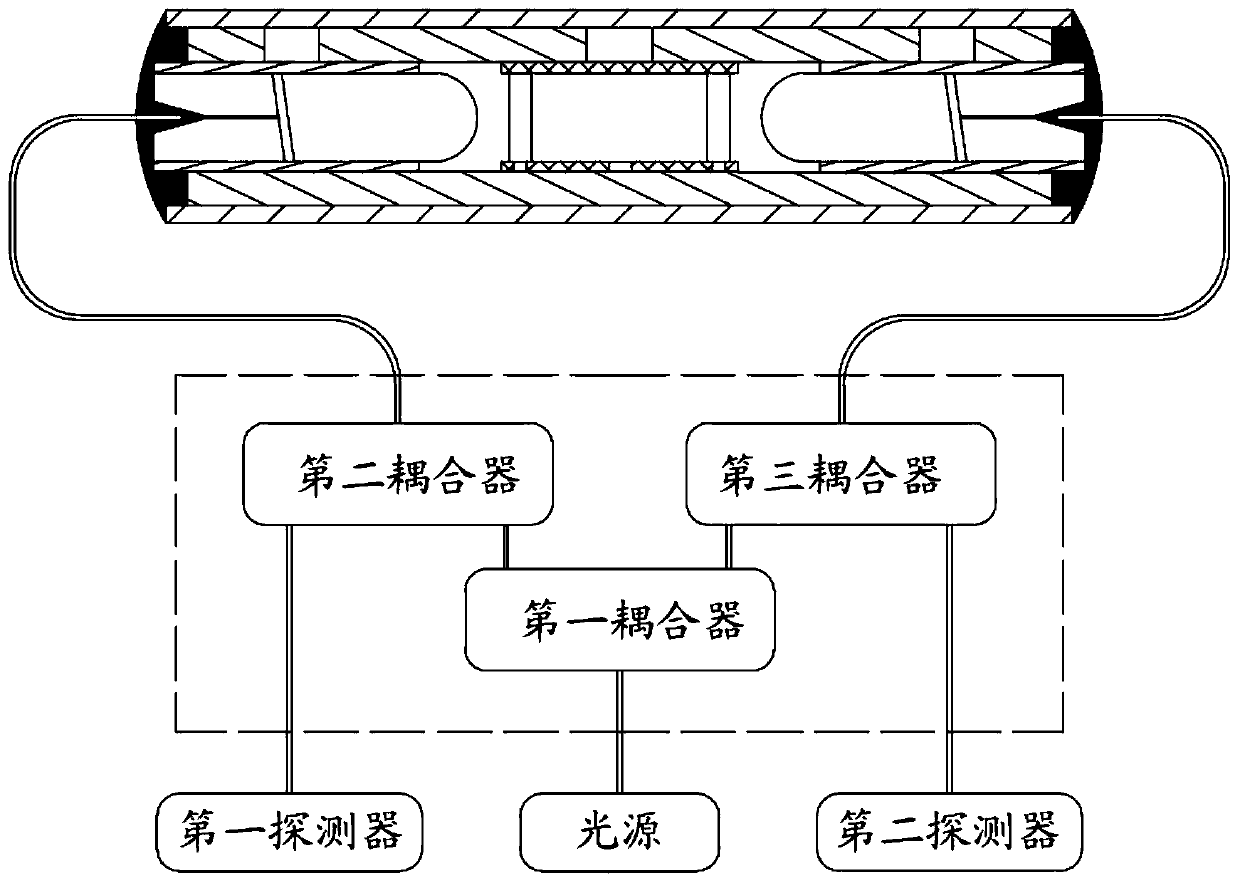

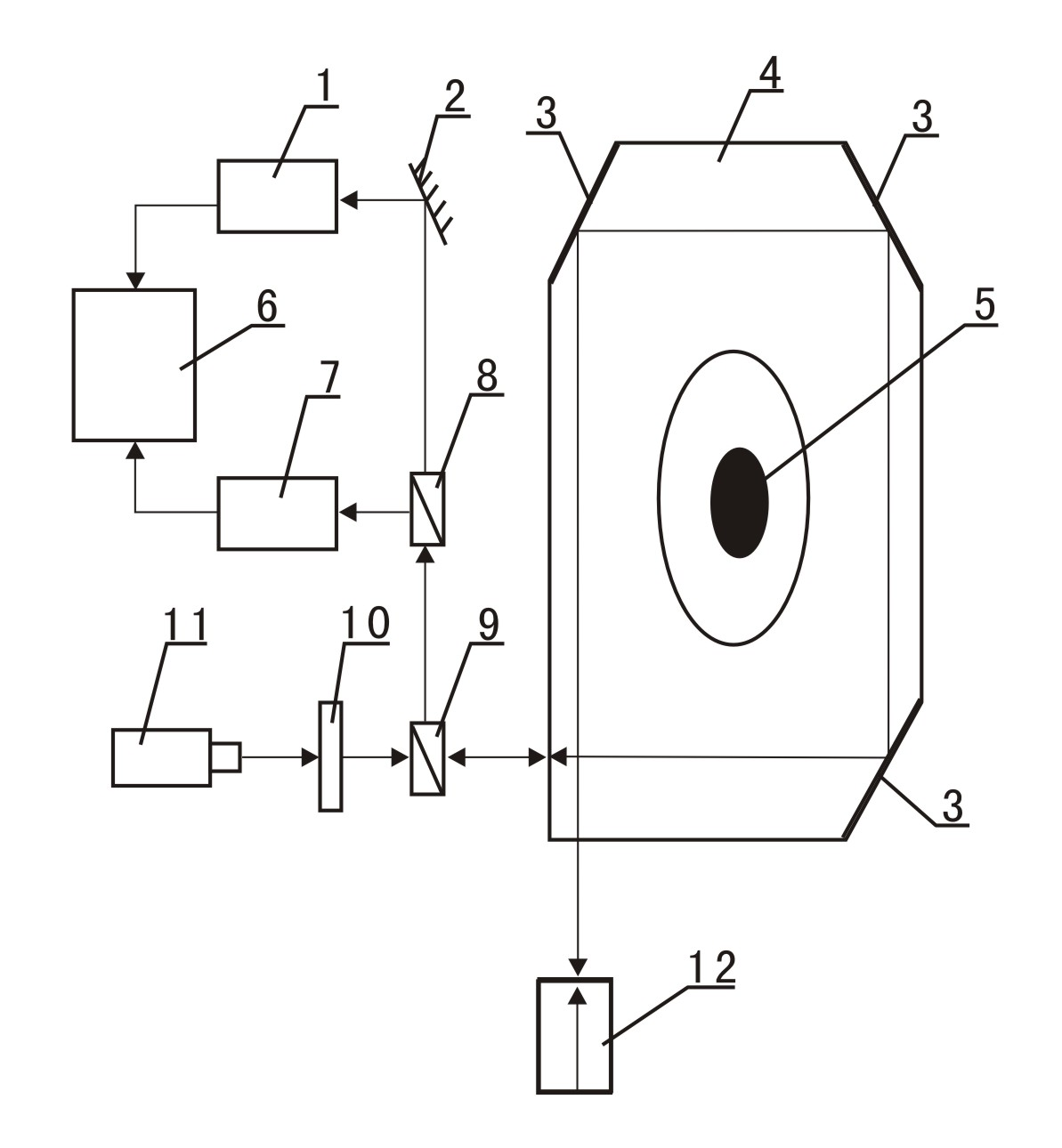

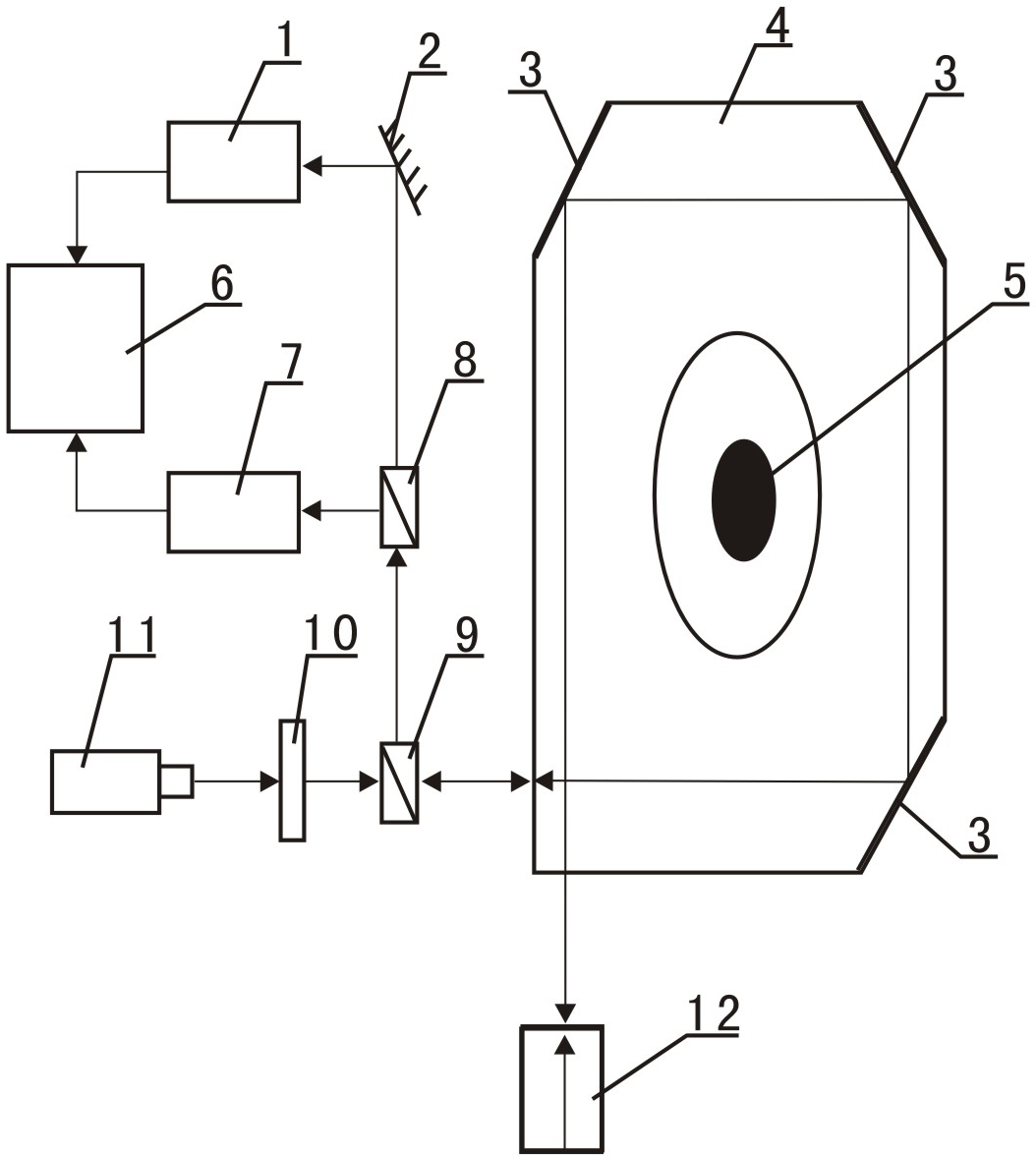

Fiber optic current sensor

ActiveUS8624579B2Increased sensitivity and precisionReduce sensitivityMaterial analysis by optical meansSagnac effect gyrometersPhotodetectorCurrent sensor

A Fiber-optic current sensor for sensing electric current carried in an electric conductor (18). Its optical section comprises: a light source (1); a directional coupler (2) with two ports (2A, 2B) of two arms each; a radiation polarizer (3); a polarization modulator (4); a fiber line (17) coupled to a current-sensing fiber loop (11); a mirror (10); and a photodetector (22). The first port of the coupler (2) is coupled to the light source (1) and to the photodetector (22). Its second port is coupled via the radiation polarizer (3) to the polarization modulator (4). The polarization modulator comprises a magneto-sensitive element (5), around which a solenoid (6) is wound. The fiber loop (11) comprises a magneto-sensitive optical fiber with embedded linear birefringence. An electronic section comprises a signal generator (21) which drives the solenoid (6); and a signal processing unit which receives the optical signal from the photodetector (22).

Owner:CLOSED PROFOTECH CJSC PROFOTECH

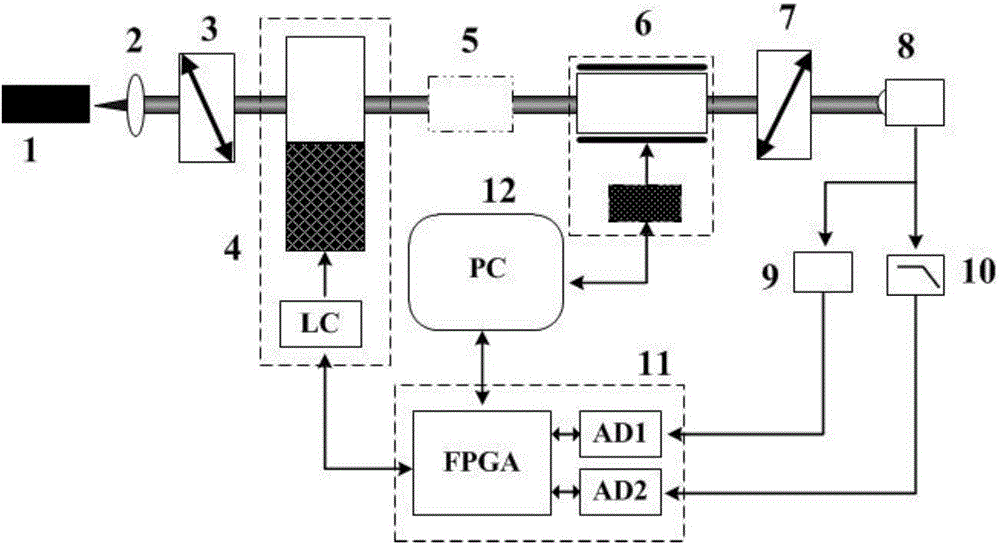

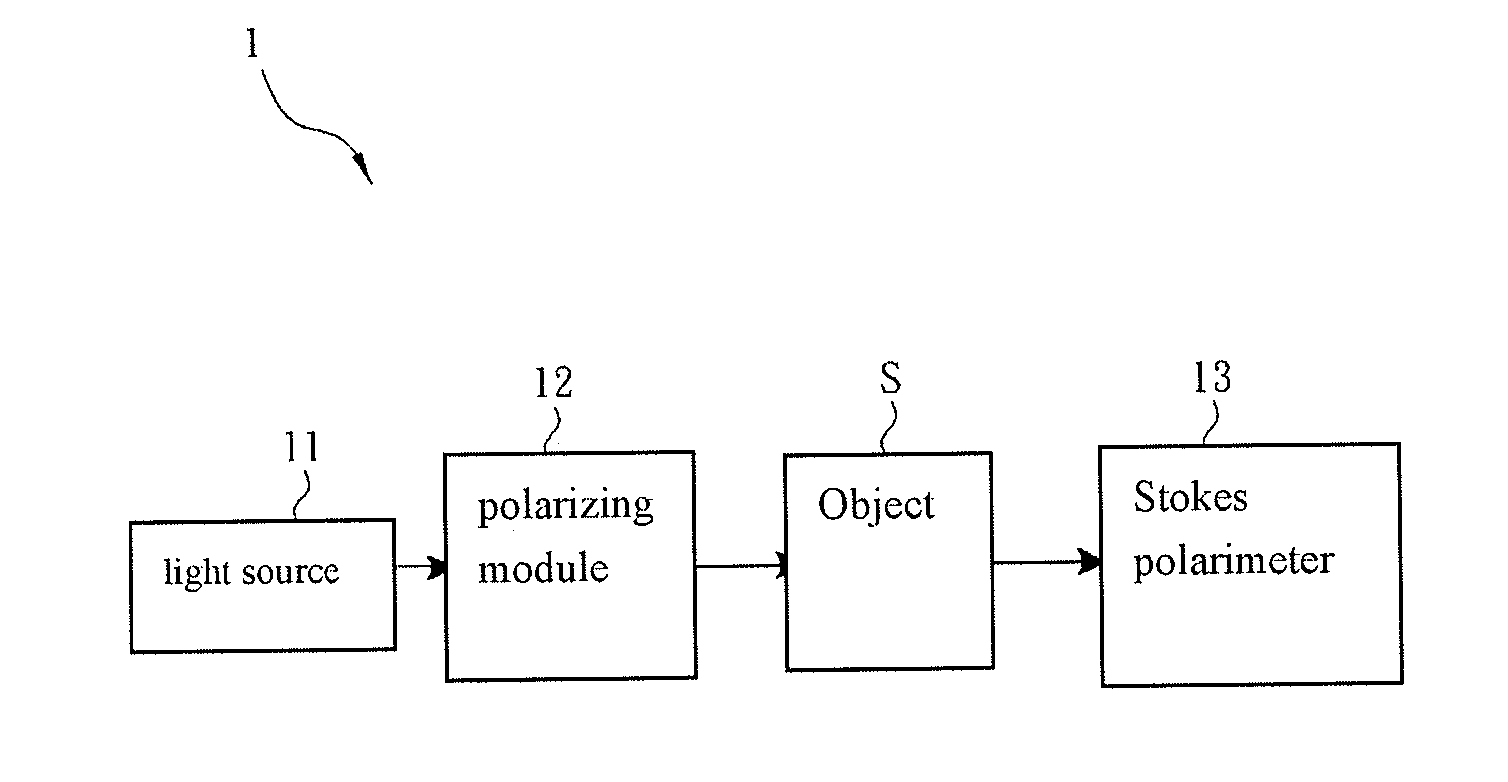

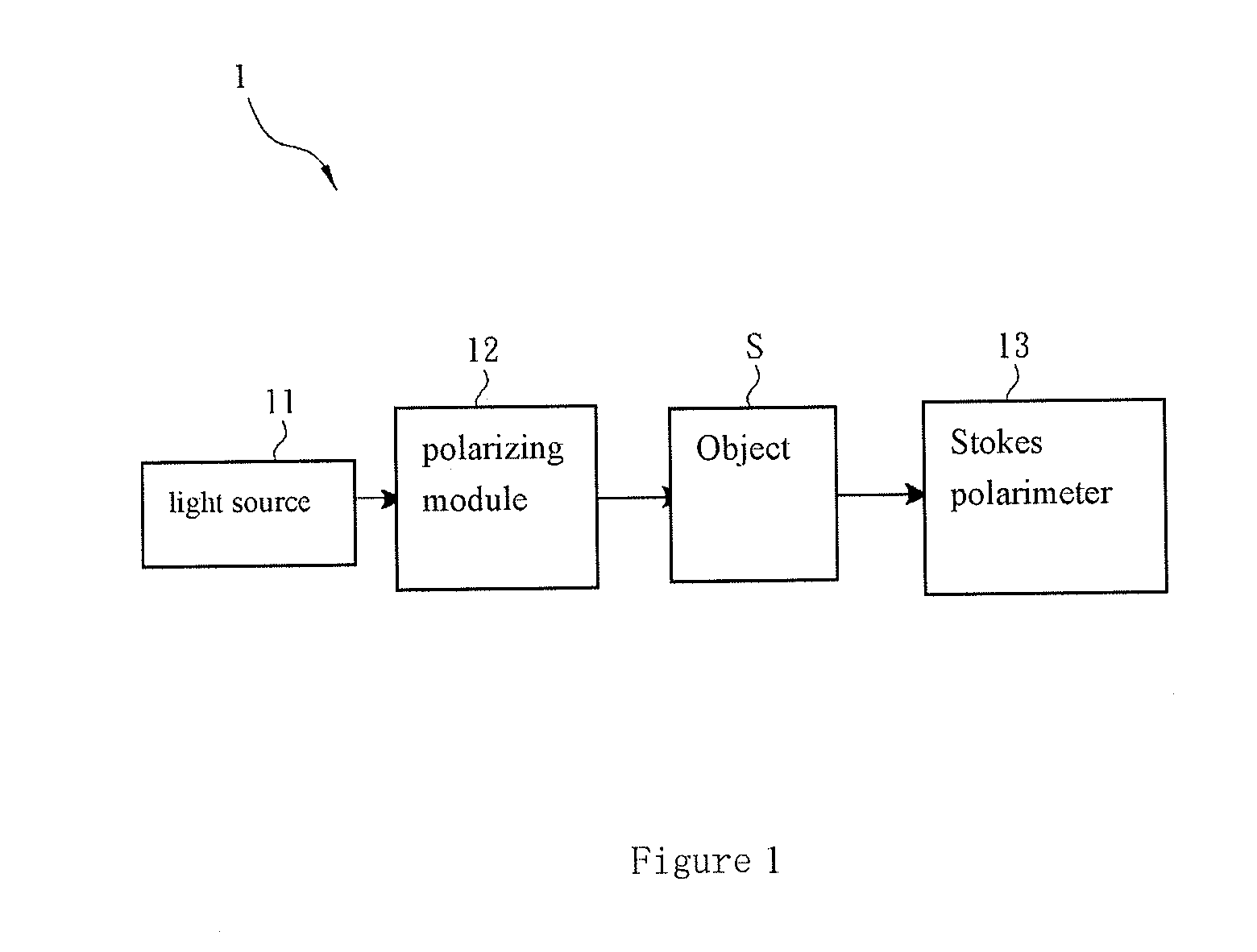

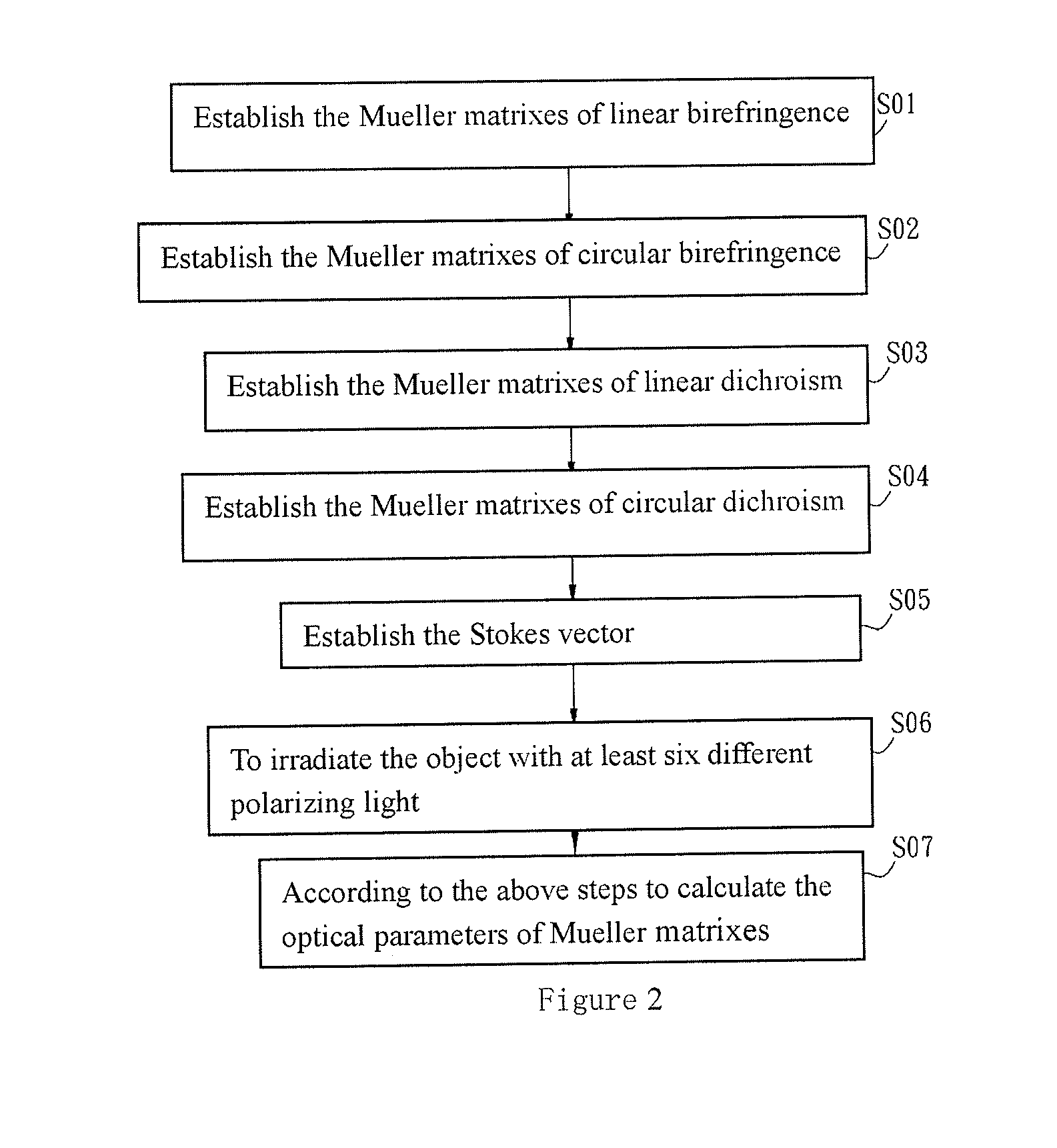

Optical parameter measuring apparatus and optical parameter measuring method

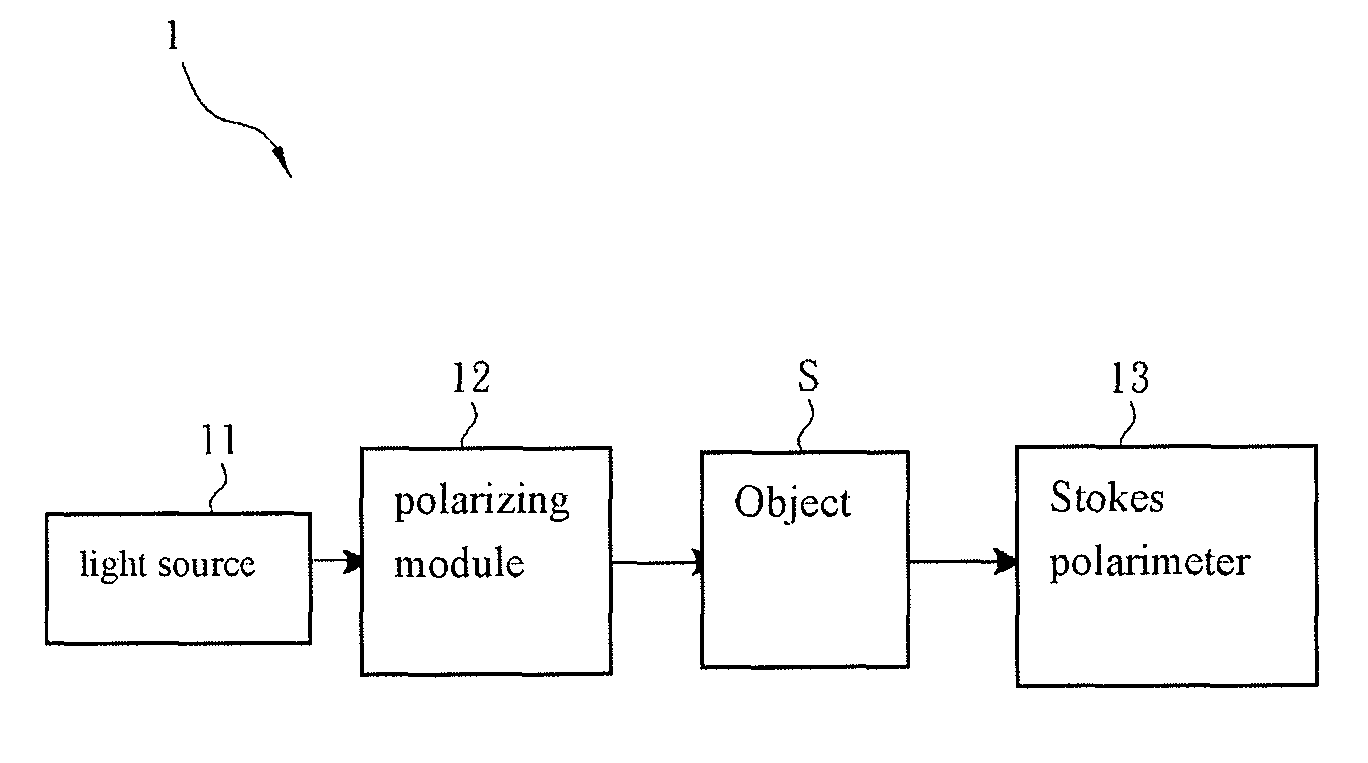

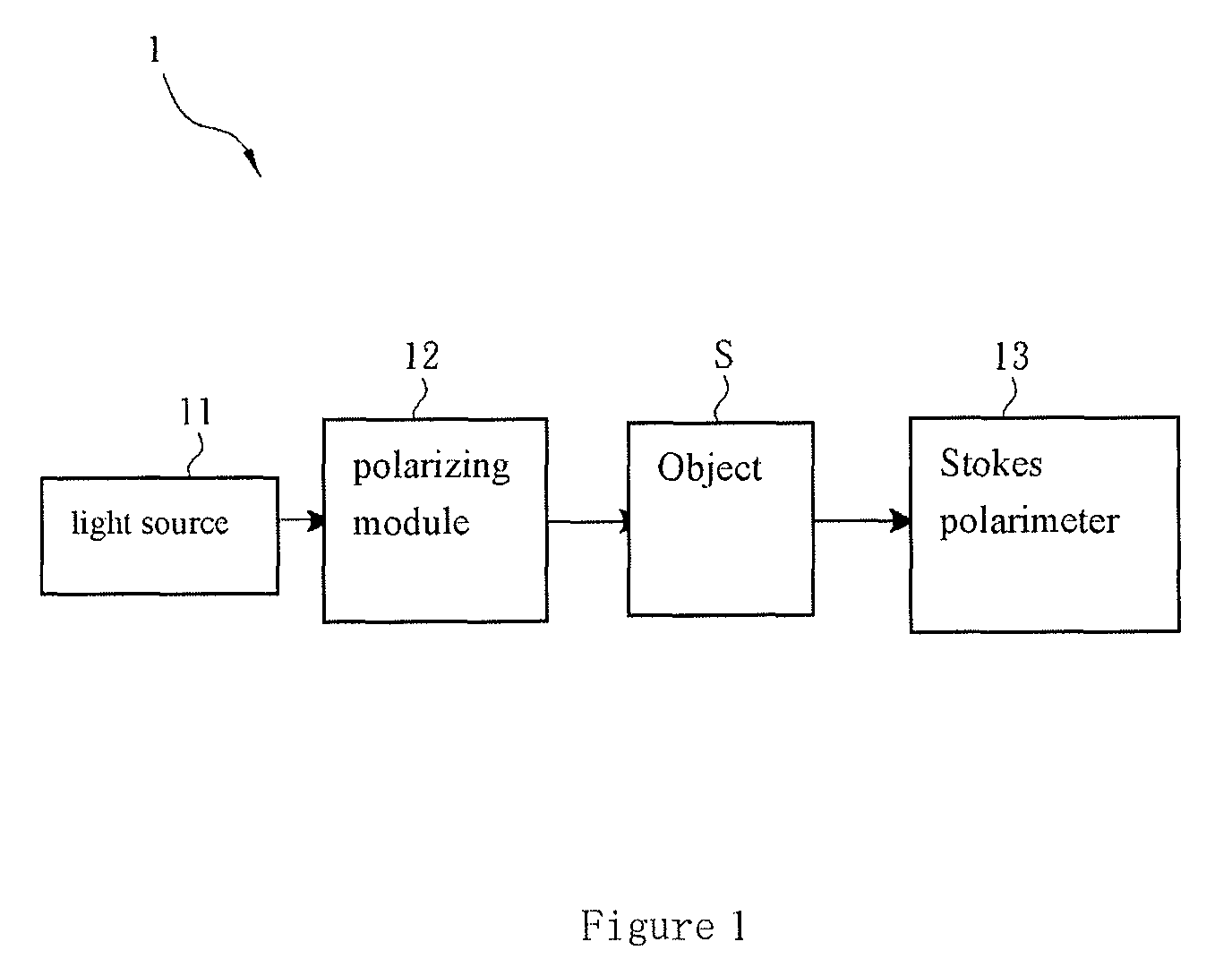

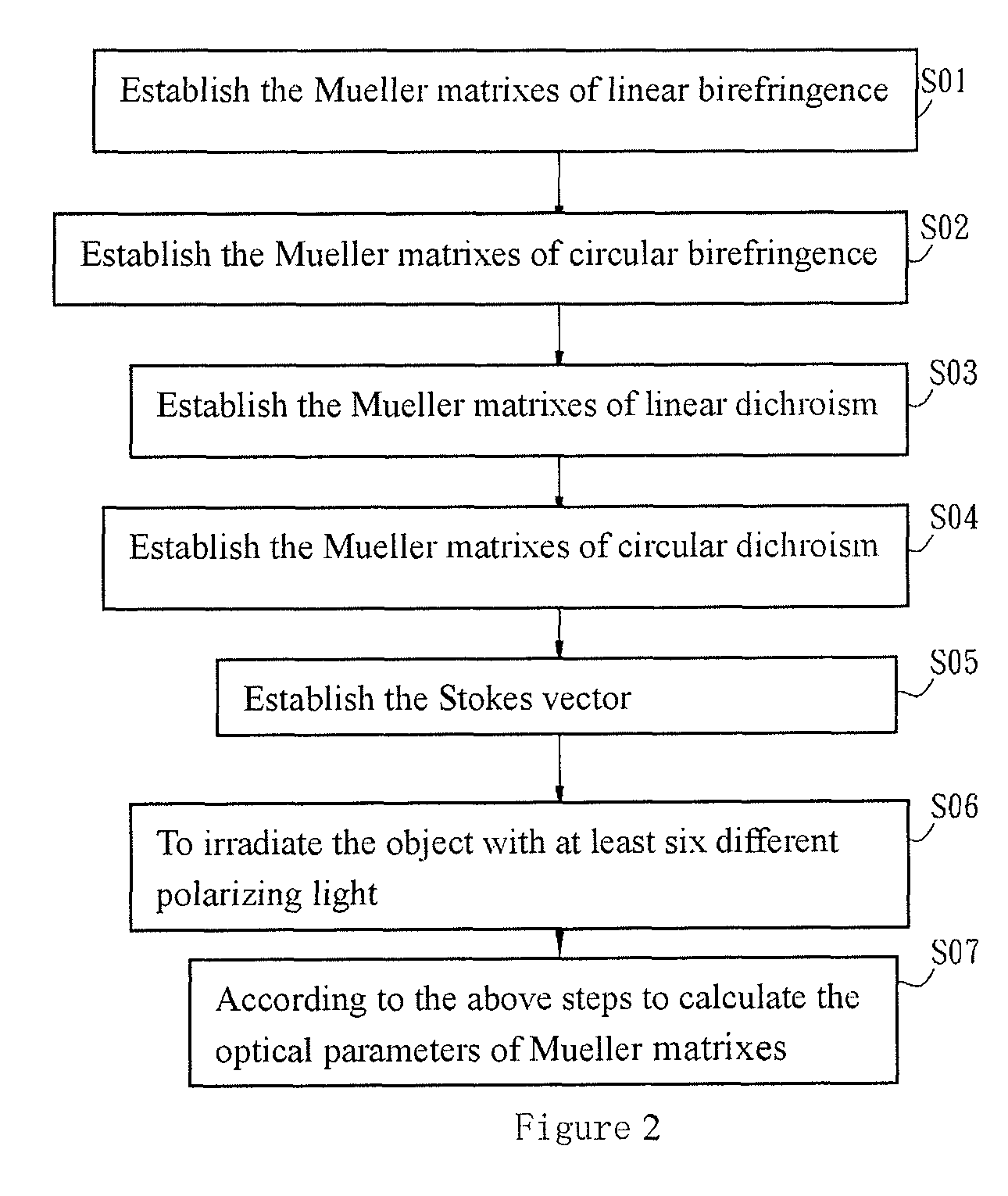

ActiveUS20120212742A1Improve efficiencySubstantial measureLight polarisation measurementLinear birefringencePolarimeter

An optical parameter measuring apparatus for measuring optical parameters of an object includes a light source, a polarizing module, a Stokes polarimeter and a calculating module. The light source emits a light which is polarized by the polarizing module and received by the Stokes polarimeter. According to the light information generated by the Stokes polarimeter, Mueller matrixes of linear birefringence, circular birefringence, linear dichroism, circular dichroism and linear / circular depolarization of the object, and Stokes vector established according to the Mueller matrixes, the calculating module calculates the optical parameters.

Owner:NAT CHENG KUNG UNIV

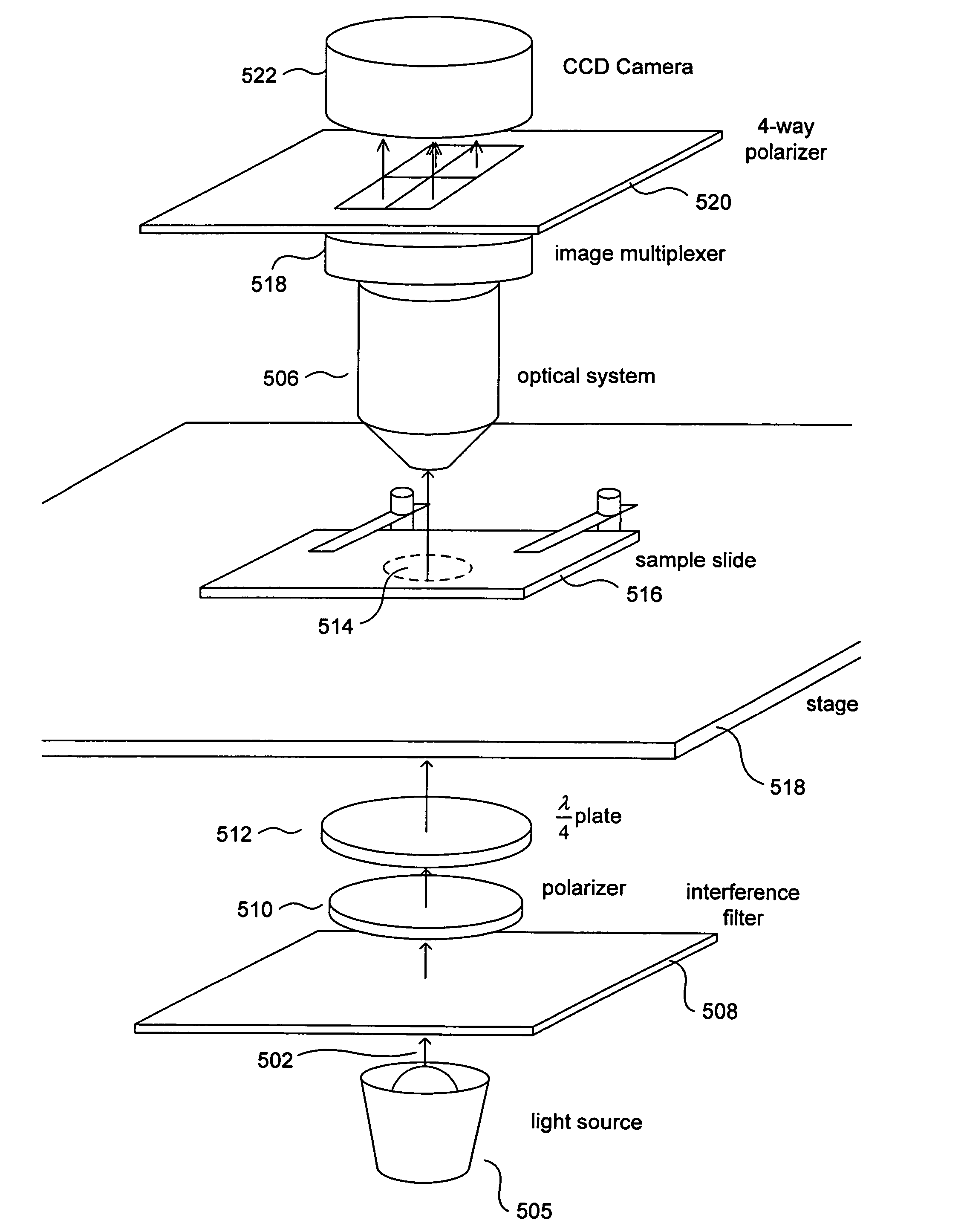

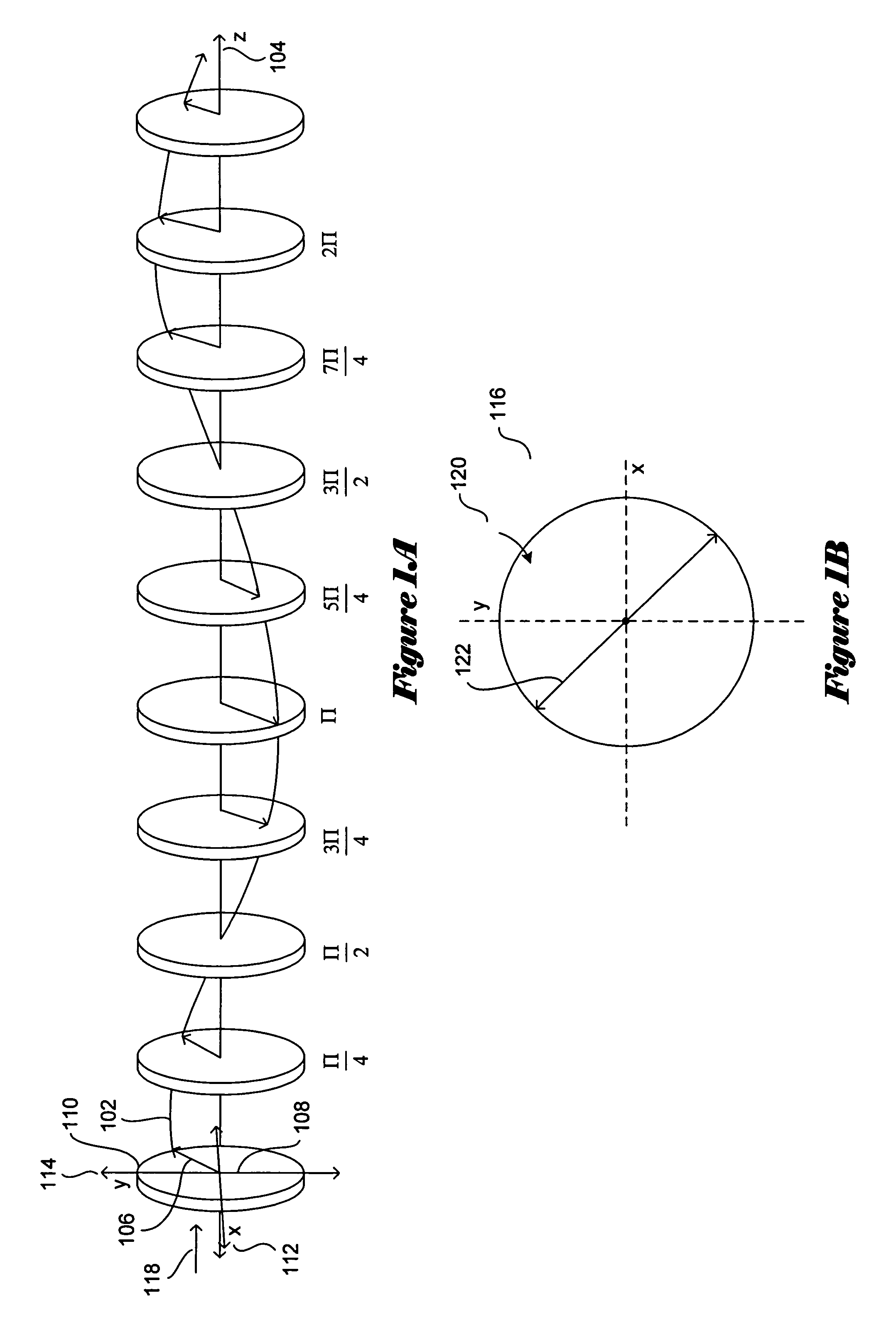

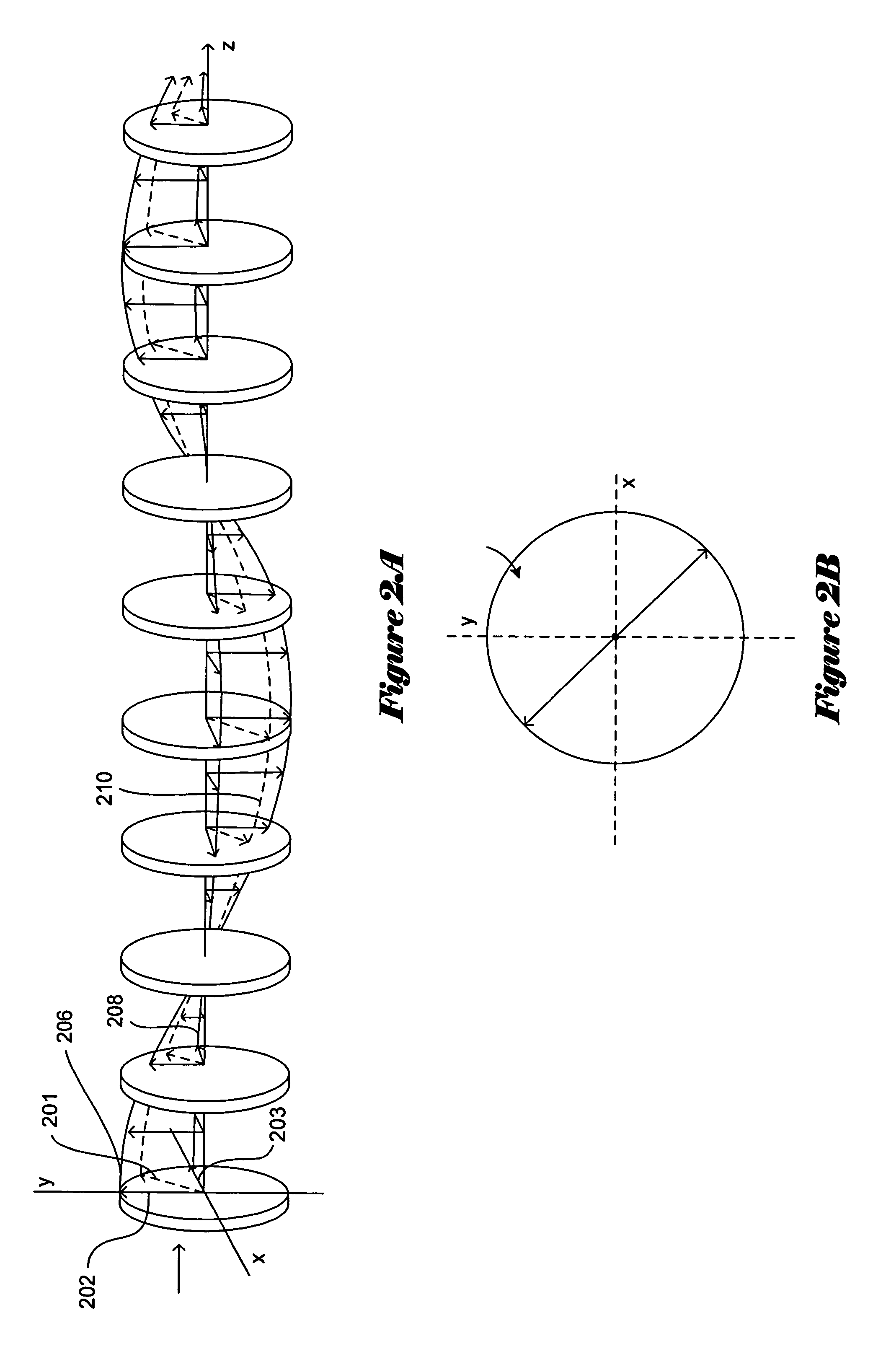

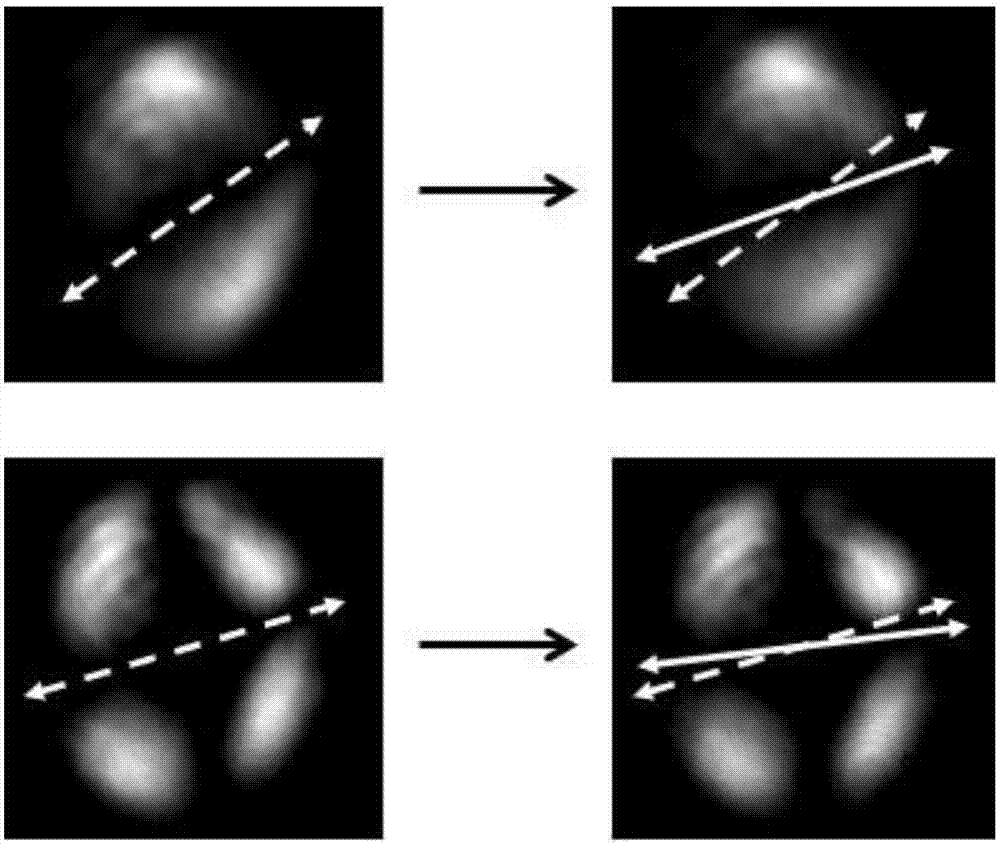

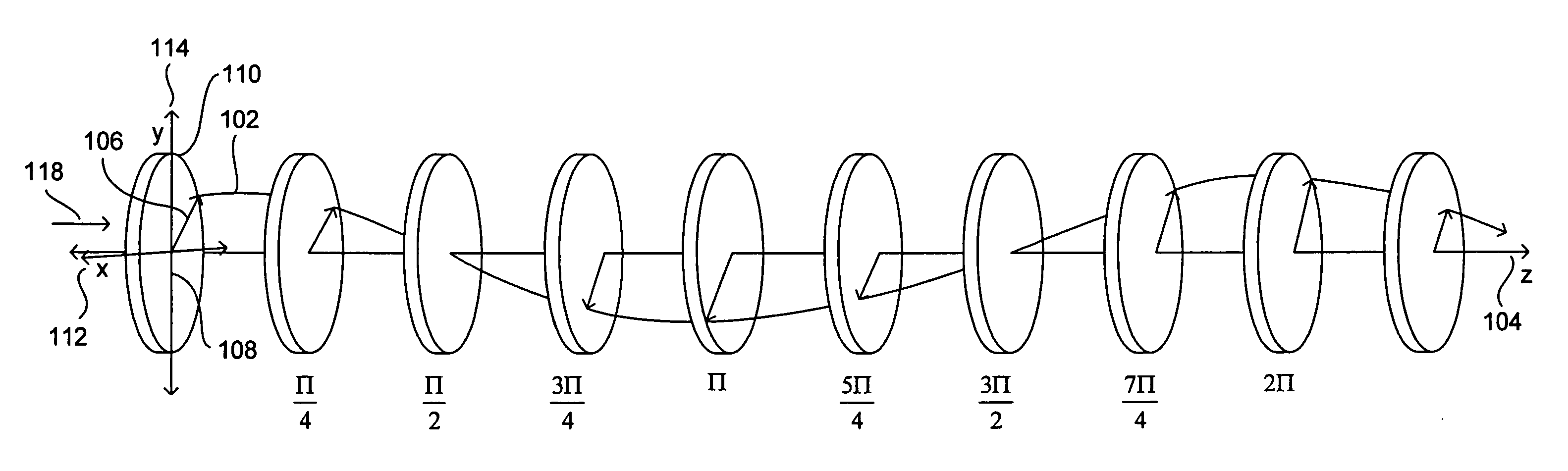

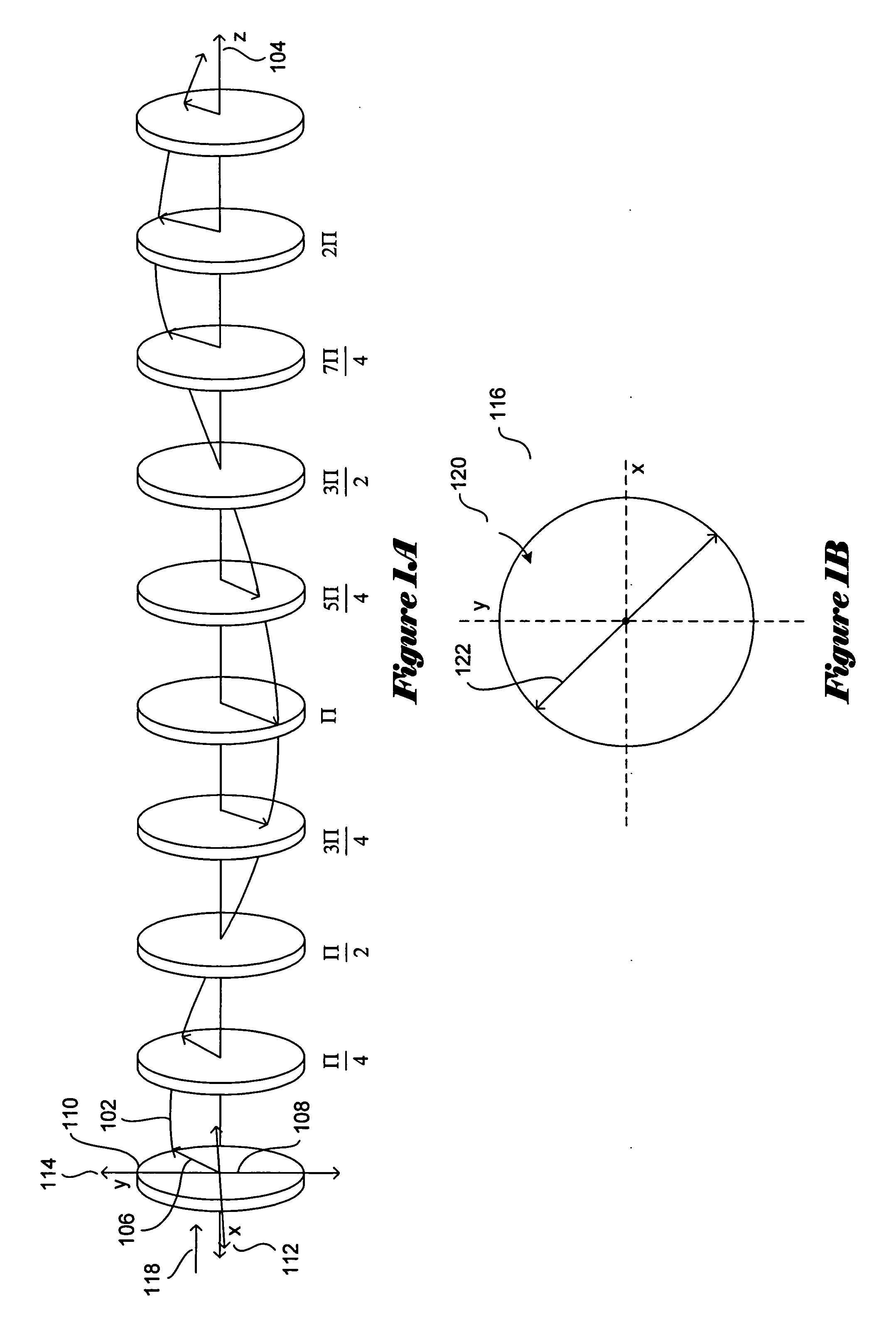

Real-time linear-birefringence-detecting polarization microscope

Various embodiments of the present invention are directed to real-time capture, analysis, and output of polarizing microscopy images that quantify detected LB signals at discrete locations within the image. In one embodiment of the present invention, circularly polarized light is passed through a sample and optically imaged by traditional polarizing-light-microscope components. The resulting image is then split four ways and analyzed by a four-way polarizer / analyzer, and the four resulting analyzed subimages are computationally processed to produce three false-color, real-time images that represent per-pixel linear birefringence, extinction angle, and transmission at each position within a quarter-sized representation of the original image produced by conventional light-microscope imaging components. The false-color images can be produced at a rate of 30 frames per second or at greater rates by employing highly efficient image capture and computational processing of captured images through efficient programming techniques.

Owner:UNIV OF WASHINGTON

Crystal current sensor based on composite optical vortex

ActiveCN107064595AEasy to operateEasy to installVoltage/current isolationOptical elementsBeam polarizationCurrent sensor

The invention discloses a crystal current sensor based on composite optical vortex. A laser emission unit is used to emit a linear polarization state fundamental mode Gaussian beam, and a composite beam generating unit is used to divide the linear polarization state fundamental mode Gaussian beam into two beams, and is used to modulate the two beams into optical vortex beams, which are combined together, and are converted into circular polarization type composite optical vortex beams. A crystal sensing unit is used to transmit the composite optical vortex beams into a crystal along the optical axis of the crystal, and is used to apply the current to the crystal to generate a magnetic field along the direction of the optical axis of the crystal. A detection unit is used to detect the light intensity distributions of the composite optical vortex beams before and after the application of the magnetic field, and the deflection of the composite optical vortex beams occurs, and the current is calculated by calculating the deflection degree, and therefore a current sensing function is realized. The circular polarization state characteristic of the optical vortex during a transmission process is maintained, and the change of the beam polarization state by using Faraday magneto-optic effect can be directly displayed in composite spots, and therefore a problem of reduction of sensitivity of an optical fiber current sensor caused by linear birefringence is effectively solved.

Owner:SHANGHAI UNIV

Linear double refraction measuring device and measuring method

ActiveCN103308175AHigh measurement accuracyLight polarisation measurementGratingAccuracy and precision

The invention discloses a linear double refraction measuring device and measuring method. The linear double refraction measuring device comprises a light source module and a measuring module; the light source module is formed by a collimated light source, a polarizer, a photoelastic modulator, a photoelastic controller and a one-dimensional optical grating; and the measuring module is formed by two polarization analyzers, two photoelectric detectors, two phase-locked amplifiers and a computer. According to the linear double refraction measuring device, the light source module and the measuring module are arranged at the same end of a double refraction sample to be measured, phase delay amount distribution and fast axial azimuth angle distribution are measured through single-end scanning, measuring light beams passes the double refraction sample twice, and the measuring accuracy is improved twice.

Owner:BEIJING GUOWANG OPTICAL TECH CO LTD

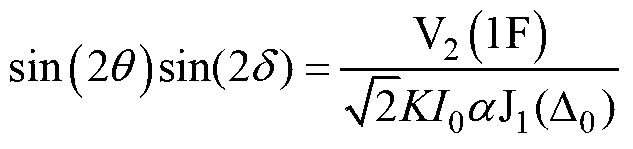

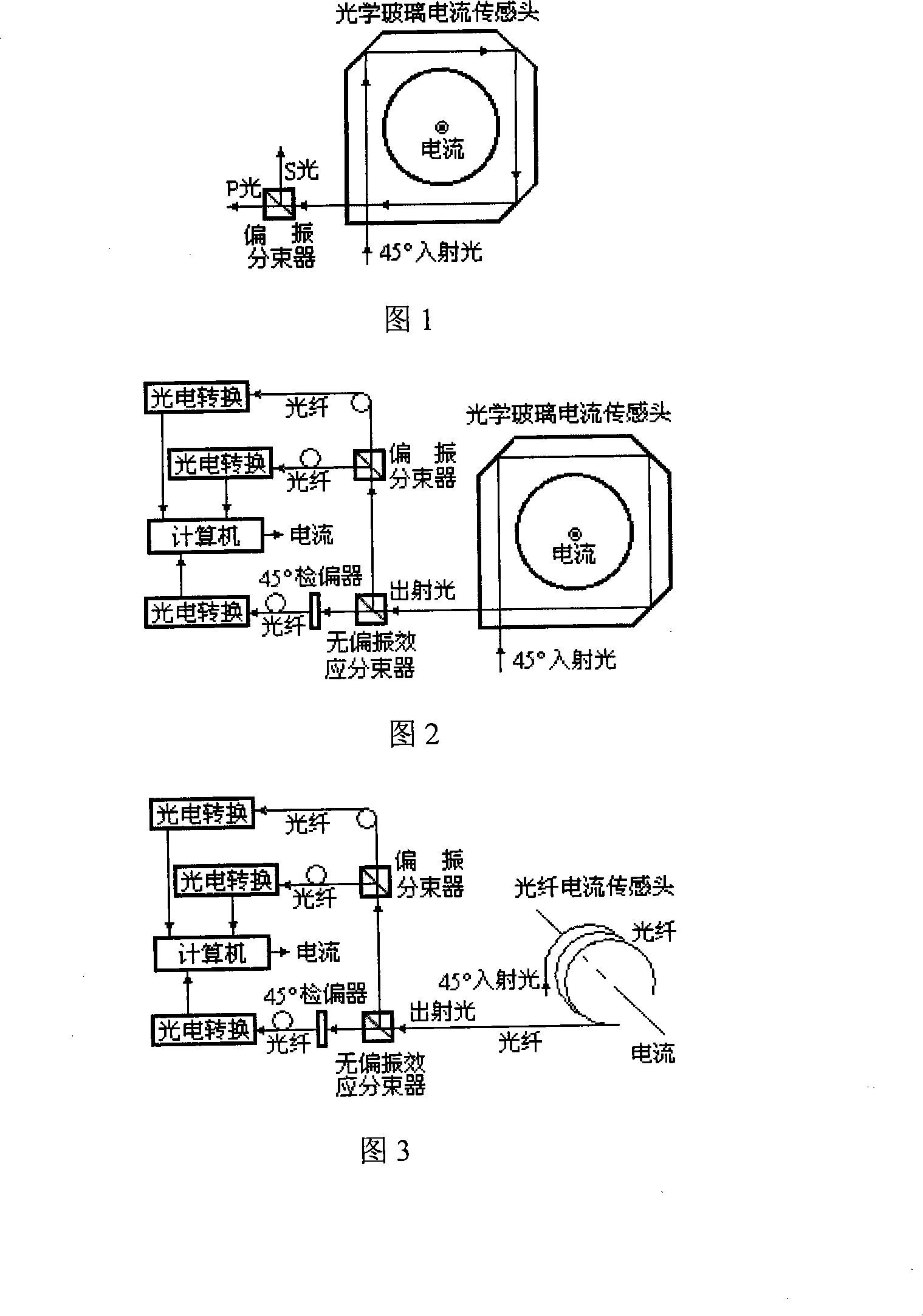

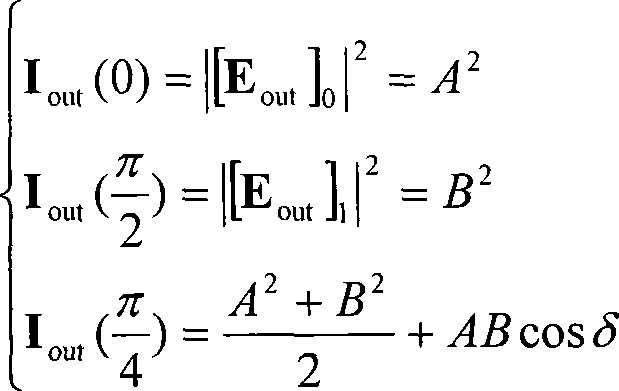

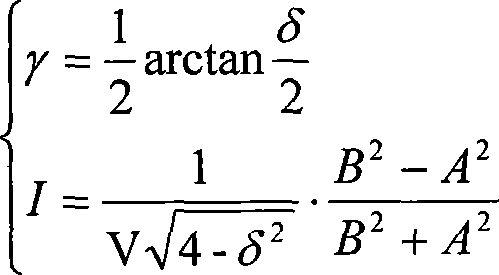

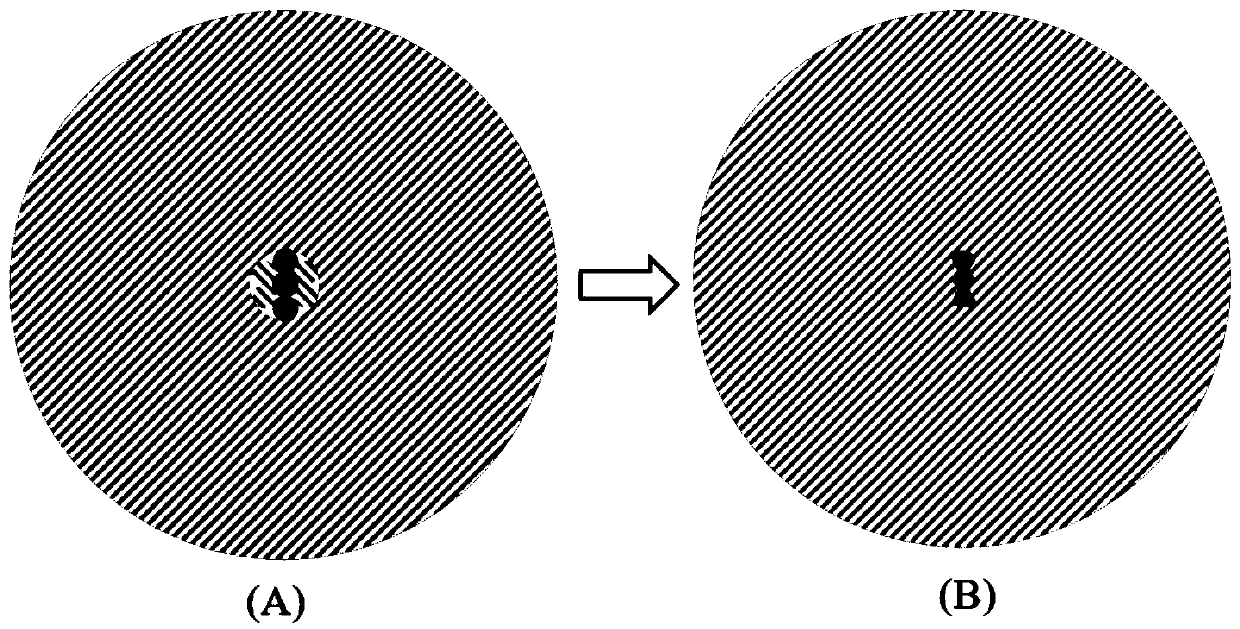

Three state polarization detection method for eliminating linear birefringence influence of optical current transformer

InactiveCN101149401AOvercoming incompletenessAccurate measurementCurrent/voltage measurementEllipseLinear birefringence

This invention provides a kind of triple polarized detection method which can remove the linear birefringence influence in optic current transformer. It measures the light intensity in three direction of polarization of ellipse polarized light output by the optic current transformer, that is the data of the level polarized intensity, the uprightness polarized intensity and the 45 degree with the level direction polarized intensity, uses the triple measurement data calculates the phasic difference information between level polarized component and uprightness polarized component, separates and detect the Faraday effect and linear birefringence in real time. The triple ellipse polarized detection project of ellipse polarized light advances in this invention can realize that the measurement of the linear birefringence and the detected current be correct and in real time by using the Faraday magneto-optic effect optic current transformer, and it can be applied in more broad field of ellipse polarized light measurement.

Owner:HARBIN ENG UNIV

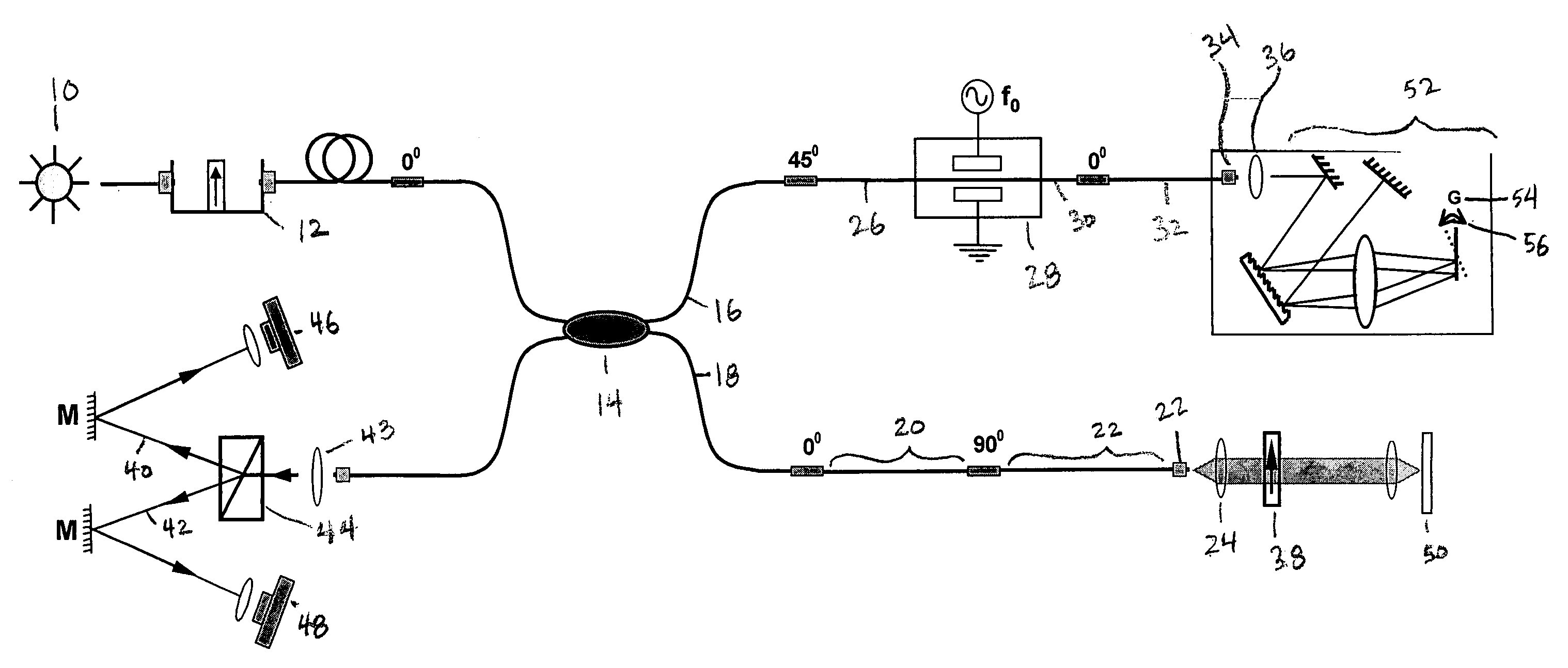

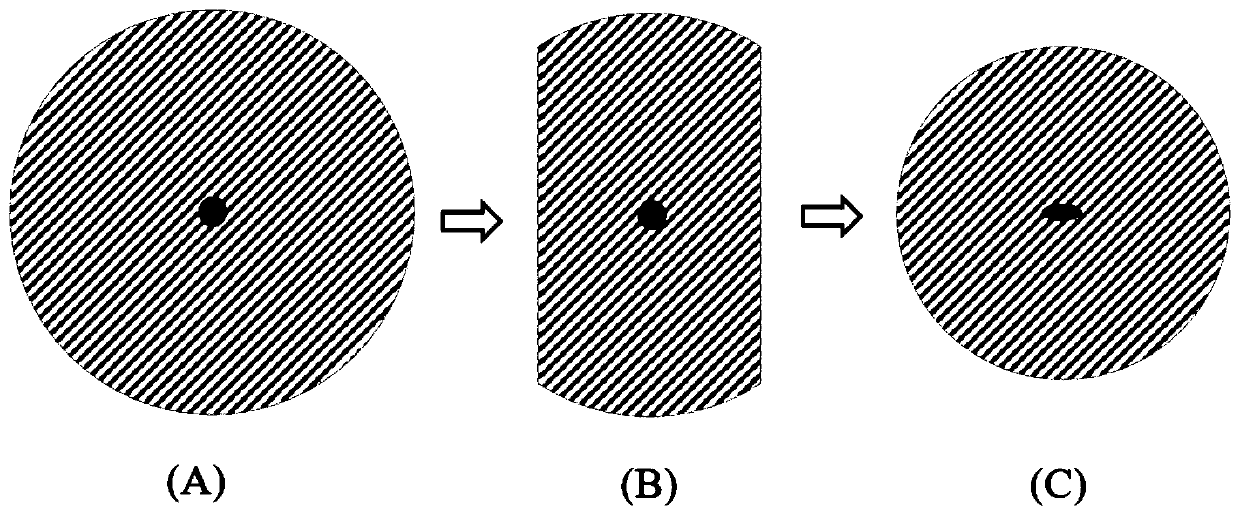

Optical fiber preform for manufacturing elliptical core polarization-maintaining optical fiber and manufacturing process of elliptical core polarization-maintaining optical fiber

InactiveCN110104945AAvoids problems with greatly reduced line birefringence effectsGood process repeatabilityGlass making apparatusLinear birefringencePolarization-maintaining optical fiber

The invention discloses an optical fiber preform for manufacturing an elliptical core polarization-maintaining optical fiber. The optical fiber preform comprises a quartz sleeve, n core rods and N pure quartz rods; the center lines of all the core rods are located in the same plane, the pure quartz rods same in number are symmetrically distributed on both sides of each core rod, the relationship between the inner diameter d0 of the quartz sleeve, the outer diameter d1 of each core rod and the outer diameter d2 of each pure quartz rod satisfies the condition that d1=d2=d0 / n, and the relationship between the number N of the pure quartz rods, the number n of the core rods and the distribution column number C of the pure quartz rods on one side of each core rod satisfies the condition that n=2C+1, wherein n is an odd number greater than one. The invention also provides a manufacturing process of the elliptical core polarization-maintaining optical fiber. The optical fiber preform is meltedat the high temperature, the core rods are melted to form an elliptical core, the pure quartz rods are fused with the quartz sleeve to form an elliptical core optical fiber cladding layer, and wire drawing is carried out to prepare the birefringent elliptical core polarization-maintaining optical fiber. The fiber core of the optical fiber preform is formed in a high-temperature melting process within a short time, and the situation is avoided that thermal diffusion of the fiber core is caused by high-temperature melting of the preform for a long time and thus effective linear birefringence issignificantly reduced.

Owner:上海康阔光智能技术有限公司

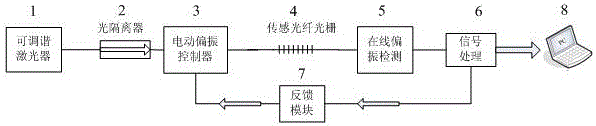

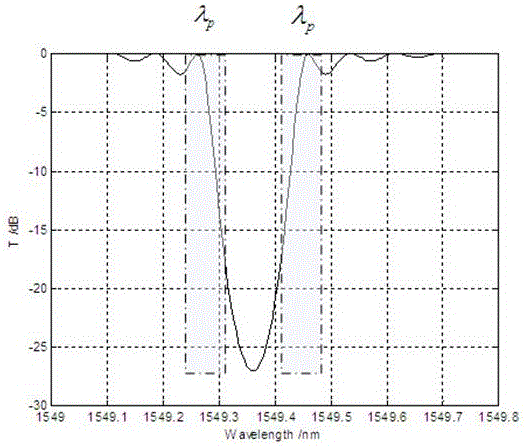

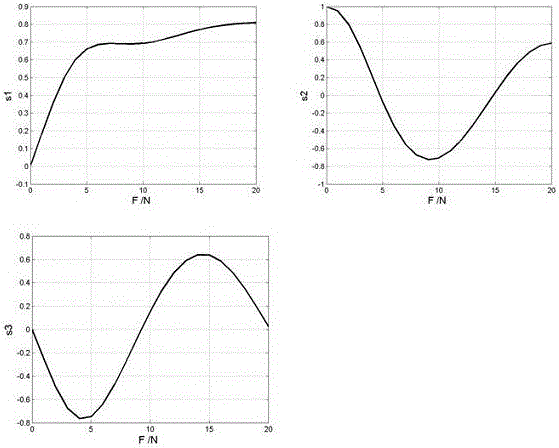

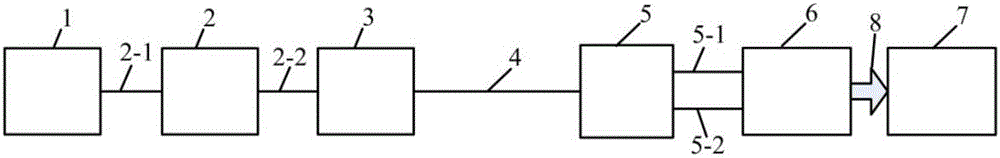

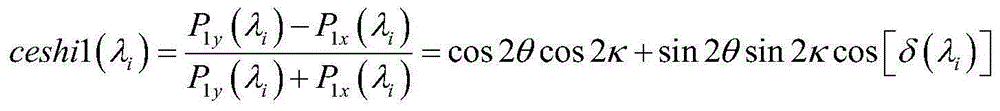

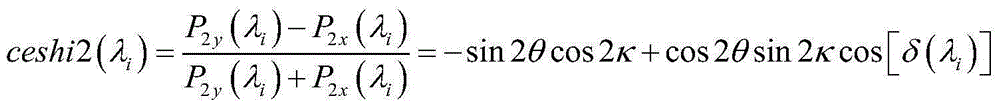

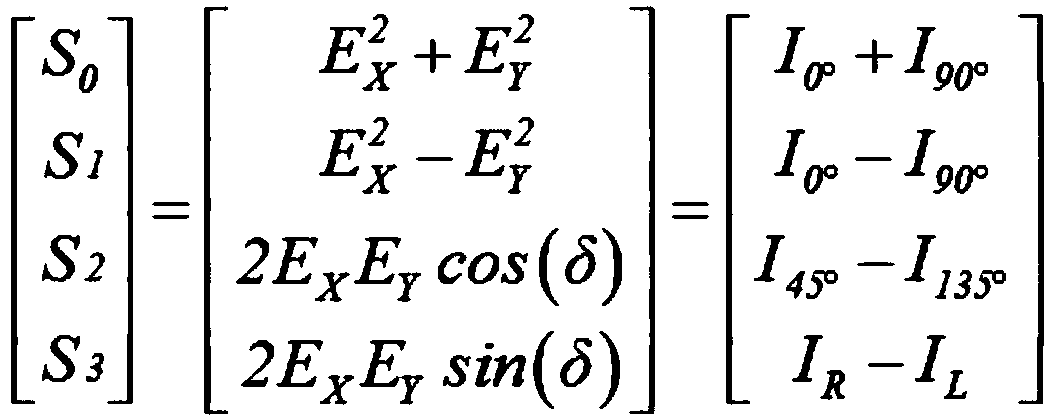

Dynamic pressure detection system and method based on fiber grating Stokes parameters

ActiveCN105698986AOvercoming the disadvantages of being unsuitable for small pressure sensingForce measurement by measuring optical property variationGratingFiber gratings

The invention discloses a dynamic pressure detection system and a method based on fiber grating Stokes parameters. The system comprises a tunable laser, an electric polarization controller, a sensing fiber grating, a polarization detection module, a signal processing module, a feedback module and a display unit, wherein the tunable laser emits laser of a certain wavelength and feeds the laser to the electric polarization controller and to the sensing fiber grating; the online polarization detection module acquires laser transmitted from the sensing fiber grating, the laser is outputted to the signal processing module, and three Stokes parameters for the polarization state of the transmitted laser are obtained; and the signal processing module feeds back the parameters to the electric polarization controller to adjust the polarization state of incident laser. Linear birefringence is generated by the fiber grating under effects of external pressure, three parameters for the transmitted laser are caused to change, a single-wavelength source is adopted to realize real-time sensing on the size of the dynamic pressure, the defect that the traditional method is not suitable for small pressure sensing can be overcome, and the defect that the sensing method based on the grating polarization parameter maximum value is not suitable for dynamic pressure sensing can be solved.

Owner:PLA UNIV OF SCI & TECH

Polarization control-based single mode fiber linear birefringence measuring device and method

ActiveCN105136680ARealize high-precision measurementAngle QuantizationMaterial analysis by optical meansPigtailOptoelectronics

The invention discloses a polarization control-based single mode fiber linear birefringence measuring device. The polarization control-based single mode fiber linear birefringence measuring device comprises a broadband light source, a polarization controller, a high speed polarization state analyzer, a polarization beam splitter, an optical spectrum analyzer, and an industrial personal computer; the output interface of the broadband light source is connected with an input fiber pigtail of the polarization controller; an output fiber pigtail of the polarization controller is connected with the input interface of the high speed polarization state analyzer; the output interface of the high speed polarization state analyzer is connected with a single mode fiber to be tested, and the single mode fiber is also taken as an input fiber pigtail of the polarization beam splitter; an output fiber pigtail of the polarization beam splitter is connected with the optical spectrum analyzer; and the optical spectrum analyzer is connected with the industrial personal computer via RS232 data line. The invention also discloses a measuring method. The polarization control-based single mode fiber linear birefringence measuring device and the measuring method are capable of eliminating influences of an angle between the polarization direction of linearly polarized light and the birefringence main axis of the single mode fiber on linear birefringence measurement, quantizing the angle between the birefringence main axis of the single mode fiber and the polarization principal axis of the polarization beam splitter, and realizing high accuracy measuring of single mode fiber linear birefringence.

Owner:CHINA UNIV OF MINING & TECH

Real-time linear-birefringence-detecting polarization microscope

Various embodiments of the present invention are directed to real-time capture, analysis, and output of polarizing microscopy images that quantify detected LB signals at discrete locations within the image. In one embodiment of the present invention, circularly polarized light is passed through a sample and optically imaged by traditional polarizing-light-microscope components. The resulting image is then split four ways and analyzed by a four-way polarizer / analyzer, and the four resulting analyzed subimages are computationally processed to produce three false-color, real-time images that represent per-pixel linear birefringence, extinction angle, and transmission at each position within a quarter-sized representation of the original image produced by conventional light-microscope imaging components. The false-color images can be produced at a rate of 30 frames per second or at greater rates by employing highly efficient image capture and computational processing of captured images through efficient programming techniques.

Owner:UNIV OF WASHINGTON

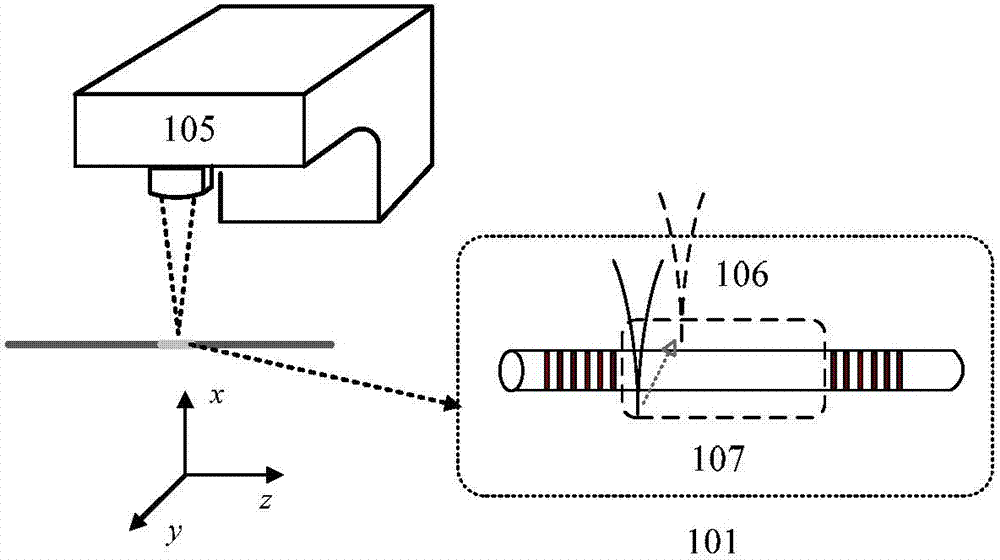

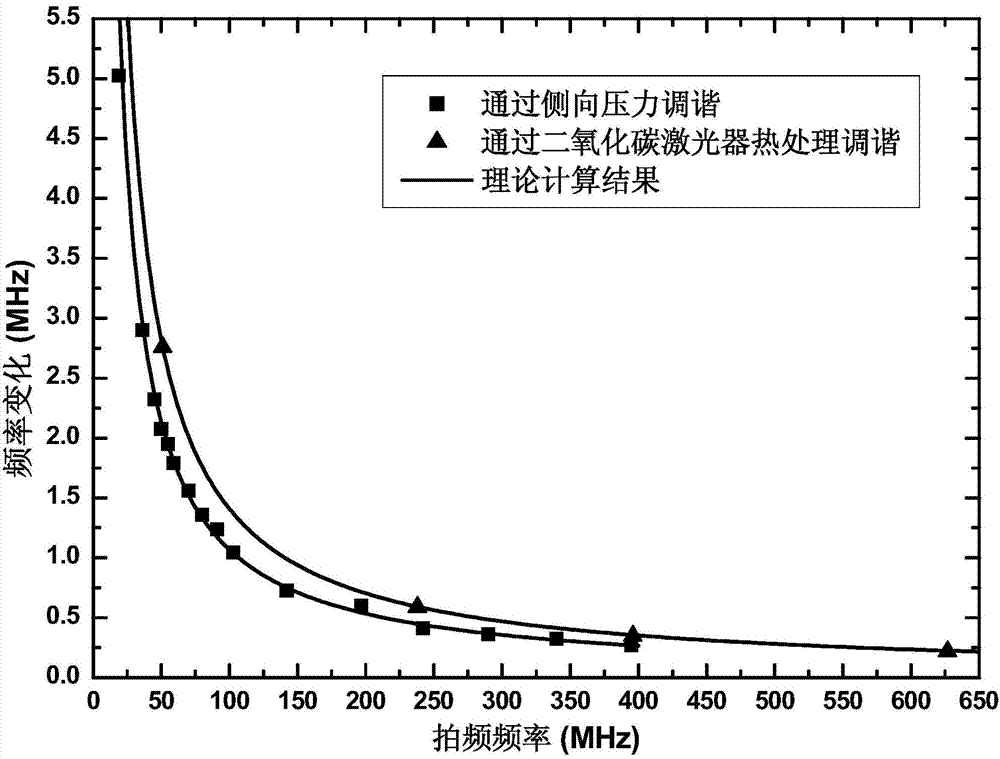

Magnetic field sensor sensitivity tuning method based on fiber bragg grating laser

InactiveCN103616649AChange sensitivityHigh sensitivityMagnetic field measurement using magneto-optic devicesFiberGrating

The invention provides a magnetic field sensor sensitivity tuning method based on a fiber bragg grating laser. Linear birefringence produced in a laser cavity and circular birefringence caused by a to-be-tested magnetic field are combined to form elliptic birefringence; the fiber bragg grating laser works in a single longitudinal mode biorthogonal polarization state and produces two laser outputs; after passing through a polarizer, the two laser outputs are input into a photoelectric detector to be mixed so as to produce a beat frequency signal; by detecting frequency changes of the beat frequency signal, changes of elliptic birefringence are calculated, and the intensity of the to-be-tested magnetic field is figured out; by means of the process means of extruding optical fibers by applying lateral pressure or conducting heat treatment on the optical fibers by adopting laser lateral irradiation or the like, the magnitude of linear birefringence in the laser cavity of the fiber bragg grating laser, and magnetic field sensor sensitivity tuning can be achieved. The magnetic field sensor sensitivity tuning method has the advantages of being simple, strong in adaptability, and capable of changing sensitivity temporarily or permanently, and individually meeting actual requirements of different applications.

Owner:JINAN UNIVERSITY

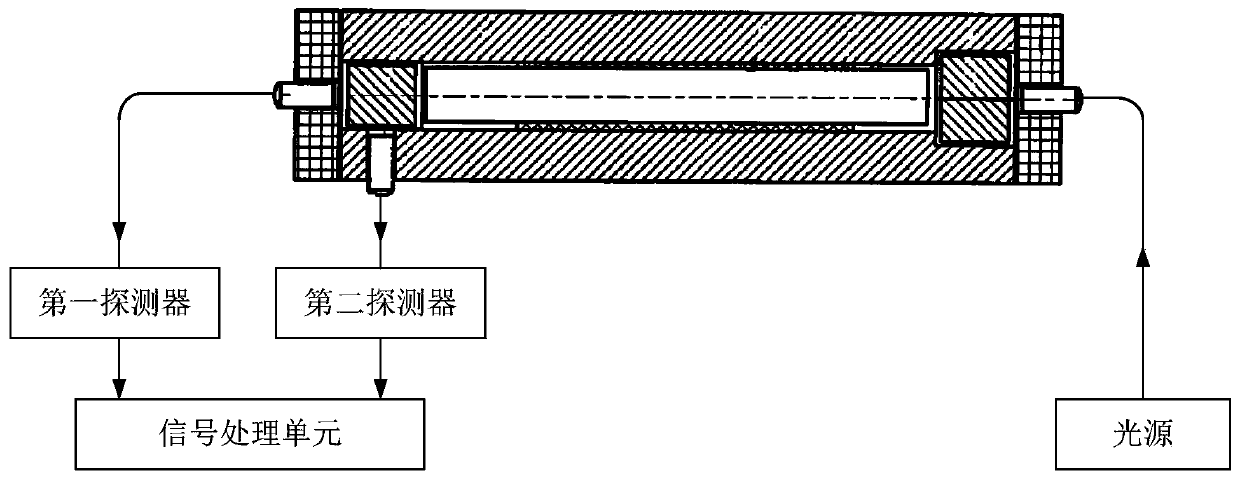

Dual-optical-path optical current sensor

ActiveCN110007125AAccurate measurementEliminate the effects of output stabilityCurrent measurements onlyBeam splitterCurrent sensor

A double-optical-path optical current sensor relates to the field of current measurement. The invention aims to solve the problem that the current direct-current component or the non-periodic component cannot be accurately measured due to linear birefringence and incident declination deviation of the existing optical current sensor. Light output by a light source is divided into two light beams through an optical fiber beam splitter, and one light beam sequentially passes through a first optical fiber collimator, a first polarization splitting prism, a magneto-optical glass light beam, a second polarization splitting prism and a second optical fiber collimator to be incident to a first detector; the other beam of light sequentially passes through a third optical fiber collimator, a secondpolarization splitting prism, a magneto-optical glass light beam, a first polarization splitting prism and a fourth optical fiber collimator and is incident to a second detector; and the electric signal output end of the first detector and the electric signal output end of the second detector are simultaneously connected with the electric signal input end of the signal processing unit. The methodis used for accurately measuring the direct current component or the non-periodic component.

Owner:HARBIN INST OF TECH +2

Linear double-refraction measuring device and method for glass material

ActiveCN107764748AAvoid errorsImprove measurement accuracyMaterial analysis by optical meansFour quadrantsLinear birefringence

The invention discloses a linear double-refraction measuring device and a linear double-refraction measuring method for a glass material. The device comprises a light source module and a measuring module; the measuring module comprises a four-quadrant detector, a focusing objective lens and an image sensor which are arranged sequentially; the four-quadrant detector comprises four light channels; and line polaroids with the polarization directions of 0 degree, 45 degrees, 90 degrees and 135 degrees are arranged on the four light channels correspondingly. Linear double-refraction measurement ofthe glass material does not relate to rotation and mechanical motion of a polarizing device, and the polarization information is the polarization information of to-be-detected light at the same time,so error caused by fluctuation of the light source and the mechanical rotation of the polarizing device can be overcome and the measuring accuracy is improved.

Owner:苏州东辉光学有限公司

Optical parameter measuring apparatus and optical parameter measuring method

ActiveUS9036151B2Improve efficiencySubstantial measureLight polarisation measurementLinear birefringencePolarimeter

An optical parameter measuring apparatus for measuring optical parameters of an object includes a light source, a polarizing module, a Stokes polarimeter and a calculating module. The light source emits a light which is polarized by the polarizing module and received by the Stokes polarimeter. According to the light information generated by the Stokes polarimeter, Mueller matrixes of linear birefringence, circular birefringence, linear dichroism, circular dichroism and linear / circular depolarization of the object, and Stokes vector established according to the Mueller matrixes, the calculating module calculates the optical parameters.

Owner:NAT CHENG KUNG UNIV

A method for measuring magneto-optical Kerr signal

ActiveCN108680875BReduce the impact of measurement accuracyImprove signal-to-noise ratioMagnetisation measurementsMaterial analysis by optical meansLow-pass filterPolarization-maintaining optical fiber

Owner:嘉兴诺恩医疗科技有限公司

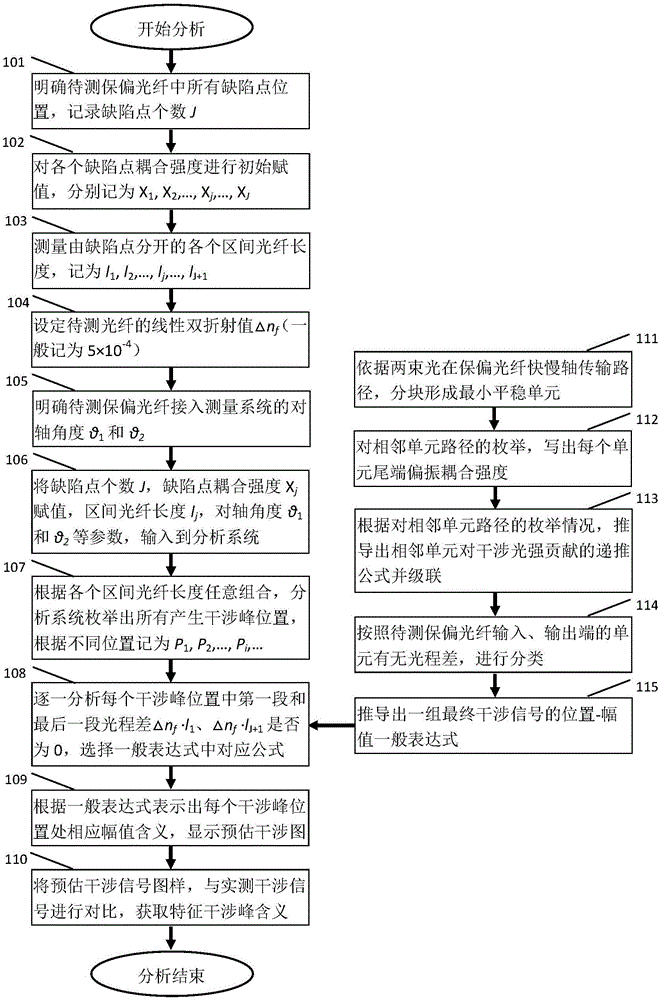

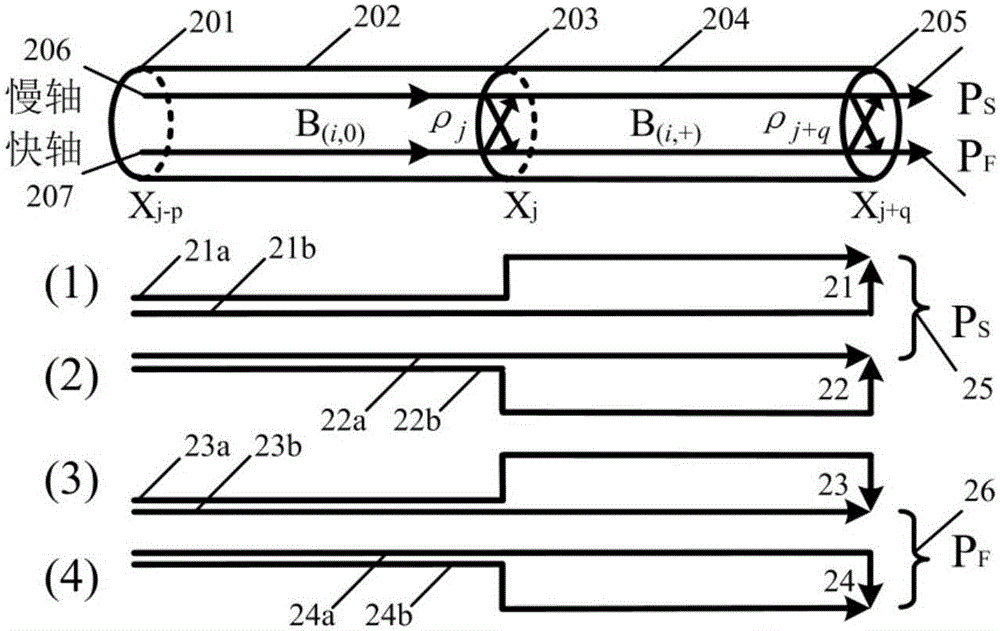

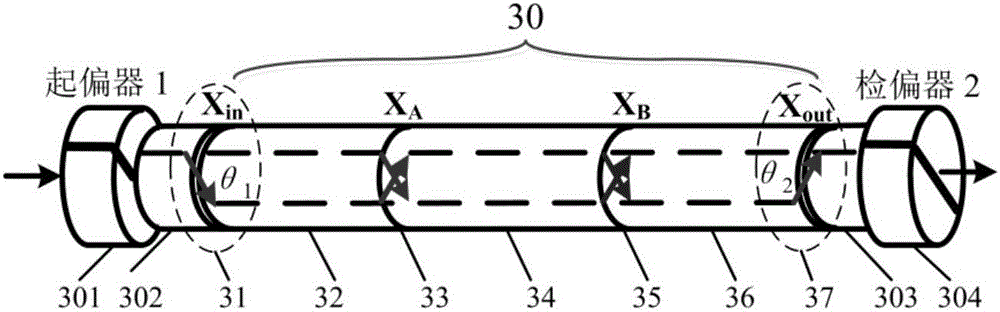

Method of pre-estimating position-amplitude meaning of interference peak in polarization maintaining optical fiber defect point detection

ActiveCN106323596AThe calculation process is simpleReduce computing timeTesting fibre optics/optical waveguide devicesLinear birefringenceAngular degrees

The invention belongs to the optical fiber measuring field, to be specific, relates to a method of pre-estimating position-amplitude meaning of an interference peak in polarization maintaining optical fiber defect point detection. A number and corresponding positions of all of defect points of a to-be-measured polarization maintaining optical fiber are determined, and the number of the defect points is recorded; the initial valuation of the coupling intensities of the various defect points is carried out; when the to-be-measured polarization maintaining optical fiber is measured, lengths of interval optical fibers divided by the defect points are measured; the linear birefringence of every interval optical fiber of the to-be-measured polarization maintaining optical fiber is set; the countershaft angle of the to-be-measured polarization maintaining optical fiber connected with a measuring system is determined; the number of the defect points, the coupling intensities of the defect points, the lengths of the interval optical fibers, and the countershaft angle are input in an analyzing system for analysis. The position-intensity general expression of the interference peak is deduced. By giving the scanning optical path of the position, a required formula is directly selected to acquire the amplitude meaning of the interference peak, and a calculation process is simplified, and calculation time is saved.

Owner:HARBIN ENG UNIV

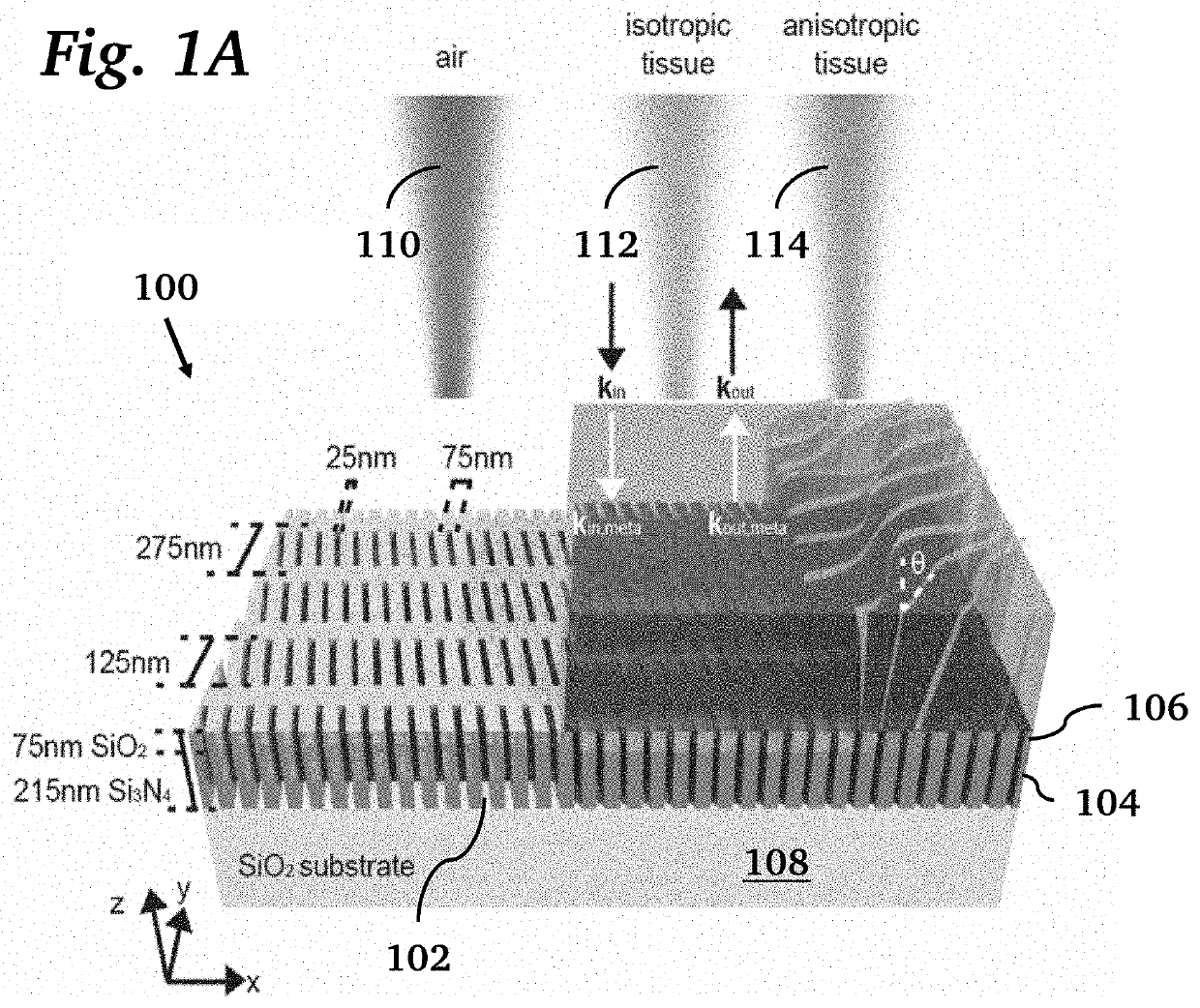

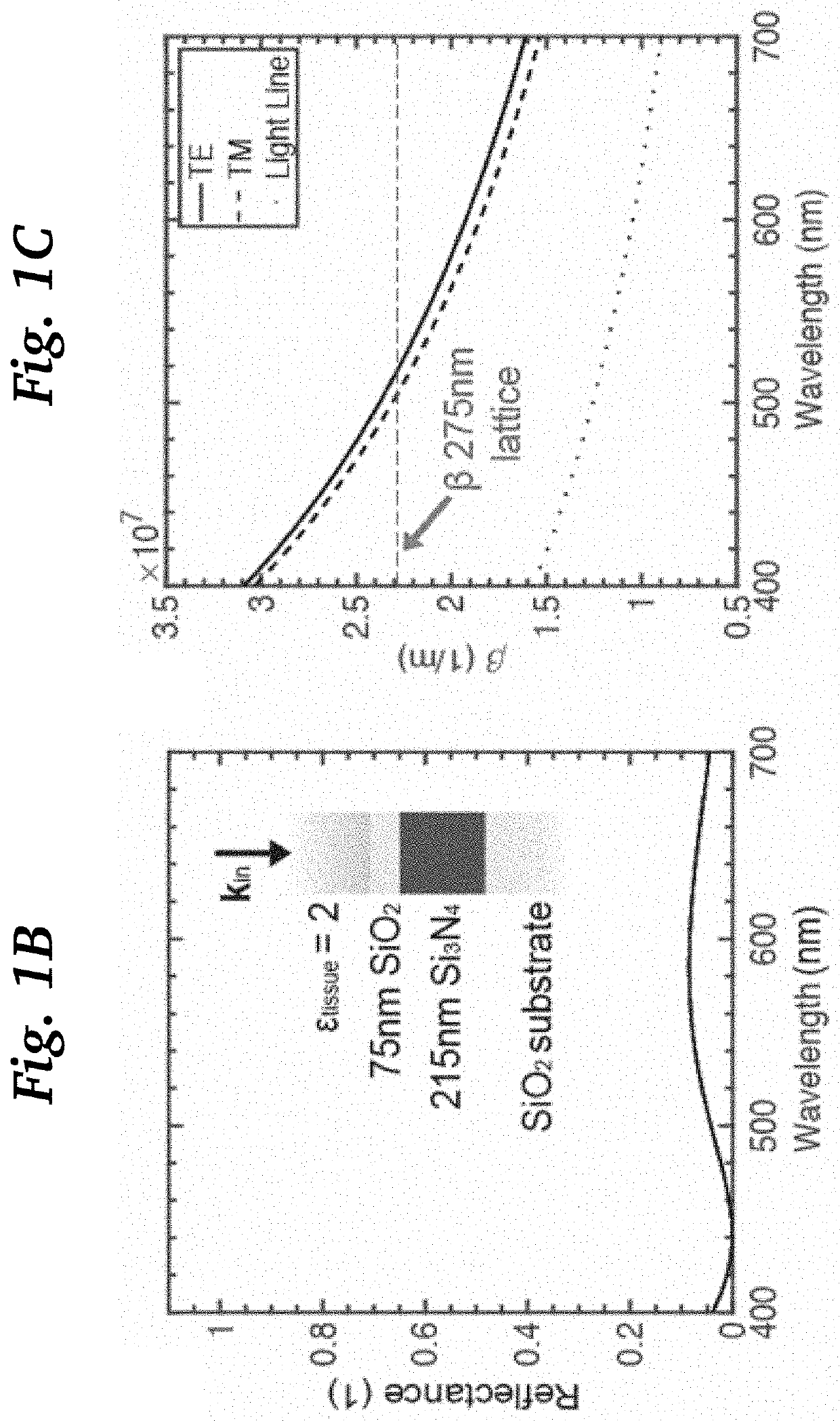

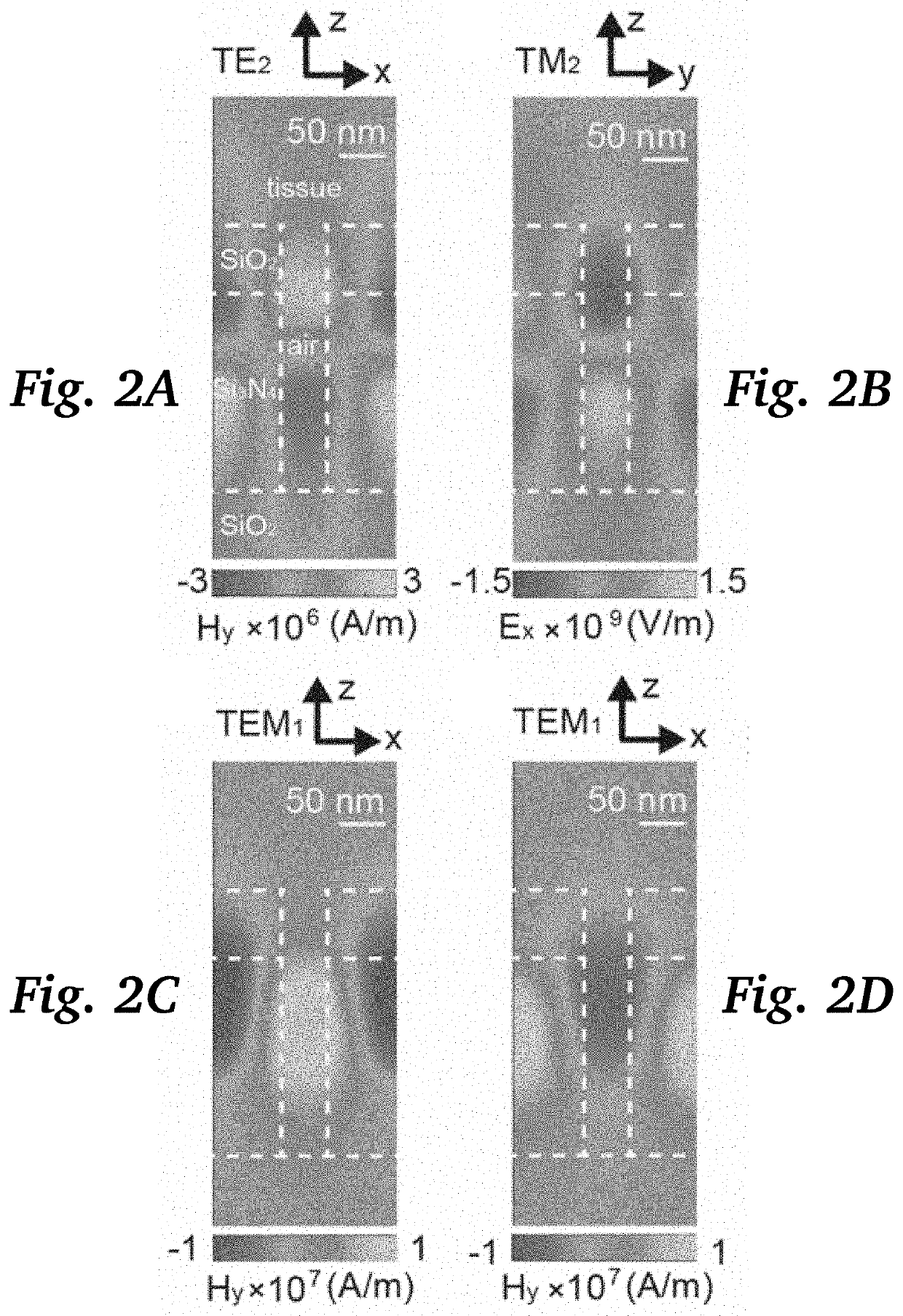

Metasurfaces for optical detection of tissue and fibrous material anisotropy

ActiveUS20210088819A1Narrow bandwidthImprove performanceFluorescence/phosphorescenceNon-linear opticsLinear birefringenceWavelength range

A metasurface optical device composed of three stacked dielectric layers which form an anti-reflective structure for wavelengths in a predetermined operational wavelength range within the visible spectrum. The anti-reflective structure contains a rectangular lattice of rhombohedral perturbations that produce guided-mode resonances within the predetermined operational wavelength range. The guided-mode-resonant dielectric metasurface device is capable of detecting by colorimetric readout the presence and orientation of a linearly birefringent anisotropic medium, such as a fibrous tissue, positioned above the stacked dielectric layers.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Faraday mirror optical current transformer for transformer substation

InactiveCN102590578AEnhanced ability to resist linear birefringence interferenceCurrent/voltage measurementVoltage/current isolationSignal processing circuitsPrism

The invention discloses a faraday mirror optical current transformer for a transformer substation. The faraday mirror optical current transformer comprises a light-emitting diode (LED) light source, a polarizing prism, an optical current sensing head, a polarization beam splitter, a first photoelectric transducer, a second photoelectric transducer, a signal processing circuit, a non-polarization beam splitter, and a faraday mirror; the non-polarization beam splitter is arranged between the incident surface of the polarizing prism and the incident surface of the optical current sensing head; a polarized light emergence optical axis of the non-polarization beam splitter is coincided with the incident optical axis of the polarization beam splitter; the faraday mirror is arranged below the emergence surface of the optical current sensing head; and the mirror surface of the faraday mirror is opposite and parallel to the emergence surface of the optical current sensing head. Due to the polarized light reflection action of the faraday mirror, light surrounds a current-carrying conductor twice in the optical current sensing head, and the polarization plane is rotated 90 degrees before and after reflection; and according to an Ampere circuital theorem, linear birefringence interference resistance capacity of the faraday mirror optical current transformer is enhanced obviously.

Owner:CHENGDU CHUANGTU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com