Crystal current sensor based on composite optical vortex

A technology of crystal current and composite light, applied in voltage/current isolation, optics, instruments, etc., can solve the problem of reducing the sensitivity of fiber optic current transformers, and achieve the effects of improving measurement accuracy and accuracy, easy installation, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention are described in detail as follows:

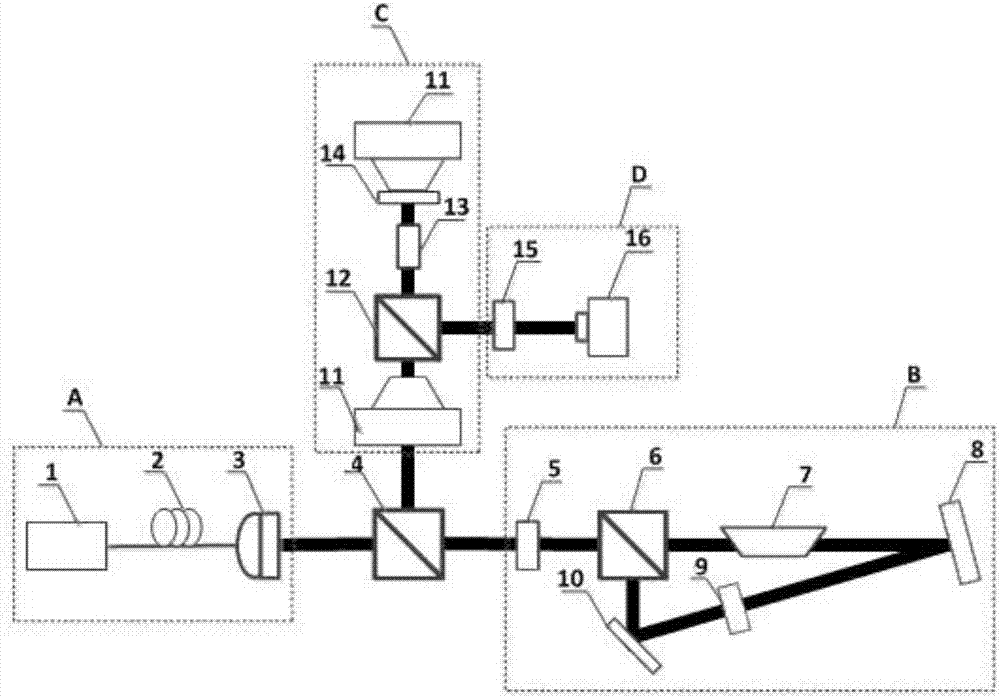

[0027] In this example, see figure 1, a crystal current sensor based on a composite optical vortex, including a laser emitting unit A, a front-end non-polarizing beam splitter 4, a composite beam generating unit B, a crystal sensing unit C and a detection unit D, and the output end of the laser emitting unit A Connect the input end of the front-end non-polarizing beam splitter 4, the input end and the output end of the composite beam generating unit B are both connected to the signal end of the front-end non-polarizing beam splitter 4, and the output end of the front-end non-polarizing beam splitter 4 is connected to the crystal sensor The input end of the unit C, the output end of the crystal sensing unit C is connected to the input end of the detection unit D; the laser emitting unit A is used to output the fundamental mode Gaussian beam of the linear polarization state, and the Gauss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com