A method for measuring magneto-optical Kerr signal

A signal measurement, magneto-optical Kerr technology, applied in magnetic properties measurement, magnetization measurement, magnetic field measurement using magneto-optical equipment, etc., can solve problems affecting measurement accuracy, affecting signal accuracy, and low signal-to-noise ratio , to reduce the impact of stray light, improve the signal-to-noise ratio, and reduce the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

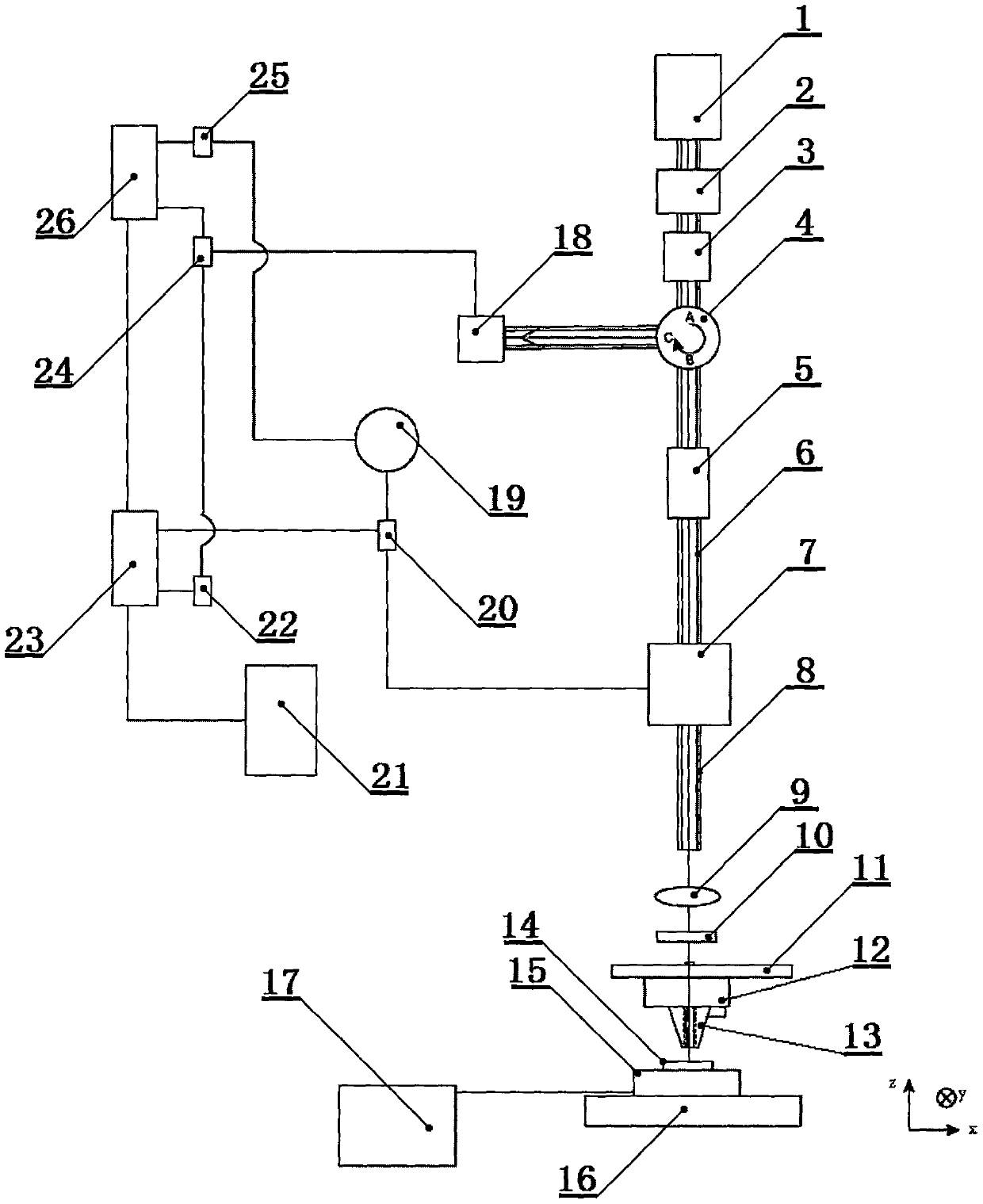

[0022] Such as figure 1It is a schematic diagram of the present invention, the lower right corner has an xyz three-dimensional direction mark, xyz is a spatial rectangular coordinate system, the xy plane is a horizontal plane, and the zx plane is perpendicular to the horizontal plane. The measuring device mainly includes a laser 1, a polarization controller 2, an isolator 3, and a polarization-maintaining ring 4, polarizer 5, polarization maintaining fiber I6, electro-optic modulator 7, polarization maintaining fiber II8, aspheric mirror 9, 1 / 4 wave plate 10, lens stand 11, atomic force microscope 12, probe 13, sample 14, magnet 15 , sample stage 16, power supply 17, photodetector 18, signal generator 19, power divider I20, computer 21, low-pass filter 22, lock-in amplifier I23, frequency multiplier 24, power divider II25, lock-in amplifier II26. The incident light path and the reflected light path. The isolator 3 has two ports, the entrance and the exit, and the light beam ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com