Magnetic field sensor and measurement method based on fiber Bragg grating laser

A technology of magnetic field sensor and optical fiber grating, which is applied in the direction of magnetic field measurement, magnetic field size/direction and other directions using magneto-optical equipment. Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

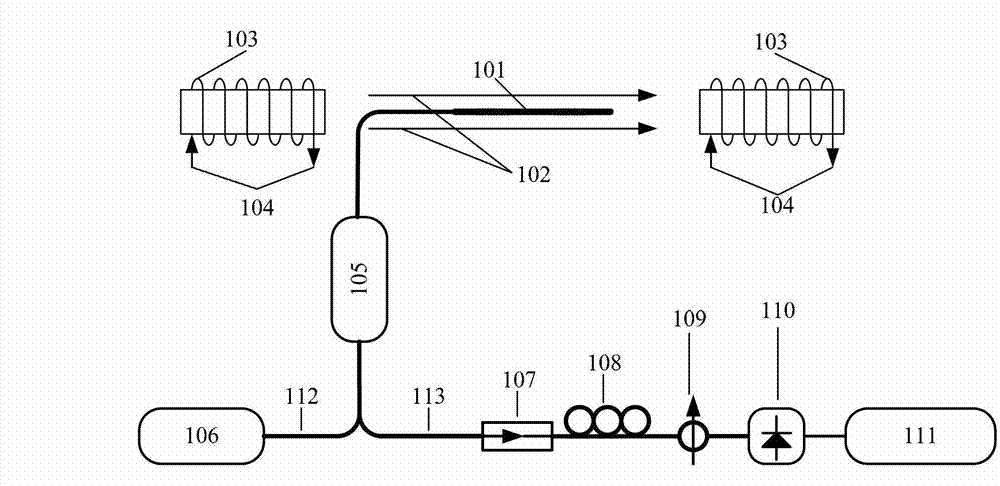

[0022] Such as figure 1 As shown, the present invention includes fiber grating laser 101, wavelength division multiplexer 105, isolator 107, polarization controller 108, polarizer 109 and photodetector 110 connected in sequence, and the Pumping light source 106, pumping light source 106 produces the light 112 that wavelength is 980 nanometers, and what transmit between isolator 107 and wavelength division multiplexer 105 is the light 113 that wavelength is 1550 nanometers; Described fiber grating laser 101 places In the axial magnetic field 102 to be measured. The fiber grating laser is a short-cavity fiber grating laser produced by conventional techniques on rare earth element-doped fibers. Due to the linear birefringence caused by factors such as the non-ideal circular shape of the fiber, the short-cavity fiber grating laser itself will produce the same The two polarization states of a longitudinal mode are orthogonal to the laser output, and there is a certain difference i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com