Optical fiber preform for manufacturing elliptical core polarization-maintaining optical fiber and manufacturing process of elliptical core polarization-maintaining optical fiber

A technology of optical fiber preform and polarization-maintaining optical fiber, which is applied in the field of optical fiber, can solve the problems of low line birefringence and poor consistency, and achieve the effects of high line birefringence effect and good process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

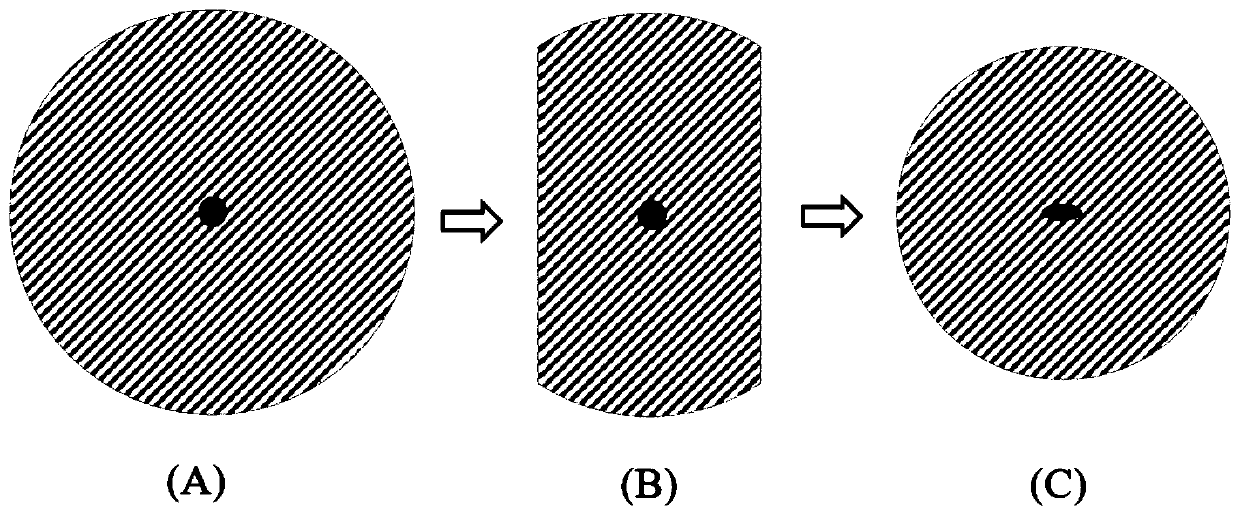

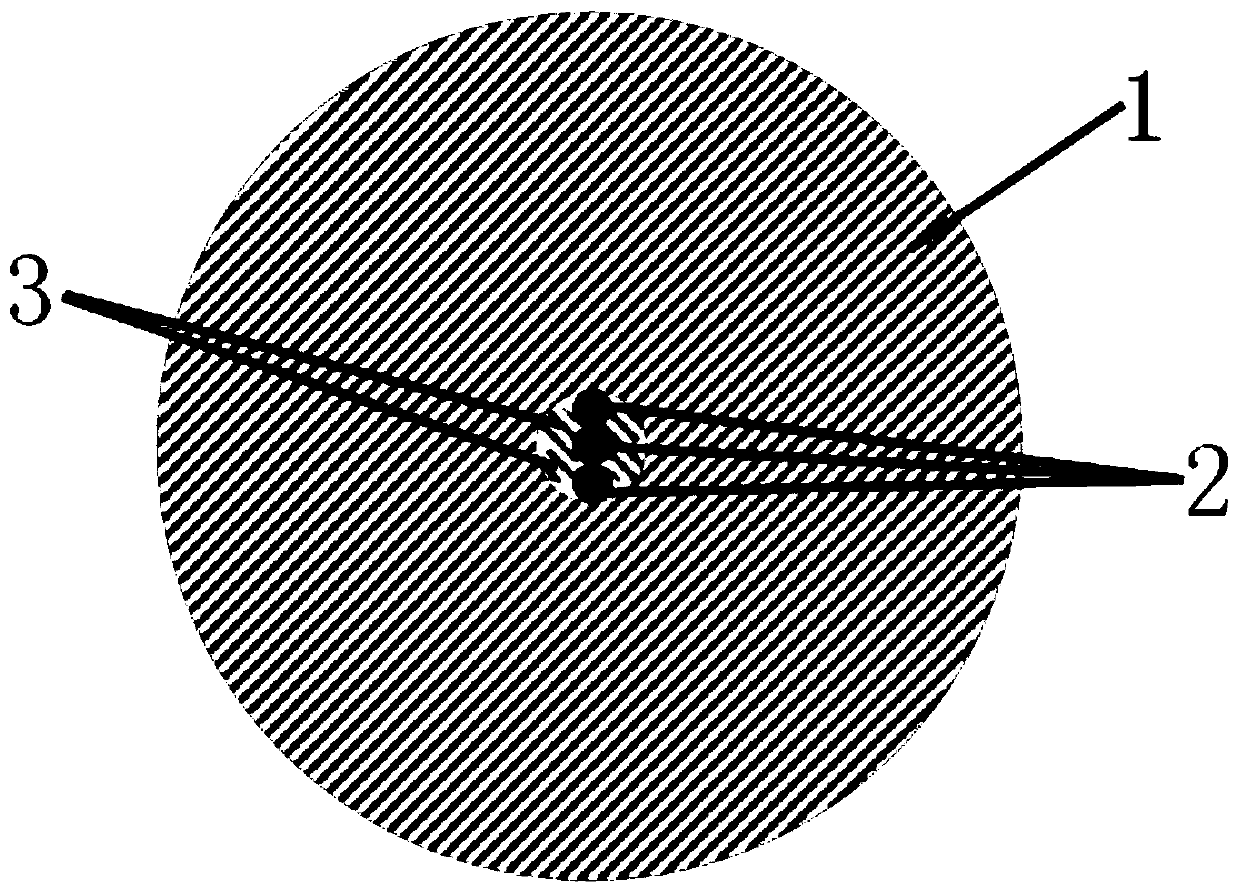

[0041] In this embodiment, the optical fiber preform comprises a quartz sleeve 1, three core rods 2 (that is, germanium-doped quartz rods) and four pure silica rods 3, and the three core rods 2 are arranged in a row, that is, the core rods 2 The center line is in the same plane, and two pure quartz rods 3 are symmetrically distributed on both sides of the core rod 2, such as figure 2 As shown, the inner diameter of the quartz sleeve 1 is d 0 , the outer diameter d of mandrel 2 1 and the outer diameter d of the pure quartz rod 3 2 Both are d 0 / 3. The outer diameter of the outer diameter of the quartz sleeve 1 is D, and the relationship between the outer diameter and the inner diameter depends on the characteristics of the optical fiber to be processed. It is usually necessary to ensure that the final polarization-maintaining optical fiber is single-mode transmission on the fast axis and the slow axis. For an elliptical core fiber, the slow axis is the long axis of the core,...

no. 2 example

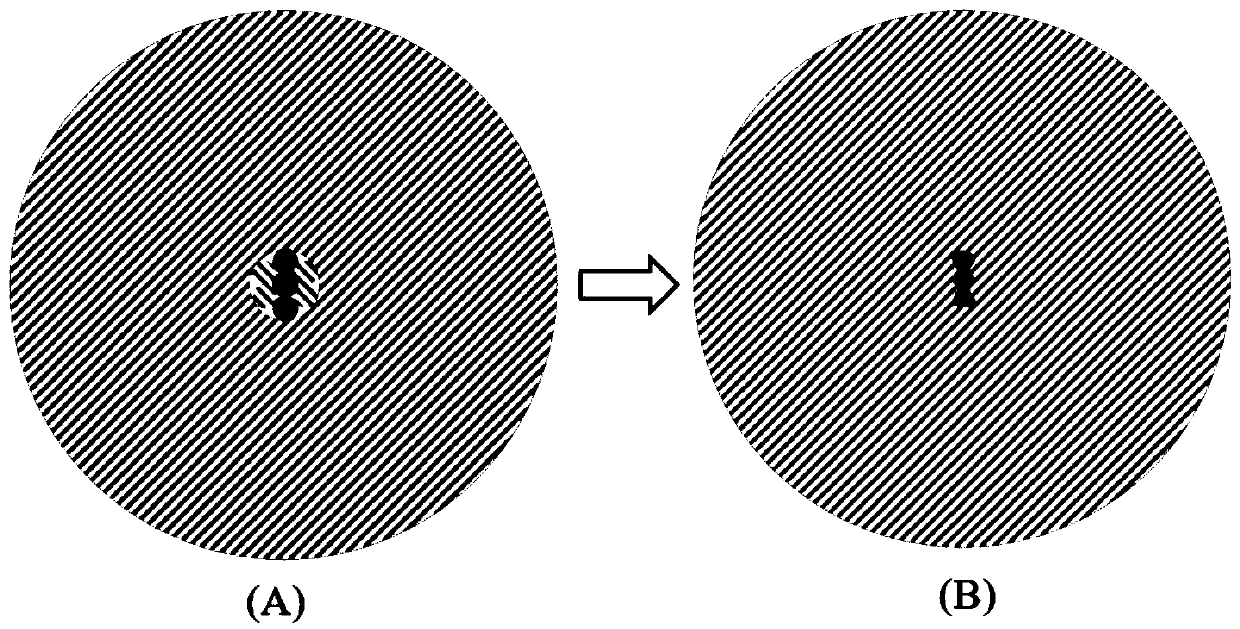

[0045] In order to further improve the birefringence of the elliptical-core polarization-maintaining optical fiber, the optical fiber preform of the present embodiment includes a quartz sleeve 1, five core rods 2 (i.e. germanium-doped quartz rods) and fourteen pure silica rods 3, Five mandrels 2 are arranged in a row, and seven pure quartz rods 3 are symmetrically distributed on both sides of the mandrel 2, such as Figure 4 As shown, the number of pure quartz rods 3 in the first row on both sides of the core rod 2 is four, and the number of pure quartz rods 3 in the second row on both sides of the core rod 2 is three, wherein the quartz casing 1 inner diameter d 0 , the outer diameter d of mandrel 2 1 and the outer diameter d of the pure quartz rod 3 2 Both are d 0 / 5. .

[0046] After the rods are melted and shrunk at high temperature, five core rods 2 are fused together to form an elliptical core (or elongated core), while fourteen pure silica rods 3 are fused together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com