Microwave electron cyclotron resonance plasma chemistry gas phase sedimentation device

A technology of chemical vapor deposition and microwave electron cyclotron, which is applied in the direction of gaseous chemical plating, metal material coating technology, coating, etc., can solve the problem that the wafer processing area and uniformity cannot be satisfied, and there is no batch scale production, wafer processing Small area and other problems, to achieve the effect of enhancing automation and production efficiency, improving process stability and repeatability, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

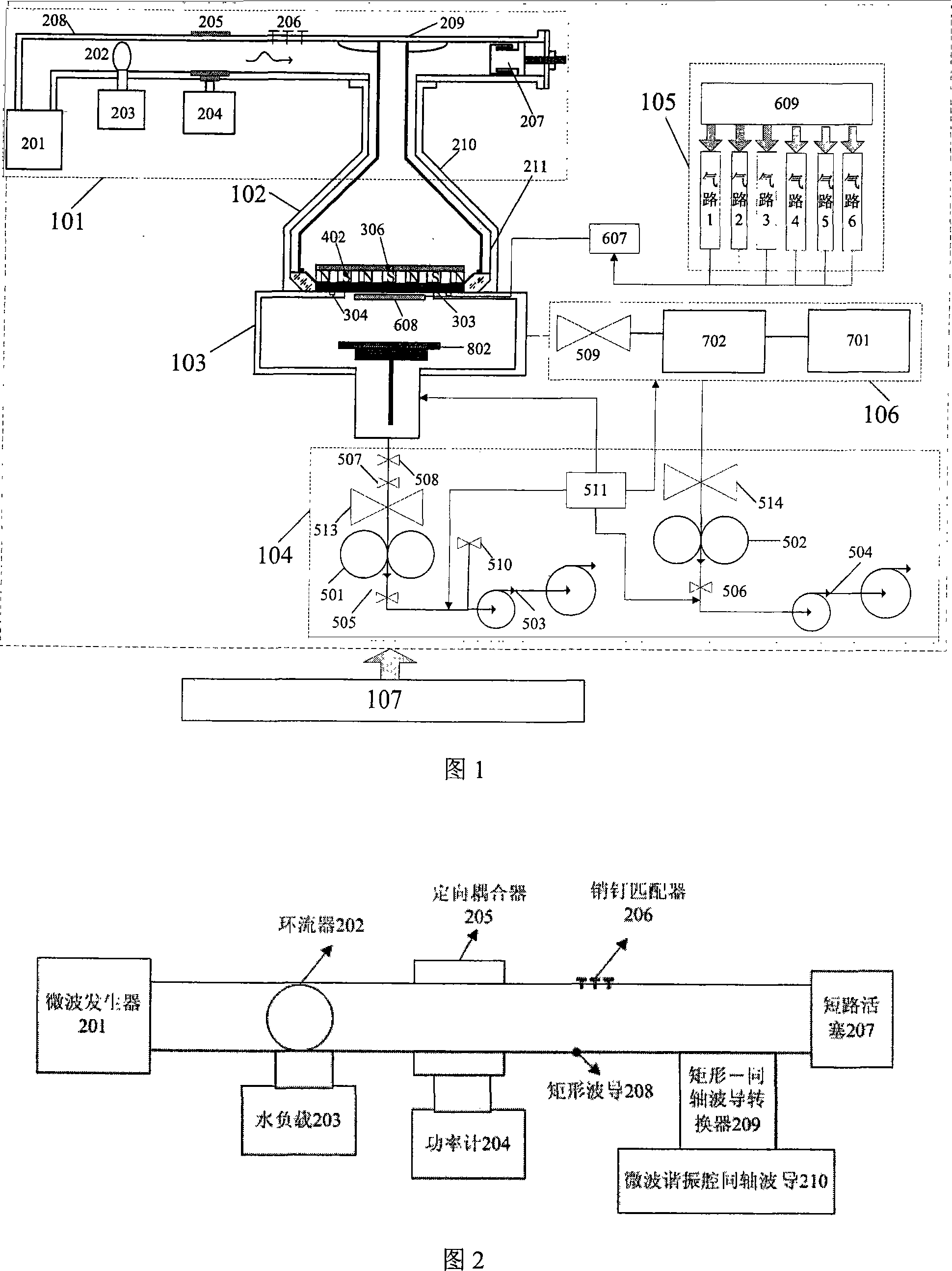

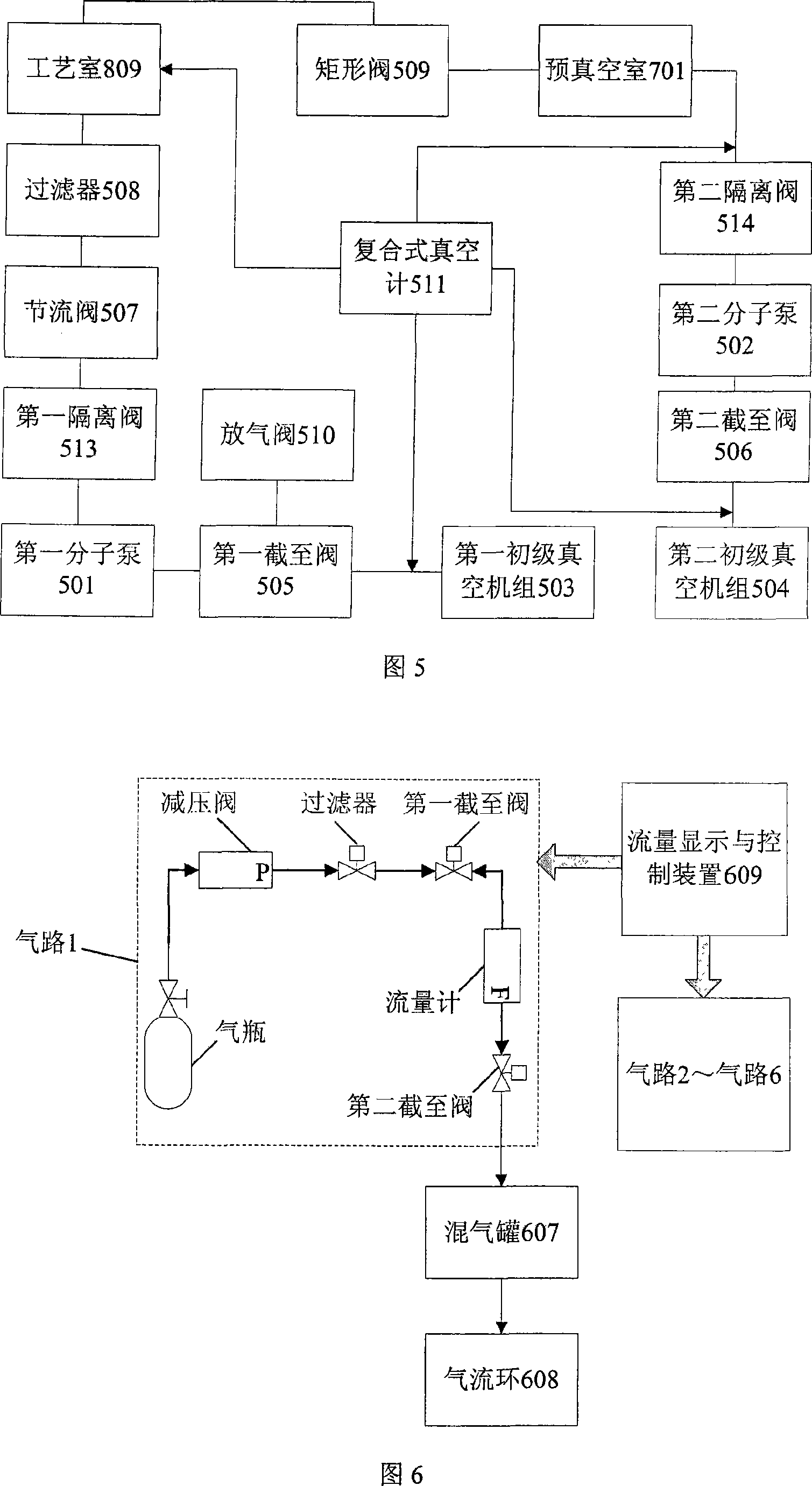

[0037] 1, the microwave electron cyclotron resonance plasma chemical vapor deposition equipment of the present invention includes a microwave power source and transmission system 101, a microwave resonant cavity 102, a process chamber and a sample stage system 103, a vacuum system 104, and a gas path system 105 , automatic film transfer system 106, control system 107. The structure of each system is shown in Figure 2-9.

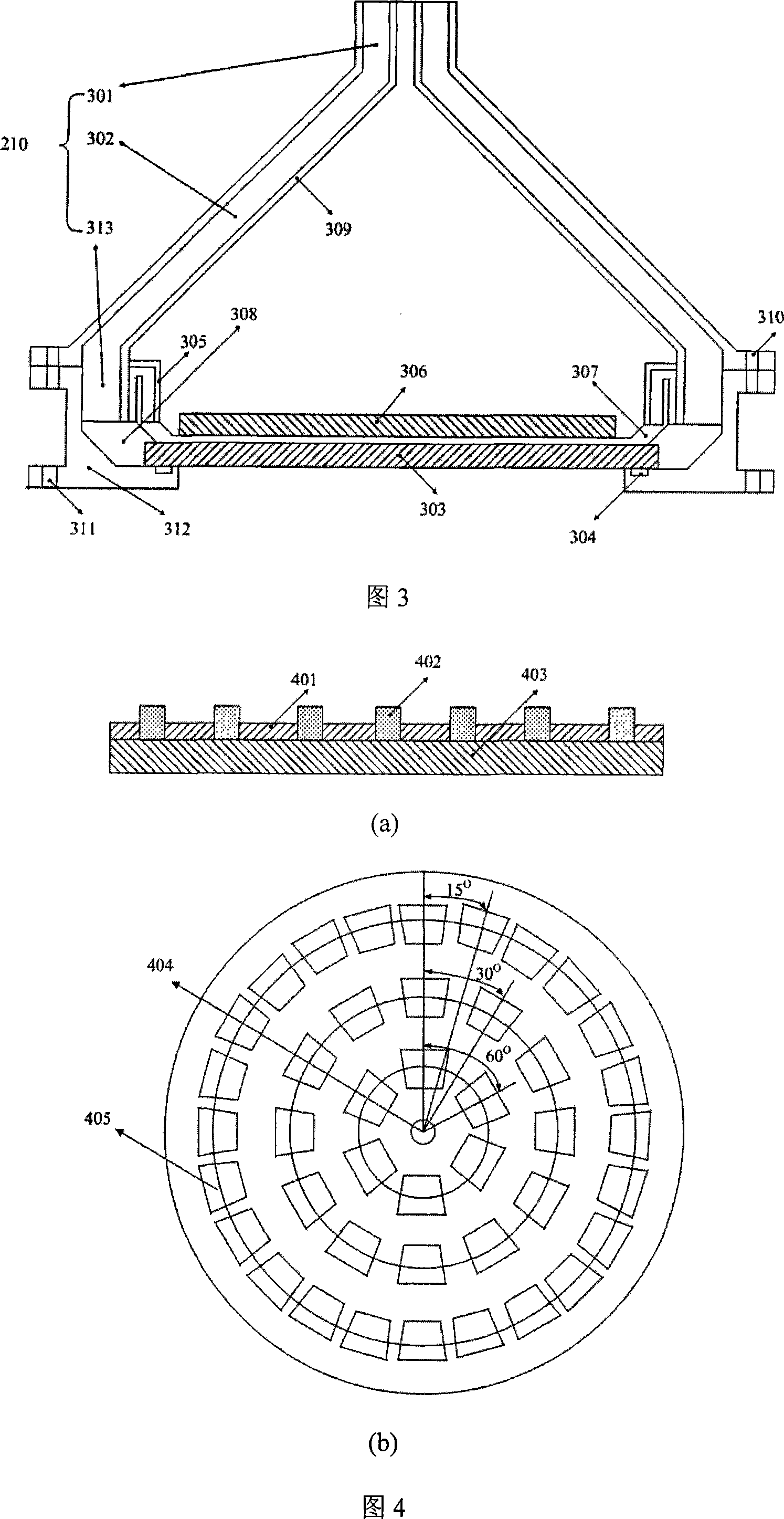

[0038]Referring to Fig. 2, the microwave power source and transmission system 101 is composed of a microwave generator 201, a circulator 202, a water load 203, a power meter 204, a directional coupler 205, a pin adjuster 206, a short circuit piston 207, a rectangular waveguide 208, a rectangular It is composed of a coaxial waveguide converter 209 and a microwave resonant cavity coaxial waveguide 210 . The connection relationship of each pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com