Sodium-rich cathode material of sodium ion battery, preparation method of sodium-rich cathode material and sodium ion battery

A sodium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability, low discharge specific capacity, etc., to improve discharge specific capacity, simplify reaction operations, and improve electrochemical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In a first aspect, the present invention provides a method for preparing a sodium-rich cathode material for a sodium-ion battery, the method comprising the following steps:

[0021] (1) Under stirring, the nickel salt solution, cobalt salt solution, manganese salt solution, oxalate solution and sodium salt solution are mixed, and the conditions of the mixing are such that Ni in the mixed solution 2+ , Co 2+ , Mn 2+ and Na + The ratio of the total moles of oxalate ions to the moles of oxalate ions is 0.8 to 1:1, preferably 1:1;

[0022] (2) in a sealed environment, the above-mentioned mixed solution is subjected to a hydrothermal reaction, followed by cooling, solid-liquid separation, washing, and drying to obtain a precursor;

[0023] (3) calcining the precursor in an air atmosphere to obtain a sodium-rich cathode material for a sodium-ion battery.

[0024] In step (1) of the method of the present invention, the mixing temperature is not particularly limited, and it...

Embodiment 1

[0052] This example is used to illustrate the sodium-rich cathode material for sodium ion battery of the present invention and the preparation method thereof.

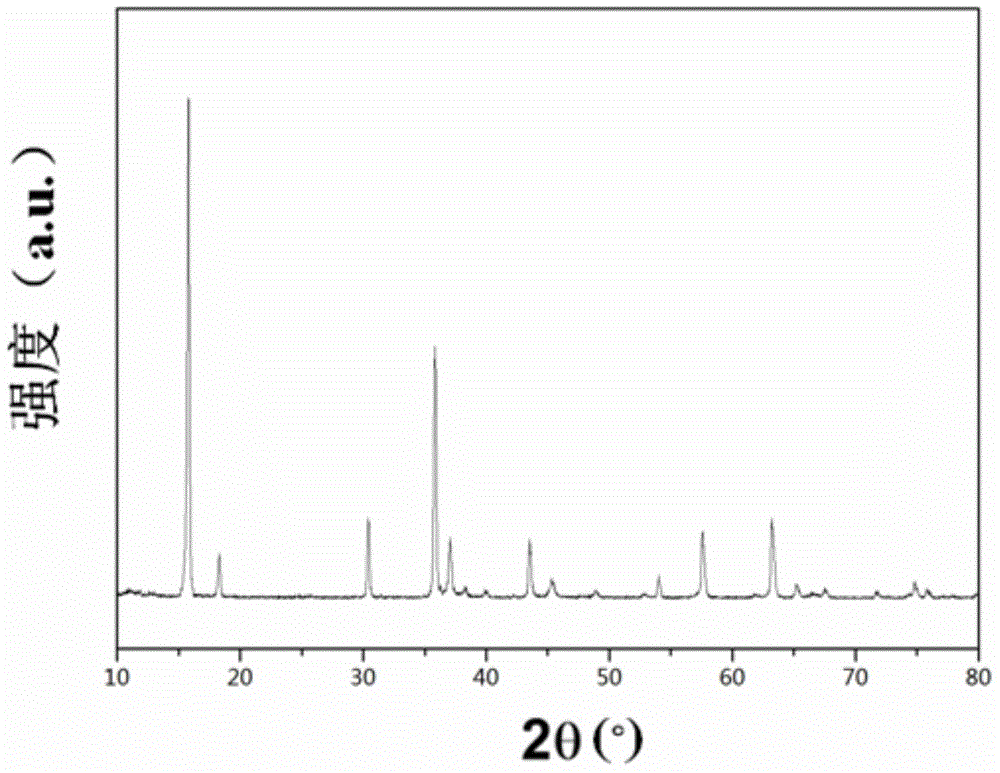

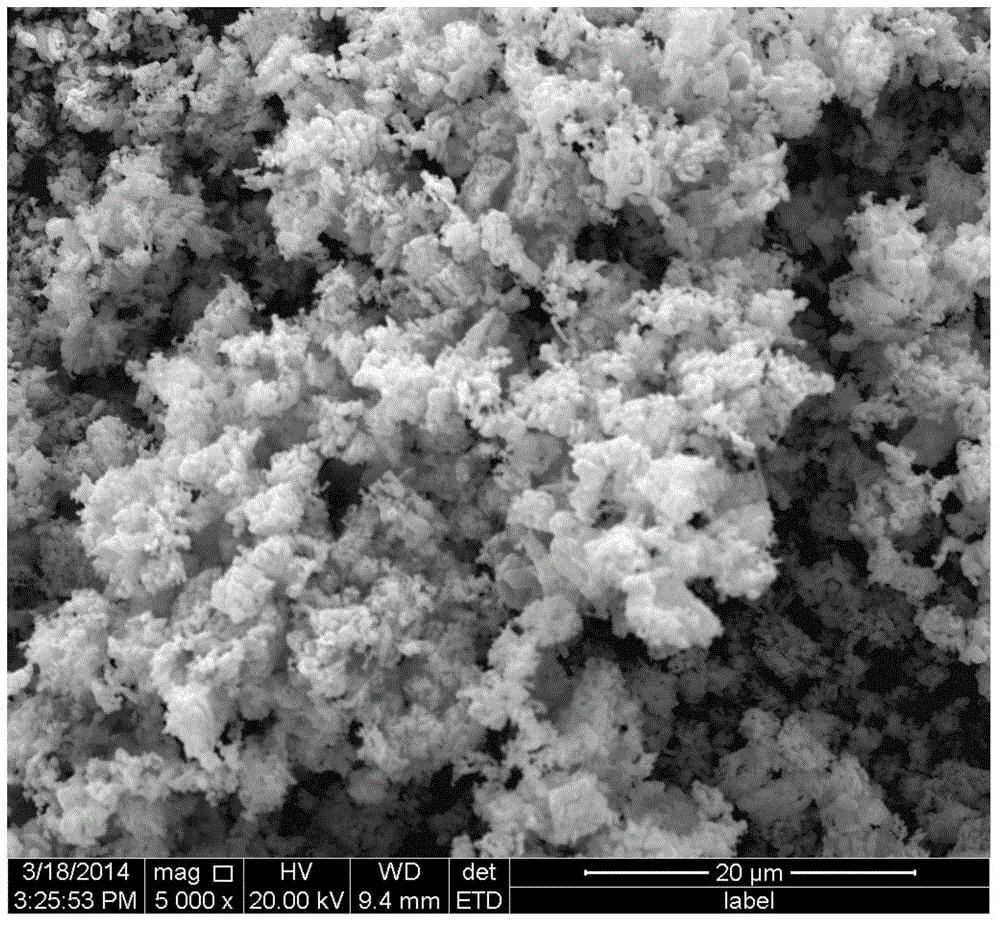

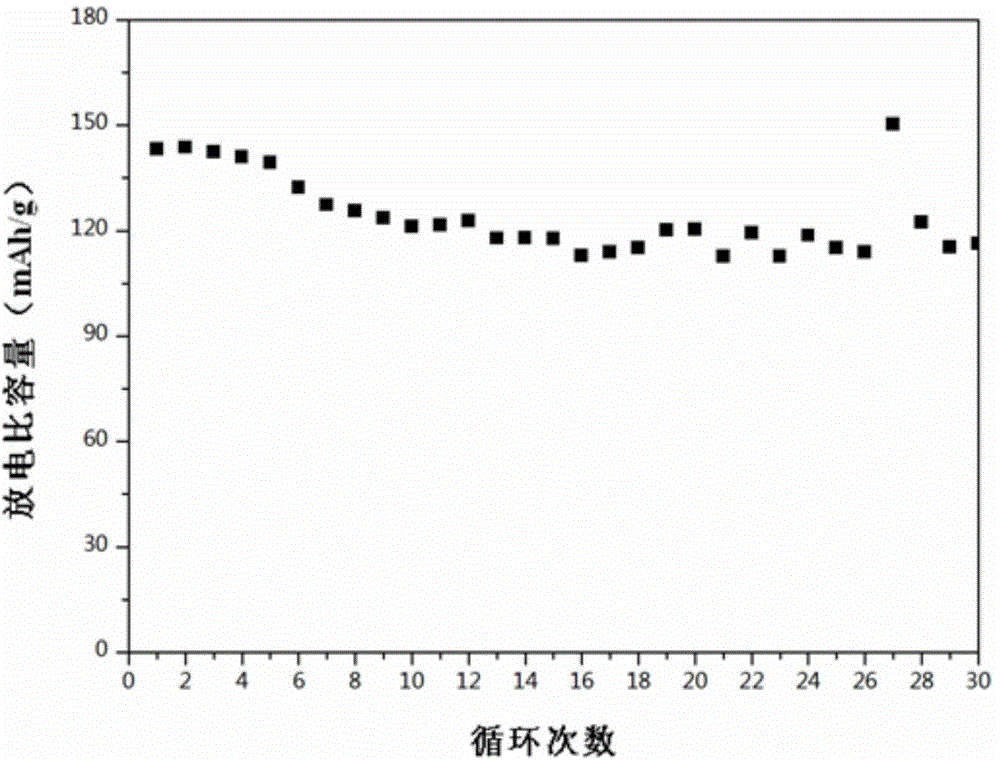

[0053] At 25°C, a mixture of 0.35g nickel acetate, 0.34g cobalt acetate and 1.87g manganese acetate (that is, the molar ratio of nickel ion, cobalt ion and manganese ion is 0.18:0.18:1) was dissolved in 50ml deionized water, stirred , to obtain a homogeneous solution 1; dissolve a mixture of 1.94 g of sodium acetate and 3.45 g of oxalic acid (that is, the molar ratio of sodium ions and oxalate is 0.62:1) in 50 ml of deionized water, and stir to obtain a homogeneous solution 2; The solution 1 and solution 2 were dropped into the constantly stirring reactor, the reactor was sealed after thorough mixing, and the hydrothermal reaction was carried out in an oven at 180 °C for 6 h, then cooled to 30 °C, and filtered to obtain a precipitate. Washed with deionized water for 3 times, dried at 60 °C for 300 min to obtain the pre...

Embodiment 2

[0057] This example is used to illustrate the sodium-rich cathode material for sodium ion battery of the present invention and the preparation method thereof.

[0058]At 25°C, a mixture of 0.3g nickel nitrate, 0.3g cobalt nitrate and 0.88g manganese nitrate (that is, the molar ratio of nickel ion, cobalt ion and manganese ion is 0.33:0.33:1) was dissolved in 50ml of deionized water and stirred. , to obtain a homogeneous solution 1; dissolve the mixture of 0.94g of sodium nitrate and 3.19g of potassium oxalate (that is, the molar ratio of sodium ions and oxalate is 0.58:1) in 50ml of deionized water, and stir to obtain a homogeneous solution 2; The obtained solution 1 and solution 2 were dropped into a continuously stirring reactor, and the reactor was sealed after being fully mixed, and the hydrothermal reaction was carried out in an oven at 120 ° C for 18 h, and then cooled to 30 ° C, and filtered to obtain a precipitate. The precipitate was washed three times with absolute e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com