NTC film heat sensitive resistance and its making method

A thin-film thermistor and thin-film technology, applied in the direction of resistors with negative temperature coefficients, etc., can solve the problems of difficult-to-chip components, long response time, poor dimensional accuracy, etc., and achieve short response time, small environmental pollution, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

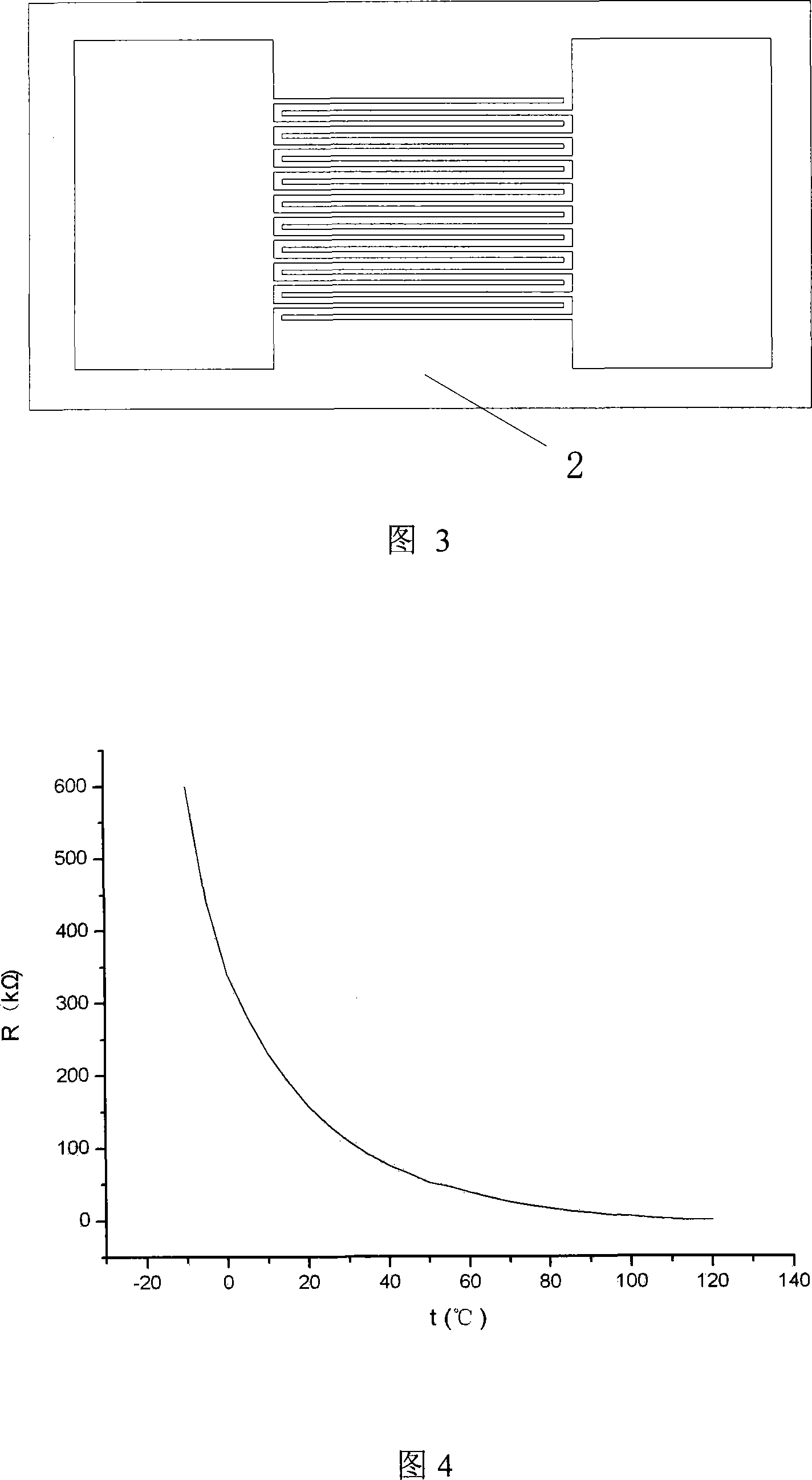

[0025] See Figure 2 and Figure 3. The structure of the NTC thin film thermistor of the present invention includes an NTC thin film resistor body and internal electrodes and terminal electrodes 5 connected thereto. The internal electrode is an interdigital electrode 3 covering the NTC thin film resistor. The NTC thin film resistor is located on the aluminum oxide substrate 1 . NTC thermistor dimensions conform to 0805, 0603 or 0402 standard chip component dimensions.

[0026] The NTC thin film thermistor prepared by the present invention has the advantages of good long-term stability of the device, short response time and high precision, as shown in FIG. 4 .

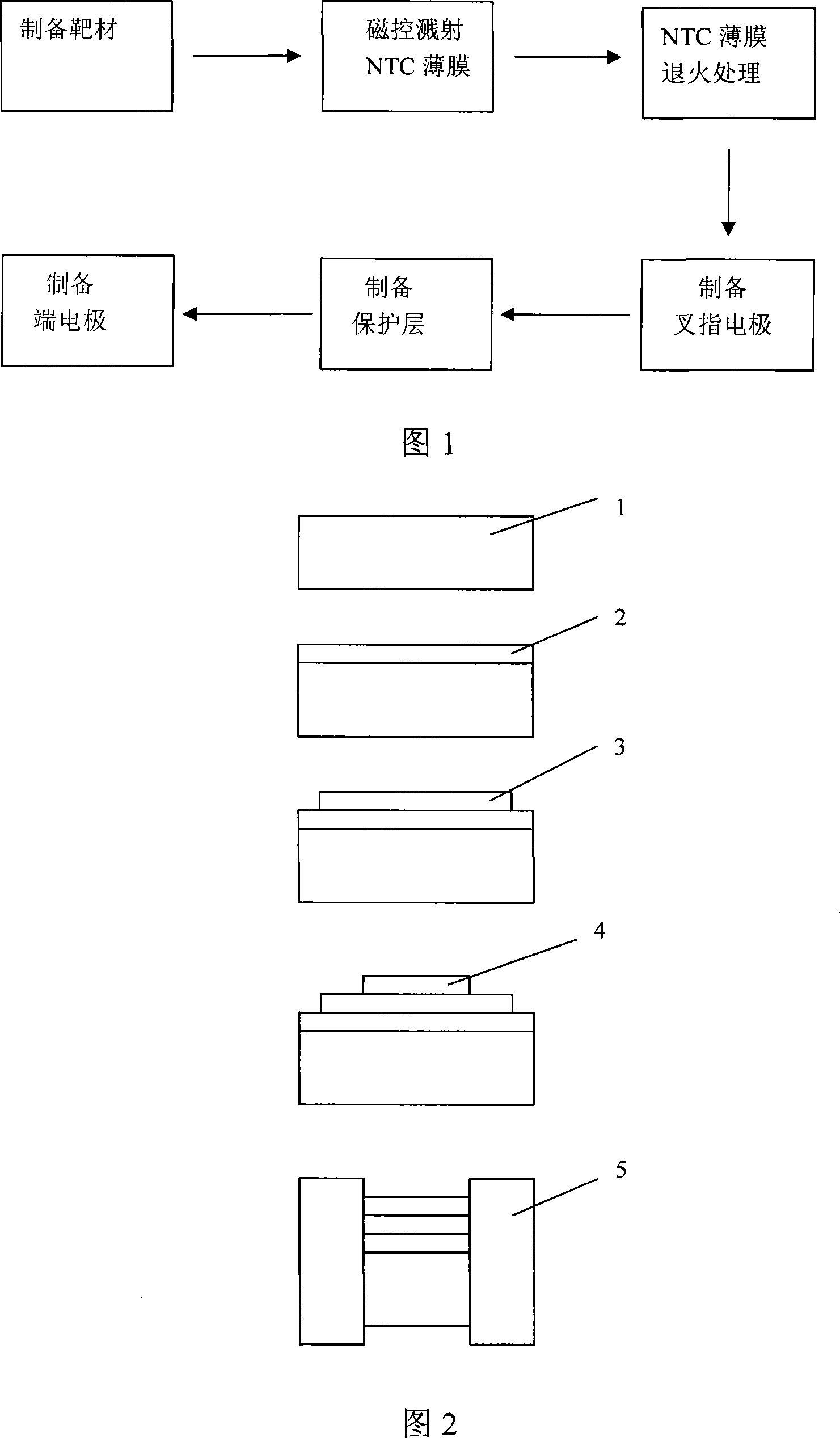

[0027] The present invention also provides a kind of preparation method of NTC thin film thermistor, see Fig. 1, specifically, comprise:

[0028] (1) Preparation of NTC ceramic targets;

[0029] (2) In a vacuum and protective gas environment, sputter the NTC material onto the substrate to form a thin film;

[0030] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com