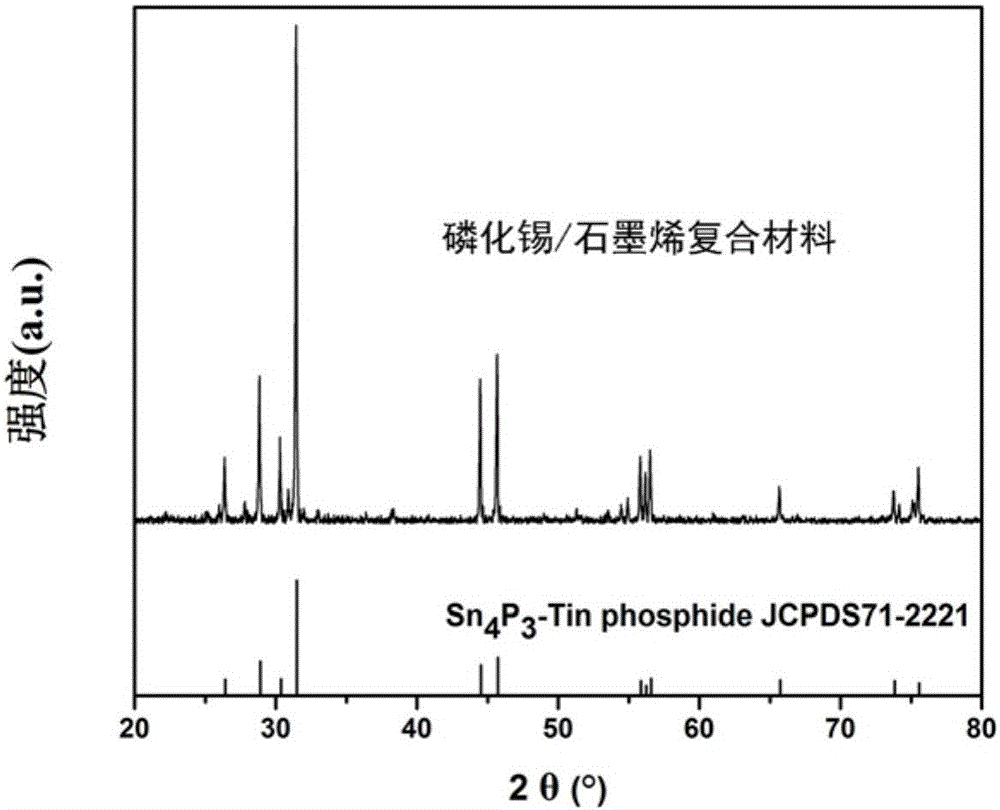

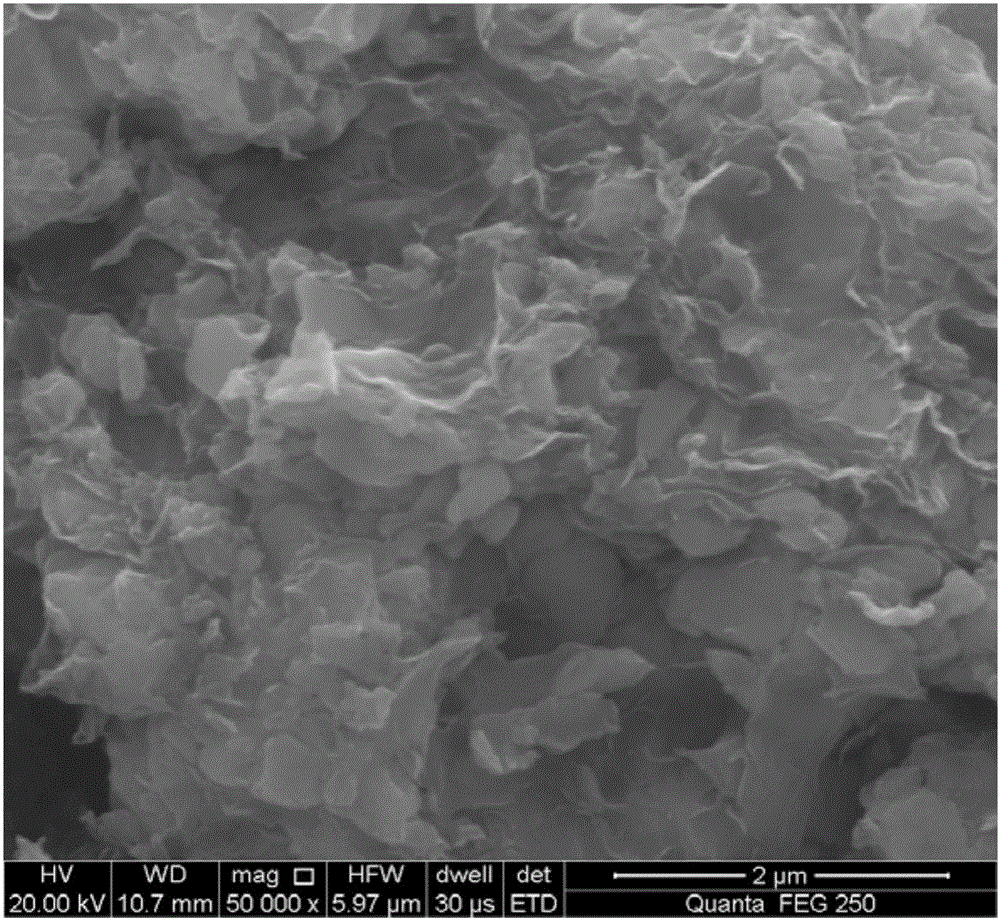

Stannic phosphide/graphene composite cathode material for sodium-ion battery and preparation method thereof

A graphene anode and composite material technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problem of no composite material preparation technology, no composite material sodium battery anode material, volume expansion cycle stability Low problems, to achieve the effect of improving battery cycle performance, improving electrochemical performance, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

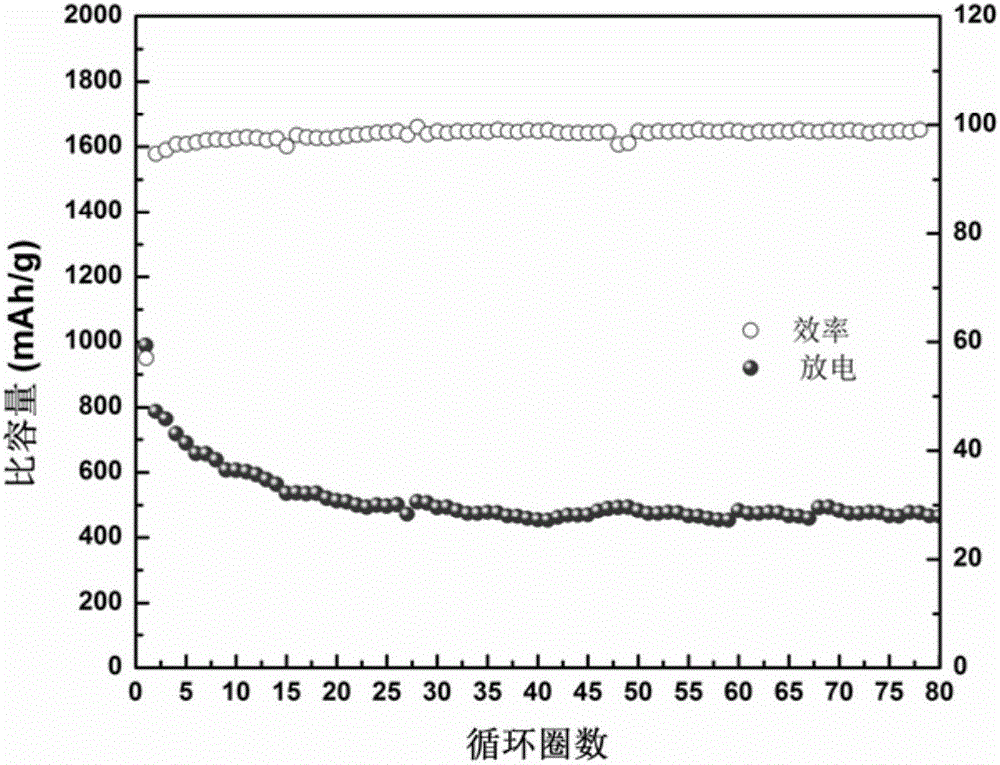

[0034] Weigh the raw materials, 0.125g of phosphorus powder, 0.6g of tin powder, and 30g of mixed grinding balls; put the raw materials and mixed grinding balls into the ball mill tank, seal it after feeding nitrogen, and then carry out ball milling at room temperature. During the ball milling process, keep the ball mill The rotating speed of the tank is 1500r / min, ball milling for 6h; weigh 0.275g graphene, add 60ml of deionized water, and ultrasonically disperse for 3h to obtain a graphene dispersion, add it to the ball milling tank, continue ball milling for 2h, filter and dry, put Dry it in a drying oven at 60°C, then raise the temperature to 750°C at a heating rate of 5°C / min in a tube furnace under the protection of nitrogen and keep it warm for 3 hours to obtain phosphorus with a nano-tin phosphide content of 72.5wt%. Tin / graphene anode composites.

[0035] The sodium battery composite negative electrode material prepared in this example and the sodium sheet are assembl...

Embodiment 2

[0041] Weigh the raw materials, 0.125g of phosphorus powder, 0.6g of tin powder, and 30g of mixed grinding balls; put the raw materials and mixed grinding balls into the tank of the ball mill, seal it after passing in argon, and then carry out ball milling at room temperature. During the ball milling process, keep The rotation speed of the ball mill tank is 1200r / min, and the ball mill is 12h; Weigh 0.6g graphene, add 100ml deionized water, and disperse it ultrasonically for 3h to obtain a graphene dispersion, add it to the ball mill tank, continue ball milling for 2h, and filter and dry, Dry it in a drying oven at 60°C, then heat it up to 750°C at a rate of 5°C / min in a tube furnace under the protection of argon and keep it warm for 3 hours to obtain a nano-tin phosphide content of 54.7wt%. tin phosphide / graphene anode composites.

[0042] The tin phosphide / graphene negative electrode composite material prepared in this example and the sodium sheet are assembled into a button...

Embodiment 3

[0044] Weigh the raw materials, 0.125g of phosphorus powder, 0.6g of tin powder, and 30g of mixed grinding balls; put the raw materials and mixed grinding balls into the ball mill tank, seal it after feeding nitrogen, and then carry out ball milling at room temperature. During the ball milling process, keep the ball mill The rotation speed of the tank was 1200r / min, and ball milled for 12 hours; weighed 0.475g graphene, added 80ml deionized water, and ultrasonically dispersed for 3 hours to obtain a graphene dispersion, which was added to the ball mill tank, continued ball milling for 2 hours, and was filtered and dried. Dry it in a drying oven at 60°C, then raise the temperature to 650°C at a rate of 10°C / min in a tube furnace under the protection of nitrogen and keep it warm for 3 hours to obtain a phosphide with a nano-tin phosphide content of 60wt%. Tin / graphene anode composites.

[0045] The tin phosphide / graphene negative electrode composite material prepared in this exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com